Abstract

Anaerobiosis is a well-established biotechnology which treats animal manure for methanogenesis. The presence of various antibiotics in poultry waste may inhibit anaerobic digestion (AD). The current study aimed at investigating the effects of various antibiotics on the AD of poultry litter. The batch experiments were performed with an inoculum/substrate ratio of 1 in sealed glass vials incubated under anaerobic conditions at 37 °C for 21 days. The antibiotics, i.e., bacitracin (BAC), erythromycin (ERY), monensin (MON), and tetracycline (TET), were added at the concentration ranges of 0.02 to 0.1 mg mL−1. During the first week, the inhibitory effects of monensin were higher (36–60%) as compared with other antibiotics. For 8–15 days and 16–21 days, the inhibitory effects caused by erythromycin were 28–38%, followed by 21–35% of TET and 20–40% of BAC. MON showed lower inhibition during the final stages of experiment which might possibly be due to its biodegradation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Large quantities of excreta are generated by poultry industry owing to worldwide expansion of the livestock and poultry sector (Li et al. 2016). FAO of the United Nations declared that the poultry sector has increased over 80% of the total livestock. According to estimates, 23 billion poultry birds were raised worldwide in the poultry farms in 2013 (Kantarli et al. 2016). Intensive poultry farming has raised serious concerns about their impact on environmental health. Conventionally, the poultry waste has been used as fertilizer; however, this is not environmentally safe practice due to associated spread of pathogens (Gerba and Smith 2005). Odorous compounds and other environmental implications have also been reported due to excessive use of poultry manure as fertilizer (Font-Palma 2012). There is a vibrant poultry sector in Pakistan annually producing with more than 530 million birds (Sheikh 2009; Rehman et al. 2017) which are operated to meet the demands of meat in Pakistan (Arshad et al. 2018). Approximately, 2 kg of litter is produced per bird in 40 days (León and Martín 2016) while 1 million tons of manure is produced every year from different poultry farms in Pakistan (Amjid et al. 2011). Antimicrobial agents are widely used as preventive and curative agents of poultry diseases (Turnidge 2004; Hao et al. 2014). Anatomical and physiological features of gastrointestinal tracts of birds influence the absorption of drugs, so these dietary antibiotics in chicken are mostly defecated along the poultry litter (Landoni and Albarellos 2015).

In spite of high concentration of useful nutrients, the mass scale utilization of poultry litter changes the ecology of water bodies and soil due to greenhouse gas emissions, air pollution, production of phytotoxic substances, and expansion of pathogens (Cerri et al. 2010; Chaump et al. 2018; Jenkins et al. 2006; Kelleher et al. 2002). Poultry manure effect is a mystery, but scientists perceive that it causes sexual changes in fish when poultry manure is applied in agricultural farms at very high rates which reach the water bodies (Harris et al. 2011; DeLaune and Moore 2013). Poultry waste can be stabilized through anaerobic digestion with its associated methanogenesis (2018). The mixture of 30% swine manure and sewage sludge produced approximately 400 dm3/kg VS of biogas. However, the ultimate biogas production from ternary mixture of the sewage sludge, swine manure, and poultry manure was only 336 dm3 kg VS (Borowski et al. 2014).

Antibiotics are administered to treat various pathogenic diseases in poultry; however, their residues (up to 75%) are not entirely absorbed in poultry which enter into the environment (Chee-Sanford et al. 2009). The presence of antibiotics in poultry manure was considered hazardous posing a serious threat to human health and the environment, and it was recommended to show the evidence of antibiotic exposure for suggesting management strategies against them (Rashid and Coyne 2019). The presence of presence gap was also pointed out by Rashid and Coyne (2019) in terms of how antibiotics were released into environment especially non-irrigation waters and extent of exposure. Yang et al. (2016) showed how the exposure of antibiotics from animal manure makes the soil microbes resistant. Moreover, humans were being exposed to almost lethal concentrations of antibiotics in the environment which may have serious implications on human health through increased resistance against these antibiotics (Rashid and Coyne 2019). Antibiotics of inorganic and organic origin in pig manure could inhibit the anaerobic process in biogas plants. Various researchers have evaluated inhibition of biogas production during AD (Chen et al. 2008; Sara et al. 2013; Lu et al. 2014; Reyes-Contreras and Vidal 2015; Yin et al. 2016). BAC is the only polypeptide antimicrobial agent licensed for worldwide use in poultry. It is usually delivered in feed for preventing/controlling necrotic enteritis (Hofacre et al. 1998) which prevents bacterial cell wall synthesis (Landoni and Albarellos 2015). ERY is composed of macrocyclic lactone structures that inhibit bacterial growth by irreversibly binding to the 50S ribosomal subunit (Tenson et al. 2003) thus retarding protein synthesis. The antibiotics belonging to this group have a comparatively broad-spectral effects on both Gram-positive and Gram-negative bacteria (Sweetman 2009).

