Abstract

Stabilization of clayey soil has been studied by mixing different additives to the soil to increase its strength and durability. Recently, there has been an increasing interest in the stabilization of soils with natural pozzolans. Nevertheless, very few articles have investigated the impact of basic oxygen furnace (BOF) slag additives under freeze–thaw cycling. This study presents the results of an experimental research study on the durability behavior of clayey soils treated with BOF slag. In this study, the effects of clay soils on the bearing value were investigated by adding 3%, 6%, 9%, 12%, 15%, and 20% BOF slag to the clay mineral sample within the scope of ASTM D-5918 tests. California bearing ratio (CBR) tests were then applied before and after freezing–thawing processes to the samples prepared at these optimum conditions. The relationship between the determined freezing and swelling speeds and the strength losses of the soil samples after freeze–thawing processes were investigated. For this purpose, eight mixtures with different geotechnical properties were subjected to freeze–thaw experiments on a total of 24 soil samples, each of which was repeated three times. Results show that the addition of steel-making slag to clay soils lead to favorable effects on freezing–thawing behavior. The effects of BOF slag on the clay sample after the freezing and thawing cycle were investigated and interpreted by considering their macro and micro phase structure. The findings indicate that using BOF slag has positive effects on strength and durability of clayey soil.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Freezing–thawing events that occur due to changing in air temperature and wetting–drying processes caused by changes in water level are effective in the characterization of the soil particles. The climate has a considerable effect on the type, structure, and degree of aggregation of the soil. One of the most important events occurring in the soil due to climatic conditions and affecting the dynamic structure of the soil is freezing–thawing. Research has shown that freezing and thawing processes affect the physical state of the soil, especially the structure of the soil and the particles (Özgan et al. 2012). The stabilization of soils in cold regions is also particularly difficult because geotechnical characteristics are affected by high soil temperatures and freezing–thawing cycles. Decreased stability of the soil after winter, known as thawing, is a common engineering problem in cold regions (Lake et al. 2017). When the soil is completely frozen (i.e., when the water in the pores is completely frozen), the water volume increases by about 9%, and cracks inevitably occur in the soil (Freitag and McFadden 1997). As the size and number of cracks increase, the strength of the clayey soil decreases.

Clay is a material that makes working areas of sectors such as construction, agriculture, and mining very difficult. Clay material is indeed a desirable raw material for use in many industrial areas, but it is rare to find and quarry it as a mine in nature (Genç 2009). Clay soils can damage structures (roads, waterways, buildings, tunnels, etc.) rested on and cause defects and damages on building materials due to the effect of seasonal freezing–thawing and salt transport (Zaimoğlu et al. 2013). Particularly in winter, freezing–thawing occurs in surface waters due to variations in temperature during the day, and this phenomenon causes swelling in the upper part of the soil (Işık 2014). In surface formations, water flow occurs in two forms: the first one is surface water, and the second one is water that flows from cracks. There is also capillary water that takes advantage of the suction force of the cavities and moves to deeper freezing zones (Işık 2014). This situation affects the pumping ability of different layers, and the internal friction of the rock material. Moreover, surface mobility affects both surface structures and underground structures. The seasonal freezing–thawing damages water, air, and saline environments, such as roads, tunnels, buildings, overpasses, and bridges. The work to be done for this purpose should contain two important stages: the first stage is defined as the swelling soil, and the second stage is the determination of the values to be used in the design by taking the appropriate samples (Demir and Kılıç 2010).

In the iron and steel sector, BOF slags have become an important necessity to reduce the load, storage area, environment, and manipulation processes of the BOF slag, as well as to reduce the economic burden of these activities and to expand their usage areas (Bölükbaşı et al. 2012). Numerous research and development studies have been carried out in order to ensure optimal utilization of waste, increase recycling rate, improve non-recyclable resources, and produce new products. Desulfurization slag (DS), a by-product generated during steel production, was used as an activator for ground granulated blast-furnace slag (GGBS) in the experimental study by Lee et al. (2016). Fakhri and Ahmadi (2017) investigated the effects of concurrent recycling of fine reclaimed asphalt pavement (RAP) and coarse steel slag aggregate (SSA) on the fracture resistance of asphalt mixes using semicircular bending (SCB) specimens with different ratios of these two marginal materials with and without warm mix asphalt (WMA) additive. The application of ground granulated blast furnace slag and steel fibers in prestressed concrete railway sleepers was presented by Shin et al. (2016).

