Abstract

An extraction method for simultaneous determination of aflatoxins (AFLAs) G2, G1, B2, and B1 in cornmeal, based on vortex-assisted matrix solid-phase dispersion (MSPD) and high-performance liquid chromatography (HPLC) with fluorescence detection was optimized by a central composite design, validated and applied. Multivariate analysis was performed to evaluate the effect of cornmeal composition on AFLA extraction. The amount and proportion of solid support (celite and C18) and volume of elution solvent (methanol and acetonitrile) were the variables tested. The mobile phase of methanol/acetonitrile/water (24:14:62, v/v/v) in isocratic elution mode provided satisfactory AFLA separation. The best recoveries (85.7 to 114.8%) were obtained when the sample preparation contained 25 mg C18 as solid support and 10 mL of elution solvent. The limits of detection ranged from 0.01 to 0.04 ng g−1, and the limits of quantification varied from 0.02 to 0.1 ng g−1. The optimized method was suitable for coarse and medium grind cornmeal. Multivariate correlation analysis showed that the main interferers for AFLA recovery were proteins and sugars.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Corn (Zea mays L.) is the third most cultivated cereal on the planet. One of the main problems of the maize production chain is the susceptibility to contamination by toxigenic fungi, which can produce mycotoxins under stress conditions (Wang et al. 2016). Among the mycotoxins that can contaminate maize (Mutiga et al. 2015; Oliveira et al. 2017) and corn flours (Alborch et al. 2012; Algül and Kara 2014) are the aflatoxins (AFLAs).

AFLAs are the most toxic compounds produced by fungi and display strong immunosuppressive, mutagenic, teratogenic, and carcinogenic effects (EFSA 2007). AFLA B1 has been reported to be the most toxic of the AFLAs and has been classified as a group 1 (human) carcinogen by the International Agency for Research on Cancer (IARC 2012). To protect consumers, many countries have set stringent regulations about the level of AFLAs permitted in food commodities. European Union legislation has mandated maximum limits of 5 μg kg−1 for AFLA B1 and 10 μg kg−1 for the sum of AFLAs G2, G1, B2, and B1, in maize and maize products (European Commission 2006). In Brazil, a level of 20 μg kg−1 has been established as the limit for corn contamination with AFLAs (G2, G2, B1, and B2) (ANVISA 2011).

In order to evaluate exposure to AFLAs, reliable data on their occurrence in various maize products are required. The development of multi-mycotoxin methods able to detect, in a single analysis, several mycotoxins, thereby promoting the lowest impact on the environment, is a trend in mycotoxin analysis (Zachariasova et al. 2010; Karami-Osboo and Mirabolfathi 2017). A promising alternative is the matrix solid-phase dispersion (MSPD) technique, which is little explored for mycotoxins (Hu et al. 2006; Manoochehri et al. 2015), especially for corn and its products. Capriotti et al. (2013) highlighted that the key factors for the success of MSPD are its feasibility, flexibility, versatility, low costs, and rapidity.

In MSPD, a small amount of sample and solid support are mixed homogenously; the powder obtained is then eluted with a solvent (Kristenson et al. 2006; Caldas et al. 2013). In this technique, sample preparation and cleaning are performed in the same step, using small amounts of solid support and solvent and thus reducing the cost and time of analysis. In addition, the use of a vortex instead of a column for the elution step protects the analyst from solvent exposure and sample handling, contributing to green chemistry strategies. The efficiency and selectivity of the extraction process are conditioned by the solid support characteristics, sample/solid support ratio, solvents and sample/solvent ratio, as well as the concentration and chemical properties of the analytes (Capriotti et al. 2010). The choice of the solid support depends on the analyte polarity and the potential coextracted components of the matrix. Several solid supports are available (Rubert et al. 2011; de Oliveira et al. 2017); however, C18 is the most used for mycotoxin analysis in cereals because its lipophilic characteristic allows good disruption, dispersion, and retention of lipophilic species (Barker 2007; Rubert et al. 2012; Serrano et al. 2012). There is no information in the literature about the effect of sample particle size in the MSPD method performance, unlike that for the dispersant (Capriotti et al. 2013).

