Abstract

The root cause of dynamic disaster such as mine rock burst and tunnel rockburst is that the over-limit of internal energy of engineering rock mass (coal mass) triggers sudden energy release. Rock is inhomogeneous medium composed of mineral particles with various sizes and different shapes after cementation. The damage failure process comes along with the energy assimilation and release. It has important significance on studying the stability. In this paper, lateral scale effect of rock was considered. Firstly, the impact of different aspect ratios on damage mechanics and energy evolution characteristic of rock was discussed by virtue of mesoscopic particle flow PFC2D software platform. After that, the constitutive model of rock damage based on energy features was analyzed. Research result indicates that: lateral scale affects uniaxial compressive strength of rock. With the increasing of aspect ratio, the uniaxial compressive strength of rock decreased and then increased, appearing “V” state; with the increasing of lateral scale of rock, various energies insides rock and energy absorption also appears increasing, but the energy release is unobvious; the fitted constitutive model based on friction energy parameter reflects stress–strain change characteristics of rock better and there is great difference between constitutive model of rock based on boundary energy feature and numerical curve.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The nature of substance damage is state unstability under energy drive (Heping et al. 2004). The loaded rock experiences energy input, accumulation, dissipation and release (Manchao et al. 2007), constant transfer and conversion (Hunsche 1991; Linming and Xueqiu 2001) in the overall process of deformation damage. Research on deformation damage rule from the aspect of energy approximates more to its failure nature, enriches and deepens the cognition of mechanical behavior of loaded rock. It drives the knowledge and research of rock mechanics difficulty such as rockburst and impact rock pressure, which brings about new view and solution to related rock engineering practice.

For research on rock energy evolution characteristics, Zhizhen and Feng (2012, 2015) studied nonlinear characteristics of rock energy evolution and confining pressure of loaded rock energy evolution under uniaxial compression; Akai et al. (2010) studied rupture and energy evolution law of soft rock under triaxial compression; Alshebani and Sinha (2000) studied energy dissipation process of masonry under the cyclic biax load; Chen and Zhan (2010) analyzed energy dissipation and release rule of rock in the shear failure process; Du et al. (2015) studied energy dissipation characteristic of fiber concrete under impact load effect. These researches had important significance on knowing rock damage failure mechanism and nature. However, these researches only analyzed rock in standard scale and it was to be considered whether the research achievement could be used for practical engineering. The specific rock scale effect in practical engineering certainly resulted in different rock energy evolution characteristics. Thus, research on rock energy evolution law under different scale was good for knowing the failure mechanism of rock further and preventing and controlling engineering rock disaster effectively. In this aspect, Bazant and Kazemi (1990) analyzed the relationship of fracture energy, process zone length and brittleness number from size effect of rock mass and concrete; Qingbin et al. (2015) studied the effect of size on the energy accumulation and dissipation of rock, and concluded that the energy of rock specimen appeared negative relation with its aspect ratio; Carpinteri and Paggi (2008) based on a unified interpretation according to fractal geometry, discussed the size-scale effects on strength, friction and fracture energy of faults. However, the surrounding rock in actual mining or lane engineering usually had lateral scale effect, namely lateral scale is larger than the height. Thus, it was necessary to study rock energy evolution characteristic under lateral scale effect.

Owing to that the in situ or indoor mechanical and energy evolution tests has the following disadvantages: one is that the rock material including many joints or fissures and the different of sampling time and spatial positions result in great discreteness of rock mass, this will inevitably lead to different mechanical and energy evolution characteristics of rock sample of different lateral scales; the other is that the in situ and indoor tests have great human errors and this may cause different experimental results. Therefore, uniaxial compression of rock was established by virtue of bond model platform (BMP) of mesoscopic particle flow software PFC2D. Through “cut-and-trial” (Itasca Consulting Group Inc. 2005), mesoscopic physical and mechanics parameter that was consistent with the indoor experiment result was acquired. Secondly, based on it, rock model with different lateral scales was established and its mechanical and energy evolution characteristic were analyzed. At last, constitutive model of rock damage based on energy feature was analyzed.

