Abstract

The phenolic acids exhibit significant antioxidant, antiinflammatory, antimutation, and tyrosinase inhibitory effects. A high efficient and specific method for separation of phenolic acids from the sugarcane rinds based on pH-zone-refining counter-current chromatography technique was established. The separation was performed with a solvent system of methyl tert-butyl ether/acetonitrile/water at a volume ratio of 4:1:5, where 5 mM trifluoroacetic acid was added to the upper phase as a retainer and 3 mM NH4OH was added to the lower phase as an eluter. As a result, three phenolic acids including 4.8 mg of caffeic acid, 12.9 mg of ferulic acid, and 65.2 mg of p-coumaric acid were successfully purified in one run from 1.00 g crude extract with the purities of 93.4, 94.6, and 98.8%, respectively. 2,2-Diphenyl-1-picrylhydrazyl radical and total antioxidant capacity assay were used to evaluate antioxidant activities. The separated individual phenolic acid had higher antioxidant activity than their mixture. Caffeic acid showed the greatest antioxidant activity, followed by ferulic acid and p-coumaric acid.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Sugarcane (Saccharum officinarum L.) is a principal raw material for the sugar industry, and cane sugar is 70% of the world’s sugars (Abbas et al. 2014). Planting area of sugarcane increased rapidly in the global harvest. A significant amount of residues including waste rinds and bagasses derive from the processing and harvesting of sugarcane (Attard et al. 2015). Sugarcane rinds which are generated in large quantities as waste by-product of the sugar industry or ethanol production are approximately 20% weight of sugarcanes (Feng et al. 2015). Previous studies have shown that sugarcane contained a lot of functional compounds, such as phenolic acids. Waste sugarcane rinds also contain many phenolic acids and could be used as a good source of phenolic acids (Duarte-Almeida et al. 2011).

Phenolic acids as antioxidants have been reported to possess potential protective effect against oxidative damage diseases, such as cancers, stroke, and coronary heart disease (Kukula-Koch et al. 2016; Wen et al. 2012). These properties of phenolic acids were exploited for cosmetics, pharmaceuticals, and functional foods. The utility of synthetic antioxidants in food industry is severely restricted due to potential safety concerns. Thus, natural phenolic antioxidants are particularly important. This is the reason why more and more attention is being paid to natural antioxidant extracts (Valls et al. 2009). A number of studies indicated that different phenolic acids have different antioxidant activities because of their different structural features and molecular sequence (Ignat et al. 2011). Many of the phenolic acids have concentration-dependent antioxidant activities (Maurya and Devasagayam 2010). Therefore, it is necessary to separate individual phenolic acid from natural sources in function research and exploitation of phenolic acids.

Sugarcane rinds, as the major resources of natural antioxidants, contain many antioxidant phenolic acids. Ultrasonic-assisted method has been widely adopted for extracting phenolic acids from sugarcane rinds (Feng et al. 2015). However, individual phenolic acid could not be obtained by this method. In addition, it is hard to obtain highly purified phenolic acids from natural sources. Ferulic acid was separated from corn bran by membrane separation with the purity of 84.45% (Zhao et al. 2014). Thus, developing a rapid and efficient separation method to obtain phenolic acids with high purities is essential.

High-speed counter-current chromatography (HSCCC), as a multitarget purification tool, has been used in the separation and purification of different constituents from complex mixtures with high recovery and efficiency as well as elimination of irreversible adsorption of samples (Liang et al. 2015; Wei et al. 2009). In the case of ionizable molecules like organic acids and bases, a pH-zone-refining mode HSCCC technology can provide ideal separation. The pH-zone-refining counter-current chromatography (CCC) is a highly efficient and peculiar method for the purification of ionizable compounds. In pH-zone-refining CCC, the pKa values and hydrophobicity of ionizable compounds decide the isolation sequence. The distinct features over conventional HSCCC are high concentration of fractions and a tenfold amount in sample loading capacity. Besides, pH-zone-refining CCC provides another way to monitor the isolation by their pH values of the effluents when no chromophores are present (Ito 2013; Sun et al. 2016). Therefore, in recent decades, pH-zone-refining CCC has been successfully applied in the separation of various kinds of natural products (Li et al. 2016; Wang et al. 2007; Weisz et al. 2007; Weisz et al. 2011). Conventional methods, such as column chromatography and preparative reversed-phase liquid chromatography, are tedious, time-consuming, and solvent wasting (Xi et al. 2015). They also cause irreversible adsorption of samples onto the solid phase, which leads to the loss of activity due to the dilution effects or decomposition of the active components, especially antioxidants (Shi et al. 2012). Up to now, there was no report on the separation of phenolic acids from sugarcane rinds by pH-zone-refining CCC. Hence, it is an optimal choice to utilizing pH-zone-refining CCC to separate phenolic acids from sugarcane rinds with high purities on a large scale.

