Abstract

Isometamidium (ISM) residues in milk can cause health problems to human beings. This manuscript described for the first time an electrochemical method for ISM analysis in milk samples. The voltammetric behavior of ISM over an extended pH range using both cyclic voltammetry and differential pulse voltammetry at a glassy carbon electrode (GCE) was also studied. In order to improve the analytical performance, GC electrodes were modified with aniline and 1,4-phenylenediamine to form a stable layer, and then single-walled carbon nanotubes (SWCNT) were covalently bound to the GC electrodes. Gold nanoparticles (AuNP) were electrodeposited to the GC electrodes through the C–Au bonds to further promote the electrode conductivity. The modified SWCNT/AuNP-GCE electrochemical sensor (EC) was successfully applied to analyze isometamidium residues in milk. The linear range was from 10 μg to 400 μg/L with limit of detection at 3 μg/L (S/N = 3). The recovery was between 79.4–94.7 % in spiked samples. The EC sensor method was also compared with a LC-MS/MS method, which proves its capability in commercial market surveillance.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Isometamidium (ISM), as a long-acting antitrypanosomal, can block the nucleic acids synthesis of trypanosome by inhibiting the activities of RNA and DNA polymerases (Shweta 2013). Up to now, ISM has been used for chemotherapy and chemoprophylaxis of the disease in cattle, sheep, and goats under conditions of natural tsetse challenge for more than 50 years (Kazunari 1999; Wesongah et al. 2004). However, the ISM can last long and cause teratogenesis and embryotoxicity when it was used in livestock. As a result, the animal-derived foods can be easily contaminated by the overuse of ISM (Geerts S 1999). For this reason, many countries and organizations have regulated the maximum residual limits (MRLs) of ISM, especially in milk which is an important food of humans for all ages. JECFA and Japan have regulated the MRL of ISM in milk is 1.0 mg/L. (Kazunari 1999). China has regulated MRL of ISM in milk at 100 μg/L. (Liu 2011) As a result, reliable and robust analytical techniques are required for food contaminant surveillance. So far, a number of laboratory based analytical techniques have been developed for determination of the ISM, such as ELISA (Ardelli 2000; Delespaux 2002; Whitelaw 1991) and RIA methods (Kinbo 1988). HPLC (Schad et al. 2012) and LC-MS/MS methods (Li et al. 2011). Compared with these methods, the electrochemical sensors (EC) provide an accurate and rapid analytical tool for chemical contaminant detection in the environmental and food matrix samples (Diculescu et al. 2006; Jain et al. 2009; Yin et al. 2012). More recently, various nanomaterials have been widely employed to improve the performance of electrode interface by improving sensitivity, selectivity, and multiplexing capacity. Among these materials, gold nanoparticles (AuNPs) and carbon nanotube (CNT) are the most commonly used types. AuNPs have been used as excellent scaffolds for the fabrication of novel electrochemical sensors (Cao et al. 2011; Chen et al. 2015; Choi et al. 2011; Zhou et al. 2013). due to its distinct physical and chemical attributes, such as a favorable microenvironment, high surface-to-volume ratio, good biocompatibility, and high conductivities between biomolecules and the electrode surface (Li et al. 2014; Marie-Christine 2004; Saha et al. 2012). CNTs have a superconductivity property when its diameter is less than 6 nm (Kociak 2001). and has been widely used as a material to amplify the electrochemical signals (Agui et al. 2008; Gomez et al. 2015; Herrasti et al. 2014; Jacobs et al. 2010; Silva et al. 2014). The hybrid of CNT with AuNPs was also reported to potentially improve the performance of electrochemical sensors. The SWCNT/AuNP-coated electrode was used directly to improve the sensitivity of chloramphenicol analysis in milk samples (Xiao et al. 2007). Li et al. used a CNT drop method and electrochemically deposited AuNPs to improve the sensitivity of pesticide triazophos analysis in vegetable samples (Li et al. 2012). The bottleneck of these methods is that the homogeneity of CNTs dropped directly on the GCE surface is hard to be controlled, and the CNT-film can be easily detached. Therefore, the approach to stabilize the CNT-film on a GCE surface is also of concern.

