Abstract

A new method was developed for the determination of four acrylamide compounds (acrylamide, methacrylamide, N-methylol acrylamide, N-(Methoxymethyl)methacrylamide) in food contact paper products, three kinds of water-based food simulants, and dry food simulant (modified polyphenylene oxide, MPPO) by using ultra-high performance liquid chromatography tandem mass spectrometry (UPLC-MS/MS). Acetonitrile was used as the extraction solvent for different kinds of samples. The extraction solution of paper products was purified with QuEChERS technology. Four analytes were separated by gradient elution in a UPLC HSS T3 column (100 mm × 2.1 mm, 1.8 μm) with methanol and 0.1 % formic acid water as mobile phases, and then detected in electrospray ionization mode of MS/MS with multiple reaction monitoring (MRM). Under the optimal conditions, the calibration curves for four analytes were linear within the range of 1.0–200 μg/L and the correlation coefficients were higher than 0.998. The quantitation limits of the method (S/N = 10) of four analytes were in the range of 0.3–20 μg/kg. The mean recoveries for five sample matrixes at three spiked concentration levels of 0.3–200 μg/kg were in the range of 81–108 % with the relative standard deviations (RSDs, n = 6) values ranging from 2.5 to 7.1 %. The developed method is accurate, simple and rapid, which can be applied to the determination of acrylamide compounds in food contact paper products and food simulants.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

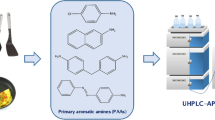

N-nitro acrylamide (AM), methacrylamide (AAM), N-methylol acrylamide (HAM), and N-(Methoxymethyl)methacrylamide, as shown in Fig. 1, are important chemical raw materials. AM is commonly used in the synthesis of polyacrylamide (PAM) and HAM is a widely-used cross-linking monomer. In paper industry, AM, PAM, AAM, HAM, and N-(Methoxymethyl)methacrylamide can polymerized with some other monomers (e.g., acrylonitrile, acrylic acid and acrylate) to form copolymers, which can be used as paper-reinforcing agents, dispersing agents, surface treatment agents, and paper pipe adhesives (Kim et al. 2015; Omar et al. 2015; Krska et al. 2012). Especially for recycled paper, it is necessary to add the above additives to improve the strength and other properties of paper during the reprocessing. Raw or boiled foodstuffs usually do not contain acrylamide (Bent et al. 2012; Kaplan et al. 2009; Omar et al. 2014). Food contact paper products were used to hold or package water-based or dry food, such as water, beverage, and some kind of food like bread. Unfortunately, some researchers have demonstrated that the residual acrylamide additives in food contact paper products are likely to migrate to food under certain conditions, which may affect the food safety and threaten human health. Besides, acrylamide monomers can be also generated from the degradation of covered polymer during storage. The presence of residual AM monomer in some paper products had already been reported, suggesting the existence of the risk of migratory contamination for paper packaging food. What is more, AM, whose LD50 is 150–180 mg/kg (rat oral), is classified as possible carcinogen for humans (group 2A) by the International Cancer Institute because of its neurotoxicity, reproductive toxicity, genetic toxicity, and teratogenicity (IARC 1994; U.S. EPA 1994; Liu et al. 2008). The toxicity of AAM (LD50 is 459 mg/kg, rat oral) is slightly lower than that of AM. However, the ingestion of AAM can probably cause the disorder of central nervous system. HAM belongs to low-toxic compounds and the LD50 of HAM is 470 mg/kg (rat oral). To the best of our knowledge, there is no literature regarding the toxicity of N-(Methoxymethyl)methacrylamide. Nevertheless, in GB 9685–2008 (GB 9685–2008 2008), the specific migration limits (SMLs, the minimum value of target analyte migrated from food contact paper product to food under certain conditions) of AM and AAM in paper package materials are 0 (the method detection limits for AM and AAM are required to be lower than 0.01 mg/kg and 0.02 mg/kg, respectively) and 0.05 mg/kg for both N-(Methoxymethyl)methacrylamide and HAM. In view of the wide application of acrylamide compounds in paper industry, the risk of migratory contamination for paper packaging food and no available detection method for AAM, HAM and N-(Methoxymethyl)methacrylamide, the establishment of an accurate and sensitive method for the detection of acrylamide compounds in food contact paper products and food simulants is necessary and of great significance.

