Abstract

Our team created and produced an innovative range of bioactive disperse dyes, depending on the functionalizing neocryptolepines connected to an azo-benzene sulfonyl moiety using various diaminoalkyl linker chains. These types of dyes are successfully applied to the creation of pastes for silkscreen printing of polyester fabric. To ascertain the dye strength, polyester printed samples underwent testing for washing, rubbing, perspiration, sublimation, and light fastness. In addition, L*, a*, and b* were used to evaluate the hue of the color dyes. Using the colony forming unit (CFU) method, the antibacterial activity of the printed polyester fabrics was assessed. The anti-gram positive actions of fabric samples treated with 6c and 6f against S. aureus were encouraging. In contrast, fabrics treated with 6b, 6d, and 6e showed only mild anti-gram negative activity against the test bacterium L. monocytogenes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Azo dyes currently have the largest dye chemistry production volume, and in the future, their relative significance might further rise. They are essential to the management of the dye and printing industries [1]. By changing between azo components with electron-withdrawing groups and coupling components with electron-donating groups, azo dyes show a range of colors, from yellow to blue–green [2, 3]. Due to their high degree of brightness when compared to azo dyes derived from aniline, the development of azo dyes based on sulfonyl group has attracted interest for an extended time [4,5,6,7,8,9,10,11]. In addition, textile printing, as distinct to dying, is the technique of transferring colors to fabric with specific patterns or designs [12, 13]. As a result, a number of variables, including the type of dyes chosen and the amount of dye employed, might influence the dyes used for printing. In other respects, they are controlled by the thickening used, the thick and sticky printing paste composition, the fabric composition, as well as the pattern of the fabric to be printed. On the other hand, due to their various biological actions, naturally occurring indole, quinoline, and indoloquinoline heterocyclic cores are particularly interesting and have motivated numerous researchers to synthesize series of hybrid systems with different spacers [14,15,16,17].

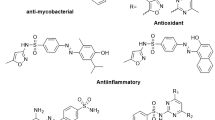

One type of tetracyclic indoloquinoline alkaloid is neocryptolepine. The ring systems of tetracyclic indoloquinolines are important structural elements found in natural products that display many kinds of biological activities. For example, the two typical alkaloids that were isolated from the roots of the African plant Cryptolepis sanguinolenta are cryptolepine (I, indolo[3,2-b]quinoline) and neocryptolepine (II, indolo[2,3-b]quinoline) (Fig. 1). Despite their relatively straightforward chemical structures, these indoloquinolines exhibit potent biological properties, including antiplasmodial, antibacterial, antifungal, and antimalarial activities [18,19,20,21]. The main objective of our research is to synthesize new monoazo disperse dyes with a sulfonamide group, which is an efficient way to enhance the fastness of azo dyes on fabrics [22]. Functional finishing and dyeing must be done in one phase by creating disperse dyes with an antibacterial component integrated into dye molecules. The two antibacterial components (neocryptolpine and sulfonyl) will be combined to form a scaffold that will be coupled by a cleavable azo linker. It was considered to be advantageous to synthesize a new series of azo-sulfonamide neocryptolpine derivatives by simple and efficient methods. Furthermore, the novel uses of azo dye in polyester printing fabric were assessed. The novel disperse dyes have exceptional antibacterial action and outstanding color fastness when applied using a printing technique.

2 Experiment

2.1 Chemicals and Reagents and Their Importance in the Printing Paste

All chemicals and reagents were of commercial grade. Thickener EM-630 is an anionic acrylic polymer, serving as coloring carrier in fabric printing with disperse dyes on polyester fabrics (Guangdong EM Chemicals Technology Co., Ltd.). The pH of printing paste was adjusted at 6 using sodium dihydrogen phosphate (NaH2PO4, 98.0%). Lyoprint EV (dispersing agent) was delivered from Ciba Company, Switzerland. 100% polyester fabric having plain weave (150 g/m2, 56 ends/cm, 34 picks/cm) was kindly obtained from El-Mahalla Company for Spinning and Weaving, El-Mahalla, Egypt and treated before printing with an aqueous solution containing 2 g/L nonionic detergent (Sera Wash M-RK, DyStar, Egypt) at a liquor to goods ratio of 50:1 and at 80 °C for 30 min, and then rinsed and allowed to dry in the open air.

2.2 Instrumentation of Spectral Analyses and Melting Points

Melting points were determined using a digital melting point apparatus (Electro Thermal 9100, Electro Thermal Engineering Ltd, serial No. 8694, Rochford, United Kingdom) and are uncorrected. The reaction progress was monitored by thin layer chromatography (TLC) using silica gel plates (POLYGRAM SILG/UV254, 0.20 mm), which were visualized under UV light 254 and 365 nm. Elemental analyses were carried out on a Perkin–Elmer 2400 analyzer (USA), and were found within ± 0.4% of the theoretical values. The infrared spectra were recorded on a Perkin–Elmer FTIR 1430 spectrophotometer using KBr disk technique. 1H– and 13C-NMR spectra were measured with a Jeol spectrometer (Japan) at 500 and 125 MHz, respectively, using TMS as the internal standard. Hydrogen coupling patterns are described as (s) singlet, (d) doublet, (t) triplet, (q) quartet, and (m) multiplet. Chemical shifts were expressed in parts per million (ppm) relative to a reference standard.