To the best of our knowledge, the electrochemical properties of ISM and the mechanisms underlying its voltammetric behavior have not been studied. An EC method for ISM analysis in milk has not yet been developed as well. In this study, we investigated the electrochemical behavior of ISM over a wide pH range and put forward the possible reaction mechanism using CV and DPV. We also pursued the modification of GCE by SWCNT/AuNPs. In order to improve the SWCNT/AuNP stability and better performance on GCE surface, a diazotization and electropolymerization method was used. Moreover, the AuNPs were electrochemically deposited by optimizing the deposition time to obtain the best performance for ISM analysis. Finally, an EC sensor method for ISM analysis in milk samples were developed, which can be potentially used for commercial market surveillance. The EC sensor method was validated by comparison with a LC-MS/MS method.

Experimental

Materials and reagents

Isometamidium chloride standard was purchased from Wako (Wako Pure Chemical Industries, Ltd, Japan). The molecular structure of ISM was shown in Fig. 1. Methanol, acetonitrile (MeCN), and formic acid (HPLC-grade) were purchased from Tedia Company (Fairfield, USA). Ammonium formate, phenylamine, p-phenylenediamine, sodium nitrite, hydrochloric acid, potassium chloride, disodium, trisodium, sodium o-phosphate and o-phosphoric acid, hydrogen tetra-chloroaurate (HAuCl4 · 4H2O) was guaranteed reagent from Sinopharm Chemical Reagent Co., Ltd, China. Single-walled carbon nanotube (SWCNT, O.D. 1–2 nm) was obtained from Sigma-Aldrich (MO, USA). A 2.5 g/L ISM stock solution was prepared by dissolving the appropriate mass in ultrapure water. Working standards were then prepared by dilution of the primary stock solution with ultrapure water. Ultrapure water was obtained from a Milli-Q Academic System, (Millipore, USA). Solutions of disodium, trisodium, sodium o-phosphate and o-phosphoric acid were made at a concentration of 0.2 M by dissolving the appropriate mass in ultrapure water. These were then titrated together to give the desired pH plus 0.1 M KCl. An appropriate volume was then added directly to the voltammetric cell and diluted with sufficient ultrapure water to give an overall phosphate concentration of 0.1 M.

Instrumentation

Cyclic voltammetry was performed using an Autolab potentiostat interfaced to a PC for data acquisition and instrument control via the Nova operating system (Autolab, The Netherlands). The voltammetric cell contained a graphite rod counter electrode, a silver/silver chloride reference electrode (Ag/AgCl) (Chen Hua Instruments, Shanghai, China) and a 3 mm diameter glassy carbon electrode as the working electrode (Chen Hua Instruments, Shanghai, China). Field emission scanning electron microscope (FE-SEM, Helios Nanolab 600i, FEI Company, USA) was used to characterize the morphology of the material. ISM was analyzed by a Waters AcquityTM UPLC with a BEH C18 column (100 mm × 2.1 mm, 1.7 μm, Waters, USA) and the MS/MS instrument (AB SCIEX QTRAP, AB SCIEX, USA).

Voltammetric behavior of ISM with bare electrode

The glassy carbon working electrode was polished to a mirror by using 1, 0.3, and 0.05 μm alumina pastes, respectively, and was then thoroughly ultra-sonicated in distilled water and ethanol before used. The electrode was dried under nitrogen flow and was placed into phosphate buffer solutions at pH values between 2.0 and 12.0 containing 0.25 g/L ISM. Cyclic voltammograms were initially recorded in plain solutions of phosphate buffer, then in the same solution containing ISM. For initial studies a starting potential of 0.0 V with a switching potential of +1.2 V was employed. Differential pulse voltammetry was taken using a starting potential of 0.0 V and a final potential of +1.2 V; using a step height of 10 mV, pulse repetition time 0.2 s, pulse amplitude of 100 mV, and pulse duration of 50 ms.

