Abstract

Non-thermal processes are employed to decontaminate juice products with less negative impact on biochemical, sensorial, and nutritional properties of the products compared with traditional thermal processing. Different non-thermal technologies have been investigated to improve the quality and/or avoid undesirable changes in fruit juices that include ultraviolet (UV) irradiation, pulsed electric field (PEF), ultrasonication, ozonation, high-pressure processing, and membrane filtration. In this review, which focuses on current studies, largely from a decade ago, the combined impacts of UV irradiation and other non-thermal technologies (hurdle concept) on fresh fruit juices are addressed. The extensively researched products regarding the application of UV light processing to improve safety, maintain overall quality, and prolong shelf life were apple and orange juices. Based on the studies reviewed, the hurdle techniques (e.g., UV + PEF, UV + mild heat at 50 °C, UV-C + coupled microwave, UV + ultrasonication) reduced (> 5 log) spoilage/pathogenic microbes, viruses, and inactivated enzymes, while maintaining the fresh-like nutritional and sensorial quality of juices. However, achieving the right balance and synergy in hurdle technologies can be a challenge which should be more addressed in the future studies. Human trials also indicated that UV-irradiated juice had no cytotoxic effects on normal intestinal cells, but it stopped human colon cancer cells from growing. Treating fruit juices with UV in combination with other non-thermal hurdles could be an alternative to traditional thermal processing technologies in the food industry. However, commercialization, scale-up, regulatory, safety, economic, and ethical concerns of these technologies should be taken into consideration.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fruit juices are a vital component of a healthy diet due to their substantial phytochemical constituents that contribute to nutritional and health-promoting effects in consumers (Khandpur & Gogate, 2015). However, the release of these phytochemicals from the fruit into the juice could be affected during uncontrolled processing conditions and subsequent improper storage conditions. For example, during improper processing and storage of fresh juices, a degradation of phenolics, flavonoids, ascorbic acid, proteins, and fatty acids takes place once the cellular protection of these compounds is no longer present after extraction. The activity of polyphenol oxidase triggers browning reactions that are enhanced by temperature, pH, and storage environment normally used in food processing and storage (Antonio-Gutiérrez et al., 2017). Several types of microorganisms can spoil fruit juice, including bacteria (e.g., Lactobacillus spp., Leuconostoc spp., Pediococcus spp., and Acetobacter spp.), yeast (e.g., Candida spp., Hanseniaspora spp. and Zygosaccharomyces spp.) and, mold (Aspergillus spp., Penicillium spp. and Cladosporium spp.) which compromise the safety and deteriorate the quality of fruit juices during storage (Pinto et al., 2022).

Conventional thermal pasteurization and sterilization technologies have been used as the standard practice to inactivate enzymes and microorganisms that compromise the safety of fruit juices. However, the thermal processing of fruit juices has been reported to affect the nutritional, physicochemical, and sensory properties of the products due to changes in color, flavor, vitamins, and volatile sensory components, as well as protein denaturation (Khandpur & Gogate, 2015). Furthermore, it has been documented that thermal processing methods (e.g., pasteurization, blanching, and ohmic heating) may activate dormant ascospores of molds in processed juices. This activation can lead to microbial spoilage during storage, causing significant economic losses (Menezes et al., 2019).

To obviate the quality problems caused by thermal processing, several non-thermal technologies have been introduced for safeguarding the quality of fruit juices mostly during processing and subsequent storage. Some of these novel technologies include ultraviolet irradiation (UV), pulsed electric field (PEF), high-pressure processing, high-power ultrasonication, ozonation and cold plasma which are effective at temperature below 50 °C and thus much lower reaction rates are generated by these technologies (Silva et al., 2020; Tiwari et al., 2009; Umair et al., 2022).

Non-thermal processing of fruit juices retains nutritional ingredients without compromising their physicochemical and sensorial properties, which has been reported for a wide range of juices such as Tiger nuts, watermelon juice, and other fruit juices (Bevilacqua et al., 2018; Bhattacharjee et al., 2019; Roobab et al., 2018). Besides, non-thermal technologies promote sustainable food production by efficient energy use, no or low waste produced, and maximizing the use of resources which could promote the adoption of a circular economy and the achievement of the Sustainable Development Goals set forth by the United Nations (Arshad et al., 2022).

In order to extend the shelf life of fruit juices, ultraviolet (UV) irradiation has been used as a promising non-thermal technique for enzyme inactivation and microbial inhibition. UV irradiation inactivates spoilage and pathogenic microorganisms by exposing the target product to UV radiation while exerting minimal changes on its chemical, nutritional properties, and sensorial quality of the fruit juice (Assatarakul et al., 2012). UV irradiation has been investigated in combination with other non-thermal technologies known as hurdle concept which entails the use of a deliberate and intelligent combination to achieve synergistic effect in the preservation of post-processing quality and shelf-life extension (Alabdali et al., 2020; Carrillo et al., 2018). Hurdle technology is a food preservation technique that involves the use of multiple techniques or hurdles to prevent the growth of microorganisms and extend the shelf life of food products (Alabdali et al., 2020).

UV radiation treatment of fruit juices has been monitored to inhibit various quality degrading enzymes, e.g., peroxidase (POD), polyphenol oxidase (PPO), pectin methyl esterase (PME), and lipoxygenase (LOX) (Aneja et al., 2014). We aimed in this review to evaluate recent information on the efficacy and application of the UV irradiation combined with other non-thermal technologies (e.g., UV + PEF, UV + mild heat) on the physicochemical quality characteristics, microbial inhibition and enzyme inactivation of fruit juices to identify research gaps and future opportunities for the development of functional foods.

Thermal-, Non-thermal Processing and Hurdle Concept in Fruit Juices

Chemical, microbiological, and enzymatic interactions are the main causes of fruit juice deterioration (Bhattacharjee et al., 2019). They cause the juice to darken and discolor as a result of their reaction with dissolved oxygen. On the other hand, non-enzymatic browning via the Millard reaction is also responsible for the browning of fruit juices during processing. Fruit juices have traditionally been preserved by thermal processing to retard microbial growth and inactivate enzymes in juices. The minimally processed fruit sector is one of the industry’s fastest expanding sectors, as consumers desire goods with a higher degree of freshness and safety for consumption. A number of milder fruit preservation techniques, some of which are currently in use commercially, had been investigated, i.e., “non-thermal food processing technologies” to balance these tendencies without compromising on food product safety. On the other hand, thermal pasteurization involves the heat transference in juice processing via conduction and convection mode of transmission. The goal of thermal pasteurization is to kill pathogens and significantly reduce the amount of spoilage microorganisms. Low temperature-long time (LTLT) and high temperature-short time (HTST) methods are two types of traditional thermal pasteurization employed in the juice processing. LTLT pasteurization includes heating a food to a temperature around 63 °C for at least 30 min, while HTST pasteurization is used in fruit juices with holding periods of 15 s at 72 °C. Despite the fact, thermal treatments have some effectiveness in maintaining microbial quality, but these affect color, flavor, and nutritional properties followed by protein denaturation, loss of vitamins, and volatile sensory components in fruit juices (Menezes et al., 2019) which reported that mold ascospores that cause food deterioration and loss of revenue can be reactivated by heat processing.

