Abstract

A novel analytical method employing immunoaffinity column (IAC) clean-up coupled with liquid chromatography-tandem mass spectrometry (LC-MS/MS) method was developed for simultaneous determination of ractopamine, chloramphenicol, and zeranols (α-zearalanol, β-zearalanol, zearalanone, α-zearalenol, β-zearalenol, and zearalenone) in animal-originated foods. The sample was first digested by β-glucuronidase/sulfatase and then extracted with ethyl acetate-diethyl ether (9:1, v/v). The extracted solution was evaporated to dryness and then the residue was dissolved by 2 mL of 50% acetonitrile solution. After filtration, 1 mL filtrate was diluted to 10 mL with PBS. The reconstituted solution was cleaned up with immunoaffinity column and then analyzed by high performance liquid chromatography-tandem mass spectrometry (LC-MS/MS). The established method was shown to be sensitive efficient and reliable as indicated by the linearity (r 2 ≥ 0.9994), precision (RSD ≤ 1.7%), average recovery (72.3–103.2%), and the limit of detection (0.05–0.10 μg/kg). The method can be used for determination of trace residues of ractopamine, chloramphenicol, and zeranols in animal-originated foods.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Ractopamine is a phenolethanolamine β-adrenoceptor agonist, which was mainly developed for the treatment of asthma in human. The previous studies have shown that ractopamine is an exogenous substance that alters the manner in which nutrients are directed toward fat deposits and muscle accretion (Spurlock ME et al. 1994). Chloramphenicol (CAP) is a broad-spectrum antibiotic, exhibiting activity against a variety of aerobic and anaerobic micro-organisms (Allen, 1984). Zearalenone (ZON), widely used as a growth stimulant in food-producing animals, is produced by a variety of fusarium fungi (Dusi G et al. 2009). ZON can be rapidly metabolized into relative toxins (α-zearalanol (α-ZAL), β-zearalanol (β-ZAL), zearalanone (ZAN), α-zearalenol (α-ZOL), and β-zearalenol (β-ZOL)) after being absorbed through the small intestine and its metabolites (zeranols) can conjugate with glucuronic acid in the body (Schaut A et al. 2008).

The illegal addition of these drugs as growth promoters in animals could result in residues in animal tissues (liver, kidney, muscle, and milk) and lead to risk for consumer safety. Ractopamine has side effects such as nausea, vomiting, muscle tremor, palpitation, trembling, headaches, and other symptoms, especially for patients suffering from diseases as hypertension, heart disease, and hyperthyroidism. CAP may cause serious adverse effects such as reversible bone marrow depression or aplastic anemia with pancytopenia, cellular bone marrow, irreversible aplastic anemia, and optic neuropathy (Hutchison HE et al. 1962; Wong S et al. 2013) and zeranols have acute and chronic toxicity, such as genotoxicity and reproductive and immunotoxicity (Marin DE et al. 2010; Zinedine A et al. 2007). In spite of these risks, these drugs are still illicitly used in livestock production because of the economic advantages. For those substances, a “zero tolerance residue limit” has been established in edible tissues, feeds, and drinking water in the USA and China (Ministry of Agriculture, No. 235; U.S. Food and Drug Administration, Section 512). In order to provide quality assurance for the consumers and to satisfy legal testing obligations, the ability to detect these illicit drug residues at low concentrations has become a very important issue.

At present, different methods have been developed for the detection of RAP, CAP, and zeranols separately, including enzyme-linked immunosorbent assay (ELISA) (Pleadin J et al. 2012; Minervini F et al. 2010; Beloglazova NV et al. 2012), gold immunochromatography assay (GICA) (Zhang et al. 2009), high performance liquid chromatography (HPLC) (QU et al. 2011; YOU et al. 2012; Urraca JL et al. 2004), liquid chromatography (LC), and gas chromatography (GC) coupled with mass spectrometry (MS) (HE et al. 2007; Akhtar MH et al. 1995; Dickson LC et al. 2009; Ashwin HM et al. 2005). Because of its high sensitivity and selectivity, liquid chromatography-tandem mass spectrometry (LC-MS/MS) is often the method of choice in the analysis of trace levels of polar contaminants (Nielen MWF et al. 2007).

