Abstract

The present study was aimed to consider the effect of light intensity on the growth and lipid accumulation properties of a freshwater microalga Chlorococcum oleofaciens KF584224.1. The microalga was cultivated at five different light intensities of 50, 100, 200, 400, and 800 μmol photons m−2 s−1 for 20 days. The culture curves illustrated the fastest growth rate for microalgae illuminated with 200 μmol photons m−2 s−1, while the longest exponential growth curve was obtained in culture illuminated with 400 μmol photons m−2 s−1. Once algae reached the stationary phase, the maximum biomass productivity (367.82 ± 21.63 mg L−1 day−1) was found in culture illuminated with 200 μmol photons m−2 s−1, while the highest lipid content (59.18 ± 1.62%) and lipid productivity (126.72 ± 3.27 mg L−1 day−1) were achieved in culture illuminated with 400 μmol photons m−2 s−1. The ratio of saturated fatty acids significantly increased with enhancing light illumination, while the ratio of monounsaturated fatty acids and polyunsaturated fatty acids tend to decline (p < 0.05). The properties of biodiesel obtained from C. oleofaciens cultured under 50 μmol photons m−2 s−1 met the specifications provided by the international biodiesel standards (European EN 14214 and US ASTM D6751), higher light illumination improved the biodiesel quality. Findings of the present study demonstrated that light intensity could improve the lipid productivity and biodiesel properties obtained from C. oleofaciens as a potential feedstock for biofuel production, especially under 400 μmol photons m−2 s−1 light intensity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Microalgae are heterogeneous organisms with a vast array of distinct advantages which their cultivation has received growing attention for biodiesel production in recent years. They represent fast generation time and high photosynthetic efficiency in various environmental conditions, while no high-quality arable land is required to grow the biomass [1]. Some algal species accumulate large amount of neutral lipids mainly in the form of triacylglycerols that can be readily converted into alkyl esters to obtain biodiesel and other sources of energy [2]. Microalgae can also utilize carbon dioxide, one of the major greenhouse gases with a significant cause of anthropogenic activities related to global warming, while their biomass residue could also be utilized for biogas or fertilizer production [3].

Growth pattern and secondary metabolite production of microalgae depend on media composition (nitrogen, phosphorous, iron, and sulfur) or growth conditions (temperature, pH, and light intensity) [4]. Basically, light is one of the most important parameters which affect the algae growth by providing the energy to support their metabolism and efficient conversion into biomass. It has been well established that microalgae could grow on various light intensities, although considerable changes may occur in their photosynthetic activity, pigments content, or lipid profile [5]. Industrial algal cultivation systems commonly use the continuous illumination to maximize the biomass production, while the appropriate light intensity varies from 60 to 120 μmol photons m−2 s−1 according to the species-specific characteristics [6]. However, the light energy beyond the saturation point may induce photoinhibition damage due to the inability of algal photosynthetic apparatus to absorb the light irradiance, leading to an impaired biomass production [7].

From the economic point of view, the selection of appropriate oil-rich algal species is the first key step for the development of a biofuel production program from microalgae [8]. Among various microalgae reported in the literature, the genus Chlorococcum is a unicellular green microalga with rapid growth rate, high lipid content, and great adaptability to various conditions making it an excellent candidate for biodiesel production [9]. In the work of Sun et al. [10], Chlorococcum sp. exhibited higher biomass productivity (131.44 mg L−1 day−1) compared to the other four microalgal species belonging to the genera Scenedesmus, Micractinium, and Neochloris. An improved lipid productivity was also stated in C. ellipsoideum (130.4 mg L−1 day−1) and C. nivale (161.7 mg L−1 day−1) under nitrogen insufficient condition [11]. Furthermore, the biodiesel properties obtained from Chlorococcum sp. found within the limits set by international standards due to the presence of more than 80% C16-C18 fatty acids in parallel with a linolenic acid (C18:3) content below 10% [9].

Knowledge about the behavior of microalgal strains under different biotic or abiotic conditions is imperative to enhance their economic feasibility for biodiesel production. Chlorococcum oleofaciens is a freshwater algal species with numerous oil droplets which can become yellow-orange during the cultures aging making it an appropriate candidate for biodiesel production [12]. While numerous investigations have carried out on the response of various Chlorococcum strains to changes in medium nutrient concentrations [10, 13], there are no systematic researches regarding the application of light intensity on the strain C. oleofaciens for biodiesel production. Accordingly, the present study was conducted to investigate the effect of light intensity on growth, lipid productivity, and fatty acid composition of C. oleofaciens. The biodiesel properties of the extracted lipid have also been evaluated based on the fatty acid profile and compared with the standard biodiesel specifications.

Materials and Methods

Strain Isolation and Culture Condition

Freshwater strain C. oleofaciens KF584224.1 was obtained from Zakarya-e-Razi Laboratory Complex, IAU University, Tehran, Iran. The isolate is originally collected from a water body in Shemiranat County, Tehran, Iran, which has a mid-latitude climate with warm and humid weather in summer (sampling time) and mild temperature in winter. The water at the collection site shows an annual basic pH value of 8.35 with average temperature of 28.5 °C, average dissolved oxygen 8.59 mg L−1, and electrical conductivity of 362.84 μS m−1. All other detained steps and operating conditions about collection, isolation, and purification were described in our previous work [14].

Monoclonal culture of C. oleofaciens was obtained by repeated plate streaking in BG11 broth as the basal culture media composed of (g L−1) NaNO3, 1.5; K2HPO4, 0.03; MgSO4.2H2O, 0.075; CaCl2.2H2O, 0.036; citric acid, 0.006; ferric ammonium citrate, 0.006; EDTA, 0.001; Na2CO3, 0.020; and trace elements 1 mL containing (g L−1) H3BO3, 2.86; MnCl2.4H2O, 1.81; ZnSO4.7H2O, 0.222; NaMoO.5H2O, 0.390; CuSO4.5H2O, 0.0790; Co(NO3)2.6H2O, 0.0494. Antibiotics such as cefotaxime (100 ppm), ampicillin (100 ppm), and erythromycin (20 ppm) were also used for the maintaining axenic status of microalgal cultures. The isolate was then grown in 1-L Erlenmeyer flasks containing 500 mL sterilized BG11 medium and incubated under constant illumination using cool white fluorescent lamps at 200 μmol photons m−2 s−1 and 100 rpm for aeration. The culture pH was kept at 7.5 ± 0.1, while the temperature was adjusted to 30 °C based on the environmental condition of isolation place and those applied for the maintenance of this species in our previous research [14]. All materials and media were autoclaved for 20 min at 121 °C to prevent any contamination throughout the isolation and cultivation.

