Abstract

Recent studies have shown that the particle size of the shielding material and photon energy has significant effects on the efficiency of radiation-shielding materials. The purpose of the current study was to investigate the shielding properties of the bismuth–silicon (Bi–Si) composite containing varying percentages of micro- and nano-sized Bi particles for low-energy X-rays. Radiation composite shields composed of nano- and micro-sized Bi particles in Si-based matrix were constructed. The mass attenuation coefficients of the designed shields were experimentally assessed for diagnostic radiology energy range. In addition, the mass attenuation coefficients of the composite were comprehensively investigated using the MCNPX Monte Carlo (MC) code and XCOM. The X-ray attenuation for two different micro-sized Bi composites of radii of 50 µm and 0.50 µm showed enhancement in the range of 37–79% and 5–24%, respectively, for mono-energy photons (60–150 keV). Furthermore, the experimental and MC results indicated that nano-structured composites had higher photon attenuation properties (approximately 11–18%) than those of micro-sized samples for poly-energy X-ray photons. The amount of radiation attenuation for lower energies was more than that of higher energies. Thus, it was found that the shielding properties of composites were considerably strengthened by adding Bi nano-particles for lower energy photons.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Since the introduction of diagnostic radiology, it has become an essential tool in all medical disciplines and specialties. Although the clear benefits of radiation in medicine are undeniable, a large number of unnecessary radiations can lead to health hazards in medical imaging examinations [1, 2]. New shielding materials are being utilized to protect radiosensitive organs during medical imaging procedures while maintaining the quality of diagnostic images that result in a very high benefit/risk ratio [3].

With the advent of nanotechnology and access to nanomaterials, this technology was introduced as a novel way to increase the efficiency of the conventional shielding used in medical radiation sciences. Many researchers have demonstrated the effects of the particle size of the filler material on the attenuation of photons of energy range higher than 1 MeV [4]. It is widely believed that nano-sized particles can improve the γ-ray attenuation ability of the composite-shielding materials [5, 6]. For instance, Malekie et al. [7] found that tungsten trioxide (WO3) nano-particles displayed a larger increase in linear attenuation coefficient than micro-sized particles did. Nambiar et al. [8] reported that nano-particles have unique properties that make them suitable as fillers in radiation-shielding materials. The investigation of effective WO3 size on mass attenuation coefficients of concrete showed that nano-particles have a superior potential to attenuate the radiation [9, 10]. Reviewing the published papers revealed that only a few studies have examined the influence of particle size on the X-ray attenuation at low energies (diagnostic radiology energy range). For example, a recent study showed that the reduction of X-ray beams produced from low tube voltages [26–30 kV, with copper oxide nano-particles (CuO)] was better than with microstructure particles. However, there was no significant difference in the attenuation rate in the X-rays produced from diagnostic tube potential (60–120 kV) [11].

As another way of enhancing shielding properties in recent times, metal-matrix composite shields have also been developed for protection from photons [12, 13]. The addition of an element with a high atomic number (filler), such as bismuth (Bi), to a radiation shield mainly containing an element with a low atomic number significantly increases the absorption of radiation by the shield [14, 15]. The advantage of adding Bi stems from its high atomic number (Z = 83), high density (9.78 g/cm3), availability, and low cost [16]. Moreover, it is important to note that the total absorption depends mainly on the exact ratio of the primary to secondary absorbers (weight ratio), size of the primary and secondary absorbers (micro or nano), and photon energy.

The analysis of studies performed on nano-particle metal-matrix composites for low-energy X-ray shielding is summarized in Table 1. A review of the studies has shown that only few have investigated the effect of particle size on attenuation of low-energy photons used in diagnostic radiology. All of the previous studies emphasized on the higher attenuation of nano-sized fillers as compared to microparticles in different energy ranges of photons. However, there is no definite pattern of the effect of nano-particles or microparticles on the amount of radiation attenuation; therefore, several improvements in radiation attenuation using nano-particles and microparticles of different elements have been reported (Table 1). The investigation of the composites filled with WO3 micro- and nano-particles demonstrated promising results for better attenuation and shielding properties due to the nano-particles. Another study by Mesbahi et al., evaluated γ-ray shielding properties for ordinary concrete filled with PbO2, Fe2O3, WO3, and H4B in different concentrations, and found that the concrete doped with nano-sized particles had higher photon attenuation coefficient (8%) than that of microparticles [17]. Mahmoud et al. studied the γ-ray shielding properties for polyethylene-based composites of lead oxide nano-powders. The results showed that nano-particles had higher mass attenuation coefficients (up to 15%) than those made of microparticles [18].