Immunoaffinity column (IAC) allowing the highly selective isolation of the analyte from a complex matrix is preferred in terms of precision, concentrating, and efficient sample clean-up for residue analysis (Zhang et al. 2013). IACs need less solvent and take less time than the conventional SPE or LLE methods because they are based on the specific interaction of antigen and antibody immobilized on an appropriate support material (Tsikas D 2010).

Our laboratory has developed methodologies for the determination of sulfonamide (Yuan et al. 2013) and zeranols (You et al. 2012) cleaned by IAC. However, these immunoaffinity columns are only suitable for the same kind of mycotoxin. Compared to the previous researches, this study adopted a new kind of immunoaffinity column developed by our research group. The aim was to provide data about the co-occurrence of multiple mycotoxins in the same sample, specifically, ractopamine, chloramphenicol, and zeranols in animal-originated foods, taking advantage of the capabilities of immunoaffinity column combined with HPLC-MS/MS analysis method, which led to a better purification effect and lower limits.

Material and Methods

Chemicals and Reagents

Ractopamine (RAP, purity ≥ 97%) and chloramphenicol (CAP, purity ≥ 98.5%) were purchased from Dr. Ehrenstorfer GmbH (Augsburg, Germany). Zearalanone, α-zearalanol, β-zearalanol, zearalenone (ZON), α-zearalenol (α-ZOL), and β-zearalenol were purchased from Sigma-Aldrich (St. Louis, MO, USA, purities ≥ 98.0%). The β-glucuronidase/sulfatase was purchased from Sigma-Aldrich (St. Louis, MO, USA).

Ethyl acetate, diethyl ether, tert-butyl methyl ether, acetonitrile, and methanol (HPLC grade) were purchased from Tedia (Fairfield, OH, USA). Ultrapure water was produced by a Milli-Q system (Millipore Corporation, USA). Ammonium hydroxide was supplied by ROE (Newark, DE, USA). Sodium hydroxide, anhydrous sodium acetate, hydrous disodium hydrogen phosphate, potassium chloride, potassium phosphate dibasic, acetic acid, and other chemicals or solvents were of HPLC or analytical grade.

Standard Solutions

RAP, CAP, ZON, α-ZOL, β-ZOL, ZAN, α-ZAL, and β-ZAL stock solutions were individually prepared by dissolving the weighed compound in methanol at final concentration of 1 mg/mL in glass vials. Mixed working standard solution was prepared by diluting individual stock solutions to obtain a solution at concentrations of 50 μg/mL for RAP and CAP, 100 μg/mL for zeranols, and then diluted with 25% acetonitrile solution to a final concentration (0.05, 0.25, 0.5, 1.0, 2.5, 10.0, 25.0 μg/L for RAP and CAP; 0.1, 0.5, 1.0, 2.0, 5.0, 20.0, 50.0 μg/L for zeranols). All standard solutions were stored at −20 °C.

Phosphate buffer solution (PBS, pH 7.4) was prepared by dissolving 8.00 g of sodium chloride, 0.20 g of potassium chloride, 2.90 g of disodium hydrogen phosphate, and 0.24 g of potassium dihydrogen phosphate in 900 mL of water and adjusting to pH 7.4 with 1.0 mol/L sodium hydroxide. Finally, the solution was diluted to the volume.

0.05 M sodium acetate buffer (pH 4.8) was prepared by dissolving 6.80 g of sodium acetate in 900 mL ultrapure water, adjusting pH to 4.8 with acetic acid, and finally being diluted to the volume.

Apparatus

LC-20 high performance liquid chromatography (Shimadzu, Japan)-API4000 tandem mass spectrometer (AB corporation, USA); XH-B vortex mixer (Jiangsu healthcare medical supplies Co., LTD.); 3–30 K refrigerated centrifuge (German, Sigma company); ZHWY-2112B constant temperature culture oscillator (Shanghai Zhicheng analytical instrument manufacturing Co., LTD.); N-EVAP116 nitrogen dry instrument (Organomation Associates, USA); and rotary vacuum evaporators (4011 Digital) was obtained from Heidolph Company (Germany). IAC for RAP, CAP, ZON, α-ZOL, β-ZOL, ZAN, α-ZAL, and β-ZAL (IAC-CRZ, 100 ng for each component; volume 3 m; Clover Technology Group Inc., Beijing, China) was used for sample purification and stored at 4 °C.

Sample

Samples of pork, fish, milk, and liver bought from the supermarkets in Chongqing, China, were used in the experiments. The samples were fully homogenized and stored at −18 °C.

