Abstract

A solid-phase extraction (SPE) combined with high-performance liquid chromatography–tandem mass spectrometry (HPLC-MS/MS) method was developed to determine five phenols in grease-rich food (i.e., hotpot seasoning). Sample added with isotope internal standards bisphenol A-d 4 (BPA-d 4) and 4-n-nonylphenol-d 4 (4-n-NP-d 4) was dispersedly dissolved in n-hexane. After centrifugation, the supernatant was purified by Carb/PSA SPE. Then, target analytes were separated on a Waters XBridge C18 column, detected under multiple reaction monitoring (MRM) mode. The developed method was validated in terms of linearity, limit of quantitation (LOQ), recovery, and precision. Results found that linear relations were favorable in the selected concentration range of 0.5–100 μg/L for all phenols, with R 2 greater than 0.995. LOQs were between 1.0 and 2.0 μg/kg. The mean recoveries for negative sample at three spiked concentration levels were in the range of 83.5–97.1%, and the intra-day and inter-day precision were calculated between 4.7 and 12.5%. This method is accurate and sensitive and has good purifying effect, which can be applied for screening and quantitation of target phenols in grease-rich food.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Bisphenol A (BPA) and alkylphenols (APs; especially nonylphenol (NP) and octylphenol (OP)) issues in foods are of increasing concern because of their endocrine-disrupting properties to human beings (Niu et al. 2011; Yang et al. 2014). It has been reported that BPA is widely used in the production of polycarbonate plastics and epoxy resins and the manufacture of polyester resin intermediates, flame retardants, and hydrogenated BPA (Matozzo et al. 2008). As for NP and OP, they have been reported to be used in the production of detergents, herbicides, and synthetic resin products. In recent years, these phenols have been strictly restricted by many regulations and countries. The Commission Directive 2004/19/EC established the specific migration limit (SML) of 0.6 μg/g in foods or food simulants for BPA (Commission Directive 2004/19/EC, Off. J. Eur. Commun. L71 (2004) 8). In addition, the tolerable daily intake for BPA was established at 10 μg/kg body weight per day by the European Commission’s Scientific Committee on Food (SCF) (European Commission, Scientific Committee on Food, Opinion of the Scientific Committee on Food on Bisphenol-A, SFC/CS/PM/3936 Final, 2002).

Unfortunately, BPA, NP, OP, and some other phenols have been found and detected ubiquitously in air, water, and various kinds of food due to their widespread use in industrial production (Dong et al. 2017b; Liu et al. 2013; Loyo-Rosales et al. 2003; Maragou et al. 2006; Yang et al. 2014). The human exposure routes to phenols seem to be multiple due to the ubiquity of these compounds in various matrix (Geens et al. 2012). However, food or diet has been reported to be the major source of overall exposure to phenols for the general population by far mainly because that these compounds could pass into food via environmental pollution and migration by contact with plastics, resin lacquers, paints from pipes, and surfactants during the processing and storage of food (Liu et al. 2013). Hence, robust and reliable methods for the determination of phenols in food are highly demanded.

Determination of phenols focused on food matrix mainly includes dairy products (Maragou et al. 2006), canned foods (Dong et al. 2017a; Dong et al. 2016; Errico et al. 2014; Noonan et al. 2011), oils (Niu et al. 2011), water (Haeri 2016), meat products (Deceuninck et al. 2014), vegetables (Wu et al. 2014), soft drinks (Regueiro and Wenzl 2015a), and ready-made foods (Luo et al. 2015; Regueiro and Wenzl 2015b; Wu et al. 2015).

The determination methods of phenols in food matrix mainly include GC-MS (Cacho et al. 2012) and HPLC with UV detection, fluorescence, or diode array detection (Alabi et al. 2014; Gallo et al. 2017; Haeri 2016). The extraction methods of target analytes from complex food matrix consisted of solid-liquid extraction (SLE), dispersive liquid-liquid microextraction (Cunha and Fernandes 2013; Haeri 2016), ultrasound-assisted extraction (Sánchez-Brunete et al. 2009), stir bar sorptive extraction (Cacho et al. 2012), and pressurized liquid extraction (Ferrer et al. 2011). However, UV and fluorescence detection have several disadvantages such as high degree of uncertainty in the identification of the target compound and tedious pretreatment due to their limited selectivity and sensitivity to complex matrices (Maragou et al. 2006). GC-MS allows identification with a high degree of confidence, but a time-consuming step of derivatization is required (Maragou et al. 2006).