Experimental Setup for Different Light Intensity

An exponentially growing culture of C. oleofaciens having the OD750 (optical density at 750 nm) of 0.8 was applied for inoculating 20 (5 × 4) sterilized 1-L Erlenmeyer flasks having autoclaved BG11 Medium (50% v/v). To explore the effect of various light intensity, each set of 4 experimental flasks were subjected to different light intensities (50, 100, 200, 400, and 800 μmol photons m−2 s−1) by keeping the cultures at various distance from the light source provided from cool white fluorescent lamps with spectral distribution ranging from 380 to 760 nm. The designated irradiances were measured at the surface of experimental flasks using a digital photometer (LI-185B, Li-COR, Lincoln, NE, USA). The experimental light intensities were selected based on previous experiments performed on the Chlorococcum genus [10, 13] and similar studies that examined the effect of different irradiances on the growth of algae for biodiesel production [6]. The cultures were cultivated under the same conditions as described above and incubated in quadruplicate for 20 days to evaluate their growth characteristics and lipid productivity under different light intensities.

Growth Estimation and Biomass Evaluation

The microalgal growth was spectrophotometrically assessed by drawing aliquots of 2 mL from the culture flasks at regular interval of 2 days and measuring the OD750 using a UV-vis spectrophotometer (UV-2401 PC, Shimadzu Corporation, Kyoto, Japan). Algal suspensions were diluted with appropriate ratios if absorbance measurements exceeded a value of 1.0 and the actual OD750 was determined by multiplying OD750 value with the dilution ratio. Cell density (No mL−1) at a given cultivation time was monitored as increase in available OD750 calibrated separately to give the cell counts under different light intensities of 50 (R2 = 0.998), 100 (R2 = 0.994), 200 (R2 = 0.997), 400 (R2 = 0.998), and 800 (R2 = 0.987) μmol photons m−2 s−1.

Dry weight was evaluated by centrifuging 20 mL of the culture medium using a high-speed centrifuge (3-30 K, SIGMA Laborzentrifugen GmbH, Osterode, Germany) at 12000×g for 15 min at 4 °C. The resulting pellets were washed twice with deionized water and lyophilized in a vacuum freeze dryer (CHRIST, Alpha 1–4 LSC, Osterode am Harz, Germany) at − 40 °C for 48 h until the constant weight was achieved for dry weight measurement. Biomass productivity (BP, g L−1 day−1) was calculated via Eq. (1):

where DW2 and DW1 were algal dry weight in mg L−1 harvested from the two sampling points t2 and t1, respectively.

Lipid Extraction and Productivity Analysis

Once algae reached the stationary phase, the total lipids were extracted from freeze-dried biomass pellets according to the well-known method of Bligh and Dyer [15]. Lyophilized algae powder (20 mg) was immersed in a mixture of chloroform: methanol (2:1, v/v) for 24 h, while ultrasonication was used at 70 Hz intensity with a sonicator for 30 min at ambient temperature to break the algal cells. The process was repeated twice until the total lipids were fully extracted. The mixture was then centrifuged at ambient temperature and stood for layer separation. The chloroform:methanol layer with total lipids was washed twice with KCl solution and evaporated using the vacuum freeze dryer at − 90 °C. Thereafter, the total lipids were weighed using an analytical balance (EP 120A, Precisa, Dietikon, Switzerland) and lipid content (LC, %) calculated as the percentage of lipid weight in the cell dry weight according to Eq. (2) [16]:

where WEL and WDA were the weight of extracted lipid and dry algal biomass, respectively. The lipid productivity (LP; g L−1 day−1) was also determined using the following Eq. (3) [16]:

where BP is the biomass productivity (g L−1 day−1) and LC is the lipid content (%).

Fatty Acid Profile Analysis

The lipid composition was assessed following the method described by Kunrunmi et al. [17] with some modifications. In brief, the extracted lipid was transesterified into fatty acid methyl esters (FAMEs) by adding 1 mg of hexane to every 5 mg of extracted lipid after using 0.5 mL methanolic potassium hydroxide (100 μl of 2 M concentration) at room temperature overnight. After the transesterification, the solution was acidified with 5 N HCl before extraction with petroleum ether at 60 °C to liberate fatty acids from the respective potassium salts. When complete phase separation occurred, the organic phase containing biodiesel was collected for FAMEs analysis.

Gas chromatographic (GC) analysis was performed by injecting 1 μl of the FAMEs sample in a Hewlett-Packard 5890 series II gas chromatograph (Palo Alto, CA, USA) equipped with a flame-ionization detector (FID) detector using an Omegawax 320 column (30 m × 0.32 mm I.D. × 0.25 μm; Supelco, Bellefonte, PA, USA). Helium was used as eluent gas with a flow rate of 30 ml min−1. The injector and detector temperature were held at 260 °C. The initial temperature of column was set at 60 °C and increased to 170 °C at a rate of 10 °C min−1, followed by a rise to 180 °C at a rate of 2 °C min−1, where it was maintained constant for 2 min. The temperature was then increased to 230 °C at a rate of 2 °C min−1, kept hold for 1 min, thereafter increased to 240 °C at a rate of 1 °C min−1, where it remained unchanged until all FAMEs were eluted. Fatty acids were identified by comparison of their retention times with those of standard ones (Supelco 37 components FAME mixture, Bellefonte, PA, USA).

