Abstract

Gamma-aminobutyric acid (GABA) has diverse physiological functions, but its production by lactic acid bacteria is costly due to the culture medium. This study aimed to enhance GABA production by L. futsaii CS3 using low-cost substrates and agri-food industries by-products. Optimal culture conditions were determined using response surface methodology with a central composite design (CCD). Batch and fed-batch fermentation techniques were employed. In the MRS medium with 2% (w/v) monosodium glutamate (MSG), L. futsaii CS3 produced 6.84 g/l of GABA. Further optimization revealed that 2% (w/v) cane sugar resulted in a maximum GABA production of 9.6 g/l, while cane molasses yielded 7.4 g/l. The modified MRS medium with 2% (w/v) MSG, 2% (w/v) cane sugar, 3.06% (w/v) tuna condensate, and 2.5% (w/v) surimi washing water exhibited the highest GABA concentration of 11 g/l. Surimi washing water had a lower GABA concentration of 4.12 g/l. Critical factors identified through CCD analysis were cane sugar, tuna condensate, and MSG. The optimized modified MRS medium consisted of 3.48% (w/v) cane sugar, 3.84% (w/v) tuna condensate, and 10.77% (w/v) MSG, resulting in an actual GABA concentration of 18.27 g/l. Under flask-scale and batch fermentation conditions (initial pH 5, temperature 37 °C), GABA concentrations of 20.63 g/l and 17.24 g/l were obtained after 48 h, respectively. In fed-batch fermentation, GABA concentrations reached 23.01 g/l at 72 h. The addition of cane sugar and tuna condensate effectively enhanced GABA production in L. futsaii CS3, highlighting their suitability as cost-effective substrates for industrial-scale GABA production.

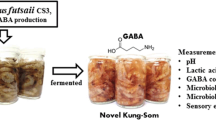

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Gamma-aminobutyric acid (GABA) is a four-carbon non-protein and water-soluble amino acid [32] and widely present in microorganisms, plants and animals [4, 22]. GABA inhibits the neurotransmitter involved in the peripheral tissues and central nervous system in animals [12, 22, 25, 27, 32]. It is mostly present in the brain, where it plays a significant inhibitory neurotransmitter role. GABA stimulates cerebral blood flow and oxygenation, which in turn enhances the metabolism of brain cells [19]. The reduction of GABA in the cells is linked to a number of neurological conditions, such as Alzheimer’s disease, Parkinson’s disease, and seizures [19, 22]. GABA is also involved in multiple physiological functions, such as tumor suppression, cortisol visual improvement, cholesterol regulation, cell homeostasis maintenance, immunity enhancement [22], induction of hypotension and diuretic, tranquillizer effects [13], anti-depressive, reducing blood pressure by expanding the blood vessels [19], preventing chronic alcoholic diseases, inhibiting cancer cell proliferation, improving brain function and promoting insulin [13, 23, 32]. Microorganisms are an important GABA source and produce GABA from L-glutamic acid by decarboxylation catalyzed by glutamic acid decarboxylase (GAD), with pyridoxal 5′-phosphate (PLP) as a cofactor [16]. Microorganisms grow faster than plants, do not need much space for cultivation, and are eco-friendly for consumers. Furthermore, it is easy to control production of microorganism [4]. A variety of lactic acid bacteria (LAB) produce large amounts of GABA [4, 16]. The GABA production capacity depends on species and strains [22]. The genus Lactobacillus has abundant GABA-producing species, including Lactobacillus brevis [4, 24, 31], L. buchneri, L. delbrueckii subsp. bulgaricus, L. fermentum, L. helveticus, L. paracasei [4], L. plantarum [4, 31, 32]. Furthermore, some Streptococcus thermophilus and Lactococcus lactis strains display GABA production abilities, which are the best candidates for production of GABA-rich milk products [4]. In recent years, it has been found that some species from the genera Enterococcus, Leuconostoc, Pediococcus, Propionibacterium and Weissella are capable of producing GABA [4]. The De Man, Rogosa and Sharpe (MRS) medium is primarily useful for cultivation of lactobacilli [14] and also is the simplest medium for GABA production of LAB. Nowadays, GABA production from microorganisms have a major concern about the high costs of the culture medium and the efficiency of GABA production.