The optimization of additives to improve the geotechnical properties of an expansive clay soil subjected to freeze–thaw effect was investigated by Olgun (2013). In the said study, lime and rice husk ashes, which are waste materials, were used in stabilization, and randomly distributed fiber was used as reinforcement. Using laboratory test, Güllü and Khudir (2014) studied the effect of freeze–thaw cycles on unconfined compressive strength (UCS) of fine grained soil (low-plasticity silt) treated with jute fiber, steel fiber, and lime. Eskişar et al. (2015) investigated the strength characteristics of Portland cement-treated fat and lean clays (CH and CL) under freeze–thaw cycles. They concluded that, the plasticity index of the specimens subjected to five freeze–thaw cycles showed a decrement for the clay which was highly plastic in its native condition. Laboratory tests have been performed to investigate the effects of randomly oriented fibers on some engineering properties such as strength and durability of fine-grained soil subjected to freeze–thaw cycles (Zaimoğlu 2010). A series of unconfined compression tests was conducted to achieve strength behavior and mass losses were also calculated after freezing–thawing cycles as criteria for durability behavior.

Clay soils are cohesive, have plasticity, and are composed of a mixture of clay minerals and some other minerals (Genç 2009). The presence of clay minerals, even in small quantities within a groundmass, can significantly affect the engineering properties of that mass. As clay quantity increases, soil behavior is controlled by clay properties (Batman 2015).

The effect of using more than 9% lime on salty soil samples was investigated. The expansion of salty soil is stabilized using lime (Liu et al. 2019). In our study, BOF slag, which is iron and steel waste, was used instead of lime. Positive results have been obtained in the improvement of clay soils by using more than 9% of BOF slag. In the literature, lime and cement containing agents have commonly been used to stabilize the expansion of the soil. The use of metallurgical wastes should be preferred instead of these agents (Vijayan and Parthiban 2020). A mixture of steelmaking slag, ladle furnace slag, and calcium chloride (CaCl2) was tested to stabilize clayey soil (Brand et al. 2020). Steelmaking slag mixed with cement was tried to improve the expansion of the soil (Wu et al. 2020). Many studies have shown that the stabilization strength and quality of the clays are provided by using Portland cement. However, energy and resources were consumed to produce Portland cement. For this reason, BOF slag can be used instead of Portland cement in the stabilization of clays (Cikmit et al. 2019). Lime is seen as one of the oldest methods used in stabilization. Mixing lime with soil increases the mechanical properties of clayey soil. However, a significant amount of energy and resources are also consumed in lime production (Bozbey et al. 2018). For this reason, it is important to use metallurgical wastes such as BOF slag to increase the mechanical properties of clay soils. An experimental study was carried out to investigate the strength of clayey soils of lime and perlite mixture. It has been observed that the addition of perlite as a pozzolanic additive in the soil stabilized with lime increases the strength and durability (Yilmaz and Fidan 2018). For this reason, it is important to use metallurgical wastes such as BOF slag to increase the mechanical properties of clay soils. There are also different studies related to steel slag in the literature (Karasahin et al. 2019; Yilmaz and Fidan 2017; Hazirbaba 2017; Lake et al. 2017; Liu et al. 2017; Mahoutian and Shao 2016; Pang et al. 2016; Brand and Roesler 2015; Cui and Zhang 2015; Roustaei et al. 2015.

It is observed that the freeze–thaw processes caused by climate change affect the physical condition of the ground, especially the soil and grain structure. In this study, the stabilization of clay soils was achieved only with BOF slag, a by-product generated during the steelmaking process. Only a few studies have used BOF slag for this purpose. This study, investigated the freezing–swelling behavior of clay–BOF slag mixture soil samples obtained from the Iskenderun region by following the American society for testing and materials (ASTM) D 5918 standard test methods. For this purpose, standard compaction tests and CBR tests were performed before and after the freezing–thawing processes. As a result of the experiments, the relationship between the determined freezing and swelling speeds and the strength losses of the soil samples after freeze-thawing were investigated. For this purpose, eight mixtures with different geotechnical properties were subjected to freeze–thaw experiments on a total of 24 soil samples, each of which was repeated three times. All soil samples were prepared by compressing the maximum dry unit volume weight and optimum water content according to the Standard Proctor experiment. Efforts have been made to eliminate the negative effects of freezing and thawing on engineering structures without harming nature and the environment. In addition to traditional geotechnical tests, the effects of macro and microstructures and phase structures on freeze–thaw cycles were analyzed and interpreted by SEM and XRD analyses. This study will also create an alternative use area for BOF slag. BOF slags create storage, environmental, and logistical problems in iron and steel factories.

Materials

Study area

In this study, freezing–thawing tests were carried out following the ASTM D-5918 standard test methods. Two types of material were used in the tests. The clay soil was obtained from the Iskenderun district of Hatay. BOF slag was obtained from the İskenderun Iron and Steel Works Co. (İSDEMİR Works Co.). In this study, 3%, 6%, 9%, 12%, 15%, and 20% BOF slag were added to clayey soil samples, and the compaction and CBR tests were performed on the mixtures. Then, the ASTM D-5918 test was applied to investigate the swelling problems of the freezing–thawing process. The bearing value of the soil and the optimum moisture content was determined. According to the values obtained from the CBR and compaction tests, the Nüve ID 300 climatic test cabin (in Fig. 1a) was used to determine the freezing–thawing behavior and the amount of swelling. Figure 1b demonstrates the freezing–thawing tests.

