Abstract

Cow dung contains high concentrations of organic matter, which can be used for methane production by anaerobic digestion. However, the refractory lignocellulose in cow dung often hiders methane production through anaerobic digestion. Ultrasonic pretreatment is an efficient method to enhance lignocellulose degradation and methane production, but the mechanism is not well studied. In this work, the influence of ultrasonic pretreatment on the anaerobic digestion of cow dung was studied. The impact of ultrasonic pretreatment on the dissolution rate of organic matter (including soluble chemical oxygen demand (sCOD) and carbohydrates) was investigated by modifying the ultrasonic power, length, and impulse time. The dissolution rate of sCOD increased by 96% with an ultrasonic power of 325 W by comparing the treatment without ultrasonic pretreatment. The optimized dissolution rates of sCOD (10,915 ± 112 mg/L) and carbohydrate (942 ± 12 mg/L) were achieved at 325 W ultrasonic power, 30 min ultrasonic time with impulse time of 2 s close and 1 s open. Under the above condition, after 26 days of anaerobic digestion, the cumulative methane production in the treatment with ultrasonic pretreatment was 851 mL, which was 1.36 times higher than that of the control without ultrasonic pretreatment (360 mL). In comparison with the treatment without ultrasonic pretreatment, the bacteria of Actinaobacteria phyla, which could degrade unselective organic substances, was significantly increased (by 44%) in the treatment with ultrasonic pretreatment. We conclude that ultrasonic pretreatment has a high potential to enhance methane production by anaerobic digestion of cow dung.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, how to economically deal with livestock waste has become very important in many parts of the world. If treated with inappropriate disposal methods, livestock manure such as cow dung (CD) may cause serious environmental problems such as pathogens in ground and surface water, odor, airborne ammonia, greenhouse gases, spills, etc. [1]. Generally, a mature cow can excrete around 15 kg of CD per day, and about 35 million tons of CD are produced annually in China [2, 3]. Recently, large volumes of CD generated from feedlot farming have increased annually, and most of them are disposed into landfills or piled up around farms without sufficient treatment [4]. The CD contains degradable organic materials, including a high content of lignin and lignocellulose fibers, about 40–50% of the total solids (TS) [5]. Anaerobic digestion (AD) is an efficient method widely used for bioenergy production from sewage sludge, animal manure, agricultural residue, industrial sludge, and energy crops in developing and developed countries [5, 6]. The process of AD includes four major steps: hydrolysis, acidogenesis, acetogenesis, and methanogenesis. In the first step, hydrolysis is the rate-limiting step of the overall process due to the dissolution of insoluble particulate matter and the biological decomposition of organic polymers with complex structures (such as lignin and cellulose) [5,6,7]. Hence, to accelerate the anaerobic digestion of CD, an efficient pretreatment method is highly recommended.

A few pretreatment methods have been developed for methane production from AD of the recalcitrant fraction of manure. These methods can be divided into four classes: physical, chemical, biological, and combined pretreatment [8]. Thermal pretreatment is a type of physical pretreatment in which the lignocellulosic biomass is subjected to heat at a certain temperature and pressure, and it can promote organic matter hydrolysis and breakdown during AD [9,10,11]. Chemical pretreatment is a widely used method to alter the physical and chemical characteristics of lignocellulose biomass [11]. Biological pretreatment is used to break down the complex structures in a substrate with enzymes such as cellulose and protein [12]. These pretreatments alter the lignocellulose structures by destroying the chemical bonds, which may improve biogas production [13]. Some pretreatments studied for biogas production are summarized in Table 1. However, there are certain limitations in the use of these pretreatments. For instance, thermal pretreatment needs high energy requirements, chemical pretreatment produces secondary pollution, and biological pretreatment needs to monitor microorganism growth [13].

Ultrasonic pretreatment is a type of physical pretreatment that is simple, time saving, environmentally friendly, and has no chemical addition [20, 21]. The ultrasonic treatment is performed through the cavitation effect, including mechanical, thermal, and sonochemical effects [22]. Previous research has established that ultrasonic technology can damage the fiber structure, break the hydrogen bonds between fiber molecules, and also increase the inner surface area of fiber [23, 24]. Quiroga et al. [25] evaluated the effect of ultrasonic pretreatment in methane production when co-digesting CD with food waste and sewage sludge. The results showed that after sonication treatment of CD and sludge, the methane yield (0.85 L CH4/L day) for mesophilic showed an increase of 31% with respect to the non-sonicated waste (0.74 L CH4/L day). Ormaechea et al. [26] studied the pretreatment by ultrasound (sonication energy of 1040 kJ/kg TS) for a mixture of cattle manure, food waste, and raw glycerine. They obtained specific methane production of 290 L CH4/kg VS without pretreatment and 520 L CH4/kg VS with pretreatment.

