Abstract

The demand for high quality foods has steadily increased as response to market pressures and to other factors. The concept of food quality (FQ) gradually evolved to address changes in consumer perceptions and due to available technological advances. Evolution followed from FQ 1.0 (defective foods removal) over FQ 2.0 (prevention-based quality assurance), FQ 3.0 (total quality management; TQM), and finally the upcoming concept of FQ 4.0 that is focused on advanced technologies (Internet of Things, Big Data, artificial intelligence, etc.) for improving traceability, food safety, and quality assurance. This evolution from FQ 1.0 up to 4.0 followed perfection of conventional/advanced methods and the expansion of their scope to include the reductions of waste/pollution. This manuscript provides background and brief overview for current and traditional concepts of FQ with consumers in focus while mentioning techniques that are traditionally used for FQ assessments. Also, it describes migration toward FQ 4.0 and how it compares with traditional FQ, while considering products, processes, systems, and sustainable (nano)technologies for improvements of manufacturing and waste reductions. Such information is useful for practical guides for stakeholders in food chain (e.g., food managers, technologists, and consultants). Findings implied importance for developing the area within the “FQ 4.0 triangle,” whose three edges are “food science,” “quality assurance,” and “industry 4.0 (that has the tools/technologies to support this industrial concept).” This area has numerous opportunities for various applications in food sector and for gathering knowledge, currently needed in the food industry. Including data on the suitability of advanced technologies for food manufacturing (e.g., 3D printing), their association with quality/safety, reduction of waste/contaminants, all in order to reach sustainable food production.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The field of food engineering has played a pivotal role in the preservation and improvement of food quality. This has been evident since the industrial revolution and has continued to evolve through five iterations, with advancements in technologies and procedures over the centuries. Over the course of time, the field of food engineering has incorporated a growing array of engineering principles to enhance the quality of food. This is accomplished by leveraging knowledge of food chemistry and physics to optimize a diverse range of factors, such as nutritional value, safety, sensory attributes (including taste, aroma, color, and texture), shelf life, and cost. As a result, food engineering and food quality are intricately linked and subject to constant change.

In recent decades, the demand for high quality food has steadily increased, as has interest in the issue of food quality, both in response to market pressures (e.g., requests from increasingly demanding and knowledgeable consumers) and in response to other factors, such as health and environmental concerns [1], climate changes [2, 3], and legislation advances such as the U.S. Food Safety Modernization Act [4], EU Regulation 2019/1381 on the transparency and sustainability of the EU risk assessment in the food chain [5], and Codex Alimentarius General principles of food hygiene [6]. The concept of food quality gradually evolved in response to these changes in consumer perceptions as well as technological advances. The food quality 1.0 stage was based on inspection-based quality control, which focused on detecting and removing defective food products after production [7, 8]. The food quality 2.0 era introduced prevention-based quality assurance, which focused on preventing defects by applying statistical process control tools and standards during production [9]. Food quality 3.0 was the next step toward customer-oriented quality improvement, which focused on meeting and exceeding customer expectations through the application of total quality management (TQM) principles and continuous improvement methods. This included the use of advanced technologies and practices, such as precision agriculture and organic farming [10,11,12,13]. Consumer awareness and demand for clean label products, as well as regulatory and industry efforts to ensure food safety and quality, were also central to this stage. The upcoming concept of food quality 4.0 could be characterized by even more advanced technologies, such as the IoT, Big Data analytics, artificial intelligence, and blockchain to improve traceability, food safety, and quality assurance [14, 15].

Consumer awareness and demand for clean label products, as well as regulatory and industry efforts to ensure food safety and quality, were also central to this stage and are of the food industry 4.0 shift toward diets that are considered as healthy, green, and sustainable [16]. In parallel, this stage could also involve more widespread adoption of alternative protein sources, such as plant- and cell-based meats, fortified/functional foods, cultured meat or precision fermentation, and personalized food and personalized diets tailored to individual needs [17].

Traditional Concept of Food Quality

Current State of Traditional Concept Food Quality

Food quality in the conventional sense is the compendium of various factors that include physical properties (color and texture), chemical composition, sensory characteristics (color, flavor, juiciness, and tenderness), microbiological and toxicological contaminants, shelf life, packaging and labeling that affect how well a food performs, interacts with its environment, and persuades consumers to purchase [18]. In recent years, nutritional value (amino acid, fatty acid, and other lipid profiles) and authenticity of foods have been considered as factors that help customers make more conscious food choices. A person’s nutritional status directly influences their health status in multiple ways. A well-balanced diet that meets individual nutrient needs is essential for optimal physical and mental well-being, disease prevention, and overall quality of life. Proper nutrition is not only about eating enough calories but also about making informed choices to ensure that the body receives the necessary nutrients to function at its best. The facilitation of making informed decisions regarding food is enhanced through the implementation of nutrition labels, which offer vital data pertaining to the nutritional composition and constituent elements of packaged food items. In numerous countries, the implementation of mandatory regulations is observed, overseen by regulatory entities such as the Food and Drug Administration (FDA) in the USA or the European Food Safety Authority (EFSA) in Europe. The labels commonly provide data regarding macronutrients (e.g., carbohydrates, proteins, and fats), vitamins, minerals, and other nutrients found in each serving. Additionally, they may include information about allergens, thereby facilitating their impact on the individual’s general health and well-being [19, 20]. Consumers are also increasingly interested in knowing where their food comes from and how it is produced. This information is essential to ensure the authenticity of foods [21].

The conventional concept of food quality, primarily understood as the absence of defects, fraud, and adulteration, was expanded by [22], which introduced the need to take into account the legitimate expectations of consumers and to ask market participants to do likewise in order to meet expected characteristics such as organoleptic and nutritional attributes or resulting benefits. Finally, quality denoted desirable characteristics that can justify added value, such as forms of production (organic farming, environmental consideration, and animal welfare), production areas (designation of origin), and associated traditions. Although the current concept of food quality strongly emphasizes the aforementioned aspects (e.g., sensory characteristics, safety, nutritional value, environmental aspects), consumers are generally unable to properly evaluate food quality without considering these characteristics. As long as only ingredients, expiration date, and basic health information are provided on labels, consumers often rely on these claims to evaluate food quality attributes [23, 24].

The Role of Consumers in Challenging the Traditional Concept of Food Quality

Consumer perceptions play an important role in understanding and evaluating food quality. Faced with twenty-first century challenges such as a growing global epidemic of diet-related non-communicable diseases (e.g., diabetes, cardiovascular disease, obesity threatening human health) and environmental issues, the modern food consumers have become cautious and concerned about the health benefits and quality of the food they purchase. These concerns have become driving forces in redefining purchasing intentions and perceptions of food quality, making food quality a key issue in today’s food economy [25, 26]. The traditional concept of food quality is now being challenged by various consumer categories, as detailed in Table 1.

Traditional Methodologies Utilized in Food Quality Assessment

There is no single standard method for determining quality parameters in food quality analysis, as different methods may be more appropriate for certain food matrices or types of analysis. However, there are a number of widely used established methods in food analytics, such as those recommended by the Association of Official Analytical Chemists (AOAC) or the International Organization for Standardization (ISO), which are recognized as the gold standard and are used to implement a quality management systems, maintain product integrity and food quality, protect consumer health, and ensure and promote international food trade [27]. In addition, these methods allow mutual recognition of laboratory reports and comparison of the results obtained, ensuring that the results meet quality requirements.