Due to the use of expensive formulations of culture media as protein sources for conventional culture media, such as peptone, tryptone, meat extract, beef extract, and yeast extract, GABA production by LAB has a high cost of the culture medium. Other protein sources can be used in place of the pricey commercial media by substituting them in the media formulation. The ability of LAB to produce GABA from inexpensive sources, such as agri-food industry by-products and low-cost substrates, is a benefit. As a source of nitrogen in the current investigation, tuna condensate and surimi washing water were both utilized. A by-product of precooking tuna at 100 °C for approximately one hour in the tuna canning industry is tuna condensate or tuna precooking water. A highly abundant of N-containing compounds in tuna condensate is still currently underutilized. It can be used to replace the pricey commercial medium and serve as an alternative nitrogen source for microbial cultivation. In addition, omega-3 fatty acids are abundant in tuna condensate [17]. Surimi produces washing water as a byproduct. There are numerous washing and dewatering procedures involved in the preparation of surimi. Many compounds are removed during washing, including sarcoplasmic proteins, inorganic salts, low-molecular weight molecules, lipids, and blood components [5]. When washing mince, one kilogram of surimi from fish could produce 27–29 L of effluent [1].

A different strategy to lower the cost of generating GABA and increase the value of the food industry is the utilization of wastes and by-products from the food industry. It may also aid in reducing issues with pollution and global warming. The current study produced GABA from L. futsaii CS3 by substituting cane sugar and cane molasses for the carbon source and tuna condensate waste and surimi washing water waste for the nitrogen source in the modified MRS medium. The culture conditions of GABA production were optimized using the response surface methodology (RSM) with central composite design (CCD) to optimize the optimal modified MRS medium. The initial pH value of the optimal modified MRS medium and the control of pH on GABA production were also optimized. Then, Batch and fed-batch fermentation were used to improve GABA productivity.

The aim of this study was to enhance L. futsaii CS3's synthesis of GABA and reduce the cost of the culture media for GABA production by the utilization of low-cost substrates and agri-food industries by-products. No reports of the microbiological synthesis of GABA from those by-products in batch or fed-batch fermentation have been made to date.

Materials and Methods

Microorganism Preparation

A GABA-producing LAB strain L. futsaii CS3 (accession no. AB839950) was previously isolated from Kong-Som, a Thai traditional fermented shrimp [20]. This strain was activated by growing it in MRS medium containing (w/v): 2% D-glucose, 0.4% yeast extract, 1% peptone, 0.8% beef extract, 0.5% CH3COONa, 0.2% K2HPO4, 0.1% Tween 80, 0.2% C6H17N3O7, 0.02% MgSO4·7H2O, 0.005% MnSO4·4H2O and 2% NaCl and incubated at 37ºC for 24 h without shaking.

Optimization of Culture Condition for GABA Production

Culture condition optimization was conducted in 250 ml Erlenmeyer flasks containing 100 ml of the culture medium. L. futsaii CS3 was cultivated in the MRS medium at 37 °C for 18 h without shaking and then used for seed culture (5% v/v) containing approximately 108 cfu/ml in a flask-scale.

Single-Factor Experiments

The modified MRS medium components were investigated for the flask-scale in order to maximize GABA synthesis from L. futsaii CS3 in a single-factor experiment. The following factors were examined for their influence on the GABA content of fermented the modified MRS medium: types of carbon sources (cane sugar and cane molasses), types of nitrogen sources (surimi washing water and tuna condensate), MSG and Pyridoxal 5′-phosphate (PLP). HPLC was used to determine the GABA content and residual MSG concentrations in the culture broths.

Carbon Sources

In the medium cultivation based on total sugar, locally available cane sugar (commercial grade; Mitr Phol, Bangkok, Thailand) and cane molasses (Mitr Phol, Bangkok, Thailand) were utilized as glucose substitutes. Cultivation was performed in the modified MRS medium containing (w/v): 0.4% yeast extract, 1% peptone, 0.8% beef extract, 0.5% CH3COONa, 0.2% K2HPO4, 0.1% Tween 80, 0.2% C6H17N3O7, 0.02% MgSO4·7H2O, 0.005% MnSO4·4H2O, 2% NaCl, 2% MSG (commercial grade; Ajinomoto, Bangkok, Thailand) and each of various carbon source: cane sugar (2%, w/v) or cane molasses (2.5%, w/v) and incubated at 37 °C for 48 h without shaking.