Biodiesel Properties Evaluation

The FAME composition obtained from C. oleofaciens was assessed for its biodiesel quality by determining the fuel attributes such as saponification value (SV), iodine value (IV), cetane number (CN), degree of unsaturation (DU), long chain saturated factors (LCSF), and cold flow plugging point (CFPP) using empirical formulas mentioned in Eqs. (4)–(9), respectively [3]:

where F is the percentage of each fatty acid, MW is the molecular weight of respective fatty acid, D is the number of double bonds, MUFA is monounsaturated fatty acids, and PUFA is polyunsaturated fatty acids.

Statistical Analysis

Results were expressed as means of four replicates ± standard deviations (SD). The data were analyzed for significant differences using one-way analysis of variance (ANOVA) followed by Duncan’s new multiple range test with the SPSS 12.0 statistical package for Windows (SPSS Inc.) software. A p value less than 0.05 was regarded as significant.

Results

Effect of Different Light Intensity on Growth Profile of C. oleofaciens

The cell growth of C. oleofaciens in the BG11 medium illuminated with different light intensities are depicted in Fig. 1. The culture curves illustrated the fastest growth rate for algae illuminated with 200 μmol photons m−2 s−1 after reaching the stationary phase on the 18th day of incubation with the maximum cell densities 1.68 and 1.39-folds higher than those grown under 50 and 100 μmol photons m−2 s−1 light intensities, respectively. A further increase in light intensities to 400 μmol photons m−2 s−1 decreased the growth rate of algae during the experiment. However, no significant difference was observed in the final cell density of algae grown in cultures illuminated with 200 and 400 μmol photons m−2 s−1. With rising light intensity to 800 μmol photons m−2 s−1, the microalgal growth leveled off to the minimum value of 0.72 × 107 cell mL−1 after 12 days. Cell cultured under 50 μmol photons m−2 s−1 illumination reached the stationary growth phase after 12 days of incubation, while cultures supplemented with 400 μmol photons m−2 s−1 exhibited the longest exponential growth phase of 18 days compared to the other experimental treatments. The algae grown under 100 and 400 μmol photons m−2 s−1 illuminations were also entered into the stationary phase after 18 and 16 days of incubation, respectively.

The specific growth rate of the strain was significantly influenced by different light intensities (Fig. 2). The highest specific growth rate of 0.39 ± 0.01 day−1 was found in the culture illuminated with 200 μmol photons m−2 s−1 that was significantly higher than those cultures illuminated with 50 and 100 μmol photons m−2 s−1. However, no significant difference was observed in specific growth rate of cells cultured under 200 and 400 μmol photons m−2 s−1 light densities.

Effect of Different Light Intensity on Biomass and Lipid Productivity of C. oleofaciens

Once cultures reached the stationary phase, the biomass productivity, overall lipid content, and lipid productivity of cells cultivated under different light intensities were determined. As shown in Table 1, the rise in light intensity resulted in increased biomass productivity with a maximum level of 367.82 ± 21.63 mg L−1 day−1 in culture illuminated with 200 μmol photons m−2 s−1. However, no significant difference was recorded in biomass productivity of cultures illuminated with 200 and 400 μmol photons m−2 s−1. Further increase in light intensity to 800 μmol photons m−2 s−1 showed a significant decrease in the biomass productivity (p < 0.05). On the other hand, the lipid content reached a maximum of 59.18 ± 1.62% in culture illuminated with 400 μmol photons m−2 s−1, beyond which the lipid content decreased significantly (p < 0.05). Similar results were also found for lipid productivity with the highest lipid productivity in culture illuminated with 400 μmol photons m−2 s−1, whereas cells cultured under light intensity of 800 μmol photons m−2 s−1 showed the lowest lipid productivity of 50.36 ± 0.35 mg L−1 day−1.

Effect of Different Light Intensity on Fatty Acid Profile of C. oleofaciens

The fatty acid composition of C. oleofaciens grown under different light intensities is given in Table 2. The isolated strain possessed fatty acids in the range of C12:0 to C22:0, while FAMEs of 16 to 18 carbon chain length accounted for more than 84.24% of total fatty acids in cells grown under various illumination. Cells cultured under 50 μmol photons m−2 s−1 had shown lipid composition of palmitic acid (C16:0; 28.23 ± 0.74%), oleic acid (C18:1; 17.61 ± 1.44%), stearic acid (C18:0; 14.32 ± 1.73%), and linoleic acid (C18:2; 13.92 ± 1.85%) as the major contributing fatty acids. When the cultural light intensity reached 400 μmol photons m−2 s−1, the major fatty acids were palmitic acid (38.06 ± 1.73%), stearic acid (29.80 ± 2.61%), myristic acid (C14:0; 9.47 ± 0.72%), and oleic acid (6.43 ± 0.82%). By increasing the cultivation irradiance, the ratio of saturated fatty acids (SFAs) significantly increased from 50.08 ± 3.51% to 89.10 ± 5.83%, while the ratio of monounsaturated fatty acids (MUFAs) and polyunsaturated fatty acids (PUFAs) significantly decreased from 26.61 ± 2.01% to 5.63 ± 0.78% and from 23.31 ± 1.93% to 5.27 ± 0.69%, respectively (p < 0.05).

Effect of Different Light Intensity on Characteristic Attributes of Biodiesel from C. oleofaciens

The intensity of light significantly affected the estimated biodiesel properties based on the fatty acid profile (Table 3). The CN of methyl esters illustrated an increasing trend with increasing light density from 55.47 in culture illuminated with 50 μmol photons m−2 s−1 to the maximum of 68.60 in culture illuminated with 400 μmol photons m−2 s−1. On the contrary, the DU significantly declined with increasing light intensity to a minimum of 26.25% in culture illuminated with 400 μmol photons m−2 s−1. The IV showed a similar trend to the DU with the lowest value of 16.30 g I2 100 g−1 in culture illuminated with 400 μmol photons m−2 s−1. On the other hand, the LCSF and CFPP positively correlated with culture light density with the highest value of 24.58 and 60.75 °C in culture illuminated with 400 μmol photons m−2 s−1, respectively. However, no significant difference was obtained in SV of oil extracted from algae grown under different light intensities.