To overcome the quality losses in heat-processed juices, non-thermal processing is an effective means to retain the physiochemical, nutritional, and sensory properties with extended shelf life. Non-thermal technologies have drawn a lot of interest in recent years as additive-free, cost-effective, and eco-friendly food processing technologies to replace thermal methods of food processing. According to Bevilacqua et al. (2018), some non-thermal techniques used in juice processing include high-pressure processing (HPP), ultrasonication (US), ozonation (O3), membrane filtration (MF), and high-pressure CO2.

Ultraviolet irradiation has several technological benefits over other non-thermal concepts due to its low maintenance and installation costs, minimum energy consumption, and ability to preserve food without causing any adverse side effects. However, the UV source efficiency, which includes the quantity and kind of UV light sources, flow rate and pattern, effectiveness of UV reactor mixing, and properties of the food to be treated (e.g., composition of the product, and viscosity), is related to the energy efficiency of the UV system (Müller et al., 2014). It was found that compared to heat pasteurization and other non-thermal technologies (e.g., HPP, MF, and PEF), the total energy consumption of a UV system is much lower (Delorme et al., 2020). Moreover, Delorme et al. (2020) emphasized that the limited application of UV when used alone could be addressed by combining UV irradiation with other interventions such as non-thermal processing for additive and/or synergistic effects. UV light wavelength in the range of 100 to 400 nm in the electromagnetic spectrum has been classified into several groups such as UV-A, UV-B, UV-C, and UV-V (Rifna et al., 2019). The UV system described in our earlier work was made up of a stainless-steel cylinder with a 5.74-cm diameter and a 22.0-cm length. A glass tube with a diameter of 2 cm and a length of 24.50 cm was put within the stainless-steel cylinder, encircling a 6-Watt UV lamp (Visuthiwan & Assatarakul, 2021). The juice sample is circulated through a thin layer between the glass tube and the outer cylinder to be exposed to the UV radiation. The low-pressure mercury lamps emit UV-C radiation on the exposed juice sample. Fruit juice variety, absorptivity, suspended particles in the liquid, and soluble solids, all affect how much UV-C radiation penetrates the liquid. The intensity of the UV-C light’s penetration into the liquid decreases as the amount of soluble solid increases (Ramesh et al., 2018). Microorganisms (e.g., bacteria, viruses, and protozoa) are susceptible to the germicidal effects of UV-C (Shah et al., 2019). UV-C irradiation at 400 J/m2 irradiation dose was recommended for fruit juice pasteurization and microbial inactivation (Bhattacharjee et al., 2019). The effectiveness of UV will also be influenced by a number of other instrumental factors, including the type and length of the lamp being used, turbidity, viscosity, and the density and absorbance coefficient of the food material being treated.

In the preservation of fruit juice, hurdle technology involves the use of several techniques to prevent the growth of microorganisms and maintain the quality of the juice. Some hurdles that can be used in the preservation of fruit juice with the combination of UV include the use of high-pressure processing (HPP) and pulsed electric field (PEF), which can kill microorganisms. As an example, UV irradiation has been employed with HPP technology to preserve nutritional ingredients, color, and flavor qualities of fresh juice products (Koutchma et al., 2016). However, the success of UV technology in hurdle systems depends on various factors, including the intensity, exposure time, and wavelength of the UV light, as well as the characteristics of the juice. The combination of UV treatment with other hurdles, such as pasteurization, refrigeration, or chemical preservatives has shown to enhance its effectiveness and provide a comprehensive approach to food preservation. By combining these different hurdles, hurdle technology can provide a more effective and comprehensive approach to preserve fruit juice, ensuring that it remains safe and high quality for a longer period of time. In a recent study, Bigi et al. (2022) concluded that the hurdle concept overcomes the limitations related to the single technologies, broadens their efficiency and application range, and minimizes their impact on food quality. However, further studies were recommended to better understand the mechanisms of mutual interaction among these techniques when combined together in specific conditions, in view of their scaling-up for commercial applications.

This study summarizes the published studies on the use of UV radiation in combination with other non-thermal processing (hurdle concept) for the preservation of fresh juice quality in recent years. Furthermore, these effects on microbial, physical, chemical, sensory, and shelf-life attributes in fruit juices have been provided in details.

An Overview of Published “Review Papers” on Hurdle Technology Using UV Irradiation in Fruit Juices

Combining non-thermal treatments, which are used in the food industry, has demonstrated the ability to improve processing efficiency at lower treatment intensities while also overcoming the limitations of single technologies (Zhang et al., 2019). A review paper on the effects of UV light and HPP processing on the nutritional value and quality of fresh fruit and vegetable juices showed that, under the conditions needed to achieve a 5-log reduction of pathogenic microorganisms, only a minor number of physicochemical properties, vitamin content, and antioxidant activity were degraded (Koutchma et al., 2016).

Delorme et al. (2020) mentioned that UV-C radiation as environment-friendly non-thermal technology can be considered an effective method for inactivating pathogenic and spoilage microorganisms in dairy products; however, the process parameters such as exposure time, UV dose, wavelength, UV light source, product type, chemical composition, viscosity, turbidity, opacity, and roughness, equipment conformation and geometry, and microorganism properties all affect how effective the procedure is. According to Shah et al. (2019), when combining ultraviolet with other procedures at low intensities, the dosage and exposure of UV-C to the fruit juice should be appropriately controlled. According to Bevilacqua et al. (2018), the advantages of hurdle technologies such as UV + mild heat, high hydrostatic pressure, and other non-thermal treatments depended on the food matrix, the compatibility of the components used in each method, and the ease with which the food industry can implement each method. They also recommended more research on non-thermal electrical treatments, such as radiation processing, high-pressure processing, ultrasound, inert gas treatments, cold plasma processing, and membrane processing, in order to manage processing systems and optimize resources, maintain nutritional value and organoleptic properties, and provide processing conditions for the industrial scale validation of these technologies. In order to examine the inactivation of microorganisms and/or the preservation of pomegranate juice quality features, particularly during the shelf life, Putnik et al. (2019) focused on combining two or more non-thermal treatments (hurdle concept).

