Abstract

Pressurized water extraction (PWE) is a technique suitable for efficient extraction of almond proteins, some of which are known as potent allergens. In this work, we present a PWE protocol that allows fast and complete isolation of almond proteins achieved within one 5-min cycle at 40°C and 15 MPa. The extracted protein contents obtained using PWE or conventional extraction method with 22 selected solvents were compared based on sodium dodecyl sulphate-polyacrylamide gel electrophoresis. Individual proteins from separation gels were excised and identified using mass spectrometry with database searching. Our results showed that the PWE of almond proteins can offer similar efficiency as the conventional extraction method while being four times faster and providing water-based extracts without any additives with low environmental impact.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Almond, drupe of Prunus dulcis, is the most commonly produced and consumed nut in the world ranking the first place in the tree nut production (Geiselhart et al. 2018). Almonds contain valuable source of nutrients such as lipids, proteins, dietary fibre, vitamins, minerals and phenolic compounds (Prgomet et al. 2017).

However, besides the high nutritional value, almonds have received increased attention since naturally occurring proteins can induce allergic reactions and may have an adverse effect on sensitized individuals. Almond allergy is the fourth most common allergy from all tree nuts. Ten groups of almond allergenic proteins were identified so far: Pru du 1, Pru du 2, Pru du 2S albumin, Pru du 3, Pru du 4, Pru du 5, Pru du 6, Pru du 8, Pru du 10 and Pru du γ-conglutin (Zhang and Jin 2020). Nevertheless, only six of them, Pru du 3–6, 8 and 10, are registered in the WHO-IUIS allergen list (WHO/IUIS Allergen Nomenclature Sub-Committee 2020).

Pru du 6, called amandin, is a major allergenic protein belonging to the cupin superfamily. Its structure is hexameric with a total molecular weight of 370 kDa, consisting of two monomers prunin 1 (61 kDa) and prunin 2 (63 kDa). Pru du 6 is relatively heat resistant. Partial unfolding was observed at high temperatures over 94°C. It tends to aggregate to a food matrix and to denature during boiling, autoclaving and high-pressure treatment (>500 MPa). On the other hand, it exhibits high antigen stability after roasting, blanching and microwave heating (Albillos et al. 2009; Cuadrado et al. 2020; Jin et al. 2009; Zhang et al. 2016).

Almond proteins can be isolated by conventional extraction methods, e.g. maceration, dynamic solvent extraction and ultrasound-assisted extraction. However, these are time-consuming and environmentally unfriendly. Considering these disadvantages, modern extraction methods were introduced such as pressurized liquid extraction and its eco-friendly alternative pressurized water extraction (PWE) (Burdejova et al. 2021). Contrary to pressurized hot water extraction, which uses water as a solvent and combines high pressure and temperature treatment in the range from 100°C and 0.1 MPa to water critical point at 374°C and 22.1 MPa, PWE is performed at lower temperatures, and, therefore, it is well suitable for thermolabile compounds isolation. Generally, the temperature has to be finely optimized to achieve efficient extraction of compounds of interest. The pressure 5–20 MPa improves the penetration of water into sample matrix and prevents water from boiling if elevated temperatures are used (Plaza and Marina 2019).

PWE is becoming popular for isolation of proteins from different plants and fungi such as black carrot (Gizir et al. 2008), shiitake (Lo et al. 2007), elderberry (Šalplachta and Hohnová 2017) or mistletoe (Burdejova et al. 2021). However, the use of PWE for the extraction of proteins from almonds has not been investigated so far.

The main aim of the presented study is to suggest a PWE extraction protocol suitable for the extraction of almond proteins. At first, the effect of different extraction solvents and defatting on almond protein extraction efficiency was investigated. Further, PWE conditions, such as temperature, time, number of extraction cycles and effect of defatting, were examined. Extracts were analysed using sodium dodecyl sulphate-polyacrylamide gel electrophoresis (SDS-PAGE) followed by matrix-assisted laser desorption/ionization connected to the time-of-flight mass spectrometry (MALDI-TOF MS/MS) to evaluate the extraction efficiency of PWE and to identify almond proteins.