Preparation of SWCNT/AuNP-functionalized electrodes

In this study, we used a diazotization method to immobilize the CNT which was easier to control and could be more stable. Modification of GCE includes two steps. First, the SWCNT was covalently linked to the surface of GCE by using diazo-reaction. The SWCNT-modified electrode was further modified by HAuCl4 to form SWCNT/AuNP-functionalized electrodes. The p-phenylenediamine modified GC electrode GC–Ph–NH2 was prepared as reported previously (Anjum S 2015; Sun and Ma 2012; Zhang et al. 2011) with the following modification. A clean GCE was dipped in HCl solution (0.5 mol/L) containing p-phenylenediamine (6 × 10−3 mol/L) and aniline (4 × 10−3 mol/L). NaNO2 (10 mg) was added to the reaction mixture and left to react overnight. The modified GCE was sonicated in ultrapure water, acetonitrile and ultrapure water to eliminate all adsorbed molecules and finally dried under a stream of nitrogen gas.

The carefully rinsed electrode (GC–Ph–NH2) was immersed overnight in 1 mL of an SWCNT dispersion (1 mg/mL) in HCl (0.5 mol/L) that contained NaNO2 (10 mg). Then the modified GCE was sonicated in ultrapure water, acetonitrile and ultrapure water and finally dried under a stream of nitrogen gas as previously described.

For the formation of the SWCNT/AuNP-modified electrode, the GCE was immersed into 1 mM HAuCl4 containing 0.1 M KCl solution which was deaerated by nitrogen gas for about 10 min before use and the gold nanoparticles were electrodeposited via potentiostatic deposition method with optimization of deposition time and voltage (vs. Ag/AgCl) (Atta et al. 2012). The resulting electrode (SWCNT/AuNPs-GCE) was removed and rinsed with ultrapure water. The process was shown in Fig. 2.

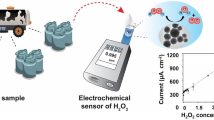

Methods development for ISM analysis in bovine milk samples by EC and LC-MS/MS

An EC method for analyzing ISM residues in bovine milk samples was developed. The skimmed milk was used for sample extraction and was obtained by centrifugation at 6000 rpm for 30 min for three times to remove the fat layer. The sample extraction procedure was described as follows: a total of 5 g of skimmed milk was extracted in a 50 mL polypropylene centrifuge tube by adding 20 mL of a mixed solvent containing ACN and methanol (1:1). The methanol contains 0.25 mol/L of ammonium formate. The mixture was shaken vigorously for 30 min and the supernatant was collected after centrifugation at 10,000 rpm for 10 min. The extraction procedure was repeated twice. All extracts were collected, and transferred into a 50-mL polypropylene centrifuge tube and dried under the nitrogen gas at 45 °C. The residue was further reconstituted in 2 mL of water, and was used for EC analysis using a DPV method after dilution four times by PBS buffer (pH = 7.0).

For the development of a LC-MS/MS method, an extraction procedure similar to EC method was used, except that the final reconstituted solvent was passed through 0.22 mm filter paper (Jinteng company, Tianjin, China), and then transferred to inserts for analysis. Mobile phases A and B were methanol and 0.2 % of formic acid in water, respectively. The gradient elution program was shown in Table S1 (Supplementary Information). The flow rate was 0.30 mL/min and the injection volume was 5 μL. The MS/MS instrument was operated using an electrospray ion source in positive mode (ESI+), and monitored using multiple reaction monitoring (MRM). The product Ion spectrum and the MRM chromatogram of ISM were shown in Fig. S1 (Supplementary Information) and Fig. S2 (Supplementary Information), respectively. In addition, the spectrometry parameters were listed in Table S2 (Supplementary Information).