Nitrogen Sources

By-products of the seafood industry include tuna condensate waste (Chotiwat Manufacturing Co., Ltd., Songkhla, Thailand) and surimi washing water waste (Man A Frozen Foods Co., Ltd., Songkhla, Thailand) were frozen and dried using a freeze dryer. In the microbial media based on total nitrogen, freeze-dried tuna condensate and surimi washing water powders were substituted for peptone, beef extract, and yeast extract. Cultivation was performed in the modified MRS medium containing 2% (w/v) MSG, selected carbon source and each of various nitrogen source: freeze-dried tuna condensate (3.06%, w/v) or freeze-dried surimi washed water (2.5%, w/v) and incubated at 37 °C for 48 h without shaking.

MSG

Cultivation was performed in the modified MRS medium containing 2% (w/v) MSG, selected carbon source and selected nitrogen source and incubated at 37 °C for 48 h without shaking. The modified MRS medium without MSG was used as control.

PLP

Cultivation was performed in the modified MRS medium containing 2% (w/v) MSG, 0.05 and 0.1 mM PLP (Sigma-Aldrich, Steinheim, German), selected carbon source and selected nitrogen source and incubated at 37 °C for 48 h without shaking. The modified MRS medium without PLP was used as control.

Response Surface Methodology (RSM)

RSM is typically used to investigate optimal experimental conditions since it is a reliable and useful statistical methodology. This experiment was examined the effects of single factors on GABA production. Effects of carbon source (X1), nitrogen source (X2) and MSG (X3) were chosen and examined using different amounts (% w/v) of each factor for GABA production. To identify the optimum condition, a Central Composite Design (CCD) was selected. The three levels (− 1, 0 and + 1) were set up according to the results of single factor experiments. The values for the carbon source (X1), nitrogen source (X2) and MSG (X3) were set at 2–4%, 2.5–4.5% and 4.5–16.5% (w/v), respectively. Total of 20 runs with central points were generated.

The model equation of the response (Y) of the three process variables (X1, X2 and X3) is:

Data was analyzed by linear multiple regression using the Design-Expert (Version 10; Stat-Ease, Inc.). To validate the regression coefficient, analysis of variance (ANOVA) for GABA production was performed.

Effect of Initial Medium pH

The optimal modified MRS medium with initial pH values of 4.5, 5, 5.5, 6, 6.5 and without pH adjustment (pH 7) were used for cultivation at 37 °C for 48 h without shaking. HPLC was used to determine the GABA content and residual MSG concentrations in the culture broths.

Effect of Controlled pH on GABA Production

In order to obtain the maximum GABA production from L. futsaii CS3, the optimal modified MRS medium with and without pH control were investigate for the fermentor scale. In a 3–l fermentor (BEM-MDL Series, B.E.Marubushi Co., Ltd., Chiyoda, Japan), 2–l of the optimal modified MRS medium with approximately 1010 cfu/ml was inoculated with the 10% (v/v) seed culture broth. The optimal modified MRS medium with the optimal initial pH value was used for cultivation at 37 °C with agitation speed 50 rpm for 48 h. During fermentation, the pH on GABA production was kept constant at pH 3.5, 4, 4.5 and 5. To maintain the given pH condition, the pH of the culture broth was automatically adjusted by 6 M NaOH or 6 M HCl. GABA content and remaining MSG concentrations in the culture broths were determined by HPLC.

Production of GABA from L. futsaii CS3 by Batch and Fed-Batch Fermentation

L. futsaii CS3 was cultivated in the MRS medium at 37 °C for 18 h and then used for seed culture in the batch and fed-batch fermentation. The batch fermentation, 10% (v/v) seed culture broth contained approximately 1010 cfu/ml was inoculated into a 2–l of the optimal modified MRS medium in a 3–l fermentor. The optimal modified MRS medium with the optimal initial pH value was used for cultivation at 37 °C with agitation speed 50 rpm for 48 h. The fed-batch fermentation was also carried out in a 3–l fermentor under following conditions: 2–l of the modified MRS medium with the optimal initial pH value, 10% (v/v) inoculum size (1010 cfu/ml), temperature 37 °C, agitation speed 50 rpm and fermentation time for 72 h. Sterile MSG was supplemented into the fermentor at 36 h of fermentation. GABA content and MSG remaining concentrations in the batch and fed-batch fermented broths were determined by HPLC.

Analysis of GABA

High-Performance Liquid Chromatography (HPLC) Analysis

Derivatization of GABA

Quantitative analysis of GABA in the culture broth was performed by derivatization with ortho-phthalaldehyde (OPA) (Sigma-Aldrich, Steinheim, Germany) before detection using HPLC [9].