Materials and Methods

Chemicals

The following chemicals of analytical, gradient and sequencing grade were used: 2-aminoethanoic acid (glycine), 2-amino-2-hydroxymethyl-propane-1,3-diol free base–Tris base, (2S,3S)-1,4-bis(sulfanyl)butane-2,3-diol (DTT—dithiothreitol), 2-iodoacetamide, 2-sulfanylethan-1-ol, ammonium hydrogen carbonate, N,N,N′,N′-tetramethylethylenediamine, protein wide range molecular weight (WRMW) marker (6.5–200 kDa), sodium dihydrogen phosphate, sodium hydrogen phosphate, trifluoroacetic acid (TFA) and urea (Sigma-Aldrich Co., St. Louis, MO, USA); acetic acid (AA), citric acid and formic acid (FA) (Penta, Prague, Czech republic); HCl, boric acid and NaOH (Lachner, Neratovice, Czech Republic); sodium dodecyl sulphate (SDS) (J.T. Baker Co., Deventer, Netherlands); acetonitrile (ACN), dimethyl sulfoxide (DMSO), ethanol (EtOH) and propan-2-ol (VWR International, Radnor, PA, USA); Rotiphorese® Gel 30 (37.5:1) (Carl Roth Gmbh & Co. Kg, Karlsruhe, Germany); Laemmli buffer and ammonium persulphate (Bio-Rad Laboratories, Hercules, CA, USA); Page Blue™ Staining Solution (Thermo Fisher Scientific, Waltham, MA, USA); trypsin (Roche Diagnostics, Mannheim, Germany); and (E)-2-cyano-3-(4-hydroxyphenyl)prop-2-enoate (CHCA—alpha-cyano-4-hydroxycinnamic acid) and peptide calibration mix 1 (LaserBio Labs, Sophia-Antipolis Cedex, France). The water used in all experiments was purified by a Milli-Q A10 Gradient (Millipore Corp., Burlington, MA, USA).

Almond Processing

Whole almonds (IBK Trade, country of origin Spain, variety Marcona) were purchased from a local store and stored vacuum sealed in the dark at ambient temperature (25 ± 2°C) for a maximum 2 months. Almonds were processed by two different ways. In the first case, they were ground to a fine powder using an electric grinder (Robert Bosch GmbH, Gerlingen, Germany) and immediately used for protein extraction. In the second case, homogenized material was defatted using hexane following slightly modified protocol of Zhang et al. (2016). Fine almond powder was defatted twice by hexane at a ratio of 1:10 (w/v) in Erlenmeyer flask with continuous stirring at 500 rpm for 2 h at ambient temperature. Defatted samples were filtered through quantitative filter grade 589/3 (Whatman, Maidstone, UK), air-dried in fume hood overnight and used for subsequent protein extraction.

Almond Protein Extraction Using Different Solvents

Twenty-two commonly used solvents were tested for extraction of proteins from almonds: (1) 0.1% and (2) 1% (v/v) TFA, (3) 0.1% and (4) 1% (v/v) FA, (5) 0.1% and (6) 1% (v/v) AA, (7) 0.1 mol L–1 citrate-phosphate buffer (CPB) pH 5.0, (8) 0.1 mol L–1 phosphate buffer (PB) pH 7.4, (9) 0.1 mol L–1 sodium borate buffer (BB) pH 8.5, (10) 0.1 mol L–1 Tris-HCl buffer (TB) pH 8.5, (11) 1% (w/v) SDS, (12) 8 mol L–1 urea, (13) deionized water (DW), (14) 10%, (15) 50%, (16) 80% (v/v) EtOH, (17) 10%, (18) 50%, (19) 80% (v/v) DMSO and (20) 10%, (21) 50%, (22) 80% (v/v) ACN.

Extraction procedure combined dynamic extraction and ultrasound-assisted extraction (further referred to as the “combined extraction method”). The extraction procedure was performed as follows: 100 mg of almond fine powder was mixed with 1 mL of the particular solvent (as mentioned above), and the mixture was continuously shaken on thermomixer Eppendorf Comfort (Eppendorf, Hamburg, Germany) for 10 min at 1400 rpm under controlled temperature of 40°C. Subsequently, it was sonicated for 5 min using ultrasound bath Sonorex Digital 10P Bandelin (Labicom s.r.o., Prague, Czech Republic) at temperature kept below 35°C and frequency 35 kHz. Finally, the mixture was centrifuged for 5 min using laboratory centrifuge Eppendorf MiniSpin plus (Eppendorf, rotor model F-45-12-11) at 14,000g and 25°C. The resulting supernatant was filtered through a 0.45-μm polytetrafluoroethylene filter (Agilent Technologies, Santa Clara, CA, USA) and used for further analysis. All solvent extractions were performed in triplicates.

Almond Protein Pressurized Water Extraction

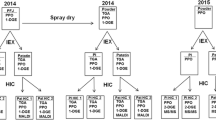

The PWE was performed using in-lab-constructed extraction instrument designed in our group working in a static mode (see Fig. 1). Extraction parameters such as temperature, time and number of extraction cycles as the most often considered parameters were optimized for both types of almond samples.

