Abstract

Artificial turf is a widespread surface used for various field sports, offering unique advantages to natural grass such as all-weather availability and durability. This study aimed to determine the influence of infill depth and the exposed fibre height on shoe–surface traction for artificial turf surfaces. Particular focus was placed upon rotational traction, which has been associated with lower extremity injuries in sports. Ten artificial turf surfaces with varying infill depth and exposed fibre length were mechanically tested, with results indicating a significant impact of infill depth on rotational traction (F = 3.150, p = 0.017, \({\eta }^{2}\) = 0.104); as infill depth increased, a reduction in rotational traction was observed. For surfaces with longer carpet fibres, a trend to a significant correlation between exposed carpet fibre length and rotational traction was also observed (R2 = 0.7236, p = 0.068). Exposed fibre lengths above 18–20 mm were associated with an increase in rotational traction. Results suggest that at around 12–18 mm, any further reduction in exposed fibre length may have little to no influence on rotational traction. These findings have implications for player safety, aligning with prior research linking excessive rotational traction to elevated injury risks and highlight the importance of maintaining prescribed infill depths and exposed fibre lengths on artificial turf surfaces.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

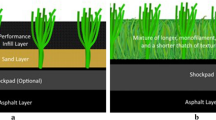

Both artificial turf and natural grass sport surfaces are commonly used for many different field sports such as soccer, American football, and rugby for various ages from children to adults. Artificial turf surfaces offer some key benefits over natural grass, including increased ‘all weather’ availability, as well as durability after high intensity use [1]. Modern artificial turf surfaces are characterised by an underlying shock pad, relatively long carpet fibres (typically 40–65 mm) with low tuft density and are commonly filled with a sand layer for stability below a layer of crumbed rubber or organic particles [1]. Research into artificial turf has investigated many aspects of these surfaces such as the type of infill, fibres, shock pad and how these components can alter the mechanical properties and the player biomechanics on a surface [2,3,4,5].

Increased rotational traction may be associated with lower extremity injury risk in sport, with a study reporting a direct relationship in high-school American football [6]. A possible mechanism for this is that increased rotational traction leads to increased loading of the lower extremity joints [7, 8]. Reducing rotational traction at the shoe–surface interface is, therefore, paramount to minimise athlete injury risk. On the other hand, there is also risk of insufficient traction, which may cause slipping and lead to decreased performance or cause injury.

Previous studies have indicated that the infill material can alter the rotational traction [2, 9,10,11]. By increasing the infill depth, less of the turf’s carpet fibre will be exposed, which may alter the traction. One of the purposes of the fibre is to restrict movement and contain the infill material. By having less exposed fibre, more infill movement may occur which may result in lower rotational traction. Having less exposed fibre will reduce the contribution that the fibre may have on the shoe–surface rotational traction [9]. Previous research has also shown that after days of use on the same turf surface, spatial variability on the field regarding the infill uniformity and infill depth may be produced [11]. This variability in infill depth and exposed fibre length may alter the rotational traction and potentially increase athlete injury risk in different zones of an artificial turf surface.

Studies have investigated methods of reducing the rotational traction of artificial turf surfaces, through various methods such as altering the infill material, carpet fibres, or the inclusion of shock pads [2,3,4,5, 9,10,11]. A method that has not been systematically investigated is the influence that the depth of the infill may have on the rotational traction [12]. Therefore, the purpose of this study was to determine the influence of infill depth and the exposed fibre height on shoe–surface rotational traction.

2 Methods

2.1 Surface construction

Ten different artificial turf surfaces were mechanically tested. These surfaces had systematic differences in their infill depth and their exposed fibre length (Table 1) based upon manufacturer’s guidelines. To alter the exposed fibre length, two identical carpet surfaces, produced by FieldTurf (Tarkett Inc., Montreal, QC, CA), with differences in the total fibre length (50 vs. 64 mm) were used.

