Abstract

Water activity (aw) is an important property of foods, with correlations to safety, quality, and shelf-life. The presence of high concentrations of non-water volatiles has been problematic for analytical aw instruments, thereby limiting potential applications of aw measurements for quality assessments of fermented beverages and foods. The objectives of this study were to measure the aw values (aws) of wines and spirits using a tunable diode laser instrument (AquaLab TDL, METER Group, Inc.), reported to be unaffected by volatiles such as ethanol, and determine the effects of ethanol and residual sugar (R.S.) concentrations on the aw. The aws of commercial wines (n = 678), other liquors (n = 42), and model solutions containing controlled concentrations of ethanol and sugars were measured using the TDL at 25 °C. The alcohol by volume (ABV) was determined by electric ebulliometer and Fourier transform infrared spectroscopy (FTIR) methods, and sugars were determined using a FTIR method. The aws of wines ranged from 0.860 to 0.968 (average 0.940 aw), the aws of spirits ranged from 0.750 to 0.909 aw, and grain alcohol had the lowest aw at 0.365 and the highest ABV (95%). The Norrish equation, accounting for ethanol, glucose, fructose, and sucrose concentrations, resulted in predicted aws of wines that were 0.012 ± 0.007 higher than the measured aws. Ethanol had a greater effect on the aw of wines than sugar contents, and the ~ 0.012 lower than predicted aws of wines were attributed to the effects of additional solutes (glycerol, acids), that were not included in the Norrish equation, on lowering the aw.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Wine, the fermented juice of grapes, is quite possibly the world’s most valuable agricultural commodity (€70 billion in annual global production value; €31 billion in global trade value) (International Organisation of Vine and Wine 2018). The fundamental production steps (destemming, crushing, fermentation of sugars into alcohol and carbon dioxide by Saccharomyces spp., and pressing thereafter for reds) have remained the same for at least 6000 years, as only recently proven by the presence of succinic acid (rather than inconclusive tartaric acid) residues at archeological sites (McGovern et al. 2017). Wine laboratory quality systems in place at commercial wineries around the world typically include eight different wine analyses: pH and titratable acidity, free and total sulfur dioxide, residual sugar (R.S.), volatile acidity, malic acid, and ethanol (Howe et al. 2015).

The determination and declaration of the alcohol (ethanol) content of a wine are relevant for both human health considerations, as well as tax purposes. In the USA, the percentage of alcohol by volume (ABV) not to be exceeded to qualify for the lowest excise tax bracket for still wine was raised in 2018 from 14 to 16% (Alcohol and Tobacco Tax and Trade Bureau 2018). This means that all wines produced via natural alcoholic fermentation are now included in this tax class. Due to a trend toward increased grape sugar concentrations at harvest—for reasons of both climate change and the popularity of wine styles emphasizing ripe fruit aromas—it had become common, particularly in California where 90% of US-wine grapes are grown, to produce (red) wines with alcohol concentrations of 14 to 15.5%, the upper limit of alcoholic fermentation by traditional wine yeast. Methods for alcohol analysis used in commercial wineries in the USA were 51% by ebulliometer, 31% by gas chromatography, 8% by near-infrared spectroscopy, and 10% by distillation/density (Butzke 2002) (Table 1). Labs were most proficient in alcohol analysis compared to all other analyses, achieving coefficients of variation between 1.2 and 1.9%, despite the use of a wide range of equipment and methods of analysis. This confirms that non-standardized methodology does not necessarily compromise the ability to produce acceptable results. However, the industry trend to make delicate alcohol adjustments to wines for sensory or tax purposes would require an even greater proficiency in order to make such decisions more precise and reproducible (Butzke 2012).

None of the existing methods of analysis for alcohol is rapid, robust, accurate, and inexpensive enough not to warrant a search for a better assay (Butzke and Ebeler 1999). The analysis of physical or chemical parameters and quantitative data from seemingly unrelated and novel or unconventional methods may help find a new technique that would improve the current state of alcohol analysis in wine as well as other alcoholic beverages such as liqueurs and distilled spirits. The analytical assessment of water activity (aw) in alcoholic beverages could potentially provide such a novel assay. The determination of the aw of many foods has been incorporated into the Code of Federal Regulations Title 21 (CFR 21), good manufacturing practices (GMPs), and hazard analysis and critical control points (HACCP) plans (Fontana 1998).

Water activity is defined as the equilibrium partial vapor pressure of water in a sample divided by the equilibrium vapor pressure of liquid water at the same pressure and temperature (Reid 2007), as shown in Eq. 1:

where Pw is the vapor pressure of water in the sample, \( {P}_{\mathrm{w}}^0 \) is the vapor pressure of pure water, and subscript T,P indicates the presence of isothermal and isobaric conditions. In dilute ideal solutions containing nonvolatile solutes, the aw is lowered from that of water (for which aw = 1) based on the mole fraction of the solute in solution (a colligative property), as can be predicted by Raoult’s law (Raoult 1887). However, the aw values (aws) of most foods deviate from ideality due to variable interactions between different types of solutes and water (Schmidt 2004), and both ethanol (Allan and Mauer 2017) and sugars (Rüegg and Blanc 1981) are known to influence aw.