Optimization was performed as follows: fine almond powder (non-defatted or defatted) was mixed at a ratio of 1:10 (w/w) with inert material (glass beads, 500 μm), the mixture was packed into 11-mL extraction vessel and it was subsequently extracted using water for 15 min at the pressure of 15 MPa. Firstly, extraction temperature was varied in the range from 40 to 120°C with 10°C step. Further, extraction times of 2, 5, 10 and 15 min were tested. Finally, the effect of number of extraction cycles from 1 to 5 was studied.

Prior to extraction, sample was rinsed 30 s with water at flow 3 mL min–1 and atmospheric pressure to avoid clogging of frit by polysaccharides contained in the sample. When extraction step was completed, the system was purged for 2 min with nitrogen. The collected extracts were cooled down to ambient temperature and processed as described below. All extractions were performed in triplicates.

Sodium Dodecyl Sulphate-Polyacrylamide Gel Electrophoresis

SDS-PAGE was performed under reducing conditions using polyacrylamide gels (12% separation gel, 4% stacking gel; size 10 cm × 8 cm × 1 mm) prepared according to manufacturer’s protocol (Bio-Rad Laboratories Inc. 2014) using Mini-PROTEAN Tetra Cell equipment (Bio-Rad Laboratories, Hercules, CA, USA).

A 10 μL of extract was mixed with 40 μL of 62.5 mmol L–1 Tris-HCl buffer pH 6.8, and mixture was vortexed and centrifuged using Eppendorf MiniSpin plus centrifuge (Eppendorf) at 14,000g and 25°C for 1 min. Diluted extract was further mixed at a ratio 1:2 (v/v) with Laemmli sample buffer with 5% (v/v) 2-sulfanylethan-1-ol, vortexed and centrifuged using centrifuge Eppendorf MiniSpin plus (Eppendorf, Hamburg, Germany) at 14,000g and 25°C for 1 min and boiled for further 15 min in water bath. Five microliters of WRMW marker or sample were loaded per each well. The gels were run in Tris-glycine buffer (25 mmol L–1 Tris, 192 mmol L–1 glycine, 0.1% (w/v) SDS) at a constant voltage of 150 V for 60 min. After the run, gels were fixated using 25% (v/v) propan-2-ol and 10% (v/v) acetic acid solution for 15 min. The gels were stained with Page Blue™ Staining Solution for 1 h and the background colour was destained with deionized water.

Each gel was scanned using Scanner HP Scanjet 8300 (Hewlett-Packard, Palo Alto, CA, USA), and the image was analysed by Quantity One 1-D Analysis Software (Bio-Rad Laboratories). Quantification of almond proteins was based on total relative extraction protein intensities of individual polypeptide bands relative to the bovine serum albumin from WRMW marker and was expressed as the average value ± standard deviation (n = 3).

In-gel Tryptic Digestion

The protein bands were excised from the gel and digested according the protocol of Jensen et al. (1999). After reduction with 10 mmol L–1 DTT and subsequent alkylation with 100 mmol L–1 2-iodoacetamide, the proteins were digested with trypsin (digestion buffer: 50 mmol L–1 ammonium hydrogen carbonate, 15 ng μL–1 of enzyme) overnight at 37°C. The resulting tryptic peptides were extracted from the gel by three exchanges of 0.1% TFA and ACN 1:1 (v/v) solution. The extracts were combined, dried in the SpeedVac Centrifuge (Eppendorf Concentrator 5301, Eppendorf, rotor model F-45-72-8), re-dissolved in 8 μL of 5% (v/v) TFA and purified using Zip Tip C18 (Millipore) prior to mass spectrometry analyses. The lane digestions were performed in triplicates for each extraction (PWE and 1% (w/v) SDS).

Mass Spectrometry and Database Searching

MALDI-TOF MS/MS experiments in positive ion mode were performed on AB SCIEX TOF/TOFTM 5800 system (AB SCIEX, Framingham, MA, USA) equipped with a 1 kHz Nd:YAG laser. The following MS and MS/MS instrument parameters were used: collision gas, air; metastable suppressor, on; mass range, 900–4000 Da; total shots, 2000 and 4000 (100 shots per sub spectra); and laser intensities of 3800 and 4600 for MS and MS/MS data collection, respectively. Solution of 1% (w/v) CHCA in ACN and 0.1% TFA mixed in ratio 1:1 (v/v) was used as matrix for dried-droplet preparation. 0.4 μL of purified peptide sample was applied on LLC Opti-TOF 384 well insert plate (size 123 × 81 mm; AB SCIEX), air-dried and further the same amount of CHCA matrix was spotted on the target. The instrument was periodically calibrated by an external standard (peptide calibration mix 1).