LC-MS/MS Conditions

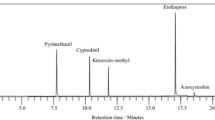

For the HPLC system, chromatographic separation was achieved on a Shimadazu Shim pack VP-ODS column (150 × 2.0 mm, 5 μm). The mobile phase and a gradient elution program are shown in Table 1. The flow rate was kept at 0.3 mL/min, and the column temperature was maintained at 40 °C.

For the mass spectrometric analysis, a mass spectrometer equipped with the manufacturer’s electrospray ionization (ESI) source, operated in positive mode (RAP) or negative mode (CAP and ZERS), was applied in multiple reaction monitoring (MRM) mode. The total online HPLC-MS/MS analysis time per sample was 15 and 8 min. Some MS/MS conditions are shown in Table 1. Mass spectrum parameters of all compounds are shown in Table 2.

Sample Preparation

The homogenized test sample (pork, fish, milk, liver) of 2.0 g was accurately weighed and put into a 50-mL centrifuge tube, 10 mL of sodium acetate buffer and 30 μL of β-glucuronidase/sulfatase were added, and the substances were mixed for 1 min with a vortex mixer. The mixture was incubated for 16 h at 37 °C. After cooling to room temperature, 15 mL ethyl acetate-diethyl ether (9:1, v/v) was added. The sample was extracted for 15 min by oscillator, and then centrifuged at 7500 r/min for 5 min. The supernatant was transferred to another 50-mL centrifuge tube. The sample was extracted with 15 mL ammonium hydroxide-ethyl acetate-diethyl ether (0.2:9:1, v/v/v) again, and the supernatant was combined. After centrifugation at 7500 r/min for 8 min, the supernatant was transferred into a 100-mL-round-bottomed flask. The extract was concentrated to almost dryness on rotary vacuum evaporator at 39 °C, and the residues were dissolved with 5 mL methanol, then all the solution were collected in a 10-mL cuvette and evaporated to dryness in a 40 °C water bath under a gentle flow of nitrogen. The residue was dissolved by 2 mL of 50% acetonitrile solution and filtrated, and 1 mL filtrated solution was diluted to 10 mL with PBS to be purified.

Clean-up Procedure

The diluted solution was loaded onto the IAC-CRZ column at a rate of about 1 drop/s until the air came through the column. The column was washed by 5 mL PBS and 5 mL ultrapure water at a rate of about 1–2 drops/s. Then the analytes were eluted with anhydrous ethanol (3 mL) at a rate of 1 drop/s. When the eluting solvent passed through, the column was suctioned to dryness. The eluted analytes were collected in a 10-mL cuvette and evaporated to dryness in a 40 °C water bath under a gentle flow of nitrogen, and the residue was reconstituted in 1 mL 25% acetonitrile solution. The final purification was filtered through a 0.22-μm nylon membrane filter and analyzed by HPLC-MS/MS.

Results and Discussion

Optimization of HPLC-MS/MS

The HPLC-MS/MS with ESI source and MRM mode provided a highly selective and sensitive method. According to the chemical structure characteristics of the target, most of the compounds contained carbonyl and fitted in ESI+ mode form [M + H]+ ions, the few compounds estrogen due to containing phenol hydroxyl suitable for ESI− mode form [M−H]− ions. In the corresponding ion mode, direct injection standard solution (1 mg/L) and determine [M + H]+ or [M−H]− molecular ion by the primary mass spectrometry, then fragment ions information was obtained by the secondary mass spectrometry. Two characteristic ions of maximum sensitivity were selected as the quantification and identification ions to optimize the MS/MS parameters.

The commonly used mobile-phase compositions such as acetonitrile/water and methanol/water were optimized. The results showed that acetonitrile/2 mmol/L ammonium acetate containing 0.2% formic acid was suitable for ESI+ and ESI− mode. Some MS/MS conditions are shown in Table 1. The mass spectrum parameters of all compounds are shown in Table 2. Under the optimal operating conditions of HPLC-MS/MS, all analytes were eluted within the 13- and 8-min analysis time.