In addition, antioxidant activities of the separated phenolic acids from sugarcane rinds were evaluated in vitro by 2,2-diphenyl-1-picrylhydrazyl (DPPH) radical scavenging and total antioxidant capacity assays in order to compare their antioxidant activities.

A rapid and efficient method of sugarcane rinds using pH-zone-refining CCC has been established, and three phenolic acids were well obtained with high purity. The established feasible method is promising and practical for the utility of sugarcane rinds.

Materials and Methods

Apparatus

pH-zone-refining CCC instrument was a Model GS20A multilayer coil planet centrifuge (Beijing Institute of New Technology Application, Beijing, China) equipped with a polytetrafluoroethylene multilayer coil of 70 m × 0.85 mm ID with a total capacity of 40 mL. The β values of the coil varied from 0.4 at the internal terminal to 0.7 at the external terminal (β = r/R, where r is the distance from the holder shaft to the coil and R is the distance between the holder axis and central axis of the planet centrifuge or the rotation radius). The revolution speed was monitored with 1600 rpm. Column was filled with solvent by using pump of invariable flow (Model NS-1007) equipped by Beijing Institute of New Technology Application. The continuous monitoring of the effluent was achieved with a Model 8823A-UV monitor (Beijing Institute of New Technology Application) operating at 254 nm and a Model 330 pH meter (ATI Orion Research, Boston, MA, USA). A manual sample injection valve with 10-mL loop was used to introduce the sample into the column. Chromatograms have been plotted in consistence of two portable recorders (Yokogama Model 3057) from Sichuan Instrument Factory, Chongqing, China. The analytical high-performance liquid chromatography (Shimadzu LC-20AVP) was fitted with two LC-20AT pumps, photodiode-array detection system (SPD-M20AVP UV/Vis), an SCL-20AVP system controller, a workstation of Class-VP-LC (Shimadzu, Kyoto, Japan), and an autosampler. An SP-720 UV-vis spectrophotometer (Shanghai Spectrum Instruments Co., Ltd., Shanghai, China) was used to determine the absorbance.

Chemicals and Reagents

All of analytical grade organic solvents were used for pH-zone-refining CCC from Tianjin DaMao Chemical Reagent Factory (Tianjin, China). Ammonia hydroxide, trifluoroacetic acid (TFA) (J&K Chemical, Beijing, China), and phosphoric acid (Beijing Chemical Factory, Beijing, China) were of reagent grade. Methanol was chromatographic grade and purchased from J&K Chemical (Beijing, China), and DPPH free radical was purchased from Sigma-Aldrich (Shanghai, China). T-AOC Kit obtained from Nanjing Jiancheng Bioengineering Institute (Nanjing, China). Sugarcane was purchased from Bobai, Guangxi, China. Ferulic acid (≥99.0%), p-coumaric acid (≥98.0%), caffeic acid (≥98.0%) were purchased from Sigma-Aldrich (Shanghai, China).

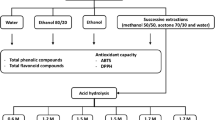

Preparation of Crude Sample

The outer layer rinds of sugarcanes were obtained by hand peeling. Rind samples were separated from the inner part with sharp knives and dried with oven at 45 °C. Then, the dried rind samples were ground into powder by a grinder. The ground powder of 30 g and 2 M NaOH of 300 mL were added into a beaker (500 mL) and stirred for 6 h at room temperature. Then, several drops of 6 M HCl were added into the mixture for the purpose of acidizing to pH 2. The above aqueous solution was extracted three times with ethyl acetate at the ratio of 1:1 (v/v). The organic fractions were obtained and evaporated under reduced pressure by rotary evaporator at 50 °C, which yielded 1.62 g crude sample for the subsequent pH-zone-refining CCC isolation and antioxidant activity evaluation.