Acquired mass spectra were processed using TOF/TOFTM Series Explorer Software (AB SCIEX) and the data were submitted to the Mascot database searching. Protein identification was assigned using the NCBIProt database with a taxonomy restriction to other green plants. Maximum tolerance for peptide masses was 0.8 Da and fragment error was 0.6 Da. Additional parameters, enzyme, trypsin; allowed missed cleavages, up to one; fixed modification, carbamidomethyl (C); variable modification, oxidation of methionine; peptide charge, +1; monoisotopic masses and instrument, MALDI-TOF/TOF, were used.

Statistical Analysis

The statistical analysis was performed using the statistical package Unistat v. 6.0 (Unistat, London, UK). Two-way analysis of variance (ANOVA) using Tukey’s HSD procedure was used for determination of significant differences in individual total relative intensities of protein bands in different solvents and optimized PWE parameters. A probability value of p ≤ 0.05 was accepted for statistically significant results.

Results and Discussion

Comparison of Solvents for Almond Protein Extraction

The first objective of the study was a selection of the most suitable solvent system for efficient almond protein extraction. Solvent variation in pH, buffer ionic strength and presence of organic solvent or surface-active substances were evaluated. The extraction efficiency was evaluated by SDS-PAGE instead of commonly used spectrophotometric assays (De Angelis et al. 2018; Sathe et al. 2009) since almonds contain a high number of interfering compounds, e.g. phenolic compounds.

Significant differences between non-defatted and defatted samples were found. The SDS-PAGE results for non-defatted and defatted samples show Fig. 2a and b. The hexane defatting significantly increased the amount of extracted proteins. According to the producers’ data, used almonds contained 52 wt% of fat in their mass. Removing a considerable amount of the fat then resulted in double protein concentration in the defatted almond mass. The increase in protein yields after defatting was approximately 100% for buffers, deionized water, SDS, urea and low concentrated organic solutions and even more than 100% for acidic solutions (see Fig. 3). This finding suggests that there are other factors influencing extraction efficiency in the case of protein isolation from non-defatted almond samples with acidic solutions. The benefit of defatting for almond extraction was in the solubilization of mass of almond fats in hexane which were subsequently removed by filtration of the remaining solids.

Effect of a solvent type and its pH value on protein mass profiles of a non-defatted and b defatted almonds extracted by the combined extraction method followed by SDS-PAGE. Used abbreviations: MW, molecular weight; TFA, trifluoroacetic acid; FA, formic acid; AA, acetic acid; CPB, citrate-phosphate buffer; PB, phosphate buffer; BB, borate buffer; TB, Tris-HCl buffer; SDS, sodium dodecyl sulphate; DW, deionized water; EtOH, ethanol; DMSO, dimethyl sulfoxide; ACN, acetonitrile; *Pru du 6 (prunin 1 and 2 basic (20–22 kDa) and acidic (42–46) kDa subunits)

Comparison of total relative extraction protein intensities according to the sample treatment for different extracts obtained by the combined extraction method. The results are based on the relative protein intensities of individual polypeptide bands related to the bovine serum albumin band intensity and expressed as a mean value ± standard deviation (n = 3). Letters on the top of the columns indicate significant differences (p < 0.05) among the extracts. Used abbreviations: MW, molecular weight; TFA, trifluoroacetic acid; FA, formic acid; AA, acetic acid; CPB, citrate-phosphate buffer; PB, phosphate buffer; BB, borate buffer; TB, Tris-HCl buffer; SDS, sodium dodecyl sulphate; DW, deionized water; EtOH, ethanol; DMSO, dimethyl sulfoxide; ACN, acetonitrile

Regardless of defatting, almond proteins were well solubilized in water, all tested buffers, denaturing solutions (1% (w/v) SDS or 8 mol L–1 urea) and low-percentage organic solutions. This points to high hydrophilicity of almond proteins. Moreover, buffers, 1% (w/v) SDS and 8 mol L–1 urea extracts contained higher molecular weight proteins (above 66 kDa, see Fig. 2b). On the other hand, increasing content of the organic solvent and acid in the solution led to the considerable lowering in the protein extraction efficiency. Also, Yoshizawa et al. (2014) demonstrated that a high concentration of EtOH increased protein-protein interactions which induced formation of aggregates and precipitates decreasing protein solubility.

Acidic solvents with a pH value below 4 showed low extraction yields of most proteins. An increase in protein yields could be observed at pH 5, with the maximum yield in the region between pH 6 and 8. Overall, the solvent pH had a much lesser effect on the protein solubility than the solvent choice and concentration of additives (e.g. salts, detergents, organic solvents).

