Abstract

The response surface methodology combined Box–Behnken design was applied to enhance the kinetic spectrophotometric methods to determine repaglinide in pharmaceutical preparations. Fixed time and the equilibrium methods added repaglinide as secondary amines with 1,3,5-trinitrobenzene to form a stable yellow-coloured complex in dimethyl sulfoxide, and absorbances were measured at 423 nm. Three independent variables, 1-chloro-2,4-dinitrobenzene volume (1–2 ml), heating time (20–30 min) and heating temperature (70–80 ºC), were optimized against the absorbance. The outcomes experienced the analysis of variance test to get the statistically crucial independent variables and their interactions with the level of significance were for p < 0.05. The analysis of variance showed the best conditions to validate with observed R2 value, adjusted R2, predicted R2 and F-values, suggesting the developed model was significant. The methods were linear within the range of 2–20 µg/ml. Additionally, Youden’s robustness test applied factorial combinations of the preferred analytical parameters and considered the effect of alternate environments. The findings were reproducible and promptly recognized for routine assessment of repaglinide in bulk, pharmaceutical dosage forms and biological fluid.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The number of people with type–2 diabetes (T2DM) has increased worldwide. It is a metabolic disorder that includes insulin resistance, enhances insulin secretion and is one of the most common chronic diseases. The International Diabetes Federation (IDF) is predicted that the number of diabetic people (18–99 years) will increase to 693 million by 2045 as per the current data of global studies [1]. The UK Prospective Diabetes Study disclosed that a decrease in β-cell function acts before diagnosing T2DM [2]. The diminishing of primary insulin secretion has been an initial indication of T2DM. Higher postprandial blood glucose levels commonly consider the newly affected patient’s functions. Therefore, early insulin secretion is essential to decrease the disease progress [3].

Repaglinide (RPG), approved by food and drug administration (FDA) in the year 1997, is chemically known as (S)-2-ethoxy-4-[2-[[3-methyl-1-[2-(1piperidinyl)phenyl] butyl] amino]-2-oxoethyl] benzoic acid. It is a non–sulfonylurea insulin secretagogue with a benzoic acid structure. It belongs to the meglitinide class. The RPG’s sulfonylurea receptors (SURs) is adjacent to the ATP-sensitive K+ channel. Thus, it brings consequent Ca2+ entry through voltage-gated Ca2+ channels, subsequently exocytosis of Ca2+ reliant on insulin granules. It binds with the receptors on pancreatic beta cells and stimulates insulin release, decreasing glucose levels [4,5,6,7]. Therefore, lowering blood glucose with low insulin resistance avoids severe long-term complications like cardiovascular disease, stroke, renal failure and blindness.

Due to the functional significance of the drug RPG for D2TM, it is necessary to provide sufficient information to the researchers about the analysis of essential SUR receptors. This medication is very important due to its growing demands in our daily lives. It was one of the fastest-growing products in the treatment of D2TM. Hence, an extensive literature survey was conducted to determine RPG in API, pharmaceutical formulations and biological fluids. The quantitation was revealed with high-performance liquid chromatography (HPLC) [8,9,10,11,12,13,14,15,16,17,18], liquid chromatography connected with tandem mass spectrophotometry (LC–MS/MS) [19, 20], ultra-pressure liquid chromatography (UPLC) [21] and capillary electrophoresis (CE) [22] in bulk and dosage forms. But all these instruments require extensive cleanup procedures. High-cost solvents with complex instrumentation settings are not affordable for academics and small pharmaceutical companies. The analysis continued with UV–Vis spectrophotometry is developed [23,24,25,26,27] in pharmaceutical dosage forms. The charge transfer complexation is established with π acceptors' reaction in 2,3-dichloro-5,6-dicyano-1,4-benzoquinone (DDQ) and p-chloranilic acid (pCA) [23].