MS/MS has been reported to have high selectivity, specificity, sensitivity, as well as anti-jamming capability in coupling with GC or LC (Dong et al. 2015; Xian et al. 2016). Therefore, LC-MS/MS can overcome limitations mentioned above and has been increasingly used in the determination of phenols (Ferrer et al. 2011; Regueiro and Wenzl 2015b; Salgueiro-González et al. 2012a). Moreover, to date, few methods have been developed for the analysis of phenols in grease-rich food such as hotpot seasoning which is a very complex and highly oil-containing matrix.

Therefore, the aim of the present work is to develop a fast, selective, and sensitive HPLC-MS/MS method for the analysis of five phenols including BPA, BPF, 4-NP, 4-n-NP, and OP in hotpot seasoning. The solid-phase extraction (SPE) with Carb/PSA as composite fillers was applied to remove impurities for favorable purification and for reducing the matrix interference. Moreover, the isotope internal standard method was adopted for the calibration of quantitation for the target analytes. The developed method was validated in terms of sensitivity, linearity, LOQ, recovery, and precision and finally applied to analyze 30 hotpot seasoning samples.

Materials and Methods

Instrumentation

A MS3 basic vortex mixer (IKA GmbH, Germany) was applied for mixing or vortexing of sample, and a 5418 high-speed centrifuge (Eppendorf Corp., Germany) was used for centrifugation of sample solution. A Turbo LV enrichment workstation (Biotage Co., USA) was adopted for drying of the sample solution. The separation and quantitation of the target analytes were performed on a 1200 HPLC system (Agilent Co., USA) coupled with a 4000 Qtrap triple quadrupole mass spectrometer (AB SCIEX Co., USA). Deionized water (18.2 MΩ cm) was made by a Milli-Q Gradient A10 deionized water generator (Millipore Corp., Bedford, USA) and used in all experiments.

Reagents, Materials, and Standards

HPLC grade of acetonitrile, methanol, acetone, n-hexane, and methylene chloride were purchased from Merck (Darmstadt, Germany). Ammonia water (28%) was of analytically pure and obtained from Guangzhou Chemical Reagent Factory (Guangzhou, China). Carb/PSA solid-phase extraction cartridge (500 mg, 6 mL), ENVI-Carb solid-phase extraction cartridge (500 mg, 6 mL), and Carb/NH2 solid-phase extraction cartridge (500 mg, 6 mL) were used for extraction and purification in sample pretreatment and were purchased from Supelco (Bellefonte, PA). NH2 solid-phase extraction cartridge (500 mg, 6 mL) was purchased from Waters (Beverly, MA). Polytetrafluoroethene (PTFE) syringe filter (0.22 μm) was purchased from Waters Corp. (Beverly, MA, USA).

Standards of bisphenol A (BPA, purity ≥ 98%), bisphenol F (BPF, purity ≥ 98%), 4-nonylphenol (4-NP, purity ≥ 98%), 4-n-nonylphenol (4-n-NP, purity ≥ 98%), and octylphenol (OP, purity ≥ 98%) were all purchased from Dr. Ehrenstorfer GmbH (Augsburg, Germany). Internal standard of bisphenol A-3,3′,5,5′-d 4 (BPA-d 4, purity ≥ 99%) was purchased from CDN Isotopes (Quebec, Canada). Internal standard of 4-n-nonylphenol-d 4 (4-n-NP-d 4, purity ≥ 96%) was purchased from Dr. Ehrenstorfer GmbH (Augsburg, Germany).

Five standards were accurately weighed and dissolved in methanol respectively to obtain the individual standard stock solutions. Then, mixed standard stock solution of 10 mg/L was prepared with methanol and stored at 4 °C. Two internal standards were also dissolved in methanol respectively to obtain individual standard stock solutions, and mixed internal standard working solution of 1 mg/L was prepared with methanol and stored at 4 °C. Required concentrations of mixed standard working solution contained with 20 μg/L of BPA-d 4 and 20 μg/L of 4-n-NP-d 4 were prepared before use by diluting with methanol.