The susceptibility of AD to antibiotics is expected to be higher as compared with aerobic treatment of wastes. AD process may be inhibited by various toxicants and microbial metabolic inhibitors and affect the efficiency of biogas production. The effects of some commonly used antibiotics, viz., BAC, ERY, TET, and MON, have not been investigated on biogas generation from poultry manure. The main aim of the present study was to investigate the inhibitory effects commonly reported antibiotics in poultry litter on biogas production.

Materials and methods

Experimental design

Poultry manure (poultry excreta plus feed residues) was collected from a poultry farm at the University of Illinois at Urbana Champaign, USA. Various dilutions of each antibiotic were made based on the amount of antibiotics anticipated in the feed. The poultry excreta plus the feed residues obtained from the poultry farms were anaerobically digested. The batch experiments were performed in sealed vials (working volume of 100 mL) in triplicate keeping the inoculum/substrate ratios of 1 on volatile solids basis. The inoculum was obtained from mesophilic lab-scale reactor. TS and VSS of inoculum were 137.37 g/L and 70.89 g/L respectively, with VS/TS ratio of 0.51. The vials were incubated under anaerobic conditions at 37 °C for 21 days.

Antibiotics widely reported in feed include BAC (55–110 mg/kg), ERY (115.6–250 mg/kg), TET 45–100 mg/kg, and MON (80–125 mg/kg) (Landoni and Albarellos 2015). Different doses of each antibiotic were prepared from stock concentrations such as BAC (1 mg/10 mL), ERY (2.5 mg/10 mL), TET (1 mg/10 mL), and MON (1.25 mg/10 mL). Various antibiotic concentrations were added to the vials according to previous report (Landoni and Albarellos 2015), and all antibiotics were in range of 0.02 to 0.1 mg per 100 mL reaction solution. VFA were analyzed on 7th, 14th, and 21st days of incubation. The control of co-digested poultry wastes was run without adding any antibiotics. The anaerobic basic medium was prepared according to the protocol of Angelidaki and Sanders (2004).

Analytical methods

Biogas pressure in vials was measured using a calibrated manometer and expressed as N/m2. VFAs were quantified by HPLC with 5 mM H2SO4 for the mobile phase and stationary phase using column BioRad Aminex HPX 87H. Glucose, acetate, lactate, succinate, formate, malate, and citrate were quantitatively assessed by HPLC (Shimadzu, Japan) with a refractive index detector (RID-10A; Shimadzu, Japan) and an Aminex HPX-87H ion exclusion column (Bio-Rad, USA). The C:N ratio was determined using an elemental CHN analyzer (2400 CHNS/O Series II System, PerkinElmer). Ammonia nitrogen and pH were measured at the end of experiment. Ammonia-nitrogen was determined by colorimetric method (Chaney and Marbach 1962). Gow-Mac GC equipped with a thermal conductivity detector conducted Methane analyses on every seventh day. The biogas samples (0.5 mL) collected from batch reactor were injected into gas chromatograph (series 580 thermal conductivity GC, Gao - Mac instrument Co., Bethlehem, PA). The GC column was 183 cm × 6.4 mm o.d. packed with Porapak Q, and the temperatures for the injection port, detector, and column were 80, 80, and 75 °C, respectively. The elemental analysis was carried out through ICP Varian Vista Pro CCD simultaneous inductively coupled plasma optical emission spectrometers (radial torch configuration) with an SPS 3 auto sampler (Varian, Palo Alto, CA, USA). Samples were atomized for transport into the radio frequency ICP, where each element releases its relevant spectrum. The photosensitive CCD microchip was used for the measurement of wavelength intensities. Data were calculated and the ICP expert computer software (Varian) was used for data storage. The internal GC column with chromium oxide as a catalyst was used for the combustion process.

