Abstract

In this study, an improved method of capillary electrophoresis for simultaneous detection of acephate and isocarbophos was developed. The ionic liquids (ILs) of 1-butyl-3-methylimidazolium tetrafluoroborate ([BMIM]BF4) and sodium dodecyl sulfate (SDS) were added as modifiers in the background electrolyte (BGE) for capillary electrophoresis to enhance the separation efficiency of acephate and isocarbophos. The separation conditions in terms of the concentrations of the IL, SDS, and pH were optimized. The limits of detection of the method for acephate and isocarbophos were 0.15 and 0.08 mg/kg. The relative standard deviation (RSD) for five replicates of acephate and isocarbophos solution (5.0 mg/L) was 1.9–3.9%, respectively. To evaluate the accuracy of this method, cucumber, cauliflower, spinach, and carrot samples spiked with acephate and isocarbophos were extracted and analyzed with good recoveries from 76.8 to 88.8%. This method was then verified by gas chromatography method.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

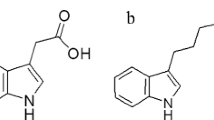

Organophosphorus pesticides are widely applied in agriculture to ensure adequate food yields. However, their extensive use also gives rise to pesticide residues in agricultural products, which have high toxicity, and are harmful to human health (Lozowicka et al. 2015). Therefore, developing a quick and accurate method for the separation and determination of organophosphorus pesticides is of great importance.

In the past decades, many different technologies have been reported for the detection of organophosphorus pesticides, such as gas chromatography with flame photometric detection (GC-FPD) (Salvador et al. 2006; Liu et al. 2014) or nitrogen-phosphorus detection (Tian et al. 2014), gas chromatography coupled with a tandem mass spectrometry (GC-MS) (Chen et al. 2009), high-performance liquid chromatography (HPLC) with an ultraviolet visible detector (Wang et al. 2015) or coupled with tandem mass spectrometry (Mol et al. 2003), biosensors (Zhang et al. 2014), immunoassays (Li et al. 2015), and capillary electrophoresis (CE) with a ultraviolet visible or QD/LIF detector (Zhao et al. 2014; Chen et al. 2010). Among these methods, CE has proven to be an attractive analysis technique for various applications due to its major advantages of high efficiency and resolution, quick analysis, and low consumption of reagents and solvents (Takeda et al. 2002).

With the introduction of micellar electrokinetic chromatography (MEKC) (Muijselaar et al. 1997), the high separation efficiency of CE is now possible for the separation of compounds. The most commonly used surfactant for MEKC is sodium dodecyl sulfate (SDS). However, the nucleus of the SDS micelles are strongly hydrophobic, so for very hydrophobic compounds, MEKC with SDS as solvent is often insufficiently selective as all the compounds tend to be almost completely absorbed into the micelles and migrate with the velocity of the micelles (Yashima et al. 1992). Several methods have been proposed to expand the application range of MEKC to more hydrophobic compounds. A frequently applied procedure is to change the solvent strength of the aqueous phase by the addition of organic modifiers such as methanol (Roy and Lucy 2002), acetonitrile (Seifar et al. 1997), or 2-propanol (Liu et al. 2002) to the background electrolyte (BGE). However, organic solvents are poor conductors of electricity, and high concentrations of organic solvents in the buffer can cause current breakdowns in CE. Moreover, most organic solvents are highly volatile and are harmful to the environment.

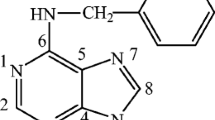

There is great interest in the use of ionic liquids (ILs) as alternatives for conventional molecular solvents. Room temperature ionic liquids are defined as materials containing only ionic species and having a melting point lower than 298 K. They exhibit many interesting properties such as negligible vapor pressure, low melting point, and unique solubility (Mwongela et al. 2003). They have been proposed as solvents in chemical reactions (Wasserscheid et al. 2000), mobile phase additives in liquid chromatography (He et al. 2003; Kaliszan et al. 2004; Xiao et al. 2004), and electrolyte additives in CE (Yanes et al. 2000; Yanes et al. 2001; Vaher et al. 2002a; Kuldvee et al. 2003).

