Abstract

Purpose

The prevalence of type 2 diabetes mellitus is one of the global concerns and almost 80% of diabetic patients are treated with oral antidiabetic drugs. GLMP as a prescribed oral antidiabetic drug for diabetic patients enhanced its necessity. Therefore, it is essential to quantify it in several drug formulations and biological samples. Hence, a simple, eco-friendly, validated kinetic spectrophotometric method was developed for quantifying GLMP in commercial dosage forms.

Methods

The method was based on the oxidation of the GLMP with potassium permanganate. The reaction was followed spectrophotometrically, measuring an increase in absorbance with time at 605 nm. RSM optimized the influence of preliminary experimental variables for the proposed procedure via BBD, a frequently used DoE. Under the optimized conditions, initial rate, fixed-time (at 6.0 min), and equilibrium method (25.0 min) were adopted for constructing the calibration graphs to determine the amount of GLMP. The robustness of the proposed method was performed, and the effect of selected analytical parameters was investigated with alternative conditions employing Youden and Steiner’s test.

Results

The outcomes of the model were significant. Hence, the performance of the analytical method was validated statistically and through recovery studies using ICH guidelines. Calibration curves were linear in the concentration ranges of 4.0–36.0 µg/ml with a detection limit of 1.60, 1.02, and 1.13 µg/ml for the initial rate, fixed-time, and equilibrium method, respectively. The proposed method’s greenness profile was assessed using the analytical Eco-Scale and found greener in terms of using harmful reagents, energy consumption, and waste production. Statistical comparison of the results is shown in good agreement with the results found by the reference method, indicating no significant difference in accuracy and precision.

Conclusion

The proposed validated kinetic method is simple, accurate, low cost, safe, and eco-friendly and might be used in research laboratories, hospitals, and pharmaceutical industries for the routine quality control analysis of GLMP in commercial dosage forms.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The prevalence of type 2 diabetes mellitus is one of the global concerns predicting more than 400 million cases by 2030 [1]. Almost 80% of diabetic patients are treated with oral antidiabetic drugs. Hence, it is crucial to establish proper guidelines for their use and dosage selection [2]. GLMP is a third-generation sulfonylurea derivative and an oral antidiabetic medication used to treat type II diabetes mellitus. It lowers blood glucose levels by stimulating insulin secretion from the pancreatic β-cells, raising peripheral insulin sensitivity, and thereby reducing insulin resistance [3, 4]. It is chemically known as 1-{(p-[2-(3-ethyl-4-methyl-2-oxo-3-pyrroline-1-carboxamide) ethyl] phenyl) sulfonyl}-3-(trans-4-methyl cyclohexyl) urea. This drug is officially listed in United States Pharmacopeia, and the monograph specifies an HPLC method for the assay of GLMP tablets in the monograph [5, 6]. It is a yellowish-white crystalline powder formulated into tablets of 1, 2, and 4 mg for oral administration. It was observed to be effective at lower dosages [7]. It is highly soluble in dimethyl sulfoxide, slightly soluble in buffers and organic solvents, and almost insoluble in aqueous and acidic media [8]. Hence, solubility enhancement of such insoluble drug molecules is one of the most challenging tasks in current research. Many physical and chemical modifications of the drug substance and other methods, like the addition of surfactant and solid dispersion, have been explored to enhance drug solubility [9, 10]. Literature reported that GLMP shows pH-dependent solubility at low values [11]. However, the dissolution rate of GLMP can be enhanced with water-soluble and pharmacologically inactive polymeric carriers such as povidone K-30 with different solid dispersion methods [12, 13].

For quality control to protect human life, it is essential to apply a suitable, rapid, and cost-effective analytical method for accurately determining APIs in pure and commercial dosage forms. Various analytical techniques were utilized significantly in assessing the quality of bulk drugs, intermediates, their degradation products, and impurities [14,15,16,17]. Attempts have been made for the determination of GLMP using expensive, time-consuming, organic solvent-based chromatographic methods such as LC [18], HPLC [19], reversed-phase HPLC [20], micellar electrokinetic chromatography [21], and LC-electrospray ionization tandem mass spectrometry [22, 23]. Few electrochemical methods were also used to determine GLMP [24, 25].

Analytical spectroscopic methods often include advantages such as sensitivity, safety, accessibility, miniaturization, economical, fast, and automated sample turnover [26, 27]. Technological advancements and modifications improve measurements; hence, it has been broadly used for chemical qualification and quantification [28,29,30]. Recent trends in spectroscopy show its inline/online applications [31, 32]. No single technique is perfect, and UV–Vis spectrophotometry is no exception. However, UV–Vis spectroscopy has a few advantages; for instance, non-destructive, quick, easy to use, inexpensive, fast response and minimal processing make it still a popular technique and used almost in all analytical laboratories. Therefore, it is considered one of the most suitable alternative analytical methods in pharmaceutical research and drug development [33]. Direct UV–Vis spectrophotometry has been used to assay GLMP developing ion-pair complexation and charge-transfer complexation reactions with dyes [34,35,36,37,38,39,40,41].

The literature survey lacks simple and robust kinetic-based analytical approaches to determine GLMP in commercial tablet formulations. The term “kinetic method” is confined to the methods based on direct or indirect measurement of the rate of a chemical reaction. It is often called the reaction-rate method [42]. Most spectrophotometric methods deal with chemical reactions in which the rate (the kinetic) of reaction or a related quantity is determined under dynamic conditions on systems approaching equilibrium. At equilibrium, the reaction has not stopped, and the forward and backward reaction rates go on at equal rates with no net change in the amounts of reactants or products. A measurement mode of the kinetic method in which the determination of initial reaction rate was made and utilized for the measurement of concentrations is known as the initial rate method. The analyte concentration is chosen over a predetermined time interval in the fixed-time method. While in the case of the equilibrium method, the analytical signal is determined by an equilibrium reaction involving the analyte by a steady state process that maintains the analyte’s concentration. In general, kinetic methods play a significant part in the analyses of environmental, clinical, pharmaceuticals, and food samples for the catalytic (enzymatic or nonenzymatic) and noncatalytic methods [43]. These methods offer advantages over direct methods, including sensitivity, improved selectivity, reduced analysis time, and simplicity. It also eliminates some pre-experimental steps, such as extraction before analysis. It decreases interference from other active ingredients in the commercial dosage formulations that may resist the chemical reaction conditions. Hence, it is one of the significant interests in analytical pharmacy for routine determinations of drug substances [44].