Determination of GABA Quantification

HPLC determination of GABA was performed with an Agilent Technologies 1200 series binary pump, autosampler and a fluorescence detector equipped with an automatic liquid sampler and injector program. The column used was a Hypersil ODS C18 column (particle size 5 μm, length 250 mm, internal diameter 4.6 mm) thermostatted at 40 °C. The HPLC mobile phase was consisted potassium phosphate buffer (1 M, pH 7) as mobile phase A, and acetonitrile as mobile phase B. Absorbance was detected at 330 and 440 nm [9].

Determination of Volumetric Productivity

The volumetric productivity (g/l/h) was determined by the following formula:

Determination of Bioconversion Rate

The bioconversion rate (%) was determined by the following formula:

Determination of Yield

The yield was determined by the following formula:

Statistical Analysis

The data figure was created using the program Microsoft Excel 2010. Program IBM SPSS Statistic was used to analyze the significant differences (p < 0.05 showed that the difference in the analysis results was significant). The response surface was designed, optimized and analyzed using the program Design Export.

Results and Discussion

Optimization of Culture Condition for GABA Production

L. futsaii CS3 has GABA producing ability and the GABA was excreted mainly in the cell culture medium. This strain was previously isolated from Kong-Som, a Thai traditional fermented shrimp [20]. Kong-Som is rich in glutamic acid which is the substrate for the biosynthesis of GABA by LAB. In previous work, L. futsaii CS3 was the most efficient microorganism for the conversion of 25 mg/ml MSG to GABA, with a maximum yield of more than 99% conversion rate within 72 h [20]. This strain produced GABA 10 mg/ml in MRS broth containing 20 mg/ml of MSG during incubation at 37 °C for 120 h [21]. In the present work, after being grown at 37 °C for 48 h without shaking, L. futsaii CS3 produced GABA 6.84 g/l in MRS broth containing 2% (w/v) MSG, with volumetric productivity and bioconversion rates of 0.14 g/l/h and 56.09%, respectively. HPLC was used to quantitatively confirm GABA production. GABA and MSG standard had retention times of approximately 15.5 ± 0.1 and 8.62 ± 0.1 min, respectively. pH, temperature, cultivation time, and culture media were all factors that affected L. futsaii CS3′s capacity to produce GABA. Commercial culture media used to produce GABA by microorganisms, however, are expensive. Due to these reasons, it is crucial to use renewable sources of nitrogen and carbon to optimize the medium for increasing GABA production. This study used low-cost substrates and by-products or wastes from food industry on GABA production for reducing the cost of culture medium and enhancing GABA formation. This is the first report of the GABA production of L. futsaii CS3 by using cane sugar and cane molasses as a carbon source as well as tuna condensate and surimi washing water as a nitrogen source substitute in the MRS medium.

Single-Factor Experiments

In a single-factor experiment, the effects of carbon sources (cane sugar and cane molasses), nitrogen sources (surimi washing water and tuna condensate), MSG and PLP was chosen and tested for GABA production of L. futsaii CS3. The results suggested that types of carbon sources, types of nitrogen sources and MSG affected on GABA production, as described below.

Carbon Sources

The modified MRS medium, which contains 2% (w/v) MSG and either 2% (w/v) cane sugar or 2.5% (w/v) cane molasses based on total sugar, was used for cultivation. HPLC analysis was used to determine L. futsaii CS3′s GABA production. When cane sugar was utilized, this strain produced the highest GABA concentrations, reaching a maximum production of 9.6 g/l and a maximum volumetric productivity and bioconversion rate of 0.2 g/l/h and 78.73%, respectively. While using cane molasses as its carbon source, this strain produced GABA concentrations of 7.4 g/l, volumetric productivity of 0.15 g/l/h, and bioconversion rate of 60.68% (Table 1).

The type of sugar included in culture media has an impact on GABA production by LAB. The highest amount of GABA was produced by each strain of LAB when various sugars were used as the carbon source. In order to produce GABA for L. brevis NCL912, glucose was a preferential carbon source over maltose [10]. Maltose (4%, w/v) outperformed conventional MRS medium with 2% (w/v) D-glucose as the most effective carbon source for L. brevis K203 to produce GABA, increasing GABA by 16% from 27.8 to 32.3 mg/ml [2]. In the fermented adzuki bean milk that had a high GABA yield of 15.42 mg/100 ml, the mixed strains of L. rhamnosus GG and Lc. lactis subsp. lactis utilized sucrose as the carbon source [7]. In fermented coconut drink (100 ml) which added sucrose (1 g), L. acidophilus co-cultured with L. brevis produced the highest GABA of 352 mg/l at 27 °C for 28 h [13]. These findings from earlier studies imply that the GABA conversion mechanism is specific and dependent on the LAB strain.

