Abstract

With portable capacitative sensors, a universal method has been established to analyze different organic compounds from real samples. Firstly, the object compounds serve as templates in the preparation of molecularly imprinted polymers (MIPs). The resulted polymers are promising materials to fabricate highly sensitive and highly selective sensors for the templates. Low mass transfer resistance in the cryogenically synthesized MIPs makes it very convenient to remove interfering substances, just by rinsing the chromatographic column-like sensors with an eluant. Five food additives were selected to testify the portable detection platform. Good linear ranges are obtained for sunset yellow (8.60 × 10−10–3.11 × 10−4 mg), sodium cyclamate (9.10 × 10−10–5.61 × 10−4 mg), citric acid (3.40 × 10−10–1.12 × 10−3 mg), benzoic acid (5.50 × 10−11–3.56 × 10−5 mg), and glyceryl monostearate (2.35 × 10−8–6.56 × 10−3 mg). In turn the detection limits are 4.79 × 10−10 mg, 2.63 × 10−10 mg, 1.34 × 10−10 mg, 3.24 × 10−11 mg, and 3.71 × 10−9 mg respectively. Finally “interference-free” analysis has been accomplished for the additives in various food samples from local markets.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Food additives are natural or synthetic substances widely used in modern food industry during processing, packaging, and transportation. They can improve food quality, stability, and durability, or adjust the color, smell, and flavor (Wang et al. 2020; Wu et al. 2021; Cox et al. 2021). Suitable amounts of additives are essential; however, excessive additives usually pose negative impacts on food quality, potentially affect human health (Obaidi et al. 2018), and worsen the stability of economic and social development (Tajik et al. 2021). Therefore, the analysis of food additives is of great importance and has attracted great attention (Li et al. 2020, 2021). Authoritative methods have been designated for those purposes and the standardizations never stop changing with technical progress.

To date, food additives are widely analyzed by gas chromatography (GC) (Azzouz et al. 2020), high-performance liquid chromatography (HPLC) (Liu et al. 2020), fluorescence detection (Coloma et al. 2021), HPLC-tandem mass spectrometry (MS/MS) (Kasperkowiak et al. 2021), capillary electrophoresis (CE) (Szigeti et al. 2021), spectrophotometry (Zhang et al. 2019), and so forth. It reveals that chromatographic methods (GC, HPLC, CE, and analogues) are predominant, obviously because of the ability to concurrently achieve separation and detection.

It is always valuable to seek reliable, convenient, and cost-effective techniques and exploit potential substitutability for the conventional methods (Carneiro et al. 2021; Xu et al. 2019; Chu and Guo 2018). The research of molecularly imprinted polymers (MIPs) blossoms continuously, marked by countless polymers with specific affinity to different templates (Yang et al. 2018, 2019a, 2017, 2016). Materials have been designed and prepared with customized properties (Yang et al. 2019b; Han et al. 2020; Sun et al. 2021), playing an important role in both the fields of science (Huynh et al. 2016) and industry including food additive analysis (Xiao et al. 2018).

In this study, we introduce a convenient method to make portable sensors, and carried out simultaneous analysis of different food additives. The sensors are based on imprinted cryogels possessing strong affinities with five exemplified additives namely sunset yellow, sodium cyclamate, citric acid, benzoic acid, and glyceryl monostearate. When molecular recognition occurs between the templates and MIPs, they create evident capacitance alterations. Because interfering substances have been previously removed by an eluant, detection signals are solely generated from the additive-MIP bindings. As a result, these chromatographic column-like capacitive sensors facilitate selective, sensitive, and fast analysis of food additives from various real samples.

Materials and Methods

Instruments and Reagents

Diallylamine was purchased from Haopeng Chemical Plant (Jinan, Shandong, China). N,N-methylenebisacrylamide (BisAM), acrylamide (AM), sodium hydrogen sulfite (SHS), ammonium peroxydisulfate (APS), and sodium chloride were purchased from Sinopharm Chemical Reagents Co., Ltd. (Shanghai, China). Sunset yellow (SY), sodium cyclamate (SC), citric acid (CA), benzoic acid (BA), glyceryl monostearate (GMS), dimethyl diallyl ammonium chloride (DMDAAC), tween 80, ammonium acetate, phosphoric acid, methanol, and ethanol were purchased from Adamas Reagent Co., Ltd. (Shanghai, China). All chemicals and reagents were of analytical grade and were used as purchased with no further purification unless otherwise stated. Real food samples were purchased from a local market. They are all supplied by mainstream manufacturers in China, and declared being produced according to national or industrial standards.