This article describes a kinetic-based spectrophotometric method performed at room temperature. The drug molecule undergoes an oxidation reaction with potassium permanganate producing a green-colored product. A subsequent increase in the absorbance of the green-colored product was recorded at 605 nm as a function of time following the initial rate, fixed-time and equilibrium method for GLMP assay in tablet formulations. Due to the importance of KMnO4 as a universal, eco-friendly, low-cost reagent, and strong oxidant [45], it has been extensively used for quantifying several APIs and commercial dosage forms by kinetic spectrophotometry [46,47,48,49,50,51,52,53].

Method optimization of a spectrophotometric procedure using the conventional method requires a longer time considering one variable at a time to achieve the target and excludes the interaction of the independent variables. DoE emerged as a powerful and well-designed setting that yields more information from the least data. DoE findings provide a procedure for planning experiments with the “best” possible composition and valid conclusion. The influence of the experimental variables in the present study was optimized by RSM via BBD and validated. Its prominent statistical approach employing the multivariate approach enables significant improvement in the method development using fewer trials [54,55,56]. The use of desirability functions approach offers an additional value in the selection of optimum experimental conditions [57, 58]. BBD was established as an independent quadratic polynomial regression model without any factorial or fractional factorial design. Prerequisite tools for DoE include statistical analysis by ANOVA, diagnostic analysis, and RSM analysis [59].

The analytical Eco-Scale is a novel comprehensive approach, an alternative to traditional green chemistry metrics and a semi-quantitative tool. It has been used to evaluate the greenness profile of the proposed analytical method based on penalty points. It includes using harmful reagents, energy consumption, and waste production, resulting in a greener approach in the current method [60]. Youden and Steiner’s robustness test was executed using factorial combinations of the selected analytical parameters and examined the influences with the alternative conditions [61]. A linear dynamic range of 4–36 µg/ml was obtained with a detection limit of 1.60, 1.02, and 1.13 µg/ml for the initial rate, fixed-time, and equilibrium method, respectively. Hence, the proposed spectrophotometric method’s novelty and practical applicability are as follows: (a) simple kinetic and economical method; (b) DoE optimized with RSM to determine GLMP in pharmaceuticals; (c) robust; (d) an eco-friendly and validated method that could be utilized in research laboratories, hospitals, and pharmaceutical industries for the routine quality control analysis of GLMP in commercial dosage forms.

Experimental

Materials

All spectrophotometric investigations were carried out with Jenway (UV–Vis 6300, UK) and Cecil (CE 7400, UK) spectrophotometers, using a 10 mm matched glass cuvette. Doubly distilled water was used throughout the experiment. The absorbance data and statistical evaluations were computed using MS-Excel 2013 (v.15.0, Microsoft Corporation, USA), SigmaPlot (Systat Software Inc., UK), and OriginLab software (USA). Design-Expert 8.0.6.1 software, Stat-Ease Inc., USA) was used for RSM-BBD. FTIR was performed with Thermo NICOLET 6700 FT-IR Spectrophotometer (Thermo Electron Corporation, USA).

Potassium permanganate (PC 223468), glacial acetic acid (PC A6283), toluene (PC 179418), methanol (PC 34860), ethyl acetate (PC 319902), and dimethylformamide (PC 319937) were purchased from Sigma Aldrich, USA, while sodium hydroxide (PC S5881 and 20252) was purchased from Sigma Aldrich, USA, and Sd-Fine Chem. Ltd. India, respectively through a local vendor. All chemicals and reagents used were of analytical grade. The GLMP tablet formulations, such as Amaryl (Sanofi-Aventis, Germany) and Glim (SPIMACO, Saudi Arabia), were purchased from the local pharmacy. Silica gel (Sisco Research Laboratories Pvt. Ltd, India) packed glass columns to extract drug content for column chromatography.

Methodology

Extraction and Dissolution of GLMP

Fifty tablets of 4 mg strength were powdered using mortar and pestle, transferred into a 200 ml volumetric flask, and a mixture of dimethylformamide: distilled water (1:4) (v/v) was added to dissolve. The column chromatographic method was performed using silica gel as a stationary phase. A mixture of polar solvents was used as the mobile phase, including methanol:water:glacial acetic acid (5:3:1) (v/v/v). Finally, it separated the drug compounds, dried them in an oven and was collected as solid GLMP. Two different concentrations (4 × 10−2 M and 5 × 10−2 M) of NaOH aqueous solutions were tested. NaOH (5 × 10−2 M) is an adequate concentration for dissolving GLMP commercial tablets.

TLC and FTIR Studies

Solid GLMP was also analyzed using silica gel G coated TLC plates with a solvent system of toluene: methanol: ethyl acetate (15:4:1, v/v/v). The IR spectrum of the extracted solid GLMP was recorded from 400 to 4000 cm−1 at a resolution of 4 cm−1 and an average of 32 scans using a Thermo NICOLET 6700 FT-IR Spectrophotometer compared with the standard IR spectrum. A fresh background spectrum was carried out with the same instrumental setting before each analysis.

Standard Solution Preparation

The KMnO4 (4 × 10−3 M) aqueous solution was freshly prepared in doubly distilled water and standardized with the titrimetric procedure. An aqueous solution of NaOH (5 × 10−2 M) was freshly prepared in doubly distilled water and used to prepare the GLMP sample solutions. A standard solution of GLMP was prepared by dissolving an accurately weighed amount of the extracted and dried drug (50 mg) in an aqueous solution of NaOH (5 × 10−2 M) into a 100 ml volumetric flask. It was further diluted to obtain a 0.4 mg/ml working standard solution. The standard stock solution prepared 20 calibration samples within the linearity range. Five synthetic mixture samples were also considered as validation samples. Each solution mixture was applied to perform the experiments to record the absorbance and optimized using RSM via BBD.

Preparation of GLMP from the Commercial Tablet Formulations

Two commercial brand tablets were obtained, claiming 2 mg of active GLMP content. Twenty tablets of one brand were crushed and powdered using a mortar and pestle; 40 mg of the drug was transferred to a 100 ml volumetric flask. Fifty milliliters of NaOH (5 × 10−2 M) solution was added and sonicated for 20 min to mix the contents. Finally, it was filtered through Whatman no. 42 filter paper (Whatman International Limited, Kent, UK) and made up to mark with NaOH (5 × 10−2 M) solution. Each brand of tablet solution was prepared similarly and used for the quantification.