The aws of wines and spirits have not been previously reported, likely due to the interference of the volatile ethanol with conventional aw measurements: chilled-mirror dewpoint (Campbell and Lewis 1998; METER Group 2013), capacitance (Rotronic, 2009; Suntola 1979), and resistive electrolytic (Horn 1990; Novasina, 2007) sensors. A newer aw measurement device, the AquaLab TDL (METER Group 2015), utilizes a tunable diode laser and Lambert-Beer law principles to measure the water vapor pressure in the headspace above a sample by the 1854 nm absorbance of water (“loss of signal strength from the laser”) (METER Group 2015). Then, the water vapor pressure above the sample is divided by the vapor pressure of pure water at the measurement temperature to calculate the aw (RH = aw × 100 = Pw / \( {P}_{\mathrm{w}}^0 \)) (METER Group 2015). This method is able to measure aw in the presence of other non-water volatiles as long as the volatiles do not also absorb at 1854 nm. The aws of a range of ethanol/water solutions measured using the TDL have been reported (Allan and Mauer 2017). Pure ethanol has a aw of 0.00 and exhibits little absorption at 1854 nm (Yano et al. 1997). The objectives of this study were to (1) document the aw of wines and spirits, and (2) correlate the measured aws to the alcohol and sugar contents of the alcoholic beverages.

Materials and Methods

Materials

A total of 678 wine samples (15 mL) from commercial wineries were collected during the 2017 Indy International Wine Competition (Purdue University, West Lafayette, IN), and larger volumes (250 mL) of a subset of these wines (109 samples) were also collected to enable ebulliometer analysis. Wine samples were categorized by the wine classes in the 2017 Indy International Wine Competition, which were determined by the wine grape species and styles as follows (with the number of each sample type collected shown in parenthesis): red Vitis vinifera (267), white Vitis vinifera (131), red hybrid (77), white hybrid (67), and American varietals (36), fruit wines (47), honey wines (15), sparkling wines (23), and fortified wines (15) (Indy International Wine Competition 2019). In addition to the wine category, the labeled alcohol by volume (ABV) content and the percent sugar reported by the wine producer on the competition entry were also recorded. Wine samples were collected in 15 mL conical polypropylene (VWR, Rannor, PA) and 250 mL high-density polyethylene (Nalgene™, Rochester, NY) containers, sealed, and stored at 4 °C to minimize any wine compositional changes until further analysis. Commercial spirit samples were donated by professors and graduate students in the College of Agriculture at Purdue University. These samples were collected into 15 mL centrifuge tubes on which the name and ABV of each product were recorded. The water used in this study was processed using reverse osmosis then filtered by a Barnstead E-Pure Lab Water System (Dubuque, IA) to > 17.4 milliohm-cm. Sugars used to produce model solutions were the monosaccharides anhydrous glucose from Sigma-Aldrich (St. Louis, MO) and fructose from Acros Organics (Pittsburgh, PA), and the disaccharide sucrose from Mallinckrodt Chemical (Phillipsburg, NJ). Ethanol (100%) was purchased from Koptec (King of Prussia, PA).

Preparation of Model Solutions

Model solutions containing various ratios of water, ethanol, and different sugars, chosen to encompass the majority of the wine compositions, were prepared and then analyzed by Fourier transform infrared spectroscopy (FTIR) and aw methods to document the effects of the varying ratios on the measurements. The compositions of the model solutions (10 mL) were 10, 12, 14, and 16% initial ABV (iABV) with 0, 5, 10, and 15% w/w glucose; 11 and 13% iABV with 0, 5, 10, and 15% w/w fructose; and 11 and 13% iABV with 5, 10, and 15% w/w sucrose. The model solutions were equilibrated overnight to allow for sugar mutarotation (Flood et al. 1996) and ethanol-water volume contraction (Lee et al. 2013) prior to analysis.

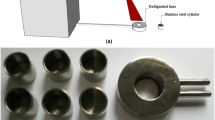

Water Activity (a w) Determination

The aws of all samples (wines, spirits, model solutions) were measured at 25 °C using an AquaLab TDL, a tunable diode laser aw measurement device with software version S4TDL-R2-12 (METER Group, Inc., Pullman, WA). Four milliliters of each solution at ambient temperature was pipetted into a high-density polyethylene cup sourced from METER Group, the cup was placed into the TDL, and the analysis was conducted using a criterion setting of two consecutive measurements within 0.003 aw at the set temperature before the instrument reported the sample aw. Each measurement took approximately 10 min. The AquaLab TDL device was verified daily using 0.920 and 0.984 aw standards purchased from the manufacturer, and offsetted as needed. A multi-point calibration was performed once a week using 0.250, 0.500, 0.760, and 1.00 manufacturer aw standards. The aw standards and TDL have accuracies of ± 0.003 and ± 0.005 aw, respectively, at 25 °C (METER Group 2015).

Alcohol by Volume Measurement

The ABVs of 109 dry wines with reported sugar contents < 2% were determined using a digital ebulliometer (Laboratoires Dujardin-Salleron, Noizay, FR) (± 0.1%ABV accuracy) following the manufacturer’s instructions (Laboratoires Dujarden-Salleron 2008). The ABVs of wines determined by the ebulliometer analysis were used to develop the FTIR ABV measurement method.