2 PFC Model of Rock with Different Lateral Scale Under Uniaxial Compression

2.1 Brief Introduction of Particle Flow

Particle flow code (short as PFC) is a new numerical simulation technology developed based on Cundall discrete unit method (Cundall 1971, 1979). It considers basic mechanical property of medium from basic particle structure of medium and thinks that the basic feature of given medium under different stress mainly depends on the change of contact state among particles. Quantitative and detailed research on crack initiation and expansion of medium could be carried out in the mesoscopic level, so PFC has been widely used in geotechnical engineering field for simulating various mesomechanics behavior characteristics of continuous and discontinuous materials (Dawei et al. 2017; Yoon 2007). Parallel bond PFC model has its unique advantage in the research on simulating mesoscopic damage and energy evolution of rock specimen. Under the compression effect of external load, the internal energy of specimen evolves and develops constantly and the energy can be monitored by using self-built FISH language of the software in real time.

2.2 Physico-mechanical Parameters of Rock Specimens

Particle flow theory represents the macroscopic physico-mechanical properties of rocks as their microscopic physico-mechanical properties. However, the microscopic parameters of rocks do not directly correspond to their macroscopic parameters. The microscopic parameters were checked and corrected prior the numerical simulation of the uniaxial compression model. During this process, a large number of numerical simulation tests were performed as either laboratory or in situ field tests under similar conditions. The numerical simulation results were compared with the laboratory or in situ field test results, and the microscopic parameters were repeatedly adjusted via trial and error.

2.2.1 Determining the Initial Value of the Physico-mechanical Parameters

The meso-mechanical parameters of the micro particle flow model mainly include the contact modulus of the particles \(E_{c}\), particle normal stiffness and tangential stiffness ratio \(k_{n} /k_{s}\), friction coefficient \(f\), parallel bond radius multiplier \(\lambda\), bond modulus \(\overline{E}_{c}\), ratio of the normal stiffness and tangential stiffness of bond \(\overline{k}_{n} /\overline{k}_{s}\), and normal and tangential bond strengths \(\overline{\sigma }_{c}\) and \(\overline{\tau }_{c}\).

The macro-mechanical parameters (including elastic modulus \(E\), Poisson’s ratio \(\nu\), compressive strength value \(\sigma_{c}\), and shear strengths \(c\) and \(\varphi\)) of the materials were determined in the indoor test. The preliminary value of particle contact modulus \(E_{c}\) and parallel bond modulus \(\overline{E}_{c}\) were decided by analyzing the macroscopic mechanical parameters.

The initial particle stiffness value is computed as follows:

where \(\overline{R}\) is the average radius of all model particles, and \(R^{[A]}\) and \(R^{[B]}\) are the radiuses of two contact particles.

The initial normal and tangential stiffness of the parallel bonding is computed as follows:

2.2.2 Determining the Meso-mechanical Properties of Rock

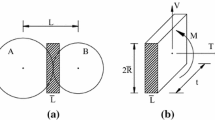

In view of the restraint of indoor experiment condition, parameters of Literature (Xuepeng et al. 2014) were adopted in this paper for numerical test. The literature took mechanical parameters of underground water seal petroleum cave depot granite of national petroleum reserve in Huangdao under triaxial compression as the basis. Through repeated adjustment and comparison using “cut-and-trial”, the paper thought mesoscopic physical and mechanics parameters in Table 1 approximate to macromechnaics parameters of real coal rock mass. After verification, it was found the macromechnaics parameters of rock specimen under the confining pressure of 6 MPa was identical to that of real granite rock. The stress–strain curves of experimental test and numerical test of granite rock mass are shown in Fig. 1 and they have a higher similarity. The elastic modulus, Poisson’s ratio and peak strength are 28.7 Gpa (28.4 Gpa), 0.2300 (0.2285) and 130.5 Mpa (132.8 Mpa) respectively. Final failure modes of the specimens, which are also consistent with the results of indoor tests, are shown in Fig. 2.

2.3 Numerical Model of Rock with Different Lateral Scale Under Uniaxial Compression

To analyze impact of different lateral scale effect on rock damage evolution energy characteristic, model (See Fig. 3) sets up specimen with 5 different aspect ratio K, the fixed height is 100 mm and the aspect ratio K are 0.5, 0.75, 1.0, 1.25 and 1.5. Each model doesn’t consider the impact of particle shape and distribution, but adopts parameters in Table 1. Through radius expansion method, the model generates enough particles in the set zone so as to meet the porosity. The total particles generated by various models are 8397, 12596, 16795, 20993 and 25192. The unbalanced force generated in the model production process is eliminated through circulation and loaded through the wall on the top of mobile model. The loading mode adopts the same strain rate and the loading rate is 0.01 mm/s.