Discussion

Among various effective factors recognized for optimization of microalgal growth, light is a key parameter to be considered since it helps in photosynthesis by producing chlorophyll and other metabolites in the microalgae [4]. As an endothermic process, carbon fixation requires light energy that enables microalgae to convert carbon dioxide and water into organic compounds such as carbohydrate and protein through photosynthetic reactions, while oxygen releases as a waste product [18]. It is well known that the fixation of a molecule of carbon dioxide in a photosynthetic system requires 8 photons of photosynthetically active radiation [19]. In the present study, an increase in light irradiation up to 200 μmol photons m−2 s−1 enhanced the cell density to the peak of 4.23 × 104 cell mL−1 and longest exponential growth phase of 18 days, showing that the radiation intensity is a limiting factor for growth of C. oleofaciens. However, an increase in the culture illumination to 400 μmol photons m−2 s−1 did not significantly correspond to the higher growth rate and longer exponential growth phase, implying that cells absorb the excess light energy, while they cannot use it for biomass production through the photosynthesis. When light intensity finally reached the maximum of 800 μmol photons m−2 s−1, a drastic decrease in the microalga cell density was observed. These findings obviously show that suitable photon flux density is required for growth maximization of C. oleofaciens, whereas the strong irradiation over the saturation limit declines its growth performance. High illumination intensities could induce photoinhibition by damaging the photosynthetic receptor system within a few minutes that inhibits the growth of microalgae due to photooxidation of light pigments such as chlorophyll and carotenoids [7].

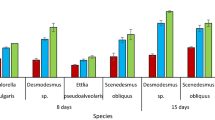

A general trend towards increasing specific growth rate with enhancing light illumination up to the saturation point has been reported in different microalgae [6]. Ho et al. [20] stated that light intensity promotes cell growth, biomass productivity, and carbon dioxide fixation in Scenedesmus obliquus with the highest value around 1.65–1.8 day−1 in the light saturation region (180–540 μmol photons m−2 s−1), while excessive illumination decreased the specific growth rate and biomass production. Wahidin et al. [21] described the maximum specific growth rate of 0.3999 day−1 with a division rate of 0.489 day−1 for Nannochloropsis sp. at light intensity of 100 μmol photons m−2 s−1 and photoperiod 18 h:06 h light:dark cycle. The maximum specific growth rate of 1.747 ± 0.03 day−1 was also reported for Neochloris oleoabundans UTEX1185 at 200 μmol photons m−2 s−1 irradiance and 25 °C [22]. Similarly, cells cultured under 200 μmol photons m−2 s−1 irradiation in the present study had the highest specific growth rate, although no significant difference was recorded between them and those cultured under 200 and 400 μmol photons m−2 s−1 light density. These findings confirmed that light irradiation is an important factor enhancing growth of. C. oleofaciens with advisable density of 200 μmol photons m−2 s−1 if the biomass production has more priority for industrial application.

Biomass productivity is a function of cellular light absorption by photosynthetic microalgae that gives an overview about bioconversion efficiency of solar energy into fuels [23]. From the biological perspective, light intensity promotes the cell growth, CO2 fixation, carbohydrate synthesis, and biochemical composition of algae by providing all energy required to support the metabolism and growth [6]. The higher the biomass productivity, the higher the photosynthetic efficiency and biomass yield will be. In the present study, cell cultured under 200 μmol photons m−2 s−1 showed the highest biomass productivity of 367.82 ± 21.63 mg L−1 day−1, which was lower than those reported for other microalgal species with suitable potential for biodiesel production such as Chlorella vulgaris (240 mg L−1 day−1; [24]), but was higher than those reported for Scenedesmus abundans (70.23 mg L−1 day−1; [25]), Amphora subtropica (130 mg L−1 day−1; [26]), and Nannochloropsis oceanica (75.56 mg L−1 day−1; [27]). However, further increase in medium light intensity to 800 μmol photons m−2 s−1 resulted in the lowest biomass concentration of C. oleofaciens, confirming the inhibitory effects of excess illumination on microalgae photosynthesis [28]. The photosynthetic light reactions commonly take place within the thylakoid membrane in the presence of oxygen molecule [29]. When the light intensity is exceeded from the photosynthetic harvesting capacity, the triplet excited state chlorophyll (3Chl*) that generate very reactive singlet oxygen (1O2) within the PSII complex can easily oxidize and degrade pigments, proteins, and lipids, leading to the lower biomass productivity of algae [30].

The lipid accumulation improvement could be accomplished by the perception of internal metabolic pathways that control the lipid biosynthesis. The photoautotroph microalgae convert carbon dioxide to sugar in the presence of photon energy [31]. The chloroplast generates the 3-phosphoglycerate which is further processed to pyruvate after Calvin cycle [32]. In the presence of pyruvate dehydrogenase, the pyruvate can be further metabolized by aerobic pathways to acetyl coenzyme A (Acetyl-CoA) that, in turn, regulates the first committed step in triacylglyceride biosynthesis [33]. The fatty acids could be finally biosynthesized through multifunctional enzyme complex that catalyzes a series of carbon chain lengthening and desaturation reactions to form mainly C16 and C18 fatty acids [2]. In the current study, lipid content of C. oleofaciens accumulated by increasing the light intensity in the culture broth and reached the peak of 59.18 ± 1.62% in medium illuminated with 400 μmol photons m−2 s−1, indicating that more carbon flux produced through the photosynthesis is channeled to the lipid accumulation. On exposure to large amount of light energy, microalgae direct the excess energy towards the metabolic pathway of neutral lipids like triacylglycerol, the main constituents of neutral lipids which serve as a sink of excessive energy absorbed by photosynthetic apparatus [34]. Lower lipid accumulation under 800 μmol photons m−2 s−1 irradiation may be associated with an increased production of free radicals, which in turn destroy the biosynthetic pathways of lipid synthesis [35].