This study contributes to the adaptation of a fast and eco-friendly analytical extraction method for simultaneous determination of AFLAs G2, G1, B2, and B1 in cornmeals, consuming few reagents with no effect on sensitivity and analytical performance. The method has been validated according to SANTE/11945/2015 guidelines (SANTE 2016). Besides, the applicability of the validated method in further matrices, to determine the impact of particle size on the sample recoveries, as well as an investigation identifying the interferences in AFLA extraction, using multivariate correlation analysis, were studied.

Material and Methods

Reagents and Samples

The AFLAs (G2, G1, B2, and B1) standards (purity > 98%) were supplied by Sigma-Aldrich, and the working standard solutions were prepared by diluting the standards with toluene/acetonitrile (MeCN) (98:2, v/v). After preparation, the mycotoxin standards were dried under nitrogen and stored at − 18 °C, to ensure their stability. The working solutions were prepared from stock solutions, which were quantified before use in a spectrophotometer, according to the AOAC (2000). The solvents (purity > 99.9%) used as mobile phase in the chromatographic system (MeCN and methanol [MeOH]) were supplied by JT Baker and were passed through a 0.45-m cellulose filter. Ultrapure H2O (> 18.2 MΩ cm−1 resistivity) was purified using a Milli-Q® SP Reagent Plus water system (Millipore Corp., Bedford, USA). The mobile phase solvents were previously degassed in an ultrasonic bath.

Cornmeals (fine, medium, and coarse) were purchased commercially from supermarkets located in the city of Rio Grande (Brazil). The corn used for the wet- and dry-milling processes was purchased directly from farmers of Parana State (Brazil).

Chromatographic Conditions

The AFLA standards were dissolved in 1 mL of ultrapure H2O/MeCN (90:10, v/v), and 20 μL was injected into a high-performance liquid chromatography system coupled with fluorescence detection (HPLC-FD) and online post-column photochemical derivatization (Romer Derivatization Unit RDU™), which pre-excites the analytes with UV light at 254 nm. The chromatographic elution from a Kromasil C18 column (5 μm, 150 mm × 4.6 mm) was performed at 40 °C, at a flow rate of 1.0 mL min−1 and the excitation and emission wavelengths were set at 365 and 440 nm, respectively. The separation of the AFLAs was evaluated using different proportions of the mobile phase (ultrapure H2O, MeCN, and MeOH), and the best condition was defined based on retention (k) and separation (α) factors.

The method limit of detection (LOD) and limit of quantification (LOQ) for each AFLA were obtained considering three and ten times the signal-to-baseline (noise) ratio, respectively. The linearity was evaluated through standard calibration curves in the concentration range of the LOQ of each AFLA to a concentration equivalent to 100-fold the LOQ value.

Preliminary Tests

Initially, three AFLA extraction methods were tested (Table 1), and after, a control sample (without solid support) was tested for method 1 (Rubert et al. 2011). The method that provided the greatest recovery of the four AFLAs was studied, using the central composite design (CCD).

Optimization of AFLAs Extraction

The experiments were performed according to Rubert et al. (2011). Aliquots of 1 g of the sample (cornmeal) were transferred to a mortar (30 mL capacity), spiked with the standard solution and, after solvent evaporation, gently homogenized with a pestle, using different amounts and proportions of the solid support (Table 2) for 5 min to homogeneity. The mixture was poured into a polypropylene centrifuge tube; different volumes of MeCN/MeOH (50:50, v/v) were added, and the content was thoroughly vortexed for 3 min. The tubes were centrifuged at 3220g for 10 min, the extract was collected, dried at 60 °C, dissolved in 1000 μL of ultrapure H2O/MeCN (90:10, v/v), and injected into the HPLC-FD. The variables, namely, the amount and solid support proportion (celite and C18), and volumes of extractor solvent (MeOH and MeCN) were defined using a 23 CCD, where AFLA recovery was the response variable. Medium cornmeal spiked with 4 ng g−1 of AFLAs mixture (1.0 ng g−1 G1 and G2, 0.6 ng g−1 B2 and 1.4 ng g−1 B1) was used in the optimization.

Method Validation

The accuracy of the method was evaluated regarding the recovery assays, in compliance with SANTE/11945/2015 (SANTE 2016) and ANVISA (2003). Aliquots of 1 g of the sample (cornmeal) were spiked with standard AFLAs at three levels for each AFLA. The levels of fortification were a concentration equivalent to the LOQ, 5-fold LOQ, and 10-fold LOQ for AFLA G2, and 2-, 10-, and 20-fold LOQ for AFLA G1, B2, and B1, respectively. Each fortification level was extracted in triplicate and injected three times (n = 9).