Each sample surface was constructed according to the manufacturer’s specifications and installed within a 60 × 90 cm tray (constructed from wood) for mechanical testing. First, the carpet layer was placed within the tray and clamped using wooden rails. The surface was manually brushed to ensure that the fibres were standing upright during installation of the infill material. The infill material, which consisted of a 1:1 volumetric mix of sand and rubber, was evenly distributed over the entire turf surface using multiple thin layered applications. Following each application, the surface was examined, infill depth was measured, and manual brushing of the surface occurred to ensure an even infill distribution and upright fibre orientation. Measurement of the infill depth was conducted using a digital calliper with the calliper probe extending to the bottom of the infill and the base of the callipers resting gently atop the infilled surface. Once the target depth was initially attained, 300 compaction cycles were performed, which consisted of rolling a 27.2 kg mass over the entire surface. Following the compaction cycles, the infill depth was again measured, and additional infill added if necessary to attain the appropriate depth. Once the surface was fully constructed, infill depth was again recorded at nine locations throughout each surface (Fig. 1) to confirm the target depth had been achieved (Table 2).

2.2 Mechanical testing

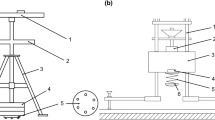

Rotational traction of the surfaces was measured using an automated footwear testing machine (Fig. 2). The machine consisted of a six degree of freedom P2000 servo-driven parallel link robotic testing machine (Mikrolar Inc. Hampton, USA) utilising a movable platform stationed under a rigid steel frame. The turf to be tested was rigidly attached to the movable platform of the robotic testing machine and a 1D35 Dynamic Motion right prosthetic foot (Otto Bock, Duderstadt, GER), which was used to simulate a physiological foot, was fitted with a size 12 shoe (adidas adizero cleat). The shoe and foot were attached to the frame of the robotic testing machine at 20° of plantarflexion to simulate the orientation of the foot to the surface during a plant and cutting manoeuvre [6] in series with a triaxial load cell rated to 22,250 N (AMTI, model MC5, Waterton, USA) to measure the forces and moments in all three orthogonal directions during testing.

Rotational traction testing was performed by raising the platform to apply a normal load to the shoe, after which the platform was internally rotated 15° at a speed of 100°/s. Force and moment data were recorded by the load cell at 500 Hz throughout the duration of each test. Rotational traction between the shoe and each surface was defined as the peak moment about the vertical axis. A total of ten trials were performed at different locations on each surface condition ensuring that each trial was in a unique position on the testing surface and avoided any influence of shifting infill from previous trials. Testing was conducted at two different normal loads, 650 N and 2800 N, to provide a practical representative range for varying player sizes from the normal load of a high-school American football athlete to the normal load of an NFL player [6, 13].

2.3 Statistics

Statistical comparisons of the rotational traction across surfaces were conducted using a two-way univariate ANOVA with the level of significance set at α = 0.05 in SPSS. The dependent variable was the measured rotational traction whilst the independent variables were the carpet length (50 or 64 mm) and infill depth (25, 32, 38, 44, and 50 mm). In addition, interaction effects were investigated between carpet length and infill depth. Lastly, Pearson correlations, with a level of significance set at α = 0.05, investigating the relationship between infill depth and rotational traction were performed.

3 Results

3.1 Main effects

Individually, total fibre length (50 mm carpet vs. 64 mm carpet) had no effect on rotational traction (F = 3.727, p = 0.056, \({\eta }^{2}\) = 0.033, Fig. 3). However, infill depth had a significant effect on rotational traction (F = 3.150, p = 0.017, \({\eta }^{2}\) = 0.104, Fig. 3, centre). The 25 mm depth had significantly greater traction than the 32 mm (p = 0.016), 44 mm (p = 0.013), and 50 mm (p = 0.010) depth, whilst the 50 mm infill depth had significantly lower traction than the 38 mm (p = 0.039) depth. Lastly, a significant effect of normal load was present, with the higher load (2800 N) increasing the rotational traction (F = 2014.933, p < 0.001, \({\eta }^{2}\) = 0.949, Fig. 3, right).