Fourier-transform infrared (FT-IR) spectrometric experiments were carried out on a 670-IR spectrometer (Varian, USA) using KBr pellets.

HPLC was carried out on a GI-3000 instrument (General Instrument Co., Ltd., Shenzhen, Guangdong, China) with a Shimazu WondaCract ODS-2 column (5 μm, 4.6 × 150 mm).

The capacitance variations were acquired by an LCR meter (M-4070, Jingyan Scientific Corp. Ltd., Dongguan, China) with a liquid crystal display read out and a computer I/O interface. It is powered by a 3.7-V lithium ion battery and its frequency can be adapted to the maximum of 500 kHz. It can realize the detection of inductance (0–100 H), capacitance (0–100 mF), and resistance (0–10,000 MΩ).

Synthesis of Molecularly Imprinted Cryogels

The synthesis of the MIPs with different templates followed a similar protocol. Each cryogel was made from a 20.0 mL deionized water with the same amount of AM, BisAM, SHS, and APS, but different templates and modifiers (Table 1). Briefly all the reagents except APS were dissolved in water. After the addition of APS, 30-s ultrasonic degassing was performed. The solutions were then transferred to a refrigerator to realize the polymerization at low temperature of − 20 \(\mathrm{^\circ{\rm C} }\) for 24 h.

The molecularly imprinted cryogels of different templates were thawed in a water bath at 50 \(\mathrm{^\circ{\rm C} }\) for 2 h. Unreacted monomers and inorganic salts were directly washed and removed with deionized water. Finally, the polymers were dried in an oven at 60 \(\mathrm{^\circ{\rm C} }\) for 3 h and then ground into powder.

As a contrast, non-imprinted polymers (NIPs) were synthesized in the same way, just without templates.

Sensor Fabrication

Plastic pipette tips were cut to 2.8 cm in length. The inner diameters are 0.8 cm at the big end and 0.5 cm at the small end. Two polyimide enameled copper wires (both 1 m in length and 0.31 mm outer diameter) were axially coiled around the wall of the plastic tube, acting as the electrodes of a capacitor (Fig. 1a).

For each sensor, 1.5 g dried MIP powder (evenly mixed 0.2 g glass wool) was put in a pipette tip to fill 80–90% of the volume (Fig. 1b). With an LCR meter, a sensor makes up a portable detecting platform of the template (Fig. 1c).

Sample Analysis

All the food additives (SY, SC, CA, BA, and GMS) were weighed to prepare stock solutions of 1.000 g L−1 in water (10% tween 80). Linear ranges and detection limits were determined with stepwise diluted solutions from the stocks.

For the selected solid samples, 0.15 g of each was ground into small particles, and soaked in 2 mL water (10% tween 80). After 15 min, it was filtered to give about 1 mL filtrate. The procedure was repeated 5 times and the filtrates were merged and transferred into a 10.0 mL volumetric flask. The liquid sample was directly filtered for three times. A filtrate of 2.00 mL was diluted with water and put in a 10.0 mL volumetric flask.

A universal procedure was followed to analyze all the samples. It can be demonstrated as “equilibration → loading → washing → detection.” After a sensor was equilibrated with the eluant, a volume (for example 2.0 mL) of samples was loaded on, and let them interact with the MIPs for 3 min. The capacitance was recorded after the sensor had been washed with 10 mL eluant.

Results and Discussion

Universal Imprint Protocol for Different Templates

Five food additives (Fig. 2) are picked out to testify the broad adaptability of the analytical method. Among them SY and SC are strong electrolytes (sulfonate). CA and BA are partially ionizable organic acid, and GMS is a non-electrolyte with poor solubility in aqueous media. They have all been imprinted with similar solutions containing the same amount of monomer (AM) and cross-linker (BisAM) (Table 1).

Because of drastically suppressed solvent effects during the polymerization, specific recognition sites are built in the MIPs with outstanding selectivity and affinity with the template, ensuring the accuracy and precision of the sensor. To further strengthen the template-MIP interactions, 2 chemicals were added to modify the polymers. Diallylamine reacts with both CA and BA, generating ionic bonds. In addition to weak interactions (hydrogen bonding etc.), this greatly increases the MIP affinities. Although no ionic bond was created between GMS and diallylamine, hydrogen bonding is inevitable and it also reinforces the recognizing power of the imprinted sites. With regard to SY and SC, the quaternary ammonium salt (DMDAAC) was used to produce “ion pairs” to enhance the template-MIP interactions. Through self-assembly, these interactions are built between the templates and the monomers/crosslinkers/modifiers in the solutions. Therewith the interactions are inherited and maintained in the template-MIP systems, establishing strong and exclusive molecular recognitions.