The inhibition percentages of the antibiotics were measured from the pressure of biogas produced in the batch tests and control reactors using the following formula (Gartiser et al. 2007).

I = is the percentage inhibition

Pt = is the biogas pressure in the test bottles at the selected time

Pc = is biogas pressure in the control bottles at the selected time

Statistical analysis

All the determinations were performed in triplicate and mean values were presented in the results. Statistical comparisons of the mean values were performed by three way analysis of variance (ANOVA) using sigma plot™ V.12 considering time, type of antibiotics and concentration as three factors (P < 0.05).

Results and discussions

Feed stock characterization

The characterization of feed stock was necessary to know the composition of raw materials used in AD. The characteristics of the poultry litter are presented in the Table 1. The initial pH values of the reactors were in the range of 6.2 to 6.5. The pH of feedstock and inoculum was 5.54 and 8.91, respectively, for the batch experiment. In addition, the TS, VS, and elemental analysis are also presented in Table 1. The C:N ratio for the poultry litter used for the experiment was 17:1. However, the C:N ratio for poultry dropping has been reported to be 6.5 (Miah et al. 2016). The C:N ratio of feed stock was 17:1 for the current experiment.

Effect of antibiotic concentrations on cumulative biogas generation

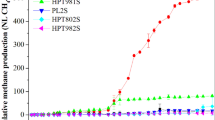

Cumulative biogas production could be regarded as an indicator of the effects of different concentrations of antibiotics on anaerobic digestion. The four tested antibiotics with concentrations are shown in Fig. 1a–d. Compared with control, lower cumulative biogas pressure was noted under the influence of various concentrations of antibiotics. On VS basis, the biogas pressure under the influence of BAC was in range of 73~89 Nm−2 g−1 VS−1, respectively. The range of biogas production under ERY was in range of 64~73 Nm−2 g−1 VS−1. The effect of TET was not severe as the range of biogas produced was 62~92 Nm−2 g−1 VS−1. The range of biogas production under monensin addition was 81~94 Nm−2 g−1 VS−1 for various added antibiotic concentrations.

Effect of different antibiotic concentrations bacitracin (a), erythromycin (b), tetracycline (c), and monensin (d) on cumulative biogas production. The data are given as the mean of 3 replicates per treatment and day of sampling. To simplify the representation, lowercase letters on each part of the figure represent the differences between different concentrations of each antibiotic at days 1, 7, 14, and 21. Different alphabets show significant differences (P < 0.05) among data points

The effects of various antibiotics on cumulative biogas production were not obvious until day 3–5 depending on the type of antibiotic. Effect of antibiotics on cumulative biogas production can be analyzed on weekly basis. As for as BAC is concerned, there was no significant difference between all the treatment during 1st week (from day 1–7) except at day 6 and 7 where control treatment was statistically significant different (P > 0.05) from all other concentrations. During 2nd week (from day8–14), same trend was observed as in 1st week, except 0.1 mg mL−1 exhibited more inhibition at day 13 and 14. During last week (from day 15–21), the values of cumulative biogas production for 0.1 mg mL−1, 0.02 mg mL−1, and control showed statistically significant difference as compared with 0.08 mg mL−1, 0.06 mg mL−1, and 0.04 mg mL−1 (no statistical significant difference between these three treatments at P > 0.05). For ERY, there was no significant difference between all the treatments till day 3 during 1st week (from day 1–7) and then from day 4 onwards control treatment was statistically significant different (P > 0.05) from all other concentrations. During 2nd week (from day8–14), same trend was observed as in 1st week, except 0.25 mg mL−1 exhibited more inhibition at day 13 and 14. During last week (from day 15–21), the values of cumulative biogas production for 0.25 mg mL−1, 0.05 mg mL−1, and control showed statistically significant difference as compared with 0.2 mg mL−1, 0.15 mg mL−1, and 0.1 mg mL−1 (no statistical significant difference between these three treatments, P > 0.05). No statistical difference was shown by different concentrations and control of TET till day 5. At day 6 and 7, inhibition effect of different concentrations over control was statistically obvious. At the end of incubation period (21 days), 0.08 mg mL−1 and 0.06 mg mL−1 showed more inhibition as compared with 0.1 mg mL−1, 0.04 mg mL−1, and 0.02 mg mL−1 (Fig. 1c). As for as monensin is concerned for cumulative biogas production, inhibition effect started appearing from day 2. Control treatment was significantly different from all other concentrations at day 2 (Fig. 1d). At day 7, control showed statistically higher biogas production from all other treatments, while 0.025 mg mL−1 and 0.05 mg mL−1 showed medium and 0.075 mg mL−1, 0.1 mg mL−1, and 0.125 mg mL−1 showed lower biogas production (Fig. 1d). Same pattern was observed for second week. At the end of the experiment (day 21), there was no statistical difference between control, 0.025 mg mL−1, and 0.05 mg mL−1 concentrations for cumulative biogas production. 0.075 mg mL−1 and 0.1 mg mL−1 concentrations showed medium biogas production, and there was no statistical difference between these two treatments, while 0.125 mg mL−1 showed the lowest biogas production from all other treatments (Fig. 1d).