The used materials

Steelmaking (BOF) slag

In the steel factory, the oxygen is blown into the converter and the unwanted elements in the steel composition are removed by oxidation. The oxides coming into the field combine with the flux materials to form the molten slag and are located on the liquid steel in the converter due to the density difference. The slag, which is poured from the slag pot into the crust, solidifies, and crystallizes to a gray, less porous material, as compared to the cooling water supplied on the control surface (Bölükbaşı et al. 2012). The structure of the BOF slag is given in Fig. 2.

BOF slags mainly contain CaO, MgO, SiO2, and FeO. In low phosphorus steel production, the total concentration of these oxides in liquid slag is around 90% (Bölükbaşı et al. 2012). For this reason, the BOF slags are considered the simplest CaO-MgO-SiO2-FeO quaternary system. The slags always contain undissolved limestone covered with fine dicalcium silicate. The chemical composition of the BOF slag used in this study is shown in Table 1. The chemical composition of the BOF slag formed by the conversion of liquid crude iron to steel mainly consists of 15–21% Fe, 4–11% SiO2, 30–40% CaO, 2.7–5.7% MnO, 2–4% MgO, and 0.95% P2O5 (Bölükbaşı et al. 2012). The particle size BOF slag is shown in Table 2. The manual sieving process in sieve tests was carried out according to the Turkish standards institute European norm (TS EN 933-1 2012). After the BOF slag was ground to −75 μm in accordance with this standard, it was mixed with the clay sample. BOF slag has a porous and brittle structure.

Clay

Clay is a material found abundantly in nature. Limestone, silica, mica, and iron oxide minerals are found mostly in the clay. Clay minerals can be divided into four main groups as illite, kaolinite, montmorillonite, and other clays. There is water suction in terms of the structure of the clay and it has different plasticity, cohesion, color and shrinking characteristics (Genç 2009). Clay is used by geotechnical engineers in many applications (Pusch 1979). It is used in the provision of impermeability in filling dams and waste storage tanks, for water retention of the ponds, and for keeping the flowing soils in the form of slurry when they are excavated. But in general, clay is an unwanted material because its presence brings about some serious engineering problems. In this study, clay samples obtained from the İskenderun region were used. The main properties of the clay mineral are given in Table 3 (Özgan et al. 2012).

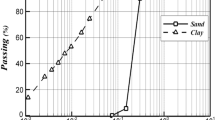

The chemical analysis of the clay soil is demonstrated in Table 4. The cumulative under size curve of the soil sample taken from the İskenderun region is shown in Fig. 3.

As seen in Fig. 3, 93.20% of the particle size of clayey soil is below 0.42 mm and the proportion of particles smaller than 2.36 mm in size is less than 97.76%.

Methods

Using the ASTM D-5918 standard test methods, the effects of clay soils on the bearing value were investigated by adding 3%, 6%, 9%, 12%, 15%, and 20% steelmaking (BOF) slag to the clay soil sample. In the experiments, the steps shown in Fig. 4 are as follows:

In the laboratory, the optimum water content and maximum dry density values were found using the compaction test, and the CBR test was performed under these optimum conditions (ASTM D-5918 2013). Freezing–thawing cycles were applied to the samples prepared in the CBR test conditions, and CBR tests were performed to investigate the effects of freezing–thawing.

In order to determine the freezing–thawing behavior, CBR tests were performed before and after freezing–thawing processes, and the results were compared. The amount of decrease in CBR values after freezing–thawing was determined. Strength losses were determined according to the CBR change rate (ΔCBR) obtained by dividing the difference between the pre-freezing–thawing CBR value (CBR1) and the post-freezing–thawing CBR value (CBR2) by the pre-freezing–thawing CBR value (CBR1) (Zaimoğlu et al. 2013).

Within the scope of our work, ensuring the climatic temperature conditions throughout the year is an important step. In order to meet these conditions, the Core ID 300 Climatic test cabin was used. The device has a volume of 290 l, a working temperature range of −40/150 °C, adjustable height (altitude), and up to 1000 h of continuous operation. It also has the ability to repeat 1–99 times of sets that are created by making the desired set of halves. The freezing–thawing cycle in Table 5 shows the process steps. This process refers to a 24-h period (within 1 period). This process was repeated 10 times in the climatization device, and the freezing–thawing cycle was carried out for a total of 10 days.