3 Analysis of Numerical Result

3.1 Strength Characteristics of Rock with Different Aspect Ratio

The stress–strain curve of rock specimen with different aspect ratio is shown in Fig. 4 and peak strength curve of rock specimen with different aspect ratio is shown in Fig. 5. According to Fig. 4, it is known that in the experimental scheme, stress–strain curve of rock experiences elastic stage, plastic stage and failure stage without airtight closing stage of real rock. It is because in PFC, the elementary particles are rigid sphere. It cannot be compressed or deformed. The particles are connected via bond without initial damage. Meanwhile, it is seen that owing to no airtight closing stage, the elastic modulus of rock in various schemes is basically the same, about 28.5 GPa.

According to Fig. 5, when aspect ratio was smaller than 1, the uniaxial compressive strength of rock declines gradually, inversely related with aspect ratio, which is consistent with the view of Hoek and Brown (1980) and Pells (1993). However, when the aspect ratio is more than 1, it will not conform to such rule. With the continuous increasing of aspect ratio, the mechanical carrying capacity of rock specimen increases gradually and is directly proportional to the aspect ratio. Moreover, the mechanical property after peak is more complicated. Generally speaking, with the increasing of aspect ratio, the uniaxial compressive strength of rock decreased and then increased, appearing “V” state. Moreover, for different aspect ratio, there is no corresponding relation between the decreasing amplitude and increasing amplitude of rock peak strength. When aspect ratio is 0.75, the uniaxial compressive strength was 125.73 MPa; when the aspect ratio is 0.5, (128.92 MPa) decreasing by 2.47%; when the aspect ratio is 1, the uniaxial compressive strength is 120.11 MPa, decreasing by 4.47% than that when the aspect ratio is 0.75; when the aspect ratio is 1.25, the uniaxial compressive strength is 123.31 MPa, increasing by 2.66% than that when the aspect ratio is 1; and when the aspect ratio is 1.5, the uniaxial compressive strength is 132.38 MPa, increasing by 7.36% than that when the aspect ratio is 1.25.

Figure 6 is the failure mode of rock specimen with different aspect ratio. According to the figure, it is known that the failures modes of rock specimens in different schemes are different. When the aspect ratio is 0.5, the failure mode is the inclined splitting damage; when the aspect ratio is 0.75, the failure mode is cross-splitting, including leftward and rightward failure cracks; when the aspect ratio is 1.0, the failure mode is also cross-splitting and more failure cracks exist; when the aspect ratio is 1.25, the failure mode appears bigger v state; and when the aspect ratio is 1.5, the failure mode appears wave-type state.

3.2 Energy Evolution Characteristic of Rock with Different Aspect Ratio

Figure 7 is energy evolution characteristic curve of rock specimen with the size of \(\phi\)50 mm * 100 mm. According to the figure, it was known that prior to yield stress, the sum of friction energy, kinetic energy, strain energy and bond energy is equal to boundary energy. The bond energy and stain energy account for a big proportion. Such part of energy is related to the generation and drive of crack and the growth and decline are related to the degradation of model material. However, the friction energy representing crack function is on the contrary. They are wane and wax relation. The crack generation needs to overcome bond energy. Then, it is expanded under the drive of strain energy. After the crack generation, friction part starts working. After the specimen reaches the peak strength, bond energy and strain energy decrease dramatically, friction energy increases dramatically and the proportion of friction energy increases gradually with the further expansion of crack. Thus, it is seen that the friction function is the main provider of residual strength. The kinetic energy accounts for a small proportion in the overall deformation of the specimen. It is related to loading process and internal dynamic equilibrium of specimen. Thus, it indicates that the specimen deformation is not acute and the crack is stable and expanded.