Optimization of Extraction Solvent

Theoretically, the pH of the extraction solvent should be two units higher than that of the pKa of the analytes to ensure that the analytes were all completely neutral and could be effectively extracted by the extraction solvent. CAP (pKa = 9.61) and RAP (pKa = 9.40) are both easy to resolve in an acidic solution. For zeranols, a similar group is present for all of them, which have pKa values above 7.42, and are more easily to be extracted by organic phase under neutral and weak alkaline condition. In order to improve the recoveries of the analytes, different solvents and solvent combinations such as acetonitrile, ethyl acetate, diethyl ether, tert-butyl methyl ether, ethyl acetate—ethanol (8:2 v/v), ethyl acetate-diethyl ether (8:2 v/v), and ethyl acetate-diethyl ether (9:1 v/v) were evaluated.

As Fig. 1 shows, using ethyl acetate-diethyl ether mixture gave better results than that of either solvent alone in terms of minimizing interference peaks on liquid chromatography or ethyl acetate-diethyl ether (9:1 v/v) could provide, satisfactory recoveries, and reproducibilities. Finally, this mixture was chosen as the extraction solvent. The recovery rates of RAP, CAP, and zeranols were satisfactory by adjusting the pH value of the aqueous phase and using a two-step extraction.

Development of the Elution Solution

The strength of the binding to the antigen is important as binding strength will influence recovery during the extraction stage. Finally, the analytes are eluted from the IAC by breaking the antibody-antigen bond. This study investigated methanol, acetonitrile, and anhydrous ethanol as the elution solutions. A sample of 0.5 mL 1 μg/kg mixed standard was diluted to 10 mL with PBS and loaded onto the IAC-CRZ column. After that, the analytes were eluted with 6 mL of methanol, acetonitrile, and anhydrous ethanol at a rate of 1 drop/s, respectively. The results (Fig. 2) showed that when using anhydrous ethanol as the elution solution, the average recovery rate of the eight target analytes was ≥94.1%.

The volume of elution solution was also investigated. The eluted solution was recollected at a 0.5-mL interval from 1 to 4 mL and determined by HPLC-MS/MS. It was demonstrated that the elution rates were improved as the volume of the eluent increased, i.e., anhydrous ethanol increased and reached its maximum when the volume was 3 mL. So, 3 mL anhydrous ethanol was selected as the eluent.

IAC-CRZ Regeneration

Regeneration of the IAC-CRZ column was investigated. Six IAC-CRZ columns were tested with standard, solution mixture of RAP, CAP, and ZERs at 10 μg/kg. In each experiment, after being eluted with 3 mL anhydrous ethanol, the columns were washed with 20 mL ultrapure water and then followed by 10 mL PBS. After the last 2 mL, PBS permeated the columns and the ends of the IAC-CRZs were sealed. The columns were used again after storage at 4 °C in a refrigerator for 24 h. As the recoveries showed, the capacities of the IAC-CRZ column for the eight substances were gradually declined. It was thought to be sufficient for the determination of residues when the capacity of the column was more than 70% of the maximum. So, the column could be recycled three times at least.

Method Validation

Calibration curves were obtained in a range of 0.1–50 μg/kg (0.05–25 μg/kg for RAP and CAP). The coefficient of correlation (r 2) was above 0.999 for all of the analytes. Each target analyst present in the samples was quantified by comparing its peak area to that of corresponding standard, as shown in Table 3. The limits of detection (LOD) and quantification (LOQ) were estimated at the lowest concentration in spiked samples corresponding to a signal-to-noise ratio (S/N) of 3:1 and 10:1, respectively. Detailed summary of the calibration curves, LODs, and LOQs is provided in Table 3.

In this study, matrix-matched calibration curves was performed at seven concentration levels (0.05, 0.25, 0.5, 1.0, 2.5, 10.0, 25.0 μg/L for RAP and CAP; 0.1, 0.5, 1.0, 2.0, 5.0, 20.0, 50.0 μg/L for zeranols) by spiking the extracts obtained from blank sample. Corresponding, standard calibration samples were obtained by diluting the appropriate volume of stock standard solutions with 25% acetonitrile solution.

As shown in Table 3, the matrix effects of the same material are different in four kinds of matrices, for the material ingredients of each matrix are not the same. SSEs were in the range of 98.3–111.5%; the linearities of matrix-matched calibration curves (r 2 ≥ 0.9987) and solvent standard calibration curves (r 2 ≥ 0.9992) were satisfactory. Moreover, the chromatograms for blank matrix and spiked sample did not contain any interfering peak (taking CAP and α-ZOL for example, Fig. 3). Based on the experimental results, the matrix effects were conspicuously eliminated after the sample solution was cleaned up by the IAC-CRZ column. Besides, external calibration curve could guarantee a reliable and accuracy quantization.