The Turkish Standards Institute European Norm (TS EN 1367-1 2009) test standard process steps are shown in Table 5. These process steps were used in the application of the ASTM D 5918 test standard. In this study, the effect of temperature difference on engineering materials (bridge, road, building, etc.) has been investigated. The 10-year thermal degradation status of the materials was investigated in the laboratory using the process steps in Table 5. In order to determine the supporting power of the soil, a compaction test was also performed within the scope of the CBR test. In order to determine the maximum tightness ratio, the soil sample was compressed in the standard molt chamber, and the remaining air spaces were filled with the optimum amount of water. The ideal water content and the dry unit volume weight for each clay floor BOF slag mixture ratio were found. These values are shown in Fig. 5.

The liquid limit experiment was conducted according to the International Organization for Standardization (ISO) 17892-12: 2018. Optimum water content values (liquid limit) of BOF slag and clay mixtures are shown in Fig. 5. The dry unit volume weight (γkmaks) of clay is 1.58 (g/cm3). The optimum water content (ωopt) of the clay material is 17.08%. The dry unit volume weight (γkmax) of the BOF slag is 1.45 (g/cm3). The optimum water content (ωopt) of the BOF slag material is 15.12%. As seen in Fig. 5, as the amount of the BOF slag in the mixture increases, the percentage (% amount) of clay with a higher liquid limit and plastic limit value in the soil mixture decreases. On the other hand, the amount of BOF slag with very low liquid limit and plastic limit values in the mixture increases. Since the water retention density (liquid limit value) of the BOF slag is less than the clay soil, it reduces the water retention density of the clayey soil. Figure 5 shows the optimum water content of the mixture of clayey soil sample and BOF slag. When the BOF slag was added to the clayey soil sample, the optimum amount of water was reduced. Depending on the increase in the amount of BOF slag in the clayey soil sample, the clayey soil sample appears to have a tighter structure.

In the previous Turkish Standards Institute European Norm (TS EN 1367-2 2010) magnesium sulfate test, 50 cycles of freeze-thawing were carried out. The effect of salt water on construction works was investigated. The effect of reinforced concrete bridge construction in Fig. 5 was also found in concrete specimens 40×40×160 mm in size prepared under laboratory conditions (Fig. 6). The reason for the damage to concrete specimens is that the water temperature or the changing temperature causes crystallization of the water in the body when the saline water or water located in the void in concrete is absorbed. This situation not only causes the concrete surface to well, to be poured in pieces, and to move to the center of the concrete, but also causes material loss (Fig. 6). This effect in the concrete samples prepared under laboratory conditions is shown in Fig. 6. The damaging effects of salt water on construction works are widely seen in concrete barriers and lighthouses at the seaside.

Results and discussion

Load–penetration values were obtained from CBR tests prepared according to the results of the proctor tests. These values were substituted in the ΔCBR (Eq. 1) to investigate the relationship between pre-freezing–thawing and post-freezing–thawing load, kgf-, and penetrations (mm).

The CBR values before and after freezing–thawing of the clay soil sample and mixture samples were given in terms of 0.5mm, 1.0mm, 1.5mm, 2.0mm, 2.5mm, and 3.0 mm penetration (Figs. 7 and 8). Among these values, CBR% values were calculated by taking the value which is high for 2.5 mm or 5.0 mm penetration. The CBR value was calculated using the standard load–penetration amount values ratio. Figure 7 shows penetration and mixing ratios of CBR values before the freezing–thawing process.

As seen, the loads for 2.5 mm penetration for 0%, 3%, 6%, 9%, 12%, 15%, and 20% BOF slag mixture ratios are 356.90 kgf, 248.81 kgf, 263.09 kgf, 377.29 kgf, 372.20 kgf, 511.90 kgf, and 689.33 kgf, respectively. It is seen that an improvement was observed in slag–mixture soils, compared with the natural clay soils.

Figure 8 shows the CBR values after the freezing–thawing process. These values were obtained after a 10 day freezing–thawing cycle between +22°C and -17.5°C, and then the CBR test was carried out.

When the values were examined, the amount of CBR2 load decreased to 254.93 kgf for a 100% clay soil sample after the freezing–thawing process. CBR1 load was obtained as 356.90 kgf. For 2.5 mm penetration on the witness sample, there was a load loss of 101.97 kgf. The increase in load–penetration resistance was 3.06 kgf in the mixture of 6% BOF + clay soil sample. After the freezing–thawing test, in the clay soil samples with 9%, 12%, 15%, 20%, and 100% BOF slag, the increase was observed in CBR2. These increases were 966.7 kgf-9% BOF slag, 1218.56 kgf-12% BOF slag, 1964.99 kgf-15% BOF slag, 2673.69 kgf-20% BOF slag, and 771.93 kgf-100% BOF slag. The CBR values obtained before and after freezing–thawing and the rate of percentage change are given in Table 6.

As seen from the CBR1, CBR2, and ΔCBR values in Table 6, the optimum results were obtained for 12%, 15%, and 20% BOF slag additions. Sensitivity of samples to freezing is created in Table 7 according to the classification system determined by Freitag and McFadden (1997).