DoE

The DoE setting based on RSM with BBD used to evaluate multivariable systems, which analyzes interaction between two-variable and optimizes their response. In the present study, based on the preliminary investigation, three significant independent variables (factors) were selected as GLMP concentration (A, µg/ml), potassium permanganate volume (B, ml), and reaction time (C, min) varied at three levels (low, medium, and high) (Table 1). Based on the BBD, 17 trails were chosen to evaluate the effects of independent variables on the response. For RSM, regression coefficients were established by fitting the predicted response value into the second-order polynomial equation and predicting the relationship between factors and the response. The equation is expressed as follows:

where Y is the response (predicted absorbance), Xi and Xj represent the experimental variables, and β0, βi, βij, and βii are the model coefficients for intercept, linear, interaction, and quadratic terms, respectively. ε is the random error.

Model validity was checked by ANOVA, which involves the assessment of statistical parameters such as model F-value, lack of fit value, correlation coefficient (R2), adjusted R-squared (R2Adj), predicted R-squared (R2Pred), PRESS, and AP. A descriptive diagram was prepared, as shown in Fig. 1.

Proposed Kinetic Procedures for the Assay of GLMP

Aliquots of 0.1–0.9 ml standard solution of GLMP (0.4 mg/ml) were pipetted into a series of 10 ml volumetric flasks. In each flask, 2.2 ml of KMnO4 (4 × 10−3 M) was added and diluted to volume with distilled water at room temperature. The contents of each flask were mixed well, and an immediate increase in absorbance at 605 nm was recorded as a function of time against the reagent blank prepared similarly without the active drug. Three different methods (Method 1, 2 and 3) were adopted to construct calibration curves.

Method 1 (Initial Rate Method)

The initial rates of the reaction (ν) were determined at different concentrations from the slope of the initial tangent of the absorbance-time curve. The calibration curve was constructed by plotting the logarithm of the initial reaction rate (log ν) vs the logarithm of the molar concentration of the GLMP (log C). The amount of the GLMP was obtained either from the calibration graph or the regression equation.

Method 2 (Fixed-Time Method)

This method measured the absorbance at 605 nm of each sample solution at a preselected fixed time against a reagent blank prepared similarly without a drug. The calibration curve was constructed by plotting the absorbance against the drug’s final concentration. A fixed time of 3, 6, 9, and 12 min was established. The amount of GLMP in each sample was computed from the calibration curve or regression equation.

Method 3 (Equilibrium-Time Method)

After 25 min, the equilibrium reaction condition was achieved. At this time, the absorbance of each sample solution was measured at 605 nm against a reagent blank prepared similarly except drug. The calibration graph was constructed by plotting the absorbance against the initial concentration of GLMP. The drug concentrations were calculated from the calibration graph or the corresponding regression equation.

Procedure for Reference Method [36]

Different aliquots of GLMP (1 × 10−3 M) were transferred into a series of 10 ml volumetric flasks. The volume (0.2–2.0 ml) of cresol-red dye solution was added to each flask and diluted with chloroform. The absorbance of the yellow-colored ion-pair complex was measured at 450 nm against the reagent blank for each solution. Linearity was obtained in the range of 10–60 μg/ml. The calibration graph was constructed by plotting absorbance versus GLMP concentration.

Youden and Steiner’s Test for Robustness Evaluation

The seven analytical parameters and eight runs were selected under standard and alternative conditions, as represented in Table 2. The nominal values of the variables were indicated by the uppercase letters A, B, C, D, E, F, and G, with their alternative values indicated by the corresponding lowercase letters a, b, c, d, e, f, and g. All seven parameters and their respective variable combined in eight runs were performed randomly using constant concentrations of GLMP (32 μg/ml) and 2.2 ml of KMnO4 (4 × 10−3 M) in the entire experiment. The analysis results are shown by letters from s to z of all seven parameters: concentration of sodium hydroxide, manufacturer of sodium hydroxide, wavelength maxima, sonication time, spectrophotometer model, filter model, and wavelength interval. From these results, the effect of each variable is estimated by obtaining the difference in the averages of the four analyses with the nominal value (uppercase letter) and the four analyses with the alternative value (lowercase letter). Considering the standard deviation of the eight runs, effect values higher than criterion s√2 (s = standard deviation) were considered significant.

Results

TLC and Spectral Studies

Air-dried TLC plates detect a single spot with an Rf value of about 0.48 ± 0.01 corresponding to GLMP, confirming the presence of the active drug component in the extracted GLMP [62].

FTIR analysis of the dried GLMP sample was performed by the KBr pellet method. The spectrum was scanned from 400 to 4000 cm−1. The FTIR spectrum of dried GLMP showed a distinct NH stretching at 3100 cm−1, aromatic ring (C-H) at 2198 cm−1, 1633 cm−1, and 1458 cm−1 due to the presence of carbonyl stretching, C–N stretching at 1365 cm−1, S = O stretching vibration at 1146 cm−1, as presented in Fig. 2. The FTIR studies revealed that GLMP is compatible with the excipients used in the formulation as it shows characteristic peaks within the range [63].

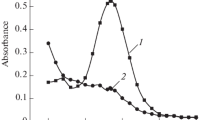

An aqueous solution of potassium permanganate exhibits an absorption peak at 527 nm. GLMP solution shows the highest absorption at 227 nm against a reagent blank. In the present study, GLMP solutions were added to the KMnO4, a bathochromic shift peaking at 605 nm (Fig. 3). Since the absorbance increases with time, this study investigated a kinetic spectrophotometric determination of GLMP.

Absorption spectra of a GLMP solution (0.4 mg/ml) in 5 × 10−2 M NaOH solution, b 2.2 ml of KMnO4 (4 × 10−3 M) solution, and c 0.8 ml GLMP (0.4 mg/ml) + 2.2 ml of 4 × 10−3 M KMnO4 diluted to 10 ml with 5 × 10−2 M NaOH versus blank (2.2 ml of 4 × 10−3 M KMnO4 diluted with 5 × 10.−2 M NaOH solution in 10 ml)

Optimization of KMnO4 Volume

The influence of KMnO4 concentration (4 × 10−3 M) on the absorbance of the product was studied in the range of 0.1–2.4 ml, keeping the constant amount of the drug (32 μg/ml). The maximum absorbance of the product was achieved with a 2.0 ml KMnO4 solution. Therefore, 2.2 ml of KMnO4 was used as the optimum value with respective standard deviations (for five measurements at each volume) shown as error bars in Fig. 4.