The recoveries of the method were evaluated by using blank samples (2.0 g) spiked with standard analytes at three concentration levels (0.025, 0.05, 0.25 μg/kg for RAP and CAP; 0.05, 0.1, 0.5 μg/kg for zeranols), each concentration being repeated for six times. The precision expressed as relative standard deviation (RSD%) was determined for each compound from six replicates of spiked samples. As show in Table 4, the average recovery at three spiking levels ranged from 75.6 to 101.1%, and the RSD was 1.2–9.1%, indicating satisfactory precisions and recoveries.

Validation Study for Pork

A real sample survey was conducted to check the effectiveness of the validated method and its feasibility in routine analysis. In order to ensure that the proposed method could be used for the determination of ractopamine, chloramphenicol, and zeranols in real samples, 15 commercial feed samples for growing-finishing pigs were collected from the market and detected. The results showed that all samples were negative, which are the same as those detected at the same time with other published methods for single drug in feeds.

Conclusions

In this study, a HPLC-MS/MS method with IAC clean-up was successfully developed to simultaneously detect ractopamine, chloramphenicol, and zeranols in animal-originated foods. The established method holds the features of good recoveries and high sensitivity. To our knowledge, this is the first report for simultaneous determination and purification of ractopamine, chloramphenicol, and zeranols with IAC method in animal-derived foods. A novel IAC-CRZ column was applied for the clean-up and concentration of RAP, CAP, and ZERS. It is efficient enough to eliminate matrix effect of the samples and guarantee the high specificity of the determination method. Besides, the IAC-CRZ column can reduce the cost of the analysis and make the clean-up procedure simple. Additionally, the developed method is successfully applied to detect the residue of RAP, CAP, and ZERS in animal-derived food, and it may be applied in other kinds of matrices in the future.

References

Akhtar MH, Danis C, Sauve A, Barry C (1995) Gas chromatographic determination of incurred chloramphenicol residues in eggs following optimal extraction. J Chromatogr A 696(1):123–130

Allen EH (1984) Review of chromatographic methods for chloramphenicol residues in milk, eggs and tissues from food-producing animals. J Assoc Off Anal Chem 68(5):990–999

Ashwin HM, Stead SL, Taylor JC, Startin JR, Richmond SF, Homer V, Bigwood T, Sharman M (2005) Development and validation of screening and confirmatory methods for the detection of chloramphenicol and chloramphenicol glucuronide using SPR biosensor and liquid chromatography–tandem mass spectrometry. Anal Chim Acta 529(1):103–108

Beloglazova NV, Speranskaya ES, De Saeger S, Hens Z, Abe S, Goryacheva IY (2012) Quantum dot based rapid tests for zearalenone detection. Anal Bioanal Chem 403(10):3013–3024

Dickson LC, Costain R, McKenzie D, Fesser AC, Macneil JD (2009) Quantitative screening of stilbenes and zeranol and its related residues and natural precursors in veal liver by gas chromatography-mass spectrometry. J Agric Food Chem 57(15):6536–6542

Dusi G, Bozzoni E, Assini W, Tognoli N, Gasparini M, Ferretti E (2009) Confirmatory method for the determination of resorcylic acid lactones in urine sample using immunoaffinity cleanup and liquid chromatography-tandem mass spectrometry. Anal Chim Acta 637(1):47–54

He L, Su Y, Zeng Z, Liu Y, Huang X (2007) Determination of ractopamine and clenbuterol in feeds by gas chromatography-mass spectrometry. Anim Feed Sci Technol 132(3):316–323

Hutchison HE, Pinkerton PH (1962) Marrow depression due to chloramphenicol. Scott Med J 7(2):96–97

Marin DE, Taranu I, Burlacu R, Tudor DS (2010) Effects of zearalenone and its derivatives on the innate immune response of swine. Toxicon 56(6):956–963

Minervini F, Lacalandra GM, Filannino A, Nicassio M, Visconti A, Dell’Aquila ME (2010) Effects of in vitro exposure to natural levels of zearalenone and its derivatives on chromatin structure stability in equine spermatozoa. Theriogenology 73(3):392–403

Ministry of Agriculture (2002) No. 235. Bulletin of the Ministry of Agriculture of the People’s Republic of China