Considering buffer solutions, PB, BB and TB were found significantly more efficient than CPB for protein extraction from defatted almonds (see Fig. 3). This was also confirmed in previous studies (L'Hocine and Pitre 2016; Tiwari et al. 2010) that focused on amandin isolation. On the other hand, Sathe et al. (2009) found that borate saline buffer and Tris-HCl buffer were the most efficient extractants even if the results varied strongly based on the used evaluation method.

While our results suggested that PB, BB and TB were promising as extraction buffers, attention was also paid to solutions of three different acids (TFA, FA and AA) and organic solvent-water mixtures (EtOH, DMSO and ACN), which can be easily used for pressurized liquid extraction without technical issues connected with salts contained in buffers.

It can be seen that for the acidic solutions, the extraction efficiency decreased in order TFA > AA > FA and TFA = FA > AA at the concentrations of 0.1% (v/v) and 1% (v/v), respectively. The study of Houen (1996) showed that the solubility of bovine serum albumin and lysozyme were equally high in TFA and FA and lower in AA. This trend was observed also in our results for protein fractions of almonds at higher acid concentrations. Decrease of the extraction yields (approximately 70% for TFA, 20% for FA and 80% for AA) associated with increasing acid concentration in extraction solvent was observed for all tested acids. A similar loss in almond protein yields was reported earlier (Tiwari et al. 2010; Wolf and Sathe 1998), and it is probably caused by acidic denaturation and following precipitation. For the presented reasons, solutions of organic acids were further excluded as possible solvents for protein isolation.

10% (v/v) solutions of EtOH, DMSO and ACN exhibited similar total protein yields regardless of the sample defatting (see Fig. 2a and b and Fig. 3). Decrease in extraction yields with increasing organic solvent content in solution was found for all solvents (see Fig. 3). Houen (1996) and Chang et al. (1991) indicated high solubility of albumins and other proteins in DMSO and highlighted its attractive properties such as high stability, low toxicity, low-cost, and possibility of its use for therapeutic applications. This correlates with our finding that extracts using solutions containing 50 or 80% (v/v) DMSO exhibited significantly higher content of proteins than EtOH and ACN extracts.

Optimization of PWE for Extraction of Almond Proteins

As mentioned earlier, buffers were not considered for pressurized liquid extraction due to the issues connected with high salt concentrations. Further, the results from combined extraction method showed that deionized water was equally or more efficient as acidic and organic water solutions for protein extraction from almonds (see Fig. 2a and b). Also, water possesses considerable advantage from the economical and ecological point of view. Therefore, we applied PWE to further enhance protein extraction efficiency for almond mass processing.

At first, temperature was optimized in the range from 40 to 120°C with 10°C step and 15-min extraction time at a constant pressure of 15 MPa. Higher temperature resulted in a reduction of protein yields probably caused by protein degradation (see Fig. 4). This trend was more noticeable in non-defatted samples (Fig. 4a). Figure 4 shows prunin 1 and 2 subunits as (marked by an asterisk) the most intensive bands on the SDS-PAGE gels. Prunin 1 and prunin 2 are polypeptides of molecular weights (MW) of 61 and 63 kDa composing the major protein of almond mass Pru du 6. Prunins 1 and 2 are further composed of acidic and basic subunits with respective MW of 42–46kDa and 20–22 kDa linked via disulphide bridge (Sathe et al. 2002). In the case of non-defatted sample, all protein bands intensities decreased continually with increase of the extraction temperature from 40 to 120°C. On the other hand, such continual decrease was not apparent for defatted samples, and rather there is a sudden decrease of protein band intensity up to 100°C. This finding correlates with work of Zhang et al. (2016), who compared the almonds heated in water at 60°C and 100°C. Also, thermostability of proteins to 90°C confirmed by Albillos et al. (2009) might be the reason of the detected abrupt decrease in protein bands intensities at temperatures above 100°C (see Fig. 4). Based on the presented PWE temperature results, the optimal temperature for extraction of almond proteins was 40°C for both sample types (see Fig. 4).

Determination of optimal pressurized water extraction (PWE) temperature for a non-defatted and b defatted almonds. c Comparison of obtained total relative extraction protein intensities according sample treatment for PWE. The results are based on relative protein intensities of individual polypeptide bands related to the bovine serum albumin band intensity and expressed as a mean value ± standard deviation (n = 3). Different letters on the top of the columns indicate significant differences (p < 0.05) among the extracts. Used abbreviations: MW, molecular weight; *Pru du 6 (prunin 1 and 2 basic (20–22 kDa) and acidic (42–46) kDa subunits)

Extraction time was optimized at the selected temperature 40°C in the next step. Four extraction times (2, 5, 10 and 15 min) at the pressure of 15 MPa were tested. The shortest (2-min) extraction time showed only slightly lower yield of almond proteins (about 5%) compared to the 5-min extraction time. Prolonging of extraction time up to 15 min showed only insignificant increase in the protein content. Therefore, the optimal extraction time was set to 5 min, and influence of number of extraction cycles from 1 to 5 was tested. It was found that one cycle with 5-min duration was sufficient for complete extraction of proteins from the sample and additional extraction cycles did not improve the extraction efficiency. The final optimal PWE conditions have been determined: temperature 40°C, extraction time 5 min and one extraction cycle at the pressure of 15 MPa. PWE optimized method shows comparable protein yields as the previous extractions with buffers (refer to Fig. 2a, b, Fig. 3, Fig. 5a, b), however, with a shorter extraction time and without the use of further additives.

