Abstract

Economical water electrolysis requires highly active non-noble electrocatalysts to overcome the sluggish kinetics of the two half-cell reactions, oxygen evolution reaction, and hydrogen evolution reaction. Although intensive efforts have been committed to achieve a hydrogen economy, the expensive noble metal-based catalysts remain under consideration. Therefore, the engineering of self-supported electrocatalysts prepared using a direct growth strategy on three-dimensional (3D) nickel foam (NF) as a conductive substrate has garnered significant interest. This is due to the large active surface area and 3D porous network offered by these electrocatalysts, which can enhance the synergistic effect between the catalyst and the substrate, as well as improve electrocatalytic performance. Hydrothermal-assisted growth, microwave heating, electrodeposition, and other physical methods (i.e., chemical vapor deposition and plasma treatment) have been applied to NF to fabricate competitive electrocatalysts with low overpotential and high stability. In this review, recent advancements in the development of self-supported electrocatalysts on 3D NF are described. Finally, we provide future perspectives of self-supported electrode platforms in electrochemical water splitting.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The limited reserves of traditional fossil energy sources and many environmental problems resulting from their use have prompted many researchers to search for efficient and clean renewable energy sources. Among various clean energy technologies, electrochemical water splitting from renewable power is one of the most promising strategies to produce sustainable hydrogen as a green chemical fuel and energy carrier [1, 2]. However, the slow kinetics of the two half-cell reactions, namely the oxygen evolution reaction (OER) and hydrogen evolution reaction (HER) at the electrode interfaces, remain the major obstacle to hydrogen economy [3, 4]. Thus, extensive attention has been paid to design highly active electrocatalysts for overall water splitting. Noble metal-based electrocatalysts, specifically Ru/Ir- and Pt-based materials, are still the most employed electrocatalysts for OER and HER, respectively, but their high cost and scarce elemental reserves restrict their further applications [5, 6]. Transition metal-based catalysts have components with a rich modulation range, including hydroxides [7], oxides [8], carbides [9], sulfides [10], phosphides [11], and nitrides [12]. Although they are easily fabricated and cheap, their electrocatalytic activity and long-term stability need improvement [13].

Different types of electrocatalysts are often prepared in the form of powder particles and developed with binders (i.e., Nafion) and conductive agents (i.e., carbon black) to form a slurry-like paste, which is then coated on the conductive substrates or known as current collectors (Fig. 1a) [14], which are utilized to prepare electroactive substrates. However, binders can clog the active sites and hinder electron transfer processes [15, 16]. Conductive agents oxidize at higher operating potentials and limit the mass transfer of reactants [17]. Moreover, under prolonged scouring of the gas bubbles produced by water electrolysis, the electrocatalytic coating tends to detach from the electrode surfaces, resulting in a decrease in or even the disappearance of catalytic activity [18]. To overcome these issues, binder-free self-supported electrocatalysts have been developed, which can be directly grown on conductive substrates (Fig. 1b) [14]. The main advantages of fabricating such self-supported electrocatalysts over powdery-coated ones are as follows:

-

1. Simple electrode preparation steps can be performed while reducing the manipulating cost and loading mass [19, 20].

-

2. More active sites are exposed at the interface without using binders or conductors [21, 22].

-

3. The catalyst particles are firmly attached to the current collector, which significantly reduces the possibility of mechanical detachment [23].

-

4. Stability and catalytic activity can be further improved by forming hydrophilic/hydrophobic interfaces by modulating the morphology and microstructure of the active substances [24, 25].

a Schematic illustration of coated powdery-type electrocatalysts; b schematic illustration of self-supported electrocatalyst. Reproduced with permission from Ref. [14]. Copyright © 2021, Wiley

These abovementioned advantages make self-supported electrocatalysts more applicable for practical engineering applications. Therefore, various conductive substrates have been used for growing many self-supported electrocatalysts, such as carbon paper [26], titanium foil [27], stainless steel [28], nickel foam (NF) [29], and copper foam [30]. Among them, NF is the most preferred conductive substrate because of its high electrical conductivity, large specific surface area for high catalyst loading and good dispersion, and continuous porous structure that facilitates mass transfer and gas bubble diffusion [31].

In fact, detailed reviews on self-supported electrocatalysts and conductive substrates have been published [14, 19, 23, 32,33,34,35,36,37,38,39]. However, no systematic review has reported surface modification strategies and related research progress on NF substrates. In this brief review, we put emphasis on several surface modification strategies commonly utilized for the direct growth of self-supported electrocatalysts on NF substrates, such as hydrothermal- and microwave-assisted growth, electrodeposition, chemical vapor deposition (CVD), and plasma treatment. Finally, we offer perspectives and challenges regarding self-supported electrode materials in water electrolysis.

Hydrothermal-Assisted Growth of Nanostructured Materials on the NF

The hydrothermal strategy is defined as the formation of materials in aqueous solutions using consecutive steps of dissolution and recrystallization in a closed system at high temperature and high pressure [40].

