Abstract

A simple, cheap, and reliable capillary zone electrophoresis (CZE) method with indirect UV detection to determine the main organic acids in several fruit juices has been developed in this work. The parameters affecting CZE separation including the chromophore reagent (2,6-pyridinedicarboxylic acid, PDC) concentration and pH in background electrolyte (BGE), temperature, and applied voltage were studied. The analytical parameters of the method as linearity, precision, and detection and quantification limits were also investigated. The proposed method was applied to the evaluation of organic acid contents of commercial fruit juices from apple, grape, mandarin, orange, and pineapple and compared with the levels allowed by European legislation. A chemometric technique such as linear discriminant analysis (LDA) was also applied to differentiate fruit juices based on CZE data. This simple and reliable developed procedure allows a rapid control of adulteration of high-value commercial fruit juices, which constitutes an important tool for authenticity texting in food industries and regulatory agencies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fruit juice is considered to be one of the healthiest foods in human diet, due to their well-known reported health benefits (source of natural vitamins and antioxidants, anti-inflammatory properties, prevention of chronic diseases, etc) (Jandric et al. 2014). In this sense, commercial prepared juices claim to preserve these nutritional and healthy effects. For these reasons, fruit juices demand higher prices compared to other types of liquid refreshments and they can be targets of adulteration. The most common forms of adulteration that occur within the fruit juice industry usually include dilution with water, addition of sugars or other additives, or blending with cheaper fruit juices (Fügel et al. 2005; Saavedra et al. 2000). However, detection and prevention of adulteration is a very complex task due to the natural variation in the cultivars, storage conditions, and processing techniques. In this regard, the European Fruit Juice Association and other regulatory agencies have provided procedures for assessing fruit authenticity and quality control (AIJN 2010). Due to the diversity in adulteration techniques, a pool of analytical methods based on the identification and quantification of several compounds (carbohydrates, phenolic compounds, amino acids, inorganic anions, etc.) have been proposed (Jandric et al. 2014; Wiley 2014; Simó et al. 2002; Simó et al. 2004; Moretti Passos et al. 2016; Fung and Lau 2003), with the measurement of organic acids always considered (Mato et al. 2005; Ehling and Cole 2011; Kelebek et al. 2009; Saavedra et al. 2000; Saavedra et al. 2001; Scherer et al. 2012; Fung and Lau 2003). Thus, organic acids showed different profiles in fruit juices, which undoubtedly influence on the organoleptic (e.g., flavors, freshness, or spoilage) and chemical features of the juice (e.g., pH, total acidity) (Chinnici et al. 2005), providing also useful “fingerprints” for authenticity purposes (Cordella et al. 2002; Ehling and Cole 2011; Kvasnicka 2005; Saavedra et al. 2000; Shui and Leong 2002). For instance, the presence of tartaric acid in high-value juices (e.g., orange and pineapple) allows the detection of grape juice addition (AIJN 2010; Ehling and Cole 2011; Saavedra et al. 2000). Similarly, excess of malic acid can be used as an indicator of apple juice addition to a more expensive juice. Also, the evaluation of some minor organic acids has demonstrated to be a useful tool to detect the adulteration (Coppola et al. 1995). In particular, the presence of high contents of isocitric acid, which occurs at much lower concentrations than other organic acids, is too expensive to be used with fraudulent purposes (Sadecka et al. 2001). Thus, it could be used to establish authenticity and quality of citrus juices (Jezek and Suhaj 2001; Kvasnicka et al. 2002). In fact, the ratio of citric acid to isocitric acid has been used as one of the parameters to ascertain a chemical profile of authentic fruit juices. For example, when the citric/isocitric ratio in orange juice is above 130, it may be indicative of fruit juice adulteration (addition of sugars, citric acid and water) (AIJN 2010). Fumaric acid is also used as an important parameter to detect the presence of microbial spoilage or the processing of decayed fruits (Trifirò et al. 1997; Kvasnicka and Voldrich 2000). According to AIJN guidelines (AIJN 2010), the content of fumaric acid in apple juices is limited to 5 mg L−1. A high content of this organic acid indicates adulteration due to addition of synthetic L-malic acid and overprocessing of apple juice (Evans et al. 1983; Gökmen and Acar 1998; Kvasnicka and Voldrich 2000).