BAC concentration of 0.1 mg mL−1 had a greater effect on cumulative biogas production than rest of the applied concentrations (Fig. 1a), whereas 0.25 mg mL−1 of ERY affected the cumulative biogas production compared with control (Fig. 1 b). In Fig. 1c, it was evident that TET concentration spectrum was quite different from the rest of four antibiotics; e.g., its 0.08 mg mL−1 and 0.06 mg mL−1 affected the cumulative biogas production more than rest of the concentrations of the same antibiotic. MON had a moderate and rather transitory effect on CH4 production. The addition of monensin has a greater inhibitory effect on metabolism of Gram-positive bacteria than Gram-negative bacteria (Łowicki et al. 2013). The main reason was that the cell walls of Gram-negative bacteria did not allow the penetration of hydrophobic molecules with high molecular size and thus the Gram-negative bacteria were not as susceptible to the action of MON (Łowicki et al. 2013). ERY inhibits protein assembly in bacteria by blocking the path of nascent proteins in the ribosomal exit tunnel (Novak and Kovač 2015). MON does not particularly affect the metabolism of methanogens and thus biogas production (Romero-Pérez et al. 2016).

Inhibition of anaerobic digestion

The effects of various concentrations of BAC, ERY, TET, and MON were analyzed to determine inhibition percentages of AD and are presented in Fig. 2.

During initial days of the experiment, the inhibition percentages for all the concentrations of BAC shown in Fig. 2 indicated that they were in the range of 20 to 40%. The BAC concentration of 0.1 mg mL−1 caused the highest inhibition percentage from day 4 to 21 of the experiment. However, percentage inhibition was the lowest for 0.02 mg mL−1 from day 10 onwards. The inhibition pattern of ERY showed that it caused lower inhibition up to day 6. The inhibition level increased after day 6. The level of 0.25 mg mL−1 ERY had the highest inhibition, whereas 0.05 mg mL−1 of ERY had the lowest inhibition. TET concentrations of 0.06 mg mL−1 and 0.08 mg mL−1 resulted in the highest inhibition percentage as compared with the rest of the concentrations. The 0.06 mg mL−1 and 0.08 mg mL−1 were consistent during the 21 days of the experiment. For all tested antibiotics, monensin had the highest inhibition it the start but the inhibition for the concentrations during latter stages decreasing over the 21-day experiment.

Initially, monensin showed higher inhibition (36–60%) as compared with other antibiotic concentrations. However, during the later stages (2nd and 3rd week), the inhibitory effect was higher for ERY (28–38%), TET (21–35%), and BAC (20–40%). MON showed lower inhibition during the later stages of experiment. This might be due to the degradation of the monensin metabolites and intermediate products by hydrolytic bacteria. For BAC and ERY, the inhibition percentages increased by the end of the 21-day experiment. This might be due to the presence of non-degraded metabolites of BAC and ERY in the latter part of experiment. Various antibiotics may have differential impact on the metabolic functions of anaerobic bacteria involved in AD. Various antibiotics may inhibit the activation of amino acids to be carried by tRNAs to the site of protein synthesis (Xiong et al. 2017). Many researchers reported variations in the volume of biogas produced upon the presence of various antibiotics in the digesters (Álvarez et al. 2010; Bauer et al. 2014; Cetecioglu et al. 2015; Cetecioglu et al. 2013). Based on functional genes analysis by qPCR, high concentrations of antibiotics were held responsible for the agitations in the structure of anaerobic microbial populations (Cetecioglu et al. 2015).