3.2 Interaction effects

A significant interaction between carpet fibre length and infill depth was present (F = 3.118, p = 0.018, \({\eta }^{2}\) = 0.103, Fig. 4). Specifically, on the 64 mm fibre length carpet, the 25 mm infill depth had significantly greater traction than the 44 mm (p < 0.001) and the 50 mm (p = 0.004), the 32 mm had significantly greater traction than the 44 mm (p = 0.026), whilst the 38 mm infill depth had greater traction than the 44 mm (p = 0.004) and the 50 mm (p = 0.024). On the 50 mm carpet, the 32 mm infill depth had significantly lower traction than the 25 mm (p = 0.033), the 38 mm (p = 0.045), and the 44 mm (p = 0.033).

No significant interactions of carpet fibre length and normal load (F = 0.564, p = 0.454, \({\eta }^{2}\) = 0.005) or infill depth and normal load (F = 0.576, p = 0.680, \({\eta }^{2}\) = 0.021) were present.

Lastly, a correlation was performed examining the relationship between the exposed fibre length and rotational traction (Fig. 5). When all data were considered (all infill depths on both the 50 and 64 mm fibre length carpets), there was a trend of nearing significant correlation (R2 = 0.3335, p = 0.080). When the correlations were performed on the individual fibre length carpets, there was a trend nearing significant correlation on the 64 mm length carpet (R2 = 0.7236, p = 0.068), whilst no significant correlations were found on the 50 mm fibre length carpet (R2 = 0.0058, p = 0.903).

4 Discussion

The purpose of this study was to determine the influence of artificial turf infill depth and exposed fibre length on rotational traction. The results of this study can confirm that alterations to the infill depth of artificial turf, which consequentially alters the length of the exposed carpet fibres, significantly alter rotational traction during mechanical testing. These data appear to demonstrate that rotational traction is dependent upon exposed fibre length, with exposed fibre lengths above 18–20 mm being associated with an increase in rotational traction.

Within this study, two different carpet fibre lengths were investigated (50 and 64 mm); however, the results indicated that the underlying length of the carpet fibres had no significant effect on rotational traction. There was, however, a significant influence of infill depth on rotational traction, with an increased infill depth resulting in a reduction in rotational traction. Whilst independently carpet length had no influence on traction, an interaction between carpet length and infill depth was present. This interaction represents the exposed fibre length, which acts to contain the infill and provide shear resistance for the infill movement [14, 15]. Within this study, a significant interaction of infill depth and carpet length was observed, which supports previous works [9, 10] that describe how the pile length and pile weight of an artificial surface can significantly influence the mechanical properties of the player–surface interaction including rotational resistance with longer carpet lengths is shown to increase rotational traction. A trend of significant correlation between exposed carpet fibre length and rotational traction was observed between the longer 64 mm carpet but not with the shorter 50 mm carpet, which would suggest that at a certain length of exposed fibre, around 12–18 mm, any further reduction in exposed fibre length has little to no influence on rotational traction.

Previous literature has suggested that the physical characteristics and mechanical properties of the infill component materials can be influenced by compaction and resulting compression of the surface. Applying greater compaction force or compressive load has been shown to increase the rubber infill material’s bulk density [16]. It has also been observed that the shear strength of the rubber infill material exhibited a direct correlation with bulk density, showing an increase with higher bulk density [9, 16]. Thus, it may be important to consider possible differences in results for players under a wide range of sizes or movements that have different loading characteristics. Variances in load can influence the infill components by applying greater compression and shear strains [16, 17]. However, in this study, no significant interactions were observed between carpet fibre length and normal load or infill depth and normal load. This absence of significant interactions with normal load proposes that traction optimization through fibre length and infill depth can be implemented without being contingent on variations in load on the artificial turf surface.

As it was demonstrated in this study, the depth of infill and length of exposed carpet fibre can modify rotational traction on an artificial turf surface. Research has indicated that excessive rotational traction has been linked to an increased risk of lower extremity injury [4, 6, 7]. Jastifer et al. [18] mention the increased likelihood of athlete injury due to reductions in infill depth resulting in increased surface hardness and traction. In addition, although not directly discussing rotational traction, Dickson et al. [19] recently underlined the relationship between infill depth and surface hardness. A decrease in infill depth has been correlated with an increase in surface hardness, where greater surface hardness has been linked to an increased risk of athlete injury, including the occurrence of concussions [18,19,20]. These data further highlight the importance of field managers in maintaining a prescribed infill depth and exposed fibre length on artificial surfaces, as deviations from specific depths may be associated with increased rotational traction or surface hardness and potentially increased athlete injury risk.