Recently, a great deal of attention has been paid to the use of ILs with CE and much effort has been directed towards understanding separation of compounds with IL-containing BGEs (François et al. 2007). Qin and Li used this technique to weaken the interactions between the analytes and the capillary wall to determine metal or ammonium ions (Qin et al. 2004). ILs have also been used as dynamic wall coatings for aqueous CE (Berthod et al. 2008). Qi et al. (2004) used ILs with BGE to analyze anthraquinones in Chinese herbs; in such a case, the ILs play dual roles: as electroosmotic flow (EOF) modifiers as well as species that associate with the analytes. ILs have also been applied to non-aqueous CE, where dynamic coating of the capillary wall is greatly decreased and/or inexistent (López-Pastor et al. 2008). Vaher et al. (2002b) separated polyphenolic compounds by applying 1-alkyl-3-methylimidazolium-based ILs possessing different counter anions. ILs have also been used as modifiers to improve separations performed through MEKC. Mwongela et al. (2003) employed imidazolium-based ILs in polymeric surfactant systems to analyze both achiral and chiral compounds. The addition of the ILs appears to increase the ionic strength and decrease the EOF, thereby influencing the migration times of the analytes. The ionic liquid 1-butyl-3-methylimidazolium tetrafluoroborate ([BMIM]BF4) was reported to be the most stable and conductive liquid at room temperature and was highly miscible in water (Puntus et al. 2010; Huddleston et al. 2001). Tian et al. (2005) added [BMIM]BF4 as a modifier for separation of lignans by MEKC. The BMIM+ cation appears to modify the SDS micelles and changes the degree of solute partitioning.

In this study, we developed a CE method using [BMIM]BF4 and SDS as modifiers to simultaneously analyze a mixture of acephate and isocarbophos. The separation conditions in terms of the types of ILs, the concentrations of IL and SDS, the applied voltage, background electrolyte types, and the pH are optimized. The applicability and accuracy of this developed method are also evaluated.

Materials and Methods

Materials and Reagents

Analytical standard acephate and isocarbophos (99%) were obtained from the Institute for the Control of Agrochemicals of Ministry of Agriculture (Beijing, China). SDS was purchased from the Peking Xizhong Chemical Factory (Peking, China). The ionic liquids [BMIM] BF4, [BMIM] Cl, and [BMIM]PF6 were purchased from Lanzhou Institute of Chemical Physics (Lanzhou, China). Other chemical reagents were analytical grade. Doubly distilled water (DDW; 18.3 μΩ cm−1) obtained from an Aike ultrapure water instrument (Tangshi Kangning Technology Company, Chengdu, China) was used throughout the experiments.

Cucumber, cauliflower, carrot, and spinach samples were supplied by Taishan Yaxiya Food Co., Ltd. (Tai’an, China), and the long bean samples were purchased randomly from a market in Taian (Shandong, China), in August 2016. Fused-silica capillaries (100 μm i.d. × 375 μm o.d.) were purchased from the Yongnian Optic Fiber Factory (Hebei, China).

Solutions

Buffer solutions with phosphate solution, carbonate solution, acetic acid-sodium acetate, and sodium borate-boric acid were prepared in DDW, and they were filtered through a 0.22-μm filter before use.

Apparatus

The CE experiments were performed on a P/ACE MDQ CE system (Beckman-Coulter, Fullerton, CA, USA) equipped with a PDA detector. Data processing and acquisition were performed using Beckman 32 K software. The separation voltage was set to 25 kV, and detection wavelength was set at 205 nm. Before use, the capillary column was preconditioned with 0.1 mol/L NaOH for 5 min and then DDW for 5 min, followed by the sodium borate-boric acid buffer solution for 10 min until the current was stable. Sample injection was conducted with 0.5 psi for 5 s at the anodic side, unless stated otherwise.