Spectra of all wines and model solutions were collected using a ThermoNicolet Nexus 670 Fourier-Transform Infrared Spectrometer (ThermoNicolet Analytical Instruments, Madison, WI) with a multi-Bounce HATR 45° ZnSe trough plate. The FTIR was equipped with a mercury cadmium telluride A (MCTA) detector and KBr beam splitter. Spectra were collected using 128 scans with a 4 cm−1 resolution from 4000 to 650 cm−1, from which a background spectrum, collected every 60 min, was subtracted using OMNIC 8.0 software (Thermo Fisher Scientific Inc., Waltham, MA), as shown in Fig. 1. The ABVs of wines were calculated from these spectra using a method developed in TQ Analyst 8.0 (Thermo Fisher Scientific Inc., Waltham, MA). For this method, the ABVs determined by the ebulliometer were assigned to the corresponding spectrum of the 109 wine samples followed by partial least square (PLS) regression analysis of the spectral regions 3005–2960 and 900–860 cm−1 with a linear baseline removed. These spectral regions encompassed the 2974 and 881 cm−1 peaks of ethanol (SDBSWeb 2018) and avoided regions wherein sugars would interfere (Max and Chapados 2007). The correlation coefficient of the PLS model of the ebulliometer measured ABVs and predicted ABVs from the spectra was 0.9792. Therefore, the dry wines with known ABVs determined by the ebulliometer were used as standards for the development of this FTIR method. The PLS method was then used to calculate the ABVs of all wines from their individual spectra.

FTIR spectra of (A) 13% iABV, 15% fructose model solution; (B) 13% iABV, 15% sucrose model solution; (C) 14% iABV, 15% glucose model solution; (D) 100% ethanol; and (E) 100% water. Regions I and III were used to quantify the ABV and regions I, II, and III were used to quantify the sugar type and amount present in a wine sample

Sugar Content Measurement

The concentrations and types of sugars present in the wines were determined using a FTIR method adapted from Moreira and Santos (2004) and Patz et al. (2004) and developed from initial analyses of the model solutions, acting as standards, containing varying sugar types and concentrations in the presence of varying ABVs. Spectra of the model solutions were collected using the same conditions and settings described above, and the ABV was determined by the FTIR approach described previously. The known sugar type(s) and concentration(s), along with the ABV, were assigned to the corresponding model solution spectrum, and then PLS regression analysis was performed on the 1506–965 cm−1 region with no baseline correction and the 3005–2960 and 900–860 cm−1 regions with a linear baseline removed using TQ Analyst 8.0 software. The correlation coefficient of this model was 0.99971. Using this PLS method, the concentrations of glucose, fructose, and sucrose (% w/w) in the wines were calculated from their individual spectra and used to calculate the total residual sugar (R.S.).

Statistical Analysis and Modeling

Most analyses were conducted in at least duplicate, except the two methods based upon repeated measures of the same sample (FTIR and aw measurements) which were done at least once. One-way ANOVA with a Tukey HSD post hoc test (α = 0.05) was performed using IBM SPSS Statistics Version 23 (Armonk, NY) to identify significant differences in aw, ABV, and sugar content between wine categories. Pearson correlation coefficients (r) were calculated using Microsoft Excel 2016 (Redmond, WA). Correlations were considered to be weak if − 0.5 ≤ r ≤ 0.5, moderate if − 0.8 < r < − 0.5 or 0.5 < r < 0.8, and strong if r ≥ 0.8 or r ≤ − 0.8 (Devore 2011). Raoult’s law (Eq. 2) was used to compare the effects of varying sugar and ethanol concentrations on the aws of the model solutions and wines:

where Xw is the mole fraction of water and γs is the activity coefficient. A γ = 1 is indicative of an ideal solution (no solute-solvent effects), and deviations of γ from 1 were used to evaluate the non-ideality solution behaviors of the wines.

A modified Norrish equation (Eq. 3) for a multiple solute system (Labuza and Altunakar 2007) was used to estimate the aws of the wines:

where Xw is the mole fraction of water, Xi (same as Xs) is the mole fraction of the solute, and Ki is the fitting constant for each solute that was calculated by taking the slope of ln (aw/Xw) (y-axis) in respect to \( {X}_{\mathrm{s}}^2 \) (x-axis) (Labuza and Altunakar 2007; Norrish 1966). The Ki for ethanol was calculated from γ data from Miyawaki et al. (1997) (for which Ki was found to equal − 0.91). The Kis used for glucose (− 2.25) and sucrose (− 6.47) were reported in Chirife et al. (1980), and the Ki for fructose (− 2.15) was reported in Chirife et al. (1982). To calculate the ethanol mole fraction, the reported density of ethanol (0.7893 g/mL (Weast 1988)) was used for the model solutions, and the ABV of wines determined using the FTIR method was converted to gram of ethanol per 100 mL using the conversion factor of 0.79 (e.g., 12% ABV × 0.79 = 9.48 g/100 mL) (Brick 2006). The aws predicted using the Norrish equation were compared to the measured wine aws. WebPlotDigitizer (Version 4.1) software was used to extract published data as follows: The activity coefficient of water in respect to the mole fraction of ethanol was extracted from Fig. 3 in Miyawaki et al. (1997) in order to calculate the Ki of ethanol, and the ethanol and sugar compositions of wine and must during fermentation were extracted from Figs. 4–11 in Boulton et al. (1999) and Fig. 7.13 in Jackson (2008b) in order to calculate the anticipated changes in aw during the fermentation progression of wines.

Results

The Water Activities of Wines and Spirits

The average aw of the 678 wines was 0.940 ± 0.011, with the aws ranging from a low of 0.860 to a high of 0.968 (Table 2). The wine category with the highest average aw was sparkling wines (0.948 aw), and the lowest average aw was found in fortified wines (0.910 aw). As a category, the fortified wines had, on average, both higher ABVs (17.2% measured ABV and 19.3% winery-reported ABV) and total sugar contents (11.8% measured total sugar and 7.2% winery-reported total sugar) than the other categories, while sparkling wines had one of the lowest ABVs (10.8% measured ABV and 11.3% winery-reported ABV) and less sugar (5.0% measured total sugar and 3.9% winery-reported total sugar) than the fortified wines (Tables 2 and S1). No significant differences in aw were found between any of the other wine categories (Table 2). The aws of non-fortified naturally fermented wines never dropped below 0.90 aw, likely due to the inability of yeast to grow in < 0.90 aw conditions (Bamforth 2008). Fortified wines, to which distilled alcohol was added, were found to have aws < 0.90 in some cases (Table 2).