2.3 Synthesis of Dyes

According to literature, the compounds methyl-2-(arylamino)-1H-indole-3-carboxylates 2a–c, 5,6-dihydro-1H-indolo[2,3-b]quinolin-11-ones 3a–c, 11-chloro-6H-indolo[2,3-b] quinolines 4a–c, and 11-aminoalkylaminoneocryptolepines 5a–f have already been published using previously established methods [23, 24].

2.3.1 General Procedure for the Synthesis of (E)-N-(Aminoalkylaminoneocryptolepines)-4-(Phenyldiazenyl) Benzenesulfonamides 6a–f

After completely dissolving 2-substituted-5-methyl-5H-indolo]2,3-b]quinolone-11-amines 5a–f (1 mmol) in dry DMF (2 mL), 4-phenyl azo benzene sulfonyl chloride (1.2 equiv, 340 mg) in dry DMF (1 mL) was added drop by drop while stirring in presence of triethylamine (2.0 equiv). The reaction was allowed to proceed at room temperature until TLC indicated that the reaction was finished (2–4 h). Using AcOEt-2N ammonia in MeOH (9:1v/v) as an eluent, the crude product was refined by flash chromatography, yielding pure products 6a–f as orange and yellow solids.

(E)-N-(3-((5-methyl-5H-indolo[2,3-b]quinolin-11-yl)amino)propyl)-4-(phenyldiazenyl) benzenesulfonamide (6a): Yield 415 mg (75%), orange solids; mp 180–182 °C; IR (KBr) νmax/cm−1 3445, 2926, 2857, 1589, 1456, 1282.1H NMR (600 MHz, DMSO-d6) δ 8.48 (m, 2H, NH), 8.37 (d, J = 8 Hz, 2H), 7.94–7.90 (m, 2H), 7.89 (m, 2H), 7.79 (d, J = 8.0 Hz, 2H), 7.64 (dt, J = 17.0, 8.5 Hz, 3H), 7.53–7.48 (m, 1H), 7.33–7.29 (m, 1H), 7.20 (t, J = 4 Hz, 1H), 7.11 (m 1H) 6.89 (d, J = 4 Hz, 1H), 6.79 (d, J = 4 Hz, 1H) 4.14 (s, 3H), 3.84 (m, 2H), 2.76 (m, 2H), 1.85–1.83 (m, 2H). 13C NMR (101 MHz, DMSO) δ 153.54, 151.84, 142.05, 137.14, 132.43, 131.17, 129.66, 129.50, 127.79, 127.28, 126.77, 125.07, 124.13, 123.12, 123.05, 122.92, 122.63, 122.29, 122.16, 120.15, 118.88, 115.86, 115.44, (27C, Ar), 45.50 (1C, CH3), 36.03 (1C, CH2), 32.98 (1C, CH2) 30.57 (1C, CH2). Anal. Calcd for C31H28N6O2S (548.20): C, 67.86; H, 5.14; N, 15.32; S, 5.84; found: C, 67.22; H, 5.32; N, 15.98; S, 5.65.

(E)-N-(2,2-dimethyl-3-((5-methyl-5H-indolo[2,3-b]quinolin-11-yl)amino)propyl)-4-(phenyldiazenyl)benzenesulfonamide (6b): Yield 420 mg (72%), yellow solids; mp 162–164 °C; IR (KBr) νmax/cm−1 3453, 2927, 2850, 1590, 1457,1131. 1H NMR (400 MHz, DMSO-d6) δ 8.49 (m, 2H, NH), 7.98 (d, J = 4 Hz, 2H), 7.97–7.94 (m, 2H), 7.89 (d, J = 4.0 Hz, 2H), 7.83 (dt, J = 8, 8.5 Hz, 3H), 7.66–7.64 (m, 2H), 7.52 (d, J = 4 Hz, 2H), 7.49 (d, J = 4 Hz, 1H), 7.33 (t, J = 4 Hz, 1H), 7.14 (t, J = 4 Hz, 1H), 6.81 (d, J = 4 Hz, 1H) 4.16 (s, 3H), 3.74 (d, J = 4 Hz, 2H), 2.60 (d, J = 4 Hz,, 2H), 0.73 (2, 6H). 13C NMR (101 MHz, CDCl3) δ 151.91, 151.66, 150.67 (2C), 131.69(2C), 129.65(4C), 129.51, 128.00(3C), 126.79, 123.03(5C), 122.91(2C), 122.61(2C), 122.19(2C), 116.48, (27C, Ar), 67.03 (1C, CH2), 45.27 (1C, CH2), 25.23 (1C, CH3), 23.06, (1C,), 8.43(2C, 2CH3). Anal. Calcd for C33H32N6O2S (576.23): C, 68.73; H, 5.59; N, 14.57; S, 5.56; found: C, 68.52; H, 5.31; N, 14.02; S, 5.11.