Figure 8 shows the evolution characteristic curve of various energies inside the rock with different lateral scale. According to the figure, it is known that with the increasing of lateral scale of rock, various energies inside the rock and the increment at energy absorption stage increase, but the progressive decrease degree at energy release stage is unobvious. When solving engineering problem using energy method, scale effect must be considered. The great difference exists between energy evolution characteristic acquired from indoor experiment and the actual error. That is to say, the energy evolution characteristic acquired from indoor experiment cannot be applied to engineering practice directly. According to Fig. 8(1), it is known that with the increasing of lateral scale, the boundary energy of rock appears proportionate increase approximately. It indicates that the bigger the lateral scale of rock is, the more energy it absorbs and the absorbed energy is directly proportional to its own lateral scale. The increment of boundary energy before peak is small, the increment of boundary energy after peak is big and the increment at residual stage tends to be stable. According to Fig. 8(2), it is known that the absorbed energy absorbed by the internal bond of rock appears proportionate increase approximately. Before the peak, with the scale increasing, the bond absorbed energy increment increases. After the peak, the internal bond releases energy. Moreover, the larger the lateral scale of rock is, the more energy is released, Entering damage residual stage, the internal bond of rock is nearly the same. It indicates that after entering damage residual stage, internal particle connection bonds of rock are nearly broken. According to Fig. 8(3), it is known that before the peak, the strain energy absorbed inside the rock appears proportionate increase approximately. Before and after the peak, with the increasing of scale, the strain energy absorbs or releases, and the increment becomes larger. It is similar with the bond energy evolution law. At the residual stage after the peak, the strain energy release inside the rock appears declining as a whole with the increasing of lateral scale. It indicates that the deformation energy of rock with different scale increases stably before the peak and appears discrete after peak release. According to Fig. 8(4), it is known that the increasing or release of kinetic energy mainly focuses on the rock failure stage before and after peak. Moreover, with the increasing of lateral scale, kinetic increase or release is different and the fluctuation is great. It indicates that the rock failure mainly focuses on before and after peak and not only does the kinetic energy evolution of rock depends on the scale of rock specimen, but also is related to failure mode of rock. According to Fig. 8(5), the friction energy is similar with kinetic energy, mainly produced at the stage before and after peak. The difference is that the friction energy can appears energy absorption state after the damage of rock and the kinetic energy appears damping and energy release state. With the increasing of lateral scale of rock, friction energy increases and the increasing amplitude becomes larger with the increasing of lateral scale.

4 Constitutive Model of Rock Damage Evolution Based on Energy Feature

The concept of damage was firstly proposed by the former Soviet Union scholar Kachanov (1958). He described the metal property deterioration characteristic law in the creeping process using continuous factor and effective stress. After that, Rabotnov (1969) adopted the damage variable in the book. Thus, it was promoted in the academic world. Because the material damage changes along with the change of microstructure and some macroscopic physical property, so there are many parameters to define damage, such as quantity of crack (Kim et al. 2013; Xiao et al. 2016), elastic modulus (Mizuno et al. 2010), yield stress (Murti et al. 1991), elongation (Shugang and Xuefu 2001), acoustic emission (Iturrioz et al. 2013; Xiao et al. 2017), energy (Xuesheng et al. 2016), etc.

The paper planned to define damage variable from the internal energy of rock. Bond energy, strain energy and kinetic energy don’t have the continuous energy absorption or release change characteristic, so boundary energy and friction energy were taken as the damage parameter to define damage variable.

Kachanov (1958) defined the damage variable as:

In the equation, \(M_{d}\) is the sectional area of material damage at one moment; and \(M\) is the sectional area of material at the initial moment without damage.

Suppose the accumulative energy when the non-destructive sectional area \(M\) of rock specimen loses bearing capacity totally is \(N_{0}\), then the accumulative energy \(N_{w}\) when the unit area of rock particle is damaged is:

When the sectional damage of coal rock reaches \(M_{d}\), the accumulative energy \(N_{d}\) is

Thus,

Rock specimen is difficult to reach absolutely total failure mode in the compression process, so we, referring to research of Baoxin et al. (2009), revise the damage variable as:

In the equation \(D_{u}\) is critical value of damage.

After normalization processing of critical value of damage according to linear function conversion method, we get:

In the equation, \(\sigma_{p}\) is peak strength and \(\sigma_{c}\) is residual strength.

