Abstract

Potatoes are at the heart of the world’s diet, being cultivated in more than 100 countries. Being the fourth largest crop after maize, wheat and rice, the potato production is of utmost interest for food industry, supporting a wide range of research projects. This is particularly the case of storage, an essential step for the potato industry, which is regularly studied. Indeed, sprouting of potatoes during storage is very problematic, resulting in a net loss for industries and increased food waste. Therefore, there has been a lot of research on sprout suppressive molecules since the beginning of the twentieth century. However, to date, there is no publication gathering all the studied molecules. This review presents an overview of the current knowledge on sprout suppressive molecules, natural and synthetic, along with a comparison of their effectiveness.

Resumen

Las papas están en el corazón de la dieta del mundo, cultivándose en más de 100 países. Siendo el cuarto mayor cultivo después del maíz, trigo y arroz, la producción de papa es de máximo interés para la industria alimentaria, respaldando una gran amplitud de proyectos de investigación. Esto es particularmente el caso de almacenamiento, un paso esencial en la industria de la papa que se estudia regularmente. De hecho, la brotación de las papas durante el almacenamiento es muy problemático, lo que resulta en pérdidas netas para la industria y en un aumento de desperdicio de comida. De aquí que ha habido mucha investigación en moléculas inhibidoras de la brotación desde principios del siglo 20. No obstante, a la fecha no hay una publicación que reúna a todas las moléculas estudiadas. Esta revisión presenta una vista general del conocimiento actual de moléculas supresoras de la brotación, naturales y sintéticas, junto con una comparación de su efectividad.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Although the history of potato began 8000 years ago in the Andean region of South America, it was only in the seventeenth century that this vegetable was adopted throughout Europe, and from there, imported to Asia before North America (International Year of the Potato 2008). Without being exhaustive, the average world’s production of potato represented 368.17 millions tons in 2018, with an average consumption of about 33.47 kg per capita in 2017 (FAOstat 2019). In North America, this number almost doubled to reach 53.79 kg per capita per year which places this vegetable as one of the most present in the North American diet (International Year of the Potato 2008; FAOstat 2019). Since markets must be supplied year-round, potatoes are stored from periods of up to several months. Long-term storage of potatoes can be problematic due to two main phenomena: spread of diseases and sprouting. In order to prevent these phenomena, a wide range of chemical products can be applied to avoid significant economic losses. Although, some of these products, such as chlorpropham (also known as CIPC), have demonstrated toxic properties for both, environment and consumer health, there are still widely used (Paul et al. 2015, 2018). In response, several governments are increasingly regulating and even considering banning the use of chlorpropham such as the European Union in June 2019 (Juncker 2019). Therefore, it becomes urgent to develop and market new sprout suppressive products, which are more environmental-friendly.

In order to develop alternative products, several research projects have investigated sprout suppressive properties of various molecules. To our knowledge, there is currently no review reporting on all the molecules (synthetic and natural) studied and their effectiveness as sprout suppressant. Therefore, the aim of this literature review is to gain an understanding of the existing research on sprout suppressive agents, and to present that knowledge into two categories: commercially available sprout suppressive products and molecules, which have shown promising results.

Storage

In order to manage different depository conditions, a reliable potato storage facility must be able to control temperature as well as humidity, and be equipped with a good ventilation system. Since potatoes may have been damaged during harvest, a pre-storage of potatoes under high relative humidity (95%) at 10–15 °C for about two weeks is usually done (Pinhero et al. 2009). The pre-storage conditions allow the potatoes to dry and heal the peel (Pinhero et al. 2009). After pre-storage, potatoes are generally stored in crates at lower temperatures for a period ranging from a few weeks to several months.

As previously mentioned, one of the main challenges during storage is early sprouting. After potato harvest, tubers are naturally dormant thus, no sprouting occurs. Unfortunately, this period of innate dormancy does not last as long as the storage period required by the market. Therefore, premature sprouting needs to be controlled, otherwise potatoes will lose weight and nutritional value. Moreover, the processing qualities of the tubers may be affected leading to major economic losses (Mani et al. 2014). Thus, inhibit sprouting by managing environmental conditions (e.g. cold temperature of storage, humidity regulation and regulated gas composition conditions) and by the application of chemical sprout suppressants (Fig. 1), help prevent these losses (Pinhero et al. 2009; Alamar et al. 2017). Regulating sprouting with chemical products comes with many challenges including the restriction of chlorpropham residues and the control of sweetening processes, ensuring tuber marketability (Alamar et al. 2017). Also, it is important to consider the storage conditions, which are different according to markets targeted. For example, cold storage is not an option for the processing sector because low temperatures increase the concentration of reducing sugars, which cause undesirable colours during frying (Wiltshire and Cobb 1996). Nevertheless, higher temperature storage of tubers is not a better option, because it increases tuber’s respiration and considerable weight loss occurs (Wiltshire and Cobb 1996). Taking that into account, potatoes to be sold for processing will be stored between 8 and 13 °C whereas the storage of fresh market potatoes is below 7 °C (Alamar et al. 2017). Processing potatoes thus need application of sprout suppressant to prevent tubers sprouting promoted by a higher storage temperature.