Results and discussion

Electrochemical behavior of isometamidium at a glassy carbon electrode

For finding the adsorptive character of the ISM at GCE, a cyclic voltammogram of ISM at 0.25 g/L in 0.1 M phosphate buffer (pH = 7.0) was recorded after 60 s preconcentration at 0 V with different scan rate as reported previously (Atta et al. 2011). As the sweep rate increased from 20 to 200 mV/s; the peak current increased steadily. Plots of peak current (i p) vs. the square root of scan rate (v ½) showed a linear dependence, indicating the electrochemical process to be diffusion controlled. However, when the pH was greater than 10, the linearity was not obvious. To investigate the influence of pH for the ISM electrochemical behavior, the voltammograms of the solution containing 2.5 mg/L of the isometamidium were taken in 0.1 M phosphate buffer solutions at pH values between 2.0 and 11.0. Oxidation peaks were observed on voltammogram, which corresponding to the amine group of ISM. The peak currents and potentials were dependent on pH, and the peak potential shifted towards more negative values as the pH increased gradually, indicating involvement of proton in the electrode process. Similar results were also found in previous study (Diculescu et al. 2006; Menek 1998).

Characterization of the SWCNT/AuNP composite

The FE-SEM was used to characterize the morphology of the hybrid nanocomposite. As illustrated in Fig. 3 (I), a long and tortuous SWCNT was covalently bound by the diazonium ions onto the surface of the GCE. Figure 3 (II) displays the SEM image of the SWCNT/AuNP-modified GCE and the top left inset exhibits the magnified view of the electrodepositied gold-nanoparticals. The size and shape of each AuNP were observed clearly from the inset image. Large amounts of AuNPs were embedded or wrapped on the SWCNT. This structure could effectively increase the surface-to-volume ratio, so it could reduce the electron transfer and result in the excellent electrical conductivity (Huang et al. 2015).

Optimization of AuNPs electrodeposition time

To show the effect of the deposition time of the AuNPs on the capability of electron transfer, the performance of the electrode fabricated in HAuCl4 solution with 100, 200, 300, 400, 500, 600, and 700 s for deposition of AuNPs was studied with DPV in 0.1 M phosphate-buffer saline (pH 7.0) containing 250 μg/L ISM (Fig. 4). The data indicated that the electrochemical sensor fabricated by the AuNPs for 600 s has a better capability for the electron transfer (Fig. 4, curve a ~ f).

Optimization of accumulation potential and accumulation time

Figure 5 (I) shows the effect of accumulation potential on the resulting i p magnitude of the oxidation peak using an accumulation time of 300 s in a 250 μg/L ISM solution (0.1 M pH 7.0 phosphate buffer). Peak current was found to increase from −0.5 V to a maximum value between −0.2 V and +0.2 V (vs. Ag/AgCl) which was then found to decline at potentials more positive than this. Consequently, further studies were carried out using an accumulation potential of 0.0 V (vs. Ag/AgCl). Figure 5 (II) indicates the effect of increasing accumulation time at an applied potential of 0.0 V using a 250 μg/L ISM solution. The oxidation stripping peak (at about 0.5 V) was found to increase with increased accumulation time and reached a maximum value at ca. 300 s.

(I) Effect of accumulation potential for a 250 μg/L ISM solution in pH 7.0, 0.1 M phosphate buffer. Accumulation time: 300 s; accumulation potential: −0.5, −0.4, −0.3, −0.2, −0.1, 0.0, 0.1 0.2 0.3, 0.4, and 0.5 V. (II) Effect of accumulation time for a 250 μg/L ISM solution pH 7.0, 0.1 M phosphate buffer. Accumulation potential: 0.0 V; accumulation time: 60, 120, 180, 240, 300, 360, and 600 s