(E)-N-(3-((2-bromo-5-methyl-5H-indolo[2,3-b]quinolin-11-yl)amino)-2,2-dimethylpropyl)-4-(phenyldiazenyl)benzenesulfonamide (6c): Yield 401 mg (61%), orange solids; mp 184–186 °C; IR (KBr) νmax/cm−1 3441, 2920, 2840, 1560, 1383, 1070. 1H NMR (400 MHz, DMSO-d6) δ 8.68 (s, 1H, NH), 8.43 (s, 1H, NH), 8.15–7.96 (m, 2H), 7.95–7.91 (m, 2H), 7.89 (m, 2H), 7.84 (dt, J = 4, 8.5 Hz, 4H), 7.78 (d, J = 4 Hz, 2H), 7.77–7.71 (m, 2H), 6.65 (d, J = 4 Hz, 1H), 6.62–6.50 (m, 1H), 7.19–7.16 (dd, J = 4 Hz, 1H) 4.38 (s, 3H), 4.03 (s, 2H), 3.24 (d, J = 4 Hz, 2H), 1.28 (s, 6H). 13C NMR (101 MHz, CDCl3) δ 149.54, 136.49, 131.86, 130.19, 125.21, 124.79, 124.12, 122.16, 118.68,117.19, 116.26, 114.66, (27C, Ar), 62.62 (1C, CH2), 53.35 (1C, CH2) 36.24, (1C, CH3) 33.12 (1C, CH), 24.01, 21.70 (2C, 2CH3). Anal. Calcd for C33H31BrN6O2S (654.14): C, 60.46; H, 4.77; Br, 12.19; N, 12.82; O, 4.88; S, 4.89; found: C, 60.82; H, 4.71; N, 12.22; S, 4.41.

(E)-N-(3-((2-fluoro-5-methyl-5H-indolo[2,3-b]quinolin-11-yl)amino)propyl)-4(phenyldiazenyl)benzenesulfonamide (6d): Yield 401 mg (56%), yellow solids; mp 201–203 °C; IR (KBr) νmax/cm−1 3449, 2925, 2857, 1590, 1458, 1072. 1H NMR (400 MHz, DMSO) δ 8.78 (d, J = 4 Hz, 1H), 7.90–7.87 (m, 2H), 7.62 (d, J = 4.0 Hz, 2H), 7.61 (dt, J = 4, 8.5 Hz, 4H), 7.35 (t, J = 4 Hz, 2H), 7.20–7.15 (m, 3H), 6.91 (d, J = 4 Hz, 1H), 6.80 (d, J = 4 Hz, 1H), 4.12 (s, 3H), 3.84 (s, 1H, NH), 3.56 (s, 1H, NH) 3.35 (dd, J = 4 Hz, 2H), 2.78 (d, J = 4 Hz, 2H), 1.89–1.86 (m, 2H). 13C NMR (101 MHz, DMSO) δ 153.92, 152.33, 152.24, 152.05, 142.52, 136.41, 133.88, 130.04, 129.91, 128.22, 127.18, 126.67, 125.68, 123.43, 123.32, 123.03, 122.60, 120.56, 118.06, 115.83, (26C, Ar), 67.45(1C, CH2), 52.45 (1C, CH2), 45.80 (1C, CH3), 25.55(1C, CH2). Anal. Calcd for C31H27FN6O2S (566.19): C, 65.71; H, 4.80; F, 3.35; N, 14.83; O, 5.65; S, 5.66; found: C, 65.14; H, 4.41; N, 14.91; S, 5.88.

(E)-N-(1-((5-methyl-5H-indolo[2,3-b]quinolin-11-yl)amino)propan-2-yl)-4-(phenyldiazenyl)benzenesulfonamide (6e): Yield 348 mg (54%), orange solids; mp 190–193 °C; IR (KBr) νmax/cm−1 3436, 2914, 2820, 1510, 1320, 1030. 1H NMR (400 MHz, DMSO) δ 8.46 (S, 2H, NH), 8.02 (d, J = 8 Hz, 2H), 7.94–7.90 (m, 4H), 7.80–7.76 (m, 3H), 7.61 (d, J = 4 Hz, 2H), 7.51 (t, J = 8 Hz, 2H), 7.39 (t, J = 8 Hz, 1H), 7.10–7.06 (m, 2H), 6.77 (d, J = 4 Hz, 1H), 4.12 (s, 3H), 3.85–3.78 (m, 2H), 2.81 (s, 1H),1.20 (s, 3H). 13C NMR (101 MHz, CDCl3) δ 162.72, 156.47, 153.94, 152.29, 148.38, 144.0, 137.68, 132.78, 131.12, 130.04, 128.06, 125.26, 124.34, 124.11, 123.52, 123.32, 122.53, 121.20, 118.64, 116.83, 115.76, 115.46, 104.95, (27C, Ar), 54.0 (1C, CH3), 50.59 (1C, CH2), 32.77 (1C, CH), 18.77 (1C, CH3). Anal. Calcd for C31H28N6O2S (548.20): C, 67.86; H, 5.14; N, 15.32; O, 5.83; S, 5.84; found: C, 67.20; H, 5.56; N, 15.50; S, 5.88.