The hurdle technology strategy of preserving the natural value of foods over long periods of time was proven in a more recent study by Putnik et al. (2019); it was also concluded that UV radiation was a useful addition to hurdle technologies. According to Roobab et al. (2018), utilizing mild heat in addition to UV irradiation is extremely promising for combating more resistant bacteria species and spores. According to Bhattacharjee et al. (2019), non-thermal processing of watermelon juice has been successfully studied in order to minimize microbial deterioration and retain nutritious components through less enzyme and microbial activity. Hurdle technology using ultraviolet (UV) technology in fruit juice processing can have several positive effects on the circular economy and contribute to achieving Sustainable Development Goals (SDGs). According to Arshad et al. (2022), incorporating UV technology into hurdle technology for fruit juices aligns with several SDGs, including those related to responsible consumption, environmental sustainability, health, and economic growth. It promotes a more circular and sustainable approach to food processing, reducing waste and resource consumption while enhancing safety and product quality.

Based on the published review papers mostly from the last decade ago (Table 1), using hurdle technology, which is capable of increasing organoleptic and sensory features and ensuring the microbiological safety of foods, could help counteract the negative impact of conventional thermal technologies. However, in a review paper, Aaliya et al. (2021) identified important challenges and future directions for hurdle technologies research. These included the following: (1) gaining a comprehensive understanding of the physicological conditions under which microbes respond to various stress adaptation processes in order to prevent cross-tolerance reactions and (2) estimating and assessing the synergistic effects of hurdle approach in order to prevent antagonistic effects. (3) In a laboratory setting, challenge testing and process validation for predictive microbiology are required. (4) Future uses should carefully plan low-cost hurdle technologies that have minimal quality deterioration and high inactivation efficacy. (5) Food researchers should follow the global harmonization of hurdle technologies in order to harmonize the processing conditions stated in different research findings.

Effect of Hurdle Technologies Using UV Irradiation on Microbial Quality of Fruit Juices

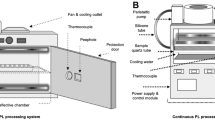

Hurdle technology using UV technology has a profound and positive impact on the microbial quality of fruit juices. It provides a safe and effective means to reduce and eliminate harmful microorganisms, extending shelf life and enhancing food safety while preserving the sensory qualities of the juice. This technology contributes to higher microbial quality, ensuring that consumers can enjoy safe and microbiologically stable fruit juices. The various studies obtained from the literature on the application and impact of UV irradiation in association with other non-thermal technologies on the microbial quality of fruit juices are presented in Table 2 and Fig. 1 and discussed in this section. In an early study, UV irradiation and PEF were used in conjunction to achieve adequate total microbial inactivation (7.1 log decrease) and to improve product quality (e.g., reducing PPO and POD activity) in comparison to heat pasteurization (Yin et al., 2015). Furthermore, the order in which the technologies were used such as UV + PEF or PEF + UV did not have an impact on the level of microbial inactivation as a whole. The future utilization of these combined technologies for fruit juice processing especially freshly squeezed apple juice was proposed in that early study. In apple juice, the synergistic effects of UV-A irradiation and fumaric acid addition (0.1%) reduced the contamination by E. coli O157:H7, S. Typhimurium and L. monocytogenes up to 3.43 log (Jeon & Ha, 2020). In the other hurdle concept, UV-C (14 mJ/cm2) and ascorbic acid (300 mg/kg) addition showed 5-log reduction of E. coli in apple juice (Usaga et al., 2017). Up to 7 log-reduction of S. cerevisiae was achieved following UV-C + mild heat (50 °C) treatment of carrot juice samples (Carrillio et al., 2018). The other study also showed that combined UV and mild heat (50 °C) treatment reduced more than 5 log cycles of the most resistant pathogens (i.e., E coli O157:H7, L. monocytogenes) in carrot juice. The application of UV-C (1.14 mW/cm2) + mild heating (53 °C) showed a microbial reduction (E. coli O157:H7) of 6.35 log CFU/mL in orange juice. During cold storage for 9 days, no microbial increments were observed after UV-C and mild heat treatment (Hernández-Carranza et al., 2021). Patulin, a mycotoxin from molds, particularly Aspergillus spp., Penicillium spp. and Byssochlamys spp. contamination in apple juice concentrate decreased up to 5% after UV exposure at 99.4 mJ/cm2, with the proportion of patulin followed by first-order kinetic modeling with an exponential relationship between UV exposure and the microbial inhibition (Yin et al., 2015). In comparison to UV radiation at 254 nm and Far UV lights at 282 nm, the inactivation of E. coli O157:H7 after exposure to Far UV light at 222 nm was greater in apple juice (Usaga et al., 2014). UV-C (38 W/m2) in apple juice at different soluble solid concentrations (12, 25, 30, 40, 50, 60, and 70°Brix) affected the inactivation of N. fischeri ascospores mold by approximately 4-log reduction (Pinto et al., 2022).

Synergistic value of hurdle concept using UV irradiation for microbial decontamination in fruit juices. Note: Synergistic effect is calculated as the combined effects of non-thermal processing divided by the summed single effect of each non-thermal processing (Ha & Ha, 2010). A positive synergistic value indicates the benefit of combining multiple non-thermal processing, while a negative result shows the decreased benefit effects and a zero value means only an additive effect not a synergistic one. The numbers indicate as follows: (1) UV + ethanol treatments reduced S. aureus, S. enterica Typhimurium and E. coli (Ha & Ha, 2010); (2) UV-C (0–10.6 kJ/m2) and mild heat (50 °C) reduced S. cerevisiae in carrot-orange juice (Carrillo et al., 2018); (3) UV-C + mild heat (50 °C) reduced mesophiles, mold, and yeast in orange juices (Hernández-Carranza et al., 2021); (4) UV-C and mild heat (50 °C) reduced S. cerevisiae in verjuice (Kaya & Unluturk, 2019); (5) UV + ultrasonication reduced yeast and mold count in pomegranate Juice (Alabdali et al., 2020); (6) UV-C + mild heat + 100 ppm citral + 1000 ppm vanillin reduced E. coli, L. plantarum, and S. cerevisiae in orange-tangerine (Fenoglio et al., 2022) and orange-banana-mango-kiwi-strawberry during 7 days of cold storage (Ferreira et al., 2020); (7) UV-C + coupled microwave reduced Saccharomyces cerevisiae and Escherichia coli in pomegranate juice (Gómez Sánchez et al., 2020); (8) UV-A + fumaric acid (0.1%) reduced E. coli O157:H7, S. Typhimurium and L. monocytogenes in apple juice (Jeon & Ha, 2020)

It should be noted that the yearly UV validation of monitoring the efficacy of frequency for commercial UV (CiderSure 3500) juice processing units is recommended to ensure safety against food-borne pathogens and spoilage microorganisms (do Prado et al., 2019). The use of UV-C reduced the spore counts and biofilm formation of Alicyclobacillus spp. in industrialized orange juice, being a promising alternative for the control of Alicyclobacillus spp. especially for the A. acidocaldarius spp. (Ferreira et al., 2020). Additionally, UV-C combined with nisin potentially eliminated A. acidoterrestris spores in industrialized orange juice and maintained the final quality without any degradation of vitamins or other nutritional components (Pala & Toklucu, 2013).