Therefore, volatilization of reactants at high temperatures, stress-induced defects, and mutual reaction between phases can be avoided. Further, the reaction conditions, such as composition, time, and temperature, can be easily controlled, thereby controlling the structure, size, morphology, and crystallinity of the resulting products [41, 42]. High-purity nanoparticles with good dispersibility, uniform morphology, and complete grain boundaries can be obtained [43]. These benefits make the hydrothermal strategy a promising method for the direct growth of electroactive catalysts on NF substrates. Tang et al. [44] prepared NiSe nanowires grown on NF by one-step hydrothermal treatment of NF using NaHSe as the selenium source (Fig. 2a). NiSe/NF presented remarkable bifunctional electrocatalytic activity in an alkaline 1.0 mol/L KOH electrolyte with an OER overpotential (η20) of 270 mV at 20 mA/cm2 and HER overpotential (η10) of 96 mV at 10 mA/cm2. Moreover, NiSe/NF exhibited good stability for overall water splitting after 20 h by applying a cell voltage of 1.74 V to deliver 20 mA/cm2. The corresponding Raman spectroscopy analysis disclosed the formation of an electroactive layer of NiOOH on the surface of NiSe nanowires during the electrolysis process. Thus, the authors concluded that the generation of the oxy-hydroxide phase (–OOH) might be the key factor for the outstanding bifunctional catalytic activity of NiSe/NF [45, 46]. Dinh et al. [47] also applied a one-step hydrothermal method for the in-situ growth of porous ultrathin NiFeV-LDH nanosheets on NF substrates (Fig. 2b). By preparing different molar ratios of Ni:Fe:V solutions and comparing the electrochemical efficiency, they observed that remarkable electrocatalytic performance can be realized using a molar ratio of 6:1:1 for the preparation of Ni0.75Fe0.125V0.125-LDHs/NF. The polarization curves of Ni0.75Fe0.125V0.125-LDHs/NF revealed an overpotential for OER at 231 mV and that for HER at 125 mV at a current density of 10 mA/cm2 in 1.0 mol/L KOH, which could be stabilized at 30 mA/cm2 for 15 h. The remarkable catalytic performance of Ni0.75Fe0.125V0.125-LDHs/NF is mainly due to the synergistic effect of the ternary metal system, which improves the intrinsic electrocatalytic activity, besides the ultrathin porous character, which increases the surface area and number of active sites. Zhang et al. [48] synthesized binary sulfides of Ni3S2/MnS nanosheets on NF by two-step hydrothermal treatment using KMnO4 and Na2S precursors, followed by electro-oxidation of the Ni3S2/MnS/NF substrate at 1.6 V vs. RHE to produce NF/T(Ni3S2/MnS–O) with ultrathin nanosheets and abundant oxygen vacancies (Fig. 2c). The abundant oxygen vacancies and hierarchical porous nanosheet structure not only provide enough space for penetration and diffusion of the electrolyte but also increase the number of active sites and accelerate the charge transfer process. Compared with other reported metal oxides and sulfides [49,50,51,52,53,54,55,56,57,58,59,60,61], NF/T(Ni3S2/MnS–O) showed promising electrocatalytic activity due to its low OER and HER overpotentials and small Tafel slopes (Fig. 2d, e).

a High-magnification SEM images of NiSe/NF. Reproduced with permission from Ref. [44]. Copyright © 2015, Wiley; b field-emission SEM images of Ni0.75Fe0.125V0.125-LDHs/NF. Reproduced with permission from Ref. [47]. Copyright © 2018, Wiley; c SEM images of NF/T(Ni3S2/MnS–O); d comparison of overpotential and Tafel slope of OER between the NF/T(Ni3S2/MnS–O) and reported metal oxide and sulfide catalysts; e comparison of overpotential and Tafel slope of HER between the NF/T(Ni3S2/MnS–O) and reported metal oxide and sulfide catalysts. Reproduced with permission from Ref. [48]. Copyright © 2018, Elsevier

Further improvement in the catalytic performance of self-supported electrode materials can be achieved by doping of nonmetallic elements via multistep processes. For instance, Lu et al. [62] built CoMoNx nanosheet arrays on NF by one-step hydrothermal treatment followed by nitridation in an NH3/Ar atmosphere. For the optimal CoMoNx-500 nanosheet arrays (NSAs)/NF (CoMoNx-500 NSAs/NF) at a current density of 10 mA/cm2, the 3D interconnected NSAs and the synergistic effect between Co2N and Mo2N improved the charge transfer process and further decreased the overpotentials of OER and HER to 231 mV and 91 mV, respectively. Using the CoMoNx-500 NSAs/NF as an electrolyzer for overall water splitting, a current density of 10 mA/cm2 was delivered by applying a cell voltage of 1.55 V. Similarly, Chen et al. [63] synthesized P-doped FeNiRh nanosheet arrays on NF by one-step hydrothermal treatment and continuous phosphatization. The prepared P-FeNiRh/NF demonstrated an OER overpotential of 226 mV at 30 mA/cm2 and an HER overpotential of 73 mV at 10 mA/cm2. It can be noted that, the P-FeNiRh/NF can be efficiently utilized for overall water splitting, with a cell voltage of 1.62 V required to realize a current density of 10 mA/cm2.

Microwave-Assisted Growth of Nanostructured Materials on the NF

Microwave-assisted growth is a common method for in situ growth of nanostructured materials on NF. It uses microwave arrays, which are a type of electromagnetic wave in the frequency range of 900 MHz–2.45 GHz, for controlling the heating process [64]. As an alternative heating source, microwave arrays transfer energy by causing dipole polarization and ion migration without changing the molecular structure [65]. Moreover, microwave arrays can uniformly heat the reactant at different depths, thus refining the crystal size and morphology of the nanomaterials [40]. Compared with the conventional hydrothermal method, the microwave-assisted method has a shorter initial heating period, which significantly speeds up the heating process and decreases the reaction time, whereas the hydrothermal method has a slow heat transfer mechanism, longer initial heating period, and nonconstant rate of heating (Fig. 3) [66, 67]. Thus, high material yield and pure and uniform nanoparticles with desired morphology can be easily fabricated using the microwave-assisted method [66].