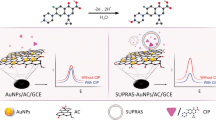

Detection of ISM with the SWCNT/AuNP-modified electrochemical sensor

The SWCNT/AuNPs-GCE exhibits good electrocatalytic activity towards the ISM. Figure 6 (I) shows the DPVs of the ISM (250 μg/L), in 0.1 M pH 7.0 phosphate buffer at the bare GCE (curve b) and the SWCNT/AuNPs-GCE (curve a), respectively. It is obvious that the electrochemical signal of the peak becomes stronger and a little wider because of the effect of the nano materials modified on the surface of the GCE. The current increases swiftly after +0.7 V, this might due to the occurrence of Au peak after +1.1 V. For further analysis of ISM with the SWCNT/AuNP-modified GCE, the potential between 0.0–+0.7 V was used.

(I) The DPVs of the ISM (250 μg/L, in pH 7.0, 0.1 M phosphate buffer) at the SWCNT/AuNPs-GCE (curve a) and bare GCE (curve b) from 0.0 V ~ +0.7 V. (II) The calibration curve of the linear dependence of cathodic peak current on the ISM concentration at the SWCNT/AuNPs-GCE (curve a) and bare GCE (curve b) ( Inset was the linearity range from 10 ~ 400 μg/L for curve a)

A calibration study was carried out using DPV in phosphate buffer (0.1 M, pH 7.0), over a concentration range 10 μg/L ~ 1000 μg/L at the SWCNT/AuNPs-GCE and 200 μg/L ~ 2000 μg/L at the bare GCE. The linear range for ISM at the SWCNT/AuNPs-GCE is 10 ~ 400 μg/L, with the plot slope of 0.011 μA/ (μg/L) and a correlation coefficient R 2 = 0.998 (Fig. 6 (II) curve a). The limit of detection (LOD) is estimated to be 3 μg/L (signal-to-noise ratio at 3). In comparison, the linear range for ISM at the bare GCE is 200 ~ 1000 μg/L, with the plot slope of 0.001 μA/ (μg/L) and a correlation coefficient R 2 = 0.994. Thus, the limit of detection for ISM using the modified GCE is far higher than that using the bare GCE.

Interferences, reproducibility, and stability

To validate the performance of the modified GCE, the interferences, reproducibility, and stability of the EC method were evaluated. Some interferences may exist in raw milk or be generated, derived from the preparation of pure milk, such as K+, Na+, Ca2+, CO3 2−, PO4 3−, and so on. These impurities can possibly interfere with the quantitative detection of ISM in milk. Therefore, the interferences of these species were conducted with the modified GCE at the optimized condition by DPV for detection of 250 μg/L ISM. Thirteen types of metal and acidic ions, i.e., K+, Na+, Ca2+, Fe2+, Mg2+, Zn2+, Cl−, I−, SO4 2−, NO3 −, CO3 2−, PO4 3−, and CH3COO− which were reported previously to be the common interfering substances in buffer solution were used for interference test (Lin et al. 2013; Sun et al. 2015; Wang et al. 2014). No interference was observed to the developed EC method, until the substances reached a rather high concentration (≥100-fold of ISM). In addition, to evaluate the reproducibility and stability of the same electrode and between electrodes, the AuNPs-GCE was prepared separately five times with use of the same GCE, as well as fabrication of five different electrodes for measurement. The oxidation peak current from a 250 μg/L ISM solution in N2 saturated PBS (0.1 M, pH 7.0) was analyzed. The relative standard deviation (RSD) of the response was 2.89 % and 5.4 %, respectively, indicating that the reproducibility of the modified electrode was satisfactory.

Analytical application: determination of the ISM in commercial milk samples

Milk samples were spiked with ISM at three concentrations (50, 100, and 200 μg/L). The results were shown in Table 1. It can be seen that the average recoveries are in the range of 79.4–94.7 % using the established EC method (n = 10). We also prove that the EC method is comparable with LC-MS/MS method (Table 1). The results demonstrate that the electrochemical sensor is adequate to practical application for detecting ISM residue in milk.