Sample Preparation

Hotpot seasoning sample (1.00 g) was accurately weighed in a 10-mL glass centrifuge tube. Then, 20 μL of mixed internal standard working solution and 5 mL of n-hexane were orderly added into the tube and mixed evenly by continuous vortexing for 2 min. The sample solution was subsequently centrifuged at 3500 rpm for 5 min, and the supernatant was transferred to the Carb/PSA solid-phase extraction cartridge which was activated previously by 10 mL of methanol-methylene chloride (3/7, v/v) and 6 mL of n-hexane. After the sample solution flows out, 6 mL of n-hexane and 6 mL of methanol-acetone (1/1, v/v) were used for leaching, and finally, 6 mL of methanol-methylene chloride (1/3, v/v) was adopted for elution. After that, the eluant was dried by nitrogen in a 50 °C water bath and subsequently dissolved with 1.0 mL of methanol. The redissolved solution was passed through a 0.22-μm PTFE syringe filter before HPLC-MS/MS analysis.

HPLC-MS/MS Conditions

A Waters XBridge C18 chromatographic column (150 mm × 4.6 mm, 5 μm) was applied for the separation of target analytes. The column was used in the condition of 35 °C at a constant flow rate of 0.5 mL/min. The mobile phase consisted of water with 0.05% ammonium hydroxide (A) and methanol (B). The gradient elution was programmed as follows: 0–3.0 min, 35–95% B; 3.0–9.0 min, 95% B; 9. 0–9.1 min, 95–35% B; 9.1–15.0 min, 35% B. The injection volume was 20 μL.

The MS/MS detection was performed with an electrospray ionization (ESI) source in negative mode. Other MS/MS conditions were described as follows: electrospray voltage, − 4500 V; ion source temperature, 500 °C; nebulizer gas (GS1), 50 psi; heater gas (GS2), 60 psi; and curtain gas, 20 psi. Data acquisition was carried out in multiple reaction monitoring (MRM) mode. The declustering potential, collision energy, and monitoring ion pair (m/z) for five phenols and two isotope internal standards were optimized and presented in Table 1. The dwell time for each ion pair was 0.05 s.

Statistical Analysis

All the data were expressed as means ± standard deviations (SDs) of triplicate. The statistical analysis was performed with the SPSS (SPSS Inc., Chicago, IL, USA).

Results and Discussion

Optimization of HPLC-MS/MS Conditions

Five phenols and two internal standard substances all contain phenolic hydroxyl groups in their molecular structures (Ferrer et al. 2011). In order to optimize the MS/MS parameters, 500 μg/L of individual standard solution for each target analyte and internal standard was directly injected into the ion source under the ESI− mode by using the injection pump, with the flow rate of 5 μL/min. Considerable signals of the [M-H]− molecular ion peaks for these five compounds were obtained. Only one fragment ion with the maximum response was acquired for 4-n-NP because the structure of which is hard to break. As for BPA, BPF, 4-NP, and OP, two secondary fragment ions of higher abundances were selected as the qualitative and quantitative ions. One fragment ion with the maximum response for each internal standard was adopted mainly for calibration. The declustering potential and collision energy were optimized in order to maximize the intensity of the characteristic ions and to obtain the best sensitivity and stability for the instrument. The optimal MS/MS parameters of the all target compounds are listed in Table 1.

In previous literatures, 0.1 or 0.05% ammonium hydroxide in water was commonly used to enhance the ionization efficiency of bisphenols and alkylphenols (Niu et al. 2011; Salgueiro-González et al. 2012b). The separation effect and response of different mobile phase including acetonitrile-0.05% ammonium water and methanol-0.05% ammonium water were compared. Results indicated that higher responses for all target analytes were obtained by using the gradient elution program of methanol-0.05% ammonium water, and the responses for three alkylphenols were even increased by 10 to 20 times. Therefore, methanol-0.05% ammonium water was selected as the mobile phase and the optimized gradient elution program was described in “HPLC-MS/MS Conditions” section.

The pH was about 9 when 0.05% ammonium water was used as the aqueous mobile phase; hence, a Waters XBridge C18 column of high stability, with applicable pH values in the range of 1–12, was adopted. Under the optimized HPLC-MS/MS conditions, the peak shapes of the target analytes separated by the Waters XBridge C18 column were much more symmetrical and had better separation than those separated by some other columns, which is better for the detection of trace levels of phenols. The extracted quantitative ion chromatograms of five target phenols and two internal standards for matrix standard solution (20 μg/L) prepared with a negative hotpot seasoning sample are presented in Fig. 1.