Many studies have reported ultrasonic pretreatment with CD can improve biogas production. However, they just focused on the ultrasonic power and time. Few researchers discussed the influence of ultrasonic impulse time on anaerobic digestion. Therefore, the main objectives of this study are to (1) evaluate the effect of different ultrasonic pretreatment conditions (power, time length, and impulse time) on CD; (2) analyze the correlation of methane production and characteristics of substrate (pH, ammonia nitrogen, and soluble organic matters) during AD process; and (3) explore the changes of microbial community after AD with and without ultrasonic pretreatment of CD.

Materials and Methods

Substrate and Inoculum

The dry CD was collected from a cow farm in Linyi, Shandong Province, China. The dry CD was cut into small pieces, milled, and then mixed with tap water to the TS of 10% before further use. Anaerobic seed sludge was collected from an anaerobic digester treating waste-activated sludge from the Haibo River sewage treatment plant, Qingdao. The CD contained about 10.69 ± 0.87%, 8.76 ± 0.58%, and 14.16 ± 1.03% of TS, VS (volatile solid), and C/N (carbon to nitrogen ratio). The initial characteristics of anaerobic seed sludge were TS 5.11 (0.53%), VS 3.82 (0.39%), and C/N 7.21 (0.64%). The substrates and inoculum were individually homogenized and stored in a refrigerator at 4 °C before further use.

Ultrasonic Pretreatment

Ultrasonication was performed using an Ultrasonic cell pulverizer (SCIENTZ, China). The sonication frequency of the device was 20 kHz, and the maximum power input was 650 W when using a 6-mm probe. A volume of 40 mL of 10% CD added in a centrifuge tube (50 mL) was manually dosed in the ultrasonic horn. During sonication, the temperature was controlled at around 30 ℃. The pretreatment study was split into two approaches. In the first approach based on the ultrasonic power (W) study, the prepared samples were kept at different applied ultrasonic powers (65, 130, 195, 260, and 325 W) [27] at an ultrasonic time of 10 min and impulse time of 2 s opened, 1 s closed. After getting the suitable power, the second approach based on time study, the prepared samples were kept at certain times (5, 10, 15, 20, and 30 min) [28]. At the suitable ultrasonic power and length, the third approach based on impulse time study, the samples were kept at different impulse times (1 s opened 1 s closed, 2 s opened 1 s closed, 2 s opened 2 s closed, 3 s opened 2 s closed, and 3 s opened 3 s closed) [29]. The control treatment without ultrasonic pretreatment was prepared in the same way.

Anaerobic Biodegradability Tests

A batch reactor was performed to test the rate and extent of anaerobic biodegradability of untreated (control) and ultrasonic pretreated CD. All batch tests were performed at 37 ℃ in 500-mL anaerobic reactors with a working volume of 400 mL. The reactors were set with a CD-to-ASS ratio of 1 based on VS content [13]. All of the reactors were purged with nitrogen for at least 3 min to remove oxygen from the reactor space in order to maintain anaerobic conditions. Each reactor was connected with an inverted bottle, containing a solution of 1.5 N sodium hydroxide (NaOH), through a silicon S-tube to ensure the scrubbing of CO2 and H2S from the biogas generated from the reactor [30]. The CH4 was gathered in aluminum foil bag. The pH value of the culture was not controlled. The experiment was conducted in triplicate for 26 days.

Analytical Methods

Scanning Electron Microscopy (SEM)

The surface morphology of the adsorbents was determined by scanning electron microscopy (SEM) (SU8010, Hitachi, Japan). The raw substrate samples were oven dried at 105 ℃ for 24 h and then analyzed after cooling to room temperature [17].

pH and Lignocellulose

The pH was determined with a pH meter (Thermo, USA). The cellulose and lignin were studied by using the titration method.

Solubility Index

Samples from the reactor were taken and the volume of methane was measured every 2 days. Before analysis, the samples were centrifuged at 10,000 rpm for 5 min and the supernatant was filtered using 0.45-μm filters. The sample’s TS, VS, and soluble chemical oxygen demand (sCOD) were obtained using standard methods [31]. The total ammonia nitrogen (TAN) content and carbohydrate were studied using the spectrophotometer (HACH, DR/2800) [32].