Several analytical methods to determine these aliphatic organic acids in fruit juices have been described in the literature, including enzymatic (Stój and Targonski 2006; Boehringer 1992) and chromatographic (Chinnici et al. 2005; Cunha and Fernandes 2002; Ehling and Cole 2011; Kelebek et al. 2009; Scherer et al. 2012; Shui et al. 2002; Ortega et al. 2001, Zhang et al. 2011; Schwarz et al. 2011; Association of Official Analytical Chemists International Official Methods of Analysis 2008) methodologies. Enzymatic methods for some organic acids require specific kits, which make them expensive and inadequate for the simultaneous analysis of all target organic acids. Within chromatographic methods, high performance liquid chromatography (HPLC) is more frequently employed, but sample pre-treatments have to be implemented, which undoubtedly slows down its application in food quality control. Compared with these methodologies, capillary electrophoresis (CE) offers some advantages such as high separation efficiency, rapid analysis, small sample consumption, and short analysis time, without the need to carry out some sample extraction (or derivatization) steps which are often necessary in chromatographic methods. Thus, organic acids can be detected using either direct (Mato et al. 2007; Saavedra et al. 2000; Navarro-Pascual-Ahuir et al. 2015) or indirect UV absorption, with the latter mode to monitor solutes that have no or scarce UV-vis absorbance, such as most organic acids. In this sense, different electrolyte systems have been proposed, generally containing quaternary ammonium salts as electroosmotic flow (EOF) reversers, and either chromate (Arellano et al. 1997; Wu et al. 1995), phthalate (Wu et al. 1995), 1,3,5-benzenetricarboxylic acid (Fung and Lau 2003), or 2,6-pyridinedicarboxylic acid (PDC) (Soga and Ross 1997; Öztekin and Erim 2001; Villiers et al. 2003; Markuszewski et al. 2003), among others, as chromophoric agents. Despite the number of CE methods published in the literature, as far as we are concerned, none matched our requirements of cheap, fast, and accurate determination of both major and minor organic acids (e.g., citric in apple, isocitric in orange, fumaric in apple) in fruit juices. Few works (Saavedra et al. 2000; Navarro-Pascual-Ahuir et al. 2015) have been reported on this topic using UV direct detection with coated capillaries, which substantially increases the analysis costs. On the other hand, an important point to be considered in the analysis of these matrices is to assure a satisfactory resolution to quantify minor compounds migrating next to major ones (e.g., citric/isocitric pair). Moreover, the fumarate analysis has problems due to its UV-absorbance at the same wavelength as several chromophores (Arellano et al. 1997; Kenney 1991). Taking into account all these aspects, and the growing demand in such organic acid analysis in fruit juice quality control and authentication, it is important to develop cheaper, faster, and reliable procedures where high analysis throughput can be implemented.

In this work, a capillary zone electrophoresis (CZE) method with indirect UV detection for the analysis of organic acids (fumaric, tartaric, malic citric, and isocitric acids) in several fruit juices was developed. The separation of these analytes was optimized in terms of an anionic chromophore (PDC) content in the BGE, pH, and other instrumental parameters. The developed method was applied to the quantitation of organic acids in different commercial fruit juices and its implications for authenticity testing. Finally, using organic acid concentration ratios as predictors, a linear discriminant analysis (LDA) model was constructed to classify juices according to the type of fruit employed.

Material and Methods

Chemicals and Samples

The following analytical grade reagents were used: sodium hydroxide (NaOH), PDC, and cetyltrimethylammonium bromide (CTAB) (Sigma-Aldrich, St. Louis, MO). Deionized water (Barnstead deionizer, Sybron, Boston, MA) was also used. The analytical standards were oxalic (used as internal standard, IS), fumaric, isocitric, malic, tartaric, and citric acids (Sigma-Aldrich). Individual stock solutions of organic acids were prepared in water at 10,000 μg mL−1, except for isocitric and fumaric acids, which were 500 and 100 μg mL−1, respectively. The 40 fruit juices employed in this study, 8 for each type of fruit (see Table 1), were purchased from the Spanish market.

Instrumentation and Procedures

An HP3D CE system (Agilent, Waldbronn, Germany) provided with a diode array spectrophotometric detector and uncoated fused-silica capillaries (Polymicro Technologies, Phoenix, AZ) of 112.5 cm length (104 cm effective length) × 75 μm id (375 μm o.d.) were used. Prior to use, new capillaries were successively flushed with 1 and 0.1 M NaOH and water at 60 °C for 10 min each. Between runs, the capillary was flushed with BGE for 5 min. Samples were injected hydrodynamically at 50 mbar × 4 s. Separations were performed at −25 kV at 10 °C. Indirect detection was done at 214 and 271 nm. Before injection, all solutions were filtered through 0.45-μm pore size nylon filters (Albet, Barcelona, Spain). The optimal BGE consisted of 10 mM PDC as chromophore and 0.5 mM CTAB (to reverse the direction of the EOF) at pH of 3.2. Data acquisition was performed with ChemStation Software (Rev.A.10.01, Agilent). Statistical data treatment was performed using SPSS (v. 15.0, Statistical Package for the Social Sciences, Chicago, IL).