Optimization of Pretreatment Conditions

Hotpot seasoning is a kind of highly oil-containing matrix which also contains components such as pigments and spices. Unfortunately, five target phenols have high lipid solubility and low concentrations, making the extraction and cleanup the key processes to the pretreatment. Two extraction ways including the salting out-acetonitrile extraction and water-n-hexane extraction were performed in our early experiment. Results indicated that recoveries were only about 10% for alkylphenols in the salting out-acetonitrile extraction and severe emulsification was found in the water-n-hexane extraction. In a previous study, an isotopic dilution liquid chromatography-tandem mass spectrometry method based on the gel permeation chromatography (GPC) cleanup was established to simultaneously determine bisphenol A and alkylphenols in plant oil (Niu et al. 2011). However, GPC cleanup is time-consuming, solvent-consuming, and of high-cost, which limits its applications. The performance of three commercial SPE sorbents (C18, PS-DVB and hydroxylated PS-DVB) was evaluated for the purification of BPA, and the C18 cartridge was eventually selected as the sample preparation procedure for the determination of BPA in milk prior to liquid chromatography-mass spectrometry (Maragou et al. 2006). In another literature, seven bisphenols were firstly extracted from environmental water samples using hydrophilic lipophilic balanced (HLB) SPE cartridges, further purified using MAX SPE cartridges, and finally determined by liquid chromatography-electrospray ionization tandem mass spectrometry (LC-ESI-MS/MS) (Li et al. 2017; Yang et al. 2014). According to the previous literatures and based on the matrix nature of hotpot seasoning sample and the properties of target analytes, the pretreatment of organic solvent-direct-extraction combined with SPE purification was selected in the present work.

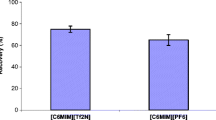

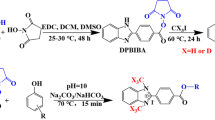

A commonly used nonpolar solvent, n-hexane, was selected to dissolve the hotpot seasoning sample and the sample solution without solid components was obtained through high-speed centrifugation. The adsorption and purification effects of four SPE cartridges which all based on normal-phase extraction mechanism, including NH2, ENVI-Carb, Carb/NH2, and Carb/PSA SPE cartridges, were compared. In our work, negative sample solution extracted by n-hexane was spiked with mixed standard solutions (20 μg/L) and pretreated by the above four SPE cartridges. The absolute recoveries were calculated by comparing with the pure solvent mixed standard solution of same concentration. It could be observed from Fig. 2 that the recoveries pretreated with Carb/PSA SPE cartridge were in the range of 88.2–93.3% for five phenols and better than those pretreated by the other three SPE cartridges. Carb/PSA SPE cartridge fills with same amount of Carb and PSA; among these fillers, Carb can effectively adsorb impurities such as sterol compounds due to its larger specific surface area, while PSA can absorb impurities such as fatty acids, organic acids, and polar pigments (Xian et al. 2016). In addition, PSA can connect with –OH to form hydrogen bond through dipole-dipole interaction and absorb and retain the target analytes, thus impurities leaching and target elution could be accomplished by using solvents of different polarity. Hence, Carb/PSA SPE cartridge was selected in the purification for the target analytes.

Optimization of Leacheate and Eluent for Carb/PSA SPE

In the purification procedure with Carb/PSA SPE, 6 mL of n-hexane (nonpolar solvent) was firstly used to wash some nonpolar impurities (the eluate was determined and no target analytes were detected); then, the polarity of leacheate was increased to remove some polar impurities. The volume of leacheate methanol-acetone (1/1, v/v) was optimized, and it could be observed from the elution curve that when the leacheate was 7 mL, approximately 15% of three alkylphenols were leached out (data not shown). Therefore, the volume of leacheate methanol-acetone (1/1, v/v) was chosen as 6 mL.

The volume of eluent methanol-methylene chloride was also optimized. It could be observed from Fig. 3 that when the volume of eluent was 3 mL, the recoveries for three alkylphenols reached the best. There was no significant change with the eluent volume increased from 3 to 9 mL. Moreover, there was no significant change of the recoveries for BPA and BPF with the eluent volume increased from 6 to 9 mL after their maximum in 6 mL. This is probably because PSA can show the weak anion adsorption exchange even if in nonaqueous medium, thus can retain negatively charged bisphenols of high acidity. Therefore, 6 mL of methanol-methylene chloride (1/3, v/v) was selected in the elution for the Carb/PSA SPE.

Method Validation

Method Electivity

Although LC-MS/MS has good specificity, the characteristic ion pairs of the target analytes can still be interfered by some impurities for complex matrix (Xian et al. 2016). In the present work, 20 negative samples were pretreated and determined according to the pretreatment method and instrumental conditions developed above. In the meantime, sample solutions added with standard analytes were also determined and analyzed by the established method. The interference of impurities in samples to the determination of target analytes was investigated. Results found that the impurities in the sample had no interference on the qualitative and quantitative ion pairs of five target phenols, indicating that the developed method based on the triple quadrupole MS had high specificity and selectivity.