Stoichiometric Ratio and Proposed Reaction Mechanism

By performing two different sets of experiments, the limiting logarithmic method ascertained the stoichiometric ratio between potassium permanganate and GLMP [64]. GLMP concentration was varied in the first set, keeping a fixed molar concentration of KMnO4 and vice versa in the other set of experiments. The logarithm of the absorbance thus obtained was plotted against the logarithm of the molar concentration of KMnO4 or GLMP. The slopes of the two straight lines were perceived in each case and found to be 0.995: 0.979, indicating the combining molar reaction ratio between GLMP and KMnO4 as 1:1 (Fig. 5). Literature reports that GLMP produces cyclohexyl hydroxy methyl derivative after the oxidative biotransformation, which is further metabolized into the carboxyl derivative of GLMP [65]. In this reaction, it has been expected that in the presence of a strong oxidizing agent, KMnO4, the oxidative attack occurs at the methyl group of the cyclohexyl ring of the GLMP molecule converted into a carboxylic acid group producing carboxy GLMP [66]. In contrast, purple-colored permanganate ion gets reduced to bluish-green manganate ion. Based on the stoichiometric ratio and literature background [67], the reaction mechanism was proposed in Fig. 6.

Analytical Data

Method 1

The initial reaction rates were calculated from the slope of the initial tangent to the absorbance-time curve (Fig. 7). Under the optimized experimental conditions, the assay of GLMP was performed in the presence of the excess amount of KMnO4. Consequently, a pseudo-first-order reaction condition was obtained concerning the large excess concentration of KMnO4. Therefore, the initial rate of reaction would depend on the concentration of the GLMP, and the rate equation can be written as follows [68]:

K′= is the pseudo-first-order rate constant, C is the concentration of the GLMP (mol/l), and n is the order of the reaction.

The logarithmic form of Eq. (1) can be log (rate of reaction) = log (ν) = log K′ + n log C.

The order of the reaction was calculated by either plotting the logarithm of the initial rate of reaction (log ν) versus the logarithm of the initial concentration of the drug or the regression analysis of the data, which yielded the equation, log (rate of reaction) = log (ν) = 2.783 + 0.995 log C with a correlation coefficient (r2) = 0.9992. The reaction’s order was found to be 0.995. The calibration curve was prepared by plotting the initial rate of the reaction against the concentration of GLMP (μg/ml). The results of regression analysis of calibration data are reported in Table 3. It can be seen from Table 3 that the calibration graphs (initial rate vs concentration) were found to be linear over the concentration range of 4–36 μg/ml. The correlation coefficient (r2 = 0.9992) with very low confidence limit values for the slope and intercept of the regression line indicates the high reproducibility of the initial rate method.

Method 2

The absorbance of the solution containing varying amounts of GLMP was measured at 605 nm with a preselected fixed time. The calibration graphs were constructed by plotting the absorbance against the initial concentration of GLMP at a preselected fixed-time of 3, 6, 9 and 12 min. The results of the statistical analysis are summarized in Table 4. The most acceptable linearity, LOD, and the LOQ were obtained with a fixed time of 6 min. Therefore, a fixed-time of 6 min was used as the optimum time and selected to quantify GLMP.

Method 3

In this equilibrium time method, the absorbance of the green-colored solution was measured after attaining the equilibrium time for different concentrations of GLMP. However, this method requires a little longer time of analysis in comparison to the fixed-time method. The linear regression equation and other statistical parameters of this method are summarized in Table 5.

RSM Using BBD for Optimization

Based on BB factorial design, a design matrix comprised of 17 trials was prepared. The variables combination for all proposed experiments is presented in Table 6. It investigated absorbance as a dependent variable (response) using Design-Expert software (Version 8.0.6.1, Free Trial, Stat-Ease Inc., USA) against independent variables.

A second-order polynomial regression equation was generated to determine the relationship between the variables and the response as absorbance, and the results are shown below.

Absorbance = 0.578 + 0.1679 A + 0.1466 B + 0.0021 C + 0.1101 AB – 0.0470 AC + 0.0512 BC – 0.1705 A2 – 0.0974 B2 – 0.1525 C.2

The highest predicted response (absorbance) was obtained with optimized conditions, including a 32.9 µg/ml GLMP, 2.37 ml of KMnO4 and 8.048 min reaction time with the maximum desirability function 1.

The ANOVA was accomplished with p-values < 0.05 (Table 7). It includes linear coefficients (A, B, C), interactive coefficients (AB, AC, BC), and quadratic coefficients (A2, B2, C2) that were significant (Table 8).

Method Validation

The developed methods are required to validate the FDA regulations followed by the ICH guidelines [69]. Validation is not only necessary for regulatory purposes, but it has a tremendous demand for long-term analysis. The standard parameters to validate a method include linearity, LOD, LOQ, accuracy, precision, stability, selectivity, recovery, ruggedness and robustness. Hence, after optimising reagent concentration, the proposed method has been validated for linear dynamic range, stability, selectivity, reproducibility, accuracy and precision, detection and quantitation limits, robustness, and recovery.

Linearity Range, LOD, and LOQ

For linearity evaluation, the data was analyzed five times at eight concentration levels: 4.0, 8.0, 12.0, 16.0, 20.0, 24.0, 32.0, and 36.0 μg/ml for the three methods to obtain a correlation coefficient greater than 0.9990. LOD and LOQ values were 1.61 and 4.88 μg/ml for method 1, 1.02 and 3.10 μg/ml for method 2, and 1.13 and 3.41 μg/ml for method 3, respectively, presented in Tables 3, 4, and 5.

Solution Stability

The stability of the GLMP in a 5 × 10−2 M NaOH aqueous solution was studied by recording the UV absorption spectra of the drug. The drug solution having λmax at 227 nm, showed no change in the absorption spectra of the sample solutions of the drug for at least four days when the solutions were stored in a dark place at room temperature.

Accuracy and Precision

The accuracy and precision of the proposed kinetic spectrophotometric method were determined in terms of intermediate precision at three concentration levels (10.0, 20.0, and 30.0 μg/ml). Five sample solutions of each concentration were prepared and tested five times in one day (intraday precision) and five consecutive days (interday precision). The standard deviations (SD), percentage relative SD, standard analytical error (SAE), and confidence limit (CL) were calculated by standard methods (Table 9). Percentage relative standard deviation (%RSD) as precision and percentage recovery as the accuracy of the suggested methods of GLMP ascertained from the calibration curves showed that the present kinetic analytical approaches have good repeatability and reproducibility.

Selectivity

This was investigated by analyzing the extracted drug and co-formulated substances present in tablets, including lactose, sodium starch glycolate, magnesium stearate, cellulose and polyvinylpyrrolidone, by performing placebo blank and synthetic mixture analyses. The results were reproducible with a % recovery between 99.484 and 100.109% (Table 9), suggesting the non-interference of tablet additives and excipients in the analysis.