Sample Preparation

Fruit juices, previously refrigerated at 5 °C, were centrifuged at 10,000 rpm for 10 min. The supernatant was 1:10 (v/v) diluted with deionized water, and for quantification purposes, the IS at 100 μg mL−1 was also added. This dilution ratio was selected in order to obtain an organic acid concentration within the linear range of calibration curves. However, for apple juices, quantification was also performed using a 1:1 (v/v) dilution due to the low content of fumaric acid in these samples (<5 μg mL−1) (AIJN 2010). The samples were analyzed in triplicate.

Results and Discussion

Optimization of Separation Conditions

In order to optimize organic acid separation, a test mixture containing the standards and the IS described in the “Chemicals and Samples” section was used. The initial BGE composition and separation conditions (at −25 kV and 15 °C) were adapted from Soga and Ross (1997). Thus, BGEs containing 5 mM PDC and 0.5 mM CTAB, at pHs comprised between 3.0 and 8.0, were initially tested. Figure 1 shows the influence of pH on the experimental effective electrophoretic mobilities of the studied organic acids. The calculated mobilities (taking into account the pKa values of each species and the pH of BGE) were also displayed (Sanz-Nebot et al. 2001; Herrero-Martínez et al. 2005). As it can be seen, the mobility of each analyte increased with the increase of pH value, until reaching pH values ranged to 7–8, where the mobilities remained nearly constant. This increase is caused by a change in the ionization states of carboxylic acids and its concentration (which is related to its pKa value). In addition, some variations in the pH of the BGE produced selectivity changes. For instance, at pH 3.0, citric and isocitric acids possess one negative charge and they migrate slower than the corresponding anions of oxalic, fumaric, tartaric, and malic acids due to its heavier molecular masses. However, when pH is raised above the pKa3 of citric and isocitric acid (ca. 6.40), the increase in citrate and isocitrate charge made up for its higher mass, and they migrated faster than did the diprotic acids except oxalic.

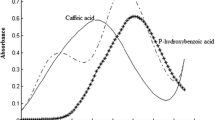

On the other hand, a detailed study of the separations performed in the tested pH range showed that an adequate separation of citric and isocitric acids was obtained when the pH of BGE was below to 4.0. This agrees with the principle that better resolution can be achieved when the separation is performed near the pKa values of analytes (Jorgenson and Lukacs 1981). In particular, these two carboxylic acids have identical molecular mass and very similar values of pKa2 and pKa3; however, at pH 3.0 (near pKa1 values, 3.13 for citrate and 3.29 for isocitrate (Dawson et al. 1991), the separation of these analytes was possible (see Fig. 2a). Besides, its ratio is a key parameter in the authentication and quality control of fruit juices (AIJN 2010). In fact, isocitric acid content is often found in very low concentrations compared to the large content of citric present (up to 22,000 μg mL−1 in the case of mandarins) (AIJN 2010), which emphasizes the need to achieve a satisfactory separation between analytes. Taking into account these considerations, a careful optimization of BGE pH was carried out over the range 3.0–3.5 (Fig. 2). As it can be seen, a BGE of pH 3.2 provided the best resolution of citric, malic, and isocitric acids. However, it is worth mentioning that an overlapping between fumaric and tartaric peaks was evidenced. In order to resolve this overlapping, lower wavelengths (200 or 214 nm) were selected, where fumarate appeared as a negative peak (data not shown). This can be explained by the fact that at this pH, fumarate has higher absorbance than that of PDC, and it can be easily distinguished from tartrate peak, thus improving the selectivity of the method. Furthermore, the joint presence of fumarate and tartrate in fruit juices is rare, since the first is characteristic of apple juice whereas the latter is representative of grape juice derivatives.

Separation of organic acid standards using a BGE containing 5 mM PDC and 0.5 mM CTAB at pH 3.0 (a), 3.2 (b), and 3.5 (c). CZE conditions as in Fig. 1. Peak identification: IS; oxalic; 1, tartaric; 2, fumaric; 3, citric; 4, malic; and 5, isocitric acids

It has been reported that the presence of metal cations in the BGE can affect the migration times and peak areas of certain acids (Soga and Ross 1997; Lalljie et al. 1993; Devêvre et al. 1994). In order to improve the resolution of separation, the addition of various salts containing metal ions such as Ca2 + and Fe3+ to the BGE was investigated. These metals form complexes with most of the organic acids studied (IUPAC Stability Constants Database web). Concentrations between 0.25 and 1 mM of both cations were studied. However, in both cases, it was observed that an increase in the content of the metal ion in the BGE led to an increase in migration times of the analytes, producing an overlapping between malic and isocitric peaks (data not shown) and a loss of peak efficiency.