To date, the detection of acrylamide compounds mentioned in literatures were only focused on the detection of acrylamide in heat-processed food and cosmetics (Kim et al. 2015; Krska et al. 2012; Michalak et al. 2013; Mo et al. 2014; Liu et al. 2008; Sun et al. 2012; Russo et al. 2014; Backe et al. 2014; Karasek et al. 2009), and the detection methods mainly included liquid chromatography (LC) (Albishri and El-Hady 2014; Wang et al. 2013), ion pair-reversed phase-high performance liquid chromatography (RP-HPLC-DAD) (Michalak et al. 2013), gas chromatography with mass spectrometry (GC-MS) (Omar et al. 2014; Mo et al. 2014), and liquid chromatography tandem mass spectrometry (Kim et al. 2015). For example, Omar et al. (2014) established a dispersive solid-phase extraction coupled to gas chromatography–mass spectrometry method to determination acrylamide in food and favorable LODs and precisions were obtained. Albishri and El-Hady (2014) developed a simple method for the reliable determination of acrylamide in food samples by utilizing liquid chromatography and ultrasonic assisted selective extraction. Moreover, a simple and sensitive liquid chromatography tandem mass spectrometry assay for the simultaneous quantification of AM and its active metabolite, glycidamide (GA) in rat plasma, urine, and 14 different tissues was established by Kim et al. (2015). GB/T 23296.9-2009 (2009) suggested the high-performance liquid chromatography for the detection of acrylamide in three kinds of water-based simulants and olive oil. The target analytes in these methods are only acrylamide, which limited the detection of other acrylamide compounds. Besides, the LC method is susceptible to impurities and its sensitivity is relatively low.

LC-MS/MS shows high sensitivity, strong anti-interference ability and high qualitative and quantitative accuracy in the multi-residue trace detection (Dong et al. 2015; Guo et al. 2013). Considering these advantages of LC-MS/MS, this research employed ultra-high performance liquid chromatography tandem mass spectrometry (UPLC-MS/MS) and QuEChERS dispersion and purification technology to establish the detection method for four acrylamide compounds in food contact paper products and food simulants, which could provide reference for the detection and specific migration study of related compounds in food contact paper products.

Materials and Methods

Chemicals and Reagents

N-nitro acrylamide (AM, CAS: 79-06-1, purity > 99.0 %) was purchased from Dr. Ehrenstorfer GmbH (Augsburg, Germany). N-methylol acrylamide (HAM, CAS: 924-42-5, purity > 98.0 %) was provided by CNW Technologies GmbH (Düsseldorf, Germany). N-(Methoxymethyl)methacrylamide, methacrylamide (AAM, CAS: 79-39-0, purity > 98.0 %) and N-(Methoxymethyl)methacrylamide standard products (CAS: 3644-12-0, purity > 85.0 %) were supplied by Tokyo Chemical Industry Co., Ltd (Tokyo, Japan). Isotope internal standard: 13C3-acrylamide (13C3-AM, purity > 98.0 %) was obtained from Cambridge Isotope Laboratories, Inc. (Andover, USA). Methanol and acetonitrile (HPLC grade) were provided by Merck Chemicals Co., Ltd (Darmstadt, Germany). Formic acid (HPLC grade), C18, and GCB adsorbent were supplied by CNW Technologies GmbH (Düsseldorf, Germany). Modified polyphenylene ether (MPPO, 60–80 meshes) was available from Buchem BV. Acetic acid and absolute ethyl alcohol (A.R. grade) were purchased from Guangzhou Chemical Reagent Factory (Guangzhou, China).

Instrumentation

The ACQUITYTM ultra-high-performance liquid chromatography and Waters XevoTM TQ tandem triple quadrupole mass spectrometer (UPLC-MS/MS, Waters Co. USA) were used for sample analysis. The samples were vortex mixed with a MS3 basic vortex mixer (IKA GmbH, Germany) and ultrasonicated by the KQ-250DV numerically controlled ultrasonic cleaning machine (Kunshan Ultrasonic Instrument Co., Ltd, China). The Milli-Q A10 (Merk Millipore, USA) was used to offer Milli-Q water. As acrylamide compounds are polar and water-soluble organic molecules, which can be separated by chromatography, so in this work, the chromatographic behaviors of acrylamide compounds on the hydrophilic interaction HILIC chromatography column (50 mm × 2.1 mm, 1.7 μm) and reverse interaction T3 chromatographic column (100 mm × 2.1 mm, 1.8 μm) were investigated.