Robustness

The effect of all seven analytical variables, the eight runs standard deviation, and criterion s√2 were calculated and used to evaluate the results. Using the requirements of Youden’s test, effect values higher than s√2 were considered significant and needed to be controlled by the changes in the concerned variable. The results indicate that a variation of 2 nm in wavelength maxima is the only variable with a more significant influence and needs to be controlled to quantify GLMP in both brand pharmaceutical formulations. It may arise due to substantial interference from the tablet excipients in the region of GLMP absorption maxima, which precludes the analytical use of zero-order spectrophotometry and deteriorates the spectral intensity signal. It concludes that the method is fairly robust concerning the parameters of sodium hydroxide concentration, sodium hydroxide supplier, sonication time, spectrophotometer model, filter model, and wavelength interval. The analytical results obtained in the robustness test are shown in Table 10.

RSM Plots

The polynomial regression equation predicting the effect of GLMP concentration (µg/ml), KMnO4 volume (ml), and reaction time (min) were explained by 3D response surface plots. The absorbance responses against the variables are investigated. The surface plot explains (Fig. 8a) as a function of the KMnO4 volume (ml) and GLMP concentration (µg/ml) at a constant time of 12 min. The absorbance increases with KMnO4 volume and GLMP concentration increment. The influence of the GLMP concentration (µg/ml) against the time at the fixed volume of 2.4 ml KMnO4 was studied (Fig. 8b). It also shows absorbances enhanced with higher GLMP concentration (36 µg/ml) and attained with a maximum reaction time of 12 min. The collective impact of reaction time (min) and KMnO4 volume (ml) on absorbance is demonstrated in which the absorbance increases with increasing reaction time and KMnO4 volume (Fig. 8c). The optimized experimental conditions were to produce the absorbances, including the volume of KMnO4 to about 2.4 ml with a reaction time of 12 min at a GLMP concentration of 36 µg/ml to achieve the highest absorbance and continued the procedure throughout the experiments to determine GLMP in pharmaceutical formulations.

Discussion

Model Calibration and Validation

The multivariate calibration regression model based on the PLS was performed in two steps, calibration, and validation. It depended on the GLMP concentration and their responses transferred into Design–Expert. The model was performed utilizing GLMP concentration, KMnO4 volume, and reaction time. It typically was selected based on the minimum to highest absorbance as a response. Then, the calibration model’s predicted and observed values were applied to calculate the coefficient of determination (R2). It can be used for validation as an accuracy parameter because it explains the closeness between the predicted and actual values. Additionally, the model’s adequacy was selected based on its capability to provide the lowest errors in calibration and validation, typically articulated with RSMEC and RMSECV. The difference in the sum of these squares is well-known as PRESS. These values were generally explained by the precision parameter because its deals with the degree of concurrence with the expected values outcomes when the process is used constantly with multiple calibration samples. Based on the DoE set, the variables were the ultimate choice for GLMP quantitative analysis. Simultaneously due to their ability to present the highest values of R2 and the lowest values of RMSEC, RMSECV, and PRESS. The R2 predicted (0.9999), calibrated (1) with the low RMSECV value (0.0008, close to 0), PRESS value 0.0001 and RMSEC value 0.0007 illustrates the prediction abilities of the calibration model acquired with cross-validation.

GLMP’s residual profile identifies the random errors in the calibration model (Fig. 9). It is noticeable that random errors ensued. However, the appearance of the residual point above and below the target value is insignificant to the systematic error. Almost the difference between the observed and predicted value is close to 0. The results produced by calibration and cross-validation decided that this model is well managed to determine the GLMP in pharmaceutical formulations with a higher value of R2 and lower PRESS, RMSEC, and RMSECV values.

Applicability of the Proposed Method

Initial rate, fixed-time, and equilibrium time methods were successfully applied to determine GLMP in their pharmaceutical dosage forms. Five replicate measurements were made in each case, and the drug concentration was computed from the corresponding calibration equations. The results of the proposed methods were compared with those obtained by the reference method [36] using point and interval hypothesis tests. In the interval hypothesis, the lower and upper acceptance limits can be calculated using the following equation [70].

The values of θL and θU of confidence interval were obtained as

where \({\overline{\mathrm{x}} }_{1}\) and \({\overline{\mathrm{x}} }_{2}\) are estimates of μ1 and μ2 based on n1 and n2 measurements, respectively. Sp is the pooled standard deviation, and ttab is the tabulated one-sided t-value, with n1 + n2 − 2 degrees of freedom at the specified significance level.

No significant difference among the proposed kinetic methods was observed, as the calculated t (paired) and F-values at 95% confidence level did not exceed the ttab values [71], thus indicating good accuracy and precision in the analysis of GLMP in commercial dosage forms. As evident from Table 11, θL and θU values of all the drug samples lie within the acceptance limit of 0.98 and 1.02, smaller than ± 2%, indicating compliance with regulatory guidelines [72].

Analytical Eco-Scale Score

It calculated the Eco-Scale score by taking the penalty points for each analytical parameter. The lower the penalty points, the higher the Eco-Scale score indicates that the analytical procedure is greener and more eco-friendly. The calculated analytical Eco-Scale score was 94 (close to the ideal green analysis score), as shown in Table 12. It proves that the proposed kinetic spectrophotometric method is greener, excellent, and, hence, more eco-friendly than the compared method.

Comparison with Existing Methods

It is the first kinetic-based spectrophotometric method reported for the assay of GLMP in commercial tablet formulations using green and universal oxidant, KMnO4, as per my knowledge and literature reports. A comparison table (Table 13) presented the performances of the existing methods with the proposed kinetic method favors many advantages, including short analysis time, good linear range, sensitivity, non-extractive, inexpensive, and avoiding harmful reagents.