Comparison of the results obtained by the combined extraction method using water (40°C, 20 min) and surfactant (40°C, 20 min, 1% (w/v) SDS) with optimized pressurized water extraction (PWE, 40°C, 5 min, 15 MPa). a SDS-PAGE photo and b graph with results from image analysis. The results are based on the relative protein intensities of individual polypeptide bands related to the bovine serum albumin band intensity and expressed as a mean value ± standard deviation (n = 3). Letters on the top of the columns indicate significant differences (p < 0.05) among the extracts. Used abbreviations: MW, molecular weight; DW, deionized water; SDS, sodium dodecyl sulphate; NDF, non-defatted; DF, defatted; *Pru du 6 (prunin 1 and 2 basic (20–22kDa) and acidic (42–46) kDa subunits)

Qualitative Differences Between Individual Extracts

To identify qualitative differences between the individual proteins extracts, SDS-PAGE protein band identification was performed using MALDI-TOF MS/MS together with database searching. Proteomic analysis included extracts obtained using either PWE or combined extraction method utilizing 1% (w/v) SDS as solvent. Total of 22 and 24 protein bands were excised from the gels corresponding to PWE and 1% (w/v) SDS extracts, respectively. PWE reduced the extraction time to 25% and removed one step (centrifugation) in the isolation procedure. This eliminated manual handling and further shortened extraction time. Lower yields of 38.7 and 34.8 kDa polypeptides and higher yields of 40, 42 kDa and 22, 20 kDa polypeptides (main acidic and basic subunits of Pru du 6) were detected in PWE compared to 1% (w/v) SDS extracts (Fig. 5a).

Table 1 summarizes proteins identified in both extracts. Most of the identified proteins are main seed storage proteins such as prunins, legumins and vicilins. Especially, prunins were found in majority of spots potentially hindering identification of less ionizing or less concentrated proteins. Pru du 2, Pru du 6, prunin 1 and 2, legumin type B, vicilin GC72-A and vicilin C72-like protein content were identified in both extracts. However, prunins and vicilins were extracted more efficiently in PWE with two vicilin-like seed storage proteins identified only with PWE. As prunins and vicilins are considered the main allergenic ingredients of almonds (Albillos et al. 2009; Costa et al. 2012; Geiselhart et al. 2018; Che et al. 2019), this is an important finding suggesting higher efficiency of PWE for extraction of allergenic proteins. In contrary, antimicrobial peptide precursor, dehydrin 2, putative lipid transfer protein and oleosin 1 were identified only in 1% (w/v) SDS extract. All these proteins have low molecular weight (<22 kDa), and two of them (putative lipid transfer protein and oleosin 1) are expected to be more hydrophobic (based on https://web.expasy.org/protscale/ analysis of hydropathicity using method of (Kyte and Doolittle 1982)). This suggests that 1% (w/v) SDS was more efficient in their extraction due to possible partitioning of the proteins into the hydrophilic core of SDS micelles.

The sequences of the selected identified peptides are summarized in the Table 2. The MALDI-TOF spectra of prunin 1 are shown in Fig. 6a and b for PWE and 1% (w/v) SDS extracts. The prunin 1 sequence coverage reached 46% and 42% for PWE and 1% (w/v) SDS extracts, respectively. Identified peptides in the case of prunin 1 were identical for both studied extracts with exception of one peptide which was identified only in PWE. Figure 6c then shows an example of fragmentation spectrum of one of the prunin 1 peptides at 1142.8 m/z with GNLDFVQPPR amino acids sequence.

The presented results confirmed that PWE is useful extraction method for almond proteins. It reaches similar or better efficiency compared to common solvents used for ultrasound-assisted extraction. However, the complete PWE can be achieved at the quarter of the time needed for sonication. Other important advantage over the conventional extraction is the absence of any additives, which considerably simplifies any further processing of the protein extracts.