In recent years, various types of polymer composites with nano-material fillers have been introduced for shielding application in different radiations. In this study, the effect of nano-sized and micro-sized bismuth–silicon (Bi–Si) composites on X-ray interactions was investigated by calculating the mass attenuation coefficients in a diagnostic radiology energy range of 60–150 keV using the Monte Carlo (MC) code. The composite shields were separately modeled according to the standards and doped separately with different percentages of Bi nano-sized (radius 50 nm) and micro-sized (two radii of 0.50 µm and 50 µm) particles at 10%, 20%, 30%, and 40% concentrations. Furthermore, the 10 weight-percentage (wt%) Bi composites were manufactured based on the nano-sized and micro-sized Bi metal particles and the characteristics of their attenuation coefficient by the X-ray spectrum beam (voltages of 60, 80, and 100 kVp) were experimentally explored using a radiology imaging equipment. Finally, the aforementioned 10 wt% Bi composites were compared with the experimental outcome.

2 Materials and methods

Based on the objectives, the current study can be categorized into three parts.

2.1 Monte Carlo simulation code

2.1.1 MCNPX simulation geometry

In the present research, MCNPX (version 2.6.0, Los Alamos National Laboratory cross-sectional libraries data) was used for the determination of X-ray mass attenuation coefficients of Bi–Si composite shields for diagnostic radiology energies. MCNPX code is a well-known MC code used for modeling the radiation transport and the interaction of particles with the matter and tracking all particles at different energies [22, 23]. MCNPX input parameters, such as cell card definitions, surface card definitions, material card definitions, and features of energy sources, have been defined in input files according to their properties.

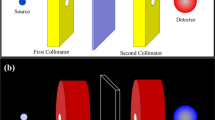

The mass attenuation coefficients for different types of Bi-composite shields in this study were calculated by X-ray photon in imaging range energies using narrow beam transmission geometry. Figure 1 shows the defined simulation geometry setup in MC code. The total simulation geometry was inserted into one cylindrical space of height 140 cm and diameter 60 cm. The importance of particle transport outside this box was considered zero. As shown in Fig. 1, the radiation source is located in front of the lead collimators (density = 11.3 g/cm3). The lead collimators have been modeled as a plane of width and length 20 × 20 cm and a thickness of 5 cm. A disk-like source with radius 0.5 cm emitted X-rays perpendicular to the surface of the composites. The samples were located between the lead collimators, and a spherical-shaped detector with radius 2 cm was defined. The cylindrical-shaped source was defined in MCNPX data card as ERG, PAR, POS, AXE, VEC, and DIR commands for energy, particle type, position, and direction. To calculate the photon flounce reaching the detector cell, the F4 tally that scores the number of photons entering a cell in terms of n/cm3 was used for photons. Simulations were performed for 30 min on a personal computer. The statistical error of MC results was less than 1% for all calculations.

The X-ray transmission was related to Lambert through the following equation:

where I0 and I represent the incident and transmitted intensities, respectively, x is the thickness of the absorbing medium, and \(\mu\) is the linear attenuation coefficient. Mass attenuation coefficient \(\left( {\left( {\frac{\mu }{\rho }} \right)\,{\text{cm}}^{ 2} / {\text{g}}} \right)\) is another parameter defined for the photon interaction that is independent of the medium density and calculated by the mixture rule, given by

where wi is the proportion by weight and \(\left( {{\raise0.7ex\hbox{$\mu $} \!\mathord{\left/ {\vphantom {\mu \rho }}\right.\kern-0pt} \!\lower0.7ex\hbox{$\rho $}}} \right)_{i}\) is the mass attenuation coefficient of the ith element. Measurements were performed for each energy in three thicknesses and plotting ln(I0/I) versus thickness, where the slope was obtained using Eqs. (1) and (2), and the mass attenuation coefficients were calculated. The definitions of composite shields were performed by considering the elemental mass fractions and densities of materials (Table 2).