Generally, the optimization of UV–Vis spectrophotometric procedures includes a traditional one-time variable approach. The shortcomings correlated with this attempt required many experimental trials to achieve the goal. But the design of experiments (DoE), an analytical procedure could identify the impacts of multiple factors with their independent variables interactions on the dependent responses in pharmaceutical product/method development. DoE is widely applied to execute Quality by Design (QbD) in research and industrial design among several mathematical modelling attempts. QbD is an efficient effort in pharmaceutical development with predefined targets. It highlights that the product and process understanding is the critical enabler ensuring the final product’s quality risk management concepts. QbD consists of a thorough interpretation of the technical process and influences of its involved variables with the execution of those variables to attain the targets. The application of QbD will support skill and technical knowledge to assist pharmaceutical progress. The objectives included acquiring significant product quality specifications, enhancing the method’s ability to reduce product variability, improving pharmaceutical development and manufacturing proficiencies, and increasing causality analysis and regulatory compliance. The DoE application is highly dependent on characteristics of optimization design likely required number of trials, number of independent variables levels, and the number of dependent variables to be performed. Hence, three–levels of factorial Box–Behnken design (BBD) is designated involves fewer runs than the Central composite and Doehlert method, as well it performs without any points at the extremes of the cubic region formed by the two-level factorial level groupings with the influence of the parameter’s variables and responses that agrees on modeling of first and second-order response surfaces [28,29,30,31,32,33,34]. Response surface methodology (RSM) is a mathematical attempt to optimise complicated practices. It can enhance the determination of independent factors' interaction with lesser experiments, indirectly minimising the cost of analysis and ultimately improving the system's model, which significantly depends on the selection DoE. The aim is to suggest a design when many factors have less or more impact on the response to determine prominent influences and interactions. The consequences of the interaction between the variables are unnoticed to quantify RPG as per the literature. RSM combined BBD is an effective statistical method to optimize the variables in the analytical process [35,36,37]. This perspective can reduce the number of experiments in the investigations and build interactions between the variables. The desirability function also plays an important factor in optimizing the experimental conditions [38, 39]. The proposed study involved an RSM–BB design in optimising the kinetic spectrophotometric method for quantifying RPG. Fixed Time (ΔA) and equilibrium methods were developed depending on the reaction of the drug's amine group with 1-chloro-2,4-dinitrobenzene (CDNB) in dimethyl sulfoxide (DMSO) to form the Meisenheimer complex that measured at 423 nm against the reagent blank. The optimization process of BBD-RSM is quite exciting. It also enhanced the method’s ability and reduced the analysis time to determine RPG in pharmaceutical formulations.

Therefore, the current study suggested the following: (a) Developing the kinetic spectrophotometric procedures with fixed time and equilibrium methods. (b) Optimize the spectrophotometric processes using RSM–BB design. (c) The interaction between independent variables, the volume of CDNB (ml), heating time (minutes) and heating temperature (ºC), depends on its absorbance responses. (c) Analytical techniques were validated per International Conference on Harmonization (ICH) compliance. (d) Youden and Steiner’s factorial design verified the robustness test included chosen variables with proposed and alternate requirements in bulk, pharmaceutical dosage forms and biological fluid.

2 Experimental

2.1 Apparatus

The UV–Vis spectrophotometers (Jenway 6300 and Cecil, UK) measured the absorbance and recorded the spectra. To develop the colour product, a water bath shaker (Thermo Scientific, UK) recorded the reaction mixture's temperature.

2.2 Materials and Reagents

The stock solution of RPG (4.4 × 10–4 mol/l; NovoNorm, Novo Nordisk, Denmark; Repandin–1, Pharaonic and Repaglinide, Eipico, Egypt) was bought from the local pharmacy of Saudi Arabia and prepared in DMSO. The CDNB (2.5 × 10–3 mol/l; Sigma-Aldrich, USA) solution was prepared in DMSO daily and further diluted as per necessity. The carbonate buffer (pH 9.4) was prepared by dissolving sodium carbonate (26.5 g, Sigma-Aldrich, USA) and sodium bicarbonate (21 g, Sigma-Aldrich, USA) in 500 ml deionized water.

2.3 RSM-BB Experimental Design and Optimization

The Box–Behnken design approach was presented to optimize the experimental variables [40] with Design Expert 8.0.7.1 (trial version). It enhances the spectrophotometric optimization process with a minimum number of experiments. Three independent experimental factors and their influences were investigated to determine the RPG. The significant factors were volumes of 2.5 × 10–3 mol/l CDNB (A), heating time in minutes (B) and heating temperature in °C (C). The optimization was presented at three levels (Table 1): A: 1 ml (− 1), 1.5 ml (0), 2 ml (+ 1); B: 20 min (− 1), 25 min (0), 30 min (+ 1); C: 70 °C (− 1), 75 °C (0), 80 °C (+ 1) on the constraint of dependent variable absorbance as a response function [41] valued with total 17 trials. The relation which could be managed to establish the experimental runs expected for Box–Behnken design is indicated below:

where k = factor number, Cp = replicate the number of central points.

The RSM is a unique design to improve the trial data variables acquired from experiments resulting from the fitting analysis of the acquired data into the second-order polynomial model shown below as:

where Y specified the predicted response (absorbance) correlated with each factor level; Xi and Xj are independent factors’ coded values; β0 indicates to intercept (constant), βi, βii and βij represents the independent input variables of linear, quadratic and interactive coefficients, respectively.

2.4 Proposed Procedure for the Quantification of RPG

Different volumes of RPG (4.4 × 10–4 mol/l) corresponding to 2–20 µg/ml were transferred into a 10 ml volumetric flask. The volume of CDNB (6.25 × 10–4 mol/l) added into it, heating time (minutes) and heating temperature (ºC) were as per the BBD. After the reaction, a yellow color product developed and was measured at 423 nm against the reference blank. The optimized experimental conditions were applied throughout the analysis. The absorbance change with heating time like t1 (5 min) and t2 (10 min) based fixed time (ΔA) method was performed and included in constructing the calibration curve against the RPG concentration.