The free ammonia nitrogen (FAN) concentration was calculated based on the following equation [33]:

where TAN is the total ammonia nitrogen, Ka is a dissociation constant that reflects on temperature with values 1.29 × 10−9 for 37 ℃, and pH is equal to the pH of the substance.

Methane Production

The produced methane was collected using an aluminum foil bag and the volume of methane was measured by using a graduated 100-mL plastic syringes.

Statistical Analysis

The analysis of the solubility index was performed in triplicate sets. The average and standard deviation of the duplicates were calculated and shown using GraphPad Prism v. 7.0 (GraphPad Software, Inc.). Also, an analysis of variance and the Tukey test were performed, with a 95% confidence interval (p < 0.05).

Results and Discussions

Pretreatment Effect on Chemical Characteristics

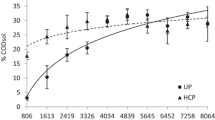

The effect of solution characteristics with various ultrasonic powers was studied under the operation condition of the ultrasonic length of 10 min with impulse time of 2 s opened and 1 s closed. The effect of ultrasonic power with constant time on CD in ultrasonic pretreatment is shown in Fig. 1a. It was observed that the increase in ultrasonic power could improve the solubilization rate, which was measured by sCOD and carbohydrate. The increase of soluble organic matter indicated that the polymer was broken and the intracellular constituents were released [22]. The maximum value was achieved by the ultrasonic power of 325 W. The maximum value of sCOD and carbohydrate reached 10,362 mg/L and 760 mg/L (94% increase in sCOD and 77% increase in carbohydrate). Qi et al. [21] proved the similar conclusion that the sCOD increased in ultrasound power and peaked at 200 W-20 min, which was 66% greater than the control sCOD. Kisielewska et al. [34] reported that ultrasound pretreatment of Sida hermaphreodita made the maximum COD solubilization by 21% increased with energy input (Es) ranging from 200 to 550 kJ/kg.

The effect of solution characteristics with various ultrasonic lengths was studied under the operation condition of ultrasonic power of 130 W with impulse time of 2 s opened and 1 s closed. Figure 1b illustrates the effect of ultrasonic time on CD measured by sCOD and carbohydrates. As seen in Fig. 3, disintegration increased after 10 min of ultrasound and then remained stable of ultrasonic length from 10 to 20 min, and increased at the ultrasonic length of 30 min. It was observed that the highest soluble organic matters, including sCOD and carbohydrate, can be achieved by 30 min of ultrasonic (96% increase in sCOD and 120% increase in carbohydrate). Apul et al. [28] indicated that soluble COD achieved the highest value by 15 min of ultrasonic pretreatment and increased nearly 5 times. Longer ultrasonic pretreatment time led to more complex reactions and resulted in fluctuations of soluble organic matter. The stabilization of sCOD and carbohydrate at the ultrasonic time from 10 to 20 min is most probably due to the entrapment of organics into floc structure since the released organics and polymers can have flocculation during the ultrasonic pretreatment [35].

The effect of solution characteristics with various ultrasonic impulse times was studied under the operation condition of ultrasonic power of 130 W and ultrasonic time of 10 min. Figure 1c evaluates the effect of sCOD and carbohydrates with different ultrasonic impulse times. It can be seen that at the impulse time of continuous time: 2 s and pulsive time: 2 s, sCOD and carbohydrate decreased sharply. While the sCOD and carbohydrate reached the highest level, increasing 58% and 67%, respectively, with the continuous time of 2 s and pulsive time of 1 s. This phenomenon indicated that smaller bubbles dissolve into the liquid more rapidly as the pulse-off time becomes longer, while an appropriate pulse-off time could increase the number of bubbles, which were adequate for sonochemical reactions [36].

Considering the energy input and the effect of solubilization, we use the condition of the ultrasonic power of 325 W, ultrasonic length of 30 min with the ultrasonic continuous time of 2 s, and pulsive time of 1 s to study the anaerobic digestion process.

SEM Analysis

The micromorphology of the untreated (control) and ultrasound-pretreated CD was studied by scanning electron microscopy (SEM). SEM images of control and ultrasound pretreated CD (Fig. 2) showed significant changes in microscopic morphology. The control sample had a rigid, compacted smooth surface with some batches, while the surface of the ultrasound-pretreated sample had more fissures and larger hollows. This was because the micro-jet produced by the cavitation effect of ultrasonic impacted the shear substances and destroyed the interior transistor of the substances [37]. Thus, the results concluded that the ultrasonic pretreatment damaged the physical structure of CD, which could increase the accessible surface and release more biodegradable substances.