Next, the effect of PDC concentration in the BGE was investigated. With a constant concentration of 0.5 mM CTAB in the BGE and the selected pH (3.2), the PDC concentration was varied between 5 and 20 mM (see Figs. 2b and 3). Concentrations below 5 mM led to a poor reproducibility in migration times, which was consistent with previous studies (Kandl and Kupina 1999; Villiers et al. 2003). As it can be observed, citric, malic, and isocitric acids were baseline resolved at PDC contents of 10 and 15 mM (Fig. 3a, b, respectively). However, any of these conditions was able to provide baseline separation between fumaric and tartaric acids. Taking into account the above considerations of these solutes, its separation was not taken into concern for the selection of the optimal PDC content. Thus, a PDC content of 10 mM was selected since it provided a little better resolution of malic and isocitric acids, a better signal-to-noise ratio, and lower analysis time.

Influence of PDC content on the separation of organic acid standards using a 10-mM (a), 15-mM (b), and 20-mM (c) PDC content in a BGE composed of 0.5 mM CTAB at pH 3.2. Other experimental conditions as in Fig. 1

Next, and in order to increase peak resolution, the effect of temperature was studied between 10 and 20 °C. At 20 °C, both analysis time and peak resolution decreased (data not shown). At 10 °C (see Fig. 4), the resolution of fumaric/tartaric and malic/isocitric peak pairs increased compared to that obtained at 15 °C (Fig. 3a). Thus, this temperature was selected for further studies.

Separation of organic acid standards at 10 °C using a BGE containing 10 mM PDC and 0.5 mM CTAB at pH 3.2. Other experimental conditions as in Fig. 1

After selection of the optimal temperature, the influence of applied voltage for analyte separation was next optimized. Thus, different applied voltages, ranging from −15 to −30 kV, were applied. When the applied voltage was lower than −25 kV, migration time increased without significant improvement in resolution, while at −30 kV, the analysis time was reduced with a concomitant decrease in the resolution, and a loss in peak efficiency was evidenced (data not shown). Thus, as a compromise between peak resolution and efficiency, a voltage of −25 kV was selected for further studies. Thus, the optimal separation conditions were BGE containing 10 mM PDC and 0.5 mM CTAB at pH 3.2, separation −25 kV at 10 °C.

Performance Characteristics of the CZE Method

The use of an IS for quantitation in CE has demonstrated to reduce the imprecision related with injection and produce a significant improvement in the reproducibility (Altria 2002). Accordingly, intra- and inter-day precision of migration times and corrected peak areas (calculated as analyte area/IS area) was evaluated by injecting the same 100 μg mL−1 solution for all analytes (except for fumaric acid that was 5 μg mL−1), ten times per day during 3 days (see Table 2). In all cases, the relative standard deviation (RSD) values were lower than 2.4 and 5.3% for migration times and peak area ratios, respectively.

External calibration curves of peak areas were obtained by injecting six standard solutions in the linear ranges indicated in Table 2 and containing IS at a constant concentration (100 μg mL−1). As can be seen, two linear ranges were adopted for citric acid: a low concentration range (5–100 μg mL−1) which was used for apple and grape juices and a high concentration range (100–5000 μg mL−1) used for the other samples. In all cases, straight lines with r 2 > 0.994 were achieved. The sensitivity of each analyte (determined as the slope from the calibration curve constructed using corrected peak areas) is also given in Table 2. The limits of detection (LODs) of each analyte were calculated by multiplying by 3, the standard deviation of the peak area, s, divided by the slope of the calibration curve (ICH guidelines 1996). The values of s for each analyte were obtained by injecting ten times aliquots of a solution containing known low concentrations of analyte that fulfill the signal-to-noise ratio of 3. The limits of quantification (LOQs) were obtained by multiplying by 3.3 the LOD values. As observed in Table 1, LODs and LOQs ranged from 0.5 to 1.6 μg mL−1 and from 1.7 to 5.3 μg mL−1, respectively. These values were similar to those reported by other authors using UV indirect detection using PDC as BGE (Soga and Ross 1997; Öztekin and Erim 2001), and in some cases even better (Villiers et al. 2003). However, these values were for some organic acids higher than those found using direct UV detection at uncommon short wavelength (185 nm) not available in commercial instruments (Mato et al. 2006) and with poly(vinyl alcohol)-coated bubble cell capillaries (Navarro-Pascual-Ahuir et al. 2015). In this latter, although some of the LODs and LOQs were lower (in concrete those of fumaric, isocitric, and citric acids), our methodology does not require coated capillaries, which undoubtedly makes it easier and more flexible and cost-effective for routine analysis of these solutes.