2.5 Determination of RPG in the Biological Fluid

To investigate the metabolic activity of biological fluid, drug-free urine samples were collected from healthy volunteers. Different aliquots from known concentrations of RPG were added with the urine sample and stored in the refrigerator. The samples were transferred into a separating funnel, added 10 ml of carbonate buffer (pH 9.4), and mixed well. The mixture was appropriately shaken and extracted with 10 ml of diethyl ether. The extraction procedure was repeated three more times for the complete recovery of the drug. The supernatant ether extract dried under the fume hood, and ether evaporated quickly due to its low boiling point. Then, the above procedure was followed to quantify the amount of RPG using the following regression equation in the biological fluid.

2.6 Procedure for Reference Method

Different concentrations of RPG corresponding to 40–200 µg were transferred into a series of 10 ml volumetric flasks. 1 ml FeCl3 and 1 ml 1,10- phenanthroline were added to each flask and mixed appropriately. It was then heated at 90 °C for 15 min, cooled it and added 2 ml orthophosphoric acid. Then, the solution was made up to the mark with distilled water. The quantitation of red-coloured product was recorded at 520 nm, and its assayed was calculated using the calibration curve method [27].

3 Results and Discussion

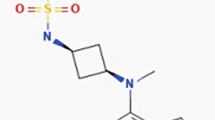

The Lewis and Bronsted bases interact with polynitroaromatic compounds, causing the development of the intensely colored product, which provides a way for limiting their quantity. The Meisenheimer complex product was assumed to form with the addition of dimethylamine and diethylamine as secondary amines with 1,3,5-trinitrobenzene in a DMSO medium [42]. The reaction was performed with optimized experimental conditions, which absorbed maximally at 423 nm. The blank comprising CDNB in DMSO has a characteristic band at 345 nm (Fig. 1). The mole ratio method determined the combining ratio between RPG and CDNB [43]. The findings noticed that the molar ratio was found to be 2:1 between RPG and CDNB. The reaction mechanism (Scheme I) was established as per the literature [44]. The formation constant and standard Gibbs free energy (ΔG°) were assessed, resulting in 1.6 × 105 and—35.97 kJ/mol, respectively, with RPG and CDNB.

3.1 Box–Behnken Model Fitting and Statistical Analysis

RSM is to be performed after precisely selecting variables that significantly affect the responses. It is usually achieved with screening designs, like factorial designs. The first-order designs assess the variable’s linear functions on the output. Still, the design could not estimate the curvature. However, second-order designs such as Box–Behnken, Doelhert and Central Composite can evaluate the variables curvature interaction and present it in terms of a quadratic equation. Among them, BBD is preferred because it needs minimum experimental trials and does not include any points at the edges of the cubic region. Initially, a model was generated with a traditional RSM design. The model was fitted after performing the experimental runs by incorporating the responses. Suppose the fitted model is insignificant in the first case. Then, repeated all the trials and re-design the model. Thus, making a model, performing the tests, and becoming a significant model fit might be time-consuming. Therefore, the selection criteria of the current investigation for the statistical design are to assess the interaction between independent factors with their responses applying the second-degree polynomial model. The RSM statistical design based on the BB design is advantageous over the typical method to optimize the several critical factors for the proposed study to estimate their influences. The suitable regression equation is achieved with the experimental data by comparing quadratic, linear and two-factor interaction models. The model was chosen based on the quadratic model due to its higher R2, low SD, higher F and lower p-value. The significance and pertinency of the selected model were confirmed by the analysis of variance (ANOVA) that comprises a summary and sequential model to attain the most significant experimental and predicted values.

The specific and collective influences of the method variables such as CDNB volume (A), heating time (B) and heating temperature (C) were evaluated utilizing the optimized BBD to quantify RPG. Absorbance was studied as a response parameter for this analysis. A complete summary of three-level factorial designs is presented in Table 2, where absorbance is indicated as a response parameter for this analysis. The absorbance values for 17 trials had revealed a difference in experimental values from 0.53 to 1.16 was very close to predicted values. Multiple regression was imperilled with the help of data to produce polynomial equations with 2FI, quadratic model. However, the model is significant with p values < 0.05 indicating that model terms are acceptable (Table 3). A positive value specifies concurring influences favouring optimization, whereas a negative sign epitomizes the factor's contrary effect, incompatibility on the designated response. The proposed mathematical model best fit the quadratic model based on the absorbance responses. The coefficients of the models were obtained to investigate the variables and their corresponding p-values. The variables were considered statistically significant, with the p-values were below 0.05 (Table 4). The R2 value was found to be 1, indicating the test variable was significant at the 5% level. The quadratic model has elevated values of the regression coefficient, R2 (0.9989), predicted R2 (0.9934), adjusted R2 (0.9977) with a minimal 0.0034 as standard deviation (SD) value. The empirical regression expression between absorbance and variables was acquired with the help of predicted and experimental absorbance response using the multi-regression analysis by the second-order polynomial equation in terms of coded factor as:

Absorbance = 1.07 + 0.0751 A + 0.1179 B + 0.075 C + 0.015 AB + 0.1338 AC + 0.0068 BC – 0.0635 A2 – 0.2175 B2 – 0.1338 C2.