With regard to monofunctional self-supported electrode materials, Duan et al. [68] employed a microwave-assisted solvothermal method to grow trimetallic molybdate nanoflowers on NF (Fig. 4a). The high specific surface area of the nanoflower-like structure and the synergistic effect between the multimetals increased the number of active sites and electrocatalytic activity. The OER overpotential of the prepared Ni0.9Al0.1MoO4/NF at 10 mA/cm2 was 266 mV, which is lower than that of the commercial RuO2/NF electrode material (274 mV) (Fig. 4b). Furthermore, Ni0.9Al0.1MoO4/NF also showed good stability for actual water splitting at a cell voltage of 1.52 V, which can deliver a current density of 10 mA/cm2 for 10 h (Fig. 4c). Furthermore, Guo et al. [69] utilized two-step hydrothermal treatments followed by microwave-assisted irradiation to grow the FeOOH/NiCo2S4 core-shell nanorod morphology on NF. It was found that the nanosheets formed by FeOOH uniformly covered the NiCo2S4 surface (Fig. 4d). The strongly coupled interface consisting of Ni/Co–S–Fe not only modulated the electronic structure of the active elements but also decreased the adsorption free energy of the reaction intermediates, which improved the catalytic activity of this electrode material. Compared with the hydrothermally synthesized NiCo2S4/NF, the microwave-irradiated FeOOH/NiCo2S4/NF showed a lower OER overpotential η10 of 198 mV, a Tafel slope of 62 mV/dec, and an outstanding stability with only 0.2% reduction after 100 h of operation at 1.49 V. (Fig. 4e, f).

a TEM images of the Ni0.9Al0.1MoO4/NF; b LSV curves of Ni0.9Al0.1MoO4/NF, NiMoO4/NF, and RuO2/NF; c Stability test of the Ni0.9Al0.1MoO4/NF (10 mA/cm2, 1 mol/L KOH). Reproduced with permission from Ref. [68]. Copyright © 2021, Wiley; d TEM images with of the FeOOH/NiCo2S4/NF; e LSV curves of NF, NiCo-precursor/NF, NiCo2S4/NF, and FeOOH/NiCo2S4/NF under 85% IR compensation; f Stability test of the FeOOH/NiCo2S4/NF (10 mA/cm2, 1 mol/L KOH). Reproduced with permission from Ref. [69]. Copyright © 2023, Springer Link

Regarding bifunctional self-supported electrode materials, Ren et al. [70] prepared RuCoMoyOx/NF using coprecipitation and microwave-assisted heating (Fig. 5a). The ratio of amorphous (RuCoMoOx) to crystalline (CoMoO4 and CoO) regions was affected by changing the reaction time, which resulted in the formation of numerous amorphous/crystalline (a/c) heterointerfaces in RuCoMoyOx/NF (Fig. 5b). The amorphous phase in the a/c heterointerface has remarkable structural flexibility due to the disordered arrangement of internal atoms, which is suitable for the reconstruction of the surface structure of the electrocatalyst and the improvement of corrosion resistance during the electrocatalytic process [71]. Concurrently, many unsaturated ligand bonds in the a/c heterointerface are involved in the construction of active sites [72]. The a/c-RuCoMoyOx/NF heterointerfaces showed remarkable bifunctional electrocatalytic activity with HER and OER overpotentials of 39 mV and 166 mV, respectively, at 10 mA/cm2. Furthermore, the a/c-RuCoMoyOx/NF could achieve a current density of 100 mA/cm2 in the overall water splitting system at a voltage of only 1.58 V and could continuously output an industrial-grade current density (500 mA/cm2) for 50 h at a constant voltage of 1.64 V (Fig. 5c, d).

a Schematic diagram of the preparation of the a/c-RuCoMoyOx/NF; b HRTEM image of the a/c heterointerface; c LSV curve of the a/c-RuCoMoyOx/NF to the overall water splitting; d Stability test of the a/c-RuCoMoyOx/NF (1.64 V, 1 mol/L KOH). Reproduced with permission from Ref. [70]. Copyright © 2023, Elsevier

In this context, Nadarajan et al. [73] constructed a heterointerface structure consisting of multiple CoMo oxides (CoO/CoMoO3/Co2Mo3O8) on NF using microwave-assisted heating followed by annealing. The multiphase heterointerface composition was optimized by changing the molar ratio of cobalt/molybdenum and annealing time to enhance its bifunctional electrocatalytic activity, which required 51 mV for HER and 293 mV OER at 10 mA/cm2. By maintaining the ratio of Co:Mo at 1.25:1, followed by annealing at 450 °C for 2 h, the CoMoO-1.25/NF electrolyzer exhibited high durability for 500 h in the water splitting process at an operating cell voltage of 1.63 V, which could deliver a current density of 10 mA/cm2.

Although hydrothermal- or microwave-assisted growth of self-supported electrodes has been broadly applied for producing novel electrocatalysts, they have some limitations summarized as follows:

-

1. Expensive autoclaves consist of a high-strength alloy shell and a polytetrafluoroethylene (PTFE) liner to withstand high temperatures and pressures (Fig. 6a) during the reaction and protect the autoclave body from corrosion by chemical solutions [66, 74].

-

2. The hydrothermal- or microwave-assisted reaction mechanism is unclear because the chemical reaction occurs in a closed system. Therefore, it is difficult to follow the nucleation and growth mechanisms [75, 76].

-

3. The desired morphology, size, and composition of the final products, particularly in the nanosized dimension, cannot be easily controlled.

-

4. There is a lack of control the catalyst quantity grown on the conductive substrate because the active substrates can interact with the reaction medium and form undesirable composite materials.

-

5. The undesired products or impurity species cannot be easily removed from the obtained self-supported electrocatalysts.

