Abstract

A sensitive and a precise method was developed for the quantification of different Sudan dyes in some Egyptian food samples. They were analyzed utilizing two-fragment ion transition under multiple reaction monitoring (MRM) mode. Separation was carried out on Kinetex 2.6u C18 100 A (75 mm × 4.6 mm) phenomenex using isocratic elution with 10:90% water and acetonitrile containing 2.0 mmol/L ammonium formate and 0.2% formic acid. The validation parameters were obtained and verified. The linearity was 0.2–10.0 ng/mL with r2 > 0.9975. LOD and LOQ were 0.06 and 0.19 ng/mL, respectively, for Sudan (I, II) whereas they were 0.07 and 0.23 ng/mL, respectively, for Sudan (III and IV), and Sudan orange G. Recoveries are ranged from 78.79 to 110.49%. The method has been successfully applied for the quantification of these dyes in 60 food samples such as spices, chili powder, turmeric, paprika, and curry. The results show that about 55% of the randomly selected food samples were adulterated with the banned dyes.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sudan I, II, III, and IV and Sudan orange G are fat-soluble substances containing azo group (–N = N–) in their structure (Scheme 1) which are responsible for color (Tsai et al. 2015). They are cheap and stable dyes relative to natural dyes with intense red–orange color; as a result, they are used as additives to various materials in different industrial and scientific applications such as fuels, oils, solvents, textile, coloring waxes, shoe polish, and cosmetic products, and in histology for cell staining (Bazregar et al. 2018). Inferable from their azoic structure and aromatic rings (Scheme 1), Sudan dyes have evident toxic consequences for the human organs. The later can result in allergy and asthmatic reactions, respiratory problem, DNA damage, thyroid tumors, chromosomal damage, hyperactivity, and abdominal pain when taken orally or absorbed by skin (Bazregar et al. 2018). Sudan dyes are metabolized or degraded to aniline and its derivatives which may cause the toxic effects (Xu et al. 2010; Zanoni et al. 2013; Pietruk et al. 2019). Moreover, the nervous system could be destroyed by the long-term intake of aniline (Rajabi et al. 2015). They are not permitted to be used as food additives in Canada, the European Union (EU), and the USA. Sudan I was found in hot chili peppers for the first time of EU notification in 2003 by the French food control. The latter was posted in the European Rapid Alert System for Food and Feed (RASFF). Moreover, Sudan dyes are classified as category 3 carcinogens by the International Agency for Research on Cancer (IARC) (European Commission. RASFF-Food and Feed Safety Alerts nd; The European, Parliament and the Council of the European Union (2002); IARC 1975; Schwacket al. 2018). About 90% of information transmitted to the human's mind is visual, and the attractive color of food is the essential part of decision about its quality, freshness, and, therefore, health benefits. The food coloring synthetic dyes, such as Sudan dyes, are preferred in manufacturing processes due to their higher stability (Zacharis et al. 2011). They are added illegally to food products, especially chili-containing foods such as chili sauce, turmeric, curry, and paprika, and palm oil-containing foodstuffs, frozen meat products, and spice mix (Xu et al. 2010; Zanoni et al. 2013; Pietruk et al. 2019).