The typical way for evaluating the influence of descriptive variables in regression analysis is ANOVA. Each variable accounted for a specific measure of the total variance of the dependent variable to quantify their relative contribution. There may be significant interactions between these variables that follow two or more independent factors that are significantly correlated. It indicates knowing which independent variable influences the variance justified in the dependent variable. The percentage contribution shows which variable has the most substantial impact in explaining the dependent variable with other variables in the model. The percent contribution (PC) associated with each variable was assessed using the formula:

where Xi and Yi are the sum of squares for each parameter and the model as represented (Table 4).

The percentage coefficient of variation (CV%) is typically evaluated by dividing the SD by mean multiplied by 100. It permits the difference between distributions of values for which capacity scales are not equivalent. The higher the CV value, the more broad the degree of scattering across the mean. The lower the CV value close to the mean, the more precise the value. The CV% of the reported model is very small, indicating that values are very close to the mean with predicted and observed values. The adequate precision usually measures the signal–noise ratio expected response associated with its related error. A ratio larger than four is advantageous for directing the model, with a higher observed value indicating adequate model bias. The achieved empirical data demonstrated an excellent relationship with expected data, showing the outcomes realistically for both studied responses. Lack-of-fit (LOF) shows us that a regression model is inadequate with experimental data. It is only possible to select insignificant variables and not to include critical conditions. It may also be for a reason that of poor experimental design. Therefore, large residuals or errors are seen when fitting the lack-of-fit model. The minimal LOF value indicates that the model is significant and selected independent variables are substantial with proper selection of experimental conditions.

The graphical approach is developed to validate the model and characterise the model's residual distribution. The normal plot of residuals typically evaluates how the normal probability is applied to assess the distribution of the model's residuals [45]. The residual’s normal probability plot (Fig. 2a) is relatively well-conducted against expected values. The ideal residual’s normal distributions reveal the accuracy of the expectations and the freedom of the residuals. The residual is usually distributed as a straight line, indicating no variance deviation that can prove experimental data’s normal distribution with the competency of the developed model. The observed against expected data used to plot predicted vs actual plot characteristically compares the null model with the recommended model that reveals its outcome with the projected against the real value. Figure 2b retains a relationship between perceived and actual data with experimental and predicted correlation (R2 = 1). All the points on the horizontal line also indicate a fitting model. The perturbation plot is generally appropriate to determine the crucial factors on the outcome. A factor's arc or steep slope indicates that the results are responsive to that factor. A reasonably flat line shows response inattentiveness to change over in that specific factor. The Box–Cox plot indicates a guide for selecting the suitable power-law conversion for power transforms [46]. The transformation has been determined on the best lambda observed (± 0.01–3.0) at the lowest point of the arc formed by the natural log of sum squares of residuals. It alters the produced value related to the normal distribution optional when reasonable with non-normal data. The model was tested with each crucial transformation, confirming that no conversion is necessary (Fig. 2c). The perturbation plot (Fig. 2d) shows that the independent variables A and C had a similar effect to determine RPG. It also revealed that increased CDNB volume increased the absorbances. The rate of absorbances increased with the increase in RPG concentration, but after a particular volume, it was almost constant. But the steep curvature due to variable B recommends that the RPG’s responses were susceptible to this parameter. Therefore, the plot suggested proposed method’s absorbances were highly influenced by heating time (B) compared to CDNB volume (A) and heating temperature (C). The investigation affects the perturbation in the Box–Cox unbiased regression with constant variance. It assesses the consequence of the critical perturbation factors on the power conversion related with the unbiased Box–Cox regression model controlled by prominent studies on the biased estimation varied from the unbiased estimators. Therefore, conclude a diagnostic approach for evaluating the influences on the constant variance perturbation on the Box–Cox biased regression model's transformation [47].