Matrix Effect

It has been accepted that matrix effect (ME) such as matrix suppression or matrix enhancement of the analyte signal is a common phenomenon in ESI analysis (Dong et al. 2015; Lin et al. 2016). The post-cleanup hotpot seasoning sample may still contained significant interference such as fatty acids and proteins which may enhance or decrease the detection signal by increasing or limiting the transfer of the target analytes into the detector (Zhang et al. 2016). Therefore, ME should be properly evaluated and considered during method validation. In the present work, a series of matrix calibration solutions were prepared by using matrix solution of negative sample which was obtained according to the pretreatment mentioned above, and same concentrations of pure solvent standard solutions were prepared with methanol. These standard solutions were all determined on the basis of instrumental conditions of the developed method. The matrix calibration curve and the pure solvent standard curve were obtained by plotting the peak area of quantitative ion pair for each analyte versus the corresponding mass concentrations (μg/L) using five concentration levels in duplicate. ME was then calculated according to the slopes’ ratio of the matrix calibration curve and the pure solvent standard curve. Previous studies have reported that ME > 1 and ME < 1 represent matrix enhancement and matrix suppression, respectively (Dong et al. 2015; Xian et al. 2016; Zeng et al. 2016). In some previous literatures, MEs were evaluated in the MS/MS analysis when complex matrix such as cosmetics and dairy products were analyzed (Dong et al. 2015; Luo et al. 2016a; Luo et al. 2016b; Xian et al. 2016). The calculated MEs were in the range of 0.94–1.23 and 0.93–1.09, respectively, and could be ignored (Dang et al. 2017; Wu et al. 2016a, 2016b). The calculated MEs in our work are presented in Table 2 and found to be in the range of 0.82–1.13, which can also be ignored in the quantitation considering the complex nature of the analyzed sample.

Linear Range and LOD

A series of mixed standard solutions including 0.5, 1.0, 2.0, 10.0, 50.0, and 100.0 μg/L which all contain 20 μg/L of BPA-d 4 and 20 μg/L of 4-n-NP-d 4 were prepared with methanol. Under the optimal pretreatment and HPLC-MS/MS conditions, each concentration level was analyzed at least in triplicate. The linear regression analysis for BPA and 4-n-NP was conducted by internal standard method which was performed by plotting the ratio (y) of quantitative ion peak area (A 2) for each target analyte to the corresponding internal standard quantitative ion peak area (A 1) versus the corresponding mass concentration (x, μg/L). As for the rest targets including BPB, BPF, 4-NP, and OP, the external standard method was adopted and the linear regression analysis was performed by plotting the quantitative ion peak area (A, y) of each target analyte versus the corresponding mass concentration (x, μg/L). The linear range, regression equation, and the correlation coefficient for six targets are summarized in Table 2. Obviously, all of the correlation coefficients were greater than 0.995, indicating the excellent linearity relationship between the quantitative ion peak areas and the corresponding concentrations for the range studied.

The sensitivity of the method was evaluated by determining the limit of detection and limit of quantitation (LOD and LOQ). In the present work, the instrument LOD and the instrument LOQ which refer to the triple signal-to-noise ratio (S/N = 3) and tenfold signal-to-noise ratio (S/N = 10) were calculated by using the quantitation ion pair (MRM 1) based on the minimum concentrations in the linearity range for each target phenol. The LOD and method limit of quantitation (MLOQ) were calculated combined with the pretreatment process and dilution ratio of the sample and are presented in Table 2. The LODs of the developed method for target analytes were in the range of 0.3–0.6 μg/kg, and the MLOQs of bisphenols and alkylphenols were 1.0 and 2.0 μg/kg, respectively, demonstrating the high sensitivity of the developed method. In addition, the stabilities of the standard stock solutions were determined monthly and compared with freshly prepared working solutions. Results indicated that the stock solutions stored at 4 °C were stable for at least 1 month.