The precision of the method was evaluated regarding the repeatability, with nine determinations; extraction of the sample by MSPD was carried out at three different fortification levels, in triplicate.

The study of the matrix effect (ME) was performed according to Eq. 1, by comparing the slopes in matrix-matched calibration solutions prepared in blank cornmeal extract and calibration solutions prepared in solvent. The extent of the effects due to the matrix components was rated according to the percentage of signal enhancement (+) or suppression (−).

where Ss is the slope in solvent and Sm is the slope in matrix. No ME is observed when the ME (%) is equal to 100%. Values above 100% indicate enhancement, and values below 100% mean suppression.

Applicability of the Method

For the application of the validated method in other matrices (fine and coarse commercial cornmeals, and cornmeals obtained by dry- and wet-milling), the validation was carried out at a concentration of 10-fold LOQ for G2 and 20-fold LOQ for the other AFLAs.

Dry-milling of the corn was performed according to Somavat et al. (2016), and wet-milling was achieved based on Malumba et al. (2015). In the dry-milling, cornmeals of fine, medium and coarse granulometry were obtained, and in the wet-milling, only fine cornmeal was prepared. Table 3 provides the granulometric profile of the different cornmeals.

All flours were characterized for protein, ash, and lipid contents (AOAC 2000); sugar was determined by the phenol–sulfuric acid method (DuBois et al. 1956), and the total starch was measured by iodometry, using a starch calibration curve.

Statistical Analyses

Statistical analysis was performed using Statistica 7.0 software at 95% significance level, considering the recovery of the four AFLAs as a response to the variables studied. The experimental plans were obtained from the 23 CCD, from which, a set of combinations were experimentally evaluated. The experimental results were used to find a statistical mathematical model, as a function of all the influenced factors. Multivariate analysis was also performed to establish correlations between the different components of the matrices and the recovery of AFLAs by the MSPD method using HPLC-FD.

Results and Discussion

Conditions for Simultaneous AFLA G2, G1, B2, and B1 Determination

Different ratios of mobile phase were tested in the chromatographic system, with the aim of achieving excellent separation of the AFLAs and an efficient elution time. The three proportions of H2O, MeCN, and MeOH allowed obtaining a short elution time of around 15 min. Both the retention (k) and separation (α) factors were estimated, to decide the best proportion of the elution components (Table 4).

The separation factor (α) shows the selectivity of the chromatographic system in relation to the four AFLAs that elute at adjacent peaks, and values higher than 1 are recommended. Both parameters (k and α) indicated that the column and the H2O/MeCN/MeOH (62:14:24, v/v/v) mobile phase allowed good separation of the four AFLAs (Fig. 1a) in 14 min, which is suitable for the routine application of the four AFLA determinations concomitantly.

After the AFLA separation, the LOD and LOQ of the instrument, and the analytical curves of the standards were determined (Table 5). Results showed the chromatographic procedure was adequate for quantification of the AFLAs, with correlation coefficients for all calibration curves higher than 0.999. The instrument LOQ for AFLA G2 was the same as that found by Telles et al. (2017) (0.05 ng mL−1). However, the LOQs of AFLA B1 and B2 were 0.04 and 0.01 ng mL−1, respectively, which are lower than those verified by the mentioned authors (2.00 and 0.03 ng mL−1). Our study applied a detector equipped with post-column photochemical derivatization, which, as stated above, pre-excites the analytes with UV light at 254 nm. Therefore, the instrument LOQs are satisfactory to determine the four AFLAs, and the linearity shows a wide application range.

Preliminary Tests

The highest recoveries values for AFLAs G2, G1, B2, and B1 (83.4–102.5%) were achieved by method 1 (Tables 1 and 6). Acceptable recoveries (94.4–112.5%) were obtained by the method that did not use the solid support. In that procedure, the structure of the physical sample acted as an abrasive and promoted the disruption of the matrix sample, providing extraction of AFLAs, but the cleanliness of the extracts was not satisfied, so it was necessary to add a solid support to eliminate some interfering components during the extraction. Method 1 (Rubert et al. 2011) was subject to a CCD, to improve the recoveries and reduce the amount of solvent and solid support used. In addition, a different solid support (celite) was evaluated to substitute the traditional and costly, C18.