Conclusions

This is the first report to investigate the voltammetric behavior of isometamidium, a molecule with a broad range of applications in clinical activities. We also developed a facile and effective method based on the diazo-reaction and electropolymerization to fabricate SWCNT/AuNP-modified GCE. This fabrication exhibited more stable and sensitive character. The prepared GCE was applied for the analysis of isometamidium in pure milk samples. The method was proved to be accurate when comparing with the reference HPLC-MS/MS method. The satisfactory performance of the electrochemical biosensor made it a qualified alternative for ISM determination in practical and routine analyses with lower cost and quicker detection rate.

References

Agui L, Yanez-Sedeno P, Pingarron JM (2008) Role of carbon nanotubes in electroanalytical chemistry: a review. Anal Chim Acta 622:11–47. doi:10.1016/j.aca.2008.05.070

Anjum SQW, Gao W, Zhao J, Hanif S, Aziz-ur-Rehman, Xu G (2015) Fabrication of biomembrane-like films on carbon electrodes using alkanethiol and diazonium salt and their application for direct electrochemistry of myoglobin. Biosens Bioelectron 65:159–165. doi:10.1016/j.bios.2014.10.037

Ardelli B, Woo PTK (2000) An antigen-capture enzyme-linked immunosorbent assay (ELISA) to detect isometamidium chloride in Oncorhynchus spp. Dis Aquat Org 39:231–236. doi:10.3354/dao039231

Atta NF, Galal A, Azab SM (2011) Determination of morphine at gold nanoparticles/Nafion® carbon paste modified sensor electrode. Analyst 136:4682–4691. doi:10.1039/c1an15423k

Atta NF, Galal A, El-Ads EH (2012) A novel sensor of cysteine self-assembled monolayers over gold nanoparticles for the selective determination of epinephrine in presence of sodium dodecyl sulfate. Analyst 137:2658–2668. doi:10.1039/c2an16210e

Cao Q et al (2011) Electrochemical immunosensor for casein based on gold nanoparticles and poly(L-Arginine)/multi-walled carbon nanotubes composite film functionalized interface. Biosens Bioelectron 26:3469–3474. doi:10.1016/j.bios.2011.01.027

Chen N, Cheng Y, Li C, Zhang C, Zhao K, Xian Y (2015) Determination of melamine in food contact materials using an electrode modified with gold nanoparticles and reduced graphene oxide. Microchim Acta 182:1967–1975. doi:10.1007/s00604-015-1533-5

Choi Y-B, Kim HG, Han GH, Kim H-H, Kim SW (2011) Voltammetric detection of trimethylamine using immobilized trimethylamine dehydrogenase on an electrodeposited goldnanoparticle electrode. Biotechnol Bioproc E 16:631–637. doi:10.1007/s12257-011-0070-2

Delespaux V, Geerts S, Brandt J, Elyn R, Eisler MC (2002) Monitoring the correct use of isometamidium by farmers and veterinary assistants in Eastern Province of Zambia using the isometamidium-ELISA. Vet Parasitol 110:117–122. doi:10.1016/S0304-4017(02)00316-3

Diculescu VC, Kumbhat S, Oliveira-Brett AM (2006) Electrochemical behaviour of isatin at a glassy carbon electrode. Anal Chim Acta 575:190–197. doi:10.1016/j.aca.2006.05.091

Geerts SDB, Eisler MC, Brandt J, Lemmouchid Y, Kageruka P, De Deken R, Ndao M, Diallb O, Schacht E, Berkvens D, Speybroeck N, Holmes PH (1999) Extension of the prophylactic effect of isometamidium against trypanosome infections in cattle using a biodegradable copolymer. Acta Trop 73:49–58. doi:10.1016/S0001-706X(99)00010-8

Gomez FJV, Martín A, Silva MF, Escarpa A (2015) Screen-printed electrodes modified with carbon nanotubes or graphene for simultaneous determination of melatonin and serotonin. Microchim Acta 182:1925–1931. doi:10.1007/s00604-015-1520-x