3.2 Model Optimization and Response Surface Plots

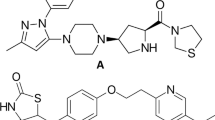

To optimize the proposed method, evaluate the minimum and maximum value of three independent parameters. The ranges of the independent variables are as follows: CDNB (1–2 ml), heating time (20–30 min) and heating temperature (70–80 ºC). The method was optimized with desirability function (= 1) selected for the equilibrium method. The desirability of 1.0 is attained with the independent parameter, and experiments were performed based on the predicted optimum values (Fig. 3). The results findings are a significant agreement with the expected values. The 3D and contour plots reveal the interaction between the two parameters even though maintaining constant with another variable. The absorbance value increases with the rise of heating time at heating temperature. This is because of the enhancement of molecular interaction but reaches stability after 25 min. No additional absorbance rise was observed, and 26.3 min of heating time was used as optimized time (Figs. 4a and 5c). It also found that absorbance increased with CDNB volume and was optimized with 1.92 ml at the constant heating (Figs. 4b and 5a). The heating temperature influenced the absorbance and its increases at constant volume. The maximum absorbance was achieved at 77.96ºC and utilized as optimum heating temperature (Figs. 4c and 5b). Therefore, different concentrations of RPG (4.4 × 10–4 mol/l) corresponding to 2–20 µg/ml were mixed with 1.92 ml CDNB (2.5 × 10–3 mol/l) into 10 ml volumetric flask. The mixture's temperature was controlled at 77.96 ºC for 26.3 min. The absorbances of yellow-coloured Meisenheimer complex was computed at 423 nm against reagent blank throughout the analysis of RPG in pharmaceutical formulations.

3.3 Analytical Data

3.3.1 Fixed Time Method

The concentration of RPG and corresponding absorbances were linear within the range of 2–20 µg/ml under optimized conditions. Initially, there was no change in color after mixing CDNB with RPG, but the reaction was resulted later by heating and absorbances of the colored product measured at 423 nm. The method was established with absorbance change as a function of time (Fig. 6). The difference of absorbance (ΔA) with time intervals 5 (10–5), 10 (15–5), 15 (20–5) and 20 (25–5) minutes was applied to build a regression equation against RPG's initial concentration. The regression data were assessed with excellent linearity, the SD of slope and intercept, variance, the limit of detection (LOD), and limit of quantitation (LOQ) and concise in Table 5.

3.3.2 Equilibrium Method

The heating time was optimized for the yellow-coloured Meisenheimer complex at 30 min. The absorbance was measured at 423 nm for the quantitation. A calibration equation was made between concentration and its respective absorbance. The calibration curve revealed a higher correlation coefficient (r2 = 0.9999), which suggested outstanding linearity of the regression equation. The small values of the SD of slope and intercept recommended better reproducibility of the equilibrium method. The limit of detection and limit of quantitation were found to be 0.57 and 1.61 µg/ml.

3.3.3 Study of Accuracy and Precision

The intraday (repeatability) and inter-day (intermediate) precision were calculated with lower, medium and higher values of RPG within the calibration range. The study was carried out with 5, 10, 20 µg/ml with seven experiments in each level in one day. It continued with seven replicates of each level with seven different days using the same solutions. The results of 20 µg/ml are presented in Table 6. The % RSD values were 0.69–0.99 and 0.52–1.11% for fixed time and equilibrium methods with intraday and inter-day precision, demonstrating the current method's excellent precision. The fixed-time and equilibrium methods were established by recovery studies applying the standard addition method. The % recoveries and % RSD were within the ranges of 98.70–99.93%, 0.38–0.85%, and 98.07–99.90%, 0.64–0.93%, respectively, for fixed time and equilibrium methods. The outcomes were allowed generously within the acceptable limits of 98–102% and ± 2% (Table 7).

3.3.4 Robustness Test

The robustness study was achieved as per Youden and Steiner’s robustness test [48] with slight changes with the optimized conditions applied for its determination. The traditional variables (upper case letter) and alternatives (lower case letter) were preferred and formulated to estimate the SD of eight experiments (Table 8). It is significant if SD were higher than the criteria, i.e. SD (s) multiplied by the square root of two (√2). The results were presented, and noticed all parameters were relatively robust (Table 9).

3.4 Application of the Proposed Method

3.4.1 Determination of RPG in Urine Samples

The fixed time and equilibrium methods were utilized to determine RPG in biological fluid. Before analysis, a known amount of RPG was spiked to the sample within the proposed linearity range. The % recovery and % RSD were in the range of 97.65–98.77%, 0.43–0.87% and 97.59– 98.91%, 0.4–0.77% (Table 10). All the values showed that the complicated biological matrix did not interfere with the absorbances. Overall, the proposed methods were successfully developed and validated with accuracy and precision.

3.4.2 Determination of RPG in Pharmaceutical Formulations

The point and interval hypothesis test was directed to evaluate bias [49]. The tests were performed to compare the proposed and reference methods findings at a 95% confidence level. The test procedure was acceptable when true to the average value within ± 2% of the reference’s method [27]. This can be written as.

0.98 < μ2 / μ1 < 1.02

which can be generalized to

θL < μ2 / μ1 < θu.

where θL and θU are lower and upper acceptance limits and calculated from the following quadratic equation [49].

The lower limit (θL) and the upper limit (θU) of the confidence interval was obtained as

where x1 and x2 are average values with n1 and n2 measurements, Sp is the pooled SD value, t is the formulated one-sided t-value at 95% confidence level with n1 + n2-2 degrees of freedom. The calculated t- (paired) and F- values were below the theoretical ones suggesting considerable changes in performing the proposed methods with the reference method at a 95% confidence level (Table 11). All the samples' true bias was lesser than ± 2%, validating that the recommended methods were consistent with adequate precision and recovery.