2.1.2 Validation study

To assess the accuracy of the developed MC geometry, we modeled well-known composites as attenuators by considering elemental density properties. The results obtained were then compared with standard XCOM data. The calculated mass attenuation coefficients by MCNPX were at par with the XCOM results. Thus, input code was validated for the calculation of the radiation mass attenuation coefficients’ composite shields doped by different percentages of Bi micro- and nano-particles. The mass attenuation coefficients were determined by calculating the transmission of X-rays through different compositions individually at the mono-energies of 60, 80, 100, 120, 140, and 150 keV.

2.1.3 Definition of micro- and nano-particles in MCNPX code

The nano-sized and micro-sized Bi particles were defined into Si in the MCNPX input file. The schematic view of nano-Bi added matrix is shown in Fig. 2. In this study, each nano- and microparticle was defined using the lattice (LAT) and universe (u) properties of MCNPX.

In all composites, nano-particles with a radius of 50 nm and microparticles with two radii of 50 and 0.5 µm were considered. For each composite, the number of nano-particles or the number of microparticles of Bi metal providing the required wt% was calculated. After obtaining the required number of particles in each composite, the dimension of a cubic cell surrounding a single Bi particle was calculated. In the simulation process, the number of micro- (radii 0.50 µm and 50 µm) and nano (radius 50 nm)-particles for all composites was in the order of 104, 1010, and 1013 per cm3, respectively. The percentage difference in the mass attenuation coefficients between nano- and microparticles was obtained by the following formula:

2.2 Fabrication of composites

2.2.1 Composites preparation

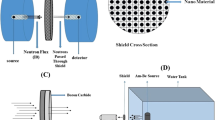

Bi-composite shields of 10 wt% Bi were fabricated by adding nano-sized (< 100 nm) and micro-sized (< 50 μm) Bi metal particles within the Si matrix (Fig. 3). The composites were prepared in dimensions of 20 × 20 cm and 1 mm thickness in the dosimetry laboratory of the Medical Physics Department, Tabriz University of Medical Sciences. These composite shields were placed in the laboratory for 2 weeks to dry the composite mixtures and to eliminate air bubbles. Once they were stable, they were employed in the experiments. Details about the preparation of the Bi–Si composite samples are available in Ref. [24].

2.2.2 Measurements of X-ray transmission

This work was carried out using a conventional radiography unit (VARIAN tube type) and a DIADOS E (PTW Company, Freiburg, Germany) at the radiology unit 29 of the Bahman hospital in Tabriz. The DIADOS E is a small size dosimeter for any type of diagnostic X-ray installation. Shields were placed at a distance of 1 m from the X-ray tube and the dosimeter was placed below the shield (Fig. 4). Experiments were carried out at the tube voltages of 60, 80, and 100 kVp. For each composite shield, four readings were recorded at each tube voltage level. The transmission of X-ray spectrum in three energies (60, 80, and 100 kVp), with and without Bi-composite shields, was calculated. The X-ray transmission was related to the equation proposed for polyenergetic spectra [25, 26], and then, linear attenuation coefficients (μ) were calculated through the following equation:

where T(x) represents the transmitted fraction for the thickness of x, and \(\eta\) is the beam-hardening coefficient. Measurements were made for thicknesses of 0.5, 1, and 1.5 mm for each photon beam.

2.2.3 Simulation of fabricated composites

As we are aware, the output of the X-ray tube is in the form of a polychromatic spectrum. Therefore, our experimental data were obtained using the spectrum. To compare the experimental data with simulations correctly, SpekCalc software was used to obtain the X-ray spectra emitted from the X-ray tube at different voltages. SpekCalc is an executable software used for calculating the X-ray emission spectra, similar to those used in diagnostic radiology [27]. We defined polychromatic spectrum in MCNPX data card as the ERG command for energy.

3 Results and discussion

The mass attenuation coefficients of composite shields with different percentages of nano- and micro-sized Bi particles were calculated using the MCNPX simulation for different photon energies of 60, 80, 100, 120, 140, and 150 keV. In addition, the mass attenuation coefficients of homemade composite shields with micro- and nano-Bi particles in three X-ray tube voltages of 60, 80, and 100 kVp were obtained and compared with the MCNPX simulation results.