Selection of Two-Phase Solvent Systems

The two-phase solvent system selection was based on partition coefficient (K). The partition coefficients (K) of the target components of the sample in the two-phase solvent system were determined by using the test tube method according to reference (Dong et al. 2015). In acidic (K acid) and basic (K base) conditions, the K value was defined as the peak area of a target compound in the upper phase divided by its peak area in the lower phase. K acid and K base values were used to evaluate the applicability of the tested two-phase solvent system.

Preparation of Two-Phase Solvent Systems and Sample Solution

To separate crude extract, the two-phase solvent system used here was composed of methyl tert-butyl ether (MTBE)/acetonitrile (ACN)/water at a volume ratio of 4:1:5. Each solvent was added to a separation funnel. The solvent mixtures were thoroughly equilibrated by shaking repeatedly and left to stand at room temperature until the two phases have a clear separation layer. Then, the two phases were isolated and added suitable acid and base, respectively. The upper phase (containing 5 mM TFA) acted as the stationary phase. The lower aqueous phase (containing 3 mM NH4OH) acted as the mobile phase. Subsequently, the two phases were degassed by sonication for 20 min shortly before use.

The crude sample was dissolved in the mixture of 5-mL upper phase with 20 μL TFA and 5-mL lower phase without NH3.

pH-Zone-Refining CCC Separation Procedures

Separation methodology of pH-zone-refining CCC was described as below: Firstly, the multilayer coil column was filled up completely with organic stationary phase using the pump. Then, the prepared sample was injected into the separation column through the sample injection valve, and then, the aqueous mobile phase was pumped into the column from head to tail at a flow rate of 0.5 mL/min, while the column was rotated at 1600 rpm. The effluent from the outlet of the column was continuously monitored with a UV detector at 254 nm. Fractions were collected manually into test tubes according to time and the chromatogram and then evaporated under reduced pressure. The pH of each eluted fraction was measured with a pH meter, and residues were prepared for purity analysis by HPLC after dissolving in methanol. The retention of the stationary phase was computed from the volume of the stationary phase collected from the column relative to the total column capacity after the separation.

HPLC Analysis

HPLC analyses of the crude sample and peak fractions were performed using an Apollo C18 column (150 × 4.6 mm, ID 5 μm) at a column temperature of 30 °C. The mobile phase was methanol (A) and water with 0.5% phosphoric acid (B), and the gradient was as follows: 0–70 min, 20–56% A. The flow rate was constantly maintained at 1.0 mL/min. The detection wavelength was 280 nm.

Evaluation of Antioxidant Activity

Antioxidant Activity by DPPH Radical Scavenging

DPPH free radical scavenging activity was measured according to the method of the reference (Brand-Williams et al. 1995; Tahir et al. 2016) with some slight modifications. Ascorbic acid was used as a control. The crude sugarcane rind extract and the three phenolic compounds separated from the extract were dissolved in methanol with different concentrations (1–1000 μg/mL). Then, 2.0 mL solutions of samples were permitted to react with 2.0 mL DPPH solution (0.10 mM). The mixtures were shaken vigorously and incubated for 30 min at 25 °C in the dark. The absorbance was monitored at 517 nm. The antioxidant activity of caffeic acid, p-coumaric acid, ferulic acid, and crude sample was evaluated by comparing with ascorbic acid. The capacity to scavenge the DPPH radical (DPPH•) was calculated as follows:

where A i is the absorbance of 2.0 mL test compounds with 2.0 mL DPPH, A j is the absorbance of 2.0 mL test compounds with 2.0 mL methanol as the blank reaction, and A c is the absorbance of 2.0 mL methanol solution with 2.0 mL DPPH as the blank reaction. The concentration of sample resulting in 50% inhibition (IC50) was calculated from the graph plotting inhibition percentage by linear regression. All determinations were carried out in triplicate, and the average value was calculated.

Total Antioxidant Capacity Assay

The test of total antioxidant capacity was in accordance with the kit manual operation. Ascorbic acid was served as a positive control. The total antioxidant capacities of the four tested samples were evaluated at different concentrations (1–1000 μg/mL) by comparison with a control. All results were manipulated in triplicate. The total antioxidant capacity was calculated as follows:

Results and Discussions

Optimization of Two-Phase Solvent System for pH-Zone-Refining CCC

pH-zone-refining CCC has been successfully applied to the separation of natural products with ionizable character at the multigram scale for alkaloids or phenolics. This mode is characterized by the addition of an acid as a retainer and a base as an eluter to the respective phases to induce the protonation/deprotonation of a molecule, and then, it transfers between the stationary and the mobile phases gradually (Kukula-Koch et al. 2016). Hence, it is the first most important step for achieving a suitable two-phase solvent system which provides ideal partition coefficient (K) values in both acidic (K acid ≫1) and basic (K base ≪1) conditions as well as good solubility of the sample in the solvent system (Sun et al. 2014).