Currently, most of the traditional measurement methods for determining food quality are destructive (e.g., testing texture, firmness, total soluble solids, acidity, color value, juice content, foodborne pathogens), require long processing times, are laborious, and involve random sampling, which increases the likelihood of incorrect evaluation [28, 29]. Other limitations of laboratory methods for food quality testing include (i) limited test scope, as conventional food quality testing often focuses on a limited number of factors, such as taste, appearance, and texture, while ignoring other important factors such as nutrient content, contaminants, and allergens [30], (ii) lack of sensitivity for detecting low levels of contaminants or adulterants in food, which can lead to inaccurate or misleading results [31], (iii) high cost and time-consuming which can be a barrier for smaller food manufacturers and producers [32], (iv) limited scalability, which makes it difficult to monitor food quality through the supply chain [33], and (v) difficulty in detecting emerging pathogens and contaminants that pose a significant risk to public health [34, 35].

As far as microbiological analysis is concerned, cultural methods are still the “gold standard” for assessing viability and identifying pathogens in food. In food microbiology, viability refers to the ability of bacterial cells to multiply in different liquid culture media or to form visible colonies on solid culture media [36]. However, the distinction between viable and dead bacterial cells is an extremely complex concept because microorganisms in foods that have been exposed to stresses or altered environmental conditions can live in a variety of metabolic states or developmental phases (sub-lethally injured, viable but non-culturable, and dormant), and in some of these states, they may temporarily lose the ability to grow on or in laboratory culture media [37, 38]. In addition, culture-based food analysis is a time-consuming process. A number of processes, including pre-enrichment, selective enrichment, plating on selective media, and biochemical or serological confirmation testing, are required before a final identification can be made, requiring 2 to 3 days for preliminary isolation and up to a week for final confirmation of the separated species. Culture-based approaches may have limited detection capacity if microorganisms in an injured or viable but non-culturable (VBNC) state are present in the food being tested [39]. Furthermore, enzyme-linked immunosorbent assay (ELISA) and real-time polymerase chain reaction (PCR) are commonly used. PCR allows faster differentiation between viable and dead cells than culture and provides quantitative results.

The values of individual macronutrients in food samples (moisture, ash, lipid, protein, and carbohydrate content) can be determined by proximate analysis [40, 41]. These values are declared as nutritional values, which are often indicated on the labels of final products, but they are also determined during food processing. The analyses used may be rapid methods for quality control or more accurate but time-consuming official methods.

Total proteins are usually measured by the Kjeldahl method (nitrogen measurement). However, the improved Dumas method is much simpler and faster (less than 4 min per measurement, compared to nearly 2 h for the Kjeldahl method) and does not require toxic chemicals or catalysts [40]. Near-infrared spectroscopy (NIRS) is an undisputed favorite among real-time sensing systems for moisture monitoring in solids manufacturing [42]. In such systems, the diffuse reflectance spectra of the process material are usually measured using an immersion probe. However, the presence of water in a food product can cause a significant reduction in the intensity of the NIRS signal, making it difficult to accurately measure the concentration of other components in the product. Alternative techniques, such as mid-infrared spectroscopy or Raman spectroscopy, which are less affected by water interference, have the potential to be used in the future [43]. Also, a fluorescence spectroscopy, as a rapid and non-invasive technique, becomes a promising tool for practical applications in quality evaluation of fish and meat products in the future [44, 45].

Fatty acid profile analysis of the food is important for nutrition labeling because it helps to understand the availability of different fatty acids in foods. This can be done by the conversion of fatty acids to methyl esters followed by gas chromatography, which is the most commonly used technique compared to others (LC–MS, GC-FID) due to its efficiency, selectivity, and cost advantages [46,47,48]. However, there is no specific system for fat extraction and derivatization for different foods. The Soxhlet method is a traditional and the most commonly used technique for extracting lipids in foods because it is unsupervised and easy to use. However, it has some disadvantages, including hazardous and flammable organic solvents, potential emissions of toxic compounds during extraction, the use of more expensive and high-purity solvents, laborious procedures, time-consuming, and the method requires three different weights. In contrast, microwave-assisted extraction (MAE) is more effective than conventional methods, and the MAE has the advantage of being fast, robust, consuming low amounts of solvent for lipid extraction, and does not require anhydrous samples. It also has the highest repeatability. However, the methods of Roese-Gottlieb, Soxhlet, and Modified Bligh and Dyer’s were very weak in terms of efficiency and repeatability [49]. Relative Raman intensity analysis proved to be more useful for rapid quality assessment of extra virgin olive oils [50].

Physical testing in the food industry (e.g., color measurement, particle size, viscosity, texture, and product consistency) is typically used to determine quality [29]. The unique textural properties of food products are typically tested using rotational rheometers, closed cavity rheometers, and capillary rheometers—a powerful tool for understanding how a material behaves under shear stress and strain. In some cases, rheological measurements can provide insight into food processing as the material is subjected to shear and temperature gradients over a period of time, which is particularly important for extrusion and three-dimensional (3D) printing processes [51]. Tensile and compression tests are the most commonly performed normal force tests. These tests measure the force required to compress or elongate a material over a specified length. In texture profile analysis, also known as “double compression testing,” a sample of defined geometry (often cut out with a corer) is compressed and relaxed twice at a specified rate between parallel plates of a larger diameter than the sample. The main objective in developing this method was to simulate a two-stage mastication process [52]. Cutting force and shear tests are also performed to evaluate “hardness” as a parameter to quantify the extent of structure and texture formation in food samples. Confocal laser scanning microscopy (CLSM) is widely used to analyze particle size and distribution of droplets and other types of particles because it has higher resolution than conventional light microscopy and allows optical sections [53]. Myoglobin, its derivatives, and denaturation of muscle proteins are responsible for the red (e.g., cuts of meat) or white-to-beige (sausages) colors of many current food products [54]. Various food colorings, such as beet juice extract, soy leghemoglobin, carrot juice extract, and lycopene, are often added to meat analogue items on the market to achieve an accurate meat resemblance [55]. Surface color is often measured with a colorimeter and specified using the CIELAB color space with D65 as the standard illuminant. Colorimeters are usually equipped with a pulsed xenon arc lamp that exposes the sample with a uniform beam of light. The light reflected from the surface of the sample is then collected by photocells and used to determine the color space coordinates. The colorimeter is calibrated with a white plate before measurement to standardize the results. In the CIELAB color space, L* defines the lightness of the sample (0 = black, 100 = white), a* ranges from green (−) to red (+), and b* ranges from blue (−) to yellow (+). In addition, the color difference factor ΔE provides information on whether or not the bare eye can detect tiny color changes in food.

Despite the numerous analytical breakthroughs and applications seen in food analytics, there are still a number of challenges to overcome in this burgeoning field of research, highlighting the urgent need for more inventive and advanced analytical methods. In the near future, the above analytical techniques (spectroscopic, biological, separation-based, solid phase extraction) will be combined with state-of-the-art non-destructive technologies such as magnetic resonance imaging (MRI), nuclear magnetic resonance (NMR), ultrasound Doppler velocimetry (UDV), acoustic approaches, computerized tomography (CT) and sensor-based methods to gradually replace the destructive, time-consuming, and tedious conventional analytical techniques.