Quantification of Organic Acids in Fruit Juices

The developed CZE method was used to analyze the fruit juices given in Table 1. Due to the differences found in the content of the different organic acids in the samples, sample dilution was next optimized. The best results were obtained with a 1:10 (v/v) sample dilution, except for apple juices, which were injected at both 1:1 (v/v) (in order to quantify fumaric acid) and 1:10 (v/v) dilution (to quantify the other acids). Analytes were identified by comparison of their migration time with standards and by spiking the samples with standards. Additionally, standard addition calibration curves were obtained by adding to the samples at least four solutions with increasing concentrations, taking into account the linearity ranges given in Table 2. All curves were linear with r2 > 0.992, and in all cases, the slope of calibration curve did not differ significantly from that obtained with the external calibration method. From these results, it can be concluded that no matrix effect was observed in the determination of these analytes in the fruit juices analyzed.

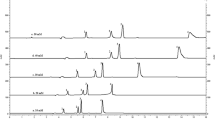

Examples of electropherograms of (A) apple, (B) grape, (C) mandarin, (D) orange, and (E) pineapple juices are depicted in Fig. 5. The levels (given as minimum and maximum values in μg mL−1) of organic acids found in the analyzed commercial fruit juices are given in Table 3. The organic acid contents obtained by the proposed method were comparable to those reported in literature (Fügel et al. 2005). Apart from the organic acid contents, the citric/isocitric ratio was also given in Table 3. As previously mentioned, this ratio is a relevant index for the assessment of the product quality and authenticity in fruit juices (AIJN 2010).

Electropherograms of the organic acids of samples of (a) apple, (b) grape, (c) mandarin, (d) orange, and (e) pineapple juices. Experimental conditions: BGE composed of 10 mM PDC and 0.5 mM CTAB at pH 3.2; separation voltage, −25 kV at 10 °C; sample dilution, 1:10 (v/v), except apple sample diluted 1:1(v/v). Other conditions as in Fig. 1. The dashed line depicts the analysis of sample A without addition of IS

As it can be observed, apple juices (A1-A8) presented large contents of malic acid in the range of 3300–4700 μg mL−1, and the contents of citric acid comprised between 65 and 130 μg mL−1. In any case, the concentrations found for both organic acids were within the levels permitted by European legislation (AIJN 2010). The presence of tartaric and isocitric acids were not detected in these samples. On the other hand, the content of fumaric acid in apple juices was within the limited range (<5 μg mL−1) (AIJN 2010), which indicated the absence of microbial spoilage or an inadequate fruit processing. Tartaric acid was the characteristic acid of the grape juices analyzed (G1-G8) with contents in agreement with those established (2000–7000 μg mL−1) by European legislation (AIJN 2010). Malic and citric acids were also found in these samples, with their concentrations within legislation. Mandarin and orange juices showed higher levels of citric acid (ranged between 7300 and 15,900 μg mL−1). Similar contents of malic acid were found in these citrus juices. The analysis of isocitric acid also gave similar levels, and the citric/isocitric ratios found in these juices (M1-M8 and O1-O8) were within the limits established by AIJN criteria (AIJN 2010). With respect to the pineapple juices, the contents of citric and malic acids were lower than those allowed by legislation (11,000 and 4000 μg mL−1, respectively) (AIJN 2010). Also, in these juices, the values of the citric/isocitric ratio found were consistent with the limit given (70) by European legislation (AIJN 2010). Moreover, the presence of tartaric acid in all these samples (except for grape juices) was not detected, which denotes that any of these juices was fortified with grape juice.

Taking into account the differences observed in organic acid concentrations, the possibility of using these levels as predictor variables for the construction of an LDA model able to discriminate between juices obtained from different fruits was next considered.

Classification of Juices Obtained from Different Fruits by LDA

LDA is a multivariate parametric technique, based on iterative search for discriminant vectors that provides the maximal resolution to classify samples into previously defined categories. In order to select the vectors to be included in the model, the Wilks’ lambda (λ w ) criterion was used (Vandeginste et al. 1998). Thus, well-resolved classes gave λ w values approaching zero, while overlapped classes gave λ w values approaching one. In this work, the SPSS stepwise algorithm was used to select the predictors that will be included in the LDA models, with the probability values adopted for entrance (Fin) and rejection (Fout) threshold of 0.05 and 0.10, respectively. Then, a data matrix was constructed using the concentration data given in Table 3, divided by pairs, and taken as original variables, in order to minimize the differences arising from the organic acid concentrations present in the fruit juices analyzed in this work. Thus, the matrix contained 40 objects which belonged to all the fruit juices of Table 1, and 10 predictors, which were obtained by dividing each analyte concentration by each one of the concentration of the other analytes, taking into account that any pair of concentrations should be considered only once. A response column, containing the categories corresponding to the five fruit types, was added to this matrix. This matrix was randomly divided to obtain the training and evaluation sets, which were constituted by 30 objects (6 juices × 5 fruit types) and by 10 objects, respectively.