-

6. Hydrothermal- and microwave-assisted reactions take a long time.

Electrodeposition of Nanostructured Materials on the NF

On the other hand, the electrodeposition strategy has garnered more and more attention because it provides a short time consumption, easy operation, and easy optimization of the loading quality on the electrode surface (Fig. 6b) [77]. Thus, the resulting electrocatalysts have high purity and strong bond energies with the substrates, which increases electron mobility and overall electrocatalytic activity [78, 79].

The design of uniformly stable and mutually coupled multiphase structures of electrocatalysts on NF conductive substrates can be easily performed by electrodeposition. For instance, Lee et al. [80] synthesized hollow CoSx triangular nanoarrays on NF using the coprecipitation–solvothermal method and then electrodeposited the CoSx nanoarrays with NiFe-LDH nanosheets to obtain a unique heterostructure H-CoSx@NiFe-LDH/NF (Fig. 7a). This unique heterointerface not only offers numerous active sites but also enhances the mass transfer and exhaust rates during water electrolysis. Meanwhile, the synergistic coupling effect between CoSx and NiFe-LDH stimulated the bifunctional electrocatalytic activity and realized HER and OER overpotentials at 95 mV and 250 mV to deliver 10 mA/cm2, respectively. Also, the actual water splitting voltage of the water electrolyzer with H-CoSx@NiFe-LDH/NF as the electrode material is only 1.59 V at 10 mA/cm2, and it can be operated stably for 100 h at a constant current density of 50 mA/cm2, demonstrating good stability (Fig. 7b, c).

a Schematic illustration of the fabrication process for the H-CoSx@NiFe-LDH/NF; b Comparison of voltage values at 10 mA/cm2 for the H-CoSx@NiFe-LDH/NF with other reported electrode materials; c Stability test of the H-CoSx@NiFe-LDH/NF (50 mA/cm2, 1 mol/L KOH). Reproduced with permission from Ref. [80]. Copyright © 2022, Wiley

Similarly, Yang et al. [81] prepared a NiFe-LDH@CoSx/NF self-supported electrode material by combining hydrothermal and electrodeposition methods to fabricate an amorphous CoSx phase on the surface of the hydrothermally synthesized NiFe-LDH nanosheets. The heterointerface constructed from CoSx and NiFe-LDH and their synergistic effects effectively promoted charge transfer and improved the bifunctional electrocatalytic activity. As a consequence, the HER and OER overpotentials of NiFe-LDH@CoSx/NF were 136 and 206 mV at 10 mA/cm2, respectively. The NiFe-LDH@CoSx/NF-based water electrolyzer had an actual water splitting voltage as low as 1.537 V at 10 mA/cm2 and demonstrated good stability for 25 h. The CoFe-LDH@NiFe-LDH/NF synthesized by Zhou et al. [82] by a similar strategy also presented outstanding bifunctional catalytic activity and stability. The CoFe-LDH@NiFe-LDH/NF-based water electrolyzer had an actual water splitting voltage of only 1.59 V at 10 mA/cm2 and could be operated for 25 h.

Other Methods for Growing Nanostructured Materials on NF

CVD

CVD is a process in which a solid material is deposited from a vapor phase by a chemical reaction occurring on or in the vicinity of a normally heated substrate surface (Fig. 8) [83].

Schematic diagrams of a typical CVD process. Reproduced with permission from Ref. [83]. Copyright © 2021, Elsevier

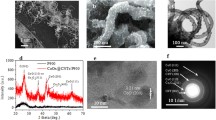

To prepare self-supported electrode materials, CVD is often combined with the above methods to dope nonmetallic elements onto the surface of the conductive substrate. The introduction of nonmetals, such as P, S, and NN, can further improve the catalytic activity of self-supported electrode materials, mainly because of the better adsorption properties of nonmetals for specific reaction intermediates compared with their metallic elements [84,85,86,87]. Sun et al. [88] grew NiO/CoO hydrothermally with nanorod and nanosheet morphologies on NF. Then, the surface of the NiO/CoO was phosphatized by plasma-enhanced CVD to produce NiCo phosphides with nanorod arrays (NiCo-P/NF), as illustrated in Fig. 9a. The doping of P elements onto NiO/CoO exhibited an outstanding HER activity with overpotentials of 78 and 80 mV at a current density of 10 mA/cm2 in 0.5 mol/L H2SO4 and 1.0 mol/L KOH, respectively. Feng et al. [89] made Mn–Co–P nanosheets on an NF electrode with a porous network by electrodeposition followed by CVD (Fig. 9b). Mn–Co-P/NF presented excellent electrocatalytic activity and stability with HER and OER overpotentials of 63 mV and 310 mV at 10 mA/cm2, respectively. The electrodes were used to construct an electrolyzer device that provided high stability for 25 h and required only 1.70 V to generate a current density of 20 mA/cm2.

Plasma Treatment

Plasma treatment is another physical surface treatment process that is often utilized as a subsequent process to hydrothermal growth or electrodeposition steps to dope nonmetallic elements on the conductive substrate surface. For example, Salem et al. [90] used a combined electrodeposition and plasma treatment method to prepare MnNiCo-P with nanoflower-like morphology (MnNiCo-P/NF) on NF (Fig. 10a, b), with an OER overpotential of 289 mV at 10 mA/cm2 in 1.0 mol/L KOH and HER overpotential as low as 14 mV. This electrode performed better than the commercially available Pt/C catalyst, and the LSV curves remained stable after 5000 cycles (Fig. 10c, d). Interestingly, the MnNiCo-P/NF-based water electrolyzer delivered a current density of 10 mA/cm2 at a cell voltage of only 1.48 V and maintained 96% of the current density after 50 h, exhibiting extremely high stability (Fig. 10e, f).