(E)-N-(4-((5-methyl-5H-indolo[2,3-b]quinolin-11-yl)amino)butyl)-4-(phenyldiazenyl) benzenesulfonamide (6f): Yield 402 mg (71%), yellow solids; mp 214–216 °C; IR (KBr) νmax/cm−1 3415, 2960, 2890, 1490, 1350, 1055. 1H NMR (400 MHz, DMSO) δ 8.51(d, J = 4 Hz 2H, NH), 7.97 (d, J = 8 Hz, 2H), 7.95–7.92 (m, 4H), 7.88–7.75 (m, 3H), 7.62 (t, J = 8.0 Hz, 1H), 7.56 (dd, J = 8, 8 Hz, 2H), 7.41 (t, J = 8 Hz, 1H), 7.28–7.21 (m, 1H), 7.07 (t, J = 4 Hz, 1H), 6.92 (d, J = 4 Hz, 1H), 6.80 (d, J = 4 Hz, 1H) 4.14 (s, 3H), 3.78 (t, J = 8 Hz, 2H), 2.71 (t, J = 4 Hz, 2H), 1.68 (t, J = 8 Hz, 2H), 1.34 (t, J = 8 Hz, 2H). 13C NMR (101 MHz, CDCl3) δ 153.99, 152.27, 148.82, 142.78, 137.75, 132.81, 131.16, 130.05, 129.22, 128.27, 127.75, 125.08, 124.41, 124.30, 123.52, 123.33, 122.48, 121.19, 120.56, 118.62, 116.70, 116.03, 115.53, (27C, Ar), 45.27, (1C, CH3), 25.13 (1C, CH2), 23.06 (1C, CH2), 28.31 (1C, CH2), 26.84 (1C, CH2). Anal. Calcd for C32H30N6O2S (562.22): C, 68.31; H, 5.37; N, 14.94; O, 5.69; S, 5.70; found: C, 68.77; H, 5.04; N, 14.93; S, 5.88.

2.4 Printing and Fastness Determination

2.4.1 Printing Paste Procedure

The essential component ratios for the printing paste are displayed in Table 1. Using the conventional silkscreen-printing method, polyester fabric samples were printed using the aforementioned printing paste. After letting the prints samples dry at room temperature, they were thermofixed for 4 min at 180 °C. Enhancing the mobility of dye molecules and hastening the transfer of dye from the printed film to the fabric are contingent upon the fixing temperatures. During thermofixing process, the textiles were subjected to simultaneous temperature treatment and stretching (tension). The textiles samples are stretched between a metal holder and inserted into a thermofixation device (180 °C for 4 min in an automatic thermostatic oven (Fyianyuan Instrument Co., model number LD-3642 China).The prints underwent four distinct washing procedures: two rounds of cold water treatment, two rounds of hot water treatment, two rounds of cold water treatment, 30 min at 60 °C, 2 g/L nonionic detergent, and drying.

2.4.2 Color Assessment

Using a Hunter Lab Ultra Scan PRO spectrophotometer, the colorimetric properties of the printed polyester fabric samples were measured following methods. It is assumed that the (K/S) values are proportionate to the dye concentration on the fiber under the printing conditions, at least at the dye concentration used (3.0 g in the paste), after the printed samples have been completely cleaned. The color intensity was determined using the Kubelka–Munk equation Eq. (1) as K/S value [4]:

R = decimal fraction of the dyed fabric reflection, K = absorption coefficient, and S = scattering coefficient.

2.4.3 Fastness Properties Methods

Standard ISO procedures were used to assess the fastness characteristics of printed samples. These procedures included washing, rubbing, perspiration, light, and sublimation. The outcomes are documented in Tables 3 and 4. The wash fastness test was assessed in accordance with the standard method ISO 105-C06 B2S (2012) using 4 g/L of ECE detergent, 1 g/L of sodium perborate, 25 steel balls) at 50 °C for 30 min and at a liquor ratio of 50:1 [25]. The rubbing fastness test was carried out in accordance with ISO 105-X12:2001 as follows; the dyed polyester fabric was placed on the base of the Crockmeter, so that it rested flatly on the abrasive cloth with its long dimension in the direction of rubbing. A square of white testing fabric was allowed to slide on the tested fabric back and forth twenty times by making ten complete turns of the crank. For the wet rubbing test, the testing squares were thoroughly immersed in distilled water. The rest of the procedure was the same as in the dry test. The staining on the white testing fabric was assessed according to the gray scale: 1—poor, 2—fair, 3—moderate, 4—good, and 5—excellent [26]. Fastness to acidic and alkaline perspiration was determined with a perspirometer set at specific pressure, temperature and time in accordance with ISO 105-E04. Any change in color of the dyed samples (Alt) and color staining on the adjacent undyed cotton (SC) and polyester (SP) fabrics was then assessed with the corresponding ISO grey scales for color change and staining rates [27]. Light fastness was also assessed using a Xenon arc lamp test in accordance with ISO 105-B02 [28]. The dry heat fastness test was carried out using a fixometer at 180 or 210 °C in accordance with ISO 105-P01 [29]. Any change in color (Alt) of the specimens and color staining of the adjacent cotton (SC) and polyester (SP) was then assessed with the corresponding ISO grey scales for color change and staining.