Sprout Suppressants Commercially Available and Currently Used

Used since the mid-twentieth century, chlorpropham (CIPC), a well-known cost effective potato sprout suppressant, is used as a postharvest product during storage. However, more and more studies shown that this product is dangerous for environment and consumer health because of the metabolites produced during its degradation and the long-lasting residues. Indeed, breakdown products of CIPC are more harmful than CIPC itself (Paul et al. 2015). For example, 3-chloroaniline (3-CA) is produced by thermal degradation of CIPC, a phenomenon which takes place during fogging and microbial or digestive activity (Paul et al. 2018). Although no studies show direct evidences of the carcinogenic effect of 3-chloroaniline (3-CA), 3-CA is highly toxic specifically on the haematopoietic and renal systems (m-Chloroaniline 1992; Arena et al. 2017). Furthermore, 3-CA has been suggested to be toxic because of its structural similarity to 4-CA known to be carcinogenic and genotoxic (Paul et al. 2018; Boehncke et al. 2003). Moreover, prolong and continuous use of CIPC lead to a gradual accumulation and its residues can be found everywhere. Actually, breakdown products of CIPC are not only found in fresh potatoes, they are also found in the processed potato products such as French fries and potatoes chips (Paul et al. 2018). CIPC residues have also been found in the oil used for frying and the water used for washing supporting the long-last presence of such residues (Paul et al. 2015, 2018). Furthermore, even in presence of low concentration of CIPC, cases of cross-contamination occurred and resulted in yield losses because of the presence of CIPC-residues exceeding the maximum level permitted (Douglas et al. 2019; Frazier and Olsen 2015).

Faced with this issue, many studies reported on alternatives less toxic and currently commercially available (Table 1). Astonishingly, CIPC is still used in over 90% of all current post-harvest sprout suppressant applications (AHDB 2020). However, it will be reduced since the ban on CIPC has begun in some countries notably the European Union (Juncker 2019).

In Canada, despite CIPC, active ingredients registered as sprout suppressant are 1,4-DMN, 2,6-DIPN, eugenol, maleic hydrazide and 3-decen-2-one (Agriculture et Agroalimentaire Canada 2017). In United States, we can add to the previous list R-carvone, hydrogen peroxide plus (Olsen 2016). In Europe, Talent is use as a sprout suppressant in the Netherlands since 1995 (Baker 1997) and orange oil is currently undergoing registration. Worldwide, organic potato production can rely clove oil, spearmint oil and caraway oil but they are also hydrogen peroxide plus and ethylene gas (Restrain) (Olsen 2016; Frazier et al. 2004).

Sprout suppressants can basically be classified according to their modes of action either preventive or curative. Preventive treatments act as a retardant to the sprouting process by prolonging dormancy through different physiological processes. For example, we can cite plant growth regulator analogs such as 2,6-DIPN or cell division inhibitor such as CIPC (Table 1). In opposition, curative treatments act by damaging sprouts, which is the case for most essential oils but also of 3-decen-2-one, HPP and CIPC. Since several of these products require several applications to maintain their effectiveness, many are currently used in combination with CIPC to ensure enhanced efficiency rate. This combination method allows to reduce both the cost of alternative product application since CIPC is cheaper and the maximum residues level of CIPC.

Beside CIPC breakdown products, residues from others sprout suppressants can also be an issue like hydrazine, a derivative of MH produce by plants, is reputed to be mutagen and carcinogen (Swietlinksa and Zuk 1978). Breakdown products of eugenol (by bacteria: ferulic acid, vanillin, vanillic acid (Tadasas and Kayahara 1983)), S-carvone (dihydrocarvone, dihydrocarveol (Patočka and Kuča 2013; Bhatia et al. 2008; Arena et al. 2018)) and HPP (oxygen, water) are considered to be safe while in other cases like 1,4-DMN (4-methyl-1-naphtanoic acid, 1-hydroxymethyl-4-naphtalene (European Food Safety Authority 2013)), 2,6-DIPN (2-[6(1-hydroxy-1-methyl)ethylnaphthalen-2-yl]-2-hydroxypionic acid (U.S. Environmental Protection Agency 2003; Höke and Zellerhoff 1998)) and 3-decen-2-one (2-decanone, 2-decanol (European Food Safety Authority 2015)), information about their toxicity is still missing.