In this study, MTBE-water (1:1), MTBE-ACN-water (2:2:3, v/v), and MTBE-ACN-water (4:1:5, v/v) were tested during the solvent system selection process (Table 1). Among those, the volume ratio of MTBE-water (1:1, v/v) was firstly investigated. Although this solvent system produced suitable K values for the main compounds, it could not be used for the separation of this crude sample due to the poor solubility of lower than 0.5 g in both phases. In consideration of the high polarity of the phenolic compounds, the solubility of the crude sample was substantially increased by adding ACN, which is used as “best solvent” to guarantee the solubility of the phenolic compounds and increase the polarity of the organic mobile phase (Hamzaoui et al. 2013). Thus, the solvent system composed of MTBE-ACN-water was examined. The K values of the two-phase solvent system at the volume ratios of 2:2:3 and 4:1:5 were evaluated. The results displayed that both of the two ratios provided ideal K acid and K base values and greatly improved the solubility of the crude sample in the solvent system (Table 1). Hence, the concentration of the retainer and eluter are particularly important.

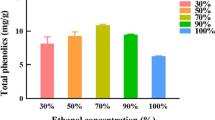

Selection of Concentration of Retainer and Eluter

During the period of pH-zone-refining CCC, the molar concentration ratio between the retainer and the eluter determines the retention time of the pH zone of analytes. Figure 1 displays the HPLC analysis of the crude extract. The peaks A, B, and C corresponded to caffeic acid, p-coumaric acid, and ferulic acid, respectively, according to phenolic acid standards. The contents of caffeic acid, p-coumaric acid, and ferulic acid were 8.2, 114.6, and 22.9 mg of 1.62 g crude sample, respectively, based on the standard curve method. Figure 2a–c shows the results of crude sample separation with two-phase solvent system at the volume ratios of 2:2:3 and 4:1:5 with different concentrations of the retainer and the eluter. The volume ratio of 2:2:3 with 5 mM TFA in the upper phase and 5 mM NH4OH in the lower phase was not acceptable because the chromatogram lost its characteristic rectangular shape and the target compounds were eluted with a lot of impurities (Fig. 2a). When the solvent system MTBE-ACN-water at the volume ratio of 4:1:5 with 5 mM TFA in the upper phase and 5 mM NH4OH in the lower phase was employed, the resolution of the target compounds and impurities could be improved. Nevertheless, only compound C was separated from the crude sample, and its purity was 90.28%. Compound B was partly separated according to HPLC analysis. The boundaries between the two absorbance platforms were ambiguous, and the crude sample was separated into two fractions. The reason might be that high eluter concentration decreased the yield of pure compounds due to the shortened pH zone width relative to that of the mixing zone. The pH-zone-refining CCC and HPLC chromatograms were shown in Fig. 2b. Seen from above results, an idea came out that the resolution could be enhanced by reducing the concentration of the eluter base in the biphasic solvent system and increasing the concentration of the retainer acid in the system. The concentration and retention time of analyte as well as the retention of the stationary phase were mainly affected by the concentration of the eluter in the mobile phase and retainer in the stationary phase. Under the condition of high eluter concentration, target compounds were eluted at high concentrations in a shorter time so that they were unable to be separated. Hence, a certain amount of the retainer and eluter were applied to the organic stationary phase and aqueous mobile phase with the purpose of achieving efficient resolution of the target compounds. When the organic phase with 5 mM TFA and the aqueous phase with 3 mM NH4OH, the solvent system could provide broad rectangular shape of pH-zone-refining CCC and three fractions were clearly observed (Fig. 2c). This result indicated that the two-phase solvent system MTBE-ACN-water (4:1:5, v/v), in which TFA (5 mM) was added to the upper organic stationary phase as a retainer and NH4OH (3 mM) to the aqueous mobile phase as an eluent, was suitable for the separation of the crude sample.