a Schematic illustration of the synthesis process for the MnNiCo-P/NF; b FESEM images of the MnNiCo-P/NF; c OER cycling stability for the MnNiCo-P/NF before and after 5000 cycles; d HER cycling stability for the MnNiCo-P/NF before and after 5000 cycles; e LSV curve of the MnNiCo-P/NF to the overall water splitting; f Stability test of the MnNiCo-P/NF (1.48 V, 1 mol/L KOH). Reproduced with permission from Ref. [90]. Copyright © 2023, Wiley

Similarly, Fan et al. [91] synthesized NiVFe-LDHs/NFF with nanoflower hydrothermally on Ni–Fe foam (NFF). Then, the catalyst surface was simultaneously nitrided and phosphatized by plasma treatment to obtain N-NiVFeP/NFF with nanosheet arrays. Motivated by the synergistic effects of the multiphase heterointerface, numerous active sites provided by the nanosheet arrays, and increased conductivity after doping with N and P elements, N-NiVFeP/NFF showed remarkable bifunctional catalytic activity with HER and OER overpotentials of 79 mV and 229 mV at 10 mA/cm2, respectively. N-NiVFeP/NFF required only 1.52 V to produce a current density of 10 mA/cm2 in the overall water splitting system and could be operated stably for 100 h.

Generally, CVD and plasma treatment are effective in doping nonmetallic elements onto the NF surface, but they cannot be used alone to grow nanostructured materials on NF. These methods are often used as after-treatments for hydrothermal-assisted growth, microwave-assisted growth, and electrodeposition growth to improve the adsorption of reaction intermediates and further enhance the intrinsic catalytic activity of self-supported electrode materials.

Conclusions and Future Perspectives

The design of efficient non-noble metal electrocatalysts via self-supported strategies on 3D NF substrates has been reported in the literature to enhance their bifunctional activity and stability and compete with commercially available noble metal-based electrodes. Various surface modification methods, such as hydrothermal-assisted growth, microwave-assisted growth, electrodeposition growth, CVD, and plasma treatment, have been employed to achieve self-supported strategies. The advantages and disadvantages of these methods are summarized in Table 1.

Briefly, no single method for constructing self-supported electrocatalysts is universally superior in catalytic activity to other methods. Researchers often propose composite process strategies to obtain self-supported electrocatalysts with higher performance. Based on the design principle of “coating, loading, and then doping,” multiphase heterostructures consisting of metal compounds are first grown on the conductive substrate by a hydrothermal, microwave, or electrodeposition method and then doped with nonmetallic elements by CVD or plasma treatment, finally producing self-supported electrode materials with a homogeneous and stable nanostructure. However, such self-supported electrode materials still face several challenges:

-

1. The synergy between the grown electrocatalysts and substrate materials is unpredictable, and a deep understanding of particular active sites is still lacking. Thus, theoretical studies and predictions of new structural compositions will be beneficial for the application of NF in water electrolysis.

-

2. The true number of active sites for the self-supported electrocatalyst that participates in OER and HER requires a deep understanding of the role of surface species, which remains unclear.

-

3. The instability of the NF-based electrode in acidic media is a significant issue that should be overcome. Thus, the development of acid-resistant NF electrode materials is imperative.

-

4. Scaling up electrolyzers for commercial applications is still difficult.

To solve these shortcomings, researchers need to pay more attention to understanding the mechanisms of nucleation and growth of self-supported electrode materials and enhance their OER and HER performance in practical industrial environments. An in-depth study of the reaction mechanism can help in constructing self-supported electrode materials with higher activity and stability. Testing and improving actual devices can help realize the commercial value of such self-supported electrocatalytic materials.

References

Yan Y, Xia BY, Zhao B et al (2016) A review on noble-metal-free bifunctional heterogeneous catalysts for overall electrochemical water splitting. J Mater Chem A 4(45):17587–17603

Chaudhari NK, Jin H, Kim B et al (2017) Nanostructured materials on 3D nickel foam as electrocatalysts for water splitting. Nanoscale 9(34):12231–12247

Xing Z, Gan F, Wang J et al (2017) Experimental and theoretical insights into sustained water splitting with an electrodeposited nanoporous nickel hydroxide@nickel film as an electrocatalyst. J Mater Chem A 5(17):7744–7748

Wang W, Xu X, Zhou W et al (2017) Recent progress in metal-organic frameworks for applications in electrocatalytic and photocatalytic water splitting. Adv Sci 4(4):1600371

Mamtani K, Jain D, Dogu D et al (2018) Insights into oxygen reduction reaction (ORR) and oxygen evolution reaction (OER) active sites for nitrogen-doped carbon nanostructures (CNx) in acidic media. Appl Catal B Environ 220:88–97

Wang K, She X, Chen S et al (2018) Boosting hydrogen evolution via optimized hydrogen adsorption at the interface of CoP3 and Ni2P. J Mater Chem A 6(14):5560–5565

Chi H, Lin J, Kuang S et al (2023) Self-supported ultrathin NiCo layered double hydroxides nanosheets electrode for efficient electrosynthesis of formate. J Energy Chem 85:267–275

Lan Q, Jin S, Yang B et al (2022) Metal-oxo cluster catalysts for photocatalytic water splitting and carbon dioxide reduction. Trans Tianjin Univ 28(3):214–225

Miao M, Pan J, He T et al (2017) Molybdenum carbide-based electrocatalysts for hydrogen evolution reaction. Chemistry 23(46):10947–10961

Wang M, Zhang L, He Y et al (2021) Recent advances in transition-metal-sulfide-based bifunctional electrocatalysts for overall water splitting. J Mater Chem A 9(9):5320–5363