Then, constitutive model of rock damage evolution based on energy characteristic and stain equivalence principle (Lemaitre et al. 1999) is:

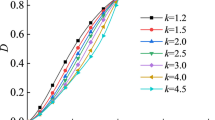

To analyze the rationality of the constitutive model of rock damage evolution based on boundary energy and friction energy, we analyze the parameter acquired by the standard specimen with the size of \(\phi\)50 mm * 100 mm. According to Fig. 9, it is known that the constitutive model fitted based on friction energy parameter can reflect the stress–strain change characteristic of rock better and there are great differences between constitutive model of rock based on boundary energy characteristic and numerical curve. The reason is that boundary energy needs to provide big energy at the beginning for rock deformation and damage, while the rock absorbs it through bond energy and deformation energy without causing any damage. Thus, when analyzing rock damage characteristic using energy, it is rational to select friction energy as the damage variable parameter.

5 Conclusion

With the increasing of aspect ratio, the uniaxial compressive strength of rock decreases and then increases, appearing “V” state. When the aspect ratio is smaller than 1, the uniaxial compressive strength of rock decreases gradually and appears inverse relation with the aspect ratio; when the aspect ratio is more than 1, it appears direct proportion to the aspect ratio. Moreover, for different aspect ratios, the decreasing amplitude has no corresponding relation with the increasing amplitude of rock peak strength.

Rock damage energy dissipation law: prior to yield stress, the bond energy and stain energy account for a big proportion. Such part of energy is related to the generation and drive of crack and the growth and decline are related to the degradation of model material. However, the friction energy representing crack function is on the contrary. They are wane and wax relation. The friction function is the main provider of residual strength. With the increasing of lateral scale of rock, various energies inside the rock and the increment at energy absorption stage increase, but the progressive decrease degree at energy release stage is unobvious. When solving engineering problem using energy method, scale effect must be considered. The great difference exists between energy evolution characteristic acquired from indoor experiment and the actual error.

The constitutive model fitted based on friction energy parameter can reflect the stress–strain change characteristic of rock better and there are great differences between constitutive model of rock based on boundary energy characteristic and numerical curve. When analyzing rock damage characteristic using energy, it is rational to select friction energy as the damage variable parameter.

References

Akai K, Ohnishi Y, Yashima A (2010) Fracture and energy dissipation of soft sedimentary rock in triaxial compression. Proc Jpn Soc Civ Eng 1982(321):123–130

Alshebani MM, Sinha SN (2000) Energy dissipation of masonry under cyclic biaxial compression. Struct Mater 2000(8):427–436

Baoxian L, Jinglin H, Zeyun W et al (2009) Study on damage evolution and acoustic emission character of coal-rock under uniaxial compression. Chin J Rock Mech Eng 28(Supply 1):3234–3238

Bazant ZP, Kazemi MT (1990) Determination of fracture energy, process zone longth and brittleness number from size effect, with application to rock and conerete. Int J Fract 44(2):111–131

Carpinteri A, Paggi M (2008) Size-Scale effects on strength, friction and fracture energy of faults: a unified interpretation according to fractal geometry. Rock Mech Rock Eng 41(5):735–746

Chen XG, Zhan QY (2010) Research on the energy dissipation and release in the process of rock shear failure. J Min Saf Eng 27(2):179–184

Cundall PA (1971) A computer model for simulating progressive large scale movements in blocky system. In: Led M (ed) Proceedings of symposium of the international society of rock mechanics, vol 1, pp 8–12. A. A. Balkema, Rotterdam

Cundall PA, Strack ODL (1979) A discrete numerical method for granular assemblies. Geotechnique 29(1):47–65

Dawei Y, Shaojie C, Xingquan L et al (2017) Effect of joint angle in coal on failure mechanical behavior of roof rock-coal combined body. Q J Eng Geol Hydrogeol. https://doi.org/10.1144/qjegh2017-041

Du B, Ma H, Lin L (2015) Dynamic split tension and energy dissipation of fiber concrete under impact loading effect. In: International conference on electromechanical control technology and transportation

Heping XIE, Ruidong P, Yang JU (2004) Energy dissipation of rock deformation and fracture. Chin J Rock Mech Eng 23(21):3565–3570

Hoek E, Brown ET (1980) Underground excavations in rock. Lond Inst Min Metall 2:43–49

Hunsche U (1991) Volume change and energy dissipation in rock salt during triaxial failure tests. In: Cocks ACF, Ponter ARS (eds) Mechanics of creep brittle materials, vol 2, pp 172–182