According to Table 7, as the amount of BOF slag in the clay soil increased, the sensitivity to freezing decreased. Sensitivity to freezing was particularly low in the clay soil sample with 12%, 15%, and 20% BOF slag. In the case of sample mixtures with 0% (witness sample), 3%, and 6% BOF slag, there was little change compared to the witness sample, but sensitivity to freezing was still observed. The combined graphical representation of sensitivity to freezing ratios and BOF slag percentages is shown in Fig. 9.

Dashed lines on the graph indicate the limits of freezing sensitivity. In this study, a total of 24 tests were carried out in eight different mixtures, three in each. The effect of the amount of BOF slag on the freezing sensitivity is shown in Fig. 9 and Table 7. As it can be seen in Fig. 9, adding the BOF slag to the clayey soil at specified ratios first reduces the freezing sensitivity, which then remains constant at moderate amounts of BOF slag.

When the degree of freezing according to mixing ratios is examined, it is observed that sensitivity to freezing decreases when the addition of BOF slag increases when the clay soil sample has a high degree of freezing sensitivity. Figure 9 shows a swelling rate varying between 6.2 and 6.8 mm/day after a 10-day freezing–thawing cycle in a 100% clay soil sample. These values are 4.15–5.4 mm/day for 3% BOF slag, 4.5–5.0 mm/day for 6% BOF slag, and 4.25–4.4 mm/day for 9% BOF slag. Similarly, for 12% BOF slag, 15% BOF slag, and 20% BOF slag, the sensitivities are 2.1–3.1 mm/day, 2.5–3.2 5mm/day, and 2.65–3.0 mm/day, respectively.

Investigation of macro structure

JEOL JSM-5500LV brand SEM device was used in this study. Acceleration voltage: 0.3–30 kV; Resolution in high vacuum mode: 3.0 nm (accelerator voltage 30 kV, WD 8 mm); Magnification: ×5–×300000; Probe current: 1 pA–1 μA; Electron welding: Eaves type tungsten filament; It is equipped with Aztec software and Oxford EDS detector. Specimen (3%, 6%, 9%, 12%, 15%, and 20%) samples obtained from BOF slag-mixed clay material (6 pieces) were magnified 250× times and examined by a SEM electronic microscope. The shapes, corners, and surface and grain structures of the BOF slag and clay mixture samples were examined by a SEM electronic microscope.

When we examine the BOF slag and clay samples in Fig. 10, it is seen that the BOF slag grains are larger and have larger surface textures. In the BOF slag, plate-shaped particles of irregular shapes can also be observed. CaO and MgO compounds found in BOF slag have an increasing effect on binding properties. BOF slag particles fill the gaps between the clay grains and reduce the grain cavities within the clay.

In general, as the amount of BOF slag increases in the clay material, it is observed that the grain structures have a fuller compact structure. The interdependence of the grains in the samples is particularly evident in BOF slag-mixed clay samples, especially at 12%, 15%, and 20% (indicated in Fig. 11d, e, f).

Investigation of micro structure with SEM analysis

Samples of a certain proportion (3%, 6%, 9%, 12%, 15%, and 20%) of BOF slag-mixed clay material were magnified 2500× times and subjected to investigation with a SEM electronic microscope. The microstructure of BOF slag and clay mixture samples were examined with a SEM electronic microscope.

When we examine the SEM images of (a-) BOF slag and (b-) clay samples in Fig. 12, it is seen that the BOF slag grains are larger. Clay minerals are not found in a pure form and are generally present with aluminum silicates and non-clay impurities such as iron, magnesium, potash, calcium, sodium, and quartz. Many clay minerals can also contain organic matter and water-soluble salts. The main rock is effective in the formation of clay, as well as transport, washing, and chemical reactions are effective. In the investigation of microstructures of clays, these mineralogical and geological features come to the beads.

In the microstructure examination, most of the BOF slag grains examined under SEM were found to have smooth, crystal structures and extremely rough surface textures (Fig. 12a). It was concluded that the increase in shear strength of the compacted clay is due to the bonds formed during the freezing and thawing cycle.

It can be evaluated that the minerals contained in the clay swelling have a significant effect. Allam and Sridharan (1981) investigated the effect of the freeze and thaw cycle of clays, and they concluded that the increase in shear strength of the compressed clay is due to the bonds formed during the freezing and thawing cycle. Collins using SEM, in his study of the microstructure of swelling soils, showed that the determination of microstructure of clay is an important factor in evaluating the swelling behavior of expanded soils (Collins 1984). It is stated by many researchers that microstructural soil is a major factor affecting engineering behavior (Pusch 1979; Mitchell and Soga 2005).

X-ray and SEM analyzes were performed on 3%, 6%, 9%, 12%, 15%, and 20% BOF slag-added samples in order to see the microstructural change in the samples before and after the cycle. Looking at the SEM analysis result (indicated in Fig. 13), 3%, 6%, 9%, and 12%, when evaluated for 15% and 20% BOF slag-blended sample BOF were more clustered in the following cycle in the sample by the amount of slag increasing, and shows a dense structure integrity.