The production cost of biofuel from microalgae is as high as fossil fuel-derived diesel [36]. To enhance the economic feasibility of biodiesel production from microalgae, it would be ideal to obtain the highest biomass productivity along with the maximum lipid cell content [37]. The biomass productivity represents the daily net increase in dry matter per unit of light intercepted. However, it cannot singly provide a reliable index of the proper condition for biodiesel production from microalgae as the faster growth may not lead to more oil production [38]. The lipid content, by contrast, expresses the amount of fat produced by each microalgal cell regardless of its growth characteristics [39]. Lipid productivity is another fundamental variable calculated as the product of lipid content and biomass productivity; hence, it creates a rational correlation between oil produced on the basis of volume and time [37]. In the present study, the highest biomass productivity of 367.82 ± 21.63 mg L−1 day−1 was obtained under 200 μmol photons m−2 s−1 light density, while it did not significantly differ with that under 400 μmol photons m−2 s−1 light density (p > 0.05). The highest lipid content was also produced in culture illuminated with 400 μmol photons m−2 s−1. On the other hand, the maximum lipid productivity of 198.32 ± 4.61 mg L−1 day−1 was attained in culture illuminated with 400 μmol photons m−2 s−1. In agreement with previous researches [40], these findings indicate that lipid productivity could be a more reliable indicator for identifying the proper conditions of biodiesel production from C. oleofaciens compared to lipid content or biomass productivity, although assessing the impact of other growth conditions could provide more comprehensive judgment.

The composition and structure of fatty acids influence the overall quality and properties of biodiesel produced from microalgae feedstock to establish its suitability for usage as fuel [41]. In the present study, the FAMEs obtained from C. oleofaciens mainly contained the fatty acids with 16 to 18 carbon chain length (more than 80%), which are most favorable for industrial biodiesel production. It has been also reported that light intensity affects the properties of microalgal-derived biodiesel by altering the percentage of SFAs, MUFAs, and PUFAs, which their proportion commonly counterbalance each other [42]. A shift in light intensity of the culture condition from 50 to 400 μmol photons m−2 s−1 in the present study caused a significant enhancement in total amount of SFAs obtained from C. oleofaciens, while the amount of MUFAs and PUFAs significantly declined (p < 0.05). Similar results were also found in Chlorella vulgaris where the content of PUFAs was reduced by exposing to higher light intensity, whereas the content of SFAs enhanced [43]. Increases in saturated and monounsaturated fatty acids were also obtained in Neochloris oleoabundans with an increase in light intensity [10]. Finally, Kumar et al. [44] demonstrated the effect of high light intensity on higher SFA concentrations in microalgal consortia collected from natural ecological water bodies. It is proven that low light intensity induces the formation of more polar lipids due to an increase in chloroplast membrane synthesis, while a stepwise increase in light intensity tends to produce more neutral lipids (mainly triacylglycerol) as a protective mechanism for the cell [45]. Under normal growth conditions, ATP and NADPH generated by photosynthesis are consumed to drive the chemical reactions necessary for (carbon fixation) generating sugars and other carbon-containing compounds like proteins and fats, with ADP and NADP+ eventually being available again as electron acceptor molecules. Under high light intensities, the microalgal cells will change the metabolic pathways to SFA synthesis which has been found to require large amounts of photosynthetic-produced ATP and NADPH derived from the excess of electron transport chain [46]. The increased fatty acid production, in turn, could help the cells to replenish the electron acceptor pool for photosynthesis and prevent them from photochemical destruction [47].

The main objective to analyze the FAME composition of extracted lipid from microalgae is to evaluate its suitability for direct usage as fuel in diesel engines. This is done by assessing the essential fuel attributes such as CN, IV, DU, LCSF, and CFPP that are calculated in the present study. The CN is of the prime dimensionless measure of biodiesel attributed to ignition delay time and combustion quality which is highly influenced by the saturation level of the fatty acids [48]. An increase in the CN means a shorter ignition delay, better engine combustion, higher oxidative stability, lower nitrogen oxide release, and reduced pollutant emission [49]. The estimated CN for biodiesel obtained from C. oleofaciens in the present study varied from 55.47 to 68.60 under different light intensities which comply with the minimum value of 47 and 51 as prescribed by the US (ASTM D6751) and European standards (EN 14214), respectively.

The IV is another chemical property of biodiesel quality related to the position of double bonds in the carbon chains of the alkyl esters which refer to the tendency of biodiesel to react with oxygen at near ambient temperature [41]. Determination of the IV provides a useful estimate of the biofuel oxidation to prevent the engine problems like glycerides polymerization and lubricant formation on engine nozzles, piston rings, and piston rig grooves [50]. The European biodiesel standard EN14214 establishes a maximum limit of 120 g I2 100 g−1 biodiesel, whereas only its measurement and registration are requested in the USA. In the present study, the IV obtained from C. oleofaciens exposed to different illumination was in the range of 16.30–75.56 g I2 100 g−1 that conformed to the EN 14214 standard specifications.

Biodiesel quality is also affected by the DU, an imperative attribute that influences the oxidative stability of biodiesel which is expressed as the sum of the monounsaturated and polyunsaturated acid masses [3]. A large degree of unsaturation leads to polymerization of biodiesel upon reaction with atmospheric air that negatively impacts on storage stability [51]. The DU from C. oleofaciens in the present study decreased from 73.23% in cells under 50 μmol photons m−2 s−1 light density to the maximum of 26.25% in cells grown under 400 μmol photons m−2 s−1, which means the biodiesel derived from C. oleofaciens cultured under higher light intensity was more feasible to longer storage that is critical for fuel application. A lower IV was also obtained at lower DU, which shows a positive correlation between IV and DU.

The SV is an important index of biodiesel analysis that represents the milligram KOH required to completely saponify 1 g of fat sample. Since all fatty acids react with one molecule of KOH, the SV indirectly gives a measure for evaluating the molecular mass of fatty acids [52]. The longer the fatty acid chain, the shorter number of carboxylic functional groups per unit mass and lower SV as well. Although the SV is not a restricted property in the EN14214 and ASTM D6751 standards, the SV of C. oleofaciens under different light intensity varied within a narrow range of 208.52 to 210.18 mg KOH g−1, which were around those stated for the other exceptional microalgal candidates for high-quality biodiesel production, such as Calothrix brevissima (226.03 mg KOH g−1) [53], Chlorella sp. (217.08 mg KOH g−1) [3], and Scenedesmus abundans (205.08 mg KOH g−1) [25].