The Influence of Pretreatment on Anaerobic Digestion

Effect of Ultrasonic Pretreatment on Methane Production

The quantity of biogas produced from CD over 26 days solid retention time (SRT) is shown in Fig. 3a. The daily methane yields of pretreatment exhibited two peaks (day 6 and day 12). In contrast, the group of control only has one peak (day 12). The maximum daily methane production was found on day 2, which was 150 and 222 mL in control and ultrasonic pretreated treatment, respectively. That may be because the dissolved organic matter and easily degradable substances existed and were digested by methanogens at the beginning of AD. The daily methane yield of ultrasonic pretreated CD reached the first peak on day 6. This result indicates that ultrasonic pretreated CD was more easily accessible to hydrolytic bacteria at the early stage of digestion [38]. The organic acids gained from macromolecule organic matter digested by hydrolytic acidification resulted in the inhibition of methanogen activity and decline in the daily menthane yield [39]. The cumulative methane production of pretreatment increased by 136% compared with the control. The result demonstrated that ultrasonic pretreatment could increase the daily methane peak and improve the total methane production of AD. This result was consistent with Braguglia et al. [40] and Zou et al. [37]. The reason for this might be that ultrasonic pretreatment dissolves the soluble substances and strengthen the activity of methanogens.

Effect of Ultrasonic Pretreatment on TAN and FAN

The variation of TAN contents was observed to evaluate the impact of ultrasonic pretreatment on CD with AD. TAN was made up of ionized ammonium nitrogen (NH4+) and unionized free ammonium nitrogen (FAN/NH3). Unionized NH3 is more toxic than ionized form due to its uncharged nature and solubility in lipids, which may cause the unionized NH3 to pass the biological cell membranes easily and can affect the stability of the microbial cells during the methane production process [41]. Figure 3b illustrates the evolution of TAN and FAN concentration following the AD time. The transitions of TAN of the group of control and pretreatment were dominated by an upward trend universally in the first 14 days as the nitrogenous organics, such as protein, were degraded by hydrolytic bacteria. Then there was a brief dip in evolution, which may be because of the rapid metabolism of TAN for methanogens growth. After that, the stages in control and ultrasonic pretreatment treatment remained stable at 450 and 390 mg/L, respectively. Ultrasonic pretreatment can enhance the activity of the methanogens, which utilize more ammonium for growth metabolism and cause the TAN concentrations to decrease after stability. The variation trends of FAN and pH were similar, and pH affected FAN concentration in the AD process [42].

Effect of Ultrasonic Pretreatment on sCOD and Carbohydrate

Ultrasonic pretreatment significantly influenced the sCOD and carbohydrates during the AD process. The variation of sCOD and carbohydrate is shown in Fig. 3c. The sCOD and carbohydrate concentration decreased at the beginning, which was different from the result of Pan et al. [39], the sCOD was increased during the first 10 days, and then decreased. This phenomenon indicated that the methanogenic rate was higher than the hydrolysis rate during the initial stages of AD. The dissolved organic matter was consumed higher than that produced by the microorganism. Ultrasonic pretreatment can effectively improve the consumption of biodegradable organic matter and enhance the activity of methanogenic microbic. The sCOD removal rate of pretreatment (58%) was higher than that of the control (36%). The same result was observed in the removal rates of carbohydrates, which were 47% and 35% in the treatment with ultrasonic pretreatment and control, respectively.

Effect of Ultrasonic Pretreatment on pH

One of the most important factors that directly affect biogas production during AD process is the pH value. The variation of pH during the AD process is shown in Fig. 3d. The pH value showed a rapid drop during the first 4 days for both control and pretreatment reactors. This phenomenon was attributed to the production of volatile fatty acids resulting from the digestible organic matter decomposition. Then, due to the consumption of volatile fatty acids by methanogens, the pH value increased gradually from day 4 to day 18. The optimum pH range during AD is estimated between 6.5 and 7.2, which is preferable for methanogenic archaea [43]. The pH of group pretreatment is lower than the group control after stable, which may be because ultrasonic pretreatment made the organic matter easier degradation and produced more volatile fatty acids.