The impact on bacterial activity depends on the concentration of antibiotics and its metabolites and degradation of intermediate products (Huang et al. 2014). It is clear from Fig. 2 that biogas production did not cease by day 21 in many reactors (except for the controls). This means that AD in the treated samples slowed down, but there was still a substantial, unused biogas potential in these reactors. However, additional experiments may be needed to confirm this hypothesis.

Effect of antibiotic concentration on methane production

Methanogenic archaea are obligate anaerobes and play a vital role in the methanogenesis with over 90% of methane produced on earth by them (Costa and Leigh 2014). There are three main methanogenic pathways: (i) acetoclastic methanogenesis; (ii) hydrogenotrophic methanogenesis; and (iii) methylotrophic methanogenesis (Borrel et al. 2013). In high ammonia digestate samples, the main metabolic pathway for methane formation was confirmed to be via the syntrophic acetate oxidation coupled with hydrogenotrophic methanogenesis responsible for 68–75% of the CH4 formation, whereas in low ammonia samples, the hydrogenotrophic pathway accounted for 9–23% of the total CH4 production (Jiang et al. 2018). The methane percentage for the current experiments presented in the Table 2 showed that the methane percentage was lower than the control after 1 week at the highest added concentration of antibiotic. However, in the last 2 weeks the methane percentage was higher than the control. These findings may be most likely results as acidogenic consortia are affected by antibiotics (Cetecioglu et al. 2013) to a greater extent than methanogenic consortia, slowing the entire metabolic pathway. However, a study involving the use of cefazolin to dairy manure showed no inhibition of methane production at 30, 60, and 90 mg L−1 in a thermophilic digester (Beneragama et al. 2013). In our study, BAC and MON at the level of inclusion showed lower inhibition of biogas production as compared with ERY and TET relative to the control. All pH values were around neutral.

Assessment of volatile fatty acid profile

Determination of volatile fatty acid (VFA) concentrations is essential to evaluate the performance of anaerobic digestion (Rittmann and McCarty 2001). During startup and operation, the presence of acetic, propionic, butyric, and isobutyric acids is normally observed at high concentrations (Rittmann and McCarty 2001) and is indicative of the coordinated activities of microbial consortia. During the 3 weeks of incubation, the VFA profile and biogas production were dynamic under the influence of various antibiotic concentrations. In the last week of the batch experiment, BAC showed acetic acid did not accumulate under the influence of antibiotics; however, little VFAs were detected in the presence of monensin. It suggested lower inhibition at the respective concentration of BAC and monensin. Higher concentrations of propionic acid in the last 2 weeks proposed that the degradation of propionate was utilized by Gram-negative bacteria (e.g., Syntrophobacter species, Pelotomaculum species) known as SPOB (syntrophic propionate-oxidizing bacteria activity) (Stams et al. 2012) and the selected concentrations of antibiotics would be expected to inhibit sensitive strains of anaerobic microbial consortia. The majority of known SPOB degrade propionate by methyl-malonyl coenzyme A pathway and the conversion of succinate and fumarate is an important step in this pathway (Stams et al. 2012). In the view of the batch incubation results, the exposure to antibiotics affected specific propionate degradation pathways. The propionic acid utilization pathway was inhibited in a ST (sulfamethoxazole–tetracycline) reactor (Aydin et al. 2015). The degradation of propionate is most often utilized by Gram-negative bacteria (e.g., Syntrophobacter species, Pelotomaculum species), and combinations of ST (sulfamethoxazole–tetracycline) antibiotics would be expected to inhibit sensitive strains of this microbial group (Aydin et al. 2015; Chopra and Roberts 2001).

Overall, the VFA results show that accumulation of VFAs was observed particularly after 7 and 14 days of incubation which was the evidence of inhibition as shown in Fig. 3. The buildup of VFA was accompanied by lower pH which might have contributed to inhibition in addition to the effects of antibiotics alone. Similar results were reported by Dreher et al. (2012) with greater acetic acid accumulation for the chlortetracycline (CTC) reactors during the first cycle (18% and 383% increase, respectively) compared with the non-CTC treatments (3% and 37% increase), suggesting a possible inhibition of methanogenesis due to the accumulation of volatile fatty acids. There was no buildup of acetic acid for either treatment during cycles three and four, indicating that acetate was efficiently utilized as a substrate for methanogenesis.