The poor cold flow properties of biodiesel fuel have been a technical reason impairing its more widespread usage [54]. The CFPP is a prime indicator for low-temperature applications of a fuel that is defined as the lowest temperature at which a given volume of pure fuel passes through a standardized filter within a given time [55]. This parameter is mostly dependent on the long chain saturated ester content as well as the chain length of the saturated esters, while the effect of unsaturated ester composition could be ignored [54]. Therefore, CFPP and LCSF are related to each other; fatty acids with longer chain length and those with higher content of saturation have higher melting point and better high-temperature properties [37]. According to EN 14214, each country could specify certain temperature limits for each season depending on climate conditions. Due to the presence of long chain SFA, especially palmitic acid (C16:0), the biodiesel from C. oleofaciens cultured under higher light intensity in the present study illustrated higher CFPP and LCSF compared to those culture under lower light intensity, making it less appropriate for utilization in colder regions. However, it is within the value expressed for Scenedesmus abundans [25], Nostoc carneum [53], and Chlamydomonas sp. [41].

Conclusion

Findings of the present study demonstrated that light intensity improves the growth performance and lipid accumulation of C. oleofaciens. When algae were grown under 400 μmol photons m−2 s−1, the highest lipid content (59.18 ± 1.62%) and lipid productivity (198.32 ± 4.61 mg L−1 day−1) were observed at the end of log phase, while no significant difference was found in specific growth rate and biomass productivity between 200 μmol photons m−2 s−1 and 400 μmol photons m−2 s−1 illumination. The fatty acid profile contained 82.30 ± 3.49% SFA with higher predominance of palmitic acid, stearic acid, and myristic acid under 400 μmol photons m−2 s−1 light intensity. The properties of biodiesel obtained from C. oleofaciens cultured under 50 μmol photons m−2 s−1 met the specifications provided by the international biodiesel standards (European EN 14214 and US ASTM D6751), although higher illumination up to 400 μmol photons m−2 s−1 enhanced the lipid characteristics produced from C. oleofaciens KF584224.1 for biofuel production. However, it is necessary to confirm the laboratory scale findings in large-scale cultivation using indigenously made photobioreactors.

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Change history

01 September 2020

The original version of this article unfortunately contained incorrect data in Fig. 2 caption.

References

Kiran B, Kumar R, Deshmukh D (2014) Perspectives of microalgal biofuels as a renewable source of energy. Energy Convers Manag 88:1228–1244. https://doi.org/10.1016/j.enconman.2014.06.022

Cagliari A, Margis R, Maraschin FS, Turchetto-Zolet AC, Loss G, Margis-Pinheiro M (2011) Biosynthesis of triacylglycerols (TAGs) in plants and algae. Int J Plant Biol 2(1):40–52. https://doi.org/10.4081/pb.2011.e10

Francisco ÉC, Neves DB, Jacob-Lopes E, Franco TT (2010) Microalgae as feedstock for biodiesel production: carbon dioxide sequestration, lipid production and biofuel quality. J Chem Technol Biotechnol 85(3):395–403. https://doi.org/10.1002/jctb.2338

Benavente-Valdés JR, Aguilar C, Contreras-Esquivel JC, Méndez-Zavala A, Montañez J (2016) Strategies to enhance the production of photosynthetic pigments and lipids in chlorophycae species. Biotechnol Rep 10:117–125. https://doi.org/10.1016/j.btre.2016.04.001

Wu H (2016) Effect of different light qualities on growth, pigment content, chlorophyll fluorescence, and antioxidant enzyme activity in the red alga Pyropia haitanensis (Bangiales, Rhodophyta). Biomed Res Int 2016:7383918–7383918. https://doi.org/10.1155/2016/7383918

Singh SP, Singh P (2015) Effect of temperature and light on the growth of algae species: a review. Renew Sust Energ Rev 50:431–444. https://doi.org/10.1016/j.rser.2015.05.024

Mulders KJM, Lamers PP, Martens DE, Wijffels RH (2014) Phototrophic pigment production with microalgae: biological constraints and opportunities. J Phycol 50(2):229–242. https://doi.org/10.1111/jpy.12173

Rawat I, Ranjith Kumar R, Mutanda T, Bux F (2013) Biodiesel from microalgae: a critical evaluation from laboratory to large scale production. Appl Energy 103:444–467. https://doi.org/10.1016/j.apenergy.2012.10.004

Del Río E, Armendáriz A, García-Gómez E, García-González M, Guerrero MG (2015) Continuous culture methodology for the screening of microalgae for oil. J Biotechnol 195:103–107. https://doi.org/10.1016/j.jbiotec.2014.12.024

Sun X, Cao Y, Xu H, Liu Y, Sun J, Qiao D, Cao Y (2014) Effect of nitrogen-starvation, light intensity and iron on triacylglyceride/carbohydrate production and fatty acid profile of Neochloris oleoabundans HK-129 by a two-stage process. Bioresour Technol 155:204–212. https://doi.org/10.1016/j.biortech.2013.12.109

Li T, Wan L, Li A, Zhang C (2013) Responses in growth, lipid accumulation, and fatty acid composition of four oleaginous microalgae to different nitrogen sources and concentrations. Chin J Oceanol Limnol 31(6):1306–1314. https://doi.org/10.1007/s00343-013-2316-7

Kawasaki Y, Nakada T, Tomita M (2015) Taxonomic revision of oil-producing green algae, Chlorococcum oleofaciens (Volvocales, Chlorophyceae), and its relatives. J Phycol 51(5):1000–1016. https://doi.org/10.1111/jpy.12343

Adams C, Godfrey V, Wahlen B, Seefeldt L, Bugbee B (2013) Understanding precision nitrogen stress to optimize the growth and lipid content tradeoff in oleaginous green microalgae. Bioresour Technol 131:188–194. https://doi.org/10.1016/j.biortech.2012.12.143

Rajabi Islami H, Assareh R (2020) Enhancement effects of ferric ion concentrations on growth and lipid characteristics of freshwater microalga Chlorococcum oleofaciens KF584224.1 for biodiesel production. Renew Energy 149:264–272. https://doi.org/10.1016/j.renene.2019.12.067