The constructed LDA model able to distinguish juices samples according to the fruit type is depicted in Fig. 6. For this model, the λw value obtained was below 0.01, which is consistent with the excellent resolution observed between all the category pairs. The standardized coefficients of discriminant functions obtained to construct the LDA model are given in Table 4. As deduced from this table, the main concentration ratios that provided the large discriminant capabilities corresponded to fumaric/malic, fumaric/tartaric, and fumaric/citric ratios. Using this model and leave-one-out validation, all the objects of the training set were correctly classified. Furthermore, all the objects of the evaluation set (represented with a cross symbol in Fig. 6) were correctly assigned within a 95% probability level, which indicated the good prediction capability of the model.

Conclusion

In this work, a simple and reliable CZE method with indirect UV detection to determine the main organic acids present in several fruit juices has been established. A good resolution between all analytes was obtained after optimizing electrolyte pH, chromophore concentration, and other instrumental parameters. Thus, organic acid analysis with satisfactory validation results was performed in uncoated capillaries, in contrast to other CZE methods reported in literature for analysis of fruit juices, which contributes to decrease the analysis costs. Also, the method allowed the measurement of minor compounds in fruit juices (e.g., isocitric and fumaric acids), which were reported to be crucial for evaluating adulteration and microbial spoilage, respectively. The contents of organic acids found in fruit juices were within the levels allowed by European legislation. On the other hand, the combination of CZE analysis of organic acids with LDA provided a simple way to classify juices from different fruits. Therefore, the present procedure could be applied as routine assay of several organic acids in the juice industry and regulatory agencies.

References

AIJN (2010) Association of the Industry of Juices and Nectars Code of Practice for Evaluation of Fruit and Vegetable Juices, Brussels.

Albert A, Serjeant EP (1984) The determination of ionization constants, Third edn. Chapman and Hall, London

Altria KD (2002) Improved performance in capillary electrophoresis using internal standard. LC-GC Europe 15:588–584

Arellano M, Couderc F, Puig L (1997) Simultaneous separation of organic and inorganic acids by capillary zone electrophoresis. Application to wines and fruit juices. Am J Enol Viticult 48:408–412

Association of Official Analytical Chemists International Official Methods of Analysis (2008). 18th ed. Method 986.13, Gaithersburg, MD.

Boehringer (1992) Methods of enzymatic food analysis 82/83. Boehringer, Mannheim

Chinnici F, Spinabelli U, Riponi C, Amati A (2005) Optimization of the determination of organic acids and sugars in fruit juices by ion-exclusion liquid chromatography. J Food Compos Anal 18:121–130

Coppola E, English N, Provost J, Smith A, Speroni J (1995) In: Nagy S, Wade RL (eds) Authenticity of cranberry products including non-domestic varieties. In methods to detect adulteration of fruit juice beverages, vol 1. Agscience Auburndale, FL, pp 287–208

Cordella C, Moussa I, Martel AC, Sbirrazzouli N, Lizzani-Cuvelier L (2002) Recent developments in food characterization and adulteration detection: technique-oriented perspectives. J Agric Food Chem 50:1751–1764

Cunha SC, Fernandes JO (2002) HPLC/UV determination of organic acids in fruit juices and nectars. Eur Food Res Technol 214:67–71

Dawson RMC, Elliott DC, Elliott WH, Jones KM (1991) Data for biochemical research. Oxford University Press, Oxford, pp 46–47

Devêvre O, Putra DP, Botton B, Garbaye J (1994) Sensitive and selective method for the separation of organic acids by capillary zone electrophoresis. J Chromatogr A 679:349–357

Ehling S, Cole S (2011) Analysis of organic acids in fruit juices by liquid chromatography-mass spectrometry: an enhanced tool for authenticity testing. J Agric Food Chem 59:2229–2234

Evans RH, van Soestbergen AW, Ristow KA (1983) Evaluation of apple juice authenticity by organic acid analysis. J AOAC Int 66:1517–1520