Screening of Sprout Suppressant Molecules According to their Effectiveness

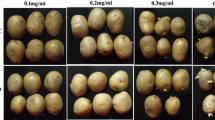

The search for molecules with sprout suppressive properties has been going on for several decades. Many studies have determined the efficiency of such molecules and they have been listed in Tables 2 and 3. Sprout suppressant molecules can be divided by their composition either single molecule or extracts. Single molecules are chemically synthesized in the lab or purified from a biological source (Table 2) whereas natural plant extracts (Table 3) which are composed of multiple molecules, biosynthesized by living organisms, all present in a mixture. Although the molecules tested in Table 2 are often of synthetic origin, it is important to note that most are also synthesized, in small amount, in plants. For example, various naphthalene molecules that have shown promising results (Table 2) have also been isolated from potatoes (Baker 1997). Yet, it was mostly chemically synthesized naphthalene molecules that were tested. It must be noted that the ranking of efficiency of the tables has been determined according to authors’ results and conclusions. It is also an approximation since the methodologies between each study differed.

The first report of use of plant extracts for their sprout suppressive properties can be traced back to the time of the Incas at the very beginning of potato cultivation. Indeed, the precursor to essential oils currently used were Muña plants, which are rich in essential oil and contain more than 98% monoterpenes (Song et al. 2008). Table 3 presents a list of plant extracts, mostly essential oils that have been tested for their sprout suppressant activities.

Many essential oils display sprout suppressant properties such as dill, coriander, spearmint and muña. However, many applications are required during storage period to maintain sprouting inhibition and since the production of essential oil is costly, it makes it difficult to implement these kinds of sprout suppressant on the market (Daniels-Lake et al. 2013; Raut and Karuppayil 2014; Martin 2013).

Could the Forest Resource Be an Avenue for Sprout Suppressive Molecules?

Canada’s forest resource is abundant, particularly in the province of Quebec where it represents 2.3% of the world’s forest (Delisle 2019). In 2018, Quebec forest industry generates alone about 2 million tons of anhydrous bark residues (Delisle 2019). Like essential oils, it has been demonstrate that barks molecules can possess a multitude of biological properties such as antioxidant, antimicrobial or anticancer (Royer et al. 2012). Then perhaps some bark extractions will have sprout suppressant properties especially since terpenoid and phenolic compounds can be enriched in bark extracts, and which are the same family compounds as found in essential oils gathered herein. In addition, because bark is a residue produced by sawmills, production cost could be lower than essential oils depending on the extraction process. This novel avenue is presently under investigation by UQTR and Innofibre.

Non-chemical Alternatives to Control Potato Sprouting

Beside the utilization of single or mixture of molecules for regulating sprouting during the storage of potatoes, other ways such as physical treatment (e.g. cold temperature, gamma radiation (Daniels-Lake et al. 2013; Rezaee et al. 2013), UV-C (Pristijono et al. 2018) or pressure treatments (Saraiva and Rodrigues 2011)) as well as biological treatment (e.g. micro-organisms (Slininger et al. 2000) or genetic engineering (Munger et al. 2015)) have been studied.

Future Perspectives

Overall, it is hard to recommend best possible options of sprout suppressant since there is a lot of variables to consider including if the production is organic or conventional, who is the end-user market, and what is the genetic variety of the potatoes (which influences dormancy period and susceptibility to diseases). The secret of managing potato sprouting probably lies in planification by coordinating applications of different treatment to retrieve maximum benefits from diversified mechanisms of action. This was the case with CIPC, before its was banned. For instance, prolonging dormancy with 2,6-DIPN (easier to apply then MH, because the window of application is easily missed with MH (Daniels-Lake et al. 2013)) combined with applications of essential oils like Talent which can also prevent the propagation of disease during storage (Baker 1997). By doing so, it would be possible to profit from the antimicrobial activity and the low toxicity of essential oil while reducing, at the same time, costs. Essential oils pose no problem regarding the storage of potato seeds in the same facility as the treated potatoes, compared to CIPC, since their effect is reversible and that their volatility makes it easy to clear the air of the storage facility from any chemical residues. Hopefully, bark extracts will prove themselves as sprout suppressant and eventually be more price competitive than essential oils.

Conclusion

Although CIPC is a sprout suppressant highly efficient and available at low cost, its consequences on environment and consumer health cannot be ignored which prompt for the development of alternatives. This review provided an overview of sprout suppressive molecules that have been tested and reported so far. A list of currently commercialized sprout suppressants along with promising molecules have been described to offer an overall guide for the research in this area. In addition, the efficiency of single molecules and mixtures of molecules from different essential oils was reported. Several alternatives showed promising results and can possess additional interesting activities such as antimicrobial, which is very valuable for industry. Indeed, the application of such agent will not only help to control sprouting and diseases of potatoes during storage but would also be cost-effective for the potato industry.

References

Afek, U., J. Orenstein, and E. Nuriel. 2000. Using HPP (hydrogen peroxide plus) to inhibit potato prouting during storage. Amer J of Potato Res 77: 63–65.

Agriculture et Agroalimentaire Canada, Profil de la culture de la pomme de terre au Canada, 2014. (2017).

AHDB, Sprout Suppression 2020. https://ahdb.org.uk/sprout-suppression-20202019].

Alamar, M.C., R. Tosetti, S. Landahl, A. Bermejo, and L.A. Terry. 2017. Assuring potato tuber quality during storage: A future perspective. Frontiers in Plant Science 8: 2034.