Standard Solutions

Isotope internal standard working solution: appropriate amount of 13C3-AM was dissolved in methanol to obtain the internal standard stock solution (20 mg/L). Then, the standard stock solution was further diluted by methanol, resulting of the standard working solution (2 mg/L), which was then stored in refrigerator at 4 °C.

Four kinds of standard samples were accurately weighed and dissolved in methanol to acquire the single standard stock solutions (100 μg/mL), respectively. The mixed standard stock solution was prepared by utilizing the single standard stock solution and methanol. The mixed standard working solution, which contained 20 μg/L of 13C3-AM, was obtained by further diluted the mixed standard stock solution to the required concentration with 20 % methanol–water solution (v/v). All of the prepared standard solutions were preserved in refrigerator at 4 °C.

Samples and Sample Preparation

Twenty food contact paper products, including six paper cups, six cake papers, four paper bags, and four paper towels, were obtained from local manufacturers. Among them, three paper cups are waxed; the remaining 17 samples are covered by polyethylene (PE) on the single side. All samples, except one paper cup covered by PE on the single side and two cake papers, have printings on their outer surface. In addition, all of the samples were conducted with permeability test and none of them were leaky. Considering that food contact paper products were used to hold or package water-based or dry food, such as drink and bread, according to GB/T 23296.1-2009 (2009) and EN 14338–2003 (2003), Milli-Q water, 3 % acetic acid solution (m/m), 10 % ethanol solution (v/v), and MPPO were used as the aqueous, acidic, and alcoholic water-based food simulants and dry food simulant, respectively. These food simulants were further prepared from the migration tests according to the requirements of GB/T 23296.1-2009 (2009) and EN 14338–2003 (2003).

Because the printing ink, pigments, as well as some alkane impurities on the surface of paper products could lead to the matrix interference and the contamination of equipment during detection, the purification of the extracting solution was necessary. Owing to the speediness, simpleness, and convenience of QuEChERS dispersion and purification technology, the extracting solution was purified by QuEChERS in this experiment. C18, PSA, and GCB were commonly dispersion fillers for QuEChERS. Specifically, C18 could adsorb non-polar impurities (fat); PSA could adsorb polar impurities, such as fatty acid and organic acid; GCB could adsorb some impurities like pigments. So, in this work, the treatment of paper products was as follows: paper products were cut into 5 mm × 5 mm in size and 0.25 g of as-prepared sample, 25 μL of internal standard working solution and 5.0 mL of acetonitrile were orderly added into a 10 mL of stoppered colorimetric tube. The mixture was ultrasonicated for 30 min, vortex mixed, and centrifuged at 2500 rpm for 5 min. After that, 2.0 mL of the extracting solution was withdrawn into 2.5 mL of plastic centrifuge tube, which contained 20 mg C18 and 20 mg GCB. The mixture was vortex mixed for 1 min and centrifuged at 10,000 rpm for 2 min. Subsequently, 1.0 mL of supernatant was withdrawn into nitrogen blowpipe and concentrated to dry in water bath at 40 °C under nitrogen blowing. Then, 0.5 mL of 20 % methanol aqueous solution was added in, and the resulting mixture was vortex mixed and filtrated (0.22 μm). Finally, the corresponding filtrate was transferred into 400 μL of intubation for subsequent UPLC-MS/MS analysis.

The treatment of dry food simulant products: 1.00 g of MPPO, 25 μL of internal standard working solution and 10 mL of acetonitrile were orderly added into a 10 mL of stoppered colorimetric tube. The above suspension was ultrasonicated for 30 min, vortex mixed, and centrifuged at 2500 rpm for 5 min. After that, 4.0 mL of the extracting solution was withdrawn into 10 mL of nitrogen blowpipe and concentrated to dry in water bath at 40 °C under nitrogen blowing. Then, 1.0 mL of 20 % methanol aqueous solution was added in. The resulting mixture was vortex mixed and filtrated (0.22 μm) for subsequent UPLC-MS/MS analysis.