Migration Toward Food Quality 4.0

Overall, traditional aspects of food quality focus on ensuring that food is safe, nutritious, and enjoyable to consume [56]. While these aspects are still important, the shift toward food quality 4.0 is expanding the scope of food quality to include additional factors such as sustainability, transparency, and digitalization [57]. Food quality 4.0 is a recent development that builds on previous stages of quality management in the food industry and it aims to integrate digital technologies and data analytics into the existing quality management systems to enable real-time monitoring, traceability, transparency, and optimization of food quality throughout the value chain [27]. The main difference between the earlier stages of food quality and stage 4.0 is the level of digitalization and data integration. Earlier stages relied mainly on manual inspection, prevention, and improvement methods, while stage 4.0 uses digital technologies and data analytics to automate and optimize quality management processes. Stage 4.0 also enables a more holistic and dynamic view of food quality across the value chain, rather than focusing on isolated segments or stages [27]. In addition, earlier stages in the development of the concept of food quality mainly used traditional quality management methods, such as statistical process control, total quality management, and continuous improvement. These methods are still relevant and useful in stage 4.0, but they are improved and complemented by new methods that leverage digital technologies and data analytics, such as (a) predictive analytics which uses data mining, machine learning, and AI to predict future outcomes and trends based on historical and current data; (b) prescriptive analytics which uses optimization, simulation, and decision support systems to recommend the best actions or solutions based on data analysis and business rules; (c) cognitive analytics which uses natural language processing, computer vision, and speech recognition to understand and interact with human speech, images, and sounds; and (d) edge computing which uses distributed computing devices at the edge of the network to process data locally and reduce latency, bandwidth, and storage costs [58,59,60,61].

Food Quality 4.0 vs. Traditional Quality

The first step in analyzing the concept of food quality 4.0 is to understand what Quality 4.0 is and apply it to the food supply chain continuum. Scientists believe that Quality 4.0 is an integration of industry 4.0 and quality management [62]. Opposed to this, quality-oriented societies such as the American Society for Quality (ASQ) presume that Quality 4.0 is the fourth evolutionary step of quality management (as the inheritor of quality control from the early twentieth century, quality assurance from the 1950s, and total quality management from the 1980s), supported by digital solutions [63]. Therefore, Quality 4.0 should be understood as a holistic synergy of quality concepts and industry 4.0 tools. This holistic approach was also confirmed in the work of Gunasekaran et al. [64], where Quality 4.0 permeates several dimensions, such as reduced quality costs, improved process and product performance, developed decision and problem solving tools, and integration of the concept into (quality) value chains. Supporting technologies for industry 4.0 are the IoT, Big Data (BD), artificial intelligence (AI), cyber-physical systems (CPS), cloud computing (CC), machine learning (ML), blockchain (BC), and virtual reality (VR) [62].

Since the digital component of Quality 4.0 generates large amounts of data, which is defined by De Mauro et al. [65], as having high velocity and diversity, it is important in food quality 4.0 to understand how to use these tools effectively. Collecting, processing, and analyzing Big Data in the food sector requires smart sensors and reliable communication [66], leading to smart products, processes/technologies and systems/factories. In this sense, it is important to analyze the food dimension of Quality 4.0 from three perspectives—food as a product, food processes, and food systems.

Food Quality 4.0—Product-Based Dimension

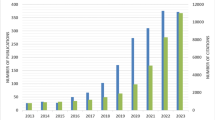

To analyze the trends and existing level of food quality 4.0, the authors conducted a bibliometric overview of publications by applying text mining with the software tool VOSViewer to identify the main research streams. It consisted of three activities: (i) data collection, (ii) data processing and cleaning, (iii) and visualization and interpretation [67]. The input data (abstract, title, keywords, affiliations) were extracted from academic papers indexed in the Web of Science with the search term “food quality” + “industry 4.0.” The search was set to include only articles/reviews papers (excluding book chapters and proceedings). The time period was set from 2013 to 2022 (10 years), bearing in mind that industry 4.0, accelerated its momentum from 2015 [68], though industry 4.0 was initiated in 2011 [69]. Although the number of publications on the topic digitalization and automation of food quality is increasing [27], our search yielded a total of 174 publications (five of which were marked as highly cited papers). Th cutoff criterion for processing and cleaning was that the terms were mentioned at least 10 + times to allow.

The analysis revealed four distinct clusters, namely cluster 1 (red color—quality characteristics), cluster 2 (green color—Internet of Things), cluster 3 (blue color—industry 4.0), and cluster 4 (yellow color—food safety), as shown in Fig. 1. The first cluster shows a strong link between quality and different analyzed quality attributes such as physicochemical or functional properties. The green cluster highlights the connection of industry 4.0 with machine learning in food sustainability and agriculture. The blue cluster focuses mainly on various Internet of Things technologies such as blockchain, artificial intelligence, and Big Data. Finally, the food safety cluster is related to the food supply chain and various predictive and traceability tools. From this overview, it is clear that food scientists are using industry 4.0 technologies mainly to analyze/improve quality and safety of food (as a product).

Food Quality 4.0—Process-Based Dimension

To meet the challenges of manufacturing products that can be considered innovative and technologically complex, it is important to introduce “controlled quality” that improves product and process quality with limited variation [70]. One of the pillars in introducing the quality dimension into a process is the analysis of data and its transformation into new knowledge perspectives [71]. The digital tools developed in the context of industry 4.0 have the potential to transform the quality perspective [72]. During the quality evolution, various quality tools have been introduced to enable companies to improve their processes [73]. In parallel, lean manufacturing practices have been introduced in the food processing industry to improve operational efficiency and productivity [74]. The rationale behind lean production in food manufacturing is to produce the required food at the required time, in the required quality and quantity, with limited waste and inventory [75].

Many authors confirmed that the use of quality tools paves the way for successful implementation of quality assurance [76,77,78]. At the same time, other authors noted that high rates of failures when these quality tools are implements [79, 80]. Kaoru Ishikawa proposed his seven basic quality tools (Fig. 2) that every company needs [81]. As a results, ASQ referred to them as “the basic seven” [82], while Montgomery refers to them as the “magnificent seven” [83].

Food companies, especially small and medium enterprises (SMEs), find it difficult to implement these basic tools. This has been confirmed in several studies in Serbia, Portugal, and Sweden [73], where less than one-third of the companies use these tools. The significance of this finding raises the question of what can be expected from the implementation of Quality 4.0 tools in food companies when the basic tools are rarely used. When it comes to lean production, the main obstacles are the complexity of food processes in relation to the specific food sector, the high variability of quality parameters related to raw materials, and the lack of knowledge and resources [74].

In the mid-1970s, the Union of Japanese Scientists and Engineers developed and promoted seven management tools (Fig. 2), shifting the focus from process control to promoting planning and innovation [82]. There is no research on the level of implementation of these new tools in the (food) industry. In the transition to Quality 4.0, ASQ identified seven new tools (Fig. 2) required for deployment in digital environments [84], artificial intelligence, Big Data, blockchain technology, deep learning, machine learning, data science, and enabling technologies. The main three most important features of Quality 4.0 are automated control, electronic-results, and digital integration of the quality loop [85].

Artificial intelligence includes various tools such as computer vision systems or the use of robots in the food industry [86, 87]. It can help in decision-making, taking into account the complexity of food [84]. An example of the use of AI is the assessment of plants at different harvesting/post-harvesting stages to detect possible diseases and decay [27]. AI as an interdisciplinary science supported by machine learning and deep learning has the ability to advance the food industry [88] by improving food quality and safety, good hygiene practices, and production [89].

Big Data strives for tools that enable the processing and analysis of large datasets [84]. The complexity of implementing this tool in the food sector is due to the large differences in the quality of different datasets, the lack of shareable data, and the lack of skills and knowledge [87]. Blockchain is a promising technology in the food sector because it enables improved traceability, supports recalls, helps combat various adulterations and food frauds, and increases trust in various claims such as organic or religious labels such as hall or kosher [90]. This technology enables traceability of goods throughout the food supply chain [91].