HPLC chromatogram of sugarcane rinds crude extract. Experimental conditions: column: Apollo C18 column (150 × 4.6 mm, ID 5 μm), mobile phase: eluent A (methanol) and eluent B (0.5% v/v phosphoric acid in water); gradient conditions: methanol 0–70 min, 20–56%, flow rate 1 mL/min, detection wavelength 280 nm, column temperature 30 °C. Peaks: caffeic acid (A), p-coumaric acid (B), and ferulic acid (C)

The different separation chromatograms of crude extract by pH zone-refining CCC under different solvent systems with various concentration of retainer and eluter. Experimental conditions: type J coil planet centrifuge equipped with multilayer coil separation column of 40-mL capacity; a solvent system: MTBE/ACN/water (2:2:3), retainer/eluter 5 mM TFA/5 mM NH4OH; b solvent system: MTBE/ACN/water (4:1:5), 5 mM TFA/5 mM NH4OH; and c solvent system: MTBE/ACN/water (4:1:5), 5 mM TFA/3 mM NH4OH; flow rate 0.5 mL/min; mobile phase: lower phase; revolution speed 1600 rpm; detection wavelength 254 nm; retention of the stationary phase: a 52.5%, b 54.2%, and c 57.5%. Peaks: caffeic acid (A), p-coumaric acid (B), and ferulic acid (C)

pH-Zone-Refining CCC Separation of the Crude Extract

Figure 2c shows a typical chromatogram for the separation of 1.00 g crude extract by pH-zone-refining CCC using the two-phase solvent system MTBE-ACN-water (4:1:5, v/v) with 5 mM TFA in the upper organic phase and 3 mM NH4OH in the aqueous phase. The total separation time was about 5 h. As seen from the chromatogram, these target phenolic acids were well eluted as three irregular rectangular peaks where impurities or minor components were highly concentrated at its front and rear boundaries (peaks A–C in Fig. 2c). The pH measurement results of the collected fractions also revealed a flat pH zone, which corresponded to the above absorbance plateaus, demonstrating the successful separation of the three components.

HPLC Analysis of the Crude Extract and pH-Zone-Refining CCC Fractions

The analytical HPLC was employed to analyze the crude extract and the purified phenolic acids. Based on the HPLC analysis and the elution curve of the pH-zone-refining CCC, all collected fractions were combined and evaporated under reduced pressure to dryness. Gradient elution was performed using eluent A (MeOH) and eluent B (0.5% v/v H3PO4 in water) for the crude extracts. When the gradient condition was as follows: 0–70 min 20–56% A, the major peaks were obtained and each peak achieved baseline separation. The HPLC chromatogram of the crude extract mainly included three peaks (Fig. 1). The peaks A, B, and C correspond to caffeic acid, p-coumaric acid, and ferulic acid, respectively, according to phenolic acid standards. Figure 2c shows the HPLC chromatogram of purified phenolic acids separated by pH-zone-refining CCC. As a result, 4.8 mg of compound A, 12.9 mg of compound C, and 65.2 mg of compound B were obtained from 1.00 g of crude sample in one run separation with the purities of 93.4, 94.6, and 98.8%, respectively. The separation and purification of sugarcane rinds using the most common solid support-based chromatographic methods, such as macroporous resin column chromatography, required several steps, which results in low recoveries of products (Ignat et al. 2011; Valls et al. 2009). In this work, the irreversible adsorptive loss of samples onto the solid support was eliminated and high recovery was achieved for compound A (89%), B (91%), and C (86%).

Mechanism for Separation of Three Phenolic Acids Using pH-Zone-Refining CCC

There was a steady-state hydrodynamic equilibrium established in the separation column. The three phenolic acids were all accumulated behind the sharp TFA border by repeating protonation and deprotonation around it. As the concentration of the three phenolic acids increased behind the sharp TFA border, increased acidity in the aqueous phase retarded the movement of ferulic acid and p-coumaric acid, leaving caffeic acid (the most polar component with the lowest pKa) still kept its moving rate higher than that of the sharp TFA border to repeat circling around it. After a while, caffeic acid formed a sharp trailing border against ferulic acid and p-coumaric acid. The above procedure was repeated until p-coumaric acid (the least polar compound with the highest pKa) developed a sharp trailing border. So, the three phenolic acids formed a succession of discrete pH zone behind the sharp retainer border in the order of their pKa values and hydrophobicities.

After this hydrodynamic equilibrium was established, all solute zones moved at the same rate as the sharp TFA retainer border. Electric impurities present in each zone were eliminated either forward or backward according to their pKa values and hydrophobicities and accumulated at the zone boundaries (Weisz et al. 1994). As a result, three phenolic acids were eluted as rectangular peaks with sharp impurity peaks at their boundaries.