X-ray diffraction analysis (XRD)

For the XRD study, samples prepared from each sample were tested with an X-ray diffractometer and clay mineral types were determined. Mineralogical phase analysis was carried out on 6 samples of BOF slag-added clay materials in parallel with optical microscope study. BOF slag-added samples were investigated with a Rigaku SmartLab X-ray diffraction device. XRD analyzes were performed using Cu Kα radiation (λCu = 0.1540 nm) and a computer-controlled Bruker AXS D8 Advance Diffractometer with 2θ angles ranging from 5° to 90°.

In laboratory conditions, 3%, 6%, 9%, 12%, 15%, and 20% BOF slag admixtures (6 samples) prepared by compacting at optimum water content were examined both before and after of the freezing and thawing cycle and swelling amount and micro structure; SEM analysis and XRD analysis were also performed (illustrated in Figs. 14, 15, and 16).

The main components of the BOF meltshop furnace slag sample were determined and the results are shown in Fig. 14. According to the test results, the main components are calcium oxide (CaO), silicon dioxide (SiO2), aluminum oxide (Al2O3), and iron (Fe). The presence of aluminum oxides (Al2O3), magnesium oxides (MgO), and other components in BOF slags as well as the abovementioned components were found to be low. In the XRD analysis, calcium and silicon compounds and silicate compounds of calcium and iron were found as the basic bond structures. XRD analyzes on clay samples are given in Fig. 15.

XRD analysis results (displayed in Fig. 15) on clay samples showed clay minerals in clays and non-clay minerals (calcite, quartz, etc.) in some shadows. XRD analysis of clay samples revealed chlorite, kaolin, vermiculite, montmorillonite, and halloysite minerals. The X-ray diffractogram results of BOF slag-added clay samples are shown collectively in Fig. 16.

As seen in the results of SEM analyzes and XRD records, during the freeze–thaw cycle, it is seen that the grains are rearranged and the structure integrity is relatively increased. As a result of the agglomeration of the resulting surface area to interact with the liquid, the surface area to be in contact with the liquid has decreased. As a result of this process, a decrease in swelling potential was observed.

When XRD and SEM analysis results are evaluated, BOF slag additive samples aggregate as a result of agglomeration compared to pre-cycle and had larger grain structure compared to pre-cycle. This effect of the freezing and thawing cycle is even more pronounced in samples with 12%, 15%, and 20% BOF slag addition. The strength enhancing effect is mostly observed in the BOF slag sample added in different proportions of binder and grain filling gaps.

When the effect of the cycle on the swelling potential of clayey soils is investigated, due to the increase in the number of cycles, the swelling ability of the soil with high swelling potential decreased with the contribution of BOF slag and increased agglomeration structure on clayey soil. Characterized in that swelling clay, the compression state of the sample and major site in particular clay mineral varied depending on the type. To understand the freeze–thaw mechanism of clays, it would be appropriate to quantitatively evaluate the microstructure of the clays.

Conclusions and recommendations

The effects on the bearing value of the soil were investigated in experiments before and after freezing–thawing. Freeze–thaw tests were applied following the ASTM D 5918 standard test methods for 240 h, and the maximum swelling amount (demonstrated in Table 7) was observed in B-0, B-3, and B-6 samples. With the addition of the BOF slag to clayey soil samples with high freezing and swelling sensitivity, it was observed that the sensitivity to freezing and the amount of swelling decreased. In the freeze–thaw experiments, it was seen that when BOF slag was added to the clayey soil sample, the best resistance to soil strength and abrasion was obtained from mixtures between 12% and 20%. TS EN 1367-1 freeze–thaw test was applied on clayey soil and BOF slag mixture sample, and it was used as a heat treatment step in ASTM D-5918 test standard. SEM images of samples containing 9% or more BOF slag after the post-freeze–thaw cycle indicate that denser and more clustered grain structures were formed compared to 3% and 6% pure samples. When the microstructure of the samples was examined (indicated in Fig. 13c, d, e, f), it was thought that the clay material was squeezed into the pores of the BOF slag to form a composite structure. Thus, it was thought that the mixture samples were less affected by the effects of both pressure and climate. When the results were evaluated, it was observed that when the BOF slag was added to the Iskenderun clayey soil sample, there was a decrease in the bearing and swelling capacity and an increase in the ground bearing capacity.