2.5 Microorganisms

The strains used in the antimicrobial activity test such as Salmonella typhimurium ATCC 14028, Staphylococcus aureus ATCC 6538, Escherichia coli ATCC 8739, Listeria monocytogenes ATCC 5980, and Bacillus cereus B-3711 were collected from the Dairy Department, National Research Centre, Egypt. The well diffusion agar method [30] was used to test the antibacterial activity of (6a–6f). The compounds were screened for antibacterial activity against two gram positive bacteria (Staphylococcus aureus and Bacillus cereus) and three gram negative bacteria (Escherichia coli, Salmonella typhimurium, and Yersinia enterocolitica). First, the examined microorganisms were struck on Mueller–Hinton agar medium to initiate their activation. They were removed from the agar medium surface after being incubated for the entire night at 37 °C. In nutritional agar (Merck, Germany), fresh inoculants were prepared for antimicrobial testing and incubated for 24 h at 37 °C. A sterile 3 mM phosphate buffer (KH2PO4; pH 6.8) was used to dilute the incubated test culture, resulting in a final concentration of 1.5–3 × 105 CFU/mL. Subsequently, 20 µl of per strain were swabbed onto the nutrient agar surface. The compounds (6a–6f) under investigation were produced as stock solutions at a concentration of 1 mg/mL. To aid in the diffusion of the chemicals into the agar medium, dimethyl sulfoxide solution (DMSO) was added. For the anti-bacterial and antifungal assay (10 μg/disk), sterile discs were impregnated with 10 µL of each compound. For each spread plate that was infected, a loading control containing 10 µL of dimethyl sulfoxide (DMSO) was also created. Using sterile forceps, the discs of (6a–6f) were placed on the agar plate. Gently press down on each disc to guarantee full contact with the agar surface. The flipped plates were incubated for 18 h at 37 °C to grow bacteria. Using sliding calipers that are held on the back of the inverted Petri plate, the diameter of the inhibitory zones was measured to the closest whole millimeter, including the diameter of the disc. (ZOI) of diameter, given in centimeters, was recorded as mean values (n = 3). When the diameter of the inhibition zone was between 10 and 15 mm, it was defined as having high activity; when it was between 7 and 10 mm, it was classed as having low activity; and when it was less than 7 mm, it was classified as having no activity. Every data were computed in triplicate using a mean ± SD pattern.

2.5.1 Assessment of Antibacterial Activity of the Printed Fabrics

The antibacterial activity of fabric samples treated with synthetic chemicals 6a–f was assessed using the colony forming unit (CFU) method [31]. Staphylococcus aureus ATCC 6538-P (a G + ve bacterium) and Escherichia coli ATCC 25933 (a G-ve bacterium) were the test strains that were used. 100 µL of freshly made liquid nutrient broth containing 5 g/L peptone and 3 g/L beef extract at pH 6.8 were filled with bacterial stocks (100 µL of stock with a CFU value of about 108) and incubated for a whole day. In 100 mL conical flasks, the bacterially infected medium was supplemented with fabrics each containing roughly 250 mg. 20 µL of bacterial inoculums was added to each flask containing 10 mL of culture media, with the control group consisting of inoculated flasks without samples. Following a 24-h incubation period at 37 °C, each sample containing the culture and the controls was serially diluted (10–1–10–4). Colony forming units (CFU) were used to measure the microbial inhibition. 50 µL of each dilution was added to petri dishes containing solidified nutrient agar medium, and the reduction growth (R%) between treated and untreated samples was computed using the following formula:

where \(A\) is CFU/mL for treated sample after 16 h incubation and \(B\) is CFU/mL for untreated sample after the same period of incubation time. At 600 nm, the incubated liquid culture medium's optical density was measured. The optical density figure was consequently directly proportional to the number of bacteria in the media; the higher the growth, the higher the turbidity.

3 Results and Discussion

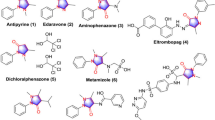

In this study, a series of neocryptolpine derivatives were conjugated with the azo-sulfonyl moiety through sulfonamide bond, utilizing different lengths of the diaminoalkyl spacers. 11-Chloroneocryptolepine derivatives would be promising precursors for the development of new functional substrates. The methodology for the synthesis of the building blocks, chloroneocryptolpines, has been already published according to previously method [23, 24]. The typical procedure includes a variety of steps, starting with the reaction between substituted N-methylaniline and indole-3-carboxylate using N-chlorosuccinnimide as a coupling reagent to generate the corresponding N-methyanilinoindole-3-carboxylate 2a–c. The thermal cyclization of the 2a–c took place under refluxing with diphenyl ether through intramolecular acylation at the C-2 of aniline, forming the tetracyclic indoloquinolinone 3a–c. Upon treatment, the indoloquinolinones with oxyphosphoric acid afforded the desired precursors, 11-chloroneocryptolepines 4a–c, as a result of dehydrative chlorination. Monofunctional neocryptolepines with the free amino group 5a–f were synthesized through the amination process of the chloro neocryptolepines 4a–c with varying diaminoalkyl linkers Scheme 1.

Synthesis chloroneocryptolepine and the corresponding aminoalkylaminoneocryptolepine derivatives. Reagents and conditions: (i) (a) N-chlorosuccinimide, 1,4-dimethylpiperazine, CH2Cl2, 0 °C, 2 h; (b) trichloroacetic acid, RT, 2 h; (ii) diphenyl ether, reflux, 1–3 h; (iii) POCl3, toluene, reflux, 6–12 h; (iv) appropriate amines, 135–155 °C. 1-4 h

Azo chromophore-linked neocryptolpine dyes 6a–f were synthesized by the sulfonylation of aminoalkylamines 5a–f with the electrophilic reagent, azo benzene sulfonyl chloride in the presence of dry DMF under basic condition, as depicted in Scheme 2.