Sudan dyes with concentration level of 100–1000 mg/kg are required to enhance foodstuff color (Lian et al. 2014; Wu et al. 2015). Low concentration of Sudan dyes may be found in foodstuffs probably due to cross-contamination during transport and storage process (Hoenicke 2006; Schummer et al. 2013). To differentiate between cross-contamination and adulteration; the European Union fixed that more than 0.5 mg/kg for the concentration level of Sudan dyes in food samples is considered adulteration. Even at low level of sub ppm of these dyes, it was still carcinogenic. Despite the fact that Sudan dyes are banned, the EU Rapid Alert System for Food and Feed has reported at least 20 cases each year of Sudan I and IV discovery in certain nourishment items that were imported from outside of the EU (Yu et al. 2015). In order to assure the consumer’s health, accurate and reliable methods are required for the quantification of these compounds in diverse foodstuff. The survey includes GC/MS (Otero et al. 2017), HPLC (Yang et al. 2019; Hu et al. 2016; Yan et al. 2012; Khalikova et al. 2014; Chen and Huang, 2014; Wu et al. 2010; Liu et al. 2018), and LC/MS/MS spectrometry (Tsai et al. 2015; Piatkowska et al. 2017; Zhao et al. 2012). Among these referenced techniques, TLC and spectrophotometry are widely used for the determination of water-soluble dyes because of their low cost although they often suffer from poor sensitivity and interference from the food matrix. The previously published LC methods use PDA or UV detectors which offer good separation, but they are taking time in the interpretation of results for overlapping peaks. The LC–MS/MS spectrometry is a powerful technique for the detection of residual chemical compounds, confirmatory identification of small organic molecules, confirmation, and quantitation of contaminants and adulterants in pharmaceutical and food samples. According to our survey, there is no previously published work in Egypt for the detection and the quantification of the mentioned analytes together, and particularly in the foodstuff by LC–MS/MS spectrometry. As a result, this study tends to develop and validate a rapid, sensitive, precise, and accurate method for the simultaneous determination of Sudan I, II, III, IV, and orange G in chili powder, turmeric, curry, and paprika utilizing LC/MS/MS spectrometry.

Experimental

Chemicals and Materials

Sudan I (97%), M.wt = 248.29 g/mol; Sudan II (90%), M.wt = 276.34 g/mol; Sudan III (96%), M.wt. = 352.39 g/mol; Sudan IV (96%), M.wt = 380.44 g/mol; and Sudan orange G (98%), M.wt. = 214.22 g/mol, analytical standards were obtained from Sigma-Aldrich (Germany). Ammonium formate (≥ 99%) and formic acid (98%) were obtained from Fluka (Germany). Acetonitrile HPLC grade was obtained from Merck (Germany) and Fisher (UK). Methanol HPLC grade was purchased from Fisher (UK). Acetone HPLC was obtained from Sigma-Aldrich (Germany). Deionized water was purified through a Milli-Q system from Millipore (USA). PTFE syringe filters (0.2 μm, 25 mm) were received from Restek (USA). Falcon tube 50 mL was obtained from China.

Instruments

The LC–MS/MS system consisted of a Shimadzu Nexera X2 LC-30 AD liquid chromatograph (Shimadzu, Japan) coupled with a 5500 triple quadrupole detector (AB Sciex, Toronto, ON, Canada), controlled by analyst software. Nitrogen generator was obtained form Peak Scientific Instruments Ltd., Chicago, IL, USA. Centrifuge sigma 3-18 K (Germany) and Vortex mixer (Taiwan) and Sonicator Branson 5510 (USA) were used for preparation of standard dyes and samples.

Standard Solutions

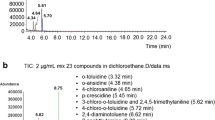

Stock solutions of Sudan I and II and Sudan orange G were prepared by dissolving 10.0 mg of each dye in 10 mL acetonitrile (1.0 mg/mL). While for Sudan III and IV, the solutions were prepared by dissolving 10.0 mg of the solid dye in 100 mL acetonitrile to prepare 0.1 mg/mL. All of the previous solutions were prepared in amber measuring flasks and were kept in dark at − 20 °C for 6 months(Piatkowska et al. 2017). Sudan III and Sudan IV undergo E-Z photo-isomerization forming isomers that appear in chromatogram before main peak (fast peaks) as shown in Fig. 1, where these isomers cannot be controlled even under all analytical precautions (Genualdi et al. 2016; Molder et al. 2007).

Working standard solutions of 0.2, 0.5, 1.0, 2.0, 5.0, 8.0, and 10.0 ng/mL were prepared by diluting the mixed standard stock solution with acetonitrile in appropriate proportions.