Optimization of AFLA Extraction Conditions

Table 2 presents the AFLA recoveries (%) in the CCD for the three variables under study (solvent volume, solid support amount, C18/celite ratio). In this design, the AFLA recoveries were in the range 43.0–113.3% (G2), 36.4–107.6% (G1), 51.7–122.8% (B2), and 38.3–100.0% (B1). For the four AFLAs, trials 1, 2, 5, and 6 demonstrated the best results, all of which showed less solid support amount, at level − 1 (0.1 g), solvent volume at level − 1 (10 mL) or + 1 (30 mL), and C18/celite proportion at level − 1 (0:1) or + 1 (1:0), than the other trials.

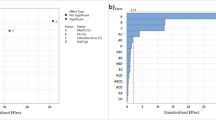

The main effect can be estimated by evaluating the difference in process performance caused by a change from low (− 1) to high (+ 1) levels (Haaland 1989), which provides a model that fulfills the recovery of the four AFLAs. Therefore, the main effect was assessed using the average of the recoveries of the four AFLAs, and the p value was used to verify the significance of the factors under study. The solid support amount was identified as the most relevant variable for the AFLA recoveries. Increasing the solid support amount from 0.1 to 1 g decreased the AFLA recoveries by an average of 34.1%. An alteration in the ratio of C18/celite, from 0:1 to 1:0, led to an average increase of 28.8% in the AFLA recoveries. The combined effect of solid support amount and their proportion (C18/celite) resulted in an average increase of 23.5% in the AFLA recoveries. The solvent volume, as well as their combinations with other variables, did not present any significant effect. Variance analysis (ANOVA) was performed, using the significant effects only (Table 7).

Based on the F-test, the model proved predictive, since its Fcalculated (12.84) was greater than Ftabulated (4.34), and significant, given the regression coefficient (0.85) was close to unity. The coded model was used to generate the contour diagram (Fig. 2).

To determine the optimal values for the significant variables (X2, X3, and their interaction), the first derivative of Eq. 2 was obtained, and the optimal values of 25 mg of the solid support (X2) and 1:0 the ratio of C18/celite (X3) were obtained. Under these conditions and setting a solvent volume of 10 mL, the model validation was performed, resulting in a 103.3% experimental result and a predictive of 125.5%, with a deviation of 21.5% from the experimental to the predictive value. These validated conditions were used for analytical method validation and applicability of the method in different cornmeals.

Method Validation

The method LOD and LOQ were 0.01–0.04 and 0.02–0.1 ng g−1, respectively (Table 8). These values were lower than those verified by Quinto et al. (2009), of LOD 0.035–0.2 ng g−1 and LOQ 0.1–0.63 ng g−1 for solid-phase microextraction and quantification of AFLAs in cereal flours by HPLC-FD with post-column photochemical derivatization. Similarly, they were also lower than those documented by Rubert et al. (2011), of LOD 0.1–1 ng g−1 and LOQ 0.25–1.5 ng g−1 for MSPD extraction and quantification of AFLAs in cereal flours by HPLC-mass spectrometry (MS). In another study, Rubert et al. (2010) optimized the extraction conditions of cereals, resulting in 0.3–0.4 ng g−1 for the LOD and the LOQ in the range of 1 ng g−1.

Paschoal et al. (2017) optimized and applied a solid–liquid extraction of AFLAs from cornmeal using MeOH/H2O/MeCN (60:20:20, v/v/v) prior to HPLC-MS quantification, and the LOD ranged from 0.24 to 0.32 ng g−1 and the LOQ from 0.80 to 1.05 ng g−1. According to Pereira et al. (2014), it is possible to obtain a LOD for HPLC-FD comparable to or better than those achieved by HPLC-tandem MS. Therefore, as the proposed method showed low values of LOD and LOQ, this is an advantage when it is desired to determine trace compounds, such as mycotoxins.

The recoveries at the three levels for the four AFLAs ranged from 85.7 to 114.8% (Table 8), which are within the criteria approved by the European Regulatory Committee. For the acceptance of analytical methods for the AFLAs, it was established that for concentrations of less than 1 μg kg−1, the recoveries should range between 50 and 120%, and for concentrations between 1 and 10 μg kg−1, the recoveries should vary between 70 and 110% (European Commission 2006).