Effect of Ultrasonic Pretreatment on the Removal Rate of Organic Matter

The removal rates of VS, cellulose, and lignin are represented in Fig. 4. The VS removal rate was increased after ultrasonic pretreatment (21.8%) compared with the control (18.4%). This result indicated the substance was easily biodegraded and used after ultrasonic pretreatment. The increasing VS removal rate could be interpreted as ultrasonic pretreatment could destroy the cell structure of organic matter, and hydrolysis, the rate-limiting step of digestion, was overcome by sonication [28]. Ultrasonic pretreatment of CD results in the alteration of the surface structure and production of oxidizing radicals that chemically attack the lignocellulosic matrix [23]. The cellulose and lignin removal rates with ultrasonic pretreatment were 30.1% and 10.4%. Without pretreatment, the removal rate of cellulose and lignin was 29.6% and 7.5%, respectively. After anaerobic digestion, the removal rate of cellulose with ultrasonic pretreatment was increased with no significant change compared with the control. However, the lignin removal rate with ultrasonic pretreatment has a major difference compared with the control. Because through pretreatment, lignin is dissolved in the liquid [44]. The hydrolysis of cellulose yields fermentable sugars such as glucose, xylose, arabinose, mannose, and galactose as by-products. These fermentable sugars can be further used as a carbon source for energy production [45].

Microbic Community

In the process of AD, microorganisms play an important role, and the stability of the microbial community can be used as an indicator of system stability. To explore which specific microbic species were predominant under ultrasonic pretreatment, we used the barplot graph to compare the average relative distribution of microbial communities at the phylum level of bacteria and the genus level of archaea, observed with and without ultrasonic pretreatment (Fig. 5). The relative abundance of microbic community in the culture with ultrasonic pretreatment is higher than control. Figure 5a shows the relative abundance of bacterial community at the phylum level. Several phyla were found ubiquitous, and three phyla (Proteobacteria, Acidobacteria, and Actinobacteria) were found to be dominant. Proteobacteria are known for utilizing glucose, acetate, propionate, and butyrate [46]. Acidobacteria encodes a wide repertoire of carbohydrate-active enzymes involved in the breakdown, utilization, and biosynthesis of diverse carbohydrates [47]. Actinobacteria have the main functions, including degradation/decomposition of all sorts of organic substances, for example, cellulose, polysaccharides, protein fats, organic acids, and so on [48]. The relative abundance of Proteobacteria was decreased after AD, which can be explained by the biodegradable substance utilized by the microorganism. The Acidobacteria abundance had no noticeable changes after ultrasonic pretreatment, while the relative abundance of Actinobacteria was increased after pretreatment (control: 6.38%, pretreatment: 9.16%). The explanation for the increasing of Actinobacteria was that ultrasonic pretreatment could enhance the hydrolysis of macromolecular organic matter and the utilization of the hydrolysate.

The relative abundance of the archaeal community at the genus level is shown in Fig. 5b. Methanothrix, a type of acetoclastic methanogen (which utilizes acetate as the substrate to produce methane), was the most abundant. The next most abundant specie was different, Methanobrevibacter for P-0 and C-0, which is hydrogenotrophic methanogens, utilizes H2/CO2 as the substrate to produce methane, while Methznolinea for C-26 and P-26, which is both hydrogenotrophic and acetoclastic methanogen, utilizes both H2/CO2 and acetate as the substrate to produce methane. The third most abundant specie was Methanomassiliicoccus, which is hydrogenotrophic methanogen [49]. And it also shows that the relative abundance of Methanothrix decreased and Methznolinea increased from day 0 to day 26, both in control and ultrasonic pretreatment. The reason for this result was that the pH in the reactor increased, and the acetate substance decreased. For day 26, the abundance of Methanothrix in the group of ultrasonic pretreated (44%) was higher than that of the control (38%). And also, the next most abundant specie was Methznolinea, with 14% detected in the control culture and 17% detected in the pretreatment culture, respectively. That may be because the soluble organic matter increased, and nutrients were provided to microbes in ultrasonic pretreatment culture.

Conclusion

Ultrasonic pretreatment can increase the solubilization rate of sCOD and carbohydrates in the anaerobic digestion of CD. Ultrasonic pretreatment significantly improves methane production by increasing the methanogen activity to utilize ammonium. During anaerobic digestion, the ultrasonic pretreatment can also change the bacterial community, where Actinobacteria phyla were significantly increased. In the future, the studies should perform the energy balance and energy benefit when using pretreatment to increase methane production.