During this investigation, the surfaces were specifically prepared and a constant infill mix (1:1 sand and rubber) was evenly distributed across the testing surface. However, this consistent distribution may not be commonly observed on an artificial turf playing surface that receives daily usage [5, 19, 20]. Over the course of a game or days of use on the same surface, zones of concentrated foot traffic can create spatial variability on the field regarding the infill uniformity and infill depth [19]. Therefore, differences in the zone of the tested surface may apply. Previous findings have also suggested that different infill materials or weights can significantly influence rotational traction or increase the rate of athlete injury [4, 11, 20, 21]. In addition, this study only considered one type of carpet fibre at different lengths and a one cleat design. Several investigations suggest that alterations in the type of carpet fibre or carpet fibre structure (monofilament/fibrillated) that is used may also provide a varying impact on the rotational traction or peak torques achieved on the surface [2, 9, 16]. Also, this study did not subject the turf surfaces to age, modified temperature, and moisture which have been shown previously to have influence on surface traction [10, 15, 19, 21]. Lastly, the mechanical testing procedure attempts to simulate the turning motion of a player; however, real-world movements may differ in a game scenario.

5 Conclusion

The findings in this study have provided insights into how the infill depth and exposed fibre length of artificial turf influence shoe–surface interaction. The results indicate that modifications in infill depth significantly affect rotational traction. Specifically, greater infill depths were associated with reduced rotational traction. The study underlined the relationship between carpet fibre length and infill depth, which collectively determines exposed fibre length. Carpet with longer fibres demonstrated a significant correlation with increased rotational traction. This suggests that exposed fibre lengths in the range of 12–18 mm may be critical in influencing rotational traction. This study also found that optimising traction through fibre length and infill depth can be done independently of variations in load. These findings can also extend to player safety, as excessive rotational traction has been linked to a greater risk of lower extremity injuries. Previous research associating lower infill weight and depth surfaces with higher injury rates can be backed by the results of this study, highlighting the importance of maintaining prescribed infill depths and exposed fibre lengths on artificial surfaces. It is essential to acknowledge that real-world artificial turf surfaces regularly experience variations in infill distribution due to extended daily usages, potentially affecting traction in different zones. Different infill materials and carpet fibre types can also influence rotational traction, emphasising the need for further exploration in these areas. In summary, this study has provided insight on the relationship between infill depth, exposed fibre length, and rotational traction on artificial turf surfaces. The findings provide valuable information for field managers, players, and researchers, emphasising the importance of carefully managing these factors to optimise both performance and player safety. Further research into different infill materials and carpet fibre types along with varying infill depths may provide additional understanding into improving player–surface interactions.

References

Fleming P (2011) Artificial turf systems for sport surfaces: current knowledge and research needs. Proc Institut Mechan Eng Part P J Sports Eng Technol 225(2):43–64. https://doi.org/10.1177/1754337111401688

Burillo P et al (2012) Mechanical assessment of artificial turf football pitches: the consequences of no quality certification. Scient Res Essays. https://doi.org/10.5897/sre11.1454

Zanetti EM, Bignardi C, Franceschini G, Audenino AL (2013) Amateur football pitches: Mechanical properties of the natural ground and of different artificial turf infills and their biomechanical implications. J Sports Sci 31(7):767–778. https://doi.org/10.1080/02640414.2012.750005

Wannop JW, Foreman T, Madden R, Stefanyshyn D (2019) Influence of the composition of artificial turf on rotational traction and athlete biomechanics. J Sports Sci 37(16):1849–1856. https://doi.org/10.1080/02640414.2019.1598923

Wannop J, Kowalchuk S, Esposito M, Stefanyshyn D (2020) Influence of artificial turf surface stiffness on athlete performance. Life 10(12):340. https://doi.org/10.3390/life10120340

Wannop JW, Luo G, Stefanyshyn DJ (2013) Footwear traction and lower extremity noncontact injury. Med Sci Sports Exerc 45(11):2137–2143. https://doi.org/10.1249/MSS.0b013e318299ac56