The microbial loads of grapes were completely inactivated after UV-C treatment at a dose of 25.2 J/mL (Groenewald et al., 2013). UV-C employed at a dosage level of 116.7 J/mL in freshly squeezed grape juice showed 3.759, 4.133, and 1.604 log CFU/mL reduction to E. coli K-12, lactic acid bacteria, and food-borne yeasts, respectively (Czako et al., 2018). UV processing inactivated Alicyclobacillus spp. spores in processed grape juice and contaminated wash water used in fruit processing which was also decontaminated (Mansor et al., 2017). The combination of UV-C (13.67 kJ/L) and SO2 reduced the microbial contamination up to 4.5 log in the grape juice samples (Czako et al., 2018). An inactivation of up to 9.10 log in S. Typhimurium was reported after UV exposure at doses of 15.45–27.63 mJ/cm2 in pummelo juice (Shah et al., 2019). UV-C irradiation with additional Dean Vortex technology was effective in pineapple juice as evidenced by 5 log CFU/mL of S. Typhimurium at a dosage level of 13.8 mJ/cm2, which was in line with the FDA standards (Kim et al., 2021). UV-C treatment (0.0–2.36 J/cm2) at 254 nm in grapefruit juice inactivated E. coli ATCC 25922 and one strain of S. cerevisiae with no significant changes on citric, malic, tartaric acids, naringin, hesperidin and neohesperidin, total phenolics, ABTS+, pH, °Brix, titratable acidity, and color of the grapefruit juices (La Cava & Sgroppo, 2019). Additionally, to forecast the shelf life of UV and thermally modified fruit juices, kinetic modeling has been examined for color and bioactive compounds, although the majority of kinetic models explored in the microbiological safety of fruit juices are traditional, such as zero-order, first-order, and second-order kinetics. However, alternative models have been used to track the kinetics of vitamin C and anthocyanin degradation in thermally processed guava pulp, cupuacu (Theobroma grandiorum) nectar, and blackcurrant juice. The effects of UV light on inoculated A. acidoterrestris spores in apple juice demonstrated that A. acidoterrestris inactivation follows a first-order kinetic (Ochoa-Velasco et al., 2018).

The combined effects of UV + ethanol treatments resulted in greater reductions in Bacillus cereus F4810/72, Cronobacter sakazakii KCTC 2949, Staphylococcus aureus ATCC 35556, Escherichia coli ATCC 10536, and Salmonella enterica Typhimuriumthan when either treatment was applied (La Cava & Sgroppo, 2019). Moreover, the synergistic values of the combined effects of UV + ethanol were reported up to 2.32. An increase in benefit from combining different therapies is shown by a positive synergistic effect value, whereas a loss in benefit is indicated by a negative result. Zero indicates that there is no synergistic, but rather additive, effect of combining the separate treatments. Figure 1 shows that hurdle technologies using UV irradiation have synergistic effects to inhibit the microbial load of fruit products. Fenoglio et al. (2020) also demonstrated that UV-C treatment with the addition of selected antimicrobials (vanillin plus citral) could result in E. coli, L. plantarum, and S. cerevisiae reduction for more than 5 logs in orange-tangerine and orange-banana-mango-kiwi-strawberry juice blends. Kaya and Unluturk (2019) reported a complete inactivation of S. cerevisiae (~ 5 log) in verjuice after treatment with the combination of UV-C (0.25 J/cm2) and mild heat (51.3 °C). Ultrasonic atomization and UV-C in combination effectively inactivated spoilage with S. cerevisiae in tangerine and grapefruit juices (Antonio-Gutierrez et al., 2017).

Overall, the management of microbiological and biochemical quality control on heat- and UV-treated fruit juices is supported by the application of food kinetics, which is a potent tool to uncover fundamental reaction mechanisms. However, compared with traditional thermal pasteurization, non-thermal hurdles like UV and other techniques may offer a higher chance for improved microbiological safety and shelf life in fruit juices.

Effect of Hurdle Technologies Using UV Irradiation on Physicochemical Quality and Enzymatic Activity of Fruit Juices

The various effects of hurdle technologies on physicochemical quality characteristics are provided in Table 3. In a recent study, grape juice extracted from post-harvest stored organic grapes and treated with UV-C at a dose of 65.6 J/m2 revealed increased levels of phenolic compounds with no interference with the basic physicochemical composition including color values and hue angle, pH, total titratable acidity, and total soluble solids (Pinto et al., 2022). Consistently, UV-C treatment at the FDA-suggested dose of 40 mJ/cm2 retained polyphenolic compounds in apple juice with significant changes in vitamin contents. It was proposed that more research be done on low oxygen exposure to enable better vitamin levels. Bioactive components were found to be higher in apple juice samples with combined UV-C and moderate heat treatment compared to pasteurization (Yıkmış et al., 2021). The other study also showed that UV-C + mild heat improved the functionality of carrot juice (Carrillo et al., 2020). In pomegranate Juice, UV + ultrasound treatment during the pasteurization process preserved the bioactive compounds (Alabdali et al., 2020). La Cava and Sgroppo (2019) reported no negative impact on the physicochemical properties of grapefruit juice after treatment with UV-C + mild heat. However, Czako et al. (2018) reported that UV-C + addition of SO2 increased turbidity in grape juice. UV-C + ultrasonic atomization revealed minimal changes in terms of color, pH, and TSS in tangerine and grapefruit juices (Antonio-Gutiérrez et al., 2017).

Visuthiwan and Assatarakul (2021) demonstrated that even using UV-C alone had no effect on pH, Brix, titratable acidity, total flavonoid concentration, or antioxidant activity in lychee juice. The treatment of apple juice by UV alone showed no major changes in color and better retention of phenolics and color (Yang et al., 2019). UV-C-treated pitaya juice preserved phenolic compounds and retarded mesophilic bacteria and yeasts including Zygosaccharomyces bailii after 10 days of storage at 4 °C (Pendyala et al., 2020). Phenolics and ascorbic acid contents of lemon, orange, papaya, and grape juices were decreased in UV-treated compared to untreated fresh juice samples (Ramesh et al., 2018). The effects of UV-C treatments (12.6 and 25.2 J/mL doses) on phenolics, antioxidant activity, and total anthocyanins of red and white grapes showed that all the tested parameters were well maintained after the UV-C exposure (Groenewald et al., 2013). Furthermore, in the pineapple-mango juice blend, UV-C at a dose of 8.4 mJ/cm2 showed higher values of ascorbic acid, total phenolic compounds, and total antioxidant activity than those of heat treatment (90 °C for 5 min) during 9 weeks of cold storage (Kaya & Unluturk, 2019).