Deep learning is a tool that enables the management of high-dimensional hyperspectral image data [92]. It helps in image classification and complex pattern recognition [84], which are applicable in the food sector and broaden the perspective of different forecasting. It has become a state-of-the-art technique associated with detection, recognition, and classification in the food sector [93] and agriculture [94].

Machine learning is the ability of various computers and devices to improve their capabilities based on collected data and its processing [87]. Machine learning combined with image recognition techniques are useful tools for food quality control [95]. It has the potential to analyze data, detect fraud, and make forecasting [84].

Data Science brings together heterogeneous data sets for further classification, analysis, pattern search, and forecasting to develop sustainable models and solutions [84]. Finally, enabling technologies supports the use of different sensors and actuators, the Internet of Things, and virtual reality to support food quality [84]. The use of facial recognition tools as an emerging technology can be applied in emotion recognition, sensory studies, and oral food processing [96].

Food Quality 4.0—System-Based Dimension

It is known that the concept of quality management system (QMS) was developed based on the philosophy of the quality gurus (Joseph Juran, Kaoru Ishikawa, Edwards Deming) and the work of Technical Committee 176 of the International Organization for Standardization [77]. The ISO 9001 standard is the basic QMS standard developed to enable companies to confirm that they are able to deliver products that meet customer’ and regulatory requirements, while achieving customer satisfaction and demonstrating continuous improvement of their products, processes, and system [97]. According to the recent survey by ISO, there are currently over one million ISO 9001 certificates in 189 countries worldwide, but less than 27,000 (2.5%) have been awarded to companies operating in the food and agriculture sector [98].

When it comes to analyzing the status of implemented management systems in the food sector, the typical approaches are time-dependent: ex ante (before implementation of a management system), ex durante (during implementation), and ex post (after completion) [99]. Although the benefits of QMS implementation are confirmed by many authors, there are few studies focusing exclusively only on the food sector [77, 100,101,102]. The majority of companies confirm some improvements (in food products/food processes), higher customer satisfaction, and improved competitiveness. However, some authors believe that the certification process is more of a marketing exercise than an actual benefit [103].

Since the food industry is not a leader in QMS implementation, and only a limited number of food companies have a certified QMS, shifting of existing management systems to Quality 4.0 is a challenge. Zulqarnain et al. [72] clearly recognize the need for quality management systems to implement the benefits Quality 4.0 and emphasize the increasing demand for user-friendly tools in SMEs. The need for standardization in implementing Quality 4.0 has been clearly recognized, e.g., Germany and Spain have formed various working groups on standardization [14]. However, when it comes to the implementation of these tools, ASQ and Boston Consulting Group conducted a survey on the state of implementation of Quality 4.0 tools. The survey was performed in the US and German manufacturing industries [104], and the results showed that only 16% of the surveyed companies have implemented Quality 4.0, with almost two-thirds of the respondents having no plans to implement it. The main obstacle identified by the companies surveyed was a lack of digital skills, followed by a limited digital quality culture, and low levels of infrastructure and data integrity. Escobar et al. [105] state that companies and their managers lack vision to take advantage of Big Data and artificial intelligence. This is in line with the study by Zonnenshain and Kenett [106] that the most important pillar in the successful implementation of Quality 4.0 is “data,” and data science should play an important role in managing real-time data in all processes.

Zulqarnain et al. [72] performed a study in Pakistani companies to assess dimensions required to implement Quality 4.0. The study found that the main barriers are the size of the companies (SME vs. large multinationals), along with problems in scalability of data, internal quality culture, and the potential for developing various portals/applications for employees within business processes. It is evident that from a food sector perspective, most food quality 4.0 studies are case studies focused on the application of a specific digital technology aimed at solving quality-related efficiency problems.

As lean manufacturing focuses on improving production processes and increasing productivity, the application of Quality 4.0 technologies such as the Internet of Things, smart process control, and Big Data optimization brings new potential. Although lean manufacturing is still not widespread in food companies, and implementation in food SMEs is insufficient due to limited knowledge, resources and organizational culture [107], the use of various digital platforms and applications tailored for SMEs could offer potential. In the food sector, such as food and refrigeration monitoring systems in the UK, there are companies that are recognized as leaders in using IoT to improve food safety and traceability systems [87].

Food Quality 4.0—a Step Beyond

Food supply chains consist of many actors that aim to deliver food to end consumers. Essentially, chains consist of four main actors—farmers, food business operators, retailers, and food consumers [108]. An important factor that is influencing food chains is the distance between each chain link, which defines them as global or local [109]. Local, short food chains may consist of only producers and consumers [110], in contrast to global chains with multiple food entrepreneurs and distribution channels [111]. This complexity affects quality and the risk of food degradation throughout the chain from farm to fork [112].

The use of various smart sensors focused on quality assurance throughout the supply chain is one of the simplest applications of Quality 4.0 technologies [88]. The IoT connects machines, information, and people through a network of connected devices, creating a system that can monitor, collect, share, and analyze data to optimize operational efficiency [113]. Automation, the use of artificial intelligence, and the Internet of Things in networks of agricultural machinery and factories enable the optimization of food supply chains at both ends of the pipeline—supply and demand [114]. Key indicators intertwine various dimensions such as finance, productivity, food quality, and prevention of various quality-related wastes and losses [108, 115]. This is discussed below in the context of advanced food technologies currently available for food production.

Food Quality 5.0

Quality 5.0 is a new concept aligning with industry 5.0. Rationale for shifting to a new level is associated with the human role as many authors criticize industry 4.0 to be machine centric as robots take over jobs and promote unequal society [116]. As a result, Coronado et al. [117] point that performance-oriented industry needs to include the human dimension associating industry 5.0 as “human-centered” [117]. The European Commission, besides human centricity, includes sustainability and resilience within industry 5.0 [118]. In parallel, Society 5.0 has been defined by Fukuyama promoting synergy between cyber and physical reality enabling economic and social advancement [119]. Human centricity within Quality 4.0 became the new paradigm of Quality 5.0 [116], focused on the quality of interaction between workers and machines. Some attributes aligned to this concept are associated with how effective and satisfied workers are in such an environment [120], as well as potentials for learning and improved knowledge [121] pointing safety as an ergonomic quality aspect. The main question that arises in the food quality context,is what should be the keystone(s) of food Quality 5.0? Bearing in mind that food companies are responsible for placing safe food on the market [122]. In this perspective, the legal liability for placing safe food of defined quality from a robotic/digital work environment needs to be of utmost priority. In parallel, potential for food quality improvement (without jeopardizing food safety) based on learnability and efficiency of food industry 5.0 contours the food quality 5.0 keystones. Table 2 provides main differences in food quality 4.0 and 5.0, modified from [116, 123].

Green and Sustainable Food Technologies for Improving Food Quality

Nonthermal Technologies

The conventional approach to food processing involves the application of various operations that often use elevated temperature as a critical processing parameter. Although, temperature treatments improve food preservation, decontamination, and mass-transfer, some important drawbacks in terms of nutritional and sensory quality should be highlighted. Degradation of heat-sensitive compounds, particularly bioactive compounds (BACs), such as vitamins, polyphenols, terpenoids, and carotenoids may occur during processing by thermal methods (sterilization, pasteurization, etc.), negatively affecting food quality and sensory properties. The heat consumed during this process is generated by fuel heaters and then transferred to the food. This is another important aspect to consider, as high energy consumption is not an environmentally friendly and cost-effective method [124]. Non-thermal technologies (NTTs) have been identified as relevant replacements for traditional approaches due to their ability to induce microbial inactivation at lower/moderate temperatures [125]. The preservative effect on heat-sensitive molecules is recognized as another important aspect of NTT, while some limitations have been observed in the inactivation of microbial spores. Lower temperatures and consequently lower energy requirements give these technologies a green aspect, as they have less impact on the environment. Leading NTTs that have been used extensively in food processing in the last decade are ultrasonic (US) treatment, pulsed-electric fields (PEF), high-pressure processing (HPP), and cold plasma (CP). Table 3 provides an overview of NTTs with the main mechanisms affecting the process and the highlighted applications to improve food quality.