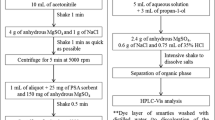

Sample Preparation

Sixty food samples, including chili, turmeric, paprika, and curry, were obtained from Egyptian local markets. One gram of each sample was weighed into a centrifuge tube; then, 20 mL of acetonitrile was added and shacked with hand for 1 min, vortex 2 min, sonication for 15 min followed by centrifugation at 4500 rpm at 15 °C for 10 min. The sample was filtered on PTFE syringe filters (0.2 μm, 25 mm). Ten microliters of the filtered sample was diluted to 1000 µL using acetonitrile. Further dilutions were carried out to eliminate the instrument contamination and this was based on the color of the resulting solution. The resulting solution was finally injected to the instrument to be analyzed.

LC–MS/MS Conditions

The mobile phase consists of water and acetonitrile (10:90%) containing 2 mmol/L ammonium formate and 0.2% formic acid with isocratic elution at 0.3 mL/min flow rate. The injection volume was 10 µL. The separation was carried on Kinetex 2.6u C18 100 A 75 × 4.6 mm phenomenex (USA) at 30 °C. The positive (ESI +) mode and multiple reaction monitoring (MRM) mode were used for the quantification with at least two transitions for each dye. The optimized instrument operating parameters for mass spectral acquisition were as follows: ion spray voltage 5500 V; curtain gas 30 psi, nebulizer gas (gas 1) 35 and heater gas (gas 2) 40 psi; turbo spray temperature 400 °C; and other parameters with precursor ions (Q1) and product ions (Q3) are summarized in Table 1.

Analytical Method Validation

Precision and Accuracy

Method validation was performed on the standard dyes and the different food samples. Quantitative investigation was completed by the external standard calibration strategy. Method validation of samples was set up by spiking 1.0 g of food samples (chili powder, turmeric, curry, and paprika) with a proper amount of stock standard solution and finally reach to the study level (1.0, 5.0, 10.0 ng/mL). Recoveries were determined by comparing the peak areas of the spiked samples with those of standard solutions. Precision was evaluated by analyzing six replicates of a sample during the same day. The sensitivity of the strategy was assessed by the evaluated limits of detection (LODs) and quantification (LOQs). The latter was resolved experimentally from the injections of spiked samples and they were determined utilizing the minimum concentration of analytes resulting in signal to noise ratios of 3 and 10, respectively. Target dyes were viewed as distinguished by the presence of two characteristic fragment ions at the right retention time with the right relative ion intensity and an accurate mass.

Specificity and Selectivity

Selectivity was examined by realizing the potential interferences between impurities and food matrix in the sample extracts and the analytes. Different samples (chili powder, turmeric, curry, and paprika) were spiked with the studied dyes, and then, they were analyzed.

Matrix Effect

After extraction of turmeric, chili, paprika, and curry samples, they were spiked with three different concentrations of standard solution of the different studied dyes 10.0, 5.0, and 1.0 ng/mL (n = 3). The matrix effect (ME) was calculated relative to the concentration of spiked sample to the concentration of the standard solution (Eq. (1)).

- Cspiked:

-

The concentration of spiked sample.

- Csample:

-

The concentration of sample contaminated with dyes.

- Cstd:

-

The concentration of standard dye in the pure solvent

Results and Discussion

LC–MS/MS Determination and Quantitation

The mass spectrometer parameters were chosen and optimized by direct infusion of each standard solution individually (20.0 ng/mL in acetonitrile) from a syringe pump at the flow rate of 10.0 μL/min in a positive mode involving choosing the precursor and the product ions for each compound. Multiple reaction monitoring (MRM) mode was established. Entrance potential (EP), decluttering potential (DP), collision energies (CEs), and cell exit potential (CXP) of each Sudan dye were optimized (Table 1). The MRM was established using the transitions of the most stable and abundant product ions for quantification and the other transition for confirmation. For the separation of the analytes, isocratic elution of water and acetonitrile (10:90%) containing 2 mM ammonium formate and 0.2% formic acid was used as a mobile phase under a flow rate of 0.3 mL/min. Ten microliters injection volume was used to achieve the chromatographic separation of all dyes in the standard solution in 15 min. The LC–MS/MS chromatograms of all dyes are shown in Fig. 1. The retention times of standard solutions are 6.34, 7.45, 8.26, 11.04, and 5.31 min for Sudan I, II, III, IV, and orange G.