Nielen MWF, Van Engelen MC, Zuiderent R, Ramaker R (2007) Screening and confirmation criteria for hormone residue analysis using liquid chromatography accurate mass time-of-flight, Fourier transform ion cyclotron resonance and orbitrap mass spectrometry techniques. Anal Chim Acta 586(1):122–129

Pleadin J, Persi N, Milić D, Vahčić N (2012) Determination of residual ractopamine concentrations by enzyme immunoassay in treated pig’s tissues on days after withdrawal. Meat Sci 90(3):755–758

Qu CH, Li XL, Zhang L, Xi CX, Wang GM, Li NB, Luo HQ (2011) Simultaneous determination of cimaterol, salbutamol, terbutaline and ractopamine in feed by SPE coupled to UPLC. Chromatographia 73(3–4):243–249

Schaut A, De Saeger S, Sergent T, Schneider YJ, Larondelle Y, Pussemier L, Van Peteghem C (2008) Study of the gastrointestinal biotransformation of zearalenone in a Caco-2 cell culture system with liquid chromatographic methods. J Appl Toxicol 28(8):966–973

Spurlock ME, Cusumano JC, Ji SQ, Anderson DB, Smith CK, Hancock DL, Mills SE (1994) The effect of ractopamine on β-adrenoceptor density and affinity in porcine adipose and skeletal muscle tissue. J Anim Sci 72(1):75–82

Tsikas D (2010) Quantitative analysis of biomarkers, drugs and toxins in biological samples by immunoaffinity chromatography coupled to mass spectrometry or tandem mass spectrometry: a focused review of recent applications. J Chromatogr B 878(2):133–148

U.S. Food and Drug Administration (1999) Federal Food, Drug and Cosmetic Act (FFDCA), Section 512, 22 December 1999, FDA, Washington, DC

Urraca JL, Marazuela MD, Moreno-Bondi MC (2004) Analysis for zearalenone and α-zearalenol in cereals and swine feed using accelerated solvent extraction and liquid chromatography with fluorescence detection. Anal Chim Acta 524(1):175–183

Wong S, Silva F, Acheson J, Plant G (2013) An old friend revisited: chloramphenicol optic neuropathy. JRSM short reports 4(3):20

You LN, Li XL, Xi CX, Tang BB, Wang GM, Zhang L, Yuan ZZ, Zhao H (2012) Simultaneous determination of residues of six zeranols in eggs by high performance liquid chromatography with immunoaffinity cleanup column. Chin J Chromatogr 30(10):1021–1025

Yuan ZZ, Zhang L, Tang BB, Xi CX, Wang GM, You LN, Zhao H (2013) Determination of 16 sulfonamide residues in animal-originated foods by high performance liquid chromatography with immunoaffinity column. J Instrum Anal 32(3):478–482

Zhang MZ, Wang MZ, Chen ZL, Fang JH, Fang MM, Liu J, Yu XP (2009) Development of a colloidal gold based lateral flow immunoassay for the rapid simultaneous detection of clenbuterol and ractopamine in swine urine. Anal Bioanal Chem 395(8):2591

Zhang QJ, Peng T, Chen DD, Xie J, Wang X, Wang GM, Nie CM (2013) Determination of chloramphenicol residuces in aquatic products using immunoaffinity column cleanup and high performance liquid chromatography with ultraviolet detection. J AOAC Int 96(4):897–901

Zinedine A, Soriano JM, Molto JC, Manes J (2007) Review on the toxicity, occurrence, metabolism, detoxification, regulations and intake of zearalenone: an oestrogenic mycotoxin. Food Chem Toxicol 45(1):1–18

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Xue Sun declares that she has no conflict of interest. Qiang Tang declares that he has no conflict of interest. Xiaoli Du declares that she has no conflict of interest. Cunxian Xi declares that he has no conflict of interest. Bobin Tang declares that he has no conflict of interest. Guomin Wang declares that he has no conflict of interest. Hua Zhao declares that he has no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed Consent

Not applicable

Rights and permissions

About this article

Cite this article

Sun, X., Tang, Q., Du, X. et al. Simultaneous Determination of Ractopamine, Chloramphenicol, and Zeranols in Animal-Originated Foods by LC-MS/MS Analysis with Immunoaffinity Clean-up Column. Food Anal. Methods 10, 3239–3246 (2017). https://doi.org/10.1007/s12161-017-0858-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-017-0858-6