Aliaga, T.J., and W. Feldheim. 1985. Hemmung der Keimbildung bei gelagerten Kartoffeln durch das ätherische Öl der südamerikanischen Munapflanze (Minthostachys spp.). Ernährung/Nutrition 9: 254–256.

AMVAC. 2019. SmartBlock. https://www.amvac.com/products/smartblock2019.

Arena M, Auteri D, Barmaz S, Bellisai G, Brancato A, Brocca D, Bura L, Byers H, Chiusolo A, Court Marques D, Crivellente F, De Lentdecker C, De Maglie M, Egsmose M, Erdos Z, Fait G, Ferreira L, Goumenou M, Greco L, Ippolito A, Istace F, Jarrah S, Kardassi D, Leuschner R, Lythgo C, Magrans JO, Medina P, Miron I, Molnar T, Nougadere A, Padovani L, Parra Morte JM, Pedersen R, Reich H, Sacchi A, Santos M, Serafimova R, Sharp R, Stanek A, Streissl F, Sturma J, Szentes C, Tarazona J, Terron A, Theobald A, Vagenende B, Verani A and Villamar-Bouza L, Peer review of the pesticide risk assessment of the active substance chlorpropham. EFSA Journal 15 (2017).

Arena M, Auteri D, Barmaz S, Brancato A, Brocca D, Bura L, Carrasco Cabrera L, Chiusolo A, Civitella C, Court Marques D, Crivellente F, Ctverackova L, De Lentdecker C, Egsmose M, Erdos Z, Fait G, Ferreira L, Greco L, Ippolito A, Istace F, Jarrah S, Kardassi D, Leuschner R, Lostia A, Lythgo C, Magrans JO, Medina P, Mineo D, Miron I, Molnar T, Padovani L, Parra Morte JM, Pedersen R, Reich H, Sacchi A, Santos M, Serafimova R, Sharp R, Stanek A, Streissl F, Sturma J, Szentes C, Tarazona J, Terron A, Theobald A, Vagenende B, Van Dijk J and Villamar-Bouza L, Peer review of the pesticide risk assessment of the active substance carvone (substance evaluated d-carvone). EFSA Journal 16 (2018).

Baker A, Use of natural sprouting inhbitors for potato storage. Horticultural Research and Development Corporation (1997).

Baydar, H., and T. Karadogan. 2003. The effects of volatile oils on in vitro potato sprout growth. Potato Research 46: 1–8.

Beveridge, J.L., J. Dalziel, and H.J. Duncan. 1981a. The assessment of some volatile organic compounds as sprout suppressants for ware and seed potatoes. Potato Research 24: 61–76.

Beveridge, J.L., J. Dalziel, and H.J. Duncan. 1981b. Dimethylnaphthalene as a sprout suppressant for seed and ware potatoes. Potato Research 24: 77–88.

Beveridge, J.L., J. Dalziel, and H.J. Duncan. 1983. Headspace analysis of laboratory samples of potato tubers treated with 1,4-Dimethylnaphthalene, Carvone, Pulegone and Citral. Journal of the Science of Food and Agriculture 34: 164–168.

Bhatia SP, McGinty D, Letizia CS and Api AM, Fragrance material review on dihydrocarveol. Food and Chemical Toxicology 46 Suppl 11:S123–S125 (2008).

Biruk M, Response of Potato (Solanum tuberosum L.) to Fertilizer Application and Post-Harvest Tuber Treatment with Plant Essential Oil Extracts in North-Eastern Ethiopia, in School of Plant Sciences, Ed. Haramaya University (2015).

Boehncke, A., J. Kielhorn, G. Könnecker, C. Pohlenz-Michel, and I. Mangelsdorf. 2003. Concise international chemical assessment document 48, Ed. Geneva: World Health Organization.

Brenntag Canada Inc., Sprout Nip E.C.: Potato Sprout Inhibitor, Ed (2008).

Burton, W.G. 1958. Experiments on the use of alcohol vapours to suppress the sprouting of stored potatoes. European Potato Journal 1: 42–51.

Burton W, Post-harvest physiology. The potato Harlow: Longman Scientific and Technical:423–522 (1989).

Burton, W.G., A. van Es, and K.J. Hartmans. 1992. The physics and physiology of storage. In The Potato Crop: The scientific basis for improvement, ed. P.M. Harris, 608–727. Netherlands: Springer.

CERTIS, Traitement de pomme de terre anti-germinatif foliaire: Fazor Star, Ed (2015).

Chauhan, S.S., O. Prakash, R.C. Padalia, Vivekanand, A.K. Pant, and C.S. Mathela. 2011. Chemical Diversity in Mentha spicata: Antioxidant and Potato Sprout Inhibition Activity of its Essential Oils. Natural Product Communications 6: 1373–1378.

CIPC. 2019. Compliant, Alternative Sprout Suppressants. http://www.cipccompliant.co.uk/alternative_sprout_suppressants/2019.