The aws of spirits and liqueurs (excluding grain alcohol) ranged from 0.750 aw to 0.909 aw, with reported ethanol contents from 14.9% ABV to 69% ABV (Table 3). Grain alcohol had the lowest aw at 0.365 and the highest ABV of 95%. Distilled spirits have little, if any, sugar (CFR 2018c), and the aw would therefore be lowered primarily by the ethanol. For example, gin and brandy samples both had 45% ABVs and had an average aw of 0.843 and 0.841, respectively. The labeled ABVs of dry distilled spirits were moderately correlated (R2 = 0.575, R = 0.758, Fig. 2) to the measured aws. In liqueurs (which must have a minimum of 2.5% sugar by weight in the finished product (CFR 2018c)) and spirits with added sugars, both ethanol and sugars will lower the aw. The aws of these samples varied widely and were lower than the aws of the dry spirits (Fig. 2). The aws of the sweetened spirits were weakly correlated to the reported ABVs (R2 = 0.152, R = 0.389, Fig. 2).

The measured aws of the model solutions containing water, ethanol, and glucose were similar to the measured aws of the wines. The aw of the 10% iABV ethanol/water solutions without any sugar was 0.959 (Table 4), which resembled the upper aws and lower ABVs (Table 2) of the wines. Similarly, the 5% glucose 12% iABV model solution had a aw = 0.947, which was similar to the average aw of wines within the “American” category (aw = 0.939) that also had a similar average ABV and sugar composition (Tables 2 and 4). Since model solutions and wines with similar compositions also have comparable aws, this suggests that the ethanol and sugar contents are the primary solutes that affect the aw in wine.

According to the principles of Raoult’s law (Eq. 2), ethanol would be expected to lower the aw more than sugars on an equal weight basis because ethanol has a lower molecular weight (46.07 g/mol (Weast 1988)) than mono- and di-saccharides (180.156–342.297 g/mol (Weast 1988)). Raoult’s law is based on colligative properties and assumes that an ideal solution is present, wherein the vapor pressure ratio of a solution (aw) is equal to the molar ratio of the solvent (Xw ≈ aw). However, as the concentration of solutes increases, the aw typically deviates from Xw due to solute-solvent intermolecular interactions. This deviation from ideality is adjusted with an activity coefficient (γ) (Eq. 2). A γ > 1 results from structure breaking, and the aw is higher than Xw; a γ < 1 results from the solute being structure forming, and the aw is lower than Xw (Miyawaki et al. 1997). Sugars (e.g., glucose, fructose, and sucrose) have structure forming interactions with water (γ < 1) and decrease the aw more than predicted by Raoult’s law (Miyawaki et al. 1997). Ethanol in low concentrations in water (Xw > 0.90, XE < 0.10) had a γ < 1 (Miyawaki et al. 1997), resulting in ethanol-water solutions with aws lower than predicted by Raoult’s law. In contrast, ethanol at higher concentrations (Xw < 0.75, XE > 0.25) had a γ > 1 and these ethanol solutions had aws higher than predicted by Raoult’s law (Allan and Mauer 2017). A similar concentration-related phenomenon was found in methanol and isopropyl alcohol solutions, and the positive deviation from Raoult’s law at lower Xw was theorized to be associated with the hydrophobic interactions in solution (Zhu et al. 1996). Based on these concentration-related trends, ethanol in wines is anticipated to be structure forming (γ < 1) resulting in the aw being less than that predicted by Raoult’s law (the average Xw of wines in this study was ≈ 0.96). In distilled alcoholic products with ABVs > 30% (Xw < 0.90) (e.g., spirits), the ethanol is anticipated to be structure breaking (γ > 1), resulting in measured aws that would be equal to or higher than predicted by Raoult’s law. Since both sugars and ethanol are known to alter aw, the determination of aw for the complete set of wines was followed by a series of studies to correlate the composition of the wines to the measured aws.

Ethanol Content in Wines

The ABV measurement is important for legal labeling requirements, and the ebulliometer is the most common technique used to determine the ABV. In the USA, the ethanol content displayed on the label (ABV) has a tolerance of ± 1.5% alcohol for wines containing ≤ 14% ABV, and a ± 1% alcohol tolerance for wines containing > 14% ABV (CFR 2018a). The ABVs measured by the ebulliometer were compared to the ABVs labeled on the wine bottles (on which no indication was given about the method used to determine ABV), and 91.3% of the labeled ABVs were found to be within the ± 1.5% ABV deviation. The ebulliometer determines the ABV based on the sample boiling point (Zoecklein et al. 1995), but this method does not account for the effects of other solutes (e.g., sugars) on the colligative properties of water, and thus errors in ABV determination are higher for sweeter wines (containing > 2% R.S.).