Rubert et al. (2010) reported recoveries ranging from 64 to 91% with the relative standard deviation (RSD) < 19% for MSPD extraction and HPLC-MS quantification of AFLAs in various cereals. In 2011, the same authors extracted 19 mycotoxins from cereal flours by MSPD and acquired AFLA recoveries between 68.8 and 80.3% (RSD < 12%). The elution step used in our work was by vortex, whereas the other authors packed the mixture (sample and solid support after maceration) in cartridges and then eluted with solvent. In the vortex-assisted MSPD method proposed in this work, after dispersing the sample with the solid support, the mixture is placed in tubes, and the elution solvent is added, followed by vortexing. This elution form has the advantage of reducing the packing time and the variations resulting from this process.

Repeatability represents the agreement between the results of successive measurements of the same method, conducted under the same measurement conditions, called repeatability conditions: same procedure, same analyst, the same instrument used under the same conditions, same location, and repetitions in a short interval of time. The RSDs were < 20% and thus conformed to the accepted limits for the concentrations used in the repeatability test (European Commission 2006).

The ME was studied to verify if the matrix interferes with the signal of the contaminant at interest. For AFLAs G2 and G1, the ME was close to 20% (18.2 and 20.1%, respectively) and for B2 and B1, this value was about 11% (11.1 and 11.8%, respectively). According to SANTE/11945/2015 (SANTE 2016), results that show a 20% ME are considered acceptable for analyses of contaminants in foods at trace level. Therefore, due to the low ME values for the four AFLAs, the quantification of the levels of the AFLAs in the samples can be undertaken, using the curve in the solvent. Moreover, this acceptable effect also avoided the false positive results.

The chromatograms in Fig. 1 represent the instrument LOD (Fig. 1a), the blank sample (medium cornmeal; Fig. 1b), and the cornmeal matrix fortified with G2, G1, B2, and B1, at 3.75, 3.0, 1.5, and 4.5 ng mL−1, respectively (Fig. 1d). It can be observed that the interferers are present at the start of the chromatogram and, after 5 min, only the AFLAs at the same retention times as the standards are seen (Fig. 1c), which shows that the extraction and detection method is reliable to predict the contamination levels of these mycotoxins in cornmeal.

Applicability of the Method

Various cornmeals were used to evaluate the applicability of the proposed method. The extraction method was adequate for coarse cornmeals, both commercial and dry-milling, with recoveries from 60.6 to 93.7% (Table 9). However, for the fine cornmeals, commercial, and dry- and wet-milling, the recoveries (40.0 to 88.5%) were below the criteria approved by the European Regulatory Committee (Commission E 2006). Thus, although all matrices were cornmeals, the AFLA recoveries varied from 40.0 to 98.4% (Table 9). Given the fine cornmeals presented the lowest recoveries, the composition and recovery data of these cornmeals were used for multivariate correlation, to verify which components of the matrix interfere in the recovery so that the extraction method can be modified accordingly.

Correlation Between Matrix Components and AFLA Recovery in Fine Cornmeal

According to Kupski and Badiale-Furlong (2015), it is fundamental to study the major components of matrices that may positively or negatively affect the mycotoxin extraction, so changes in the method may be made according to the presence or absence of the target component. To evaluate these interferences, the multivariate statistical technique was used to determine the correlation between the components of the fine cornmeal matrix and the G2, G1, B2, and B1 AFLA recoveries (Table 10). For this, the results presented in Table 9 were used.

Proteins demonstrated a significant interference in the recovery of AFLA G2, with a correlation of − 0.99 while sugars were the significant interferers (r = − 0.99) in G1 recovery (Table 10). For the recovery of AFLAs B1 and B2, these compounds did not significantly affect the determination, an important fact considering the frequency of these two AFLAs in food matrices.