Data Availability

The datasets are available from the corresponding author upon reasonable request.

References

Harikishan S, Sung S (2003) Cattle waste treatment and class A biosolid production using temperature-phased anaerobic digester. Adv Environ Res 7:701–706. https://doi.org/10.1016/S1093-0191(02)00034-5

Li K, Yang Z, Zhang Y et al (2022) Effect of pretreated cow dung fiber on mechanical and shrinkage properties of cementitious composites. J Clean Prod 348:131374. https://doi.org/10.1016/j.jclepro.2022.131374

Shen R, Chen R, Yao Z et al (2021) Engineering and microbial characteristics of innovative lab and pilot continuous dry anaerobic co-digestion system fed with cow dung and corn straw. Bioresour Technol 342:126073. https://doi.org/10.1016/j.biortech.2021.126073

Liu Y, Wang T, Xing Z et al (2022) Anaerobic co-digestion of Chinese cabbage waste and cow manure at mesophilic and thermophilic temperatures : digestion performance, microbial community, and biogas slurry fertility. Bioresour Technol 363:127976. https://doi.org/10.1016/j.biortech.2022.127976

Alfa IM, Dahunsi SO, Iorhemen OT et al (2014) Comparative evaluation of biogas production from poultry droppings, cow dung and lemon grass. Bioresour Technol 157:270–277. https://doi.org/10.1016/j.biortech.2014.01.108

Liu L, Zhang T, Wan H et al (2015) Anaerobic co-digestion of animal manure and wheat straw for optimized biogas production by the addition of magnetite and zeolite. Energy Convers Manag 97:132–139. https://doi.org/10.1016/j.enconman.2015.03.049

Veluchamy C, Raju VW, Kalamdhad AS (2017) Prerequisite – an electrohydrolysis pretreatment for anaerobic digestion of lignocellulose waste material. Bioresour Technol 235:274–280. https://doi.org/10.1016/j.biortech.2017.03.137

Meegoda JN, Li B, Patel K, Wang LB (2018) A review of the processes, parameters, and optimization of anaerobic digestion. Int J Environ Res Public Health 15(10):2224. https://doi.org/10.3390/ijerph15102224

Atelge MR, Atabani AE, Banu JR et al (2020) A critical review of pretreatment technologies to enhance anaerobic digestion and energy recovery. Fuel 270:117494. https://doi.org/10.1016/j.fuel.2020.117494

Menardo S, Airoldi G, Balsari P (2012) The effect of particle size and thermal pre-treatment on the methane yield of four agricultural by-products. Bioresour Technol 104:708–714. https://doi.org/10.1016/j.biortech.2011.10.061

Zhou S, Zhang Y, Dong Y (2012) Pretreatment for biogas production by anaerobic fermentation of mixed corn stover and cow dung. Energy 46:644–648. https://doi.org/10.1016/j.energy.2012.07.017

Oh Y, Shih I, Tzeng Y, Wang S (2000) Protease produced by Pseudomonas aeruginosa K-187 and its application in the deproteinization of shrimp and crab shell wastes. Enzyme Microb Technol 27:3–10. https://doi.org/10.1016/S0141-0229(99)00172-6

Rajput AA, Zeshan VC (2018) Effect of thermal pretreatment on chemical composition, physical structure and biogas production kinetics of wheat straw. J Environ Manage 221:45–52. https://doi.org/10.1016/j.jenvman.2018.05.011

McVoitte WPA, Clark OG (2019) The effects of temperature and duration of thermal pretreatment on the solid-state anaerobic digestion of dairy cow manure. Heliyon 5:e02140. https://doi.org/10.1016/j.heliyon.2019.e02140

Wang C, Shao Z, Qiu L (2021) The solid-state physicochemical properties and biogas production of the anaerobic digestion of corn straw pretreated by microwave irradiation. R Soc Chem 11:3575–3584. https://doi.org/10.1039/d0ra09867a

Veluchamy C, Raju VW, Kalamdhad AS (2018) Electrohydrolysis pretreatment for enhanced methane production from lignocellulose waste pulp and paper mill sludge and its kinetics. Bioresour Technol 252:52–58. https://doi.org/10.1016/j.biortech.2017.12.093

Jaffar M, Pang Y, Yuan H et al (2016) Wheat straw pretreatment with KOH for enhancing biomethane production and fertilizer value in anaerobic digestion. Chinese J Chem Eng 24:404–409. https://doi.org/10.1016/j.cjche.2015.11.005