Conclusion

In this study, we compared twenty-two solvents for extraction efficiency of almond proteins using the combined extraction method. Non-defatted and defatted fine almond powder was used for extraction. PB, BB and TB were the most efficient solvents providing the highest total protein content. CPB, 10% (v/v) organic solvents, deionized water, 1% (w/v) SDS and 8 mol L–1 urea showed slightly lower protein yields than PB, BB and TB. The lowest extraction yields were observed for acidic solutions and organic solvents at concentrations above 10% (v/v) in the case the results obtained by the combined extraction method. Results from the combined extraction method were further used as a basis for comparison with PWE.

Our results have demonstrated that PWE was efficient and reliable extraction method for almond protein isolation. One cycle of 5-min extraction of the defatted sample with pressurized water at 40°C and 15 MPa was found optimal for protein isolation. The designed PWE method was faster and more efficient than a combined extraction method using dynamic and ultrasound-assisted extraction using deionized water and 1% (w/v) SDS and comparable in extraction efficiency with the combined extraction method using buffers. Moreover, PWE did not require any additives, and it was four times faster than the combined extraction method.

Overall, the developed PWE method was found beneficial for rapid and efficient extraction of proteins from almonds. The main advantages of suggested PWE method are environmental friendliness, simplicity, speed and automation of the extraction process.

Availability of Data and Material

The complete set of manuscript data is available at authors upon request.

Code Availability

Not applicable.

References

Albillos SM, Menhart N, Fu TJ (2009) Structural stability of Amandin, a major allergen from almond (Prunus dulcis), and its acidic and basic polypeptides. J Agric Food Chem 57:4698–4705. https://doi.org/10.1021/jf803977z

Bio-rad Laboratories Inc. (2014) Bulletin 6201 - Protocol: handcasting polyacrylamide gels. http://www.bio-rad.com/webroot/web/pdf/lsr/literature/Bulletin_6201.pdf. Accessed 5th May 2020

Burdějová L, Moravcová D, Strouhalová D, Lunerová K (2021) Pressurized water extraction - the fast and efficient method for isolation of bioactive proteins from Viscum album leaves. J Pharm Biomed Anal 195:113850. https://doi.org/10.1016/j.jpba.2020.113850

Costa J, Mafra I, Carrapatoso I, Oliveira MB (2012) Almond allergens: molecular characterization, detection, and clinical relevance. J Agric Food Chem 60:1337–1349. https://doi.org/10.1021/jf2044923

Cuadrado C, Sanchiz A, Vicente F, Ballesteros I, Linacero R (2020) Changes induced by pressure processing on immunoreactive proteins of tree nuts. Molecules 25:1–11. https://doi.org/10.3390/molecules25040954

De Angelis E, Bavaro SL, Forte G, Pilolli R, Monaci L (2018) Heat and pressure treatments on almond protein stability and change in immunoreactivity after simulated human digestion. Nutrients 10:1–20. https://doi.org/10.3390/nu10111679

Geiselhart S, Hoffmann-Sommergruber K, Bublin M (2018) Tree nut allergens. Mol Immunol 100:71–81. https://doi.org/10.1016/j.molimm.2018.03.011

Gizir AM, Turker N, Artuvan E (2008) Pressurized acidified water extraction of black carrot [Daucus carota ssp sativus var. atrorubens Alef.] anthocyanins. Eur Food Res Technol 226:363–370. https://doi.org/10.1007/s00217-006-0546-z

Houen G (1996) The solubility of proteins in organic solvents. Acta Chem Scand 50:68–70. https://doi.org/10.3891/acta.chem.scand.50-0068

Chang N, Hen SJ, Klibanov AM (1991) Protein separation and purification in neat dimethyl sulfoxide. Biochem Biophys Res Commun 176:1462–1468. https://doi.org/10.1016/0006-291X(91)90451-C

Che H, Zhang Y, Lyu SC, Nadeau KC, McHugh T (2019) Identification of almond (Prunus dulcis) vicilin as a food allergen. J Agric Food Chem 67:425–432. https://doi.org/10.1021/acs.jafc.8b05290

Jensen ON, Wilm M, Shevchenko A, Mann M (1999) Sample preparation methods for mass spectrometric peptide mapping directly from 2-DE Gels. In: Jink L (ed) 2-D Proteome Analysis Protocols. Humana Press, Totowa, pp 513–530

Jin T, Albillos SM, Guo F, Howard A, Fu TJ, Kothary MH, Zhang YZ (2009) Crystal structure of prunin-1, a major component of the almond (Prunus dulcis) allergen amandin. J Agric Food Chem 57:8643–8651. https://doi.org/10.1021/jf9017355

Kyte J, Doolittle RF (1982) A simple method for displaying the hydropathic character of a protein. J Mol Biol 157:105–132. https://doi.org/10.1016/0022-2836(82)90515-0