Ultrasonic waves can be used as an aid in various food processing technologies, namely inactivation of microorganisms, cutting, drying, freezing, extraction, and foaming [126].

According to Bhat et al. [127], US contributes to the modification of the quality characteristics of animal products (e.g., dairy products, meat, eggs) by affecting processing in several important reactions (such as oxidation, Maillard reaction, proteolysis, and esterification). The same authors also found that this treatment also alters food structure and improves digestibility of protein rich animal foods. The main mechanisms underlying these phenomena are changes in protein structure, consequently, food microstructure, and the release of hydrolytic sites for better contact with digestive enzymes. Although, US technology has proven to be effective in treating muscle foods, it should be emphasized that improper US treatment can have diminishing effects on food quality parameters [128].

High-intensity US treatment shows promising results in liquid food processing. The positive effects of this treatment are shown in microbial and enzymatic inactivation, which consequently improves stability and shelf life. However, special attention should be paid to the optimization of process conditions to prevent the loss of volatile compounds, nutrients, and BACs [129]. In contrast to microbial inactivation, high-intensity US with “mild” process parameters could be used to stimulate of microbial growth, which is useful in the production of probiotic and fermented beverages. According to Guimarães et al. [130], fermentation time was reduced, probiotic viability was improved, and lactose content was reduced. In addition, a higher concentration of oligosaccharides, bioactive peptides, and fewer organic acids was found in the US-treated product.

Drinks and beverages fortified with nutraceuticals and BACs have found their place in the modern market. The application of thermal treatment is limited in two ways: (a) heat can cause undesirable physico-chemical changes in the final products and (b) many BACs have insufficient stability and could be damaged by elevated temperatures. US and HPP treatments have been proven to be excellent technologies for the production of functional foods based on the encapsulation of BACs in dairy products and beverages [131]. US-assisted extraction of BACs from medicinal and aromatic plants has shown tremendous advantages over conventional extraction processes in terms of reducing resource consumption and improving the yield and quality of extracts, especially in the case of moderately polar compounds, such as the major classes of polyphenols (phenolic acids, flavonoids, anthocyanins, etc.) [132].

Besides the current trends and innovations in the development of novel foods, raw fresh foods (e.g., vegetables, fruits, and meats) continue to be an important part of the human diet. Although these foods can usually provide all the essential nutrients, there are several issues related to their quality, safety, and shelf life. They are particularly susceptible to deterioration, either from a biochemical or microbial perspective. According to Zhang et al. [133], PEF treatment can be used to modify the structural, textural, and functional properties of meat. Proteolysis of meat occurs through PEF-induced electroporation of the cell membrane. The damage caused to the ultrastructure of the muscles can improve the tenderness of the meat as an indicator of quality, which translates into better sensory characteristics and consumer acceptance. The drawback of this treatment could cause undesirable changes in lipid oxidation. The interaction between (pro)oxidants and oxidant-prone compounds (phospholipids and unsaturated fatty acids) affects nutritional quality, resulting in off-flavors. PEF treatment can also affect other parameters in meat products, such as mineral content, color, weight loss, and cooking loss. Therefore, optimization of process parameters is highly case-dependent and should be thoroughly considered.

For fresh fruits and vegetables, high losses during post-harvest are the main reason for thorough investigation of preservation technologies. PEF-assisted drying of fruits and vegetables is used to improve heat and mass transfer properties, reduce time, and prevent loss of nutrients and BACs [133]. Another benefit that could be obtained from this treatment is the inactivation of the indigenous microbiota and enzymes responsible for oxidative decay.

PEF-assisted extraction has been shown to be a novel approach for the isolation of various BACs (polyphenols, carbohydrates, carotenoids, organosulfur compounds, terpenoids, etc.) [134]. Cell membrane poration occurs within the electric field, reducing resistance during mass transfer improving diffusion for the plant matrix. Although isolation of BACs from common plant materials is an important issue, the use of sustainable raw materials for efficient valorization and recovery of BACs is an even greater challenge [135]. PEF-assisted extraction has been successful in isolating BACs from fruit and vegetable wastes, aqua-product wastes, food industry by-products, and agricultural wastes. Nevertheless, there are certain problems that should be solved for the novel food products developed by PEF: (a) the hygienic features of the PEF system must be fully integrated, (b) special attention must be paid to the allergic aspect of these products because PEF treatment could reduce or enhance it, (c) there is a risk for the degradation of BACs, and (d) certain limitations for industrial applications [136]. PEF treatment is particularly suitable for improving the extraction yield of fruit juices. In addition to increasing the yield of valuable compounds, PEF treatment also causes microbial and enzymatic inactivation, which translates into better stability, safety, and longer shelf life of the products [133]. Due to these effects, PEF has been successfully applied in the fermented wine industry, as it has been reported to increase yield and polyphenol content of grape juice, shorten maceration time, improve color, and inactivate microbial spoilage [137].

Commercially available foods processed by HPP are (a) fruits and vegetables (juices, smoothies, purees, etc.), (b) meat and meat products, (c) seafood products, and (d) ready-to-eat meals. On the other hand, the predominant foodborne pathogens responsible for recent large foodborne outbreaks are Escherichia coli, Salmonella spp., and Listeria monocytogenes [138]. The same authors highlighted that HPP at 600 MPa is capable of achieving the recommended 5- to 8- log reductions of the above bacteria. The limitations of HPP in inactivating microbial spores could be overcome by the application of supercritical CO2. The mechanism of inactivation is based on the disruption of cell structure and degradation of cellular proteins and enzymes [139]. The addition of water as a co-solvent provides synergistic effects in spore inactivation, while the mild process temperature ensures the stability of the textural, nutritional, and sensory properties of the treated product.

HPP treatment alters the physico-chemical and nutritional properties of polysaccharides (pectin, starch, etc.) in various food matrices. This has been applied to improve the technical functions (gelling, film formation, foaming, and emulsification) and nutritional value (digestibility) of polysaccharides without changing the taste and appearance of the products compared to heat treatment [140]. It also improved the bioavailability of minerals, polyphenolic antioxidants, and folic acid, which was particularly observed in HPP-treated whole grains and legumes [141].

According to Šojić et al. [142], lipid extracts rich in terpenoids could be used as natural antimicrobial agents and antioxidants in various meat products as substitutes for synthetic and toxic additives (e.g., nitrites). Hydrodistillation requires high temperatures for essential oil production, and chemical changes occur during this process. SFE offers tremendous advantages over hydrodistillation because it is carried out at moderate temperatures that prevents the degradation of target compounds, the extract has a higher yield compared to pure essential oil, and the energy and time required are lower, so SFE can be considered an environmentally-friendly technique [132]. Most importantly, these extracts have better preservative effect on quality parameters of meat products and better sensory properties [142].

CP has been analyzed as an effective non-thermal technique to improve the shelf life of various foods through microbial and enzymatic inactivation, improvements in food dehydration and food packaging [143]. More importantly, this technique shows promising results on a wide range of foods, namely fruits and vegetables (including juices and fresh-cut products), seafood, ready-to-eat meals, sprouts, cereals, meat products, and spices [144].