Type of Extraction Solvent

The selection of an extraction solvent is of great importance in the solvent extraction methods. To develop an extraction protocol, 1.0 g of each food sample was weighed into a centrifuge tube and mixed with working standard solution of the five dyes (resulted fortification level was 10.0 ng/mL). Acetonitrile, methanol, and acetone were checked for the good extraction result to confirm that acetonitrile gave the best result due to its compatibility with the mobile phase (Fig. 2).

Method Validation

The method was validated using different matrices (3 different products for each type).

Selectivity

Selectivity is characterized as the ability of the bioanalytical strategy to quantify a substance unequivocally and to separate between the analyte(s) and impurities that might be available (Zhu et al. 2015). Under the optimized LC–MS/MS parameters, Sudan I–IV and orange G in the blank samples are separated with excellent selectivity and sensitivity (Fig. 1). The results showed that there was no significant interference observed at the corresponding retention time of each target analyte.

Linearity, LOD, and LOQ

Standard curves were made in triplicate for each concentration of the dyes under study. Different concentrations (0.2, 0.5, 1.0, 2.0, 5.0, 8.0, 10.0 ng/mL (n = 3 for each concentration)) were tested for the method. The results showed good linearity over the studied concentration range, with correlation coefficients (r2) of 0.9993–0.9997. LOD and LOQ were calculated by signal to noise ratio (S/N) of 3 and 10, respectively. LOD was 0.06 ng/mL for Sudan I and II, and was 0.07 ng/mL for Sudan III, IV, and orange G. LOQ was 0.19 ng/mL for Sudan I and II and 0.23 ng/mL for Sudan III, IV, and orange G (Table 2 and Fig. 3).

Recovery

The precision of the method was verified by measuring recoveries of spiked blank samples with different matrices at three concentration levels. Three duplicates of spiked samples were prepared for each concentration level and analyzed according to the experimental section. The obtained recoveries are 88.60–99.83%, 81.75–99.27%, 87.94–109.06%, 89.36–110.49%, and 78.79–100.32% with relative standard deviation (RSD%) of 1.69–8.01%, 1.70–6.44%, 0.92–7.64%, 0.83–8.21%, and 1.43–5.79% for Sudan I, II, III, IV, and orange G, respectively (Table 3).

Robustness

It was determined by injecting the same standard solution of each dye with a concentration of 5.0 ng/mL under different flow rates (0.29, 0.30, and 0.31 mL/min). The recovery was calculated relative to the theoretical concentration of each standard. The results showed that the value is slightly affected by the later change; the percentage error was from 0.05 to 4.07%.

Matrix Effect

It was studied as described in the “Experimental” section. Table 4 shows the ionization suppression/enhancement effect in different matrices. In turmeric samples, ionization enhancement from 3.36 to 24.87% in all dyes, chili samples enhance ionization slightly in Sudan I and II from 2.89 to 8.93% and suppress the ionization in Sudan III and Sudan IV from 2.76 to 12.89% while 11.58 to 14.52% in Sudan orange G. Paprika samples suppress the ionization in Sudan I and II from 2.18 to 14.28% and Sudan III and IV enhance ionization from 6.98 to 28.31%, but in Sudan orange G no effect at low concentration, suppression with 5.48 to 11.14% at two other concentrations. Curry samples enhance all dyes from 1.74 to 22.73% except Sudan orange G in higher concentration is slightly suppressed with 0.3%. Matrix effect of different samples of concentration of 10 ng/mL is shown in Fig. 4.