L'Hocine L, Pitre M (2016) Quantitative and qualitative optimization of allergen extraction from peanut and selected tree nuts. Part 1. Screening of optimal extraction conditions using a D-optimal experimental design. Food Chem 194:780–786. https://doi.org/10.1016/j.foodchem.2015.08.031

Lo TCT, Tsao HH, Wang AY, Chang CA (2007) Pressurized water extraction of polysaccharides as secondary metabolites from Lentinula edodes. J Agric Food Chem 55:4196–4201. https://doi.org/10.1021/jf070035j

Plaza M, Marina ML (2019) Pressurized hot water extraction of bioactives. TrAC Trends Anal Chem 116:236–247. https://doi.org/10.1016/j.trac.2019.03.024

Prgomet I, Goncalves B, Dominguez-Perles R, Pascual-Seva N, Barros A (2017) Valorization challenges to almond residues: phytochemical composition and functional application. Molecules 22:1–27. https://doi.org/10.3390/molecules22101774

Sathe SK, Venkatachalam M, Sharma GM, Kshirsagar HH, Teuber SS, Roux KH (2009) Solubilization and electrophoretic characterization of select edible nut seed proteins. J Agric Food Chem 57:7846–7856. https://doi.org/10.1021/jf9016338

Sathe SK, Wolf WJ, Roux KH, Teuber SS, Venkatachalam M, Sze-Tao KW (2002) Biochemical characterization of amandin, the major storage protein in almond (Prunus dulcis L.). J Agric Food Chem 50:4333–4341. https://doi.org/10.1021/jf020007v

Šalplachta J, Hohnová B (2017) Pressurized hot water extraction of proteins from Sambucus nigra L. branches. Ind Crop Prod 108:312–315. https://doi.org/10.1016/j.indcrop.2017.06.053

Tiwari RS, Venkatachalam M, Sharma GM, Su M, Roux KH, Sathe SK (2010) Effect of food matrix on amandin, almond (Prunus dulcis L.) major protein, immunorecognition and recovery. Lwt-Food Sci Technol 43:675–683. https://doi.org/10.1016/j.lwt.2009.11.012

WHO/IUIS Allergen Nomenclature Sub-Committee (2020) Allergen Nomenclature. http://www.allergen.org/. Accessed 5th May 2020

Wolf WJ, Sathe SK (1998) Ultracentrifugal and polyacrylamide gel electrophoretic studies of extractability and stability of almond meal proteins. J Sci Food Agric 78:511–521. https://doi.org/10.1002/(SICI)1097-0010(199812)78:4<511::AID-JSFA148>3.0.CO;2-X

Yoshizawa S, Arakawa T, Shiraki K (2014) Dependence of ethanol effects on protein charges. Int J Biol Macromol 68:169–172. https://doi.org/10.1016/j.ijbiomac.2014.04.041

Zhang Y, Jin T (2020) Almond allergens: update and perspective on identification and characterization. J Sci Food Agric 100:4657–4663. https://doi.org/10.1002/jsfa.10417

Zhang Y, Zhang J, Sheng W, Wang S, Fu TJ (2016) Effects of heat and high-pressure treatments on the solubility and immunoreactivity of almond proteins. Food Chem 199:856–861. https://doi.org/10.1016/j.foodchem.2015.12.063

Acknowledgements

We would like to acknowledge for financial support from Grant no. 19-00742S supported by Czech Science Foundation and from the Czech Academy of Sciences Institutional Research Plan RVO: 68081715.

Funding

This work was funded by Czech Science Foundation (Grant no. 19-00742S) and from the Czech Academy of Sciences (Institutional Research Plan RVO: 68081715).

Author information

Authors and Affiliations

Contributions

Lenka Burdějová, methodology, formal analysis, investigation, data curation, visualization, writing (original draft), and writing (review and editing); Filip Duša, conceptualization, visualization, and writing (review and editing); Dana Strouhalová, formal analysis, visualization, and writing (review and editing); Dana Moravcová, methodology and writing (review and editing); Pavel Karásek, methodology and writing (review and editing).

Corresponding author

Ethics declarations

Ethics Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed Consent

Informed consent is not applicable.

Conflicts of Interest

Lenka Burdějová declares that she has no conflict of interest. Filip Duša declares that he has no conflict of interest. Dana Strouhalová declares that she has no conflict of interest. Dana Moravcová declares that she has no conflict of interest. Pavel Karásek declares that he has no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Burdějová, L., Duša, F., Strouhalová, D. et al. Pressurized Water Extraction as a Tool for Rapid and Efficient Isolation of Proteins from Almonds. Food Anal. Methods 14, 1953–1963 (2021). https://doi.org/10.1007/s12161-021-02016-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-021-02016-1