Herrasti Z, Martínez F, Baldrich E (2014) CNT wiring for signal amplification in electrochemical magnetosensors. Procedia Engineering 87:712–715. doi:10.1016/j.proeng.2014.11.637

Huang N, Liu M, Li H, Zhang Y, Yao S (2015) Synergetic signal amplification based on electrochemical reduced graphene oxide-ferrocene derivative hybrid and gold nanoparticles as an ultra-sensitive detection platform for bisphenol. Anal Chim Acta 853:249–257. doi:10.1016/j.aca.2014.10.016

Jacobs CB, Peairs MJ, Venton BJ (2010) Review: carbon nanotube based electrochemical sensors for biomolecules. Anal Chim Acta 662:105–127. doi:10.1016/j.aca.2010.01.009

Jain R, Dwivedi A, Mishra R (2009) Stripping voltammetric behaviour of toxic drug nitrofurantoin. J Hazard Mater 169:667–672. doi:10.1016/j.jhazmat.2009.03.138

Kazunari K, Masakazu H, Mitsunori M, Takashi S, Masatake T (1999) Determination of residual isometamidium in cattle tissues and milk by HPLC. J Food Hyg Soc Jpn 40:211–217

Kinbo LDB, Bogan JA (1988) Development of a radioimmunoassay for isometamidium. Vet Res Commun 12:375–382

Kociak M, Kasumov AY, Gueron S, Reulet B (2001) Superconductivity in ropes of single-walled carbon nanotubes. Phys Rev Lett 2416:2419. doi:10.1103/PhysRevLett.86.2416

Li YG et al (2011) Determination of isometamidium residues in animal-derived foods by liquid chromatography-tandem mass spectrometry. J Chromatogr B 879:1008–1012. doi:10.1016/j.jchromb.2011.02.040

Li H, Xie C, Li S, Xu K (2012) Electropolymerized molecular imprinting on gold nanoparticle-carbon nanotube modified electrode for electrochemical detection of triazophos. Colloids Surf B Biointerfaces 89:175–181. doi:10.1016/j.colsurfb.2011.09.010

Li N, Zhao P, Astruc D (2014) Anisotropic gold nanoparticles: synthesis, properties, applications, and toxicity. Angew Chem 53:1756–1789. doi:10.1002/anie.201300441

Lin X, Ni Y, Kokot S (2013) Glassy carbon electrodes modified with gold nanoparticles for the simultaneous determination of three food antioxidants. Anal Chim Acta 765:54–62. doi:10.1016/j.aca.2012.12.036

Liu K, Zhao Y, Zhang SX, Cheng LL, Wang Y (2011) Development high performance liquid chromatograph (HPLC) method for determination of isometamidium residue in beef and milk. J China Agric Univ 16:116–120

Marie-Christine D, Didier A (2004) Gold nanoparticles: assembly, supramolecular chemistry, quantum-size-related properties, and applications toward biology, catalysis, and nanotechnology. Chem Rev 104:293–346. doi:10.1021/cr030698+

Menek N (1998) Polarographic and voltammetric behaviour of 2-hydroxy-3-methoxy-5-(2-propenyl) azobenzene. Anal Lett 31:275–282. doi:10.1080/00032719808002045

Saha K, Agasti SS, Kim C, Li X, Rotello VM (2012) Gold nanoparticles in chemical and biological sensing. Chem Rev 112:2739–2779. doi:10.1021/cr2001178

Schad GJ, Euerby MR, Skellern GG, Tettey JN (2012) Chromatographic retention behaviour, modelling and separation optimisation of the quaternary ammonium salt isometamidium chloride and related compounds on a range of reversed-phase liquid chromatographic stationary phases. Anal Bioanal Chem 404:239–255. doi:10.1007/s00216-012-6105-5