3.1 Color Strength Measurements (K/S) and Analyses

A Hunter Lab Ultra Scan PRO spectrophotometer was used to measure the colorimetric properties of all the dyed samples. The value of (a*) indicates the degree of redness (positive) and greenness (negative), and the value of (b*) indicates the degree of yellowness (positive) and blueness (negative). L* stands for lightness (100 denotes white, 0 denotes black) [32]. The Kubelkae Munk equation shows a direct correlation between the recorded K/S values provided by the reflectance spectrometer and the dye concentration on the dye substrate. Table 2 presents the acquired results.

On polyester fabrics, the color coordinates indicate that the dyes have good affinity with moderate to very good brightness and depth.The color lightness value (L*) of the dyes 6a–f vary from (16.44–33.03). It was observed that all of the colors showed good saturation. In our investigation, the hues of the colors are pushed towards reddish and yellowish on the red–green axis and yellow–blue axis, respectively, according to the color coordinates a* and b* values. The K/S values, which determine the range of print values, are clearly influenced by the chemical structure and kind of substituent on the aromatic moiety of the dye generated. The results were better and the color strength of the dyes was higher. This might be by introducing –SO2NH– group is effective in increasing the fastness and K/S values [33].

3.2 Structure Activity Relationship (SAR) Studies on Color and Fastness Properties

By changing the length and structure of the linker that connects the two nitrogen atoms as well as the substitution pattern of the distal amino group, we tried to investigate a variety of indoloquinoline analogues with different side-chains. This resulted in various color strength (K/S) and fastness properties of the synthesized azo disperse dye derivatives.

The side chains at C11 of 5a–f were introduced by using the reaction 4a–c with branching 1,2-diaminopropane and 1,3-diaminopropanes 6b, 6c, and 6e. They were compared to compounds 6a, 6d, and 6f, which lacked a branched aminoalkylamino substituent at C-11, in terms of color strength and fastness properties. According to the data, dye 6c absorption wavelength (λmax) 420 nm, which is a significant improvement (λmax) over other dyes. This could be because having bromine atoms in it. There is an effect known as the “heavy atom effect” when bromine is involved [34]. It was noticed that the length of alkyl diamine linking group allocated between the indoloquinoline and phenylazosulphonyl groups has slightly effect on the color strength and the dye uptake of the shorter propane-1,2-diamine group 6e was higher than the dyes 6a and 6f of propyl and butyl groups, respectively. Table 3 shows that all dyes have good fastness properties for washing, perspiration, sublimation, and light. However, when rubbing, the large dye molecules (such as 6c) readily generate as big particles of dye floating color on the surface of the fiber after printing. Furthermore, the dye's concentration is typically excessively high, which reduces its fastness against rubbing [35].

3.3 Fastness Properties

3.3.1 Washing Fastness

The capacity of colored materials to hold onto their color after being washed with soap and detergent is known as wash fastness. Results from polyester textiles printed with dyes 6a–f ranged from good to excellent (3–5). Due to their increased size, they will be pushed into the interpolymer chain area of the polyester fabric, increasing the quantity of aromatic rings and hydrophobicity.

3.3.2 Perspiration Fastness

Table 3 provides information on perspiration fastness (in basic and acidic solutions). The molecular weight of the dye and the force of attraction that binds the azo dispersion dye to the polyester fabric have an impact on how well the dye is removed from the fabric's surface. The grey scale was used to evaluate the differences in color. The polyester fabric printed with dyes 5a–f produced very good-to-excellent (4–5) results.

3.3.3 Rubbing Fastness

Table 3 illustrates how the surface of the printed polyester fabric was cleaned of loosely oriented or adherent dye structure. After printing, the dye has a lower rubbing colorfastness, a larger dye molecule, and is more inclined to produce big dye particles floating on the fiber's surface. The aim of this experiment (both wet and dry) is to find out how much color is transferred by rubbing from the surface of colored materials to another undyed fabric surface. Most of dyes have good rubbing fatness, which may be due to greater dye fixing on fabric or enough dye molecule absorption into textiles.

3.3.4 Light Fastness

One of the most crucial things to check for dyed textiles that will be exposed to light during use is their light fastness. It establishes how long and printed dyes resist fading under sunlight irradiation. On a normal blue scale of one to eight, where one was very poor and eight was excellent, it was given a grade. Light fastness describes how well a dye resists fading when exposed to sunlight. Most produced heterocyclic disperse azo dyes have acceptable light fastness (5–7).

3.3.5 Sublimation Fastness

The results for sublimation fastness are displayed in Table 4. Heat treatment has an impact on the migration of azo dispersion dyes from polyester fabric surfaces. Positive findings that matched the global geometric gray scale were routinely obtained from the sublimation fastness tests using the undyed polyester-cotton fabric. The successful sublimation of colors may depend on various elements, such as the presence of SO2NH groups in all dyes and the polarity of the substituent groups [36].

3.4 Antimicrobial Activities

The antibacterial activities of the screened compounds (6a–6f) differed depending on the tested compound and the screened microbial strains, according to the results of the antimicrobial activities of the compounds (Table 5). The chemicals under investigation demonstrated varying degrees of inhibition of the metabolic growth of the tested bacteria, indicating their broad spectrum features. The diverse configurations and substituents of the examined compounds undoubtedly held a significant influence and were deemed the fundamental element responsible for their biological action. The presence of indoloquinoline functional groups may account for the observed compounds' activity.