References

Allam MM, Sridharan A (1981) Effect of wetting and drying on shear strength. J Soil Mechanics Foundations Div 107(4):421–438. https://doi.org/10.11648/j.ajce.20160404.15

ASTM D-5918 (2013) Standard test methods for frost heave and thaw weakening susceptibility of soils, Active ASTM Standards. https://www.astm.org/Standards/D5918.htm Accessed 18 Sept 2020. https://doi.org/10.1520/D5918-06

Batman A (2015) Investıgatıon of the effects of ground quartz sand into the strength properties of clay. MSc Thesis, Atatürk University, Erzurum (in Turkish). 13-15 September 2012. ISBN No: 978-605-01, 912-922

Bölükbaşı ÖS, Demir U, Uçar A (2012) Enriched BOF slag used at Isdemir Sinter Plant, 16th International Metallurgy & Materials Congress. IMMC, İstanbul

Bozbey I, Kelesoglu MK, Demir B, Komut M, Comez S, Ozturk T, Oztoprak S (2018) Effects of soil pulverization level on resilient modulus and freeze and thaw resistance of a lime stabilized clay. Cold Reg Sci Technol 151:323–334. https://doi.org/10.1016/j.coldregions.2018.03.023

Brand AS, Roesler JR (2015) Steel furnace slag aggregate expansion and hardened concrete properties. Cem Concr Compos 60:1–9. https://doi.org/10.1016/j.cemconcomp.2015.04.006

Brand AS, Singhvi P, Fanijo EO, Tutumluer E (2020) Stabilization of a clayey soil with ladle metallurgy furnace slag fines. Materials 13(19):4251

Cikmit AA, Tsuchida T, Kang G, Hashimoto R, Honda H (2019) Particle-size effect of basic oxygen furnace steel slag in stabilization of dredged marine clay. Soil Found 59(5):1385–1398. https://doi.org/10.1016/j.sandf.2019.06.013

Collins K (1984) Characterization of expansive soil microfabric. In: Fifth International Conference on Expansive Soils 1984: Preprints of Papers. Institution of Engineers, Australia, p 37

Cui Z, Zhang Z (2015) Comparison of dynamic characteristics of the silty clay before and after freezing and thawing under the subway vibration loading. Cold Reg Sci Technol 119:29–36. https://doi.org/10.1016/j.coldregions.2015.07.004

Demir S, Kılıç M (2010) Identification of swollen soils and soil improvement methods. Gaziosmanpaşa University Fac Agric J 27(1):95–104 (in Turkish)

Eskişar T, Altun S, Kalıpcılar İ (2015) Assessment of strength development and freeze–thaw performance of cement treated clays at different water contents. Cold Reg Sci Technol 111:50–59. https://doi.org/10.1016/j.coldregions.2014.12.008

Fakhri M, Ahmadi A (2017) Evaluation of fracture resistance of asphalt mixes involving steel slag and RAP: Susceptibility to aging level and freeze and thaw cycles. Constr Build Mater 157:748–756. https://doi.org/10.1016/j.conbuildmat

Freitag DR, McFadden TT (1997) Introduction to cold regions engineering. Am Soc Civil Engineers. 758

Genç S (2009) Expansive soils and the swelling behaviour of bentonite – kaolinite mixtures. MSc Thesis, Istanbul Technical University, İstanbul (in Turkish)

Güllü H, Khudir A (2014) Effect of freeze–thaw cycles on unconfined compressive strength of fine-grained soil treated with jute fiber, steel fiber and lime. Cold Reg Sci Technol 106–107:55–65. https://doi.org/10.1016/j.coldregions.2014.06.008

Hazirbaba K (2017) Field and laboratory performance of a cold-region sand stabilized with geofiber and synthetic fluid. Cold Reg Sci Technol 135:16–27. https://doi.org/10.1016/j.coldregions.2016.12.009

Işık A (2014) Experimental investigation of freeze and thaw on compacted soils. MSc Thesis, Istanbul Technical University, İstanbul (in Turkish)

ISO 17892-12 (2018) Geotechnical investigation and testing — Laboratory testing of soil — Part 12: Determination of liquid and plastic limits. https://www.iso.org/obp/ui/#iso:std:iso:17892:-12:ed-1:v1:en Accessed 20 Sept 2020.

Karasahin M, Keskin E, Sahinoğlu İ (2019) Effect of lime on unconfined compressive strength of a low plasticity clayey soil. Eurasian J Civil Eng Architect 3(2):32–40

Lake CB, Yousif MA, Jamshidi RJ (2017) Examining freeze/thaw effects on performance and morphology of a lightly cemented soil. Cold Reg Sci Technol 134:33–44. https://doi.org/10.1016/j.coldregions.2016.11.006

Lee B, Kim G, Nam J, Cho B, Hama Y, Kim R (2016) Compressive strength, resistance to chloride-ion penetration and freezing/thawing of slag-replaced concrete and cementless slag concrete containing desulfurization slag activator. Constr Build Mater 128:341–348. https://doi.org/10.1016/j.conbuildmat.2016.10.075

Liu T, Xua X, Yang J (2017) Experimental study on the effect of freezing-thawing cycles on wind erosion of black soil in Northeast China. Cold Reg Sci Technol 136:1–8. https://doi.org/10.1016/j.coldregions.2017.01.002