Accuracy and Precision

The accuracy and precision of the developed method were determined by spiking the mixed standard solutions into the negative hotpot seasoning sample. Three different concentration levels including 1 × MLOQ, 2 × MLOQ, and 10 × MLOQ spiked in negative sample were used to test the recoveries and intra-day precision according to the proposed method, with six identical samples tested at each concentration (n = 6). In addition, the inter-day precision was also investigated on five consecutive days in triplicate over a period of 60 days by analyzing five spiked replicates (n = 5) at the 2 × MLOQ level. The accuracy and precision results for six target phenols are presented in Table 3. It could be observed that the recoveries of the five target phenols were in the range of 83.5–97.1%, which fell into the acceptable range of 70–120% suggested by the Codex Alimentarius requirement. The intra-day precision (n = 6) and the inter-day precision (n = 5) were in the range of 4.7–10.5 and 6.9–12.5%, respectively, indicating the good reproducibility of the method and favorable accuracy and precision.

Analysis of Real Samples with the Developed and Validated Method

The concentrations of phenols in food have to be strictly controlled due to the health concerns for consumers. To verify the applicability of the developed and validated method, determination of the concentrations of the target phenols in 30 hotpot seasoning samples from various local supermarkets was performed. Unfortunately and surprisingly, 4-NP was detected in three samples with the concentrations from 4.32 to 167 μg/kg. The rest four phenols were not detected in all 30 samples.

Conclusions

Solid-phase extraction with composite packings was used to remove highly oil-containing impurities for favorable purification and for reducing the matrix interference. On the basis of this extraction and isotope dilution for calibration, an accurate and robust HPLC-MS/MS method was established for simultaneous analysis of two bisphenols and three alkylphenols in hotpot seasoning. The pretreatment and HPLC-MS/MS conditions were optimized, and the optimum analytical conditions were obtained. Methodology results indicated that the developed method has favorable specificity, recovery, accuracy, and intra-day and inter-day precision. This method was confirmed to be suitable for the accurate determination of phenols in hotpot seasoning, which is beneficial for monitoring the contaminations of phenols in hotpot seasoning and controlling the quality of hotpot seasoning products.

References

Alabi A, Caballero-Casero N, Rubio S (2014) Quick and simple sample treatment for multiresidue analysis of bisphenols, bisphenol diglycidyl ethers and their derivatives in canned food prior to liquid chromatography and fluorescence detection. J Chromatogr A 1336:23–33

Cacho JI, Campillo N, Viñas P, Hernández-Córdoba M (2012) Stir bar sorptive extraction coupled to gas chromatography–mass spectrometry for the determination of bisphenols in canned beverages and filling liquids of canned vegetables. J Chromatogr A 1247:146–153

Cunha SC, Fernandes JO (2013) Assessment of bisphenol A and bisphenol B in canned vegetables and fruits by gas chromatography–mass spectrometry after QuEChERS and dispersive liquid–liquid microextraction. Food Control 33(2):549–555

Dang H, Liu D, Hou X, Wu Y, Wang B, Dong H, Xian Y (2017) One-step extraction prior to two-step detection by ultra high performance liquid chromatography tandem mass spectrometry (UHPLC-MS/MS) to determine different groups of antibacterial agents in infant disposable hygiene products. Anal Methods 9(3):482–489

Deceuninck Y, Bichon E, Durand S, Bemrah N, Zendong Z, Morvan ML, Marchand P, Dervilly-Pinel G, Antignac JP, Leblanc JC, Le Bizec B (2014) Development and validation of a specific and sensitive gas chromatography tandem mass spectrometry method for the determination of bisphenol A residues in a large set of food items. J Chromatogr A 1362:241–249

Dong H, Guo X, Xian Y, Luo H, Wang B, Wu Y (2015) A salting out-acetonitrile homogeneous extraction coupled with gas chromatography–mass spectrometry method for the simultaneous determination of thirteen N-nitrosamines in skin care cosmetics. J Chromatogr A 1422:82–88

Dong H, Xiao K, Luo D (2017b) Stability of carbon and nitrogen isotopic compositions of the protein extracted from milk and their potential as “fingerprints” of geographical origin. RSC Adv 7(31):18946–18952

Dong H, Xiao K, Xian Y (2017a) Isotope ratio mass spectrometry coupled to element analyzer and liquid chromatography to identify commercial honeys of various botanical types. Food Anal Methods 10(8):2755–2763

Dong H, Xiao KJ, Luo DH, Xiang YP, Luo HY, Guo XD, Li C, Zhao MM (2016) Adulteration identification of commercial honey with the C-4 sugar content of negative values by an elemental analyzer and liquid chromatography coupled to isotope ratio mass spectroscopy. J Agric Food Chem 64(42):8071–8071