A Shimadzu 2010 gas chromatograph (GC) equipped with a flame photometric detector (Shimadzu, Kyoto, Japan) was used for the separation and determination of acephate and isocarbophos residue in vegetables. The separation was conducted on a RTX-1701 capillary column (30 m × 250 μm i.d. × 0.1-μm film thickness). Nitrogen was used as the carrier gas at a constant flow rate of 1.0 mL min−1. The injection volume was 1.0 μL. The injection port temperature was set at 180 °C at a split mode with a split ratio of 2:1. The detector temperature was held constant at 250 °C. The makeup flow rate was 30.0 mL min−1.

Sample Preparation

To check the accuracy of the developed method, the fortified cucumber, cauliflower, carrot, and spinach samples were prepared, which were determined to be free of acephate and isocarbophos by GC before spiking. Briefly, 5.0 g of cucumber, cauliflower, carrot, or spinach samples were cut into pieces and spiked with 1.0 mL of two mixes of standard solution (2.0 mg/L isocarbophos and 3.0 mg/L acephate, and 4.0 mg/L isocarbophos and 6.0 mg/L acephate). After being incubated for 4 h, the spiked samples were ultrasonically extracted with 3 × 10 mL acetone for 8.0 min. All the organic phases were collected and condensed by a rotary evaporator, and then accurately re-dissolved in 1.0 mL of DDW. Finally, the extractions were filtered using a 0.22-μm filter membrane and the filtrate was injected into the CE for analysis.

To evaluate the applicability of this method, long bean sample randomly purchased from a market was analyzed. The long bean sample (5.0 g) was prepared according to the above process, except for spiking with the standard solutions. Finally, the extraction was filtered using a 0.22-μm filter membrane and the filtrate was then injected into the CE for analysis, and the acephate and isocarbophos levels were calculated.

Gas Chromatography Analysis

To assess the accuracy of this method, the long bean sample was also analyzed by GC according to the method described in GB/T 5009.20–2003 (China). Briefly, 50.0 g of long bean sample was mashed and separately weighed into a 250-mL conical flask. After 100 mL acetone and 50 mL DDW were added, the mixture was extracted by ultrasonication for 20.0 min. After filtration, the resulting extraction was transferred to a 500-mL separatory funnel. When 10 g of sodium chloride was added, the separatory funnel was quickly shaken for 5 min. The aqueous phase was separated again by adding 2 × 50 mL dichloromethane. All the organic phases were collected and condensed by a rotary evaporator, and then accurately re-dissolved in 1.0 mL of chromatography-grade dichloromethane. Finally, the extractions were filtered using a 0.22-μm filter membrane, and 1.0 μL of the filtrate was injected into the GC for analysis.

Statistical Analysis

The difference between the results obtained by CE and GC methods was evaluated using ANOVA (SAS Institute, Cary, NC, USA).

Result and Discussion

Optimization of Electrophoretic Conditions

To achieve good separation for CE, the electrophoretic conditions such as buffer solution composition, buffer pH, and separation voltage were investigated.

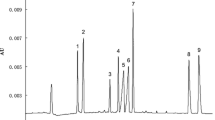

In this study, different buffer solutions including phosphate solution, carbonate solution, acetic acid-sodium acetate, and sodium borate-boric acid were investigated (Fig. 1). The results showed that the acephate and isocarbophos have no CE signal in the phosphate solution system (Fig. 1 (a)). The background noise of CE was very big in the carbonate solution system and the acetic acid sodium acetate system (Fig. 1 (b and c)). However, in the sodium borate-boric acid system, less background noise was observed and a higher CE signal was obtained (Fig. 1 (d)). Therefore, sodium borate-boric acid was chosen as the buffer system.

The pH of the buffer solution had an important influence on the separation by CE. In this study, the pH of the sodium borate-boric acid in the range of 7.6–8.2 was investigated (Fig. 2). The result indicated that the peak area increased with the increasing pH until 8.0, above which the peak area began to decrease. Thus, sodium borate-boric acid at pH 8.0 was selected as the buffer solution for following study.