Using a laminar flow UV system, an efficient inactivation of endospores in watermelon juice was reported with no major changes in the concentration of ascorbic acid, volatile aroma, or flavor components (Aguilar et al., 2018). Ultraviolet and visible light (UV–Vis) had no negative effects on properties (e.g., color values, acidity, vitamin C content, sugar content); however, it was effectively inactivated enzyme in peach juices of different varieties (Sauceda-Gálvez et al., 2021). Pala and Toklucu (2013) reported that UV-C treatment (36.09 kJ/L) in orange juice resulted in no negative impact on chemical quality parameters such as organic acid content, antioxidant capacity, and phenolic compounds but little impact on the ascorbic acid content, aroma, and flavor characteristics of juice. Based on such findings, optimization of UV-C dose was suggested to guarantee microbial safety in the context of retaining the fresh-like characteristics of juice. A scale-up study on orange juice and sweet lime showed that the combined effect of non-thermal techniques consisted of UV and ultrasound to create fruit juices that are high in nutrients and have a long shelf life, opening the door to widespread commercialization of the technology (Khandpur & Gogate, 2015).

From the studies in terms of physicochemical properties, it could be derived that the hurdle technology which uses non-thermal technologies instead of pasteurization is frequently used in conjunction with various hurdles, such as heat treatment, UV or pulsed light, and antimicrobial compounds, to provide synergistic effects and enhance the overall quality of (functional) juices. Putnik et al. (2020) concluded in a review paper that because hurdle technology is effective and has no effects on the qualities of the juice, it may be a viable method for preserving fruit juices; however, optimization of all processing parameters is still necessary.

Effect of Hurdle Technologies Using UV Irradiation on Sensorial Quality and Shelf Life of Fruit Juices

The shelf life of fruit and fruit products should be extended by some interventions and treatments to prevent from spoilage. On the other hand, the creation of simple, low-cost, energy-efficient methods for storage without refrigeration that could be used to preserve fruits and fruit products was the main objective for the design of these combined approaches (hurdle concept). The combined use of UV-C (21.5 J/mL) and ultra-high-pressure homogenization (300 MPa) considerably altered the overall flavor and detectable aroma of cloudy apple juice, even if the treated samples’ criteria for taste were equal to those of the raw juice, according to sensory evaluation (Table 4) (Amanina et al., 2019). Sauceda-Gálvez et al. (2021) mentioned that UV-C + pressure homogenization resulted in no negative effects on sensorial qualities (i.e., taste, sweetness, sourness, freshness, and texture) of cloudy apple juice. In carrot juice, UV-C treated samples had better sensory characteristics compared to the thermally processed, as well as extended shelf life by 8 days (Riganakos et al., 2017).

A sensory analysis test confirmed that UV-C and mild thermal treatment of orange juice showed no significant difference on consumer acceptance compared to the fresh juice (Hernández-Carranza et al., 2021). The application of UV-C (100.47 kJ/L) vs UV-B reduced contamination and increased shelf life in apple and grape juices (Kim et al., 2021). Kinetic modeling of microbial degradation in lychee juice subjected to UV radiation (0–74.88 J/cm2) showed that UV-treated (18.72 and 37.44 J/cm2) samples extended the shelf life in juice approximately 7 days with no effects on pH, °Brix, titratable acidity, and antioxidant activity (Visuthiwan & Assatarakul, 2021). In carrot juice, UV-C and mild heat treatment could extend the shelf life up to 29 days (Gouma et al., 2020). The other study showed that UV-C and mild heat resulted in a superior sensory quality in carrot-orange juice than the pasteurized one (Carrillo et al., 2020). La Cava and Sgroppo (2019) demonstrated that the combined treatment of UV-C and mild heat helped in longer microbial shelf stability and maintained the physicochemical properties of the grapefruit juice during 28 days of storage at 4 °C. The combination of UVC + trans-cinnamaldehyde improved the shelf life in grapefruit juice without any physicochemical or microbial alterations (Ochoa-Velasco et al., 2018). Visuthiwan and Assatarakul (2021) reported that UV-C treatment extended the shelf life of lychee juice by 7 days when stored at 4 °C compared to the control sample. UV reactor equipped by a quartz glass sleeve extended the shelf life of the pineapple juice for up to 5 weeks during storage (Mansor et al., 2017).

The UV-C treatments (doses, 0.0–3.94 J/cm2) enhanced the shelf life of grapefruit juice during storage at 4 and 10 °C, but ascorbic acid and antioxidant capacity (up to 30%) decreased especially when higher doses were applied (Ochoa-Velasco et al., 2018). The shelf life of lemon-melon mixed juice was extended to 30 days in UV irradiation compared to the control juice sample without any treatment which lasted only for 2 days (Fenoglio et al., 2020). Yıkmış et al. (2021) reported that UV-C and moderate heat treatment caused prolonged shelf life in apple juice. Yang et al. (2019) also confirmed that even using UV alone caused 3 weeks longer shelf life in apple juice. UV exposure at 14.2–99.4 mJ/cm2 also showed only minor changes to the physical and chemical properties and sensory qualities of apple juice (Assatarakul et al., 2012).

From the studies in terms of sensory qualities and shelf life extension, it could be derived that combining UV treatment with other non-thermal technologies (hurdle concept) can enhance overall preservation while minimizing sensory changes. Additionally, proper product development and quality control procedures can help maintain the desired sensory attributes of the juice while ensuring safety and extended shelf life.

Conclusions and Future Perspectives

This review highlighted the impacts of hurdle technologies using UV irradiation on the physicochemical characteristics, microbial inactivation, and sensorial and shelf-life properties of fruit juices. Twenty distinct varieties of fruit juices were UV-processed, according to nearly 60 research papers. The most researched items in terms of using UV light processing to enhance safety, preserve overall quality, and extend shelf life were apple and orange juices. The application of UV irradiation alone or in conjunction with different non-thermal technologies was able to produce products with little to no enzyme and microbial activity thereby retaining fresh-like nutritional and sensorial quality. The combinations of UV and PEF, UV + mild heat, UV + ultrasonication, and many more showed synergistic effects on the inactivation of various microorganisms (e.g., E. coli, Listeria monocytogenes, Salmonella enteritidis). However, hurdle technology using ultraviolet irradiation comes with its set of challenges and areas for future work. Future research on the cytotoxicity of various fruit juices utilizing the hurdle concept using UV irradiation is expected. Besides, combining UV irradiation with other non-thermal processing (hurdle technology) to achieve the desired shelf life and safety can be complex. Achieving the right balance and synergy in hurdle technologies can be a challenge. The other challenge could be scaling up for commercial production which may pose technical and economic challenges. Ensuring consistent results and cost-effectiveness on a larger scale can be difficult. It is also advisable to undertake studies on the energy demands of hurdle technologies to identify the optimal processing conditions. In conclusion, using UV to treat fruit juices in combination with other non-thermal processing (hurdle concept) is a potential alternative to conventional thermal treatments. However, more collaborations between food producers and the food chain are needed to conserve natural resources, food safety, and energy in different food processing phases.