Conclusion

This paper reports a simple, robust, eco-friendly, and first-time kinetic spectrophotometric method for quantifying GLMP in commercial tablets using KMnO4. Beer’s law was obeyed in the range of 4–36 µg/ml with a detection limit of 1.60, 1.02, and 1.13 µg/ml for the initial rate, fixed-time, and equilibrium method, respectively. No organic or harmful solvents/reagents were used to develop this method except for extracting GLMP content from the commercial tablet formulations. Moreover, no laborious clean-up procedures are involved at any analysis stage. The method shows no interferences by the common excipients of commercial tablet formulations. A widely accepted, descriptive, and three-level factorial DoE (BBD-RSM) was used to optimize the experimental data variables. A quadratic equation was generated and showed an excellent correlation between actual and predicted responses. Youden’s test was performed to investigate the influence of alternative conditions to check the robustness of the kinetic spectrophotometric procedure. The method was validated following ICH guidelines. The proposed kinetic spectrophotometric approach was found sensitive, accurate, and precise. Lower penalty points and higher Eco-Scale scores indicate that the analytical procedure is greener and more eco-friendly. Thus, it can be a good and worthy alternative method for GLMP determination in dosage forms. Easy availability of the instrumental technique and inexpensive reagents enable frequent applications in research laboratories, pharmaceutical industries, and hospitals.

Data Availability

The datasets generated during this work can be available upon request.

Abbreviations

- ANOVA:

-

Analysis of variance

- AP:

-

Adequate precision

- APIs:

-

Active pharmaceutical ingredients

- BBD:

-

Box–Behnken design

- CL:

-

Confidence limit

- DoE:

-

Design of experiment

- FDA:

-

Food and Drug Administration

- FTIR:

-

Fourier transform infrared

- GLMP:

-

Glimepiride

- HPLC:

-

High-performance liquid chromatography

- ICH:

-

International Conference on Harmonization

- LC:

-

Liquid chromatography

- LOD:

-

Limit of detection

- LOQ:

-

Limit of quantitation

- MS:

-

Mass spectrometry

- NMR:

-

Nuclear magnetic resonance

- PC:

-

Product code

- PLS:

-

Partial least square

- PRESS:

-

Predicted residual error sum of squares

- RSD:

-

Relative standard deviation

- RSM:

-

Response surface methodology

- RMSEC:

-

Root mean square error calibration

- RMSECV:

-

Root mean square error cross-validation

- SAE:

-

Standard analytical error

- SD:

-

Standard deviation

- SPIMACO:

-

Saudi Pharmaceutical Industries & Medical Appliances Corporation

- TLC:

-

Thin layer chromatography

- UK:

-

United Kingdom

- USA:

-

United States of America

- UV-Vis:

-

Ultraviolet-visible

References

Shaw JE, Sicree RA, Zimmet PZ. Global estimates of the prevalence of diabetes for 2010 and 2030. Diabetes Res Clin Pract. 2010;87(1):4–14.

Tanabe M, Motonaga R, Terawaki Y, Nomiyama T, Yanase T. Prescription of oral hypoglycemic agents for patients with type 2 diabetes mellitus: A retrospective cohort study using a Japanese hospital database. J Diabetes Investig. 2016;8(2):227–34.

Costello RA, Nicolas S, Shivkumar A. Sulfonylureas. In: StatPearls. Treasure Island (FL): StatPearls Publishing; 2022. https://www.ncbi.nlm.nih.gov/books/NBK513225/. Accessed 1 Oct 2022.

González-Ortiz M, Guerrero-Romero JF, Violante-Ortiz R, Wacher-Rodarte N, Martínez-Abundis E, C. Aguilar-Salinas C. et al. Efficacy of glimepiride/metformin combination versus glibenclamide/metformin in patients with uncontrolled type 2 diabetes mellitus. J Diabetes Complicat. 2009;23(6):37–379.

United States Pharmacopoeia 32 National Formulary 27, The United States Pharmacopeia Convention, Rockville, MD, 2009.

United States Pharmacopoeia, GLMP tablets monograph, 33th edition, The United States Pharmacopoeial Convention, 2010.

Muller G, Geisen K. Characterization of the molecular mode of action of the sulfonylurea, glimepiride, at adipocytes. Horm Metab Res. 1996;28(9):469–87.

Mayur DC, Raju OS, Laxmikant Z, Sasmita N, Sanjay BB. Solubility and dissolution enhancement of poorly water soluble glimepiride by using solid dispersion technique. Int J Pharmacy Pharm Sci. 2012;4(suppl5):534–9.

Shrestha P, Bhandari SK, Islam SMA, Adhikari S. Dissolution enhancement of glimepiride by solid dispersion technique. RJPBCS. 2014;5(5):977–90.

Savjani KT, Gajjar AK, Savjani JK. Drug solubility: importance and enhancement techniques. ISRN Pharmaceutics. Volume 2012, Article ID 195727, https://doi.org/10.5402/2012/195727.

Rani SG, Lohita M, Preethi PJ, Madhavi R, Sunisitha B, Mounika D. Glimepiride: a review of analytical methods. Asian J Pharm Anal. 2014;4:178–82.

Vidyadhara S, Babu JR, Sasidhar RLC, Ramu A, Prasad SS, Tejasree M. Formulation and evaluation of glimepiride solid dispersions and their tablet formulations for enhanced bioavailability. Pharmanest. 2011;2(1):15–20.

Tiwari A, Mishra MK, Nayak K, Verma G, Yadav SK, Shukla A. a review article on glimeperide: an oral hypoglycaemic drug. Int J Adv Res. 4(11):920–927.https://doi.org/10.21474/IJAR01/2166.

Siddiqui MR, AlOthman ZA, Rahman N. Analytical techniques in pharmaceutical analysis: A review. Arab J Chem. 2017;10(Suppl1):S1409-1421. https://doi.org/10.1016/j.arabjc.2013.04.016.

AlOthman ZA, Rahman N, Siddiqui MR. Review on pharmaceutical impurities, stability studies and degradation products: an analytical approach. Rev Adv Sci Eng. 2013;2(2):155–66.

Rahman N, Azmi SNH, Wu HF. The importance of impurity analysis in pharmaceutical products: an integrated approach. Accred Qual Assur. 2006;11:69–74. https://doi.org/10.1007/s00769-006-0095-y.

Hussain A, Iram F, Siddiqui AA, Almutairi SM, Mohammed OB, Khan SA, Azmi SNH, Rahman N. Identification of metabolic pathways involved in the biotransformation of eslicarbazepine acetate using UPLC-MS/MS, human microsomal enzymes and in silico studies. J King Saud Uni Sci. 2021;33: 101281. https://doi.org/10.1016/j.jksus.2020.101281.

Khan MA, Sinha S, Vartak S, Bhartiya A, Kumar S. LC determination of glimepiride and its related impurities. J Pharm Biomed Anal. 2005;39(5):928–43. https://doi.org/10.1016/j.jpba.2005.06.007.

Wanjari DB, Gaikwad NJ. Reversed phase HPLC method for determination of glimepiride in tablet dosage form. Ind J Pharm Sci. 2005;67(2):253–5.