Breton-deval L, Méndez-acosta HO, González-álvarez V et al (2018) Agave tequilana bagasse for methane production in batch and sequencing batch reactors : acid catalyst effect, batch optimization and stability of the semi-continuous process. J Environ Manage 224:156–163. https://doi.org/10.1016/j.jenvman.2018.07.053

Shen F, Li H, Wu X et al (2018) Effect of organic loading rate on anaerobic co-digestion of rice straw and pig manure with or without biological pretreatment. Bioresour Technol 250:155–162. https://doi.org/10.1016/j.biortech.2017.11.037

Zou S, Wang H, Wang X et al (2016) Application of experimental design techniques in the optimization of the ultrasonic pretreatment time and enhancement of methane production in anaerobic co-digestion. Appl Energy 179:191–202. https://doi.org/10.1016/j.apenergy.2016.06.120

Qi N, Zhao X, Zhang L et al (2021) Performance assessment on anaerobic co-digestion of Cannabis ruderalis and blackwater: ultrasonic pretreatment and kinetic analysis. Resour Conserv Recycl 169:105506. https://doi.org/10.1016/j.resconrec.2021.105506

Chen W, Gao X, Xu H et al (2017) Influence of extracellular polymeric substances (EPS) treated by combined ultrasound pretreatment and chemical re-flocculation on water treatment sludge settling performance. Chemosphere 170:196–206. https://doi.org/10.1016/j.chemosphere.2016.12.004

Hassan SS, Williams GA, Jaiswal AK (2018) Emerging technologies for the pretreatment of lignocellulosic biomass. Bioresour Technol 262:310–318. https://doi.org/10.1016/j.biortech.2018.04.099

Chu X, Cheng Q, Xu Y et al (2021) Anaerobic digestion of corn straw pretreated by ultrasonic combined with aerobic hydrolysis. Bioresour Technol 341:125826

Quiroga G, Castrillón L, Marañón E et al (2014) Effect of ultrasound pre-treatment in the anaerobic co-digestion of cattle manure with food waste and sludge. Bioresour Technol 154:74–79. https://doi.org/10.1016/j.biortech.2013.11.096

Ormaechea P, Castrillón-pelaez L, Marañón E et al (2017) Influence of the ultrasound pretreatment on anaerobic digestion of cattle manure, food waste and crude glycerine. Environ Technol 38:682–686. https://doi.org/10.1080/09593330.2016.1208278

Wang H, Yang SC, Cai W et al (2019) Enhanced organic matter and nutrient release from waste activated sludge using ultrasound and surfactant synergetic pre-treatment. Bioresour Technol Reports 6:32–38. https://doi.org/10.1016/j.biteb.2019.01.017

Apul OG, Sanin FD (2010) Ultrasonic pretreatment and subsequent anaerobic digestion under different operational conditions. Bioresour Technol 101:8984–8992. https://doi.org/10.1016/j.biortech.2010.06.128

Qu R, Tang M, Wang Y, et al (2020) TEMPO-oxidized cellulose fibers from wheat straw: effect of ultrasonic pretreatment and concentration on structure and rheological properties of suspensions. Carbohydr Polym 117386. https://doi.org/10.1016/j.carbpol.2020.117386

Dhamodharan K, Kumar V, Kalamdhad AS (2015) Effect of different livestock dungs as inoculum on food waste anaerobic digestion and its kinetics. Bioresour Technol 180:237–241. https://doi.org/10.1016/j.biortech.2014.12.066

Association APH (2012) Standard methods for the examination of water and wastewater. DC, US, Washington

Xue Y, Liu H, Chen S et al (2015) Effects of thermal hydrolysis on organic matter solubilization and anaerobic digestion of high solid sludge. Chem Eng J 264:174–180. https://doi.org/10.1016/j.cej.2014.11.005

Angelidaki I (2013) Effect of ammonium and acetate on methanogenic pathway and methanogenic community composition. FEMS Microbiol Ecol 83:38–48. https://doi.org/10.1111/j.1574-6941.2012.01456.x

Kisielewska M, Rusanowska P, Dudek M et al (2020) Evaluation of ultrasound pretreatment for enhanced anaerobic digestion of Sida hermaphrodita. Bioenergy Res 13:824–832. https://doi.org/10.1007/s12155-020-10108-9

Laurent J, Pierra M, Casells M et al (2009) Activated sludge properties after ultrasonic and thermal treatments and their potential influence on dewaterability. J Residuals Sci Technol 6:19–26