Separation voltage is an important parameter in a CE system. The effect of separation voltages ranging from 20 to 30 kV was investigated in our study. Although the acephate and isocarbophos could be separated at 20 kV, the analysis time was longer than at 25 and 30 kV. The analysis time decreased with the increasing applied voltage, while the resolution of the analytes reached a maximum at 25 kV. Considering these results, the separation voltage was set to 25 kV.

Effect of Ionic Liquid Types

In order to study the effect of the anionic moiety of the ILs on the separation of the acephate and isocarbophos, the performance of additives [BMIM] PF6, [BMIM] BF4 and [BMIM] Cl were compared (Fig. 3). We found that the addition of [BMIM] PF6 did not improve the separation of acephate and isocarbophos, while the [BMIM] BF4 or [BMIM] Cl had a dramatic effect. The effect of [BMIM] BF4 was better than that of [BMIM]Cl. Therefore, [BMIM] BF4 was selected as the modifier in the next experiments.

Effect of [BMIM] BF4 Concentration

The effect of [BMIM] BF4 concentration (5–30 mmol/L) on the separation efficiency of the acephate and isocarbophos was studied (Fig. 4a). It was found that resolution was greatly improved as the concentration of [BMIM] BF4 increased from 10 to 30 mmol/L. However, the analysis time increased with the increasing concentration of [BMIM] BF4. As shown in Fig. 4b, a larger electropherogram peak was achieved when 10 mmol/L [BMIM] BF4 was added. So, 10 mmol/L [BMIM] BF4 was employed in subsequent experiments.

a Electropherograms of acephate and isocarbophos at the [BMIM]BF4 concentrations of 5 mmol/L (a), 10 mmol/L (b), 20 mmol/L (c), and 30 mmol/L (d). b The peak area of acephate and isocarbophos at the [BMIM]BF4 concentrations of 5 mmol/L (a), 10 mmol/L (b), 20 mmol/L (c), and 30 mmol/L (d). Conditions borate-boric buffer containing 10 mmol/L SDS, pH 8.0

Effect of SDS Concentration

The effect of different addition level of SDS (3–15 mmol/L) on the separation of acephate and isocarbophos was also investigated. Results indicated that the addition of 3 mmol/L SDS did not improve the separation of the acephate and isocarbophos (Fig. 5a), but resolution was greatly improved with a concentration of SDS ranging from 5 to 15 mmol/L. Figure 5b shows that both migration time and resolution increased when the concentration of SDS increased. The analytes could be baseline separated with an SDS concentration ranging from 5 to 15 mmol/L. However, when the SDS concentration was higher than 10 mmol/L, the analysis time increased significantly. Based on above results, a concentration of 10 mmol/L SDS was selected.

a Electropherograms of acephate and isocarbophos at the SDS concentrations of 3 mmol/L (a), 5 mmol/L (b), 10 mmol/L (c), and 15 mmol/L (d). b The migration time and resolution of acephate and isocarbophos at the SDS concentrations of 3 mmol/L (a), 5 mmol/L (b), 10 mmol/L (c), and 15 mmol/L (d). Conditions borate-boric buffer containing 10 mmol/L [BMIM]BF4, pH 8.0

Optimization of Ultrasonic Extraction

To improve sensitivity, we optimized the solvent types used in extraction, ultrasonication power, and extraction time.

The type of solvent used during extraction had a strong effect on the extraction efficiency. In this study, the spiked cucumber was ultrasonically extracted with acetone, acetonitrile, or DDW (Fig. S1A). It was found that the recovery of the spiked cucumber extracted with acetone was greater than that with acetonitrile or DDW. Therefore, acetone was selected as the extraction solvent in the next experiments.

Different ultrasonication power (200–500 W) was also investigated (Fig. S1B). The recovery rates of acephate and isocarbophos in spiked cucumber increased quickly as the power of ultrasonic increasing and reached maximum at 500 W. Therefore, 500 W was set as the ultrasonication power in the following experiments.

The extraction time also had an important influence on the extraction efficiency. In this study, different extraction times (0–10 min) were tested (Fig. S1C). We found that the recovery rate of spiked cucumber increased quickly with the extraction time ranging from 0 to 8 min. There was no obvious change when the extraction time was further extended. Therefore, 8.0 min was selected as an extraction time in the further experiments.