McGhie D, Ettema G (2013) Biomechanical analysis of traction at the shoe-surface interface on third-generation artificial turf. Sports Eng 16(2):71–80. https://doi.org/10.1007/s12283-013-0115-1

Wannop JW, Stefanyshyn DJ (2016) The effect of translational and rotational traction on lower extremity joint loading. J Sports Sci 34(7):613–620. https://doi.org/10.1080/02640414.2015.1066023

Severn KA, Fleming PR, Clarke JD, Carre MJ (2011) Science of synthetic turf surfaces: Investigating traction behaviour. Proc Instit Mech Eng Part P J Sports Eng Technol 225(3):147–158. https://doi.org/10.1177/1754337111408980

Sánchez-Sánchez J, García-Unanue J, Gallardo AM, Gallardo L, Hexaire P, Felipe JL (2018) Effect of structural components, mechanical wear and environmental conditions on the player–surface interaction on artificial turf football pitches. Mater Des 140:172–178. https://doi.org/10.1016/j.matdes.2017.11.066

Dickson K, Sorochan J, Strunk W (2020) Impact of alternative synthetic turf infills on athlete performance and safety. 13th Conference of the International Sports Engineering Association. https://doi.org/10.3390/proceedings2020049035

Jastifer J et al (2022) The development of mandatory practices for the testing and maintenance of synthetic turf fields in the National Football League. Int Turfgrass Soc Res J 14(1):352–363. https://doi.org/10.1002/its2.94

Kent R et al (2015) The mechanical interactions between an American football cleat and playing surfaces in-situ at loads and rates generated by elite athletes: a comparison of playing surfaces. Sports Biomech 14(1):1–17. https://doi.org/10.1080/14763141.2015.1024277

Tay SP, Fleming P, Hu X, Forrester S (2017) Skin friction related behaviour of artificial turf systems. J Sports Sci 35(15):1500–1507. https://doi.org/10.1080/02640414.2016.1223330

Forrester S, Fleming P (2019) Traction forces generated during studded boot-surface interactions on third-generation artificial turf: a novel mechanistic perspective. Engineering Reports, In Proceedings of the 13th Conference of the International Sports Engineering Association. 49(35). https://doi.org/10.1002/eng2.12066

Severn KA (2010) Science of synthetic turf surfaces: player-surface interactions. Loughborough University. Thesis. https://hdl.handle.net/2134/7216

Sujae IH, Abdul Jabbar K, Ong CY, Hamill J (2022) Differences in joint loading during a side-step cutting manoeuvre on different artificial turf infill depths. Sports Biomech 21(9):981–992. https://doi.org/10.1080/14763141.2020.1713206

Jastifer JR, McNitt AS, Mack CD, Kent RW, McCullough KA, Coughlin MJ, Anderson RB (2019) Synthetic turf: History, design, maintenance, and athlete safety. Sports Health 11(1):84–90. https://doi.org/10.1177/1941738118793378

Dickson KH, Straw CM, Thoms AW, Carson TD, Sorochan JC (2022) Impact of third generation synthetic turf athletic field age on surface hardness and infill depth spatial variability. Proc Instit Mech Eng Part P J Sports Eng Technol 236(3):192–199. https://doi.org/10.1177/17543371211002947

Meyers MC (2019) Incidence, mechanisms, and severity of game-related high school football injuries across artificial turf systems of various infill weights. Orthopaedic J Sports Med. https://doi.org/10.1177/2325967119832878

McGowan H et al (2023) Understanding the variability in rotational traction testing on artificial turf. Sports Eng. https://doi.org/10.1007/s12283-023-00426-4

Funding

This research was funded by the Natural Science and Engineering Research Council of Canada (NSERC) and by FieldTurf—grant number CRDPJ 533859–18.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest. Although this project was partially funded by FieldTurf, FieldTurf was not involved in data collection or in the interpretation of the results.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ruschkowski, J., Varughese, J.M., Stefanyshyn, D.J. et al. Influence of infill depth and fibre height of artificial turf on rotational traction. Sports Eng 27, 13 (2024). https://doi.org/10.1007/s12283-024-00455-7

Accepted:

Published:

DOI: https://doi.org/10.1007/s12283-024-00455-7