The treatment of three kinds of water-based food simulant products: 5.0 g of three kinds of water-based food simulants were added into a 50-mL Teflon centrifugal tube with cover, respectively. The pH value of the acidic food simulant was adjusted to 7.0 and the alcohol food simulation was diluted with 5.0 mL of Milli-Q water. Then, 10.0 μL of internal standard working solution and 7.0 mL of acetonitrile were orderly added in and the mixtures were vortex extracted for 1 min. Followed by the addition of NaCl (5.0 g for the aqueous and acidic food simulants, 8.0 g for the alcohol food simulants) and further vortex extracted for 1 min and centrifuged at 4000 rpm for 5 min. The supernatant was withdrawn into 15 mL of nitrogen blowpipe and the remaining residue was extracted again with 7.0 mL of acetonitrile. The extracting solution was combined and concentrated to dry in water bath at 40 °C under nitrogen blowing. Then, 1.0 mL of 20 % methanol aqueous solution was added in. The resulting mixture was vortex mixed and filtrated (0.22 μm) for subsequent UPLC-MS/MS analysis.

The preparation of spiked samples: the preparation procedures of the spiked samples are the same as the treatments described above expect for the addition of appropriate concentrations of mixed standard and internal standard working solution. The spiked samples were stayed at room temperature until the standard solution was entirely adsorbed.

UPLC-MS/MS Conditions

ACQUITY UPLC HSS T3 chromatographic column (100 mm × 2.1 mm, 1.8 μm) was finally chosen for separation. Column temperature was set as 30 °C. Methanol and 0.1 % formic acid aqueous solution were chosen as mobile phases. The flow gradient was initiated at a composition of 20:80 (methanol/water, v/v) with a flow rate of 0.2 mL/min. Then methanol was linearly increased to 70 % in 3 min. After returning to the initial composition of 20:80 in 0.1 min, the column was allowed to re-equilibrate for 1.9 min giving a total run time of 5 min (Table 2). The injection volume was 5 μL.

The electrospray ionization source was operated in a positive mode with capillary voltage set to 0.5 kV and samples were detected in the multiple reaction monitoring (MRM) mode. The ion source and desolvation temperatures were optimized at 150 and 500 °C. The desolvation gas, cone gas, and collision gas flow rates were set at 800 L/h, 50 L/h and 9 L/h, respectively. Monitoring ion pair (m/z), cone voltage, collision energy, retention time, and other parameters of the acrylamide analytes and isotope internal standard were shown in Table 1.

Statistical Analysis

Statistical calculation and between-variable correlation were investigated using the SPSS (SPSS Inc., Chicago, IL, USA). All the data were expressed as means ± standard deviations (SDs) of triplicate determinations and significance was determined at P < 0.05 by analysis of variance (ANOVA) followed by Duncan’s least significant test.

Results and Discussion

Optimization of Extraction Condition

Because acrylamide compounds are soluble in water and polar organic solvents, such as alcohol and acetonitrile, they can be extracted from porous paper products under sonication. Acetonitrile is a common used extraction solvent and could extract few amounts of the non-polar dye materials in paper products. Besides, for the water-based food stimulant, acetonitrile can extract homogeneously and then split phase by salting out. Therefore, the extraction recoveries of samples with acetonitrile as extractant were investigated and determined to be in the range of 87–114 %, which suggested a good efficiency of the extraction procedure.

It should be noted that the acid in the acidic food simulant and the ethanol in alcoholic food stimulant could affect the distribution amount of acrylamide compounds in acetonitrile phase during the extraction procedure. Thus, before the extraction, the regulation of pH value to 7.0 and the reduction of ethanol content should be conducted to ensure the extraction effect.

The effect of different sonication time (10, 20, 30, 40, and 50 min) on the extraction efficiencies of solid samples (paper product and dry food simulant) was investigated in this experiment and shown in Fig. 2. The results showed that the extraction recoveries of four acrylamide analytes in tight textured paper box tended to be balanced after sonication for 30 min. Therefore, the sonication time was selected to be 30 min in this experiment.