FTIR compositional analysis of wine is a rapid method, requiring minimal sample preparation, that can simultaneously measure multiple components in wines (e.g., ethanol, sugar, organic acids, glycerol) (Moreira and Santos 2004; Patz et al. 2004). However, the accuracy is highly dependent on the rigidity of calibration (Patz et al. 2004). The ABVs of the 678 wine samples, as determined by FITR, are summarized in Table 2 and ranged from a low of 5.4% to a high of 20.5% ABV. Within this dataset, 95.7% of the ABVs determined by the FTIR analysis were within a ± 1.5% ABV error range of the ebulliometer-measured ABVs, and the FTIR and ebulliometer measured ABVs of the model solutions without sugar were within 0.3% ABV of each other (Table 4). It is also important to note that the iABV is typically greater than the final equilibrated ABV measured by the FTIR and ebulliometer (Table 4), attributed to a 2–4% volume contraction in 0.1–0.2 mol fraction (0.90–0.80 aw) ethanol solutions (Lee et al. 2013).

The following Pearson’s correlation coefficients were found when relating the ABVs to the measured aws by linear regression: R2 = 0.410 (r = 0.640) for the ebulliometer-measured ABVs and measured aws of 109 dry wines; R2 = 0.298 (r = 0.546) for the FTIR-determined ABVs and measured aws of the 678 wine dataset; and R2 = 0.278 (r = 0.527) for the labeled ABVs and measured aws of the 678 wine dataset. As a comparison, the R2 for the ABVs and aws of solutions containing only ethanol and water was R2 = 0.986 (r = 0.993), while the R2 for the model solutions with sugars, ethanol, and water was R2 = 0.203 (r = 0.451). The aw of a solution containing only ethanol and water was strongly correlated to the ABV; however, this correlation greatly decreased in the presence of other solutes such as sugars, and therefore it is not possible to accurately estimate the aw of a wine based on its ABV, or vice versa, in the absence of more compositional information.

Sugar Content in Wines

The residual or added sugars present in wine will lower the aw from that of water, with increasing concentrations resulting in lower aws. Some amount of sugar is likely to be present in wines, ranging from < 2 g/L in dry wines up to 200 g/L in sweet dessert wines (Jeffery and Wilkinson 2014). Residual sugar (sugar that was present in the must but not fermented) can be present in larger quantities (i.e., > 2 g/L) in the following situations: if the primary fermentation did not finish due to early sterile filtration, when dosing with large quantities of sulfur dioxide (SO2) (e.g., 200 mg/L), if a stuck fermentation occurs, and/or when starting with a must with a high sugar content (e.g., for Sauternes or ice wines) (Jeffery and Wilkinson 2014). Sugars in the form of juice or concentrated juice can be added to sweeten wines (CFR 2018b); however, adding sucrose to wine is not a common practice (except in sparkling wines) and is frowned upon or not legal in some regions (Jackson 2008c). Soluble solids (sugars) in grape juice are easily measured using a refractometer (Zoecklein et al. 1995). Soluble solids and fermentation progression can also be monitored by measuring the specific gravity using a hygrometer (Jeffery and Wilkinson 2014; Zoecklein et al. 1995). However, refractometry and hygrometry are not specific to sugars and are hampered by the presence of ethanol; therefore, other more specific techniques may be used to quantify sugars, including high-performance liquid chromatography with a refractive index or variable UV detector, enzymatic-spectrometric assays, redox reactions (The Australian Wine Research Institute 2018), and near- or mid-infrared spectroscopy methods (Bauer et al. 2008; Fernández-Novales et al. 2009; Patz et al. 2004). The spectroscopy techniques are rapid but require a high degree of calibration with known standards (Jeffery and Wilkinson 2014).

In this study, the sugar contents in wines were determined using an FTIR method that was calibrated using spectra of model solutions containing controlled concentrations of glucose, fructose, sucrose, and ethanol. The correlation coefficient of the measured versus actual sugar concentrations in the model solutions was R2 > 0.999. The total sugar contents in the wines, determined using the FTIR analysis, ranged from 0 to 25.9% w/w (Table 2). The concentrations of glucose and fructose were more prevalent than sucrose (Table S1), as expected since sucrose is not naturally found in grapes at substantial concentrations (Liu et al. 2006) and, if it was added, the low pH of wine would catalyze the hydrolysis of sucrose into glucose and fructose (Wilker 1992). No correlation (R2 = 0.020, r = 0.141) was found between the measured aw and the total R.S. contents determined by FTIR analysis. This could be due to a relatively low molar ratio of sugars present in wines and the presence of other solutes that have more influence on the aw. For example, a 25.9% w/w 6-carbon monosaccharide solution (the highest glucose + fructose concentration measured in a wine sample in this study) would lower the aw only by ≈ 0.034 (Eq. 2, Xw = 0.966). As a comparison, the effect of a sugar concentration of ≈ 10% w/w on aw is observable in fruit juices, for which the aw is 0.986–0.988 aw (Schmidt and Fontana Jr 2007). The relatively minor effect of sugars on the aw of wines, and absence of correlation of R.S. content and measured aw indicate that the sugars are not the primary solutes that affect the aw of most wines.