The FT-IR spectra of the MIPs are shown in Fig. 3, highly alike to each other. Few differences can be seen for the imprinted cryogels of the different food additives. It indicates that the same chemical groups can be applied to construct distinct microstructures for the recognition of various template molecules.

Molecular Recognition Procedures and Sensor Features

Capacitance generally changes along with the interaction of an MIP-template system. It is the theoretical foundation of an MIP-based capacitive sensor.

As abovementioned, acidic templates (citric and benzoic acid) reacted with diallylamine in the prepolymerizing solutions. Afterwards the reactions also take place between the templates and the MIPs:

where HN < is the amino group tethered on the polymers. It significantly strengthens the MIP-template interaction (Fig. 4) and sensor selectivity. Reaction (1) creates both anions and cations. Therefore, the capacitance increases as either BA or CA rebinds to the imprinted sites of its MIP. However, the space shapes of the MIPs are different from each other, for instance the imprinted site for benzoic acid in Fig. 4. It guarantees the selectivity of a designated MIP.

In the same way, the recognition of SY or SC by its MIPs can be expressed as.

There is an inorganic salt (NaCl) and a less ionizable polymer-sulfo “ion pair” compound formed in reaction (2). As a whole, capacitance elevations can be observed in the sensors.

Because GMS is a neutral compound, no ionization occurs when it is recognized by the MIP. However, the formation of hydrogen bond could occupy polar groups from both GMS and the MIP. The total polarity of the MIP-template system declines and that leads to capacitance reduction.

Linear Ranges and Detection Limits

Herein detection was carried out by adding small amount of samples in the sensors, rather than immersing the sensors in sample solutions. It is proved that the capacitance increase or decrease is correlated to the total mass of the template recognized in the sensor. There is a linearity between the capacitance variation (C) and the logarithmic template mass (log m):

As indicated in “Molecular Recognition Procedures and Sensor Features,” the capacitance increases along with the amounts (here the related logarithms) of SY, SC, CA, and BA. The linear ranges of these compounds are 8.60 × 10−10–3.11 × 10−4 mg, 9.10 × 10−10–5.61 × 10−4 mg, 3.40 × 10−10–1.12 × 10−3 mg, and 5.50 × 10−11–3.56 × 10−5 mg respectively (Fig. 5a, b, c, and d). Different from this, the sensor signal decreases as GMS is continuously added. Meanwhile a narrower linearity (2.35 × 10−8–6.56 × 10−3 mg) is obtained for the neutral template (Fig. 5e).

Based on 3 times the values of the sensor noises, detection limits have been calculated. They are 4.79 × 10−10 mg for SY, 2.63 × 10−10 mg for SC, 1.34 × 10−10 mg for CA, 3.24 × 10−11 mg for BA, and 3.71 × 10−9 mg for GMS.

Detection of Food Additives in Real Samples

Some standard analytical methods of the exemplified food additives are listed in Table 2. They are quoted from the technical specifications of the international organization for the standardization (ISO), the state standard of China (GB), and some industrial standards. Besides 1 enzymatic and few spectrometric methods, chromatography (gas or liquid) dominates the authoritative detection protocols. More than 80% of the total (19 out of 23) are GC, HPLC, or IC (ion chromatography), being used to determine the additives in diverse foods including breads, biscuits, candy, ice cream, drinks, fruits, juice, vegetables, and others. Synchronous implementation of separation and detection can be the outstanding advantage of chromatographic techniques. This is also the best reason that chromatography surpasses other methods when subjected to the analysis of complex samples.

Currently it is costly and laborious to perform chromatography. To whether GC or HPLC, it is prerequisite to prepare a complete set of expensive devices such as pump, injector, column, detector, and so on. For the most commonly used UV–Vis detector in HPLC, many compounds are undetectable for lack of suitable chromophores. On the contrary, portable capacitive sensors operate based on very simple devices. Because permittivity differences between chemical substances are ubiquitous, a capacitance analysis method can always work to analyze almost all organic compounds existing in aqueous solutions.