Zhang H, Maijenburg AW, Li X et al (2020) Bifunctional heterostructured transition metal phosphides for efficient electrochemical water splitting. Adv Funct Mater 30(34):2003261

Dutta S, Indra A, Feng Y et al (2019) Promoting electrocatalytic overall water splitting with nanohybrid of transition metal nitride-oxynitride. Appl Catal B Environ 241:521–527

Sahoo DP, Das KK, Mansingh S et al (2022) Recent progress in first row transition metal Layered double hydroxide (LDH) based electrocatalysts towards water splitting: a review with insights on synthesis. Coord Chem Rev 469:214666

Yang H, Driess M, Menezes PW (2021) Self-supported electrocatalysts for practical water electrolysis. Adv Energy Mater 11(39):2102074

Geng B, Yan F, Zhang X et al (2021) Conductive CuCo-based bimetal organic framework for efficient hydrogen evolution. Adv Mater 33(49):e2106781

Zhao Y, Wei S, Xia L et al (2022) Sintered Ni metal as a matrix of robust self-supporting electrode for ultra-stable hydrogen evolution. Chem Eng J 430:133040

Katsounaros I, Cherevko S, Zeradjanin AR et al (2014) Oxygen electrochemistry as a cornerstone for sustainable energy conversion. Angew Chem Int Ed Engl 53(1):102–121

Sun H, Xu X, Yan Z et al (2018) Superhydrophilic amorphous Co–B–P nanosheet electrocatalysts with Pt-like activity and durability for the hydrogen evolution reaction. J Mater Chem A 6(44):22062–22069

Sun H, Yan Z, Liu F et al (2020) Self-supported transition-metal-based electrocatalysts for hydrogen and oxygen evolution. Adv Mater 32(3):1806326

Yan Z, Sun H, Chen X et al (2018) Anion insertion enhanced electrodeposition of robust metal hydroxide/oxide electrodes for oxygen evolution. Nat Commun 9(1):2373

Kwon J, Han H, Choi S et al (2019) Current status of self-supported catalysts for robust and efficient water splitting for commercial electrolyzer. ChemCatChem 11(24):5898–5912

Wang Y, Cao Q, Guan C et al (2020) Recent advances on self-supported arrayed bifunctional oxygen electrocatalysts for flexible solid-state Zn-air batteries. Small 16(33):e2002902

Ma TY, Dai S, Qiao SZ (2016) Self-supported electrocatalysts for advanced energy conversion processes. Mater Today 19(5):265–273

Shan X, Liu J, Mu H et al (2020) An engineered superhydrophilic/superaerophobic electrocatalyst composed of the supported CoMoSx chalcogel for overall water splitting. Angew Chem Int Ed Engl 59(4):1659–1665

Liu JN, Zhao CX, Ren D et al (2022) Preconstructing asymmetric interface in air cathodes for high-performance rechargeable Zn-air batteries. Adv Mater 34(11):e2109407

Chen Y, Ren Z, Fu H et al (2018) NiSe-Ni0.85Se heterostructure nanoflake arrays on carbon paper as efficient electrocatalysts for overall water splitting. Small 14(25):1800763

Ganesan P, Sivanantham A, Shanmugam S (2017) Nanostructured nickel-cobalt-titanium alloy grown on titanium substrate as efficient electrocatalyst for alkaline water electrolysis. ACS Appl Mater Interfaces 9(14):12416–12426

Liu X, You B, Sun Y (2017) Facile surface modification of ubiquitous stainless steel led to competent electrocatalysts for overall water splitting. ACS Sustainable Chem Eng 5(6):4778–4784

Gultom NS, Abdullah H, Hsu CN et al (2021) Activating nickel iron layer double hydroxide for alkaline hydrogen evolution reaction and overall water splitting by electrodepositing nickel hydroxide. Chem Eng J 419:129608

Huang X, Gong L, Xu H et al (2020) Hierarchical iron-doped CoP heterostructures self-assembled on copper foam as a bifunctional electrocatalyst for efficient overall water splitting. J Colloid Interface Sci 569:140–149

Zhang W, Li D, Zhang L et al (2019) NiFe-based nanostructures on nickel foam as highly efficiently electrocatalysts for oxygen and hydrogen evolution reactions. J Energy Chem 39:39–53

Li J, Zhang J, Shen J et al (2023) Self-supported electrocatalysts for the hydrogen evolution reaction. Mater Chem Front 7(4):567–606

Wang P, Jia T, Wang B (2020) A critical review: 1D/2D nanostructured self-supported electrodes for electrochemical water splitting. J Power Sources 474:228621

Ratsoma MS, Poho BLO, Makgopa K et al (2023) Application of nickel foam in electrochemical systems: a review. J Electron Mater 52(4):2264–2291

Zhang T, Sun J, Guan J (2023) Self-supported transition metal chalcogenides for oxygen evolution. Nano Res 16(7):8684–8711

Zhang Y, Xiao J, Lv Q et al (2018) Self-supported transition metal phosphide based electrodes as high-efficient water splitting cathodes. Front Chem Sci Eng 12(3):494–508

Zhang J, Si C, Kou T et al (2020) Recent progress in self-supported two-dimensional transition metal oxides and (oxy)hydroxides as oxygen evolution reaction catalysts. Sustain Energy Fuels 4(6):2625–2637

Liu J, Zhu D, Zheng Y et al (2018) Self-supported earth-abundant nanoarrays as efficient and robust electrocatalysts for energy-related reactions. ACS Catal 8(7):6707–6732

Verma S, Sinha-Ray S, Sinha-Ray S (2020) Electrospun CNF supported ceramics as electrochemical catalysts for water splitting and fuel cell: a review. Polymers 12(1):238