This technique is particularly suitable for the treatment of fresh-cut fruits and vegetables, which have a very short shelf life because they are not exposed to harsh processing conditions. The preservation effects of treating CP are reflected in the antimicrobial effects on the common foodborne pathogens Escherichia coli, Salmonella spp. and Listeria monocytogenes, as well as yeasts and molds [145]. The inactivation effects are based on the damage to microbial biomolecules (DNA, proteins, and enzymes), lipid peroxidation, and disintegration of compact cell structure. The free radicals generated by CP affect the vitamins, enzymes, and antioxidants in the fresh-cut products, and it has been observed that their content generally decreases due to this treatment. For the same reasons, CP is also effective for preserving fruit juices. Pohl et al. [146] emphasized that CP has no negative impact on the nutritional profile. In fact, the content of BACs in CP-treated juices can be increased, along with and improvement in texture and sensory properties.

CP exhibited a broader spectrum of microbial and biochemical inactivation compared to other non-thermal techniques. Literature data suggest that promising results in inactivating bacteria and fungi (including their spores), viruses, and parasites in all types of foods [147]. The same authors suggested that the chemical changes which occur in foods during the treatment of CP could be beneficial as they could have a mitigating effect on food allergens and anti- nutrient factors, toxins, and food contaminants such as pesticides. Positive effects of CP on germination of various industrial crops, spices, and cereal seeds have been observed. According to Mehta and Yadav [148], the mechanism is based on the penetration of reactive plasma species through the seed coat and their effect on the intracellular material. This also promotes water and oxygen penetration, which is essential for seed germination.

Although CP has proven to be particularly beneficial in the laboratory, there are certain technological and safety limitations that should be considered. There is still a lack of safety and toxicological data on the free radicals formed during treatment and how exactly they modify food components is still severely missing [143]. Other limitations are associated with scale, as relatively small amounts of juices can be treated at one time [146].

Considering the potential applications of NTT, as well as their advantages and limitations, it is obvious that none of the above approaches is universally suitable for all types of foods. The selection of the appropriate approach is highly case-dependent and requires extensive process optimization work. The combination of NTTs known as “hurdle concept” approach, aims to highlight the synergistic effect of selected techniques in a predictive manner to improve food quality and minimize drawbacks and diminishing effects on food properties. According to Bigi et al. [149], this approach allows us overcoming the limitations of a single technology, increases efficiency and a range of applications, and preserves food quality. The hurdle concept approach has already been extensively tested and showed promising results in the preservation of functional fruit juices [150], however, there are still some problems related to industrial application that need to be solved.

Additive Manufacturing as Emerging Industry 4.0

Three-dimensional (3D) printing technology is a new sustainable technology that is attracting great interest from researchers, industry, and the public with its various applications such as medicine, hospitality, engineering, manufacturing, and art. The main feature of this technology is the layer-by-layer addition of material, enabling the production of complex product geometries that would be difficult or impossible to achieve using traditional production methods [151].

Recently, 3D food printing technology as a new dimension in food production processes is gaining global attention. The Data Bridge Market Research reveals that the global 3D food printing market is predicted to grow at a CAGR of 52.30% by 2021–2028. Spreading awareness among food industry innovators of the necessity to upgrade food production technologies is an important issue rising the food 3D printing market growth [152].

The particular importance of the application of this technology is reflected in the production of functional foods, especially in the pandemic and global crisis period. The demand for functional foods is constantly increasing, as is personalized nutrition prepared according to the individual needs of consumers [153].

This technology enables the computer-controlled creation of three-dimensional geometrically complex objects of food of different composition [154]. In the food sector, 3D printing technology has a wide range of applications, from the production of food for the elderly and children, to the production of functional food and confectionery, to use in space missions.

The technology of three-dimensional printing (3DP), first presented in 1986, describes the process of applying materials in layers with the aim of creating a digitally designed 3D object. The method of adding materials is done layer by layer; hence, this technology is also known as “additive manufacturing” [155]. This technology allows the creation of complex 3D models without unnecessary waste of material [153] and without the use of molds, dies, stiffeners, and cutting tools common in traditional production [156].

The concept of 3D printing can be traced back to 1977, and the first patent for the manufacture of a food product followed in 2001 [153]. Nevertheless, 3D printing technology was officially introduced to the food sector in 2007 by a team of scientists from Cornell University with the first “cheap” printer (Fab@Home Model 1) based on extrusion technology. Although the Model 1 resembled a traditional solid freeform fabrication (SFF) printer, it could use a significantly wider range of materials [157]. Two years later, the Fab@Home project released Model 2 with reduced prices and greater availability [158]. The most relevant patents concerning 3D printed foods were published from 2013 are given in Baiano [159].

Currently, several 3DP technologies are available for additive manufacturing purposes in the food sector such as extrusion-based printing, selective sintering printing, binder jetting, and inkjet printing. The most widely used printing process is extrusion, i.e., extruding the prepared material from the print head (extruder) layer by layer onto the substrate with the aim of forming a programmed 3D shape. The main component of the device based on this technique is a nozzle with a piston. During the printing process, the printing material is continuously extruded from the moving nozzle and then added to the pre-printed layers. In producing an attractive product, precision and accuracy of 3DP are critical and depend on several factors such as extrusion mechanism, material properties (e.g., rheological properties, gelation, melting and glass transition temperature), extrusion parameters (e.g., height and diameter of nozzle, extrusion speed), and subsequent processing [160]. By regulating the temperature of the substrate and the distance between the print head and the substrate, the consistency, the degree of crosslinking and the heat treatment of the product can be controlled [153, 161]. Selective sintering technology uses the energy of the laser to selectively fuse powder particles layer by layer to form the final 3D structure. The laser scans the cross-sections of each layer and selectively fuses the powder. After scanning each cross-section, a new layer of powder is applied with a roller, and the process is repeated until the desired shape is achieved. The sintered powder forms the product, and the rest of the powder serves as a support structure that is removed after printing and used for the next printing [160, 162]. This technology allows the production of 3D structures with high resolution and complexity, but is limited to the use of powder materials such as sugar and fat or starch granules. The physicochemical properties of the material (e.g., particle size, density, fluidity, moisture, and compressibility.) have a great influence on the thickness of the layer and thus on the quality of the print [163]. The layer of powder material must be thin and uniform, which is crucial for the mechanical strength and precision of the object to be printed. In addition, the powder should be loose and not tend to form agglomerates or adhere to contact surfaces [164]. As with any 3DP, in addition to material properties, processing factors such as the type of laser and the power and diameter of the laser spot are important [165].

In contrast to the selective sintering technique, the binder jetting printing uses a liquid binder to bond the layers. The binder is ejected according to the programmed path so that it binds the powder layers together, which eventually form the desired shape. Unbonded powder in this case also serves as a support structure, which is removed after completion [160, 162]. In this process, the properties of the powder material and the means of bonding the layers are important. The binder must have the appropriate density, viscosity, concentration, surface tension, and good injection properties from the nozzle to avoid unwanted scattering and spreading [160]. Water- or alcohol- based agents (e.g., sugar solutions, and xanthan gum.) are the most commonly used [166], and they can be colored or flavored [167], allowing producing of final products in a wide range of colors and flavors. As with laser sintering technology, the physicochemical properties of the powdered material are also critical for depositing thin films, which are crucial for producing precise objects.