Herein the 5 capacitive sensors all act like chromatographic columns (Fig. 1a and b). When a real sample is loaded on the sensor, the analyte and interfering substances are inevitably introduced at the same time. Because an analyte is the template used to synthesize the MIP, there are specific interaction sites for it in the polymer. It makes the adsorption of the analyte stronger than that of other species, ensuring an “interference-free” status to detect the analyte. Taking benzoic acid as an example, the interfering substances are removed after washed with 10 mL eluant (Fig. 6a). Benzoic acid itself is eluted from 23 to 50 mL. As the capacitance changes are read and recorded from 10 to 23 mL, benzoic acid is the unique molecule detained in the sensor. As a result, the detection signals are solely caused by the analyte-MIP binding, without any interfering species in the sensor.

By comparison, benzoic acid is eluted from an NIP column by 15 mL eluate, exhibiting negligible retention. According to the ratio of the retention factors (kMIP/kNIP), the imprinting factor is calculated to be about 3.0. Likely higher imprinting factors (4.1–5.6) are obtained for other additives. Theoretically a template can be exclusively detected if the imprinting factor is more than 1.5. The efficient imprints guarantee all the food additives can be analyzed in an “interference-free” status.

As a structural analogue, salicylic acid is very similar to benzoic acid. However, its retention volume is just 12 mL, far from that of benzoic acid and close to that of the interfering substances (Fig. 6b). Thereout even very analogous compounds show inferior retention to the template, and can be removed along with the dissimilar substances, giving ignorable interference to the sensor.

A simple sampling protocol was followed in this study. Seven additive-rich foods, especially snacks and drinks, were directly extracted with 10% tween 80 to make experiment samples. At the same time, a similar “equilibrate-load-wash” process was carried out to determine all the analytes. The results are shown in Table 3, showing recoveries from 94.2 to 105.4% for the standard compounds added in the real samples. Good selectivity is ensured when the sensors respond to the analytes in complex samples. Relative standard deviations (RSDs) are calculated based on 5 times of repeated detections, giving values from 3.0 to 6.5% and showing good precision of the method.

For comparison, the samples of SY, CA, and BA were also analyzed by HPLC. The results are listed in Table 4, indicating good consistence with the data from the sensors. However, derivative reaction is necessary for sodium cyclamate prior to HPLC analysis, and it is found to be of low efficiency in the real samples. With respect to glyceryl monostearate, there is no suitable detection wavelength even after derivative reactions. These multifarious and inconvenient operations exactly demonstrate the advantages of the sensor method.

Besides the aforesaid standard curve method, rapid analysis can also be done by a standard addition method. Because a, b, and mx are unknown in Eq. (3), standard addition should be done twice

where \(\Delta {\mathrm{C }}_{\mathrm{x}},\Delta {\mathrm{C }}_{1}\mathrm{ and \Delta }{\mathrm{C }}_{2}\) are the capacitance changes from the original determinand and the samples with known additive amounts m1, m2.

Also because the samples are determined without interfering substances, the ternary linear equation group can be further simplified

Now it is equivalently an external standard method. Two known samples and the unknown sample are tested individually. The result is obtained just by resolving the ternary linear Eqs. (5).

Conclusions

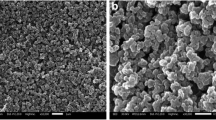

Molecularly imprinted cryogels are outstanding molecular recognition materials to make portable capacitive sensors for organic compounds. They are macroporous (> 50 μm) materials of low mass transfer resistance, enabling speedy equilibriums and fast detection with the chromatographic column-like sensors. By washing the sensors with an eluant, all interfering substances are removed prior to the analytes. This results into an “interference-free” status to determine the target compound. Capacitance changing signals are solely resulted from the analyte-MIP interaction. Meanwhile a simple and universal pretreatment can work regardless of sample complexity. It offers a promising method with high sensitivity and selectivity, to analyze organic compounds in diverse samples.

Data Availability

All data generated or analyzed during this study are included in this published article.

References

Azzouz A, Colon LP, Hejji L, Ballesteros E (2020) Determination of alkylphenols, phenylphenols, bisphenol A, parabens, organophosphorus pesticides and triclosan in different cereal-based foodstuffs by gas chromatography-mass spectrometry. Anal Bioanal Chem 412:2621–2631

Carneiro SV, Holanda MHB, Cunha HO, Oliveira JJP, Pontes SMA, Cruz AAC et al (2021) Highly sensitive sensing of food additives based on fluorescent carbon quantum dots, Journal Of Photochemistry And Photobiology a-Chemistry, 411

Cheese and processed cheese products - determination of citric acid content - enzymatic method: ISO/TS 2963–2006[S]. 2006.