Application to Real Samples

The developed method in this study was used for the determination of the target dyes in different real samples. Sixty commercial samples were collected randomly from different markets in Egypt. Two MRM transitions for each compound were monitored during LC–MS/MS analysis for the identification and confirmation of the different dyes. Samples for each type were repeated 3 times and injected 3 times. Twenty-seven samples were found to be free from all studied dyes. All 60 samples are free from Sudan II. Table 5 shows the found concentrations of Sudan I, II, IV, and orange G in the other 33 samples. It was observed that Sudan I was not found in sample nos. 21, 22, and 29. Sudan III was found in three samples (nos. 20, 21, and 22). Sudan IV was found in thirteen samples (nos. 1, 4, 5, 6, 8, 9, 10, 11, 12, 13, 15, 19, and 32). Sudan Orange G was found in only two samples (22 and 29). Figure 5 shows an overview for the adulteration in different selected samples with respect to their types.

A comparison between the current study and previously published methods is tabulated in Table 6 with respect to the instrument type, column, mobile phase, linearity, LOD, LOQ, and the total run time.

Conclusion

Monitoring of synthetic Sudan dyes in foodstuffs is very important in both domestic and imported foods. This study presents a suitable analysis method for the extraction, detection, and quantitation of five Sudan dyes (Sudan I, II, III, IV, and orange G) utilizing LC–MS/MS spectrometry in chili, paprika, turmeric, and curry Egyptian samples. The developed preparation procedure, through the extraction of acetonitrile, is sensitive, rapid, and simple and offers good recovery and precise results. The LC–MS/MS method under multiple reactions monitoring (MRM) mode is able to detect all target compounds in a single run with an LOQ 0.2 ng/mL. Overall, the LC–MS/MS method can be applied in routine Sudan dye testing and surveillance programs for the control of the presence of Sudan dyes in chili, paprika, turmeric, and curry. The results showed that 55% of the randomly selected samples are contaminated with dyes in different concentrations.

Code Availability

Not applicable.

References

Al Tamim A, AlRabeh M, Al Tamimi A, AlAjlan A, Alowaifeer A (2020) Fast and simple method for the detection and quantification of 15 synthetic dyes in sauce, cotton candy, and pickle by liquid chromatography/tandem mass spectrometry. Arab J Chem 13:3882–3888. https://doi.org/10.1016/j.arabjc.2019.09.008

Bazregar M, Rajabi M, Yamini Y, Arghavani-Beydokhti S, Asghari A (2018) Centrifugeless dispersive liquid-liquid microextraction based on salting-out phenomenon followed by high performance liquid chromatography for determination of Sudan dyes in different species. Food Chem 244:1–6. https://doi.org/10.1016/j.foodchem.2017.10.006

Bessaire T, Savoy M, Mujahid C, Tarres A, Mottier P (2019) A new high-throughput screening method to determine multiple dyes in herbs and spices. Food Addit Contam Part A 36:836–850. https://doi.org/10.1080/19440049.2019.1596320

Chen B, Huang Y (2014) Dispersive liquid-phase microextraction with solidification of floating organic droplet coupled with high-performance liquid chromatography for the determination of Sudan dyes in foodstuffs and water samples. J Agric Food Chem 62:5818–5826. https://doi.org/10.1021/jf5006403

European Commission (nd) RASFF-Food and Feed Safety Alerts. http://ec.europa.eu/food/safety/rasff_en

Genualdi S, MacMahon S, Robbins K, Farris S, Shyong N, DeJager L (2016) Method development and survey of Sudan I-IV in palm oil and chilli spices in the Washington, DC, area. Food Addit Contam Part A 33:583–591. https://doi.org/10.1080/19440049.2016.1147986

Hoenicke K (2006) Detection of low amounts of Sudan dues and other illegal dyes in food and oleoresins. AOAC Europe Section-International Workshop “Foods to Dye For,” Brussels, pp. 1–20

Hu M, Wu L, Song Y, Li Z, Ma Q, Zhang H, Wang Z (2016) Determination of Sudan dyes in juice samples via solidification of ionic liquid in microwave-assisted liquid-liquid microextraction followed by high-performance liquid chromatography. Food Anal Methods 9:2124–2132. https://doi.org/10.1007/s12161-015-0389-y