Analytical Parameters of the CE Method

The analytical parameters of the presented method for determination of acephate and isocarbophos were evaluated under optimal experimental conditions for a BGE containing 10 mmol/L [BMIM] BF4 and 10 mmol/L SDS. The data are shown in Table 1. The linear equations for the calibration curve were y = 572.98× + 204.91 (R 2 = 0.998) and y = 2098.3× + 234.77 (R 2 = 0.999) for acephate and isocarbophos, respectively. The limit of detection (LOD) (S/N = 3) of the CE method for the acephate and isocarbophos was 0.15 and 0.08 mg/kg, respectively. The relative standard deviation (RSD) of the method for five replicates of acephate and isocarbophos solution (5.0 mg/L) was 1.9–3.9%.

Evaluation of Accuracy and Applicability

To evaluate the accuracy of the CE method, the cucumber, cauliflower, carrot, and spinach samples spiked with 1.0 mL of a mixed standard solution containing 2.0 mg/L isocarbophos and 3.0 mg/L acephate, and 4.0 mg/L isocarbophos and 6.0 mg/L acephate, were extracted and analyzed by this developed method. For each solution, triple measurements were performed. The analytical data are shown in Table 2. Good recoveries ranging from 76.8 to 88.8% were achieved.

In order to evaluate the practical application of the CE method, the acephate and isocarbophos residues in the long bean sample were detected. The isocarbophos was detected at level of 1.08 ± 0.04 mg/kg. No acephate was found in long bean sample. The accuracy of the CE method was validated by comparative analysis of the long bean sample with GC. Similarly, the results of GC showed 1.06 ± 0.04 mg/kg of isocarbophos and no acephate in long bean sample. There was no significant difference (P > 0.05) between the results obtained by the two methods. Above results also indicated that this CE method has high accuracy and precision, and can be used to analyze acephate and isocarbophos in primary production samples.

Interference Study

Potential interference was investigated using ions and organic matter commonly present in vegetables (Table 3). The tolerable limit for an interfering species was set at a relative error of less than ±5%. Using the CE method developed in this study, the tolerable concentration ratios with respect to a mixed standard solution of 5 mg/L acephate and 5 mg/L isocarbophos for interferences were over 1000 for K+, Cl−, and NO3 −; over 500 for glucose, sucrose, Zn2+, and SO4 2−; and over 200 for Ca2+, Na+, and Ba2+. These results showed that there was no significant interference effect with the method.

Conclusion

In this study, a novel CE method for simultaneous detection of acephate and isocarbophos was developed. With high separation efficiency and satisfactory accuracy, this method has potential to be used as a promising tool for separation and determination of acephate and isocarbophos in vegetables.

References

Berthod A, Ruiz-Ángel MJ, Carda-Broch S (2008) Ionic liquids in separation techniques. J Chromatogr A 1184(1–2):6–18

Chen Q, Fung Y (2010) Capillary electrophoresis with immobilized quantum dot fluorescence detection for rapid determination of organophosphorus pesticides in vegetables. Electrophoresis 31(18):3107–3114

Chen H, Chen R, Feng R, Li S (2009) Simultaneous analysis of carbamate and organophosphorus pesticides in water by single-drop microextraction coupled with GC–MS. Chromatographia 70(1):165–172

François Y, Varenne A, Juillerat E, Servais AC, Chiap P, Gareil P (2007) Nonaqueous capillary electrophoretic behavior of 2-aryl propionic acids in the presence of an achiral ionic liquid-a chemometric approach. J Chromatogr A 1138(1–2):268–275

He L, Zhang W, Zhao L, Liu X, Jiang S (2003) Effect of 1-alkyl-3-methylimidazolium-based ionic liquids as the eluent on the separation of ephedrines by liquid chromatography. J Chromatogr A 1007(1):39–45

Huddleston JG, Visser AE, Reichert WM, Willauer HD, Broker GA, Rogers RD (2001) Characterization and comparison of hydrophilic and hydrophobic room temperature ionic liquids incorporating the imidazolium cation. Green Chem 3(4):156–164