Bligh EG, Dyer WJ (1959) A rapid method of total lipid extraction and purification. Can J Biochem Physiol 37:911–917. https://doi.org/10.1139/o59-099

Rai MP, Nigam S, Sharma R (2013) Response of growth and fatty acid compositions of Chlorella pyrenoidosa under mixotrophic cultivation with acetate and glycerol for bioenergy application. Biomass Bioenergy 58:251–257. https://doi.org/10.1016/j.biombioe.2013.08.038

Kunrunmi O, Adesalu T, Kumar S (2017) Genetic identification of new microalgal species from Epe Lagoon of West Africa accumulating high lipids. Algal Res 22:68–78. https://doi.org/10.1016/j.algal.2016.12.009

Gonçalves AL, Simões M, Pires JCM (2014) The effect of light supply on microalgal growth, CO2 uptake and nutrient removal from wastewater. Energy Convers Manag 85:530–536. https://doi.org/10.1016/j.enconman.2014.05.085

Amaro HM, Guedes AC, Malcata FX (2011) Advances and perspectives in using microalgae to produce biodiesel. Appl Energy 88(10):3402–3410. https://doi.org/10.1016/j.apenergy.2010.12.014

Ho S-H, Chen C-Y, Chang J-S (2012) Effect of light intensity and nitrogen starvation on CO2 fixation and lipid/carbohydrate production of an indigenous microalga Scenedesmus obliquus CNW-N. Bioresour Technol 113:244–252. https://doi.org/10.1016/j.biortech.2011.11.133

Wahidin S, Idris A, Shaleh SRM (2013) The influence of light intensity and photoperiod on the growth and lipid content of microalgae Nannochloropsis sp. Bioresour Technol 129:7–11. https://doi.org/10.1016/j.biortech.2012.11.032

Loera Quezada MM, Angeles G, Olguín EJ (2017) Effect of irradiance on the cell density, size and lipid accumulation of Neochloris oleoabundans. Rev Latinoam Biotecnol Amb Algal 2(2):81–92

Sørensen B (2017) 5 - energy transmission and storage. In: Sørensen B (ed) Renewable energy (Fifth Edition). Academic Press, Boston, pp 569–646. doi:https://doi.org/10.1016/B978-0-12-804567-1.00005-0

Griffiths MJ, van Hille RP, Harrison STL (2012) Lipid productivity, settling potential and fatty acid profile of 11 microalgal species grown under nitrogen replete and limited conditions. J Appl Phycol 24(5):989–1001. https://doi.org/10.1007/s10811-011-9723-y

Rai MP, Gupta S (2017) Effect of media composition and light supply on biomass, lipid content and FAME profile for quality biofuel production from Scenedesmus abundans. Energy Convers Manag 141:85–92. https://doi.org/10.1016/j.enconman.2016.05.018

BenMoussa-Dahmen I, Chtourou H, Rezgui F, Sayadi S, Dhouib A (2016) Salinity stress increases lipid, secondary metabolites and enzyme activity in Amphora subtropica and Dunaliella sp. for biodiesel production. Bioresour Technol 218:816–825. https://doi.org/10.1016/j.biortech.2016.07.022

Ashour M, Elshobary ME, El-Shenody R, Kamil A-W, Abomohra AE-F (2019) Evaluation of a native oleaginous marine microalga Nannochloropsis oceanica for dual use in biodiesel production and aquaculture feed. Biomass Bioenergy 120:439–447. https://doi.org/10.1016/j.biombioe.2018.12.009

Li Z, Wakao S, Fischer BB, Niyogi KK (2009) Sensing and responding to excess light. Annu Rev Plant Biol 60(1):239–260. https://doi.org/10.1146/annurev.arplant.58.032806.103844

Bastien O, Botella C, Chevalier F, Block MA, Jouhet J, Breton C, Girard-Egrot A, Maréchal E (2016) Chapter one - new insights on thylakoid biogenesis in plant cells. In: Jeon KW (ed) International review of cell and molecular biology, vol 323. Academic press, pp 1–30. https://doi.org/10.1016/bs.ircmb.2015.12.001

Takahashi S, Badger MR (2011) Photoprotection in plants: a new light on photosystem II damage. Trends Plant Sci 16(1):53–60. https://doi.org/10.1016/j.tplants.2010.10.001

Faried M, Samer M, Abdelsalam E, Yousef RS, Attia YA, Ali AS (2017) Biodiesel production from microalgae: processes, technologies and recent advancements. Renew Sust Energ Rev 79:893–913. https://doi.org/10.1016/j.rser.2017.05.199

Maity JP, Bundschuh J, Chen C-Y, Bhattacharya P (2014) Microalgae for third generation biofuel production, mitigation of greenhouse gas emissions and wastewater treatment: present and future perspectives – a mini review. Energy 78:104–113. https://doi.org/10.1016/j.energy.2014.04.003

Heldt H-W, Piechulla B (2011) 15 - lipids are membrane constituents and function as carbon stores. In: Heldt H-W, Piechulla B (eds) Plant biochemistry (Fourth Edition). Academic Press, San Diego, pp 359–398. doi:https://doi.org/10.1016/B978-0-12-384986-1.00015-6

Difusa A, Talukdar J, Kalita MC, Mohanty K, Goud VV (2015) Effect of light intensity and pH condition on the growth, biomass and lipid content of microalgae Scenedesmus species. Biofuels 6(1–2):37–44. https://doi.org/10.1080/17597269.2015.1045274

Barber J, Andersson B (1992) Too much of a good thing: light can be bad for photosynthesis. Trends Biochem Sci 17(2):61–66. https://doi.org/10.1016/0968-0004(92)90503-2

Sibi G, Shetty V, Mokashi K (2016) Enhanced lipid productivity approaches in microalgae as an alternate for fossil fuels – a review. J Energy Inst 89(3):330–334. https://doi.org/10.1016/j.joei.2015.03.008

Griffiths MJ, Harrison STL (2009) Lipid productivity as a key characteristic for choosing algal species for biodiesel production. J Appl Phycol 21(5):493–507. https://doi.org/10.1007/s10811-008-9392-7