Fügel R, Carle R, Schieber A (2005) Quality and authenticity control of fruit purées, fruit preparations and jams—a review. Trends Food Sci Technol 16:433–441

Fung YS, Lau KM (2003) Analysis of organic acids and inorganic anions in beverage drinks by capillary electrophoresis. Electrophoresis 24:3224–3232

Gökmen V, Acar J (1998) An investigation on the relationship between parulin and fumaric acid in apple juice concentrates. Lebensm-Wiss Technol 31:480–483

Herrero-Martínez JM, Sanmartin M, Rosés M, Bosch E, Ràfols C (2005) Determination of dissociation constants of flavonoids by capillary electrophoresis. Electrophoresis 26:1886–1895

International Conference on Harmonization (ICH guidelines), Validation of analytical procedures: Text and Methodology 1996 ICH-Q2, Geneva

IUPAC Stability Constants Database, SC-Database and Mini-SCDatabase web http://www.acadsoft.co.uk/scdbase/scdbase.htm

Jandric Z, Roberts D, Rathor MN, Abrahim A, Islam M, Cannavan A (2014) Assessment of fruit juice authenticity using UPLC–QToF MS: a metabolomics approach. Food Chem 148:7–17

Jezek J, Suhaj M (2001) Application of capillary isotachophoresis for fruit juice authentication. J Chromatogr A 916:185–189

Jorgenson JW, Lukacs KD (1981) Zone electrophoresis in open-tubular glass capillaries. Anal Chem 53:1298–1302

Kandl T, Kupina S (1999) An improved capillary electrophoresis procedure for the determination of organic acids in grape juice and wine. Am J Enol Viticult 50:155–161

Kelebek H, Selli S, Canbas A, Cabaroglu T (2009) HPLC determination of organic acids, sugars, phenolic compositions and antioxidant capacity of orange juice and orange wine made from a Turkish cv. Kozan. Microchem J 91:187–192

Kenney BF (1991) Determination of organic acids in food samples by capillary electrophoresis. J Chromatogr A 546:423–430

Kvasnicka F (2005) Capillary electrophoresis in food authenticity. J Sep Sci 28:813–825

Kvasnicka F, Voldrich M (2000) Determination of fumaric acid in apple juice by on-line coupled capillary isotachophoresis–capillary zone electrophoresis with UV detection. J Chromatogr A 891:175–181

Kvasnicka F, Voldrich M, Pys P, Vins I (2002) Determination of Isocitric acid in citrus juice—a comparison of HPLC, enzyme set and capillary isotachophoresis methods. J Food Compos Anal 15:685–691

Lalljie SPD, Vindevogel J, Sandra P (1993) Quantitation of organic acids in sugar refinery juices with capillary zone electrophoresis and indirect UV detection. J Chromatogr A 652:563–569

Markuszewski MJ, Otsuka K, Terabe S, Matsuda K, Nishioka T (2003) Analysis of carboxylic acid metabolites from the tricarboxylic acid cycle in Bacillus subtilis cell extract by capillary electrophoresis using an indirect photometric detection method. J Chromatogr A 1010:113–121

Mato I, Huidobro JF, Simal-Lozano J, Sancho MT (2006) Simultaneous determination of organic acids in beverages by capillary zone electrophoresis. Anal Chim Acta 565:190–197

Mato I, Suárez-Luque S, Huidobro JF (2005) A review of the analytical methods to determine organic acids in grape juices and wines. Food Res Int 38:1175–1188

Mato I, Suárez-Luque S, Huidobro JF (2007) Simple determination of main organic acids in grape juice and wine by using capillary zone electrophoresis with direct UV detection. Food Chem 102:104–112

Passos HM, Cieslarova Z, Simionato AVC (2016) CE-UV for the characterization of passion fruit juices provenance by amino acids profile with the aid of chemometric tools. Electrophoresis 37:1923–1929

Navarro-Pascual-Ahuir M, Lerma-García MJ, Simó-Alfonso EF, Herrero-Martínez JM (2015) Quality control of fruit juices by using organic acids determined by capillary zone electrophoresis with poly(vinyl alcohol)-coated bubble cell capillaries. Food Chem 188:596–603

Ortega C, Lopez R, Cacho J, Ferreira V (2001) Fast analysis of important wine volatile compounds: development and validation of a new method based on gas chromatographic–flame ionisation detection analysis of dichloromethane microextracts. J Chromatogr A 923:205–214

Öztekin N, Erim FB (2001) Simultaneous determination of inorganic anions and organic acids by capillary electrophoresis. Turk J Chem 25:145–150

Saavedra L, García A, Barbas C (2000) Development and validation of a capillary electrophoresis method for direct measurement of isocitric, citric, tartaric and malic acids as adulteration markers in orange juice. J Chromatogr A 881:395–401