In performing the extraction for the multivariate analysis of the AFLA recovery from the fine cornmeal, anhydrous sodium sulfate (0.25 g) was added as the solid support, and the C18 amount was increased to 0.1 g, to minimize the effect of significant interferences, like sugars and protein. With these modifications, recoveries of 75.9, 97.7, 59.4, and 59.5% were obtained for G2, G1, B2, and B1, respectively. AFLA G2 recovery increased from 41.5 to 75.9%. As observed in Table 9, the proteins obtained a correlation of − 0.99 with the G2 recovery. Among the proteins present in maize, zein is highlighted, which has a hydrophobic molecular structure (Shukla and Cheryan 2001). Thus, this increase of 34.4% in the recovery of G2 can be attributed to the increase in C18 (from 25 to 100 mg), since this limits the effect of apolar compounds (Anastassiades et al. 2003). AFLA G1 recovery increased from 51.2 to 97.7%. According to Prestes et al. (2009), anhydrous sodium sulfate improves extraction of polar compounds, which may have contributed to alleviating the effect of interfering sugars (correlation of − 0.99 with G1). This behavior was also evidenced by Kupski and Badiale-Furlong (2015) in the extraction of ochratoxin A from cereal by the QuEChERS method. For AFLAs B1 and B2, method modifications did not lead to significant increases in the recoveries, since none of the major components of the cornmeals had a significant impact on the recovery of these mycotoxins (Table 9).A comparison of MSPD with standard method (immunoaffinity column cleanup) for the determination of aflatoxins is presented in Table 11, and some differences between the methods are illustrated. It can be concluded that the standard method has lower LOD for AFLA G2 and B1 and lower LOQ only for AFLA G2, recoveries have no important differences, and the proposed method showed lower sample amount and solvent volume consumption.

Conclusion

A precise and accurate method for the extraction of AFLAs G2, G1, B2, and B1 was established using a low solvent volume and solid support amount. Acceptable recoveries (85.7 to 114.8%) were obtained under the following extraction conditions: 1 g sample, 25 mg C18, and 10 mL MeCN/MeOH (50:50, v/v). The optimized method was suitable for coarse and medium grind cornmeals. The multivariate correlation analysis identified were proteins (r = − 0.99) and sugars (r = − 0.99) as the main interferers in the determination of AFLA G2 and G1 in fine cornmeal.

References

Alborch L, Bragulat MR, Castellá G, Abarca ML, Cabañes FJ (2012) Mycobiota and mycotoxin contamination of maize flours and popcorn kernels for human consumption commercialized in Spain. Food Microbiol 32:97–103. https://doi.org/10.1016/j.fm.2012.04.014

Algül I, Kara D (2014) Determination and chemometric evaluation of total aflatoxin, aflatoxin B1, ochratoxin A and heavy metals content in corn flours from Turkey. Food Chem 157:70–76. https://doi.org/10.1016/j.foodchem.2014.02.004

Anastassiades M, Lehotay SJ, Štajnbaher D, Schenck FJ (2003) Fast and easy multiresidue method employing acetonitrile extraction/partitioning and “dispersive solid-phase extraction” for the determination of pesticide residues in produce. J AOAC Int 86:412–431

ANVISA (2011) RDC No 7, DE 18 DE FEVEREIRO DE 2011. Limites máximos tolerados (LMT) para micotoxinas em alimentos

ANVISA (2003) Guía para validação de métodos analíticos e bioanalíticos. Resolução RE n 899, 29 de maio de 2003 1–15

AOAC (2000) Official methods of analysis of AOAC international. Assoc Official Anal Chemists Int Method ce 9:2–66. https://doi.org/10.3109/15563657608988149

Baltaci C, Ilyasoǧlu H, Yüksel F (2013) Single-laboratory validation for the determination of aflatoxin B1, B2, G1, and G2in foods based on immunoaffinity column and liquid chromatography with postcolumn derivatization and fluorescence detection. Food Anal Methods 6:36–44. https://doi.org/10.1007/s12161-012-9417-3

Barker SA (2007) Matrix solid phase dispersion (MSPD). J Biochem Biophys Methods 70:151–162. https://doi.org/10.1016/j.jbbm.2006.06.005

Caldas SS, Rombaldi C, Barnes M et al (2013) Avanços recentes da MSPD para extração de resíduos de agrotóxicos, PPCPs, compostos inorgânicos e organometálicos. Scientia Chromatographica 5:190–213. https://doi.org/10.4322/sc.2014.004

Capriotti AL, Cavaliere C, Giansanti P, Gubbiotti R, Samperi R, Laganà A (2010) Recent developments in matrix solid-phase dispersion extraction. J Chromatogr A 1217:2521–2532. https://doi.org/10.1016/j.chroma.2010.01.030

Capriotti AL, Cavaliere C, Laganà A, Piovesana S, Samperi R (2013) Recent trends in matrix solid-phase dispersion. TrAC - Trends Analytical Chemistry 43:53–66. https://doi.org/10.1016/j.trac.2012.09.021