Data Availability

The data used to support the findings of this study are included within the article.

References

Aaliya, B., Sunooj, K. V., Navaf, M., Akhila, P. P., Sudheesh, C., Mir, S. A., ... & George, J. (2021). Recent trends in bacterial decontamination of food products by hurdle technology: A synergistic approach using thermal and non-thermal processing techniques. Food Research International, 147, 110514.

Aguilar, K., Garvín, A., & Ibarz, A. (2018). Effect of UV–Vis processing on enzymatic activity and the physicochemical properties of peach juices from different varieties. Innovative Food Science & Emerging Technologies, 48, 83–89.

Alabdali, T. A., Icyer, N. C., Ucak Ozkaya, G., & Durak, M. Z. (2020). Effect of stand-alone and combined ultraviolet and ultrasound treatments on physicochemical and microbial characteristics of pomegranate juice. Applied Sciences, 10(16), 5458.

Ali, N., Popović, V., Koutchma, T., Warriner, K., & Zhu, Y. (2020). Effect of thermal, high hydrostatic pressure, and ultraviolet-C processing on the microbial inactivation, vitamins, chlorophyll, antioxidants, enzyme activity, and color of wheatgrass juice. Journal of Food Process Engineering, 43, e13036.

Amanina, A. K. Z., Rosnah, S., Noranizan, M. A., & Alifdalino, S. (2019). Comparison of UV-C and thermal pasteurisation for the quality preservation of pineapple-mango juice blend. Food Research, 3, 362–372.

Aneja, K. R., Dhiman, R., Aggarwal, N. K., & Aneja, A. (2014). Emerging preservation techniques for controlling spoilage and pathogenic microorganisms in fruit juices. International journal of microbiology, 758942.

Antonio-Gutiérrez, O., López-Malo, A., Ramírez-Corona, N., & Palou, E. (2017). Enhancement of UVC-light treatment of tangerine and grapefruit juices through ultrasonic atomization. Innovative Food Science & Emerging Technologies, 39, 7–12.

Arshad, R. N., Abdul-Malek, Z., Roobab, U., Ranjha, M. M. A. N., Jambrak, A. R., Qureshi, M. I., ... & Aadil, R. M. (2022). Nonthermal food processing: A step towards a circular economy to meet the sustainable development goals. Food Chemistry: X, 16, 100516.

Assatarakul, K., Churey, J. J., Manns, D. C., & Worobo, R. W. (2012). Patulin reduction in apple juice from concentrate by UV radiation and comparison of kinetic degradation models between apple juice and apple cider. Journal of Food Protection, 75(4), 717–724.

Bevilacqua, A., Petruzzi, L., Perricone, M., Speranza, B., Campaniello, D., Sinigaglia, M., & Corbo, M. R. (2018). Nonthermal technologies for fruit and vegetable juices and beverages: Overview and advances. Comprehensive Reviews in Food Science and Food Safety, 17(1), 2–62.

Bhattacharjee, C., Saxena, V. K., & Dutta, S. (2019). Novel thermal and non-thermal processing of watermelon juice. Trends in Food Science & Technology, 93, 234–243.

Bigi, F., Maurizzi, E., Quartieri, A., De Leo, R., Gullo, M., & Pulvirenti, A. (2022). Non-thermal techniques and the “hurdle” approach: How is food technology evolving? Trends in Food Science & Technology, 132, 11–39.

Carrillo, M. G., Ferrario, M., & Guerrero, S. (2018). Effectiveness of UV-C light assisted by mild heat on Saccharomyces cerevisiae KE 162 inactivation in carrot-orange juice blend studied by flow cytometry and transmission electron microscopy. Food Microbiology, 73, 1–10.

Carrillo, M., Ferrario, M., Schenk, M., & Guerrero, S. (2020). Effect of an UV-C light-based hurdle strategy for carrot-orange juice processing on candida parapsilosis inactivation and physiological state: Impact on juice sensory and physicochemical quality parameters. Food and Bioprocess Technology, 13, 1954–1967.

Czako, P., Zajác, P., Čapla, J., Vietoris, V., Maršálková, L., & Čurlej, J.,& Martišová, P. (2018). The effect of UV-C irradiation on grape juice turbidity, sensoric properties and microbial count. Potravinarstvo Slovak Journal of Food Sciences, 12(1), 1–10.

Delorme, M. M., Guimarães, J. T., Coutinho, N. M., Balthazar, C. F., Rocha, R. S., Silva, R., ... & Cruz, A. G. (2020). Ultraviolet radiation: An interesting technology to preserve quality and safety of milk and dairy foods. Trends in Food Science & Technology, 102, 146–154.

do Prado, D. B., dos Anjos Szczerepa, M. M., Capeloto, O. A., Astrath, N. G. C., Dos Santos, N. C. A., Previdelli, I. T. S., ... & de Abreu Filho, B. A. (2019). Effect of ultraviolet (UV-C) radiation on spores and biofilms of Alicyclobacillus spp in industrialized orange juice. International Journal of Food Microbiology, 305, 108238.

Fenoglio, D., Ferrario, M., Andreone, A., & Guerrero, S. (2022). Development of an orange-tangerine juice treated by assisted pilot-scale UV-C light and loaded with yerba mate: Microbiological, physicochemical, and dynamic sensory studies. Food and Bioprocess Technology, 15(4), 915–932.

Fenoglio, D., Ferrario, M., García Carrillo, M., Schenk, M., & Guerrero, S. (2020). Characterization of microbial inactivation in clear and turbid juices processed by short-wave ultraviolet light. Journal of Food Processing and Preservation, 44(6), e14452.

Ferreira, T. V., Mizuta, A. G., de Menezes, J. L., Dutra, T. V., Bonin, E., Castro, J. C., ... & de Abreu Filho, B. A. (2020). Effect of ultraviolet treatment (UV–C) combined with nisin on industrialized orange juice in Alicyclobacillus acidoterrestris spores. LWT, 133, 109911.

Gabriel, A. A. (2015). Combinations of selected physical and chemical hurdles to inactivate Escherichia coli O157: H7 in apple and orange juices. Food Control, 50, 722–728.