Conclusion

The overall results showed that all the treatments with antibiotics showed decreased methane productions when compared with an untreated control. However, the concentrations of ERY and TET showed higher inhibition as compared with BAC and MON. The respective ranges of biogas inhibition by BAC, ERY, MON, and TET were 6~23%, 23~33%, 1~15%, and 3~27%. Proper care and corrective measures should be adopted when using poultry waste during full scale operations. It was clear that biogas production did not cease by day 21 in many reactors (except for the controls). This means that AD in the treated samples slowed down, but there was still a substantial, unused biogas potential in these reactors. The pH 6.2–6.3 and C/N = 17 were not optimal for AD; biogas/biomethane production was therefore limited by these parameters in addition to the antibiotics. Overall, the VFA results show that accumulation of VFAs was observed particularly after 7 and 14 days of incubation which was the evidence of inhibition. The buildup of VFA was accompanied by lower pH which might have contributed to inhibition in addition to the effects of antibiotics alone. For effective control and better biogas outcome, continuous monitoring of the antibiotics in anaerobic digesters is key step.

Abbreviations

- AD:

-

Anaerobic digestion

- BAC:

-

Bacitracin

- C:N:

-

Carbon to nitrogen ratio

- FAO:

-

Food and Agriculture Organization

- ERY:

-

Erythromycin

- HPLC:

-

High-performance liquid chromatography

- MON:

-

Monensin

- qPCR:

-

Quantitative polymerase chain reaction

- TET:

-

Tetracycline

- TS:

-

Total solids

- VSS:

-

Volatile suspended solids

References

Álvarez J, Otero L, Lema J, Omil F (2010) The effect and fate of antibiotics during the anaerobic digestion of pig manure. Bioresour Technol 101(22):8581–8586

Amjid SS, Bilal MQ, Nazir MS, Hussain A (2011) Biogas, renewable energy resource for Pakistan. Renew Sust Energ Rev 15(6):2833–2837

Angelidaki I, Sanders W (2004) Assessment of the anaerobic biodegradability of macropollutants. Re/Views Environ Sci Bio/Technol 3(2):117–129

Arshad M, Bano I, Khan N, Shahzad MI, Younus M, Abbas M, Iqbal M (2018) Electricity generation from biogas of poultry waste: an assessment of potential and feasibility in Pakistan. Renew Sust Energ Rev 81:1241–1246

Aydin S, Ince B, Cetecioglu Z, Arikan O, Ozbayram EG, Shahi A, Ince O (2015) Combined effect of erythromycin, tetracycline and sulfamethoxazole on performance of anaerobic sequencing batch reactors. Bioresour Technol 186:207–214

Bauer A, Lizasoain J, Nettmann E, Bergmann I, Mundt K, Klocke M, Rincón M, Amon T, Piringer G (2014) Effects of the antibiotics chlortetracycline and enrofloxacin on the anaerobic digestion in continuous experiments. BioEnergy Res 7(4):1244–1252

Beneragama N, Lateef SA, Iwasaki M, Yamashiro T, Umetsu K (2013) The combined effect of cefazolin and oxytertracycline on biogas production from thermophilic anaerobic digestion of dairy manure. Bioresour Technol 133:23–30

Borowski S, Domański J, Weatherley L (2014) Anaerobic co-digestion of swine and poultry manure with municipal sewage sludge. Waste Manag 34(2):513–521

Borrel G, O’Toole PW, Harris HM, Peyret P, Brugère J-F, Gribaldo S (2013) Phylogenomic data support a seventh order of methylotrophic methanogens and provide insights into the evolution of methanogenesis. Genome Biol Evol 5(10):1769–1780

Cerri CC, Bernoux M, Maia SMF, Cerri CEP, Costa Junior C, Feigl BJ, Frazão LA, de Castro Mello FF, Galdos MV, Moreira CS (2010) Greenhouse gas mitigation options in Brazil for land-use change, livestock and agriculture. Sci Agric 67(1):102–116