The Combined Effects of Ethanol and Sugars on the Water Activity of Wine

Following water, ethanol and sugars often comprise the highest concentrations in wines (Patz et al. 2004), although the concentration of glycerol may exceed that of sugar in dry wines (Bamforth 2008; Jackson 2008a). Between ethanol and sugars, the aw-lowering power of ethanol per gram is greater than that of sugars (both mono- and di-saccharides) because of its lower molecular weight. The average and median ABVs of wines in this study were both 12.5%, and therefore the average mole fraction of ethanol was ≈ 0.041, while the average and mean percent total sugars were 3.1 and 1.5% w/w, respectively, corresponding to mole fractions of ≈ 0.003 and ≈ 0.002. Differences in the aw-lowering power of solutes per mole are adjusted by the activity coefficient γ term in Raoult’s law (Eq. 2). Without γ, assuming an ideal solution, 99% of the aws for the wines predicted using Eq. 2 were higher than the measured aws (Fig. 3). The aws of model solutions were also lower than the Xw, and γ was found to range from 0.979 to 0.993. Thus, wines and model solutions did not behave as ideal solutions because the ethanol and sugar concentrations were high enough to cause the aw to deviate from ideality, i.e., Xw. In addition, solutes other than sugars and ethanol (e.g., organic acids and glycerol) had the potential to also contribute to lowering the aw.

To determine if the aw of wine could be predicted if both the ethanol and sugar concentrations were known, a modified Norrish equation (Eq. 3) was applied to the data collected from model solutions (Table 4), and then to the data collected from the wines (Fig. 3). Since the samples did not behave as ideal solutions, Ki values were used in the Norrish equation as fitting constants for each solute, similar in concept to the activity coefficients (γ) in Raoult’s law (Eq. 2). The Ki values used for the sugars and ethanol were reported in previous studies (− 2.25 for glucose, − 2.15 for fructose, − 6.47 for sucrose, and − 0.91 for ethanol) (Chirife et al. 1982, Chirife et al. 1980; Miyawaki et al. 1997). Ki is associated with solute-solution intermolecular interactions such as hydrogen bonding and has been roughly correlated to the number of hydroxyl groups on the solute (Chirife et al. 1980; Miyawaki et al. 1997; Norrish 1966). Using the Norrish equation (Eq. 3) with these Ki values to predict the aws of model solutions containing only water, ethanol, and sugar resulted in strong correlation (R2 = 0.982, r = 0.991) between the measured and predicted aws (Table 4). More variation was found between the predicted and measured aws of wines (Fig. 3), with the predicted aws being 0.012 ± 0.007 higher than the measured aws, and only 4.4% of the measured aws of wines were higher than the predicted aws.

While the aws of wines were primarily influenced by the ethanol followed by the sugar content (based on composition and influence of these solutes on lowering the aw), the differences between the predicted and measured aws indicated that additional solutes were likely also lowering the aw beyond the contributions of ethanol and sugar. Wines are known to contain glycerol and organic acids. The upper concentration of organic acids in wines (14.1 g/kg, 0.002 Xs for tartaric acid) reported in Patz et al. (2004) would lower the aw by ≈ 0.002 in an ideal solution (following Raoult’s law). Similarly, the upper limit of glycerol (27.8 g/kg of solution, 0.005 Xs (Patz et al. 2004)) would lower the aw by ≈ 0.005. While it is possible, and likely, that these additional solutes affect the aw of wines, it is plausible that the aw of a wine could be predicted using the Norrish equation within 0.012 ± 0.007 aw using only the ABV and the sugar content and assuming that the sugar is either fructose or glucose.

Applications

Using the reported sugar and ethanol compositions of wine during fermentation from Boulton et al. (1999) and the theoretical wine compositions reported in Jackson (2008b), the Norrish equation was used to demonstrate that the aw will decrease as fermentation proceeds (as shown in Fig. 4). The initial changes of the aw (osmolarity) of wine have been suggested to be an important indicator of the initial stages of yeast fermentation (Jones and Greenfield 1986). As shown in Fig. 4, the greatest changes in aw were found earlier in the fermentation process based on the reported compositional changes occurring during that time period. Measuring the aw of wine requires only a calibrated TDL instrument, placement of ~ 5 mL of wine into a sample cup, and ~ 10 min of analysis time. Because the aw of wine is based primarily on ethanol and sugar content, with some small contribution from other solutes, it seems that there could be a niche application for using aw measurements to monitor the initial stages of fermentation, as shown in Fig. 4.

Calculated aws of wine during fermentation using the Norrish equation (ethanol Ki = − 0.91, glucose Ki = − 2.25). Data were from ABVs and sugar contents reported in Boulton et al. (1999) (circle, initial sugar ≈ 21.6%, final ABV ≈ 12.6% and final sugar ≈ 0.0%) and a theoretical figure in Jackson (2008b) (square, initial sugar ≈ 19.3%, final ABV ≈ 11.0% and final sugar ≈ 2.1%)

The required accuracy of the commercial determination of the alcohol content of wines and spirits depends on several factors, including (Butzke 2012):

- 1.

Differences in alcohol concentration can relate to the perceived sensory properties of ethanol itself (“hotness”) as well as the relative volatility of aroma compounds in the headspace of a tasting glass.

- 2.

Reporting of taxable production volumes is often based on alcohol concentration (“proof gallons” vs “wine gallons” in the USA), and tax brackets are historically based on arbitrary concentrations of alcohol by volume (the higher tax bracket is now at > 16% ABV).

- 3.

The absolute concentration of ethanol is relevant for nutritional and public health considerations, e.g., the prediction of blood alcohol concentration, as well as labeling. The labeling requirements currently allow an error variance of ± 1.5% in wines with < 14% ABV and ± 1.0% in wines with ≥ 14% ABV.