Golombek, P., Wacker, M., Buck, N., & Durner, D. (2021). Impact of UV-C treatment and thermal pasteurization of grape must on sensory characteristics and volatiles of must and resulting wines. Food Chemistry. https://doi.org/10.1016/j.foodchem.2020.128003

Gómez-Sánchez, D. L., Antonio-Gutiérrez, O., López-Díaz, A. S., Palou, E., López-Malo, A., & Ramírez-Corona, N. (2020). Performance of combined technologies for the inactivation of Saccharomyces cerevisiae and Escherichia coli in pomegranate juice: The effects of a continuous-flow UV-Microwave system. Journal of Food Process Engineering, 43(12), e13565.

Groenewald, W. H., Gouws, P. A., Cilliers, F. P., & Witthuhn, R. C. (2013). The use of ultraviolet radiation as a nonthermal treatment for the inactivation of alicyclobacillus acidoterrestris spores in water, wash water from a fruit processing plant and grape juice concentrate. Journal for New Generation Sciences, 11(2), 19–32.

Gouma, M., Álvarez, I., Condón, S., & Gayán, E. (2020). Pasteurization of carrot juice by combining UV-C and mild heat: Impact on shelf-life and quality compared to conventional thermal treatment. Innovative Food Science & Emerging Technologies, 64, 102362.

Ha, J. H., & Ha, S. D. (2010). Synergistic effects of ethanol and UV radiation to reduce levels of selected foodborne pathogenic bacteria. Journal of Food Protection, 73(3), 556–561.

Hernández-Carranza, P., Peralta-Pérez, A., Avila-Sosa, R., Israel Ruiz-Lopez, I., Cesar Benitez-Rojas, A., & Enrique Ochoa-Velasco, C. (2021). Effect of ultraviolet-C light and mild thermal treatment on the storage life of orange juice. Czech Journal of Food Sciences, 39(2).

Jeon, M. J., & Ha, J. W. (2020). Inactivating foodborne pathogens in apple juice by combined treatment with fumaric acid and ultraviolet-A light, and mechanisms of their synergistic bactericidal action. Food Microbiology, 87, 103387.

Kaya, Z., & Unluturk, S. (2019). Pasteurization of verjuice by UV-C irradiation and mild heat treatment. Journal of Food Process Engineering, 42(5), e13131.

Khan, I., Tango, C. N., Miskeen, S., Lee, B. H., & Oh, D. H. (2017). Hurdle technology: A novel approach for enhanced food quality and safety–A review. Food Control, 73, 1426–1444.

Khandpur, P., & Gogate, P. R. (2015). Effect of novel ultrasound based processing on the nutrition quality of different fruit and vegetable juices. Ultrasonics Sonochemistry, 27, 125–136.

Kim, G. H., Lee, C. L., & Yoon, K. S. (2021). Combined hurdle technologies using UVC waterproof LED for inactivating foodborne pathogens on fresh-cut fruits. Foods, 10(8), 1712.

Koutchma, T., Popović, V., Ros-Polski, V., & Popielarz, A. (2016). Effects of ultraviolet light and high-pressure processing on quality and health-related constituents of fresh juice products. Comprehensive Reviews in Food Science and Food Safety, 15(5), 844–867.

La Cava, E. L. M., & Sgroppo, S. C. (2019). Combined effect of UV-C light and mild heat on microbial quality and antioxidant capacity of grapefruit juice by flow continuous reactor. Food and Bioprocess Technology, 12, 645–653.

Linhares, Md. F. D., Alves Filho, E. G., Silva, L. M. A., Fonteles, T. V., Wurlitzer, N. J., de Brito, E. S., & Rodrigues, S. (2020). Thermal and non-thermal processing effect on açai juice composition. Food Research International, 136, 109506.

Mansor, A., Shamsudin, R., Mohd Adzahan, N., & Hamidon, M. N. (2017). Performance of UV pasteurization with quartz glass sleeve on physicochemical properties and microbial activity of pineapple juice. Journal of Food Process Engineering, 40(1), e12263.

Meléndez-Pizarro, C. O., Calva-Quintana, A., Espinoza-Hicks, J. C., Sánchez-Madrigal, M. Á., & Quintero-Ramos, A. (2020). Continuous flow UV-C irradiation effects on the physicochemical properties of Aloe vera gel and pitaya (Stenocereus spp.) blend. Foods, 9(8), 1068.

Menezes, N. M. C., Tremarin, A., Junior, A. F., & de Aragão, G. M. F. (2019). Effect of soluble solids concentration on Neosartorya fischeri inactivation using UV-C light. International Journal of Food Microbiology, 296, 43–47.

Mesta-Vicuña, G., Quintero-Ramos, A., Meléndez-Pizarro, C., Galicia, T., Sánchez-Madrigal, M., Delgado, E., & Ruiz-Gutiérrez, M. (2022). Physical, Chemical and Microbiological Properties during Storage of Red Prickly Pear Juice Processed by a Continuous Flow UV-C System. Applied Sciences, 12, 3488. https://doi.org/10.3390/app12073488

Müller, A., Stahl, M. R., Greiner, R., & Posten, C. (2014). Performance and dose validation of a coiled tube UV-C reactor for inactivation of microorganisms in absorbing liquids. Journal of Food Engineering, 138, 45–52.

Ochoa-Velasco, C. E., Salcedo-Pedraza, C., Hernández-Carranza, P., & Guerrero-Beltrán, J. A. (2018). Use of microbial models to evaluate the effect of UV-C light and trans-cinnamaldehyde on the native microbial load of grapefruit (Citrus×paradisi) juice. International Journal of Food Microbiology, 282, 35–41.

Pagal, G. A., & Gabriel, A. A. (2020). Individual and combined mild heat and UV-C processes for orange juice against Escherichia coli O157: H7. LWT-Food Science and Technology, 126, 109295.

Pala, Ç. U., & Toklucu, A. K. (2013). Microbial, physicochemical and sensory properties of UV-C processed orange juice and its microbial stability during refrigerated storage. LWT-Food Science and Technology, 50(2), 426–431.

Pendyala, B., Patras, A., Ravi, R., Gopisetty, V. V. S., & Sasges, M. (2020). Evaluation of UV-C irradiation treatments on microbial safety, ascorbic acid, and volatile aromatics content of watermelon beverage. Food and Bioprocess Technology, 13, 101–111.

Pinto, E. P., Perin, E. C., Schott, I. B., Düsman, E., da Silva Rodrigues, R., Lucchetta, L., ... & Rombaldi, C. V. (2022). Phenolic compounds are dependent on cultivation conditions in face of UV-C radiation in ‘Concord’grape juices (Vitis labrusca). LWT-Food Science and Technology, 154, 112681.

Putnik, P., Kresoja, Ž, Bosiljkov, T., Jambrak, A. R., Barba, F. J., Lorenzo, J. M., ... & Kovačević, D. B. (2019). Comparing the effects of thermal and non-thermal technologies on pomegranate juice quality: A review. Food Chemistry, 279, 150–161.