Claassens, M.M., J. Verhees, L.H. van der Plas, A.R. van der Krol, and D. Vreugdenhil. 2005. Ethanol breaks dormancy of the potato tuber apical bud. Journal of Experimental Botany 56: 2515–2525.

Coleman, W.K., G. Lonergan, and P. Silk. 2001. Potato sprout growth suppression by Menthone and Neomenthol, volatile oil components of Minthostachys, Satureja, Bystropogon, and Mentha species. Amer J of Potato Res 78: 345–354.

Costa, E., M. Silva, Galhano CIC, and Moreira Da Silva AMG. 2007. A new sprout inhibitor of potato tuber based on carvone/β-cyclodextrin inclusion compound. Journal of Inclusion Phenomena and Macrocyclic Chemistry 57: 121–124.

Currah, I.E., and D.F. Meigh. 1968. Nonyl alcohol vapour in potato stores during sprout suppression. Journal of the Science of Food and Agriculture 19: 409–415.

Dai, H., M. Fu, X. Yang, and Q. Chen. 2016. Ethylene inhibited sprouting of potato tubers by influencing the carbohydrate metabolism pathway. Journal of Food Science and Technology 53: 3166–3174.

Daniels-Lake, B.J., R.K. Prange, W. Kalt, C.L. Liew, J. Walsh, P. Dean, and R. Coffin. 1996. The effects of ozone and 1,8-cineole on sprouting, fry color and sugars of stored russet Burbank potatoes. American Potato Journal 73: 469–481.

Daniels-Lake B, Olsen N, Delgado HL and Zink R, Efficacy of Potato Sprout Control Products to Minizime Sprout Production. North American Plant Protection Organization (2013).

de Vries RG, Sprout inhibiting and/or anti-fungal composition for potatoes. United States Patent 6001773 (1999).

Delisle, J.-F. 2019. Ressources et industries forestières du Québec, Portrait statistique 2018. Ministère des Forêts: de la Faune et des Parcs.

Dhaif Allah, M.S., F.I. El-Adgham, S.M. El-Araby, and I.M. Ghoneim. 2018. Influence of Jasmonic acid and Chlorpropham treatments on sprouting, Quality and Storability of Potato Tubers during Cold Storage. Alex J Agric Sci 63: 303–311.

DormFresh. 2019. 1,4 SIGHT®. http://www.dormfresh.co.uk/products/14dmn/2019.

Douglas, L., G. MacKinnon, G. Cook, H. Duncan, A. Briddon, and S. Seamark. 2019. The risk of chlorpropham cross-contamination of grain in potato stores. Food Control 98: 1–8.

El-Awady Aml, A., A.M. Moghazy, A.E.A. Gouda, and R.S.A. Elshatoury. 2014. Inhibition of sprout growth and increase storability of processing potato by Antisprouting agent. Trends in Horticultural Research 4: 31–40.

Elbashir, H.A., Ahmed, Ahmed AHR, and K.S. Yousif. 2014. Efficacy of Different Applications of Spearmint Oil on Storability and Processing Quality of two Potato Varieties. Journal of Agri-Food and Applied Sciences 2: 124–133.

Ellison, J.H. 1952. Inhibition of potato sprouting by 2,3,5,6-Tetrachloronitrobenzene and methyl Ester of A-Naphthaleneacetic acid. The American Potato Journal 29: 176–181.

Eshel D, Orenstein J, Tsror L and Hazanovsky M, Environmentally Friendly Methode for the Control of Sprouting and Tuber-Borne Diseases in Stored Potato.363–368 (2009).

European Food Safety Authority, Conclusion on the peer review of the pesticide risk assessment of the active substance 1,4-dimethylnaphthalene. EFSA Journal 11 (2013).

European Food Safety Authority, Conclusion on the peer review of the pesticide risk assessment of the active substance (3E)-3-decen-2-one (applied for as 3-decen-2-one). EFSA Journal 13 (2015).

FAOstat, FAOSTAT statistical database, Ed. [Rome] : FAO, c2019- (2019).

Farooqi AHA, Agarwal KK, Fatima S, Ahmad A, Sharma S and Kumar S, Anti-Sprouting Agent for Potato Tuber and a Method for Producing the Same. United States Patent 6313073B1 (2001).

Filmer, A.A.E., and M.J.C. Rhodes. 1984. An assessment of 1,4,6-trimethylnaphthalene as a sprout suppressant for stored potato tubers. Potato Research 27: 383–392.

Filmer, A.A.E., and M.J.C. Rhodes. 1985. Investigation of sprout-growth-inhibitory compounds the volatile fraction of potato tubers. Potato Research 28: 361–377.

Findlen, H. 1955. Effect of several chemicals on sprouting of stored table-stock potatoes. American Potato Journal 32: 159–167.

Frazier, M.J., and N. Olsen. 2015. The effects of Chlorpropham exposure on field-grown potatoes. American Journal of Potato Research 92: 32–37.