Based on these considerations, it is suggested that any method of analysis for alcohol in wines and spirits has an accuracy of no less than ± 0.2% ABV. If the Norrish equation had been more accurate in predicting the aw of wine based on only ethanol and sugar content, then it might have been possible to use aw measurement to predict ABV if the sugar content of the wine was known. However, with the 0.012 ± 0.007 aw error found when the Norrish equation was applied to wines, the estimation of ABV would be off by a margin greater than the desired ± 0.2% ABV. For example, accounting for only ethanol in the Norrish equation a 12.0% ABV wine would be predicted to have a aw of 0.959 and a 14.8% ABV wine a aw of 0.949. Therefore, a 0.01 aw error in aw measurement would result in as much as a 2.8% ABV difference using this approach. Thus, it was concluded that the margin of error was too great to use aw measurements to estimate the ABV of wines.

Conclusions

The aws of model solutions, wines, and spirits were determined using a water activity instrument capable of measuring aw in the presence of volatiles such as ethanol. Increasing concentrations of both ethanol and sugars decreased the aws of model solutions in a manner that was predictable by the Norrish equation. The greater complexity of composition of wines compared to model solutions resulted in measured aws for wines that were lower than the predicted aw values by a margin of 0.012 ± 0.007 aw. This margin of error in aw prevents the use of aw measurement for accurate predictions of wine ABV using the Norrish equation, since solutes other than ethanol and sugar are contributing to the wine aw. While it is simple to measure the aw of wines and spirits, and there is some correlation of aw to changing ethanol and sugar concentrations that occur during fermentation, a niche application for use of aw measurement for alcoholic beverages has yet to be found.

References

Alcohol and Tobacco Tax and Trade Bureau (2018) Tax and fee rates. https://www.ttb.gov/tax_audit/taxrates.shtml#Wine18

Allan M, Mauer LJ (2017) Dataset of water activity measurements of alcohol: water solutions using a tunable diode laser. Data Brief 12:364–369

Bamforth CW (2008) Food, fermentation and micro-organisms. John Wiley & Sons

Bauer R, Nieuwoudt H, Bauer FF, Kossmann J, Koch KR, Esbensen KH (2008) FTIR spectroscopy for grape and wine analysis. Anal Chem 80:1371–1379

Boulton RB, Singleton VL, Bisson LF, Kunkee RE (1999) Yeast and biochemistry of ethanol fermentation. In: Principles and practices of winemaking. Springer US, Boston, pp 102–192. https://doi.org/10.1007/978-1-4757-6255-6_4

Brick J (2006) Standardization of alcohol calculations in research. Alcohol Clin Exp Res 30:1276–1287

Butzke C (2012) Wine appreciation, 2nd edn. Kendall Hunt Publishing Company, Dubuque

Butzke CE (2002) 2000/2001 survey of winery laboratory proficiency. Am J Enol Vitic 53:163–169

Butzke CE, Ebeler SE (1999) Survey of analytical methods and winery laboratory proficiency. Am J Enol Vitic 50:461–465

Campbell GS, Lewis DP (1998) Water activity and dew point temperature measuring apparatus and method. United States Patent 5,816,704

CFR (2018a) Alcoholic content. Code of Federal Regulations

CFR (2018b) Production of wine. Code of Federal Regulations

CFR (2018c) The standards of identity. Code of Federal Regulations

Chirife J, Favetto G, Fontán CF (1982) Water activity of fructose solutions in the intermediate moisture range. Lebensm Wiss Technol 15:150–160

Chirife J, Fontán CF, Benmergui E (1980) The prediction of water activity in aqueous solutions in connection with intermediate moisture foods IV. Aw prediction in aqueous non electrolyte solutions. Int J Food Sci Technol 15:59–70

Devore JL (2011) Probability and statistics for engineering and the sciences. 8th edn. Cengage Learning, Manson

Fernández-Novales J, López M-I, Sánchez M-T, Morales J, González-Caballero V (2009) Shortwave-near infrared spectroscopy for determination of reducing sugar content during grape ripening, winemaking, and aging of white and red wines. Food Res Int 42:285–291. https://doi.org/10.1016/j.foodres.2008.11.008

Flood AE, Johns MR, White ET (1996) Mutarotation of d-fructose in aqueous-ethanolic solutions and its influence on crystallisation. Carbohydr Res 288:45–56. https://doi.org/10.1016/S0008-6215(96)90775-2

Fontana AJ (1998) Water activity: why it is important for food safety. In: International conference on food safety. pp 177–185

Horn P (1990) Apparatus and method for the measuring of dew points. Switzerland Patent 4,898,475

Howe PA, Ebeler SE, Sacks GL (2015) Review of thirteen years of CTS winery laboratory collaborative data. Am J Enol Vitic 66:321–339

Indy International Wine Competition (2019) Wine class listing. http://www.indyinternational.org/competition/classes/. Accessed 7.3.2019

International Organisation of Vine and Wine (2018) OIV statistical report on world Vitiviniculture. http://www.oiv.int/public/medias/6371/oiv-statistical-report-on-world-vitiviniculture-2018.pdf

Jackson RS (2008a) 6 - chemical constituents of grapes and wine. In: Wine Science (Third Edition). Academic Press, San Diego, pp 270–331. https://doi.org/10.1016/B978-012373646-8.50009-3

Jackson RS (2008b) 7 - fermentation. In: Wine Science (Third Edition). Academic Press, San Diego, pp 332–417. https://doi.org/10.1016/B978-012373646-8.50010-X

Jackson RS (2008c) 10 - wine Laws, authentication, and geography. In: Wine Science (Third Edition). Academic Press, San Diego, pp 577–640. https://doi.org/10.1016/B978-012373646-8.50013-5

Jeffery DW, Wilkinson KL (2014) Wine. In: Bamforth CW, Ward RE (eds) The Oxford handbook of food fermentations. Oxford Handbooks, New York, pp 54–147