Inkjet printing is used for surface filling and decoration of food products such as cakes, cookies, or pizzas. The principle of inkjet printing is that droplets of the food material to be printed (called ink) are passed through a thermal or piezoelectric head [168]. There are two types of inkjet printing: continuous inkjet printing and drop-on-demand printing. In continuous inkjet printing, ink is ejected continuously through a piezoelectric crystal that oscillates at a constant frequency, while in drop-on-demand printing, ink is ejected in the form of droplets under the pressure of a valve. In general, drop-on-demand printing is a slower process than continuous printing, but the resolution and precision of the printed images are significantly higher [169]. Inkjet printing uses low viscosity materials that do not have sufficient mechanical strength to maintain a 3D structure and are therefore used to print two-dimensional images. From the perspective of printing precision and accuracy, the compatibility between the ink and the substrate surface, viscosity, rheological properties, and temperature of the ink, and printing speed is crucial [160].

Regardless of the 3DP technology used, the process of 3D printing food can be divided into three main phases. In the first step, the food is pre-processed and/or further processed, i.e., brought into a printable form. Since the ingredients are printed in the form of powder, liquid, dough or paste, preliminary operations such as milling (flour), cooking (potatoes or starchy substances), or mixing (meat) must be carried out [153]. Various additives (e.g., hydrocolloids) usually must be added to achieve a blend formulation with optimal rheological properties [170]. The second stage, for which several techniques are available today, is 3DP of prepared material. The third phase consists of the processes by which the product becomes ready to eat or is necessary to achieve the final desired texture. Common examples are freezing, baking, and roasting [170].

The materials used for 3D extrusion printing must meet selected properties that are significant for their extrudability and buildability. Extrudability depends on material properties related to the deposition process, such as flow through the die and extrusion force. Processability depends on material properties related to the ability of the edible ink to form a semi-solid or solid structure after printing on the platform, such as yield stress, gelling temperature, or gelling time. So far, several mathematical models have been proposed to define the printability of certain food materials [171]. Materials for printing 3D products can be classified according to the ease of printing, the main ingredients related to nutrition and health (e.g., proteins, starches, fibers, functional compounds) (e.g., vitamins and antioxidants), and the origin of the material (e.g., dairy-based inks, meat, fruits, and vegetables). “Naturally extrudable materials” are those with rheological and mechanical properties that can be directly extruded without the addition of additives such as gums [172]. The most popular such materials for printing are chocolate and mashed potatoes. Due to the high fat content in chocolate and the high starch content in potato, such blends can well integrate bioactive compounds and other functional ingredients that improve printing quality [153]. In addition to the aforementioned materials, cheese [173] is also a food that can be easily printed, while dough [174] and sugar paste [175] are somewhat more challenging. Traditional foods that lack the properties required for direct printing (e.g., fruits and vegetables, rice, and meats) require the addition of additives that regulate rheological and mechanical properties as well as nutritional value. The nutritional value of chocolate can be enhanced by the addition of vitamin C, cranberry powder [176], or plant sterol powder [177].

Severini et al. [178] formulated a material for printing from fruits and vegetables (a mixture of carrots, kiwi, broccoli, avocado, and pear) with fish collagen as a coagulant, while Kouzani et al. [179] used a mixture of canned tuna, beets, and butternut squash for printing. The printing process did not change the phenolic content, sensory, and antioxidant properties. Regarding 3DP of meat, Lipton et al. [180] printed a product with a complex structure of turkey meat and celery with the addition of transglutaminase as a binder, while Hertafeld et al. [181] used crab paste or ground chicken in combination with other ingredients such as egg whites. After printing, the products were slowly cooked or fried, and a meat product with good shape retention was obtained [153]. Alternative ingredients that can replace conventional foods are also used in 3D food printing. Functional ingredients such as proteins and fibers can be isolated from insects [182], algae, seaweed, or mushrooms [161]. Alternative ingredients in paste or powder form can be mixed with conventional ingredients and used to create customized meals [153]. In addition, 3DP technology increases the acceptability of using non-traditional foods such as insects (rich in protein), algae (rich in fiber), fruits and vegetables (rich in fiber and bioactive compounds), or meats, which become more attractive to consumers by changing their shape and composition [153].

3DP is a promising method of functional food production that offers many possibilities (Table 4), such as the production of personalized foods (meeting a person’s nutritional needs, enriching meals with targeted nutrients, etc.), high complexity of texture, and customized shape design. Moreover, 3DP has already been used to create plant-based meat analogs with a lower fat content, good printability, acceptable texture, and fibrous sensation [183].

Digitalization of the process allows monitoring of the product during the printing process and provides the ability to input desired changes into the design. 3D printing technology reduces the amount of waste and carbon dioxide emissions, as well as the cost of energy, preparation, and transportation, and opens up much room for innovation [161, 204,205,206,207,208].

Although the possibilities of 3D food printing technology are great, there are still many challenges that need to be overcome, such as printing complexly designed foods with multiple ingredients, parts, or textures (e.g., hamburgers) that require specialized and sophisticated processing, and using different food ingredients with large differences in physicochemical properties [207]. The main challenges in the production of 3D-printed food are the safety, labeling on the declaration, the complexity of handling and transportation, and the organization of larger production, which act as a constraint and can further challenge the 3D food printing market [159]. The application of sustainable, non-thermal technologies to maintain the quality and extend the shelf life of 3D-printed foods has not been sufficiently explored, so these are certainly challenging that will be explored next.

Prevention of Waste

Agriculture is in many ways one of the first steps in food production that determines the quality of food after subsequent industrial processing. Water, soil, air, and the other environmental factors perpetually influence the food quality at all levels and are the logical places to prevent numerous quality-based wastes and losses, such as decreasing expenditures on water and other essential natural resources.

Recent innovations in nanotechnology have transformed a number of scientific and industrial fields, including the food industry. Applications of nanotechnology have emerged with the increasing need for nanoparticles in various areas of food science and food microbiology, including food processing, food packaging, functional food development, detection of foodborne pathogens, and shelf life extension of food and/or food products [209]. Additionally, the potential of nanoparticles for their application in the food industry is very important to provide safe and contamination-free food to consumers. Overall, the use of nanotechnology in food and agriculture aims to improve the quality, safety, and sustainability of food and support sustainable agriculture [210]. Accordingly, aspects of nanotechnology application related to reducing food contamination have been discussed in this subsection, along with insight into efficient purification techniques of pollution sources.

Population growth and industrialization have led to the use of many synthetic and natural compounds to meet the needs of modern society [211]. Several million tons of pesticides, pharmaceuticals, and dyes are used in consumer and industrial products as well as fertilizers [212,213,214]. Nowadays, the demand for pesticides has increased due to their excessive use in agriculture. Indeed, the use of pesticides is a common practice to increase the yield of crops [215]. Pharmaceuticals are widely used to control disease and improve human, animal, and ecosystem health [216]. Residues of pharmaceutical products can enter the environment during their manufacture, use irrigation with wastewater, off-label emissions, and disposal [217]. Sources of organic dyes in the food industry also include food colorants, pigments from raw materials, and illegally added industrial dyes [218]. Food colorants are a type of additive that can be used to enhance or improve the color and luster of food. They can improve the taste of food while playing a certain role in increasing appetite [219].

Most of the above micropollutants originated from the rapidly developing agricultural and industrial sectors have been released into the environment and can accumulate in the food web (e.g., drinking water), with unknown short- and long-term impacts on human health, aquatic life, and wildlife [220,221,222]. Moreover, the food-processing industry is one of the largest consumers of drinking water in the world [223]. With the increasing scarcity of drinking water, the reuse of wastewater streams has become an important economic and environmental concern. In view of the above, chemical contaminants have become food safety responsibility as residues of the above environmental pollutants have been detected in food supply. Persistent organic pollutants are biomagnified throughout the food chain and bio-accumulate in organisms. Therefore, the highest concentrations of mentioned pollutants are found in organisms at the top of the food chain. Therefore, environmental pollution is a growing global issue [224].