3.1 Validation of simulation geometry

To test the validity of the advanced MCNPX code in this study, we calculated the radiation mass attenuation coefficients for pure Bi and pure Si using MCNPX simulation and XCOM data (Fig. 5). As seen here, good agreement was achieved between the MCNPX and XCOM standard data. Consequently, the developed MCNPX simulation geometry has been considered as a precise and usable simulation input for the definition of nano- and microparticles in MCNPX at different energies for the rest of our study.

3.1.1 Experiment and MCNPX results for 10 wt% Bi composites

The results of the photon attenuation measurements for constructed composites for three photon beams are shown in Fig. 6. It shows that there is good agreement between mass attenuation coefficient values obtained from both MCNPX code and experimental data.

The possible reasons for the complete mismatch apparent discrepancy between experimental and simulation data could be due to laboratory errors in the construction of the shield, as well as the uncertainty of the size of the purchased nano-particles. Based on experimental and simulation results (Table 3), it was observed that attenuation of the poly-energy polychromatic X-rays for by the nano-Bi composite was 11–18% higher than micro-Bi under the same X-ray tube voltage. This clearly shows that the amount of radiation attenuation in lower energies was more than the higher energies, which means that shielding was more effective for low-energy photons. Furthermore, as expected, the mass attenuation coefficients of the Bi–Si composites calculated by MCNPX code were higher than the experimental results. Mass attenuation coefficients obtained for the Bi shields at three tube voltages are presented in Table 3.

3.2 Effect of increased Bi amount on mass attenuation properties of composite

The calculated mass attenuation coefficients for different amounts of Bi–Si nano-composites in terms of photon energy are shown in Fig. 7. It can be seen that the lowest values of mass attenuation coefficients for all energies are obtained in the pure Si sample. With gradual increase in the Bi amount, an increase in the mass attenuation coefficients is observed. However, in low wt% of Bi, the characteristic of K-edge absorption cannot be clearly seen. By increasing the Bi metal in the composites, the effect of the K-shell is more pronounced with the increase in the mass attenuation coefficients at that energy. In the vicinity of the K-edge of Bi at 90.53 keV, the mass attenuation coefficient rose quickly due to the dominance of the photoelectric effect [28]. Therefore, it is clearly observed that by increasing the percentage of Bi in the composites, the mass attenuation coefficient for each energy increases.

3.3 Effect of Bi-particle size on mass attenuation properties of composites

To investigate the effect of Bi-particle size on the radiation-shielding properties of composites, the mass attenuation coefficient of radiation shields for X-ray photons for three different sizes of micro- and nanostructure Bi particles was calculated (Fig. 8). At the initial glance, it was clear that there was a noble agreement between the mass attenuation coefficient values from both MCNPX code and XCOM data. As per the main result seen in Fig. 8, the composite samples doped with nano-Bi had good radiation-shielding properties than those with micro-Bi particles in the same mixture. As noted above, the density of nano-particles (with radius 50 nm) was much higher than the microparticles (radii 50 µm and 0.50 µm) in each of the wt% in the order of 109 and 103, respectively. Therefore, the abundance of nano-particles in shields led to an increase in the number of interactions between photons and matter. Second, the distribution of the nano-sized Bi in the Si would be different from that offered by micro-sized Bi, thus resulting in a uniform dispersion in the matrix. The shielding efficiency of all samples decreased when the photon energy was increased. Photons at this energy interact with high atomic number matter elements mainly by photoelectric interaction. It should be noted that all composite samples revealed stronger shielding ability at around 100 keV than at other energies, because Bi atom has a K-edge at 90.53 keV [29].

As shown in these figures, the differences in mass attenuation coefficients of the micro-sized (radius of 0.50 µm) and nano-sized Bi became larger for all the samples at 100 keV and all composites with different Bi percent composition. The lowest and highest differences of mass attenuation coefficients occurred at 150 and 100 keV, respectively. This trend was also observed for all the other loadings. The calculated results for mass attenuation coefficients of different micro- and nano-Bi composites are presented in Table 4. There was an obvious difference in mass attenuation coefficients of micro- and nano-Bi-composite mixtures.

The results showed that Bi nano-particles, as compared to Bi microparticles of radius 50 µm, increased by approximately 37–79% of the attenuation coefficients over the diagnostic energy range.