Chu J, Guo W (2018) Electrochemical sensor for sulfide determinationin food additives. Functional Materials 25:184–187

Coloma A, del Pozo M, Martinez-Moro R, Blanco E, Atienzar P, Sanchez L et al (2021) MoS2 quantum dots for on-line fluorescence determination of the food additive allura red, Food Chem, 345

Cox S, Sandall A, Smith L, Rossi M, Whelan K (2021) Food additive emulsifiers: a review of their role in foods, legislation and classifications, presence in food supply, dietary exposure, and safety assessment. Nutr Rev 79:726–741

Determination of 11 synthetic colorants in foods such as beverage and ice cream for export - Liquid chromatography: SN/T 4457–2016[S]. 2016.

Determination of alluring red, acid red, brilliant blue and sunset yellow in foods - High performance liquid chromatography: SN/T 1743–2006[S]. 2006.

Determination of benzoic acid and sorbic acid in vinegar for export-LC and LC-MS/MS method: SN/T 2012–2019[S]. 2019.

Determination of benzoic acid, sorbic acid and p-hydroxybenzoic acid esters antiseptics in milk and dairy products for export - HPLC method: SN/T 4262–2015[S]. 2015.

Determination of benzoic acid, sorbic acid and saccharin sodium in foods: GB 5009.28–2016[S]. 2016.

Determination of lactic, ciric and fumaric acid in fruit juice for import and export - HPLC: SN/T 2007–2007[S]. 2007.

Determination of multiple synthetic dyes in bottom material of chafing dish for export: SN/T 3845–2014[S]. 2014.

Determination of organic acids and anions in vegetables - Ion chromatography: NY/T 2277–2012[S]. 2012.

Determination of organic acids in foods: GB 5009.157–2016[S]. 2016.

Determination of six kinds of artificial sweeteners in foodstuffs for export-LC-MS/MS method: SN/T 3538–2013[S]. 2013.

Determination of sodium cyclamate in foods (press release): GB 5009.97–2016[S]. 2016.

Determination of sodium cyclamate in foods for import and export-HPLC-MS/MS method: SN/T 1948–2007[S]. 2007.

Determination of synthetic color in fruit tins - high performance liquid chromatography: GB/T 21916–2008[S]. 2008.

Determination of various preservaives in foods for export: SN/T 3545–2013[S]. 2013.

Food additive - glyceryl mono- and distearate: GB 1986–2007[S]. 2007.

Fruit and vegetable products - determination of benzoic acid content (benzoic acid contents greater than 200 mg per litre or per kilogram) - molecular absorption spectrometric method: ISO 6560–1983[S]. 1983.

Fruit and vegetable products - determination of benzoic acid and sorbic acid concentrations - high performance liquid chromatography method: ISO 22855–2008[S]. 2008.

Fruits, vegetables and derived products - determination of benzoic acid content - spectrophotometric method: ISO 5518–2007[S]. 2007.

Han XJ, Ji XF, Zhang Q, Sun JW, Sun PX, Pan WJ et al (2020) Giant "molecular capacitor" arrays - portable sensors to determine ionizable compounds, J Electroanal Chem, 865.

Huynh T-P, Wojnarowicz A, Kelm A, Woznicki P, Borowicz P, Majka A et al (2016) Chemosensor for selective determination of 2,4,6-trinitrophenol using a custom designed imprinted polymer recognition unit cross-linked to a fluorophore transducer. Acs Sensors 1:636–639

Kasperkowiak M, Beszterda M, Banczyk I, Franski R (2021) Differentiation of bisphenol F diglycidyl ether isomers and their derivatives by HPLC-MS and GC-MS-comment on the published data. Anal Bioanal Chem 413:1893–1903

Li L, Zhang M, Chen W (2020) Gold nanoparticle-based colorimetric and electrochemical sensors for the detection of illegal food additives. J Food Drug Anal 28:641–653

Li WQ, Diao KS, Qiu DY, Zeng YF, Tang KJ, Zhu YF et al (2021) A highly-sensitive and selective antibody-like sensor based on molecularly imprinted poly(L-arginine) on COOH-MWCNTs for electrochemical recognition and detection of deoxynivalenol, Food Chem, 350