Liu Y, Wang Q, Liu S, Shang Guan Y, Fu H, Ma B, Yuan X (2019) Experimental investigation of the geotechnical properties and microstructure of lime-stabilized saline soils under freeze-thaw cycling. Cold Reg Sci Technol 161:32–42. https://doi.org/10.1016/j.coldregions.2019.03.003

Mahoutian M, Shao Y (2016) Production of cement-free construction blocks from industry wastes. J Clean Prod 137:1339–1346. https://doi.org/10.1016/j.jclepro.2016.08.012

Mitchell JK, Soga K (2005) Fundamentals of soil behavior, vol 3. Wiley, New York

Olgun M (2013) The effects and optimization of additives for expansive clays under freeze–thaw conditions. Cold Reg Sci Technol 93:36–46. https://doi.org/10.1016/j.coldregions.2013.06.001

Özgan E, Ertürk S, Serin S (2012) Investigation of the effects of freezing and thawing on the physical properties of cohesive soils. J Adv Technol Sci 1:7–16 (in Turkish)

Pang B, Zhou Z, Cheng X, Du P, Xu H (2016) ITZ properties of concrete with carbonated steel slag aggregate in salty freeze-thaw environment. Constr Build Mater 114:162–171. https://doi.org/10.1016/j.conbuildmat.2016.03.168

Pusch R (1979) Unfrozen water as a function of clay microstructure. Eng Geol 13(1-4):157–162

Roustaei M, Eslami A, Ghazavi G (2015) Effects of freeze–thaw cycles on a fiber reinforced fine grained soil in relation to geotechnical parameters. Cold Reg Sci Technol 120:127–137

Shin H, Yang J, Yoon Y, Mitchell D (2016) Mix design of concrete for prestressed concrete sleepers using blast furnace slag and steel fibers. Cem Concr Compos 74:39–53. https://doi.org/10.1016/j.cemconcomp.2016.08.007

TS EN 1367-1 (2009) Tests for thermal and weathering properties of aggregates – part 1: determination of resistance to freezing and thawing. Turkish Standards Institute European Norm, Ankara

TS EN 1367-2 (2010) Tests for thermal and weathering properties of aggregates- part 2: magnesium sulfate test. Turkish Standards Institute European Norm, Ankara

TS EN 933-1 (2012) Tests for geometrical properties of aggregates - part 1: determination of particle size distribution - sieving method. Turkish Standards Institute European Norm, Ankara

Vijayan DS, Parthiban D (2020) Effect of solid waste based stabilizing material for strengthening of expansive soil-a review. Environ Technol Innov:101108. https://doi.org/10.1016/j.eti.2020.101108

Wu Y, Qiao X, Yu X, Yu J, Deng Y (2020) Study on properties of expansive soil improved by steel slag powder and cement under freeze-thaw cycles. KSCE J Civil Eng:1–12

Yilmaz F, Fidan D (2017) Effect of wetting-drying cycles on volumetric stability of clayey soil stabilized with lime and perlite. Eur J Tech 7(2):207–218

Yilmaz F, Fidan D (2018) Influence of freeze-thaw on strength of clayey soil stabilized with lime and perlite. Geomech Eng 14(3):301–306. https://doi.org/10.12989/gae.2018.14.3.301

Zaimoğlu AŞ (2010) Freezing–thawing behavior of fine-grained soils reinforced with polypropylene fibers. Cold Reg Sci Technol 60:63–65. https://doi.org/10.1016/j.coldregions.2009.07.001

Zaimoğlu AŞ, Hattatoğlu F, Akbulut RK (2013) Freezing-thawing behaviour of fine-grained soils subjected to surcharge loads. Pamukkale Univ J Eng Sci 19(3):117–120. https://doi.org/10.5505/pajes.2013.35744

Author information

Authors and Affiliations

Contributions

ömer saltuk bölükbaşı: Investigation, supervision, methodology, formal analysis, characterization and measurements, and software. kemal tahir öngü: Formal analysis, investigation, original draft preparation. The author(s) read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Responsible Editor: Zeynal Abiddin Erguler

Highlights

• BOF slags of 1.7 million tons/year are produced in Turkey, and only 5% of it can be used.

• This study has created an important area of use for BOF slag.

• As the usage ratio of BOF slag increased, the strength values of clay soil improved.

• The best mixing ratio of the BOF slag in the clay soil was between 12% and 20%.

• This process lasted for 10 days with a 24-h period of freezing–thawing cycle.

Rights and permissions

About this article

Cite this article

Bölükbaşı, Ö.S., Öngü, K.T. Exploratory of the freezing–thawing behavior of clay and steel slag mixtures. Arab J Geosci 14, 618 (2021). https://doi.org/10.1007/s12517-021-06956-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-021-06956-0