Frazier, M., G. Kleinkopf, and T. Brandt. 1998. Effects of spearmint and peppermint oil used as alternative sprout and disease suppressants. American Journal of Potato Research 75: 276.

Frazier, M., G. Kleikopf, and T. Brandt. 2000. Spearmit oil and peppermint oil used as alternative sprout suppressants. American Journal of Potato Research 72: 737–747.

Frazier, M.J., N. Olsen, and G. Kleinkopf. 2004. Organic and Alternative Methods for Potato Sprout Control in Storage, in College of Agricultural and Life Sciences, 4. Idaho: Ed. University of Idaho.

Gnimassou Y-M, Étude de l'inhibition de la germination des pommes de terre par l'éthylène, in Faculté des sciences de la santé et des services communautaires, Ed. Université de Moncton (2017).

Gómez-Castillo, D., E. Cruz, A. Iguaz, C. Arroqui, and P. Vírseda. 2013. Effects of essential oils on sprout suppression and quality of potato cultivars. Postharvest Biology and Technology 82: 15–21.

Goodarzi F, Kalvandi R, Rrazaghi K, Shaabanian M, Mansouri A and Fatemian H, Effect of some hamedan herbal plants extract on potato sprouting control. Agricultural Engineering Research Institute of Iran (2014).

Goodarzi, F., A. Mirmajidi, and K. Razaghi. 2016. Comparing inhibitory effect of chlorpropham and coriander essential oils on potato sprouting during storage. IIOABJ 7: 558–562.

Hartmans, K.J., P. Diepenhorst, W. Bakker, and L.G.M. Gorris. 1995. The use of carvone in agriculture; sprout suppression of potatoes and antifungal activity against potato tuber and other plant diseases. Industrial Crops and Products 4: 3–13.

Höke, H., and R. Zellerhoff. 1998. Metabolism and toxicity of diisopropylnaphthalene as compared to naphthalene and monoalkyl naphthalenes: A minireview. Toxicology 126: 1–7.

Hutchinson, P.J.S., J. Felix, and R. Boydston. 2014. Glyphosate carryover in seed potato: Effects on mother crop and daughter tubers. American Journal of Potato Research 91: 394–403.

International Year of the Potato (2008). http://www.fao.org/potato-2008/en/potato/index.html.

Jia, B., L. Xu, W. Guan, Q. Lin, C. Brennan, R. Yan, and H. Zhao. 2019. Effect of citronella essential oil fumigation on sprout suppression and quality of potato tubers during storage. Food Chemistry 284: 254–258.

Juncker, J.-C. 2019. Règlement d'exécution (UE) 2019/989 de la comission du 17 juin 2019, in L 160/11. Bruxelles: Ed by européenne C. Journal officiel de l'Union européenne.

Lee, W.C., T.L. Li, P.C. Chang, and S.S. Chou. 2001. High performance liquid chromatographic detemination of maleic hydrazide residue in potatoes. Journal of Food and Drug Analysis 9: 167–172.

Lewis, M.D., G.E. Kleinkopf, and K.K. Shetty. 1997. Dimethylnaphthalene and diisopropylnaphthalene for potato sprout control in storage: 1. Application methodology and efficacy. American Potato Journal 74: 183–197.

Luiz Finger F, Mayana de Sousa Santos M, Ferreira Araujo F, Carvalho Lima PC, Cavalcante da Costa L, de Fatima Martins França C and da Costa Queiroz M, Action of Essential Oils on Sprouting of Non-Dormant Potato Tubers. Brazilian Archives of Biology and Technology 61 (2018).

Lulai E, Orr P and Glynn M, Natural Suppression of Sprouting in Stored Potatoes using Jasmonates. United States Patent 5436226 (1995).

Lulai E, Orr P and Glynn M, Suppression of sprouting in stored potatoes using aromatic acids. United States Patent 5635452 (1997).

Mani, F., T. Bettaieb, N. Doudech, and C. Hannachi. 2014. Physiological mechanisms for potato dormancy release and sprouting: A review. African Crop Science Journal 22: 155–174.

Manrique Klinge K and Palomino RE, Muña (sp. Minthostachis mollis) essential oil, as a natural alternative to control potato sprouting tested under different storage conditions., in 15th Triennial ISTRC Symposium, Ed, pp 126–130 (2009).

Martin M, Le choix des inhibiteurs de germination s'étoffe! Perspectives agricoles 403 (2013).

m-Chloroaniline. 1992. Occupational Toxicants 3: 38–43.

Mehta, A. 2004. Sprout suppression in stored potatoes by natural growth inhibitor - diphenylamine. Journal of Food Science and Technology 41: 539–541.

Mehta, A., and H.N. Kaul. 2002. Evaluation of menthol and menthe oil as potato sprout inhibitors. Journal Indian Potato Association 29: 107–112.

Meigh, D.F. 1969. Suppression of sprouting in stored potatoes by volatile organic compounds. Journal of the Science of Food and Agriculture 20: 159–164.