Cane sugar (refined cane sugar) and cane molasses were utilized in this experiment as carbon sources to increase L. futsaii CS3′s synthesis of GABA. Cane molasses contained sucrose (48.8% dry matter; DM), glucose and fructose (5.3% and 8.1% DM, respectively). Additionally, minerals (sulfates, phosphates, and chlorides) as well as organic acids (lactic, aconitic, citric, malic, formic and oxalic acid) and volatile fatty acids (acetic, propionic and butyric acid) were discovered in cane molasses [15]. This experiment found that sucrose was the best kind of sugar for GABA production of L. futsaii CS3. The modified MRS medium produced the highest GABA concentrations (9.6 g/l) when cane sugar was utilized as a carbon source. In contrast to the carbon sources of cane molasses and D-glucose, this strain generated GABA concentrations of 7.4 and 6.84 g/l, respectively. Due to the presence of several organic acids, volatile fatty acids and some minerals that may influence the formation of GABA [13, 19], the GABA content in cane molasses was lower than that in cane sugar.

Nitrogen Sources

The modified MRS medium, which contains 2% (w/v) of MSG, 2% (w/v) of cane sugar, and either 2.5% (w/v) of surimi washing water or 3.06% (w/v) of tuna condensate as nitrogen sources based on total nitrogen was used for cultivation. The GABA content was measured from each nitrogen source using HPLC. The highest GABA concentrations were found in tuna condensate, which had a maximum production of 11 g/l and maximum volumetric productivity and bioconversion rates of 0.23 g/l/h and 90.21%, respectively. Surimi washing water, on the other hand, had low GABA concentrations of 4.12 g/l, volumetric productivity of 0.09 g/l/h, and a bioconversion rate of 33.79% after being grown at 37 °C for 48 h without shaking (Table 1). The best carbon and nitrogen sources for GABA synthesis were cane sugar and tuna condensate, which increased GABA by 61% (from 6.84 to 11 g/l) as compared to standard MRS medium.

The source of the nitrogen and its concentration have both an impact on the GABA that microorganisms produce. Varying sources of nitrogen applied to the culture media provide different yields of GABA. The best nitrogen sources for L. brevis NCL912 to produce GABA were beef extract, soya peptone, and yeast extract. A concentration of 2.5% (w/v) led to a greater GABA yield. When maize extract was employed as the nitrogen source, a reduced amount of GABA was produced [10]. A large amount of GABA (76.8 g/ml) was produced by L. brevis BJ-20 when nitrogen sources, yeast extract at 3% (w/v), and 5 brix sea tangle (Saccharina japonica) extract were added [6]. Using the medium containing 100 g/L yeast extract, L. plantarum EJ2014 produced the highest GABA of 19.8 g/L compared to previous studies using various L. plantarum strains. Due to high amounts of yeast extract contain large amounts of L-glutamic acid that might also be used as a substrate for GABA production [16].

The highest GABA concentrations (11 g/l) were produced by L. futsaii CS3 when tuna condensate was utilized as a nitrogen source in the modified MRS medium. This strain produced low GABA concentrations of 4.12 g/l when surimi washing water was used as the nitrogen source, and 6.84 g/l when yeast extract, peptone, and beef extract were used as the nitrogen sources in MRS medium. This is due to tuna condensate's higher concentration of lipids and proteins, which are simple, soluble, and digestible for this strain′s GABA production and cell proliferation. In addition, some compounds and minerals in surimi washing water might affect the growth and GABA production of this strain [13, 19].

MSG

MSG is a neutral salt of L-glutamic acid. Thus, MSG could act as a buffer that prevents medium pH from decreasing [6, 16]. MSG is a substrate for producing GABA. When MSG or glutamate is converts to GABA by decarboxylation by GAD, the release of carbon dioxide coincide with the consumption of hydrogen (H+), resulting in an increase in pH in medium. Therefore, MSG concentration increases, buffering capacity of medium will also increase and help to stabilize pH [16]. Although L-glutamic acid is an optimal substrate for GABA production but its price is extremely higher than MSG. Therefore, MSG was used as substrate for GABA production in this study. The modified MRS medium, which contains 2% (w/v) MSG, 2% (w/v) cane sugar, 3.06% (w/v) tuna condensate, and no MSG, was used for cultivation. HPLC was used to compare the amount of GABA produced in this medium with and without MSG. The findings revealed that after being grown at 37 °C for 48 h without shaking, L. futsaii CS3 was unable to produce GABA when MSG was not added to the modified MRS medium. However, this strain produced 11 g/l of GABA when grown in a modified MRS medium containing 2% (w/v) MSG (Table 1). MSG is the sodium salt of glutamic acid. It is widely known that the catalytic activity of GAD in the cell produces GABA from MSG [6, 16]. Therefore, it is crucial to add enough MSG to a GABA-producing LAB's culture medium in order to produce a high amount of GABA.