Optimization of Purification Condition for Paper Samples

The purification effects of these three kinds of fillers (20 mg of each) of QuEChERS on the extracting solution of the pigment matrix were investigated (Fig. 3). It could be seen that the recoveries of C18 and GCB were higher (P < 0.05) than that of PSA. Because the adsorption effect of GCB on pigment was the best, and GC-MS full scan mass spectrometry implied that the elimination of the alkane impurity by C18 was the best. Hence, for good purification effect, the combination of C18 (20 mg) and GCB (20 mg) were adopted to carry out QuEChERS and the favorable recoveries (92–98 %, n = 6) were obtained. In a research paper published by Omar et al. (2015), aluminum oxide (Al2O3) as dispersive solid phase extraction (dSPE) material combined with the QuEChERS preparation method for the extraction of acrylamide from food samples were used and favorable results could also be obtained. Recoveries of acrylamide ranging from 90 to 97 % (n = 3) indicating that the proposed Al2O3 dSPE method could be successfully applied to the analysis of acrylamide in real food samples.

Recoveries of QuEChERS by different sorbents (n = 4). 1, 2, 3, and 4 represent N-nitro acrylamide (AM), methacrylamide (AAM), N-methylol acrylamide (HAM), and N-(Methoxymethyl)methacrylamide, respectively. For each analyte, values in three columns followed by the different letters are significantly different (P < 0.05)

Optimization of Chromatography and Mass Spectrometry Conditions

Under ESI+ mode, the four acrylamide analytes show high-response [M + H]+ molecular ion peaks and the corresponding parent and characteristic fragment ions could be determined through primary and secondary scanning of mass spectrometry. Specifically, with the lost of −NH3 and −CH2 = CH2, the corresponding fragment ions of AM are m/z 55 and 44. AAM miss −CHN and −NH2, yeilding the fragment ions m/z 58 and 69. The fragment ions of HAM are determined to be m/z 55 and 84 as the result of losing −CH4NO and −OH. As for N-(Methoxymethyl)methacrylamide, the fragment ions are m/z 69 and 98 after missing −C2H6NO and −CH3O. The mass spectrometric parameters, such as characteristic ion, cone voltage and collision voltage, were optimized to achieve the best response for each compound. The optimized parameters were shown in Table 1.

For HILIC chromatography column, the four acrylamide analytes simultaneously show peaks at 0.85 min with acetonitrile 5 mmol/L ammonium acetate (95:5, v/v) for isocratic elution (flow rate was 0.2 mL/min), which indicated that good separation was difficult to achieve. Besides, this co-outflow was liable to generate the ionization competition of mass spectrometry, resulting of the inhibition effect of matrix. As for the T3 chromatographic column, the four analytes had good retention time, separation degree, and half peak width by utilizing methanol–0.1 % formic acid water as mobile phase for the gradient elution (Fig. 4). The change of the mobile phase was due to the weaker elution ability of methanol and the higher ionization efficiency of analytes in acidic mobile phase. As a result, T3 chromatographic column and mobile phase of methanol–0.1 % formic acid water were selected for the chromatographic separation.

Under the optimized instrument condition, selective ion chromatograms of standard solutions for four acrylamide analytes were shown in Fig. 4.

Linear Range, Detection Limit, and Matrix Effect

A series of mixed standard solutions with mass concentrations of 1.0–200 μg/L for four acrylamide analytes were prepared and tested at the optimal experiment conditions. For AM, the ratio of target analyte quantitative ion peak area to the internal standard quantitative ion peak area peak area was used as ordinate y. For the remaining three analytes, the respective quantitative ion peak area was used as ordinate y. The corresponding mass concentration (μg/L) was used as abscissa x. The linear regression was performed to obtain the correlation coefficients of various compounds (Table 2). Obviously, all of the correlation coefficients were more than 0.998, indicating the good linear relationship between the quantitative ion peak areas and analyte concentrations.

A series of matrix calibration solutions were prepared by using five kinds of negative matrix-extracting solutions, and the corresponding matrix calibration curves were obtained. For these compounds, the slope ratios between matrix calibration curves and pure standard solution curves were in range of 0.89–1.09, indicating that the matrix effect was very small and thus could be neglected.