Meigh, D.F., A.A.E. Filmer, and R. Self. 1973. Growth-inhibitory volatile aromatic compounds produced by Solanum tuberosum tubers. Phytochemistry 12: 987–993.

Munger, A., M.A. Simon, M. Khalf, M.C. Goulet, and D. Michaud. 2015. Cereal cystatins delay sprouting and nutrient loss in tubers of potato, Solanum tuberosum. BMC Plant Biology 15: 296.

Nyankanga, R.O., W.W. Murigi, S.I. Shibairo, O.M. Olanya, and R.P. Larkin. 2018. Effects of foliar and tuber sprout suppressants on storage of ware potatoes under tropical conditions. American Journal of Potato Research 95: 539–548.

Olsen N, Sprouting in storage: Impact and control, in Colloque sur la pomme de terre, CRAAQ, Ed (2016).

Olsen, N. 2020. Sprout Suppression 2020- A technical viewpoint. https://ahdb.org.uk/sprout-suppression-2020.

Oosterhaven, K., K.J. Hartmans, and H.J. Huizing. 1993. Inhibition of potato (Solanum tuberosum) sprout growth by the Monoterpene S-Carvone: Reduction of 3-Hydroxy-3-Methylglutaryl coenzyme a Reductase activity without effect on its mRNA level. Journal of Plant Physiology 141: 463–469.

Oosterhaven, K., K.J. Hartmans, and J.J.C. Scheffer. 1995. Inhibition of potato sprout growth by carvone enantiomers and their bioconversion in sprouts. Potato Research 38: 219–230.

Owolabi, M.S., L. Lajide, M.O. Oladimeji, and W.N. Setzer. 2010. The effect of essential oil formulations for potato sprout suppression. Natural Product Communications 5: 645–648.

Patočka, J., and K. Kuča. 2013. Biologically active alcohols: Cyclic alcohols. Military Medical Science Letters 82: 162–171.

Paul V and Ezekiel R, Suppression of potato sprout growth by alcohols, acetaldehyde and 2, 4-dichlorophenoxy acetic acid-ethyl ester at higher temperatures. Journal of The Indian Potato Association (India) (2002).

Paul, V., and R. Ezekiel. 2003. Suppression of sprout growth of potato (Solanum tuberosum L.) tuber by Triadimefon. Journal of Plant Biology 30: 353–356.

Paul, V., and R. Ezekiel. 2006a. Sprout suppression of potato tubers stored at 18° C by pre-and post-harvest application of sub-lethal doses of glyphosate. Indian Journal of Plant Physiology 11: 300–305.

Paul V and Ezekiel R, Inhibition of potato sprout growth by pre-harvest foliar application of glyphosate. Potato Journal 33 (2006b).

Paul, V., R. Pandey, R. Ezekiel, and D. Kumar. 2014. Potential of glyphosate as a sprout suppressant for potato (Solanum tuberosum L.) tubers during storage. Indian Journal of Plant Physiology 19: 293–305.

Paul, V., R. Ezekiel, and R. Pandey. 2015. Sprout suppression on potato: Need to look beyond CIPC for more effective and safer alternatives. Journal of Food Science and Technology 53: 1–18.

Paul, V., R. Ezekiel, and R. Pandey. 2018. Use of CIPC as a potato sprout suppressant: Health and environmental concerns and future options. Quality Assurance and Safety of Crops & Foods 10: 17–24.

Pinhero RG, Coffin R and Yada RY, Post-harvest Storage of Potatoes. Elsevier Inc., pp 339–370 (2009).

Pristijono P, Bowyer MC, Scarlett CJ, Vuong QV, Stathopoulos CE and Golding JB, Effect of UV-C irradiation on sprouting of potatoes in storage. Acta Horticulturae:475–478 (2018).

Raut, J.S., and S.M. Karuppayil. 2014. A status review on the medicinal properties of essential oils. Industrial Crops and Products 62: 250–264.

Rezaee, M., M. Almassi, S. Minaei, and F. Paknejad. 2013. Impact of post-harvest radiation treatment timing on shelf life and quality characteristics of potatoes. Journal of Food Science and Technology 50: 339–345.

Riggle BD and Schafer RK, Sprout Inhibition Compositions Comprising Chlorpropham and Substituted Nahpthalenes and Methods of Using Same. United States Patent 5622912 (1997).

Rossilion F, Inhibiteurs de germination: État des lieux d'une situation en évolution, in Le journal de la pomme de terre, Ed. Éditeur CNIPT, Paris, pp 1–4 (2018).

Royer, M., R. Houde, Y. Viano, and T. Stevanovic. 2012. Non-wood Forest products based on extractives - a new opportunity for the Canadian Forest industry part 1: Hardwood Forest species. Journal of Food Research 1: 8–45.

Sanli, A., T. Karadogan, M. Tonguç, and H. Baydar. 2010. Effects of caraway (Carum carvi L.) seed on sprouting of potato (Solanum tuberosum L.) tubers under different temperature conditions. Turkish Journal of Field Crops 15: 54–58.