Although it contains relatively little glutamate, tuna condensate is a good source of glutamine. Combining the two functions of glutaminase and GAD can result in the conversion of glutamine via glutamate to GABA. Through the activity of GAD in the modified MRS medium containing tuna condensate and MSG, L. futsaii CS3 was able to produce high quantities of GABA from glutamate or glutamic acid. However, because L. futsaii CS3 was unable to produce glutaminase, which is required for the conversion of glutamine in tuna condensate to glutamate. Therefore, this strain was unable to create GABA in this medium without MSG. As a result, this medium lacked glutamate, a necessary substrate for the production of GABA.

GABA is produced from the bioconversion of glutamate catalyzed by GAD in many microorganisms including LAB [4, 22]. However, most LAB are not capable of synthesizing enough L-glutamate for GABA production. Therefore, the supplementation of MSG to the culture media is indispensable as MSG can be easily hydrolyzed to L-glutamate [4, 22]. Pediococcus pentosaceus MN12 produced GABA 17.6 mM when supplemented 60 mM MSG [22]. A starter culture of L. futsaii CS3 produced the highest GABA reaching 10,500 mg/kg in Kung-Som production that added 0.5% (w/w) MSG and this strain remained prominently throughout the Kung-Som fermentation revealed Polymerase chain reaction denaturing gradient gel electrophoresis (PCR-DGGE) [18]. L. sakei B2-16 increased GABA production up to 17,014 mg/l when 3% (w/v) MSG concentration was added to substrate fermentation [13]. L. brevis NCL912 produced high amounts of GABA with 205.8 g/l while extremely high amount of L-glutamic acid with 250 g/l was used as a substrate [24]. Therefore, GABA-producing ability is varied widely among the strains of LAB and it is significantly affected by medium composition and culture additives.

PLP

PLP, one among the active forms of vitamin B6, is a coenzyme of GAD. In order to create GABA, GAD catalyzes the irreversible α-decaboxylation of glutamate [31]. The GABA production of LAB could be effectively increased by adding PLP to the medium. Especially, when PLP was added at 48 h of fermentation, GABA production was higher than PLP addition at 0 and 24 h of fermentation. However, PLP could have easily been influenced by some metabolites and lost its function as coenzyme of GAD during the fermentation. Therefore, it may be more efficient to enhance GABA yield by the addition of PLP at 48 h [4]. When PLP was added, the fermentation with Strep. salivarius subsp. thermophilus Y2 produced more GABA [28]. A concentration of 6% (w/v) MSG and the addition of 0.02 mM PLP were found to be optimal conditions for L. brevis K203 for GABA production [31]. However, this study discovered that adding 0.05 and 0.1 mM PLP to the modified MRS medium containing 2% (w/v) MSG, 2% (w/v) cane sugar and 3.06% (w/v) tuna condensate for the production of GABA by L. futsaii CS3 did not increase the amount of GABA (11.05 and 11.07 g/l, respectively), compared with no PLP addition (11 g/l) (Table 1). The findings suggested that L. futsaii CS3 could synthesize the PLP on its own and that PLP had no significant influence on GABA synthesis. In a previous study, the addition of PLP in the culture medium had no effect on GABA production of L. brevis NCL912 [8].

RSM Results

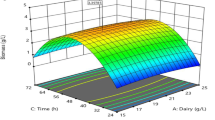

To identify the optimum condition, CCD and RSM were used to obtain a quadratic model, and then appraise the quadratic results and central points to estimate the GABA production variability, with GABA content as a response. In a single-factor experiment, three compositions consisted of cane sugar, tuna condensate and MSG, that significantly affected on GABA production. Three compositions were optimized by RSM using a 3-factor-5-level CCD. A total of 20 runs with central points were generated. Table 2 shows the 20 various combination sets and the corresponding GABA content for both the actual and predicted values. The experimental results were analyzed by ANOVA and following quadratic regression, an equation was obtained in terms of GABA content.