Itasca Consulting Group Inc. (2005) Manual of particle flow code in2-dimension (Version 3.10). Itasca Con- sulting Group Inc, Minneapolis

Iturrioz I, Lacidogna G, Carpinteri A (2013) Acoustic emission detection in concrete specimens: experimental analysis and lattice model simulations. Int J Damage Mech 23(3):327–358

Kachanov LM (1958) Time rupture process under creep conditions. Izvestia Akademii Nauk SSSR, Otdelenie Tekhnicheskich Nauk 12(8):26–31

Kim J, Yi J, Kim J et al (2013) Fatigue life prediction methodology using entropy index of stress interaction and crack severity index of effective stress. Int J Damage Mech 22(22):375–392

Lemaitre J, Sermage JP, Desmorat R (1999) A two-scale damage concept applied to fatigue. Int J Fract 97(1–4):67–81

Linming DOU, Xueqiu HE (2001) Prevention theory and technology of rockburst. China University of Mining and Technology Press, Xuzhou, pp 6–7

Manchao HE, Jinli MIAO, Dejian LI et al (2007) Experimental study of rock burst process of granite specimen at great depth. Chin J Rock Mech Eng 26(5):865–876

Mizuno M, Okayasu M, Odagiri N (2010) Damage evaluation of piezoelectric ceramics from the variation of the elastic coefficient under static compressive stress. Int J Damage Mech 19(3):375–390

Murti V, Zhang W, Valliappan S (1991) Stress invariants in an orthotropic damage space. Eng Fract Mech 40(6):985–990

Pells PJN (1993) Uniaxial strength testing, comprehensive rock engineering principles, practice and projrcts. Pergamon Press, Oxford

Qingbin M, Lijun H, Hai P et al (2015) Experimental on the effect of strain rate and size on the energy accumulation and dissipation of rock. J China Coal Soc 40(10):2386–2398

Rabotnov YN (1969) Creep rupture. Applied mechanics. Springer, Berlin, pp 342–349

Shugang CAO, Xuefu X (2001) Testing study on the characteristics of creep and damage of coal and other rocks. Chin J Rock Mech Eng 20(6):817–822

Xiao W, Zhijie W, Yujing J (2016) Time-space effect of stress field and damage evolution law of compressed coal-rock. Geotech Geol Eng 34(6):1933–1940

Xiao W, Zhijie W, Yujing J et al (2017) Experimental study on mechanical and acoustic emission characteristics of rock-like material under non-uniformly distributed loads. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-017-1363-3

Xuepeng Z, Gang W, Yujing J et al (2014) Simulation research on granite compression test based on particle discrete element model. Yantu Lixue Rock Soil Mech 35(Supply 1):99–105

Xuesheng L, Jianguo N, Yunloiang T et al (2016) Damage constitutive model based on energy dissipation for intact rock subjected to cyclic loading. Int J Rock Mech Min Sci 85:27–32

Yoon J (2007) Application of experimental design and optimization to PFC model calibration in uniaxial compression simulation. Int J Rock Mech Min Sci Geomech 44(6):871–889

Zhizhen Z, Feng G (2012) Research on nonlinear characteristics of rock energy evolution under uniaxial compression. Chin J Rock Mech Eng 31(6):1198–1207

Zhizhen Z, Feng G (2015) Confining pressure effect on rock energy. Chin J Rock Mech Eng 34(1):1–11

Acknowledgements

The authors thank the National Natural Science Foundation “Investigation of optimization of non-uniform perforation-clustering in long horizontal wells in homogeneous shale formations” (Item No. 51674272), National Science and Technology Major Project “The design and optimize new technology of clustering perforation in complex structural well” (Item No. 2017ZX05009), the Science Foundation of China University of Petroleum (Beijing) “Research on optimization method of cluster perforation parameters in anisotropy shale gas reservoirs” (Item No. 2462015QZDX05), the State Key Laboratory of Shale Oil and Gas Enrichment Mechanisms and Effective Development Project “Research of casing loading spectrum under coupled effects of multi-factors in shale gas wells” for contributions to this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yan, X., Jun, L., Yijin, Z. et al. Research on Lateral Scale Effect and Constitutive Model of Rock Damage Energy Evolution. Geotech Geol Eng 36, 2415–2424 (2018). https://doi.org/10.1007/s10706-018-0473-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-018-0473-3