Errico S, Bianco M, Mita L, Migliaccio M, Rossi S, Nicolucci C, Menale C, Portaccio M, Gallo P, Mita DG, Diano N (2014) Migration of bisphenol A into canned tomatoes produced in Italy: dependence on temperature and storage conditions. Food Chem 160:157–164

Ferrer E, Santoni E, Vittori S, Font G, Mañes J, Sagratini G (2011) Simultaneous determination of bisphenol A, octylphenol, and nonylphenol by pressurised liquid extraction and liquid chromatography–tandem mass spectrometry in powdered milk and infant formulas. Food Chem 126(1):360–367

Gallo P, Di Marco Pisciottano I, Esposito F, Fasano E, Scognamiglio G, Mita GD, Cirillo T (2017) Determination of BPA, BPB, BPF, BADGE and BFDGE in canned energy drinks by molecularly imprinted polymer cleaning up and UPLC with fluorescence detection. Food Chem 220:406–412

Geens T, Aerts D, Berthot C, Bourguignon J-P, Goeyens L, Lecomte P, Maghuin-Rogister G, Pironnet A-M, Pussemier L, Scippo M-L, Van Loco J, Covaci A (2012) A review of dietary and non-dietary exposure to bisphenol-A. Food Chem Toxicol 50(10):3725–3740

Haeri SA (2016) Bio-sorption based dispersive liquid–liquid microextraction for the highly efficient enrichment of trace-level bisphenol A from water samples prior to its determination by HPLC. J Chromatogr B 1028:186–191

Li C, Li X, You L, Fu X, Liu RH (2017) Fractionation, preliminary structural characterization and bioactivities of polysaccharides from Sargassum pallidum. Carbohydr Polym 155:261–270

Lin S, Xian Y, Xun Z, Li S, Liu X, Du W, Huang J, Guo X, Dong H (2016) Solid-phase extraction coupled with ultra performance liquid chromatography tandem mass spectrometry to determine seven halogenated salicylanilides in cosmetics. RSC Adv 6(54):49011–49018

Liu S, Xie Q, Chen J, Sun J, He H, Zhang X (2013) Development and comparison of two dispersive liquid–liquid microextraction techniques coupled to high performance liquid chromatography for the rapid analysis of bisphenol A in edible oils. J Chromatogr A 1295:16–23

Loyo-Rosales JE, Schmitz-Afonso I, Rice CP, Torrents A (2003) Analysis of octyl- and nonylphenol and their ethoxylates in water and sediments by liquid chromatography/tandem mass spectrometry. Anal Chem 75(18):4811–4817

Luo D, Dong H, Luo H, Xian Y, Guo X, Wu Y (2016a) Multi-element (C, N, H, O) stable isotope ratio analysis for determining the geographical origin of pure milk from different regions. Food Anal Methods 9(2):437–442

Luo D, Dong H, Luo H, Xian Y, Wan J, Guo X, Wu Y (2015) The application of stable isotope ratio analysis to determine the geographical origin of wheat. Food Chem 174:197–201

Luo D, Luo H, Dong H, Xian Y, Guo X, Wu Y (2016b) Hydrogen (H-2/H-1) combined with carbon (C-13/C-12) isotope ratios analysis to determine the adulteration of commercial honey. Food Anal Methods 9(1):255–262

Maragou NC, Lampi EN, Thomaidis NS, Koupparis MA (2006) Determination of bisphenol A in milk by solid phase extraction and liquid chromatography–mass spectrometry. J Chromatogr A 1129(2):165–173

Matozzo V, Gagné F, Marin MG, Ricciardi F, Blaise C (2008) Vitellogenin as a biomarker of exposure to estrogenic compounds in aquatic invertebrates: a review. Environ Int 34(4):531–545

Niu Y, Zhang J, Wu Y, Shao B (2011) Simultaneous determination of bisphenol A and alkylphenol in plant oil by gel permeation chromatography and isotopic dilution liquid chromatography–tandem mass spectrometry. J Chromatogr A 1218(31):5248–5253

Noonan GO, Ackerman LK, Begley TH (2011) Concentration of bisphenol A in highly consumed canned foods on the U.S. market. J Agric Food Chem 59(13):7178–7185

Regueiro J, Wenzl T (2015a) Determination of bisphenols in beverages by mixed-mode solid-phase extraction and liquid chromatography coupled to tandem mass spectrometry. J Chromatogr A 1422:230–238

Regueiro J, Wenzl T (2015b) Development and validation of a stable-isotope dilution liquid chromatography–tandem mass spectrometry method for the determination of bisphenols in ready-made meals. J Chromatogr A 1414:110–121