Shweta A, Mandal TK, Sinha S (2013) Effect of dose on disposition kinetics of isometamidium chloride/hydrochloride in trypanosomiasis induced calves. Afr J Pharm Pharmaco 7:801–808. doi:10.5897/ajpp2013.3521

Silva TA, Zanin H, Vicentini FC, Corat EJ, Fatibello-Filho O (2014) Differential pulse adsorptive stripping voltammetric determination of nanomolar levels of atorvastatin calcium in pharmaceutical and biological samples using a vertically aligned carbon nanotube/graphene oxide electrode. Analyst 139:2832–2841. doi:10.1039/c4an00111g

Sun X, Ma Z (2012) Highly stable electrochemical immunosensor for carcinoembryonic antigen. Biosens Bioelectron 35:470–474. doi:10.1016/j.bios.2012.02.061

Sun Y, He K, Zhang Z, Zhou A, Duan H (2015) Real-time electrochemical detection of hydrogen peroxide secretion in live cells by Pt nanoparticles decorated graphene-carbon nanotube hybrid paper electrode. Biosens Bioelectron 68C:358–364. doi:10.1016/j.bios.2015.01.017

Wang Z, Yang F, Zheng H, Qin X, Luo J, Li Y, Xiao D (2014) Voltammetric determination of TBHQ at a glassy carbon electrode surface activated by in situ chemical oxidation. Analyst 139:3622–3628. doi:10.1039/c4an00325j

Wesongah JO, Jones TW, Kibugu JK, Murilla GA (2004) A comparative study of the pharmacokinetics of isometamidium chloride in sheep and goats. Small Ruminant Res 9:14. doi:10.1016/j.smallrumres.2003.06.003

Whitelaw DD, Gault EA, Holmes PH, Sutherland IA (1991) Development of an enzyme-linked immunosorbent assay for the detection and measurement of the trypanocidal drug isometamidium chloride in cattle. Res Vet Sci 50:185–189. doi:10.1016/0034-5288(91)90103-U

Xiao F, Zhao F, Li J, Yan R, Yu J, Zeng B (2007) Sensitive voltammetric determination of chloramphenicol by using single-wall carbon nanotube-gold nanoparticle-ionic liquid composite film modified glassy carbon electrodes. Anal Chim Acta 596:79–85. doi:10.1016/j.aca.2007.05.053

Yin H, Zhou Y, Ai S, Ma Q, Zhu L, Lu L (2012) Electrochemical oxidation determination and voltammetric behaviour of 4-nitrophenol based on Cu2O nanoparticles modified glassy carbon electrode. Int J Environ An Ch 92:742–754. doi:10.1080/03067319.2010.520123

Zhang Y, Li B, Yan C, Fu L (2011) One-pot fluorescence detection of multiple analytes in homogenous solution based on noncovalent assembly of single-walled carbon nanotubes and aptamers. Biosens Bioelectron 26:3505–3510. doi:10.1016/j.bios.2011.01.035

Zhou N, Li J, Chen H, Liao C, Chen L (2013) A functional graphene oxide-ionic liquid composites-gold nanoparticle sensing platform for ultrasensitive electrochemical detection of Hg2+. Analyst 138:1091–1097. doi:10.1039/c2an36405k

Acknowledgments

Funding

This work was supported by the Natural Science Foundation of China (31371779) and the International Science & Technology Cooperation Program of China (2015DFG31890).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

Dan Zhu declares that she has no conflict of interest. Qiangqiang Li declares that she has no conflict of interest. Xiumei Pang declares that she has no conflict of interest. Yuwei Yuan declares that he has no conflict of interest. Gang Chen declares that he has no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

Not applicable.

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 70.3 KB)

Rights and permissions

About this article

Cite this article

Zhu, D., Li, Q., Pang, X. et al. Electrochemical behavior of isometamidium and its determination in milk at a SWCNT/AuNP-modified electrode. Food Anal. Methods 9, 1963–1969 (2016). https://doi.org/10.1007/s12161-015-0376-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-015-0376-3