Antioxidant Activity

The reduction of DPPH to the corresponding hydrazine is a classic, simple, and fast method for evaluating the radical scavenging activity of antioxidants (Wollinger et al. 2016). In the DPPH test, the antioxidants reduce the DPPH• from a purple compound to a yellow compound and the extent of the reaction depends on the hydrogen-donating ability of the antioxidants. The DPPH• exhibits a stable organic free radical with an absorption maximum band around 515–528 nm (Sun et al. 2009). As shown in Fig. 3, a significant decrease of the absorbance at 517 nm appeared during the reaction. That meant that DPPH• exhibited a characteristic absorbance at 517 nm, which decreased dramatically due to exposure to proton radical scavengers. The free radical scavenging activities of the initial crude extract, caffeic acid, p-coumaric acid, and ferulic acid separated from pH-zone-refining CCC, along with the positive control ascorbic acid, were determined by the DPPH assay, and the results are shown in Fig. 4a and Table 2. The scavenging capacities on DPPH• were expressed as IC50 values. IC50 means 50% radical scavenging activity concentration of the antioxidant, and a lower IC50 value indicated a higher scavenging activity (Gontijo et al. 2012). The IC50 value of control ascorbic acid was 5.08 μg/mL. Caffeic acid had higher antioxidant activity than the control. Its IC50 value was 3.96 μg/mL. The high reactivity of caffeic acid is probably due to its better accessibility to DPPH• and low redox potential (Xie and Schaich 2014). The antioxidant activities of ferulic acid and p-coumaric were lower than the control. Their IC50 values were 25.40 and 137.70 μg/mL, respectively. The crude extract showed a weak radical scavenger.

The test of total antioxidant capacity is based on the direct reduction of Fe3+ to Fe2+, and the latter reacts with phenanthroline to form a red purple complex, which can be monitored at 520 nm. The greater the reducing power of the analyte, the higher is the concentration of formed complex, generating higher total antioxidant capacity. The activities of different treatments by this assay were similar to results of the DPPH test. As indicated in Fig. 4b, caffeic acid exhibited the strongest total antioxidant capacity (170 U/mL) with saturation concentration of 500 μg/mL. The total antioxidant capacities of ferulic acid and p-coumaric were lower. The crude extract showed the lowest activity. The above results of the two tests indicated that the separated individual phenolic acids had higher antioxidant activity than their mixture. Therefore, the separation of phenolic antioxidants was quite important for the maximum utilization of waste sugarcane rinds.

The high antioxidant activity of phenolic antioxidants is attributed to their –OH moieties, which are potent H donors because the stabilization of the resulting phenoxy radicals by electron delocalization across the molecule efficiently. The separated three phenolic compounds are hydroxyl derivative of cinnamic acid that has –OH moieties. Antioxidant activity depends on the number and positions of hydroxyl groups and other substituents. Caffeic acid is the dominating delegate of hydroxycinnamic acids. It showed the highest antioxidant activity probably due to the presence of a catechol group with an α, β-unsaturated carboxylic acid chain. The catechol group, which can give two active oxygen radicals, possess significant antioxidant activity (Goupy et al. 2003). Another important feature of caffeic acid is the planarity of the molecule, which allows conjugation and electron delocalization. This is why the antioxidant activity of ascorbic acid was a bit lower than caffeic acid. Ferulic acid was less active than caffeic acid due to the presence of only one available hydroxyl radical. The antioxidant activity of p-coumaric was low due to the absence of methoxy group, which existed in ferulic acid. The methoxy group raised the H donation power of the molecule, and resulting radicals were more delocalized.

Conclusions

In this study, a rapid, high recovery and efficiency method was established for successful separation of the sugarcane rinds using pH-zone-refining CCC. Thereafter, three phenolic acids caffeic acid (4.8 mg), ferulic acid (12.9 mg), and p-coumaric acid (65.2 mg) with high purities of 93.4, 94.6, and 98.8%, respectively, were obtained from 1.00 g crude extract. Foreseeably, this method may be applied in the large-scale production for phenolic acids from waste sugarcane rinds and natural by-products. The antioxidant activity assays showed that sugarcane rinds could be a good source of antioxidants. As a phenolic-rich resource, sugarcane rinds may supply natural antioxidants for food, cosmetics, and medicine purposes.