Given the widespread occurrence of chemical contaminants in food and their serious health risks, prevention of food contamination is a public health priority [225]. However, although all natural resources are equally exposed to the dangerous effects of different contaminants, the presence of persistent organic pollutants in the aqueous environment is one of the most serious global concerns [226, 227]. Many emerging organic contaminants are not easily removed by conventional biological wastewater treatment processes, as evidenced by their presence in drinking water (Ebele et al., 2017; Sharma and Feng, 2017). Consequently, pollutants, such as pesticides, have severely impacted water resources due to their persistent and toxic nature [216]. According to the UNESCO 2020 Development Report, 68% of the world’s population does not consume sanitized water, and water pollution caused $2.2 billion worth of damage in the United States [228]. In addition, the occasional extensive use of pesticides leads to the contamination of natural waters in agricultural areas [229,230,231]. As a result of extensive use and high runoff potential, surface waters may also be contaminated. Another source of surface water pollution can be spray drift from wind [232]. Finally, wastewater from the food industry contains recalcitrant organic compounds and some degree of toxicity. Current wastewater treatment plants are inadequate to deal with the increasing complexity of effluents from the modern food industry. Consequently, the inadequately treated wastewaters can seriously threaten the health of aquatic organisms and lead to spoiled soils. Complete removal of pesticides from wastewater is therefore a challenge for the industry.

Different technologies, such as physical processes (e.g., filtration and adsorption) and chemical oxidation processes, are being investigated as alternatives or improvements to existing wastewater treatment processes for sustainable water decontamination [233, 234]. In particular, light-driven (e.g., ultraviolet (UV)/sunlight) and radical-based (e.g., hydroxyl) processes have been proposed to remove micropollutants from water and wastewater [235,236,237,238,239]. The development of advanced wastewater treatment techniques and their use is being pursued for the effective removal of pollutants, especially pharmaceutical and pesticides [211]. Advanced oxidation processes (AOPs) are new green chemical technologies that are promising and sustainable alternatives to the conventional techniques mentioned above. AOPs are based on the formation of highly reactive oxygen species, such as •OH radicals that degrade hazardous pollutants by SO 9001 standard is the basic QMS standaconverting them from their reduced forms to their final, non-toxic oxidized form [240, 241]. Among the different AOPs, such as the Fenton process, ozonation, catalytic wet peroxide oxidation, catalytic wet air oxidation, and electrochemical oxidation or the combination of some of them, photocatalysis, especially its heterogeneous alternative, is the most actively investigated sustainable process for water purification [242]. Photocatalytic reactions rely on the interaction between the semiconductor (photocatalyst) and light with sufficient energy (specific wavelength) to produce highly reactive oxidizing species that interact with the pollutants [243]. This process proves to be very effective as a large number of (generated) reactive free radicals attack organic contaminants and change their chemical structure. Moreover, photocatalysis has proven to be highly efficient and environmentally friendly in degrading harmful organic pollutants by utilizing the renewable and clean solar energy [244].

To date, many semiconductors have been investigated and used as photocatalysts, with TiO2 and ZnO proving to be the most popular [244]. In general, nanomaterials are capable of absorbing or degrading more pollutants than conventional materials because they have a larger surface-to-volume ratio and contain more active sites, which also contributes to enhanced photocatalytic activity [245]. Nowadays, great attention is paid to the fabrication of different nanomaterials based on TiO2 for photocatalytic and other purposes. Nanomaterials can be synthesized in various dimensions such as 0D, 1D, 2D, and 3D structures. For example, spherical TiO2 as a 0D nanomaterial has a large surface area, which is an important factor in adsorption and photocatalysis. Subsequently, 1D fiber and tube structures can reduce the potential recombination of photogenerated electron–hole pairs due to the short distance for carrier diffusion, light-scattering properties, and fabrication of self-standing nonwoven mats. Furthermore, 2D nanosheets have smooth surface and strong adhesion, while 3D-monoliths have high carrier mobility [246]. Similar approaches have also been investigated in the case of ZnO. Namely, ZnO as a nanomaterial can also arise in 1D, 2D, and 3D nanostructures. Indeed, ZnO nanomaterials in 1D group can occur in the following forms: needles, nanorods helixes, rings and springs, ribbons, tubes, belts, combs, and wires [247]. In 2D structures, ZnO can be obtained in the form of nanosheet and nanoplate. In addition, in the 3D group, there are some examples of structures of zinc oxide such as flowers, coniferous, snowflakes, urchin-like, dandelion, and other shapes [248].

There are several approaches for the synthesis of nanoparticles. However, these techniques require the use of harmful organic chemicals (toxic and non-biodegradable precursors), among other limitations such as expensive equipment, the need for expertise, low yield of products, and long reaction times [249]. The application of green techniques is becoming a popular method for the synthesis of new and the improvement of already known nanomaterials. This fact is confirmed by the growing number of publications on this topic [250]. Therefore, the selection and application of green methods (based on plant extracts) for the synthesis of sustainable phyto-photocatalysts are fully justified from several aspects, such as the wide plant diversity and the “reagent- and waste-free” technological approaches. Namely, the phytochemicals contained in the natural extracts act as reducing and covering agents, so the synthesis process can be carried out without the use of expensive toxic organic stabilizers and complicated time-consuming procedures. Moreover, the plant extracts used for sustainable synthesis can further enhance the photocatalytic activity due to the biomolecules and other natural compounds they contain. However, the exact effects of plant-derived biomolecules in nanoparticles synthesis, as well as photocatalytic processes are not well-known and require further investigation.

As an emerging technology, nanomaterial photocatalysis is a green chemistry–based nanotechnology that effectively improves the degradation rate of contaminants in agriculture. Especially, TiO2-based photocatalysts are usually used for the photodegradation of polluted pesticide water. In recent years, ZnO nanomaterials have also received considerable attention for the efficient photodegradation of pesticides. This suggests that ZnO-based photocatalysts are very suitable and attractive for potential applications in photodegradation of agricultural pollutants. Although such recalcitrant compounds can be converted into intermediate and non-toxic end products by this technology, the reaction conditions to achieve high degradation performance with each type of nanomaterial were very different [251].

Food colorants and illegal additives have been overused to some extent in the food industry and eliminated together with industrial wastewater [219]. Therefore, the removal of these substances from industrial wastewater is a very important concern. The photocatalytic degradation of organic dyes by nanomaterials has been studied and applied to the degradation and removal of pigment pollution in industrial wastewater from the food industry to provide a theoretical basis and a new idea for the development of a new and efficient technology [219]. Despite the significant progress in the synthesis of photocatalysts for environmental remediation, their photocatalytic performance for the degradation and mineralization of emerging organic pollutants and their intermediates still need to be further improved for practical applications [217].

In summary, water is the most widely used raw material in the food and beverage industry. This industrial sector has a negative impact on the environment and the economy due to the increasing demand for water and the production of wastewater, as well as the resulting negative impact on food quality. Water purification methods based on green nanomaterials are promising technologies with the benefits of energy-saving and environmental protection. In order to push forward the development of this technology, solar absorbers need to be further optimized from the aspects of substrate influence, service life, and recycling, and finally, of course, a perfect solar thermal steam-generating wastewater treatment technology needs to be developed [219].

Conclusions