4 Conclusion

According to ICH guidelines, efficient and reliable RSM included BBD optimized kinetic spectrophotometric methods based on fixed time and equilibrium were developed and validated in bulk and pharmaceutical dosage forms. The factorial permutation of the selected variable’s influence with standard and alternative conditions was performed to determine Youden’s robustness test for both methods. The BBD reduced the number of trials indirectly decreased the time and cost. It was also able to assess involved significant independent variables on the response at the resulting enhanced settings: CDNB volume (1.92 ml), heating time (26.3 min) and heating temperature (77.96 ºC) with desirability function to quantify RPG within the linear dynamic range of 2–20 µg/ml short of any interfering from common bulking agents in the pharmaceutical formulations. The method's validity, accuracy and precision were evident from the statistical and diagnostic parameters attained. Therefore, the procedures fitting application with true bias computed for assessing RPG was within adequate limits with routine quality control samples, pharmaceutical dosage forms and biological fluid.

References

Cho, N.H.; Shaw, J.E.; Karuranga, S.; Huang, Y da Rocha Fernandes, J.D.; Ohlrogge, A.W.; Malanda, B.: IDF Diabetes Atlas Global estimates of diabetes prevalence for 2017 and projections for 2045. Diabetes. Res. Clin. Pract. 138, 271–281 (2018).

Saisho, Y.: β-cell dysfunction: Its critical role in prevention and management of type 2 diabetes. World J. Diabetes 6, 109–124 (2015)

Yang, W.; Lu, J.; Weng, J.; Jia, W.; Ji, L.; Xiao, J.; Shan, Z.; Liu, J.; Tian, H.; Ji, Q.; Zhu, D.; Ge, J.; Lin, L.; Chen, L.; Guo, X.; Zhao, Z.; Li, Q.; Zhou, Z.; Shan, G.; He, J.: China National Diabetes and Metabolic Disorders Study Group. Prevalence of diabetes among men and women in China. N. Engl. J. Med. 362, 1090–1101 (2010).

Pia, V.; Bingbing, W.; Yixian, L.; Weiping, H.: Pancreatic regulation of glucose homeostasis. Exp. Mol. Med. 48, e219 (2016).

Zhou, S.F.; Zhou, Z.W.; Yang, L.P.; Cai, J.P.: Substrates, inducers, inhibitors and structure-activity relationships of human cytochrome P450 2C9 and implications in drug development. Curr. Med. Chem. 16, 3480–3675 (2009)

Hansen, A.M.; Christensen, I.T.; Hansen, J.B.; Carr, R.D.; Ashcroft, F.M.; Wahl, P.: Differential interactions of nateglinide and repaglinide on the human beta-cell sulphonylurea receptor 1. Diabetes 51, 2789–2795 (2002)

Hu, S.; Wang, S.; Fanelli, B.; Bell, P.A.; Dunning, B.E.; Geisse, S.; Schmitz, R.; Boettcher, B.R.: Pancreatic beta-cell K (ATP) channel activity and membrane binding studies with nateglinide: A comparison with sulfonylureas and repaglinide. J. Pharmacol. Exp. Ther. 293, 444–452 (2000)

Navamanisubramanian, R.; Panchagiri, S.; Nerella, R.; Duraipandian, C.; Seetharaman, S.: Stability indicating rp-hplc method for estimation of repaglinide in rabbit plasma. Int. J. Pharm. 11, 206–210 (2019)

Han, D.G.; Kwak, J.; Seo, S.W.; Kim, J.M.; Yoo, J.W.; Jung, Y.; Lee, Y.H.; Kim, M.S.; Jung, Y.S.; Yun, H.; Yoon, I.S.: Pharmacokinetic evaluation of metabolic drug interactions between repaglinide and celecoxib by a bioanalytical hplc method for their simultaneous determination with fluorescence detection. Pharm. 11, 382 (2019)

Aslan, S.S.; Yılmaz, B.: Derivative spectrophotometric and isocratic high-performance liquid chromatographic methods for simultaneous determination of repaglinide and metformin hydrochloride in pharmaceutical preparations. Am. J. Anal. Chem. 8, 541–552 (2017)

Elkady, E.F.; El-Zaher, A.A.; Elwy, H.M.; Saleh, M.A.: Validated liquid chromatographic method for simultaneous determination of metformin, pioglitazone, sitagliptin, repaglinide, glibenclamide and gliclazide-application for counterfeit drug analysis. J. Anal. Bioanal. Tech. S13, 007 (2015)

Fouad, M.M.; Rashed, N.S.: Development and validation of chromatographic and spectroscopic methods for estimation of repaglinide and metformin hcl in combined dosage form. J. Global Trends Pharm. Sci. 5, 1844–1848 (2014)