References

Abbas SR, Sabir SM, Ahmad SD, Boligon AA, Athayde ML (2014) Phenolic profile, antioxidant potential and DNA damage protecting activity of sugarcane (Saccharum officinarum). Food Chem 147:10–16

Attard TM, McElroy CR, Rezende CA, Polikarpov I, Clark JH, Hunt AJ (2015) Sugarcane waste as a valuable source of lipophilic molecules. Ind Crop Prod 76:95–103

Brand-Williams W, Cuvelier ME, Berset C (1995) Use of a free radical method to evaluate antioxidant activity. LWT - Food Sci Technol 28:25–30

Dong G, Xu J, Gu Y, Wei Y (2015) A general separation method of phenolic acids using pH-zone-refining counter-current chromatography and its application to oat bran. J Chromatogr B 992:36–42

Duarte-Almeida JM, Salatino A, Genovese MI, Lajolo FM (2011) Phenolic composition and antioxidant activity of culms and sugarcane (Saccharum officinarum L.) products. Food Chem 125:660–664

Feng S, Luo Z, Tao B, Chen C (2015) Ultrasonic-assisted extraction and purification of phenolic compounds from sugarcane (Saccharum officinarum L.) rinds. LWT - Food Sci Technol 60:970–976

Gontijo VS, de Souza TC, Rosa IA, Soares MG, da Silva MA, Vilegas W, Júnior CV, dos Santos MH (2012) Isolation and evaluation of the antioxidant activity of phenolic constituents of the Garcinia brasiliensis epicarp. Food Chem 132:1230–1235

Goupy P, Dufour C, Loonis M, Dangles O (2003) Quantitative kinetic analysis of hydrogen transfer reactions from dietary polyphenols to the DPPH radical. J Agric Food Chem 51:615–622

Hamzaoui M, Renault JH, Reynaud R, Hubert J (2013) Centrifugal partition extraction in the pH-zone-refining displacement mode: an efficient strategy for the screening and isolation of biologically active phenolic compounds. J Chromatogr B 937:7–12

Ignat I, Volf I, Popa VI (2011) A critical review of methods for characterisation of polyphenolic compounds in fruits and vegetables. Food Chem 126:1821–1835

Ito Y (2013) pH-zone-refining counter-current chromatography: origin, mechanism, procedure and applications. J Chromatogr A 1271:71–85

Kukula-Koch W, Koch W, Angelis A, Halabalaki M, Aligiannis N (2016) Application of pH-zone refining hydrostatic countercurrent chromatography (hCCC) for the recovery of antioxidant phenolics and the isolation of alkaloids from Siberian barberry herb. Food Chem 203:394–401

Li H, Cheng Y, Dong H, Wang X, Li J, Gao Q (2016) Preparation of salvianolic acid A by the degradation reaction of salvianolic acid B in subcritical water integrated with pH-zone-refining counter-current chromatography. J Chromatogr A 1468:42–48

Liang X, Zhang Y, Chen W, Cai P, Zhang S, Chen X, Shi S (2015) High-speed counter-current chromatography coupled online to high performance liquid chromatography–diode array detector–mass spectrometry for purification, analysis and identification of target compounds from natural products. J Chromatogr A 1385:69–76

Maurya DK, Devasagayam TPA (2010) Antioxidant and prooxidant nature of hydroxycinnamic acid derivatives ferulic and caffeic acids. Food Chem Toxicol 48:3369–3373

Shi S, Ma Y, Zhang Y, Liu L, Liu Q, Peng M, Xiong X (2012) Systematic separation and purification of 18 antioxidants from Pueraria lobata flower using HSCCC target-guided by DPPH–HPLC experiment. Sep Purif Technol 89:225–233

Sun Y, Zhu H, Wang J, Liu Z, Bi J (2009) Isolation and purification of salvianolic acid A and salvianolic acid B from Salvia miltiorrhiza by high-speed counter-current chromatography and comparison of their antioxidant activity. J Chromatogr B 877:733–737

Sun C, Li J, Wang X, Duan W, Zhang T, Ito Y (2014) Preparative separation of quaternary ammonium alkaloids from Coptis chinensis Franch by pH-zone-refining counter-current chromatography. J Chromatogr A 1370:156–161

Sun C, Liu F, Sun J, Li J, Wang X (2016) Optimisation and establishment of separation conditions of organic acids from Usnea longissima ach. By pH-zone-refining counter-current chromatography: discussion of the eluotropic sequence. J Chromatogr A 1427:96–101