Commission E (2006) Commission regulation (EC) 401/2006 of 23 february 2006 laying down the methods of sampling and analysis for the official control of the levels of mycotoxins in foodstuffs. Off J Eur Union 2006:5–24

de Oliveira GB, de Castro Gomes Vieira CM, Orlando RM, Faria AF (2017) Simultaneous determination of fumonisins B1 and B2 in different types of maize by matrix solid phase dispersion and HPLC-MS/MS. Food Chemistry 233:11–19. https://doi.org/10.1016/j.foodchem.2017.04.091

DuBois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356. https://doi.org/10.1021/ac60111a017

EFSA (2007) Opinion of the Scientific Panel on Contaminants in the Food Chain on a request from the commission related to the potential increase of consumer health risk by a possible increase of the existing maximum levels for aflatoxins in almonds, hazelnuts and pis. EFSA J 446:1–127

European Commission (2006) Commission Regulation (EC) No 1881/2006 of 19 December 2006 setting maximum levels for certain contaminants in foodstuffs. Official J European Communitites L364:5–24. https://doi.org/10.2203/dose-response.06-012.Hanekamp

Haaland PD (1989) Experimental design in biotechnology. Marcel Dekker

Hu Y, Zheng P, Zhang Z, He Y (2006) Determination of aflatoxins in high-pigment content samples by matrix solid-phase dispersion and high-performance liquid chromatography. J Agric Food Chem 54:4126–4130

IARC (2012) Agents classified by the IARC monographs, Volumes 1–104. IARC Monographs 7:1–25. https://doi.org/10.1007/s13398-014-0173-7.2

Karami-Osboo R, Mirabolfathi M (2017) A novel dispersive nanomagnetic particle solid-phase extraction method to determine aflatoxins in nut and cereal samples. Food Anal Methods 10:4086–4093. https://doi.org/10.1007/s12161-017-0975-2

Kristenson EM, Ramos L, Brinkman U a T (2006) Recent advances in matrix solid-phase dispersion. TrAC - Trends Analytical Chemistry 25:96–111. https://doi.org/10.1016/j.trac.2005.05.011

Kupski L, Badiale-Furlong E (2015) Principal components analysis: an innovative approach to establish interferences in ochratoxin A detection. Food Chem 177:354–360. https://doi.org/10.1016/j.foodchem.2015.01.005

Malumba P, Boudry C, Roiseux O, Bindelle J, Beckers Y, Béra F (2015) Chemical characterisation and in vitro assessment of the nutritive value of co-products yield from the corn wet-milling process. Food Chem 166:143–149. https://doi.org/10.1016/j.foodchem.2014.06.001

Manoochehri M, Asgharinezhad AA, Safaei M (2015) Determination of aflatoxins in rice samples by ultrasound-assisted matrix solid-phase dispersion. J Chromatogr Sci 53:189–195. https://doi.org/10.1093/chromsci/bmu018

Mutiga SK, Hoffmann V, Harvey J et al (2015) Assessment of aflatoxin and fumonisin contamination of maize in western Kenya. Phytopathology 105:1250–1261. https://doi.org/10.1094/PHYTO-10-14-0269-R

Oliveira MS, Rocha A, Sulyok M, Krska R, Mallmann CA (2017) Natural mycotoxin contamination of maize (Zea mays L.) in the South region of Brazil. Food Control 73:127–132. https://doi.org/10.1016/j.foodcont.2016.07.033

Paschoal FN, de Azevedo Silva D, von Sperling de Souza R et al (2017) A rapid single-extraction method for the simultaneous determination of aflatoxins B1, B2, G1, G2, fumonisin B1, and zearalenone in corn meal by ultra performance liquid chromatography tandem mass spectrometry. Food Analytical Methods 10:1631–1644. https://doi.org/10.1007/s12161-016-0712-2

Pereira VL, Fernandes JO, Cunha SC (2014) Mycotoxins in cereals and related foodstuffs: a review on occurrence and recent methods of analysis. Trends Food Sci Technol 36:96–136. https://doi.org/10.1016/j.tifs.2014.01.005