The limit of detection (LOD) and limit of quantitation (LOQ) of the instrument, which refers the triple signal-to-noise ratio (S/N = 3) and tenfold signal-to-noise ratio (S/N = 10), were measured by gradually diluting the standard solution. By taking the pretreatment processes and the recoveries of various samples into consideration, the corresponding method limit of detection (MLOD) and the method limit of quantitation (MLOQ) were in the ranges of 0.1–6.5 μg/kg and 0.3–20 μg/kg, respectively, which are lower than those of 9.1–12.8 μg/kg and 27.8–38.9 μg/kg by a gas chromatography–mass spectrometry analysis (Omar et al. 2014), suggesting that the method was sensitive and could satisfy the monitor requirement of GB 9685-2008 (2008).

Recovery and Precision

At the optimal experiment condition, the spiked recoveries of three added levels were performed in the negative sample matrixes (paper product, three kinds of water-based food simulants and dry food simulant). Each added level includes six parallel experiments. The results (Table 3) showed that the average recoveries of three added levels were in the range of 81–108 % and the relative standard deviations ranged from 2.5 to 7.1 %. The recoveries obtained in this work are quite close to those of 91.6–110 % by a liquid chromatography tandem mass spectrometry method developed by Kim et al. (2015), demonstrating the good precision and accuracy of this method.

Analysis of Practical Samples

To evaluate the application of the method, 20 food contact paper products were examined with this method. Among these samples, two facial tissue samples were found to contain AM and the contents were determined to be 517 μg/kg and 169 μg/kg, respectively. One paper cup was detected to have 13 μg/kg of N-(Methoxymethyl)methacrylamide; the remaining samples showed no detection of any acrylamide analytes. The typical selective ion chromatograms for the tissue sample and the paper cup sample were shown in Fig. 5a and b.

Conclusions

With the utilization of UPLC-MS/MS, QuEChERS dispersion and purification technology and isotope dilution technique, a new analytical method was developed for the detection of four acrylamide compounds in the food contact paper products, water-based food simulants, alcohol-based food simulants, and dry food simulant. The calibration curves were linear over the selected concentration ranges of 1.0–200 μg/L for all analytes, with the correlation coefficients higher than 0.998. The MLOD and MLOQ were in the ranges of 0.1–6.5 μg/kg and 0.3–20 μg/kg, respectively. Favorable recoveries (81–108 %) were obtained at three spiked concentration levels of 0.3–200 μg/kg, with the RSDs (n = 6) values ranging from 2.5 to 7.1 %. The developed method was simple, accurate, sensitive, and widely applicable, which could provide new reference for the research of residue detection and specific migration in food contact paper products.

References

Albishri HM, El-Hady DA (2014) Eco-friendly ionic liquid based ultrasonic assisted selective extraction coupled with a simple liquid chromatography for the reliable determination of acrylamide in food samples. Talanta 118:129–136

Backe WJ, Yingling V, Johnson T (2014) The determination of acrylamide in environmental and drinking waters by large-volume injection-hydrophilic-interaction liquid chromatography and tandem mass spectrometry. J Chromatogr A 1334:72–78

Bent GA, Maragh P, Dasgupta T (2012) Acrylamide in Caribbean foods-residual levels and their relation to reducing sugar and asparagine content. Food Chem 133:451–457

Dong H, Guo X, Xian Y, Luo H, Wang B, Wu Y (2015) A salting out-acetonitrile homogeneous extraction coupled with gas chromatography-mass spectrometry method for the simultaneous determination of thirteen N-nitrosamines in skin care cosmetics. J Chromatogr A 1422:82–88

EN 14338–2003 (2003) Paper and board intended to come into contact with foodstuffs-Conditions for determination of migration from paper and board using modified polyphenylene oxide (MPPO) as a stimulant, European Committee for Standardization

GB 9685–2008 (2008) Hygienic standards for uses of additives in food containers and packaging materials, National Standard of the People’s Republic of China

GB/T 23296.1-2009 (2009) Materials and articles in contact with foodstuffs-Plastics substances subject to limitation-Guide to test methods for the specific migration of substances from plastics to foods and food simulants and the determination of substances in plastics and the selection of conditions of exposure to food simulants, National Standard of the People’s Republic of China

GB/T 23296.9-2009 (2009) Food contact materials-polymer-Determination of acrylamide in food stimulants-High performance liquid chromatography, National Standard of the People’s Republic of China