Yang G, Park SJ (2019) Conventional and microwave hydrothermal synthesis and application of functional materials: a review. Materials 12(7):1177

Ashik UPM, Kudo S, Hayashi J et al (2018) Synthesis of inorganic nanomaterials. Woodhead Publishing, Cambridge

Kim HY, Shin J, Jang IC et al (2019) Hydrothermal synthesis of three-dimensional perovskite NiMnO3 oxide and application in supercapacitor electrode. Energies 13(1):36

Kang Y, Deng C, Chen Y et al (2020) Binder-free electrodes and their application for Li-ion batteries. Nanoscale Res Lett 15(1):112

Tang C, Cheng N, Pu Z et al (2015) NiSe nanowire film supported on nickel foam: an efficient and stable 3D bifunctional electrode for full water splitting. Angew Chem Int Ed Engl 54(32):9351–9355

Görlin M, Chernev P, Ferreira de Araújo J et al (2016) Oxygen evolution reaction dynamics, faradaic charge efficiency, and the active metal redox states of Ni-Fe oxide water splitting electrocatalysts. J Am Chem Soc 138(17):5603–5614

Burke MS, Kast MG, Trotochaud L et al (2015) Cobalt-iron (oxy)hydroxide oxygen evolution electrocatalysts: the role of structure and composition on activity, stability, and mechanism. J Am Chem Soc 137(10):3638–3648

Dinh KN, Zheng P, Dai Z et al (2018) Ultrathin porous NiFeV ternary layer hydroxide nanosheets as a highly efficient bifunctional electrocatalyst for overall water splitting. Small. https://doi.org/10.1002/smll.201703257

Zhang Y, Fu J, Zhao H et al (2019) Tremella-like Ni3S2/MnS with ultrathin nanosheets and abundant oxygen vacancies directly used for high speed overall water splitting. Appl Catal B Environ 257:117899

Zhao Y, Chang C, Teng F et al (2017) Defect-engineered ultrathin δ-MnO2 nanosheet arrays as bifunctional electrodes for efficient overall water splitting. Adv Energy Mater 7(18):1700005

Yao L, Zhang N, Wang Y et al (2018) Facile formation of 2D Co2P@Co3O4 microsheets through in-situ toptactic conversion and surface corrosion: bifunctional electrocatalysts towards overall water splitting. J Power Sources 374:142–148

Shi H, Liang H, Ming F et al (2017) Efficient overall water-splitting electrocatalysis using lepidocrocite VOOH hollow nanospheres. Angew Chem Int Ed Engl 56(2):573–577

Kölbach M, Fiechter S, van de Krol R et al (2017) Evaluation of electrodeposited α-Mn2O3 as a catalyst for the oxygen evolution reaction. Catal Today 290:2–9

Liu J, Yang Y, Ni B et al (2017) Fullerene-like nickel oxysulfide hollow nanospheres as bifunctional electrocatalysts for water splitting. Small. https://doi.org/10.1002/smll.201602637

Shit S, Chhetri S, Jang W et al (2018) Cobalt sulfide/nickel sulfide heterostructure directly grown on nickel foam: an efficient and durable electrocatalyst for overall water splitting application. ACS Appl Mater Interfaces 10(33):27712–27722

Ren JT, Yuan ZY (2017) Hierarchical nickel sulfide nanosheets directly grown on Ni foam: a stable and efficient electrocatalyst for water reduction and oxidation in alkaline medium. ACS Sustain Chem Eng 5(8):7203–7210

Liu D, Lu Q, Luo Y et al (2015) NiCo2S4 nanowires array as an efficient bifunctional electrocatalyst for full water splitting with superior activity. Nanoscale 7(37):15122–15126

Zhong X, Tang J, Wang J et al (2018) 3D heterostructured pure and N-doped Ni3S2/VS2 nanosheets for high efficient overall water splitting. Electrochim Acta 269:55–61

Zhang X, Zhang S, Li J et al (2017) One-step synthesis of well-structured NiS–Ni2P2S6 nanosheets on nickel foam for efficient overall water splitting. J Mater Chem A 5(42):22131–22136

Ren H, Huang ZH, Yang Z et al (2017) Facile synthesis of free-standing nickel chalcogenide electrodes for overall water splitting. J Energy Chem 26(6):1217–1222

Zhu W, Yue X, Zhang W et al (2016) Nickel sulfide microsphere film on Ni foam as an efficient bifunctional electrocatalyst for overall water splitting. Chem Commun 52(7):1486–1489

Zhang B, Wang H, Zuo Z et al (2018) Tunable CoFe-based active sites on 3D heteroatom doped graphene aerogel electrocatalysts via annealing gas regulation for efficient water splitting. J Mater Chem A 6(32):15728–15737

Lu Y, Li Z, Xu Y et al (2021) Bimetallic Co-Mo nitride nanosheet arrays as high-performance bifunctional electrocatalysts for overall water splitting. Chem Eng J 411:128433

Chen MT, Duan JJ, Feng JJ et al (2022) Iron, rhodium-codoped Ni2P nanosheets arrays supported on nickel foam as an efficient bifunctional electrocatalyst for overall water splitting. J Colloid Interface Sci 605:888–896

Faraji S, Ani FN (2014) Microwave-assisted synthesis of metal oxide/hydroxide composite electrodes for high power supercapacitors–a review. J Power Sources 263:338–360

Sun J, Wang W, Yue Q (2016) Review on microwave-matter interaction fundamentals and efficient microwave-associated heating strategies. Materials 9(4):231

Gerard O, Numan A, Krishnan S et al (2022) A review on the recent advances in binder-free electrodes for electrochemical energy storage application. J Energy Storage 50:104283