Cetecioglu Z, Ince B, Gros M, Rodriguez-Mozaz S, Barceló D, Orhon D, Ince O (2013) Chronic impact of tetracycline on the biodegradation of an organic substrate mixture under anaerobic conditions. Water Res 47(9):2959–2969

Cetecioglu Z, Ince B, Gros M, Rodriguez-Mozaz S, Barceló D, Ince O, Orhon D (2015) Biodegradation and reversible inhibitory impact of sulfamethoxazole on the utilization of volatile fatty acids during anaerobic treatment of pharmaceutical industry wastewater. Sci Total Environ 536:667–674

Chaney AL, Marbach EP (1962) Modified reagents for determination of urea and ammonia. Clin Chem 8(2):130–132

Chaump K, Preisser M, Shanmugam SR, Prasad R, Adhikari S, Higgins BT (2018) Leaching and anaerobic digestion of poultry litter for biogas production and nutrient transformation. Waste Manag 84:413–422

Chee-Sanford J, Mackie R, Koike S, Krapac I, Maxwell S, Lin Y-f, Aminov R (2009) Fate and transport of antibiotic residues and antibiotic resistance genetic determinants during manure storage, treatment, and land application. J Environ Qual 38:1086–1108

Chen Y, Cheng JJ, Creamer KS (2008) Inhibition of anaerobic digestion process: a review. Bioresour Technol 99(10):4044–4064

Chopra I, Roberts M (2001) Tetracycline antibiotics: mode of action, applications, molecular biology, and epidemiology of bacterial resistance. Microbiol Mol Biol Rev 65(2):232–260

Costa KC, Leigh JA (2014) Metabolic versatility in methanogens. Curr Opin Biotechnol 29:70–75

DeLaune P, Moore P (2013) 17β-estradiol in runoff as affected by various poultry litter application strategies. Sci Total Environ 444:26–31

Dreher TM, Mott HV, Lupo CD, Oswald AS, Clay SA, Stone JJ (2012) Effects of chlortetracycline amended feed on anaerobic sequencing batch reactor performance of swine manure digestion. Bioresource Technology 125:65–74

Font-Palma C (2012) Characterisation, kinetics and modelling of gasification of poultry manure and litter: an overview. Energy Convers Manag 53(1):92–98

Gartiser S, Urich E, Alexy R, Kümmerer K (2007) Anaerobic inhibition and biodegradation of antibiotics in ISO test schemes. Chemosphere 66(10):1839–1848

Gerba CP, Smith JE (2005) Sources of pathogenic microorganisms and their fate during land application of wastes. J Environ Qual 34(1):42–48

Hao H, Cheng G, Iqbal Z, Ai X, Hussain HI, Huang L, Dai M, Wang Y, Liu Z, Yuan Z (2014) Benefits and risks of antimicrobial use in food-producing animals. Front Microbiol 5:288

Harris CA, Hamilton PB, Runnalls TJ, Vinciotti V, Henshaw A, Hodgson D, Coe TS, Jobling S, Tyler CR, Sumpter JP (2011) The consequences of feminization in breeding groups of wild fish. Environ Health Perspect 119(3):306–311

Hofacre C, Froyman R, Gautrias B, George B, Goodwin M, Brown J (1998) Use of Aviguard and other intestinal bioproducts in experimental Clostridium perfringens-associated necrotizing enteritis in broiler chickens. Avian Dis 42(3):579–584

Huang L, Wen X, Wang Y, Zou Y, Ma B, Liao X, Liang J, Wu Y (2014) Effect of the chlortetracycline addition method on methane production from the anaerobic digestion of swine wastewater. J Environ Sci 26(10):2001–2006

Jenkins MB, Endale DM, Schomberg HH, Sharpe RR (2006) Fecal bacteria and sex hormones in soil and runoff from cropped watersheds amended with poultry litter. Sci Total Environ 358(1):164–177

Jiang Y, Banks C, Zhang Y, Heaven S, Longhurst P (2018) Quantifying the percentage of methane formation via acetoclastic and syntrophic acetate oxidation pathways in anaerobic digesters. Waste Manag 71:749–756

Kantarli IC, Kabadayi A, Ucar S, Yanik J (2016) Conversion of poultry wastes into energy feedstocks. Waste Manag 56:530–539