Tuziuti T, Yasui K, Lee J et al (2008) Mechanism of enhancement of sonochemical-reaction efficiency by pulsed ultrasound. J Phys Chem A 112:4875–4878. https://doi.org/10.1021/jp802640x

Zou S, Wang X, Chen Y et al (2016) Enhancement of biogas production in anaerobic co-digestion by ultrasonic pretreatment. Energy Convers Manag 112:226–235. https://doi.org/10.1016/j.enconman.2015.12.087

Zhu J, Wan C, Li Y (2010) Enhanced solid-state anaerobic digestion of corn stover by alkaline pretreatment. Bioresour Technol 101:7523–7528. https://doi.org/10.1016/j.biortech.2010.04.060

Pan J, Ma J, Liu X et al (2019) Effects of different types of biochar on the anaerobic digestion of chicken manure. Bioresour Technol 275:258–265. https://doi.org/10.1016/j.biortech.2018.12.068

Braguglia CM, Gagliano MC, Rossetti S (2012) High frequency ultrasound pretreatment for sludge anaerobic digestion: effect on floc structure and microbial population. Bioresour Technol 110:43–49. https://doi.org/10.1016/j.biortech.2012.01.074

Ngo T, Shahsavari E, Shah K et al (2022) Improving bioenergy production in anaerobic digestion systems utilising chicken manure via pyrolysed biochar additives: a review. Fuel 316:123374. https://doi.org/10.1016/j.fuel.2022.123374

Wang H, Fotidis IA, Angelidaki I (2015) Ammonia effect on hydrogenotrophic methanogens and syntrophic acetate-oxidizing bacteria. FEMS Microbiol Ecol 91:1–8. https://doi.org/10.1093/femsec/fiv130

Lahbab A, Djaafri M, Kalloum S et al (2021) Co-digestion of vegetable peel with cow dung without external inoculum for biogas production : experimental and a new modelling test in a batch mode. Fuel 306:121627. https://doi.org/10.1016/j.fuel.2021.121627

Ren N, Wang A, Cao G et al (2009) Bioconversion of lignocellulosic biomass to hydrogen: potential and challenges. Biotechnol Adv 27:1051–1060. https://doi.org/10.1016/j.biotechadv.2009.05.007

Prapinagsorn W, Sittijunda S, Reungsang A (2018) Co-digestion of napier grass and its silage with cow dung for bio-hydrogen and methane production by two-stage anaerobic digestion process. Energies 11:. https://doi.org/10.3390/en11010047

Li Y, Achinas S, Zhao J et al (2020) Co-digestion of cow and sheep manure: performance evaluation and relative microbial activity. Renew Energy 153:553–563. https://doi.org/10.1016/j.renene.2020.02.041

Dedysh SN, Sinninghe Damsté JS (2018) Acidobacteria. Encycl Life Sci 1–10. https://doi.org/10.1002/9780470015902.a0027685

Anadan R, Dhanasekaran D. MGP (2016) An Introduction to Actinobacteria. Basics Biotechnol Appl 3–38. https://doi.org/10.5772/62329

Wang P, Peng H, Adhikari S et al (2020) Enhancement of biogas production from wastewater sludge via anaerobic digestion assisted with biochar amendment. Bioresour Technol 309:123368. https://doi.org/10.1016/j.biortech.2020.123368

Funding

This study was jointly supported by the National Key Research and Development Program of China (No. 2020YFD1100303) and the Taishan Scholar Foundation of Shandong Province (No. tsqn201909126).

Author information

Authors and Affiliations

Contributions

All the authors contributed to the conception and design. Yuxing Xu: first draft of the manuscript and data analysis; Hao Chang: experimental operation and data collection; Chen Yang: experimental operation; Changqing Liu: funding acquisition, supervision, and reviewing; Yihua Xiao: funding acquisition and reviewing.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

The impact of the dissolution rate of organic matter was studied based on different ultrasonic parameters.

The dissolution rate of sCOD and carbohydrates increased by 96% and 120% after ultrasonic pretreatment.

Cumulative methane production was improved by 136% when compared to the control.

The bacterial community was significantly changed after ultrasonic pretreatment.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yuxing, X., Hao, C., Chen, Y. et al. Ultrasonic Pretreatment of Cow Dung for Anaerobic Digestion: Effect on Methane Production and Microbial Community. Bioenerg. Res. 17, 660–668 (2024). https://doi.org/10.1007/s12155-023-10629-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-023-10629-z