Saavedra L, Rupérez FJ, Barbas C (2001) Capillary electrophoresis for evaluating orange juice authenticity: a study on spanish oranges. J Agric Food Chem 49:9–13

Sadecka J, Polonsky J, Simko P, Karasova G (2001) Determination of citric and isocitric acids in fruit juices by capillary isotachophoresis. Eur Food Res Technol 213:161–164

Sanz-Nebot V, Benavente F, Toro I, Barbosa J (2001) Migration behavior of therapeutic peptide hormones: prediction of optimal separation by capillary electrophoresis. Electrophoresis 22:4333–4340

Scherer R, Poloni Rybka AC, Ballus CA, Dillenburg Meinhart A, Teixeira Filho J, Teixeira Godoy H (2012) Validation of a HPLC method for simultaneous determination of main organic acids in fruits and juices. Food Chem 135:150–154

Schwarz M, Rodríguez MC, Guillén DA, Barroso CG (2011) Analytical characterisation of a Brandy de Jerez during its ageing. Eur Food Res Technol 232:813–819

Shui G, Leong LP (2002) Separation and determination of organic acids and phenolic compounds in fruit juices and drinks by high-performance liquid chromatography. J Chromatogr A 977:89–96

Simó C, Barbas C, Cifuentes A (2002) Sensitive micellar electrokinetic chromatography−laser-induced fluorescence method to analyze chiral amino acids in orange juices. J Agric Food Chem 50:5288–5293

Simó C, Martín-Alvarez PJ, Barbas C, Cifuentes A (2004) Application of stepwise discriminant analysis to classify commercial orange juices using chiral micellar electrokinetic chromatography-laser induced fluorescence data of amino acids. Electrophoresis 25:2885–2891

Soga T, Ross GA (1997) Capillary electrophoretic determination of inorganic and organic anions using 2,6-pyridinedicarboxylic acid: effect of electrolyte’s complexing ability. J Chromatogr A 767:223–230

Stój A, Targonski Z (2006) Use of content analysis of selected organic acids for the detection of berry juice adulterations. Pol J Food Nutr Sci 15(56):41–47

Trifirò A, Saccani G, Gherardi S, Vicini E, Spotti E, Previdi MP, Ndagijimana M, Cavalli S, Reschiotto C (1997) Use of ion chromatography for monitoring microbial spoilage in the fruit juice industry. J Chromatogr A 770:243–252

Vandeginste BGM, Massart DL, Buydens LMC, De Jong S, Lewi PJ, Smeyers-Verbeke J (1998). In Data Handling in Science and Technology, Part B; Elsevier Science: Amsterdam. The Netherlands; p 237

Villiers A, Lynen F, Crouch A, Sandra P (2003) A robust capillary electrophoresis method for the determination of organic acids in wines. Eur Food Res Technol 217:535–554

Wiley HW (2014) Beverages and their adulteration: origin, composition, manufacture, natural, artificial, fermented, distilled, alkaloidal and fruit juices. Literary Licensing, LLC

Wu CH, Lo YS, Lee YH, Lin TI (1995) Capillary electrophoretic determination of organic acids with indirect detection. J Chromatogr A 716:291–301

Zhang A, Fang YL, Meng JF, Wanga H, Chen SX, Chen SX (2011) Analysis of low molecular weight organic acids in several complex liquid biological systems via HPLC with switching detection wavelength. J Food Compos Anal 24:449–455

Acknowledgements

This work was supported by project CTQ2014-52765-R (MINECO of Spain and FEDER funds), PROMETEO/2016/145 (Generalitat Valenciana), and Agilent technologies Spain, S.L. The authors also thank to Refresco Iberia, S.A.U, for supplying the fruit juice samples.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

This article does not contain any studies with human or animal subjects.

Conflict of Interest

María Navarro-Pascual-Ahuir declares that she has no conflict of interest. María Jesús Lerma-García declares that she has no conflict of interest. Ernesto F. Simó-Alfonso declares that he has no conflict of interest. José Manuel Herrero-Martínez declares that he has no conflict of interest.

Informed Consent

Not applicable

Rights and permissions

About this article

Cite this article

Navarro-Pascual-Ahuir, M., Lerma-García, M.J., Simó-Alfonso, E.F. et al. Analysis of Aliphatic Organic Acids in Commercial Fruit Juices by Capillary Electrophoresis with Indirect UV Detection: Application to Differentiation of Fruit Juices. Food Anal. Methods 10, 3991–4002 (2017). https://doi.org/10.1007/s12161-017-0963-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-017-0963-6