We also observed that using microparticles of radius 0.5 μm, mass attenuation coefficients’ differences between the nano and microparticles fell over. The results revealed that mass attenuation coefficients for nano-composites in comparison with micro-composites of radius 0.5 μm increased by approximately 5–24%. Similar studies showed that the filler particle size in the polymer composite shields is very determinative and the addition of nano-particles to the matrix leads to enhancement of the radiation-shielding characteristics [4, 20, 21, 30].

4 Conclusion

In our work, 10 wt% Bi-composite shields based on nano-sized and micro-sized Bi metal were manufactured. The mass attenuation coefficients of nano-structured and micro-structured of 10 wt% Bi–Si composites as well as those simulated by MCNPX were obtained. In addition, the effect of Bi-particle sizes on the shielding properties in nano-sized and micro-sized Bi–Si composites was investigated at 60, 80, 100, 120, 140, and 150 keV X-rays using MCNPX code and XCOM program data. The results indicated that nano-sized particles have greater attenuation properties as compared to micro-sized particles.

The composites doped with nano-Bi showed significantly improved attenuation property as compared to those doped with micro-Bi particles and showed a higher attenuation efficiency at the lower energy (60–80 kVp) than the higher energy (100–120 kVp) used in diagnostic radiology.

References

de Gonzalez AB, Darby S. Risk of cancer from diagnostic X-rays: estimates for the UK and 14 other countries. Lancet. 2004;363(9406):345–51.

Mehnati P, Amirnia A, Jabbari N. Estimating cancer induction risk from abdominopelvic scanning with 6-and 16-slice computed tomography. IJRB. 2017;93(4):416–25.

Gaikwad D, Obaid SS, Sayyed M, Bhosale R, Awasarmol V, Kumar A, et al. Comparative study of gamma ray shielding competence of WO3–TeO2–PbO glass system to different glasses and concretes. Mater Chem Phys. 2018;213:508–17.

Tekin HO, Singh V, Manici T. Effects of micro-sized and nano-sized WO3 on mass attenuation coefficients of concrete by using MCNPX code. Appl Radiat Isot. 2017;121:122–5.

Kim J, Seo D, Lee BC, Seo YS, Miller WH. Nano-W dispersed gamma radiation shielding materials. Adv Eng Mater. 2014;16(9):1083–9.

Mehnati P, Yousefi Sooteh M, Malekzadeh R, Divband B. Synthesis and characterization of nano Bi2O3 for radiology shield. Nanomed J. 2018;5(4):222–6.

Malekie S, Hajiloo N. Comparative study of micro and nano size WO3/E44 epoxy composite as gamma radiation shielding using MCNP and experiment. Chin Phys Lett. 2017;34(10):108102.

Nambiar S, Osei EK, Yeow JT. Polymer nanocomposite-based shielding against diagnostic X-rays. J App Polym Sci. 2013;127(6):4939–46.

Verdipoor K, Alemi A, Mesbahi A. Photon mass attenuation coefficients of a silicon resin loaded with WO3, PbO, and Bi2O3 micro and nano-particles for radiation shielding. Radiat Phys Chem. 2018;147:85–90.

Aghaz A, Faghihi R, Mortazavi S, Haghparast A, Mehdizadeh S, Sina S. Radiation attenuation properties of shields containing micro and nano WO3 in diagnostic X-ray energy range. IJRR. 2016;14(2):127.

Botelho M, Künzel R, Okuno E, Levenhagen RS, Basegio T, Bergmann CP. X-ray transmission through nanostructured and microstructured CuO materials. App Radiat Isot. 2011;69(2):527–30.

Rawal SP. Metal-matrix composites for space applications. JOM. 2001;53(4):14–7.

Wagatsuma K, Oda K, Miwa K, Inaji M, Sakata M, Toyohara J, Ishiwata J, Sasaki M, Ishii K. Effects of a novel tungsten-impregnated rubber neck shield on the quality of cerebral images acquired using 15O-labeled gas. Radiol Phys Technol. 2017;10(4):422–30.

Mehnati P, Malekzadeh R, Sooteh MY. Use of bismuth shield for protection of superficial radiosensitive organs in patients undergoing computed tomography: a literature review and meta-analysis. Radiol Phys Technol. 2019;12(1):6–25.