Kaliszan R, Marszałł MP, Markuszewski MJ, Baczek T, Pernak J (2004) Suppression of deleterious effects of free silanols in liquid chromatography by imidazolium tetrafluoroborate ionic liquids. J Chromatogr A 1030(1–2):263–271

Kuldvee R, Vaher M, Koel M, Kaljurand M (2003) Heteroconjugation-based capillary electrophoretic separation of phenolic compounds in acetonitrile and propylene carbonate. Electrophoresis 24(10):1627–1634

Li Y, Zhao F, Zhao L, Yang Z (2015) Development of a broad-specificity immunoassay for determination of organophosphorus pesticides using dual-generic hapten antigens. Food Anal Method 8(2):420–427

Liu S, Tian X, Chen X, Hu Z (2002) Micellar electrokinetic capillary chromatographic separation of diastereoisomers of podophyllum lignans at the c4 position. Chromatographia 56(11):687–691

Liu HM, Kong WJ, Qi Y, Gong B, Miao Q, Wei JH, Yang MH (2014) Streamlined pretreatment and GC–FPD analysis of multi-pesticide residues in perennial Morinda roots: a tropical or subtropical plant. Chemosphere 95:33–40

Lópezpastor M, Simonet BM, Lendl B, Valcárcel M (2008) Ionic liquids and CE combination. Electrophoresis 29(1):94–107

Lozowicka B, Abzeitova E, Sagitov A, Kaczynski P, Toleubayev K, Li A (2015) Studies of pesticide residues in tomatoes and cucumbers from Kazakhstan and the associated health risks. Environ Monit Assess 187(10):1–19

Mol H, Dam RV, Steijger OM (2003) Determination of polar organophosphorus pesticides in vegetables and fruits using liquid chromatography with tandem mass spectrometry: selection of extraction solvent. J Chromatogr A 1015:119–127

Muijselaar PG, Otsuka K, Terabe S (1997) Micelles as pseudo-stationary phases in micellar electrokinetic chromatography. J Chromatogr A 780(1–2):41–61

Mwongela SM, Numan A, Gill NL, Agbaria RA, Warner IM (2003) Separation of achiral and chiral analytes using polymeric surfactants with ionic liquids as modifiers in micellar electrokinetic chromatography. Anal Chem 75(22):6089–6096

Puntus LN, Pekareva IS, Lyssenko KA, Shaplov AS, Lozinskaya EI, Zdvizhkov AT, Vygodskii YS (2010) Influence of ionic liquid anion nature on the properties of Eu-containing luminescent materials. Opt Mater 32(6):707–710

Qi S, Cui S, Chen X, Hu Z (2004) Rapid and sensitive determination of anthraquinones in chinese herb using 1-butyl-3-methylimidazolium-based ionic liquid with beta-cyclodextrin as modifier in capillary zone electrophoresis. J Chromatogr A 1059(1–2):191–198

Qin W, Li SFY (2004) Determination of ammonium and metal ions by capillary electrophoresis-potential gradient detection using ionic liquid as background electrolyte and covalent coating reagent. J Chromatogr A 1048(2):253–256

Roy KI, Lucy CA (2002) Dielectric friction as a mechanism for selectivity alteration in capillary electrophoresis using acetonitrile-water media. Electrophoresis 23(3):383–392

Salvador IM, Frenich AG, González FJE, Vidal JLM (2006) Determination of organophosphorus pesticides in vegetables by GC with pulsed flame-photometric detection, and confirmation by MS. Chromatographia 64(11):667–672

Seifar RM, JCK, Kok WT (1997) Mechanism of electrokinetic separations of hydrophobic compounds with sodium dodecyl sulfate in acetonitrile-water mixtures. Anal Chem 69(69):2772–2778

Takeda S, Omura A, Chayama K, Tsuji H, Fukushi K, Yamane M, Terabe S (2003) Separation and on-line concentration of bisphenol A and alkylphenols by micellar electrokinetic chromatography with anionic surfactant. J Chromatogr A 1014(1):103–107