Tahir HE, Zou XB, Shi JY, Mariod AA, Wiliam T (2016) Rapid determination of antioxidant compounds and antioxidant activity of Sudanese Karkade (Hibiscus sabdariffa L.) using near infrared spectroscopy. Food Anal Methods 9:1228–1236

Valls J, Millán S, Martí MP, Borràs E, Arola L (2009) Advanced separation methods of food anthocyanins, isoflavones and flavanols. J Chromatogr A 1216:7143–7172

Wang X, Geng Y, Li F, Liu J (2007) Large-scale separation of salvianolic acid B from the Chinese medicinal plant salvia miltiorrhiza by pH-zone-refining counter current chromatography. J Sep Sci 30:3214–3217

Wei Y, Xie Q, Dong W, Ito Y (2009) Separation of epigallocatechin and flavonoids from Hypericum perforatum L. by high-speed counter-current chromatography and preparative high-performance liquid chromatography. J Chromatogr A 1216:4313–4318

Weisz A, Scher AL, Shinomiya K, Fales HM, Ito Y (1994) A new preparative-scale purification technique: pH-zone-refining countercurrent chromatography. J Am Chem Soc 116:704–708

Weisz A, Idina A, Ben-Ari J, Karni M, Mandelbaum A, Ito Y (2007) Preparative separation of isomeric and stereoisomeric dicarboxylic acids by pH-zone-refining counter-current chromatography. J Chromatogr A 1151:82–90

Weisz A, Mazzola EP, Ito Y (2011) Preparative separation of 1,3,6-pyrenetrisulfonic acid trisodium salt from the color additive D&C Green No. 8 (pyranine) by pH-zone-refining counter-current chromatography. J Chromatogr A 1218:8249–8254

Wen L, Yang B, Cui C, You L, Zhao M (2012) Ultrasound-assisted extraction of phenolics from longan (Dimocarpus longan Lour.) fruit seed with artificial neural network and their antioxidant activity. Food Anal Methods 5:1244–1251

Wollinger A, Perrin É, Chahboun J, Jeannot V, Touraud D, Kunz W (2016) Antioxidant activity of hydro distillation water residues from Rosmarinus officinalis L. leaves determined by DPPH assays. C R Chim 19:754–765

Xi L, Mu T, Sun H (2015) Preparative purification of polyphenols from sweet potato (Ipomoea batatas L.) leaves by AB-8 macroporous resins. Food Chem 172:166–174

Xie J, Schaich KM (2014) Re-evaluation of the 2, 2-Diphenyl-1-picrylhydrazyl free radical (DPPH) assay for antioxidant activity. J Agric Food Chem 62:4251–4260

Zhao SQ, Yao SW, Ou SY, Lin J, Wang Y, Peng XC, Li AJ, Yu B (2014) Preparation of ferulic acid from corn bran: its improved extraction and purification by membrane separation. Food Bioprod Process 92:309–313

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The manuscript has not been published previously. The manuscript has not been submitted to more than one journal for simultaneous consideration.

Consent to submit has been received explicitly from all co-authors, as well as from the institute/organization where the work has been carried out, before the work is submitted.

Authors whose names appear on the submission have contributed sufficiently to the scientific work and therefore share collective responsibility and accountability for the results.

Funding

This work was supported by National Natural Science Foundation of China (NSFC, Grant No. 21075007), Program for New Century Excellent Talents in University (NCET-11-0563), Beijing Nova Program Interdisciplinary Cooperation Project (Z161100004916045), and the Fundamental Research Funds for the Central Universities (YS1406).

Conflict of Interest

Ying-tong Fang declares that she has no conflict of interest. Quan Li declares that he has no conflict of interest. Ao-cheng Cao declares that he has no conflict of interest. Yuan Li declares that she has no conflict of interest. Yun Wei declares that she has no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed Consent

Informed consent is not applicable in this study.

Rights and permissions

About this article

Cite this article

Fang, YT., Li, Q., Cao, AC. et al. Isolation and Purification of Phenolic Acids from Sugarcane (Saccharum officinarum L.) Rinds by pH-Zone-Refining Counter-Current Chromatography and Their Antioxidant Activity Evaluation. Food Anal. Methods 10, 2576–2584 (2017). https://doi.org/10.1007/s12161-017-0824-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-017-0824-3