Mehnati P, Sooteh YM, Malekzadeh R, Divband B, Refahi S. Breast conservation from radiation damage by using nano bismuth shields in chest CT scan. Crescent J Med Biol Sci. 2019;6(1):46–50.

Mehnati P, Malekzadeh R, Sooteh MY, Refahi S. Assessment of the efficiency of new bismuth composite shields in radiation dose decline to breast during chest CT. Egypt J Radiol Nucl Med. 2018;49(4):1187–9.

Mesbahi A, Ghiasi H. Shielding properties of the ordinary concrete loaded with micro-and nano-particles against neutron and gamma radiations. App Radiat Isot. 2018;136:27–31.

Mahmoud ME, El-Khatib AM, Badawi MS, Rashed AR, El-Sharkawy RM, Thabet AA. Fabrication, characterization and gamma rays shielding properties of nano and micro lead oxide-dispersed-high density polyethylene composites. Radiat Phys Chem. 2018;145:160–73.

Tekin H, Sayyed M, Issa SA. Gamma radiation shielding properties of the hematite-serpentine concrete blended with WO3 and Bi2O3 micro and nano particles using MCNPX code. Radiat Phys Chem. 2018;150:95–100.

Li R, Gu Y, Wang Y, Yang Z, Li M, Zhang Z. Effect of particle size on gamma radiation shielding property of gadolinium oxide dispersed epoxy resin matrix composite. Mater Res Express. 2017;4(3):035035.

Zhou D, Zhang Q-P, Zheng J, Wu Y, Zhao Y, Zhou Y-L. Co-shielding of neutron and γ-ray with bismuth borate nanoparticles fabricated via a facile sol-gel method. Inorgan Chem Commun. 2017;77:55–8.

Hayati H, Mesbahi A, Nazarpoor M. Monte Carlo modeling of a conventional X-ray computed tomography scanner for gel dosimetry purpose. Radiol Phys Technol. 2016;9(1):37–43.

Mesbahi A, Jamali F. Effect of photon beam energy, gold nanoparticle size and concentration on the dose enhancement in radiation therapy. BioImpacts. 2013;3(1):29.

Mehnati P, Arash M, Akhlaghi P. Bismuth–silicon and bismuth–polyurethane composite shields for breast protection in chest computed tomography examinations. J Med Phys. 2018;43(1):61.

Bjärngard BE, Shackford H. Attenuation in high-energy X-ray beams. Med Phys. 1994;21(7):1069–73.

Mesbahi A, Alizadeh G, Seyed-Oskoee G, Azarpeyvand A-A. A new barite–colemanite concrete with lower neutron production in radiation therapy bunkers. Ann Nucl Energy. 2013;51:107–11.

Poludniowski G, Landry G, DeBlois F, Evans P, Verhaegen F. SpekCalc: a program to calculate photon spectra from tungsten anode X-ray tubes. Phys Med Biol. 2009;54(19):N433.

Shirmardi S, Singh V, Medhat M, Adeli R, Saniei E. MCNP modeling of attenuation coefficients of steel, red brass, pearl and beryl in comparison with experimental and XCOM data. J Nucl Energy Sci Power Gener Technol. 2016;5:2.

Dong M, Sayyed M, Lakshminarayana G, Ersundu MÇ, Ersundu A, Nayar P, et al. Investigation of gamma radiation shielding properties of lithium zinc bismuth borate glasses using XCOM program and MCNP5 code. JNCS. 2017;468:12–6.

Yu D, Shu-Quan C, Hong-Xu Z, Chao R, Bin K, Ming-Zhu D, et al. Effects of WO3 particle size in WO3/epoxy resin radiation shielding material. Chin Phys Lett. 2012;29(10):108102.

Acknowledgements

This study was supported by the office of the vice president of research of Tabriz University of Medical Sciences, Iran.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that there is no conflict of interest.

Ethical approval

Not applicable.

Informed consent

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

About this article

Cite this article

Malekzadeh, R., Mehnati, P., Sooteh, M.Y. et al. Influence of the size of nano- and microparticles and photon energy on mass attenuation coefficients of bismuth–silicon shields in diagnostic radiology. Radiol Phys Technol 12, 325–334 (2019). https://doi.org/10.1007/s12194-019-00529-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12194-019-00529-3