De AK, Bera AK, Ghatak S, Chowdhary PP, Chattopadhyaa SP, Chakraborty MR. A rapid and validated R.P. - HPLC method for estimation of glimepiride in solid dosage form. J Ind Chem Soc. 2010;87(8):1007–1012.

Maier V, Znaleziona J, Jirovsky D, Skopalova J, Petr J, Sevcik J. Determination of antihyperglycemic drugs in nanomolar concentration levels by micellar electrokinetic chromatography with non-ionic surfactant. J Chromatogr A. 2009;1216(20):4492–8. https://doi.org/10.1016/j.chroma.2009.03.052.

Isam IS, Idrees J, Tamini IAI. Determination of glimepiride in human plasma by liquid chromatography electrospray ionization tandem mass spectrometry. J Chromatogr B. 2004;799(1):103–9.

Pistos C, Koutsopoulou M, Panderi I. Improved liquid chromatographic tandem mass spectrometric determination and pharmacokinetic study of glimepiride in human plasma. Biomed Chromatogr. 2005;19(5):394–401. https://doi.org/10.1002/bmc.465.

Badawy WA, El-Ries MA, Mahdi IM. Carbon Paste- and PVC membrane electrodes as sensitive sensors for the determination of antidiabetic drugs for type 2 diabetic patients. Anal Sci. 2009;25(12):1431–6.

Ma HL, Xu MT, Qu P, Ma XH. Polarographic behavior and determination of glimepiride. Yao Xue Xue Bao. 2005;40(8):750–3.

Silge A, Weber K, Cialla-May D, Müller-Bötticher L, Fischer D, Popp J. Trends in pharmaceutical analysis and quality control by modern Raman spectroscopic techniques. Trends Anal Chem. 2022;153:16623. https://doi.org/10.1016/j.trac.2022.116623.

Li A, Yao C, Xia J, Wang H, Cheng Q, Penty R, Fainman Y, Pan S. Advances in cost-effective integrated spectrometers. Light Sci Appl. 2022;11:174. https://doi.org/10.1038/s41377-022-00853-1.

Yun YH, Techniques MSA, In: Chemometric methods in analytical spectroscopy Technology. Springer. Singapore. 2022. https://doi.org/10.1007/978-981-19-1625-0_2.

Huang, Y. Chemometric methods in analytical spectroscopy technology, In: Chemometric methods in analytical spectroscopy technology. Singapore: Springer, 2022:1–29. https://doi.org/10.1007/978-981-19-1625-0_1.

Mishra M. Spectroscopic Techniques for the Analysis of Food Quality. In: Advanced spectroscopic techniques for food quality, chemistry, and function. London: RSC Publishing. 2022:1–22. https://doi.org/10.1039/9781839165849-00001.

Kessler RW, Kessler W, Inline and Online Process analytical technology with an outlook for the petrochemical industry. In: Ozaki Y, Huck C, Tsuchikawa S, Engelsen SB, editors. Near-Infrared Spectroscopy. Singapore: Springer, 2021. https://doi.org/10.1007/978-981-15-8648-4_23.

Szantay C Jr, Beni Z, Balogh G, Gati T. The changing role of NMR spectroscopy in off-line impurity identification: a conceptual view. Trends Anal Chem. 2006;25(8):806–20.

Gorog S, Szantay C Jr. Spectroscopic methods in drug quality control and development. In: Lindon J, Koppenaal E, editors. Encyclopedia of spectroscopy and spectrometry. Oxford: Elsevier; 2010. p. 2640–50.

Al-Tamimi S, Nawal A, Al-Hashim H. Kinetic and spectrophotometric methods for determination of two hypoglycemic drugs, pioglitazone hydrochloride and glimepiride in their pharmaceutical formulations. Res J Chem Environ. 2011;15(2):963–72.

Bonfilio R, Magali BA, Herida RN. Development and validation of an UV-derivative spectrophotometric method for determination of glimepiride in tablets. J Braz Chem Soc. 2011;22(2):292–301.

Chafle D, Awale L. Development and validation of direct spectrophotometric method for the estimation of glimepiride. JPRI. 2021;33(30A):176–82. https://doi.org/10.9734/jpri/2021/v33i30A31629.

Naveed S, Qamar H, Jawaid W, Bokhari U. Simple spectrophotometric assay of glimepiride. Open Sci J Clin Med. 2014;2(4):94–101.

Altinoz S, Takeli D. Analysis of glimepiride by using derivative UV spectrophotometric method. J Pharm Biomed Anal. 2001;24(3):507–15. https://doi.org/10.1016/s0731-7085(00)00445-3.

Ramdan AA, Zeino S. Development and validation of spectrophotometric determination of glimepiride in pure and tablet dosage forms through ion-pair complex formation using bromothymol blue. Res J Pharm Tech. 2018;11(7):3049–56.

Sakala B, Gopisetty S, Pantu S, Kota A, Shreekanth N. UV Spectrophotometric method for determination of glimepiride in pharmaceutical dosage form. Int J Pharm Sci Rev Res. 2013;21(2):131–3.

Sevgi TU. Spectrophotometric determination of glimepiride in pharmaceutical preparation based on the formation of charge transfer and ion-pair complexes. J Anal Chem. 2013;68(7):606–10.

Persez-Bendit D, Silva M. Kinetc Methods in Analytical Chemistry, chapter II. New York, USA: John Wiley & Sons; 1988.

Bendito DP, Estela JM, Maya F. Editor(s): Worsfold P, Poole C, Townshend A, Miró M. In: Encyclopedia of Analytical Science, 3rd edition. Academic Press, 2019.

Perez-Bendito D, Gomez-Hens A, Silva M. Advances in drug analysis by kinetic methods. J Pharm Biomed Anal. 1996;14(8–10):917–30.

Rahman H. Analytical applications of permanganate as an oxidant in the determination of pharmaceuticals using chemiluminescence and spectrophotometry: a review. Curr Anal Chem. 2020;16(6):670–86.

Rahman N, Rahman H, Haque SM. Kinetic spectrophotometric method for the determination of perindopril erbumine in pure and commercial dosage forms. Arab J Chem. 2017;10(1):S831–8. https://doi.org/10.1016/j.arabjc.2012.12.017.

Rahman N, Khan S. Kinetic modelling for the assay of nortriptyline hydrochloride using potassium permanganate as oxidant. AAPS PharmSciTech. 2015;16(3):569–78. https://doi.org/10.1208/s12249-014-0230-8.