Christou M, Alexopoulou E, Cosentino SL, Copani V, Nogues S, Sanchez E, Monti A, Zegada-Lizarazu W, Pari L, Scarfone A (2018) 4 - Giant reed: from production to end use. In: Alexopoulou E (ed) Perennial grasses for bioenergy and bioproducts. Academic press, Cambridge, pp 107–151. https://doi.org/10.1016/B978-0-12-812900-5.00004-7

Tan KWM, Lee YK (2016) The dilemma for lipid productivity in green microalgae: importance of substrate provision in improving oil yield without sacrificing growth. Biotechnol Biofuels 9:255–255. https://doi.org/10.1186/s13068-016-0671-2

Kim DW, Shin W-S, Sung M-G, Lee B, Chang YK (2019) Light intensity control as a strategy to improve lipid productivity in Chlorella sp. HS2 for biodiesel production. Biomass Bioenergy 126:211–219. https://doi.org/10.1016/j.biombioe.2019.05.014

Nascimento IA, Marques SSI, Cabanelas ITD, Pereira SA, Druzian JI, de Souza CO, Vich DV, de Carvalho GC, Nascimento MA (2013) Screening microalgae strains for biodiesel production: lipid productivity and estimation of fuel quality based on fatty acids profiles as selective criteria. Bioenergy Res 6(1):1–13. https://doi.org/10.1007/s12155-012-9222-2

Wacker A, Piepho M, Harwood JL, Guschina IA, Arts MT (2016) Light-induced changes in fatty acid profiles of specific lipid classes in several freshwater phytoplankton species. Front Plant Sci 7:264–264. https://doi.org/10.3389/fpls.2016.00264

Amini Khoeyi Z, Seyfabadi J, Ramezanpour Z (2012) Effect of light intensity and photoperiod on biomass and fatty acid composition of the microalgae, Chlorella vulgaris. Aquac Int 20(1):41–49. https://doi.org/10.1007/s10499-011-9440-1

Kumar G, Nguyen DD, Huy M, Sivagurunathan P, Bakonyi P, Zhen G, Kobayashi T, Xu KQ, Nemestóthy N, Chang SW (2019) Effects of light intensity on biomass, carbohydrate and fatty acid compositions of three different mixed consortia from natural ecological water bodies. J Environ Manag 230:293–300. https://doi.org/10.1016/j.jenvman.2018.09.026

Sharma KK, Schuhmann H, Schenk PM (2012) High lipid induction in microalgae for biodiesel production. Energies 5(5):1532–1553. https://doi.org/10.3390/en5051532

Richmond A (2013) Biological principles of mass cultivation. In: Richmond A, Hu Q (eds) Handbook of Microalgal Culture: Biotechnology and Applied Phycology. CRC Press, Blackwell Publishing Company, Oxford, pp 169–204. https://doi.org/10.1002/9780470995280.ch8

Rochaix J-D (2011) Regulation of photosynthetic electron transport. BBA- Bioenergetics 1807(3):375–383. https://doi.org/10.1016/j.bbabio.2010.11.010

Bhatia SC (2014) 22 - Biodiesel. In: Bhatia SC (ed) Advanced renewable energy systems. Woodhead publishing India, New Delhi, pp 573–626. https://doi.org/10.1016/B978-1-78242-269-3.50022-X

Knothe G (2009) Improving biodiesel fuel properties by modifying fatty ester composition. Energy Environ Sci 2(7):759–766. https://doi.org/10.1039/B903941D

Oromí-Farrús M, Villorbina G, Eras J, Gatius F, Torres M, Canela R (2010) Determination of the iodine value of biodiesel using 1H NMR with 1,4-dioxane as an internal standard. Fuel 89(11):3489–3492. https://doi.org/10.1016/j.fuel.2010.06.016

Singh B, Guldhe A, Rawat I, Bux F (2014) Towards a sustainable approach for development of biodiesel from plant and microalgae. Renew Sust Energ Rev 29:216–245. https://doi.org/10.1016/j.rser.2013.08.067

Gopinath A, Puhan S, Nagarajan G (2009) Theoretical modeling of iodine value and saponification value of biodiesel fuels from their fatty acid composition. Renew Energy 34(7):1806–1811. https://doi.org/10.1016/j.renene.2008.11.023

Anahas AMP, Muralitharan G (2018) Characterization of heterocystous cyanobacterial strains for biodiesel production based on fatty acid content analysis and hydrocarbon production. Energy Convers Manag 157:423–437. https://doi.org/10.1016/j.enconman.2017.12.012

Imahara H, Minami E, Saka S (2006) Thermodynamic study on cloud point of biodiesel with its fatty acid composition. Fuel 85(12):1666–1670. https://doi.org/10.1016/j.fuel.2006.03.003

Knothe G (2005) Dependence of biodiesel fuel properties on the structure of fatty acid alkyl esters. Fuel Process Technol 86(10):1059–1070. https://doi.org/10.1016/j.fuproc.2004.11.002

Author information

Authors and Affiliations

Contributions

Conceptualization: Houman Rajabi Islami; alga purification and identification: Houman Rajabi Islami; formal analysis and investigation: Marzie Rayati and Mehdi Shamsaie; writing of the first draft of the manuscript: Marzie Rayati; writing of the final version of the manuscript: Houman Rajabi Islami; supervision: Houman Rajabi Islami. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Ethics Statement

All the protocols and procedures employed in the current experiment were performed according to the standard guidelines for the care and use of experimental organisms by Islamic Azad University, Science and Research Branch, and have been approved by the committee on ethics matched biomedical researchers.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original version of this article was revised: Incorrect data in Fig. 2 caption.

Electronic supplementary material

ESM 1

(PDF 530 kb)

Rights and permissions

About this article

Cite this article

Rayati, M., Rajabi Islami, H. & Shamsaie Mehrgan, M. Light Intensity Improves Growth, Lipid Productivity, and Fatty Acid Profile of Chlorococcum oleofaciens (Chlorophyceae) for Biodiesel Production. Bioenerg. Res. 13, 1235–1245 (2020). https://doi.org/10.1007/s12155-020-10144-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-020-10144-5