Hu Z, Qi P, Wang N, Zhou QQ, Lin ZH, Chen YZ, Li C (2020) Simultaneous determination of multiclass illegal dyes with different acidic–basic properties in foodstuffs by LC-MS/MS via polarity switching mode. Food Chem 309:125745. https://doi.org/10.1016/j.foodchem.2019.125745

International Agency for Research on Cancer (1975) Monographs on the evaluation of the carcinogenic risk of chemical to man: Some aromatic azo compounds. France, Lyon, pp 224–231

Khalikova MA, Satinsk YD, Smidrkalova T, Solich P (2014) On-line SPE-UHPLC method using fused core columns for extraction and separation of nine illegal dyes in chilli-containing spices. Talanta 130:433–441. https://doi.org/10.1016/j.talanta.2014.07.038

Lian Y, Gao W, Zhou L, Wu N, Lu Q, Han W, Tie X (2014) Occurrence of Sudan I in paprika fruits caused by agricultural environmental contamination. J Agric Food Chem 62:4072–4076. https://doi.org/10.1021/jf5013067

Liu X, Qi X, Zhang L (2018) 3D hierarchical magnetic hollow sphere-like CuFe2O4 combined with HPLC for the simultaneous determination of Sudan I-IV dyes in preserved bean curd. Food Chem 241:268–274. https://doi.org/10.1016/j.foodchem.2017.08.113

Molder K, Kunnapas A, Herodes K, Leito I (2007) Fast peaks in chromatograms of Sudan dyes. J Chromatogr A 1160:227–234. https://doi.org/10.1016/j.chroma.2007.05.052

Moreno-Gonzalez D, Jac P, Svec F, Novakova L (2020) Determination of Sudan dyes in chili products by micellar electrokinetic chromatography-MS/MS using a volatile surfactant. Food Chem 310:125963. https://doi.org/10.1016/j.foodchem.2019.125963

Otero P, Saha SK, Hussein A, Barron J, Murray P (2017) Simultaneous Determination of 23 Azo Dyes in Paprika by Gas Chromatography-Mass Spectrometry. Food Anal Methods 10:876–884. https://doi.org/10.1007/s12161-016-0648-6

Piatkowska M, Jedziniak P, Olejnik M, Pietruk K, Zmudzki J, Posyniak A (2017) Simultaneous determination of ten illegal azo dyes in feed by ultra-high performance liquid chromatography tandem mass spectrometry. J Vet Res 61:299–305. https://doi.org/10.1515/jvetres-2017-0040

Pietruk K, Piatkowska M, Olejnik M (2019) Electrochemical reduction of azo dyes mimicking their biotransformation to more toxic products. J Vet Res 63:433–438. https://doi.org/10.2478/jvetres-2019-0044

Rajabi M, Sabzalian S, Barfi B, Arghavani-Beydokhti S, Asghari A (2015) In-line micro-matrix solid-phase dispersion extraction for simultaneous separation and extraction of Sudan dyes in different spices. J Chromatogr A 1425:42–50. https://doi.org/10.1016/j.chroma.2015.11.017

Schummer C, Sassel J, Bonenberger P, Moris G (2013) Low-level detections of sudan I, II, III and IV in spices and chili-containing foodstuffs using UPLC-ESI-MS/MS. J Agric Food Chem 61:2284–2289. https://doi.org/10.1021/jf400602a

Schwack W, Pellissier E, Morlock G (2018) Analysis of unauthorized Sudan dyes in food by high-performance thin-layer chromatography. Anal Bioanal Chem 410:5641–5651. https://doi.org/10.1007/s00216-018-0945-6

The European, Parliament and the Council of the European Union (2002) Regulation (EC) no 178/2002 of 28 January 2002 laying down the general principles and requirements of food law, establishing the European food safety authority and laying down procedures in matters of food safety. Off J Eur Union L 31:1–24

Tsai CF, Kuo CH, Shih DYC (2015) Determination of 20 synthetic dyes in chili powders and syrup-preserved fruits by liquid chromatography/tandem mass spectrometry. J Food Drug Anal 23:453–462. https://doi.org/10.1016/j.jfda.2014.09.003