Model equation: GABA content = − 60.38695 + 5.40577X1 + 22.51027X2 + 4.09330X3 + 0.55X1X2 + 0.049167X1X3 − 0.29X2X3 − 1.19098X12 − 2.54686X22 − 0.15039X32

X1 = Cane sugar, X2 = Tuna condensate, X3 = MSG.

The GABA production regression model was highly significant (P < 0.0001). The compositions of cane sugar (P < 0.0001), tuna condensate (P < 0.0001), and MSG (P < 0.0001) were found to significantly affect the synthesis of GABA using regression analysis. A regression model for which the coefficient of variation (R2) value was higher than 0.9; is considered to present a high correlation. In this case, the value of R2 (0.9991) indicated a high correlation between the actual and predicted values from the model equation. The “Lack of Fit F-value” of 4.85 implied that the “Lack of Fit” was not significant relative to the pure error (Table 3). The “Pred R-Squared” of 0.9942 is in reasonable agreement with the “Adj R-Squared” of 0.9984 and a low coefficient of variation (CV = 2.52%) (Table 3). This means that this equation can be used for predicting the GABA content under conditions that varied with the three variables in the experimental range.

Among the run sets, the maximum GABA actual content produced by L. futsaii CS3 was 15.96 g/l in run no. 16 (Table 1) [X1 = 3% (w/v), X2 = 3.5% (w/v) and X3 = 10.5% (w/v)] while the predicted GABA value in this run was 15.76 g/l. The response surface for the GABA production of L. futsaii CS3 in the optimal modified MRS medium at various cane sugar, tuna condensate and MSG concentrations are shown in Fig. 1. Numerical optimization used to generate optimal conditions of maximum GABA production and confirm this model equation. The results found that the highest actual GABA was 18.27 g/l [X1 = 3.48% (w/v), X2 = 3.84% (w/v) and X3 = 10.77% (w/v)] while the predicted GABA value in this run was 16.73 g/l. The results from this experiment indicated that substrate concentration is important for achieving high GABA yield.

Effect of Initial Medium pH on GABA Production

The optimal modified MRS medium, according to the findings of the CCD test, had 3.48% (w/v) cane sugar, 3.84% (w/v) tuna condensate, and 10.77% (w/v) MSG. The impact of the initial medium pH (4.5, 5, 5.5, 6, 6.5, and 7) on the synthesis of GABA was therefore studied using these composition values. L. futsaii CS3 began producing GABA in the flask-scale during the late-exponential growth phase (24 h), and the highest GABA levels were attained during the late-stationary growth phase (36–48 h). The expression of the gad gene may have been induced as a result. All the initial medium pH, MSG rapidly decreased within 24 h and converted to GABA within 48 h of cultivation. GAD, a reaction-producing enzyme found in Lactobacillus species, would be responsible for this reaction [8].

Within 36 h of cultivation, GABA production increased significantly at initial pH levels of 5 and 5.5 (17.47 and 12.67 g/l, respectively), indicating that the GABA production was influenced by the initial pH of the medium. The optimum modified MRS medium, with an initial pH value of 5, produced significantly the greatest GABA concentrations of 20.63 g/l with cell dry weight of 19.1 g/l and the highest yield of 1.08 after 48 h of cultivation. Additionally, the volumetric production and bioconversion rate at this initial pH was the highest at 0.43 g/l/h and 31.42%, respectively (Table 4 and Fig. 2). This result was in accordance with the report that the adjustment of the initial pH medium to an acidic condition (pH 4.5–5.5) could improve GABA production due to GABA biosynthesis is closely related to an acidic pH [31].

The initial medium pH has an impact on LAB′s ability to produce GABA and stimulate microbial growth. Because different microorganisms' biochemical properties of GAD varies, the initial medium pH for the maximal GABA production of LAB depends on the species. Many reports have shown that the initial pH medium affected GABA synthesis. L. plantarum and L. buchneri produced the highest GABA at an initial pH of 6 and 5, respectively [3]. L. brevis NCL912 produced the maximum GABA level at initial pH 5.0 [10]. Compared with initial pH 4.0 and 6.0, GABA production of L. paracasei NFRI 7415 was significantly enhanced reaching 210 mM at initial pH 5.0 [4]. L. brevis GABA100 produced the highest GABA at initial pH 3.5. Therefore, the optimal conditions of GABA production by microorganisms vary according to the different properties of GADs, with optimal pH ranging from pH 3.5–5 [4].