Rosa R, Ponzoni C, Leonelli C (2014) Direct energy supply to the reaction mixture during microwave-assisted hydrothermal and combustion synthesis of inorganic materials. Inorganics 2(2):191–210

Duan Y, Huang Z, Zhao C et al (2021) In-situ generated trimetallic molybdate nanoflowers on Ni foam assisted with microwave for highly enhanced oxygen evolution reaction. Chem 27(35):9044–9053

Guo ML, Wu ZY, Zhang MM et al (2023) Coupling interface constructions of FeOOH/NiCo2S4 by microwave-assisted method for efficient oxygen evolution reaction. Rare Met 42(6):1847–1857

Ren J, Du Y, Wang Y et al (2023) Modulating amorphous/crystalline heterogeneous interface in RuCoMoyOx grown on nickel foam to achieve efficient overall water splitting. Chem Eng J 469:143993

Cao X, Wang T, Qin H et al (2023) Crystalline—amorphous interfaces of NiO-CrOx electrocatalysts for boosting the urea oxidation reaction. Nano Res 16(3):3665–3671

Guo C, Shi Y, Lu S et al (2021) Amorphous nanomaterials in electrocatalytic water splitting. Chin J Catal 42(8):1287–1296

Nadarajan R, Gopinathan AV, Dileep NP et al (2023) Heterointerface engineering of cobalt molybdenum suboxide for overall water splitting. Nanoscale 15(37):15219–15229

Nunes D, Pimentel A, Santos L et al (2019) Metal Oxide Nanostructures for sensor applications. Semicond Sci Technol 34:043001

Sonawane GH, Patil SP, Sonawane SH et al (2018) Applications of nanomaterials. Woodhead Publishing, Cambridge

Ma ZY, Yu ZL, Xu ZL et al (2020) Origin of batch hydrothermal fluid behavior and its influence on nanomaterial synthesis. Matter 2(5):1270–1282

Biswal HJ, Kaur JJ, Vundavilli PR et al (2022) Recent advances in energy field assisted hybrid electrodeposition and electroforming processes. CIRP J Manuf Sci Technol 38:518–546

Shojaei Z, Khayati GR, Darezereshki E (2022) Review of electrodeposition methods for the preparation of high-entropy alloys. Int J Miner Metall Mater 29(9):1683–1696

Percival SJ, Lu P, Lowry DR et al (2022) Electrodeposition of complex high entropy oxides via water droplet formation and conversion to crystalline alloy nanoparticles. Langmuir 38(5):1923–1928

Lee YJ, Park SK (2022) Metal-organic framework-derived hollow CoSx nanoarray coupled with NiFe layered double hydroxides as efficient bifunctional electrocatalyst for overall water splitting. Small 18(16):2200586

Yang Y, Xie Y, Yu Z et al (2021) Self-supported NiFe-LDH@CoSx nanosheet arrays grown on nickel foam as efficient bifunctional electrocatalysts for overall water splitting. Chem Eng J 419:129512

Yang R, Zhou Y, Xing Y et al (2019) Synergistic coupling of CoFe-LDH arrays with NiFe-LDH nanosheet for highly efficient overall water splitting in alkaline media. Appl Catal B Environ 253:131–139

Mittal M, Sardar S, Jana A et al (2021) Handbook of nanomaterials for sensing applications. Elsevier, Amsterdam

Li K, He J, Guan X et al (2023) Phosphorus-modified amorphous high-entropy CoFeNiCrMn compound as high-performance electrocatalyst for hydrazine-assisted water electrolysis. Small 19(42):2302130

Lai D, Kang Q, Gao F et al (2021) High-entropy effect of a metal phosphide on enhanced overall water splitting performance. J Mater Chem A 9(33):17913–17922

Wang R, Huang J, Zhang X et al (2022) Two-dimensional high-entropy metal phosphorus trichalcogenides for enhanced hydrogen evolution reaction. ACS Nano 16(3):3593–3603

Joo J, Kim T, Lee J et al (2019) Morphology-controlled metal sulfides and phosphides for electrochemical water splitting. Adv Mater 31(14):e1806682

Sun M, Gao B, Wang S et al (2020) Study on the electrocatalytic performance of porous conductive materials based on an in situ growth of bimetal phosphides with plasma. Int J Electrochem Sci 15(4):3242–3254

Feng Z, Sui Y, Sun Z et al (2021) Controllable synthesis of flower-like Mn–Co–P nanosheets as bifunctional electrocatalysts for overall water splitting. Colloids Surf A Physicochem Eng Aspects 615:126265

Salem KE, Saleh AA, Khedr GE et al (2023) Unveiling the optimal interfacial synergy of plasma-modulated trimetallic Mn–Ni–Co phosphides: tailoring deposition ratio for complementary water splitting. Energy Environ Mater 6(2):e12324

Fan H, Chen W, Chen G et al (2020) Plasma-heteroatom-doped Ni-V-Fe trimetallic phospho-nitride as high-performance bifunctional electrocatalyst. Appl Catal B Environ 268:118440

Acknowledgements

This research was supported by The Chinese Academy of Sciences (CAS) President’s International Fellowship Initiative (No. 2023VCB0014), The National Natural Science Foundation of China (No. 52203284), Shenzhen Science and Technology Program (Nos. GJHZ20220913143801003 and RCBS20221008093057026).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflicts of interest

The authors declare there is no conflict of interests.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, C., Wang, X., Huang, Z. et al. Engineering of Self-Supported Electrocatalysts on a Three-Dimensional Nickel Foam Platform for Efficient Water Electrolysis. Trans. Tianjin Univ. 30, 103–116 (2024). https://doi.org/10.1007/s12209-024-00389-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12209-024-00389-y