Kelleher B, Leahy J, Henihan A, O'dwyer T, Sutton D, Leahy M (2002) Advances in poultry litter disposal technology–a review. Bioresour Technol 83(1):27–36

Landoni M, Albarellos G (2015) The use of antimicrobial agents in broiler chickens. Vet J 205(1):21–27

León E, Martín M (2016) Optimal production of power in a combined cycle from manure based biogas. Energy Convers Manag 114:89–99

Li F, Cheng S, Yu H, Yang D (2016) Waste from livestock and poultry breeding and its potential assessment of biogas energy in rural China. J Clean Prod 126:451–460

Łowicki D, Huczyński A, Ratajczak-Sitarz M, Katrusiak A, Stefańska J, Brzezinski B and Bartl F (2009) Structural and antimicrobial studies of a new Nphenylamide of monensin A complex with sodium chloride. J Mol Struct 923(1):53–59

Lu X, Zhen G, Liu Y, Hojo T, Estrada AL, Li Y-Y (2014) Long-term effect of the antibiotic cefalexin on methane production during waste activated sludge anaerobic digestion. Bioresour Technol 169:644–651

Miah MR, Rahman AKML, Akanda MR, Pulak A, Rouf MA (2016) Production of biogas from poultry litter mixed with the co-substrate cow dung. J Taibah Univ Sci 10(4):497–504

Novak I, Kovač B (2015) Electronic structure of antibiotic erythromycin. Spectrochim Acta A Mol Biomol Spectrosc 138:550–552

Rashid A, Coyne MS (2019) Chronic exposure and the risk of building antibiotic resistance in rural communities of the developing world. World J Agric Soil Sci 1(5):2019

Rehman A, Jingdong L, Chandio AA, Hussain I (2017) Livestock production and population census in Pakistan: determining their relationship with agricultural GDP using econometric analysis. Inform Process Agric 4(2):168–177

Reyes-Contreras C, Vidal G (2015) Methanogenic toxicity evaluation of chlortetracycline hydrochloride. Electron J Biotechnol 18(6):445–450

Rittmann BE, McCarty PL (2001) Environmental biotechnology: principles and applications. McGrawHill, New York, p 400

Romero-Pérez A, Okine E, Guan L, Duval S, Kindermann M, Beauchemin K (2016) Effects of 3-nitrooxypropanol and monensin on methane production using a forage-based diet in Rusitec fermenters. Anim Feed Sci Technol 220:67–72

Sara P, Michele P, Maurizio C, Luca C, Fabrizio A (2013) Effect of veterinary antibiotics on biogas and bio-methane production. Int Biodeterior Biodegradation 85:205–209

Sheikh MA (2009) Renewable energy resource potential in Pakistan. Renew Sust Energ Rev 13(9):2696–2702

Stams AJ, Sousa DZ, Kleerebezem R, Plugge CM (2012) Role of syntrophic microbial communities in high-rate methanogenic bioreactors. Water Sci Technol 66(2):352–362

Sweetman SC (2009) Martindale: the complete drug reference. Pharmaceutical press

Tenson T, Lovmar M, Ehrenberg M (2003) The mechanism of action of macrolides, lincosamides and streptogramin B reveals the nascent peptide exit path in the ribosome. J Mol Biol 330(5):1005–1014

Turnidge J (2004) Antibiotic use in animals—prejudices, perceptions and realities. J Antimicrob Chemother 53(1):26–27

Xiong Y, Harb M, Hong P-Y (2017) Performance and microbial community variations of anaerobic digesters under increasing tetracycline concentrations. Appl Microbiol Biotechnol 101:5505–5517

Yang Q, Wang R, Ren S, Szoboszlay M, Moe LA et al (2016) Practical survey on antibiotic-resistant bacterial communities in livestock manure and manure-amended soil. J Environ Sci Health B 51:14–23

Yin F, Dong H, Ji C, Tao X, Chen Y (2016) Effects of anaerobic digestion on chlortetracycline and oxytetracycline degradation efficiency for swine manure. Waste Manag 56:540–546

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Amjad Kallel

Rights and permissions

About this article

Cite this article

Shah, F.A., Mahmood, Q., Iqbal, A. et al. Inhibition of biomethane production under antibiotics in poultry litter. Arab J Geosci 13, 614 (2020). https://doi.org/10.1007/s12517-020-05668-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12517-020-05668-1