Saraiva, J.A., and I.M. Rodrigues. 2011. Inhibition of potato tuber sprouting by pressure treatments. International Journal of Food Science & Technology 46: 61–66.

Sawyer, R.L., and W.H. Thorne. 1962. Alcohols for sprout inhibition of potatoes. American Potato Journal 39: 167–175.

Shukla, S., S.S. Pandey, M. Chandra, A. Pandey, N. Bharti, D. Barnawal, C.S. Chanotiya, S. Tandon, M.P. Darokar, and A. Kalra. 2019. Application of essential oils as a natural and alternate method for inhibiting and inducing the sprouting of potato tubers. Food Chemistry 284: 171–179.

Slininger PJ, Burkhead KD, Schisler DA and Bothast RJ, Biological Control of Sprouting in Potatoes. United States Patent 6107247 (2000).

Song, X., M. Bandara, and K.K. Tanino. 2008. Potato dormancy regulation: Use of essential oils for sprout suppression in potato. Fruit, Vegetable and Cereal Science and Biotechnology 2: 110–117.

Sorce, C., R. Lorenzi, and P. Ranalli. 1997. The effects of (S)-(+)-carvone treatments on seed potato tuber dormancy and sprouting. Potato Research 40: 155–161.

Suttle, J.C., L.L. Olson, and E.C. Lulai. 2015. The involvement of gibberellins in 1,8-cineole-mediated inhibition of sprout growth in russet Burbank tubers. American Journal of Potato Research 93: 72–79.

Swietlinksa, Z., and J. Zuk. 1978. Cytotoxic effects of maleic hydrazide. Mutation Research 55: 15–30.

Tadasas, K., and H. Kayahara. 1983. Initial steps of Eugenol degradation pathway of a microorganism. Agricultural and Biological Chemistry 47: 2639–2640.

Tayler PN, Method of Inhibiting Sprout Growth on Agronomic Crops using Acetohydroxy Acid Synthase Inhibiting Herbicides. United States Patent 5244866 (1993).

Tayler P, Gussin E and Leck K, Control of sprouting in potatoes from applications made under commercial conditions, in Proceedings of the 13th Triennial Conference of the European Association for Potato Research Pudoc, Wageningen, Ed, pp 589–590 (1996).

Teper-Bamnolker, P., N. Dudai, R. Fischer, E. Belausov, H. Zemach, O. Shoseyov, and D. Eshel. 2010. Mint essential oil can induce or inhibit potato sprouting by differential alteration of apical meristem. Planta 232: 179–186.

U.S. Environmental Protection Agency, 2,6-Diisopropylnaphthalene, in Biopesticide registration action document, Ed. U.S. Environmental Protection Agency (2003).

Van Es A and Hartmans K, Dormancy, sprouting and sprout inhibition. Storage of potatoes: post-harvest behavior, store design, storage practice, handling:114–132 (1987).

Vaughn, S.F., and G.F. Spencer. 1991. Volatile Monoterpenes inhibit potato tuber sprouting. American Potato Journal 68: 821–831.

Vaughn, S.F., and G.F. Spencer. 1993. Naturally occuring aromatic compounds inhibit potato tuber sprouting. American Potato Journal 70: 527–533.

Vokou, D., S. Vareltzidou, and P. Katinakis. 1993. Effects of aromatic plants on potato storage; sprout suppression and antimicrobial activity. Agriculture, Ecosystems and Environment 47: 223–235.

Wang CY, Buta JG, Moline HE and Hruschka HW, Potato sprout inhibition by camptothecin, a naturally occurring plant growth regulator [in storage]. Journal American Society for Horticultural Science 105 (1980).

Weber F, Décision relative à une demande d'autorisation de mise sur le marché d'un produit phytopharmaceutique, Ed. Agence nationale de sécurité sanitaire de l'alimentation, de l'environnement et du travail (2017).

Wiltshire, J.J.J., and A.H. Cobb. 1996. A review of the physiology of potato tuber dormancy. The Annals of Applied Biology 129: 553–569.

Acknowledgements

The authors wish to thank Olivier Rezazgui for his helpful comments and for the revision of the manuscript. The authors gratefully acknowledge Mitacs and the Fonds de recherche du Québec Nature et technologies (FRQNT) for scholarship to M.B. Also, the Consortium de Recherche et Innovations en Bioprocédés Industriels au Québec (CRIBIQ), project number 2017-042-C30, is acknowledged for its financial support to N.B, S.B. and I.D-P. This review was also funded by the Canada Research Chair on plant specialized metabolism Award No 950-232164 to I.D-P. Thanks are extended to the Canadian taxpayers and to the Canadian government for supporting the Canada Research Chairs Program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Boivin, M., Bourdeau, N., Barnabé, S. et al. Sprout Suppressive Molecules Effective on Potato (Solanum tuberosum) Tubers during Storage: a Review. Am. J. Potato Res. 97, 451–463 (2020). https://doi.org/10.1007/s12230-020-09794-0

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12230-020-09794-0