Wu N, Gao W, Zhou L, Lian Y, Li F, Han W (2015) Identifying potential sources of Sudan I contamination in Capsicum fruits over its growth period. Food Chem 173:99–104. https://doi.org/10.1016/j.foodchem.2014.10.004

Wu YL, Li C, Xia X, Liu YJ, Shen JZ (2010) Development and validation of a confirmatory HPLC method for simultaneous determination of Sudan dyes in animal tissues and eggs. J Chromatogr Sci 48:63–67. https://doi.org/10.1093/chromsci/48.1.63

Xu H, Heinze TM, Paine DD, Cerniglia CE, Chen H (2010) Anaerobe Sudan azo dyes and Para Red degradation by prevalent bacteria of the human gastrointestinal tract q. Anaerobe 16:114–119. https://doi.org/10.1016/j.anaerobe.2009.06.007

Yang Y, Zhang J, Yin J, Yang Y (2019) Fast simultaneous determination of eight sudan dyes in chili oil by ultra-high-performance supercritical fluid chromatography. J Anal Methods Chem. https://doi.org/10.1155/2019/3731028

Yan H, Qiao J, Pei Y, Long T, Ding W, Xie K (2012) Molecularly imprinted solid-phase extraction coupled to liquid chromatography for determination of Sudan dyes in preserved beancurds. Food Chem 132:649–654. https://doi.org/10.1016/j.foodchem.2011.10.105

Yu W, Liu Z, Li Q, Zhang H, Yu Y (2015) Determination of Sudan I-IV in candy using ionic liquid/anionic surfactant aqueous two-phase extraction coupled with high-performance liquid chromatography. Food Chem 173:815–820. https://doi.org/10.1016/j.foodchem.2014.10.091

Zacharis CK, Kika FS, Tzanavaras PD, Rigas P, Kyranas ER (2011) Development and validation of a rapid HPLC method for the determination of five banned fat-soluble colorants in spices using a narrow-bore monolithic column. Talanta 84:480–486. https://doi.org/10.1016/j.talanta.2011.01.043

Zamzam NS, Rahman MHA, Ghany MFA (2020) UPLC-MS/MS analysis of Sudan I, butylated-hydroxytoluene and its major metabolites from sampling sites along the Nile River-Egypt: Environmentally evaluated study. Microchem J 153:104432. https://doi.org/10.1016/j.microc.2019.104432

Zanoni TB, Lizier TM, Assis MD, Zanoni MVB, De Oliveira DP (2013) CYP-450 isoenzymes catalyze the generation of hazardous aromatic amines after reaction with the azo dye Sudan III. Food Chem Toxicol 57:217–226. https://doi.org/10.1016/j.fct.2013.03.035

Zhao S, Yin J, Zhang J, Ding X, Wu Y, Shao B (2012) Determination of 23 dyes in chili powder and paste by high-performance liquid chromatography–electrospray ionization tandem mass spectrometry. Food Anal Methods 5:1018–1026. https://doi.org/10.1007/s12161-011-9337-7

Zhu H, Chen Y, Huang C, Han Y, Zhang Y, Xie S (2015) Simultaneous determination of four Sudan dyes in rat blood by UFLC-MS/MS and its application to a pharmacokinetic study in rats. J Pharm Anal 5:239–248. https://doi.org/10.1016/j.jpha.2015.03.001

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical Approval

This article does not contain any studies with human or animal subjects.

Informed Consent

Informed consent not applicable.

Conflict of Interest

Sabrein. H. Mohamed declares that she has no conflict of interest. Alyaa. I. Salim declares that she has no conflict of interest. Yousry. M, Issa declares that he has no conflict of interest. Rihab H. Nassar declares that she has no conflict of interest. Manal A. Atwa declares that she has no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mohamed, S.H., Salim, A.I., Issa, Y.M. et al. Evaluation of Different Sudan Dyes in Egyptian Food Samples Utilizing Liquid Chromatography/Tandem Mass Spectrometry. Food Anal. Methods 14, 2038–2050 (2021). https://doi.org/10.1007/s12161-021-02036-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-021-02036-x