Herein, we highlighted that compound (6a) exhibited promising antibacterial activity against S. typhmirum and L. monocytogenes (17.5 ± 0.07 and 15.5 ± 0.14 mm, respectively) (Fig. 2A, D), and moderate activity against S. aureus and B. cerus (9.5 ± 0.07 and 12 mm) (Fig. 2B, C). On the other hand, compound (6b) showed a potent activity against S. typhmirum strain (14.5 ± 0.35 mm); also, compounds (6d, 6e and 6f) displayed satisfactory activities against S. typhmirum range between (9.5–15.5 mm). However, an entirely different trend in antibacterial activity against E. coli was observed with all compounds that were inactive Table 5. The presence of electron withdrawing group (F) substituent on compound (6d) improves the antibacterial activity against S. aureus and S. typhmirum (15 and 13 ± 0.14, respectively) that is supported by Sharma studies [37].

3.4.1 Colony-Forming Unit (CFU) Results

Printed polyester fabrics by dyes 6a–f were screened for their in vitro antibacterial activities against Staphylococcus aureus (Gram positive) and L.monocytogenes (Gram negative). The results obtained are recorded in Table 6. Using the AATC 100–1999 method, the antibacterial activity of treated fabrics was also studied. Table 6 shows the results of antibacterial test after four washings cycle of polyester fabrics that were printing with noval synthetic dyes. As can be seen from the results in Table 6, the colored materials exhibit varied degrees of inhibition against the tested bacteria. According to the antimicrobial results, Staphylococcus aureus is significantly inhibited by the dyed fabric with color (6f) within 18 h of contact time. Interestingly, the fabric colored with 6b showed the strongest antibacterial activity against L. monocytogenes, with a reduction of more than 85%, among all dyed fabrics. The method of antimicrobial activity evaluation and the population of microorganisms determine the level of interest in a particular antimicrobial azo sulfonamide dye. In addition, newly produced substances have the ability to prevent bacterial growth by deactivating protein synthesis by reacting with thiol groups [38,39,40] or to prevent DNA replication by reacting with phosphorus moieties.

4 Conclusions

A novel class of dispersing azo dyes with a chromophore of neocryptolepine has been synthesized and evaluated. The new synthetic dyes allowed for silkscreen printing on polyester fabrics. The dyes produced have color measurements and light fastness capabilities ranging from moderate to high, concerning washing, perspiration, rubbing, and light fastness. Once the dyes are successfully synthesized, new antimicrobial azo disperse dyes with improved significance tests ought to be created.

Data availability

The authors declare that the data supporting the findings of this study are available within the paper. Should any raw data files be needed in another format they are available from the corresponding authors upon reasonable request.

References

S. Benkhaya, S. M’rabet, A. El Harfi, Heliyon 6, e03271 (2020)

A. Abel, The history of dyes and pigments, 2nd edn. (Elsevier Ltd., Amsterdam, 2012)

Y. Qian, G. Wang, G. Xiao, B. Lin, Y. Cui, Dyes Pigm. 75, 460 (2007)

N.H. Bahtiti, W.E. Elgammal, A.A. Ali, A. Belal, O. Abdullah, M.M. Ghoneim, M.S. Qenawy, M.M. Abdou, ACS Omega 9, 447 (2024)

M. Metwally, S. Bondock, I. El-Desouky, M. Abdou, Color. Technol. 129, 1 (2013)

M. Metwally, S. Bondock, S. El-Desouky, M. Abdou, J. Korean Chem. Soc. 56, 82 (2012)

M. Metwally, S. Bondock, S. El-Desouky, M. Abdou, J. Korean Chem. Soc. 56, 348 (2012)

M. Abdou, Am. J. Chem. 3, 59 (2013)

M. Metwally, S. Bondock, I. El-Desouky, M. Abdou, Am. J. Chem. 2, 347 (2012)

M. Metwally, S. Bondock, S. El-Desouky, M. Abdou, Int. J. Mod. Org. Chem. 1, 165 (2012)

M. Abdou, Am. J. Chem 3, 126 (2013)

I. A. El-Thalouth, M. Rekaby, A.H. Abdel-Rahman, A. El-khabery Sh, Res. J. Text. Appar. 16(1), 68 (2012)

F.A. Mohamed, E. Shaban, H.M. Ibrahim, Egypt. J. Chem. 65, 597 (2022)

X. Yan, Z. Lv, J. Wen, S. Zhao, Z. Xu, Eur. J. Med. Chem. 143, 899 (2018)

W.J. Lu, M. Świtalska, L. Wang, M. Yonezawa, I.E.T. El-Sayed, J. Wietrzyk, T. Inokuchi, Med. Chem. Res. 22, 4492 (2013)

N. Wang, K.J. Wicht, L. Wang, W.J. Lu, R. Misumi, M.Q. Wang, A.A.A. El Gokha, M. Kaiser, I.E.T. El Sayed, T.J. Egan, T. Inokuchi, Chem. Pharm. Bull. 61, 1282 (2013)

N. Altwaijry, S. El-Ghlban, I.E.T. El Sayed, M. El-Bahnsawye, A.I. Bayomi, R.M. Samaka, E. Shaban, E.I. Elmongy, T.A. El-Masry, H.M.A. Ahmed, N.G.M. Attallah, Molecules 26, 754 (2021)