Tian K, Qi SD, Cheng YQ, Chen XG, Hu ZD (2005) Separation and determination of lignans from seeds of schisandra species by micellar electrokinetic capillary chromatography using ionic liquid as modifier. J Chromatogr A 1078(1–2):181–187

Tian F, Liu WJ, Fang HS, An M, Duan SS (2014) Determination of six organophosphorus pesticides in water by single-drop microextraction coupled with GC-NPD. Chromatographia 77:487–492

Vaher M, Koel M, Kaljurand M (2002a) Ionic liquids as electrolytes for nonaqueous capillary electrophoresis. Electrophoresis 23(3):426–430

Vaher M, Koel M, Kaljurand M (2002b) Application of 1-alkyl-3-methylimidazolium-based ionic liquids in non-aqueous capillary electrophoresis. J Chromatogr A 979(1–2):27–32

Wang Q, Zhang X, Xu Z, Gao H (2015) Simultaneous determination of three trace organophosphorus pesticide residues in vegetables using molecularly imprinted solid-phase extraction coupled with high-performance liquid chromatography. Food Anal Method 8(8):2044–2051

Wasserscheid P, Keim W (2000) Ionic liquids—new ‘solutions’ for transition metal catalysis. Angew Chem Int Edit 39(21):3772–3789

Xiao X, Liang Z, Xia L, Jiang S (2004) Ionic liquids as additives in high performance liquid chromatography: analysis of amines and the interaction mechanism of ionic liquids. Anal Chim Acta 519(2):207–211

Yanes EG, Gratz SR, Stalcup AM (2000) Tetraethylammonium tetrafluoroborate: a novel electrolyte with a unique role in the capillary electrophoretic separation of polyphenols found in grape seed extracts. Analyst 125(11):1919–1923

Yanes EG, Gratz SR, Baldwin MJ, Robison SE, Stalcup AM (2001) Capillary electrophoretic application of 1-alkyl-3-methylimidazolium-based ionic liquids. Anal Chem 73(16):3838–3844

Yashima T, Tsuchiya A, Morita O, Terabe S (1992) Separation of closely related large peptides by micellar electrokinetic chromatography with organic modifiers. Anal Chem 64(23):2981–2984

Zhang C, Wang L, Tu Z, Sun X, He Q, Lei Z, Liu X (2014) Organophosphorus pesticides detection using broad-specific single-stranded DNA based fluorescence polarization aptamer assay. Biosens Bioelectron 55:216–219

Zhao T, Gao H, Wang X, Zhang L, Qiao X, Xu Z (2014) Study on a molecularly imprinted solid-phase extraction coupled to capillary electrophoresis method for the determination of trace trichlorfon in vegetables. Food Anal Method 7(6):1159–1165

Acknowledgements

This work was supported by the National Natural Science Foundation of China (project no. 31471649) and Western Economic Uplift and Poverty Alleviation Development Projects of Shandong, China (project no. 49).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Funding

Dr. Zhixiang Xu has received research grants from the National Natural Science Foundation of China and Poverty Alleviation Development Projects of Shandong, China.

Conflict of Interest

Deqing Li declares that he/she has no conflict of interest. Mingdi Jiang declares that he/she has no conflict of interest. Xuguang Qiao declares that he/she has no conflict of interest. Zhixiang Xu declares that he/she has no conflict of interest.

Ethical Approval

This article does not contain any studies with animals performed by any of the authors.

Informed Consent

Informed consent was obtained from all individual participants included in the study.

Additional information

Mingdi Jiang and Deqing Li contributed equally to this work.

Electronic Supplementary Material

ESM 1

(DOCX 27 kb)

Rights and permissions

About this article

Cite this article

Li, D., Jiang, M., Xu, L. et al. Simultaneous Determination of Acephate and Isocarbophos in Vegetables by Capillary Electrophoresis Using Ionic Liquid and Sodium Dodecyl Sulfate as Modifiers. Food Anal. Methods 10, 3368–3374 (2017). https://doi.org/10.1007/s12161-017-0897-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-017-0897-z