Prestes OD, Friggi CA, Adaime MB, Zanella R (2009) QuEChERS – UM MÉTODO MODERNO DE PREPARO DE AMOSTRA PARA DETERMINAÇÃO MULTIRRESÍDUO DE PESTICIDAS EM ALIMENTOS POR MÉTODOS CROMATOGRÁFICOS ACOPLADOS À ESPECTROMETRIA DE MASSAS. Química Nova 32:1620–1634

Quinto M, Spadaccino G, Palermo C, Centonze D (2009) Determination of aflatoxins in cereal flours by solid-phase microextraction coupled with liquid chromatography and post-column photochemical derivatization-fluorescence detection. J Chromatogr A 1216:8636–8641. https://doi.org/10.1016/j.chroma.2009.10.031

Rubert J, Soler C, Mañes J (2011) Evaluation of matrix solid-phase dispersion (MSPD) extraction for multi-mycotoxin determination in different flours using LC-MS/MS. Talanta 85:206–215. https://doi.org/10.1016/j.talanta.2011.03.046

Rubert J, Soler C, Mañes J (2012) Application of an HPLC-MS/MS method for mycotoxin analysis in commercial baby foods. Food Chem 133:176–183. https://doi.org/10.1016/j.foodchem.2011.12.035

Rubert J, Soler C, Mañes J (2010) Optimization of matrix solid-phase dispersion method for simultaneous extraction of aflatoxins and OTA in cereals and its application to commercial samples. Talanta 82:567–574. https://doi.org/10.1016/j.talanta.2010.05.008

SANTE (2016) Analytical quality control and method validation procedures for pesticide residues analysis

Serrano AB, Font G, Ruiz MJ, Ferrer E (2012) Co-occurrence and risk assessment of mycotoxins in food and diet from Mediterranean area. Food Chem 135:423–429. https://doi.org/10.1016/j.foodchem.2012.03.064

Shukla R, Cheryan M (2001) Zein: the industrial protein from corn. Industruial Crops Products an Int J 13:171–192

Soleimany F, Jinap S, Rahmani A, Khatib A (2011) Simultaneous detection of 12 mycotoxins in cereals using RP-HPLC-PDA-FLD with PHRED and a post-column derivatization system. Food Additives Contaminants - Part A Chemistry, Analysis, Control, Exposure Risk Assessment 28:494–501. https://doi.org/10.1080/19440049.2010.551547

Somavat P, Li Q, de Mejia EG, Liu W, Singh V (2016) Coproduct yield comparisons of purple, blue and yellow dent corn for various milling processes. Ind Crop Prod 87:266–272. https://doi.org/10.1016/j.indcrop.2016.04.062

Telles AC, Kupski L, Furlong EB (2017) Phenolic compound in beans as protection against mycotoxins. Food Chem 214:293–299. https://doi.org/10.1016/j.foodchem.2016.07.079

Wang Y, Dong Y, Li Z, Deng LG, Guo CY, Zhang SQ, Li DP, Zhao SC (2016) Fast determination of multi-mycotoxins in corn by dispersive solid-phase extraction coupled with ultra-performance liquid chromatography with tandem quadrupole time-of-flight mass spectrometry. J Integr Agric 15:1656–1666. https://doi.org/10.1016/S2095-3119(15)61287-4

Zachariasova M, Lacina O, Malachova A, Kostelanska M, Poustka J, Godula M, Hajslova J (2010) Novel approaches in analysis of Fusarium mycotoxins in cereals employing ultra performance liquid chromatography coupled with high resolution mass spectrometry. Anal Chim Acta 662:51–61. https://doi.org/10.1016/j.aca.2009.12.034

Acknowledgments

The authors acknowledge the support of Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES, Brazil), Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq, Brazil), and Fundação de Amparo à Pesquisa do Estado do Rio Grande do Sul (FAPERGS, Brazil).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Kelly Cristina Massarolo declares that she has no conflict of interest. Cláudia Fetter Jorge Ferreira declares that she has no conflict of interest. Larine Kupski declares that she has no conflict of interest. Eliana Badiale-Furlong declares that she has no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed Consent

Not applicable.

Rights and permissions

About this article

Cite this article

Massarolo, K.C., Ferreira, C.F.J., Kupski, L. et al. Optimization of Matrix Solid-Phase Dispersion Method for Extraction of Aflatoxins from Cornmeal. Food Anal. Methods 11, 3342–3351 (2018). https://doi.org/10.1007/s12161-018-1311-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-018-1311-1