Sánchez-Brunete C, Miguel E, Tadeo JL (2009) Determination of tetrabromobisphenol-A, tetrachlorobisphenol-A and bisphenol-A in soil by ultrasonic assisted extraction and gas chromatography–mass spectrometry. J Chromatogr A 1216(29):5497–5503

Salgueiro-González N, Concha-Graña E, Turnes-Carou I, Muniategui-Lorenzo S, López-Mahía P, Prada-Rodríguez D (2012a) Blank and sample handling troubleshooting in ultratrace analysis of alkylphenols and bisphenol A by liquid chromatography tandem mass spectrometry. Talanta 101:413–419

Salgueiro-González N, Concha-Graña E, Turnes-Carou I, Muniategui-Lorenzo S, López-Mahía P, Prada-Rodríguez D (2012b) Determination of alkylphenols and bisphenol A in seawater samples by dispersive liquid–liquid microextraction and liquid chromatography tandem mass spectrometry for compliance with environmental quality standards (Directive 2008/105/EC). J Chromatogr A 1223:1–8

Wu Y-T, Zhang Y-H, Zhang M, Liu F, Wan Y-C, Huang Z, Ye L, Zhou Q, Shi Y, Lu B (2014) Selective and simultaneous determination of trace bisphenol A and tebuconazole in vegetable and juice samples by membrane-based molecularly imprinted solid-phase extraction and HPLC. Food Chem 164:527–535

Wu Y, Luo D, Dong H, Wan J, Luo H, Xian Y, Guo X, Qin F, Han W, Wang L, Wang B (2015) Geographical origin of cereal grains based on element analyser-stable isotope ratio mass spectrometry (EA-SIRMS). Food Chem 174:553–557

Wu Z, Xu Y, Li M, Guo X, Xian Y, Dong H (2016a) Determination of three fluorescent whitening agents (FWAs) and their migration research in food contact plastic packaging containers and food simulants by UPLC-MS/MS method. RSC Adv 6(22):17941–17946

Wu Z, Xu Y, Li M, Guo X, Xian Y, Dong H (2016b) Simultaneous determination of fluorescent whitening agents (FWAs) and photoinitiators (PIs) in food packaging coated paper products by the UPLC-MS/MS method using ESI positive and negative switching modes. Anal Methods 8(5):1052–1059

Xian Y, Dong H, Wu Y, Guo X, Hou X, Wang B (2016) QuEChERS-based purification method coupled to ultrahigh performance liquid chromatography–tandem mass spectrometry (UPLC–MS/MS) to determine six quaternary ammonium compounds (QACs) in dairy products. Food Chem 212:96–103

Yang Y, Lu L, Zhang J, Yang Y, Wu Y, Shao B (2014) Simultaneous determination of seven bisphenols in environmental water and solid samples by liquid chromatography–electrospray tandem mass spectrometry. J Chromatogr A 1328:26–34

Zeng X, Bai W, Xian Y, Dong H, Luo D (2016) Application of QuEChERS-based purification coupled with isotope dilution gas chromatography-mass spectrometry method for the determination of N-nitrosamines in soy sauce. Anal Methods 8(26):5248–5254

Zhang C, Xian Y, Guo X, Liu H, Dong H, Xun Z, Huang J, Feng X (2016) Isotope internal standard method for determination of four acrylamide compounds in food contact paper products and food simulants by ultra-high performance liquid chromatography tandem mass spectrometry. Food Anal Methods 9(7):1895–1903

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Zhiming Hao declares that he has no conflict of interest. Yanping Xiao declares that she has no conflict of interest. Lanlan Jiang declares that she has no conflict of interest. Weidong Bai declares that he has no conflict of interest. Wenshan Huang declares that he has no conflict of interest. Lipeng Yuan declares that he has no conflict of interest.

Ethical Approval

This article does not contain any studies with animals performed by any of the authors.

Informed Consent

Not applicable.

Rights and permissions

About this article

Cite this article

Hao, Z., Xiao, Y., Jiang, L. et al. Simultaneous Determination of Bisphenol A, Bisphenol F, 4-Nonylphenol, 4-n-Nonylphenol, and Octylphenol in Grease-Rich Food by Carb/PSA Solid-Phase Extraction Combined with High-Performance Liquid Chromatography Tandem Mass Spectrometry. Food Anal. Methods 11, 589–597 (2018). https://doi.org/10.1007/s12161-017-1029-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-017-1029-5