Dhole, S.M.; Khedekar, P.B.; Amnerkar, N.D.: Comparison of uv spectrophotometry and high-performance liquid chromatography methods for the determination of repaglinide in tablets. Pharm. Methods 3, 68–72 (2012)

Patil, K.; Rane, V.; Yeole, R.; Shinde, D.: A validated chiral lc method for the enantiomeric separation of repaglinide on immobilized amylose based stationary phase. J. Braz. Chem. Soc. 23, 1048–1053 (2012)

Sharma, M.C.; Sharma, S.: Stability indicating rp-hplc method for determination and validation of repaglinide in pharmaceutical dosage form. Int. J. ChemTech Res. 3, 210–216 (2011)

Tatiparthi, R.; Duraiswamy, D.; Bannoth, C.K.: Method development and validation of metformin and repaglinide in rabbit plasma by rp-hplc. FABAD J. Pharm. Sci. 35, 69–75 (2010)

Rani, P.A.; Sekaran, B.C.; Archana, N.; Teja, S.P.; Aruna, B.: Determination of repaglinide in pharmaceutical formulations by rp-hplc method. J. Appl. Sci. Res. 5, 1500–1504 (2009)

Gandhimathi, M.; Ravi, T.K.; Renu, S.K.: Determination of repaglinide in pharmaceutical formulations by hplc with uv detection. Anal. Sci. 19, 1675–1677 (2003)

Li, J.K.; Li, Y.; Chen, M.; Yang, J.; Song, Y.; Wang, C.; Jia, Y.Y.; Wen, A.D.: Uncertainty evaluation for the determination of repaglinide in human plasma by lc-ms/ms. Accred. Qual. Assur. 18, 61–70 (2013)

Zhang, J.; Gao, F.; Guan, X.; Sun, Y.T.; Gu, J.K.; Fawcett, J.P.: Determination of repaglinide in human plasma by high-performance liquid chromatography-tandem mass spectrometry. Acta Pharm. Sinica B 1, 40–45 (2011)

Xavier, C.M.; Basavaiah, K.: Development and validation of a simple stability indicating UPLC method for the determination of repaglinide in pharmaceuticals. Thai J. Pharm. Sci. 37, 84–94 (2013)

Li, C.; Jiang, Y.: Analysis of repaglinide enantiomers in pharmaceutical formulations by capillary electrophoresis using 2,6-di-o-methyl-β-cyclodextrin as a chiral selector. J. Chromatogr. Sci. 50, 739–743 (2012)

Cijo, M.X.; Basavaiah, K.; Sameer, A.M.; Abdulrahman, S.; Vinay, K.B.: spectrophotometric determination of repaglinide in tablets based on charge transfer complexation reaction with chloranilic acid and dichloro-dicyano benzoquinone. Chem. Ind. Chem. Eng. Quart. 17, 469–476 (2011)

Kharbade, S.; Asnani, A.; Pratyush, K.: Development and validation of uv spectrophotometric method for simultaneous estimation of metformin hcl and repaglinide in pharmaceutical formulation. J. Drug Deliv. Therapeu. 9, 344–347 (2019)

Mishra, J.; Nayak, S.K.; Sahoo, S.K.: Development, validation and stability study of uv spectrophotometric method for determination of Repaglinide in bulk and pharmaceutical dosage forms. J. Innov. Appl. Pharm. Sci. 1, 10–16 (2016)

Patel, N.K.; Patel, K.R.: Development and validation of uv spectrophotometric method for simultaneous estimation of metformin hcl and repaglinide in bilayer tablet dosage form. J. Pharm. Sci. Biosci. Res. 5, 104–109 (2015)

Sekaran, C.B.; Rani, A.P.; Archana, A.; Teja, P.S.: Validation of quantitative spectrophotometric methods for the determination of repaglinide in pharmaceutical formulations. J. Pharm. Res. 3, 201–204 (2010)

Bajpai, M.; Katoch, S.S.; Kadier, A.; Ma, P.C.: Treatment of pharmaceutical wastewater containing cefazolin by electrocoagulation (EC): Optimization of various parameters using response surface methodology (RSM), kinetics and isotherms study. Chem. Eng. Res. Des. 176, 254–266 (2021)

Abdulhameed, A.S.; Hum, N.N.M.F.; Rangabhashiyam, S.; Jawad, A.H.; Wilson, L.D.; Yaseen, Z.M.; Kahtani, A.A.A.; AlOthman, Z.A.: Statistical modeling and mechanistic pathway for methylene blue dye removal by high surface area and mesoporous grass-based activated carbon using K2CO3 activator. J. Environ. Chem. Eng. 9, 105530 (2021)

Reghioua, A.; Barkat, D.; Jawad, A.H.; Abdulhameed, A.S.; Kahtani, A.A.A.; AlOthman, Z.A.: Parametric optimization by Box-Behnken design for synthesis of magnetic chitosan-benzil/ZnO/Fe3O4 nanocomposite and textile dye removal. J. Environ. Chem. Eng. 9, 105166 (2021)