Liu Z, Ren K, Feng Y, Uong T, Krepich S, You H (2020) Rapid and economic determination of 13 steviol glycosides in market-available food, dietary supplements, and ingredients: single-laboratory validation of an HPLC method. J Agric Food Chem 68:10142–10148

Obaidi I, Higgins M, Bahar B, Davis JL, McMorrow T (2018) Identification of the multifaceted chemopreventive activity of curcumin against the carcinogenic potential of the food additive, KBr O3. Curr Pharm Des 24:595–614

Sun PX, Han XJ, Chen LJ, Chen ZJ, Pan WJ, Zhang Q et al (2021) Determination of glucose by a molecular capacitor array based using a 3-(acrylamido) phenylboronic acid prepared molecularly imprinted polyacrylamide cryogel, Anal Lett.

Szigeti M, Meszaros-Matwiejuk A, Molnar-Gabor D, Guttman A (2021) Rapid capillary gel electrophoresis analysis of human milk oligosaccharides for food additive manufacturing in-process control. Anal Bioanal Chem 413:1595–1603

Tajik S, Beitollahi H, Jang HW, Shokouhimehr M (2021) A simple and sensitive approach for the electrochemical determination of amaranth by a Pd/GO nanomaterial-modified screen-printed electrode. RSC Adv 11:278–287

Wang D, Wang Z, Wang X, Zhuang X, Tian C, Luan F et al (2020) Functionalized copper nanoclusters-based fluorescent probe with aggregation-induced emission property for selective detection of sulfide ions in food additives. J Agric Food Chem 68:11301–11308

Wu L, Zhang CH, Long YX, Chen Q, Liu Zhang WM, GZ, (2021) Food additives: from functions to analytical methods. Crit Rev Food Sci Nutr 6:1–21

Xiao DL, Jiang Y, Bi YP (2018) Molecularly imprinted polymers for the detection of illegal drugs and additives: a review, Microchimica Acta, 185.

Xu J-W, Cui Z-M, Liu Z-Q, Xu F, Chen Y-S, Luo Y-L (2019) Organic-inorganic nanohybrid electrochemical sensors from multi-walled carbon nanotubes decorated with zinc oxide nanoparticles and in-situ wrapped with poly(2-methacryloyloxyethyl ferrocenecarboxylate) for detection of the content of food additives, Nanomaterials, 9

Yang C, Zhou XL, Liu YR, Wang J, Tian LL, Zhang Y et al (2016) Charged groups synergically enhance protein imprinting in amphoteric polyacrylamide cryogels. J Appl Polym Sci 133:6

Yang C, Zhang Y, Cao W-Q, Ji X-F, Wang J, Yan Y-N et al (2018) Synthesis of molecularly imprinted cryogels to deplete abundant proteins from bovine serum. Polymers 10:97

Yang C, Ji X-F, Cao W-Q, Wang J, Zhang Q, Zhong T-L et al (2019) Molecularly imprinted polymer based sensor directly responsive to attomole bovine serum albumin. Talanta 196:402–407

Yang C, Ji X-F, Cao W-Q, Wang J, Zhang Q, Zhong T-L et al (2019) An ultra sensitive and selective impedance sensor based on protein-imprinted polymer. Sensors Actuators b: Chem 282:818–823

Yang C, Liu YR, Zhang Y, Wang J, Tian LL, Yan YN et al (2017) Depletion of abundant human serum proteins by per se imprinted cryogels based on sample heterogeneity, Proteomics, 17.

Zhang R, Zhang MX, Zhang Y, Yan H, Li X, Xie WH (2019) The simultaneous detection of food dyes from different samples in a 96-well plate by spectrophotometry. Anal Methods 11:5793–5802

Funding

This work was partly supported by the Priority Academic Program Development of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Pei-Xia Sun declares that he has no conflict of interest. Juan Cai declares that he has no conflict of interest. Li-Jie Chen declares that he has no conflict of interest. Jian Wang declares that he has no conflict of interest. Chun Yang declares that he has no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed Consent

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sun, PX., Cai, J., Chen, LJ. et al. MIP-Based Portable Sensors for the Simultaneous Analysis of Multiple Food Additives. Food Anal. Methods 15, 2335–2345 (2022). https://doi.org/10.1007/s12161-022-02273-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-022-02273-8