Jones RP, Greenfield PF (1986) Role of water activity in ethanol fermentations. Biotechnol Bioeng 28:29–40

Laboratoires Dujarden-Salleron (2008) Electric Ebulliometer with electronic probe brochure

Labuza TP, Altunakar B (2007) Water activity prediction and moisture sorption isotherms. In: Barbosa-CÃ GV, Anthony J. Fontana Jr, Shelly J. Schmidt, and Theodore P. Labuza (ed) Water Activity in Foods-Fundamentals and Applications Blackwell Publishing and the Institute of Food Technologists, pp 109–154. doi:https://doi.org/10.1002/9780470376454.ch5

Lee I, Park K, Lee J (2013) Precision density and volume contraction measurements of ethanol–water binary mixtures using suspended microchannel resonators. Sensors Actuators A Phys 194:62–66. https://doi.org/10.1016/j.sna.2013.01.046

Liu HF, Wu BH, Fan PG, Li SH, Li LS (2006) Sugar and acid concentrations in 98 grape cultivars analyzed by principal component analysis. J Sci Food Agric 86:1526–1536

Max J-J, Chapados C (2007) Glucose and fructose hydrates in aqueous solution by IR spectroscopy. J Phys Chem A 111:2679–2689

McGovern P et al (2017) Early Neolithic wine of Georgia in the South Caucasus. Proc Natl Acad Sci 114:E10309–E10318

METER Group (2013) Aqualab 4TE-Operator's manual. Pullman, WA

METER Group (2015) TDL tunable diode laser water activity Meter-Operator's manual. Pullman, WA

Miyawaki O, Saito A, Matsuo T, Nakamura K (1997) Activity and activity coefficient of water in aqueous solutions and their relationships with solution structure parameters. Biosci Biotechnol Biochem 61:466–469

Moreira JL, Santos L (2004) Spectroscopic interferences in Fourier transform infrared wine analysis. Anal Chim Acta 513:263–268

Norrish R (1966) An equation for the activity coefficients and equilibrium relative humidities of water in confectionery syrups. Int J Food Sci Technol 1:25–39

Novasina AG (2007) LabMaster-aw operating instructions. Lachen

Patz CD, Blieke A, Ristow R, Dietrich H (2004) Application of FT-MIR spectrometry in wine analysis. Anal Chim Acta 513:81–89. https://doi.org/10.1016/j.aca.2004.02.051

Raoult F-M (1887) Loi générale des tensions de vapeur des dissolvants. C R Hebd Seances Acad Sci 104:1430–1433

Reid DS (2007) Water activity: fundamentals and relationships. In: Barbosa-Canovas GV, Fontana AJ, Schmidt SJ, Labuza TP (eds) Water activity in foods: fundamentals and applications. First edn. Blackwell Publishing and the Institute of Food Technologists, pp 15–28

Rotronic AG (2009) AwTherm manual vol version 1.1. Bassersdorf

Rüegg M, Blanc B (1981) The water activity of honey and related sugar solutions. Lebensm Wiss Technol 14:1–6

Schmidt SJ (2004) Water and solids mobility in foods. Adv Food Nutr Res 48:1–101

Schmidt SJ, Fontana Jr A (2007) Water Activity Values of Select Food Ingredients and Products. In: Barbosa-CÃ GV, Anthony J. Fontana Jr, Shelly J. Schmidt, and Theodore P. Labuza (ed) Water Activity in Foods-Fundamentals and Applications Blackwell Publishing and the Institute of Food Technologists, pp 413–414

SDBSWeb (2018) Ethyl Alcohol. National Institute of Advanced Industrial Science and Technology. https://sdbs.db.aist.go.jp

Suntola TS (1979) Capacitive humidity transducer. Finland patent 4,164,868,

The Australian Wine Research Institute (2018) Measurement of residual sugar in wine. https://www.awri.com.au/industry_support/winemaking_resources/laboratory_methods/chemical/rs/#titration

Weast RC (1988) Handbook of chemistry and physics. 1st student edn. CRC Press, Boca Raton

Wilker KL (1992) Hydrolysis of sucrose in eastern US table wines. Am J Enol Vitic 43:381–383

Yano T, Aimi T, Nakano Y, Tamai M (1997) Prediction of the concentrations of ethanol and acetic acid in the culture broth of a rice vinegar fermentation using near-infrared spectroscopy. J Ferment Bioeng 84:461–465

Zhu H, Yuen C, Grant DJ (1996) Influence of water activity in organic solvent + water mixtures on the nature of the crystallizing drug phase. 1. Theophylline. Int J Pharm 135:151–160

Zoecklein BW, Fugelsang KC, Gump BH, Nury FS (1995) Labratory procedures. In: Wine analysis and production. Springer, pp 310–516

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Matthew Allan declares that he has no conflict of interest. Erica Grush declares that she has no conflict of interest. Bartek Rajwa declares that he has no conflict of interest. Christian Butzke declares that he has no conflict of interest. Lisa Mauer declares that she has no conflict of interest.

Ethical Approval

This article does not contain any studies with human or animal subjects.

Informed Consent

Informed consent is not applicable in this article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

ESM 1

(DOCX 33 kb)

Rights and permissions

About this article

Cite this article

Allan, M.C., Grush, E.N., Rajwa, B.P. et al. Determination of the Water Activities of Wines and Spirits. Food Anal. Methods 12, 2753–2763 (2019). https://doi.org/10.1007/s12161-019-01632-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-019-01632-2