M. von Itzstein, Angew. Chemie Int. Ed. 50, 6705 (2011)

J. Lavrado, R. Moreira, A. Paulo, Curr. Med. Chem. 17, 2348 (2010)

K. Cimanga, T. De Bruyne, L. Pietars, M. Claeys, A. Vlietinck, Tetrahedron Lett. 37, 1703 (1996)

K. Cimanga, T. De Bruyne, L. Pieters, J. Totte, L. Tona, K. Kambu, D. Vanden Berghe, A.J. Vlietinck, Phytomedicine 5, 209 (1998)

S.S. Ragab, A.M.K. Sweed, Z.K. Hamza, E. Shaban, A.A. El-Sayed, Fibers Polym. 23, 2114 (2022)

I. El Sayed, P. Van Der Veken, K. Steert, L. Dhooghe, S. Hostyn, G. Van Baelen, G. Lemière, B.U.W. Maes, P. Cos, L. Maes, J. Joossens, A. Haemers, L. Pieters, K. Augustyns, J. Med. Chem. 52, 2979 (2009)

E. Shaban, M. Switalska, L. Wang, N. Wang, F. Xiu, I. Hayashi, T.A. Ngoc, S. Nagae, S. El-Ghlban, S. Shimoda, A.A.A. El Gokha, I.E.T. El Sayed, J. Wietrzyk, T. Inokuchi, Molecules 22(11), 1954 (2017)

SIST EN ISO 105-C06:2012-Textiles-Tests for Colour Fastness-Part C06: Colour Fastness to Domestic and Commercial Laundering (ISO 105-C06:2010). https://standards.iteh.ai/catalog/standards/sist/0b4ae06f-25ab-4d0a-ab27-21fb0b32e8cc/sist-en-iso-105-c06-2012. Accessed 12 Sept 2022

ISO 105-X12:2001-Textiles-Tests for Colour Fastness-Part X12: Colour Fastness to Rubbing.: https://standards.iteh.ai/catalog/standards/iso/877d92c5-fbfe-490c-8275-7415d38cc3e8/iso-105-x12-2001. Accessed 12 Sept 2022

ISO 105-E04:2008 (Textiles-Tests for Colour Fastness-Part E04: Colour Fastness to Perspiration).https://www.iso.org/cms/render/live/en/sites/isoorg/contents/data/standard/04/13/41374.html. Accessed 12 Sept. 2022

ISO 105-B02:2014(En), Textiles-Tests for Colour Fastness-Part B02: Colour Fastness to Artificial Light: Xenon Arc Fading Lamp Test Available online: https://www.iso.org/obp/ui/#iso:std:iso:105:-B02:ed-6:v1:en . Accessed on 12 Sept 2022

EN ISO 105-P01:1995-Textiles-Tests for Colour Fastness-Part P01: Colour Fastness to Dry Heat. https://standards.iteh.ai/catalog/standards/cen/50d2e435-1a82-49fe-b512-79d62b38e5f8/en-iso-105-p01-1995. Accessed 12 Sept 2022

K.E. Anwer, Z.K. Hamza, R.M. Ramadan, Sci. Rep. 13(1), 15598 (2023)

D. Gupta, S.K. Khare, A. Laha, Color. Technol. 120, 167 (2004)

H.A. Hekal, R.M. Kassab, H.A. Abd El Salam, E. Shaban, F.M. Atlam, ChemistrySelect 8(14), e202204075 (2023)

L. Yang, Z. Xu, H. Li, C. Wang, Y. Wang, C. Lu, Fibers Polym. 22, 1000 (2021)

E.M. Kirilova, A.I. Puckins, E. Romanovska, M. Fleisher, S.V. Belyakov, Spectrochim. Acta A Mol. Biomol. Spectros. 202, 41 (2018)

F. Wang, L. Wang, X. Cai, Y. Sun, L. Su, L. Zhang, G. Wang, Color. Technol. 128, 425 (2012)

S.M. Al-Mousawi, M.A. El-Apasery, M.H. Elnagdi, Molecules 18, 11033 (2013)

D. Sharma, B. Narasimhan, P. Kumar, V. Judge, R. Narang, E. De Clercq, J. Balzarini, Eur. J. Med. Chem. 44, 2347 (2009)

S. Alsharif, S. Salah Salem, M. Abdel-Rahman, A. Fouda, A. Eid, E.-D. Saad, S. Hassan, M. Ahmed Awad, A. Mohamed, Heliyon 6, 03943 (2020)

A. Fouda, G. Abdel-Maksoud, M.A. Abdel-Rahman, A.M. Eid, M.G. Barghoth, M.A.-H. El-Sadany, Cellulose 26, 6583 (2019)

K.M. Hassan, S.A.S. ElKhabiery, G.M. ElHaddad, J. Iran. Chem. Soc. 19, 147 (2022)

Acknowledgements

The authors extend their appreciation to Deanship of Scientific Research at King Khalid University for funding this work through the large Group Research Project under grant number (RGP. 2/344/45).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Alzahrani, A.Y., Rizk, H.F., Hamza, Z.K. et al. Design, Synthesis, Antibacterial Activity, and Printing Performance of a Novel Class of Neocryptolpine Azo Disperse Dyes. Fibers Polym (2024). https://doi.org/10.1007/s12221-024-00675-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12221-024-00675-5