Guo X et al (2013) Quantitative determinations of seven fluorescent whitening agents in polystyrene and polyvinyl chloride plastics by ultrahigh performance liquid chromatography-tandem mass spectrometry. Anal Methods 5:6086–6093

IARC (1994) Acrylamide. Monographs on the evaluation of carcinogenic risks to humans: some industrial chemicals (Vol. 60, pp. 389–433). Lyon, France

Kaplan O, Kaya G, Ozcan C, Ince M, Yaman M (2009) Acrylamide concentrations in grilled foodstuffs of Turkish kitchen by high performance liquid chromatography-mass spectrometry. Microchem J 93:173–179

Karasek L, Wenzl T, Anklam E (2009) Determination of acrylamide in roasted chestnuts and chestnut-based foods by isotope dilution HPLC-MS/MS. Food Chem 114:1555–1558

Kim TH et al (2015) Determination of acrylamide and glycidamide in various biological matrices by liquid chromatography-tandem mass spectrometry and its application to a pharmacokinetic study. Talanta 131:46–54

Krska R et al (2012) Challenges and trends in the determination of selected chemical contaminants and allergens in food. Anal Bioanal Chem 402(1):139–162

Liu J, Zhao G, Yuan Y, Chen F, Hu X (2008) Quantitative analysis of acrylamide in tea by liquid chromatography coupled with electrospray ionization tandem mass spectrometry. Food Chem 108:760–767

Michalak J, Gujska E, Kuncewicz A (2013) RP-HPLC-DAD studies on acrylamide in cereal-based baby foods. J Food Compos Anal 32:68–73

Mo W, He H, Xu X, Huang B, Ren Y (2014) Simultaneous determination of ethyl carbamate, chloropropanols and acrylamide in fermented products, flavoring and related foods by gas chromatography–triple quadrupole mass spectrometry. Food Control 43:251–257

Omar MMA, Ibrahim WAW, Elbashir AA (2014) Sol–gel hybrid methyltrimethoxysilane-tetraethoxysilane as a new dispersive solid-phase extraction material for acrylamide determination in food with direct gas chromatography–mass spectrometry analysis. Food Chem 158:302–309

Omar MMA, Elbashir AA, Schmitz OJ (2015) Determination of acrylamide in Sudanese food by high performance liquid chromatography coupled with LTQ Orbitrap mass spectrometry. Food Chem 176:342–349

Russo MV et al (2014) Rapid and simple determination of acrylamide in conventional cereal-based foods and potato chips through conversion to 3-[bis(trifluoroethanoyl)amino]-3-oxopropyl trifluoroacetate by gas chromatography coupled with electron capture and ion trap mass spectrometry detectors. Food Chem 146:204–211

Sun S, Fang Y, Xia Y (2012) A facile of acrylamide in starchy food by using a solid extraction-GC strategy. Food Control 26:220–222

U.S. Environmental Protection Agency (EPA) (1994) EPA 749-F-94-005a: Chemical summary for acrylamide

Wang H et al (2013) HPLC-UV quantitative analysis of acrylamide in baked and deep-fried Chinese foods. J Food Compos Anal 31:7–11

Acknowledgments

This work was supported by National Centre for Quality Supervision and Testing of Processed Food (Guangzhou) in China. At the same time, the authors would like to thank all the workers for sampling, sample preparation and measurement.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

Cong Zhang declares that he has no conflict of interest. Yanping Xian declares that she has no conflict of interest. Xindong Guo declares that he has no conflict of interest. Huidi Liu declares that he has no conflict of interest. Hao Dong declares that he has no conflict of interest. Zhiqing Xun declares that he has no conflict of interest. Jinfeng Huang declares that she has no conflict of interest. Xiang Feng declares that he has no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed Consent

Informed consent was obtained from all individual participants included in the study.

Rights and permissions

About this article

Cite this article

Zhang, C., Xian, Y., Guo, X. et al. Isotope Internal Standard Method for Determination of Four Acrylamide Compounds in Food Contact Paper Products and Food Simulants by Ultra-High Performance Liquid Chromatography Tandem Mass Spectrometry. Food Anal. Methods 9, 1895–1903 (2016). https://doi.org/10.1007/s12161-015-0373-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-015-0373-6