Rahman, N.; Nasir, M.: Effective removal of acetaminophen from aqueous solution using Ca (II)-doped chitosan/β-cyclodextrin composite. J. Mol. Liq. 301, 112454 (2020)

Naveen, N.R.; Kurakula, M.; Gowthami, B.: Process optimization by response surface methodology for preparation and evaluation of methotrexate loaded chitosan nanoparticles. Mat. Today Proceed. 33, 2716–2724 (2020)

Kurakula, M.; Naveen, N.R.: In situ gel loaded with chitosan-coated simvastatin nanoparticles: promising delivery for effective anti-proliferative activity against tongue carcinoma. Mar. Drugs. 18, 201 (2020)

Rahman, N.; Sameen, S.; Kashif, M.: Application of Box-Behnken design and desirability function in the optimization of spectrophotometric method for the quantification of WADA banned drug: acetazolamide. J. Mol. Liq. 274, 270–277 (2019)

Khalil, A.; Kashif, M.: Development of uv-visible spectrophotometric methods for the quantitative and in silico studies for cilazapril optimized by response surface methodology. Drug Dev Ind. Pharm. 47, 1100–1111 (2021)

Kaur, I.; Gaba, S.; Kaur, S.; Kumar, R.; Chawla, J.: Spectrophotometric determination of triclosan based on diazotization reaction: response surface optimization using Box-Behnken design. Water Sci. Technol. 77, 2204–2212 (2018)

Wani, Y.B.; Patil, D.D.: An experimental design approach for optimization of spectrophotometric method for estimation of cefixime trihydrate using ninhydrin as derivatizing reagent in bulk and pharmaceutical formulation. J. Saudi Chem. Soc. 21(Suppl. 1), S101–S111 (2017)

Leardi, L.: Experimental design in chemistry: a tutorial. Anal. Chim. Acta 652, 161–172 (2009)

Candioti, L.V.; De Zan, M.M.; Camara, M.S.; Goicoechea, H.C.: Experimental design and multiple response optimization using the desirability function in analytical methods. Talanta 124, 123–138 (2014)

Ferreira, S.L.C.; Bruns, R.E.; Ferreira, H.S.; Matos, G.D.; David, J.M.; Brandao, G.C.; da Silva, E.G.P.; Portugal, L.A.; dos Reis, P.S.; Souza, A.S.; dos Santos, W.N.L.: Box-Behnken design: an alternative for the optimization of analytical methods. Anal. Chim. Acta 597, 179–186 (2007)

Kurakula, M.; Naveen, N.R.; Patel, B.; Manne, R.; Patel, D.B.: Preparation, optimization and evaluation of chitosan-based avanafil nanocomplex utilizing antioxidants for enhanced neuroprotective effect on PC12 cells. Gels. 7, 96 (2021)

Strauss, M.J.: Anionic sigma complexes. Chem. Rev. 70, 667–712 (1970)

Sawyer, D.T.; Heinemann, W.R.; Beebe, J.M.: Chemistry experiments for instrumental methods. Wiley, USA, p. 200 (1984).

Coombes, R.G.: Nitro and nitroso compounds, In comprehensive organic chemistry: the synthesis and reactions of organic compounds, Sutherland, I. O. Eds.; Pergamon Press: UK, 2, p. 352 (1979).

Jawad, A.H.; Abdulhameed, A.S.; Wilson, L.D.; Hassan, S.S.A.S.; AlOthman, Z.A.; Khan, M.R.: High surface area and mesoporous activated carbon from KOH-activated dragon fruit peels for methylene blue dye adsorption: optimization and mechanism study. Chin. J. Chem. Eng. 32, 281–290 (2021)

Velez, I.J.; Correa, C.J.; Fernando, M.R.: A new approach to the Box-Cox transformation. Front. Appl. Math. Stat. 1, 00012 (2015)

Fang, L.; Zhou, Z.; Hong, Y.: Symmetry analysis of the uncertain alternative Box-Cox regression model. Symmetry 14, 22 (2022)

Youden, W.J.; Steiner, E.H.: Statistical manual of AOAC-association of official analytical chemistry. Washington: AOAC, p. 88 (1975).

Hartmann, C.; Verbeke, J.S.; Pinninckx, W.; Heyden, Y.V.; Vankeerberghen, P.; Massart, D.L.: Reappraisal of hypothesis testing for method validation: detection of systematic error by comparing the means of two methods or of two laboratories. Anal. Chem. 67, 4491–4499 (1995)

Funding

This research did not obtain any financial grant to complete the work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Manirul Haque, S. Validated Kinetic Spectrophotometric Methods to Optimize Robustness Study with Youden Factorial Combinations to Determine Repaglinide Using Response Surface Methodology via Box–Behnken Design. Arab J Sci Eng 48, 129–144 (2023). https://doi.org/10.1007/s13369-022-06782-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-022-06782-w