Putnik, P., Pavlić, B., Šojić, B., Zavadlav, S., Žuntar, I., Kao, L., ... & Kovačević, D. B. (2020). Innovative hurdle technologies for the preservation of functional fruit juices. Foods, 9(6), 699.

Ramesh, T., Yaparatne, S., Tripp, C. P., Nayak, B., & Amirbahman, A. (2018). Ultraviolet light-assisted photocatalytic disinfection of Escherichia coli and its effects on the quality attributes of white grape juice. Food and Bioprocess Technology, 11, 2242–2252.

Rifna, E. J., Ramanan, K. R., & Mahendran, R. (2019). Emerging technology applications for improving seed germination. Trends in Food Science & Technology, 86, 95–108.

Riganakos, K. A., Karabagias, I. K., Gertzou, I., & Stahl, M. (2017). Comparison of UV-C and thermal treatments for the preservation of carrot juice. Innovative Food Science & Emerging Technologies, 42, 165–172.

Roobab, U., Aadil, R. M., Madni, G. M., & Bekhit, A. E. D. (2018). The impact of nonthermal technologies on the microbiological quality of juices: A review. Comprehensive Reviews in Food Science and Food Safety, 17(2), 437–457.

Sauceda-Gálvez, J. N., Codina-Torrella, I., Martinez-Garcia, M., Hernández-Herrero, M. M., Gervilla, R., & Roig-Sagués, A. X. (2021). Combined effects of ultra-high pressure homogenization and short-wave ultraviolet radiation on the properties of cloudy apple juice. LWT, 136, 110286.

Sauceda-Gálvez, J. N., Tió-Coma, M., Martinez-Garcia, M., Hernández-Herrero, M. M., Gervilla, R., & Roig-Sagués, A. X. (2020). Effect of single and combined UV-C and ultra-high pressure homogenisation treatments on inactivation of Alicyclobacillus acidoterrestris spores in apple juice. Innovative Food Science & Emerging Technologies, 60, 102299.

Shah, N. N. A. K., Sulaiman, A., Sidek, N. S. M., & Supian, N. A. M. (2019). Quality assessment of ozone-treated citrus fruit juices. International Food Research Journal, 26(5), 1405–1415.

Silva, E. K., Meireles, M. A. A., & Saldaña, M. D. (2020). Supercritical carbon dioxide technology: A promising technique for the non-thermal processing of freshly fruit and vegetable juices. Trends in Food Science & Technology, 97, 381–390.

Souza, V. R., & Koutchma, T. (2021). Repair mechanisms of UV-induced damage of microorganism in foods.

Tiwari, B. K., & O’donnell, C. P., & Cullen, P. J. (2009). Effect of non thermal processing technologies on the anthocyanin content of fruit juices. Trends in Food Science & Technology, 20(3–4), 137–145.

Tremarin, A., Brandão, T. R., & Silva, C. L. (2017). Inactivation kinetics of Alicyclobacillus acidoterrestris in apple juice submitted to ultraviolet radiation. Food Control, 73, 18–23.

Umair, M., Jabeen, S., Ke, Z., Jabbar, S., Javed, F., Abid, M., ... & Conte-Junior, C. A. (2022). Thermal treatment alternatives for enzymes inactivation in fruit juices: Recent breakthroughs and advancements. Ultrasonics Sonochemistry, 86, 105999.

Usaga, J., Churey, J. J., Padilla-Zakour, O. I., & Worobo, R. W. (2014). Determination of the validation frequency for commercial UV juice processing units. Journal of Food Protection, 77(12), 2076–2080.

Usaga, J., Manns, D. C., Moraru, C. I., Worobo, R. W., & Padilla-Zakour, O. I. (2017). Ascorbic acid and selected preservatives influence effectiveness of UV treatment of apple juice. LWT, 75, 9–16.

Visuthiwan, S., & Assatarakul, K. (2021). Kinetic modeling of microbial degradation and antioxidant reduction in lychee juice subjected to UV radiation and shelf life during cold storage. Food Control, 123, 107770.

Yang, Y., Shen, H., Tian, Y., You, Z., & Guo, Y. (2019). Effect of thermal pasteurization and ultraviolet treatment on the quality parameters of not-from-concentrate apple juice from different varieties. CyTA - Journal of Food, 17(1), 189–198. https://doi.org/10.1080/19476337.2019.1569725

Yıkmış, S., Barut Gök, S., Levent, O., & Kombak, E. (2021). Moderate temperature and UV-C light processing of Uruset apple juice: Optimization of bioactive components and evaluation of the impact on volatile profile, HMF and color. Journal of Food Process Engineering, 44(12), e13893.

Yin, F., Zhu, Y., Koutchma, T., & Gong, J. (2015). Inactivation and potential reactivation of pathogenic Escherichia coli O157: H7 in apple juice following ultraviolet light exposure at three monochromatic wavelengths. Food Microbiology, 46, 329–335.

Zhang, Z. H., Wang, L. H., Zeng, X. A., Han, Z., & Brennan, C. S. (2019). Non-thermal technologies and its current and future application in the food industry: a review. International Journal of Food Science & Technology, 54(1), 1–13.

Zhao, D., Barrientos, J. U., Wang, Q., Markland, S. M., Churey, J. J., Padilla-Zakour, O. I., ... & Moraru, C. I. (2015). Efficient reduction of pathogenic and spoilage microorganisms from apple cider by combining microfiltration with UV treatment. Journal of Food Protection, 78(4), 716–722.

Funding

This research is funded by Chulalongkorn University (No. ReinUni_65_03_33_22). This study is supported by the Second Century Fund (C2F), Chulalongkorn University for granting a postdoctoral fellowship to Dr. Saeid Jafari, and Dr. Khursheed Ahmad Shiekh. The Faculty of Science, Chulalongkorn University, was also acknowledged to support this work.

Author information

Authors and Affiliations

Contributions

Saeid Jafari and Khursheed Ahmad Shiekh: investigation and writing—original draft. Anet Režek Jambrak, Randy W. Worobo, Alaa El-Din Ahmed Bekhit, Sajid Maqsood, Isaya Kijpatanasilp, and Mahdi Ebrahimi: review and editing. Kitipong Assatarakul: conceptualization, funding acquisition, writing—original, review and editing, project administration, and supervision.

Corresponding author

Ethics declarations

Ethical Approval

Not applicable.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jafari, S., Shiekh, K.A., Jambrak, A.R. et al. Hurdle Technologies Using Ultraviolet Irradiation as Preservation Strategies in Fruit Juices: Effects on Microbial, Physicochemical, and Sensorial Qualities. Food Bioprocess Technol (2024). https://doi.org/10.1007/s11947-024-03385-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11947-024-03385-1