Rahman N, Anwar N, Kashif M, Hoda MN, Rahman H. Determination of labetalol hydrochloride by kinetic spectrophotometry using potassium permanganate as oxidant. J Mex Chem Soc. 2011;55(2):105–12.

Rahman N, Bano Z, Azmi SNH, Kashif M. A kinetic spectrophotometric method for the determination of lansoprazole in pharmaceutical formulations. J Serb Chem Soc. 2006;71(10):1107–20. https://doi.org/10.2298/JSC0610107R.

Rahman N, Rahman H, Azmi SNH. Validated kinetic spectrophotometric method for the determination of metoprolol tartrate in pharmaceutical formulations. Chem Pharm Bull. 2005;53(8):942–8.

Rahman N, Ahmad Y, Azmi SNH. Kinetic spectrophotometric method for the determination of norfloxacin in pharmaceutical formulations. Eur J Pharm Biopharm. 2004;57(2):359–67. https://doi.org/10.1016/S0939-6411(03)00192-9.

Rahman N, Khan NA, Azmi SNH. Kinetic spectrophotometric method for the determination of silymarin in pharmaceutical formulations using potassium permanganate as oxidant. Die Pharmazie - An Int J Pharm Sci. 2004;59(2):112–6.

Rahman N, Kashif M. Kinetic spectrophotometric determination of famotidine in commercial dosage forms. Anal Sci. 2003;19(6):907–11. https://doi.org/10.2116/analsci.19.907.

Azmi SNH, Al-Masrouri ZN, Al-Lamki IR, Al-Jabri AK, Rahman N, Nasir M, Abdelrahman K, Fnais MS, Alam M. Development and validation of spectrophotometric method for determination of imipramine hydrochloride in tablets (solid materials). J King Saud Uni Sci. 2022;34:101823. https://doi.org/10.1016/j.jksus.2022.101823.

Rahman N, Samin S, Kashif M. Application of Box-Behnken design and desirability function in the optimization of spectrophotometric method for the quantification of WADA banned drug: Acetazolamide. J Mol Liq. 2019;274:270–7. https://doi.org/10.1016/j.molliq.2018.10.120.

Rahman N, Khan S. Experimental design approach in the optimization of potentiometric method for lansoprazole determination using lansoprazole-tungstate based ion-selective electrode. Ind Eng Chem Res. 2018;57:9351–61. https://doi.org/10.1021/acs.iecr.8b01281.

Haque SM. Validated kinetic spectrophotometric methods to optimize robustness study with youden factorial combinations to determine repaglinide using response surface methodology via box–behnken design. Arab J Sci Eng. 2022. https://doi.org/10.1007/s13369-022-06782-w.

Haque SM. Box–Behnken experimental design for optimizing the HPLC method to determine hydrochlorothiazide in pharmaceutical formulations and biological fluid. J Mol Liq. 352:2022;118708. https://doi.org/10.1016/j.molliq.2022.118708.

Yuangyai C, Nembhard HB. Design of Experiments: A Key to Innovation in Nanotechnology. In: Emerging Nanotechnologies for Manufacturing, USA: Academic Press, 2009:207–234.

Galuszka A, Konieczka P, Migaszewski ZM, Namiesnik J. Analytical Eco-Scale for assessing the greenness of analytical procedures. Trends Anal Chem. 2012;37:61–72. https://doi.org/10.1016/j.trac.2012.03.013.

Youden, WJ, Steiner EH. Statistical Manual of AOAC – Association of official analytical chemistry. Washington; 1975.

Retnaningtyas Y, Wulandiri L, Punu GF. Development and validation of a TLC densitometric method for determination of glimepiride in tablets. Indo J App Chem (JKTI). 2014;16(1):11–5.

Fahim F, Naseer A, Ahmed S, Sherazi STH, Bhanger MI. A green approach for the determination of selected anti-diabetic drugs in pharmaceutical formulation by transmission FTIR spectroscopy. J Braz Chem Soc. 2014;25(11):2032–8. https://doi.org/10.5935/0103-5053.20140188.

Rose J. Advanced Physico-chemical experiments. London: Pitman; 1964.

Brittain HG, In: Profiles of Drug Substances, Excipients and Related Methodology. Chapter 5. 1st ed. USA: Elsevier, Academic Press; 2011.

Gurjar MK, Joshi RA, Chaudhuri SR, Joshi SV, Barde AR, Gediya LK, et al. Total synthesis of cis and trans-hydroxyglimepiride: active metabolite of glimepiride. Tetrahed Lett. 2003;44(26):4853–5. https://doi.org/10.1016/S0040-4039(03)01145-6.

El-Haj BM, Ahmed SBM. Metabolic-Hydroxy and Carboxy Functionalization of Alkyl Moieties in Drug Molecules: Prediction of Structure Influence and Pharmacologic Activity. Molecules. 2020;25(8):1937. https://doi.org/10.3390/molecules25081937.

Yatsimirskii KB. Kinetic Methods of Analysis. Oxford: Pergamon Press; 1996.

International Conference of Harmonization (ICH) of technical requirements for the registration of pharmaceuticals for human use. Validation of analytical procedure methodology. ICH-Q2(R1): 2005.

Hartmann C, Verbeke JS, Pennickx W, Hyden YV, Vankeerberghen P, Massart DL. Reappraisal of hypothesis testing for method validation: Detection of systematic error by comparing the means of two methods or of two laboratories. Anal Chem. 1995;67(24):4491–4499. https://pubs.acs.org/doi/10.1021/ac00120a011.

Christian GD. Analytical Chemistry. 4th ed. NewYork: Wiley; 1986.

Canada Health Protection Branch. “Drugs Directorate guidelines, Acceptable methods”. Ottawa, Canada: Ministry of National Health and Welfare, Draft; 1992.

Acknowledgements

The author is thankful to Dr. Nasser Al-Jassem, Chairman, General Studies Department, and Dr. Mohamed Wali Hakami, Chairman, Department of Chemical and Process Engineering Technology, for providing all required assistance and experimental facilities.

Author information

Authors and Affiliations

Contributions

The author designed the whole manuscript which include literature search,concept, design, data collection, analysis, and writing.

Corresponding author

Ethics declarations

Ethics Approval

The author declared that no ethics approval is required for the proposed research work.

Conflict of Interest

The author declares no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rahman, H. Box–Behnken Design-Based Optimized Kinetic Approach to Develop an Eco-friendly Analytical Method for the Quantitation of Glimepiride Using Spectrophotometry. J Pharm Innov 18, 893–910 (2023). https://doi.org/10.1007/s12247-022-09691-5

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12247-022-09691-5