Effect of Controlled pH on GABA Production

In the optimum modified MRS medium with an initial pH value of 5, L. futsaii CS3 produced the most GABA (20.63 g/l, 48 h) for the flask-scale. The influence of pH on GABA synthesis by batch fermentation in a 3–l fermentor with and without pH control was examined using the optimum modified MRS medium with an initial pH value of 5. The pH on GABA production was maintained constant during fermentation at pH 3.5, 4, 4.5, and 5. According to the findings, the production of GABA by L. futsaii CS3 was found to be impacted by the pH maintained throughout fermentation. GABA production rapidly increased to 14.48 and 13.57 g/l, respectively, during 36 h of fermentation when the pH in the medium was controlled at 3.5 and 4, and it reached 15.83 and 15.68 g/l, respectively, at 48 h of fermentation. Additionally, the fermentation that was not pH-controlled demonstrated that the GABA production increased significantly within 36 h (15.19 g/l), reaching 16.14 g/l after 48 h (Table 5 and Fig. 3).

The pH of the medium dropped from 5 to 3.7 after 36 h of fermentation without pH-controlled, and remained till the fermentation was finished (48 h). The GABA production at 36 h was lower than that at 3.5 and 4 and without pH control (5.74 and 6.4 g/l, respectively), and it increased to 14.65 and 14.48 g/l, respectively, during 48 h of fermentation when the pH in the medium was regulated at 4.5 and 5. (Table 5 and Fig. 3). These findings suggested that batch fermentation without pH control is suitable for L. futsaii CS3′s production of GABA. Furthermore, these findings demonstrated that L. futsaii CS3′s GAD activity is optimum at a pH between 3.5 and 4. The partial loss of GAD activity may be caused by higher or lower pH.

In general, GABA may give bacterial cells resistance in an acidic environment [28]. According to some research, GABA synthesis makes E. coli and Lc. lactis resistant to an acidic pH [26]. The pH value is a key factor for GABA synthesis by LAB. It not only influences the growth of microorganisms but also affects the GAD activity. Maintaining low pH (about 5) is necessary for effective GABA production [4]. During the fermentation of LAB, the pH value of the culture continuously decreases. GABA production of Strep. thermophilus Y2 was significantly increased by adjusting the pH of culture medium to pH 4.5 every 12 h for 24 h [28].

Production of GABA from L. futsaii CS3 by Batch and Fed-Batch Fermentation

In batch fermentation, substrate is added in the fermentor once only at the beginning of fermentation. The higher initial concentration of fermentation substrate can inhibit the cell growth or waste material resource. Moreover, the lower concentration of substrate is not enough for high production. Fed-batch fermentation can compensate for the shortcoming. One or more components are fed in the fermentor during fed-batch fermentation, while cells and products remain in the fermentor until the end of operation. It may help to obtain a high yield and productivity [10]. Utilization of whole cells for the biocatalytic conversion of glutamate to GABA has some drawbacks including the conversion of GABA to succinic semialdehyde by the enzyme GABA transaminase (GABA-T). That is often found in bacteria and might decrease GABA yields during cultivation. Fed-batch fermentation effectively increase GABA productivity by improving cell viability resulting in extended periods of cultivation [31].

In order to increase GABA synthesis from L. futsaii CS3, fed-batch fermentation (without pH control) was used in this work. GABA production of L. futsaii CS3 by batch and fed-batch fermentation (without pH controlled) were divided to two stages, i.e., cell growth stage and GABA production stage. Cells grew well (12–24 h) without significant GABA synthesis when the culture pH was in the range necessary for cell development because GAD has a very low catalytic activity. Since GAD became active in the low pH condition as the cells approached the stationary phase (36–48 h), GABA synthesis rose quickly.

The maximum GABA (17.24 g/l) was synthesized in batch fermentation at 48 h, and volumetric productivity, bioconversion rate and yield of 0.36 g/l/h, 26.25% and 1.37, respectively, were obtained (Table 6). MSG (7.5% w/v) was introduced to the fermentor during fed-batch fermentation at the 36 h of fermentation to boost GABA synthesis. At 72 h of fermentation, the maximum GABA (23.01 g/l) was produced with a volumetric productivity, bioconversion rate and yield of 0.32 g/l/h, 20.66% and 1.43, respectively. With a 33.47% increase in GABA (from 17.24 to 23.01 g/l) compared to batch fermentation, GABA production in fed-batch fermentation was obviously higher than GABA production in batch fermentation. At 72 h of fermentation, MSG remained at 11.35 g/l, L. futsaii CS3 had a cell dry weight of 16.1 g/l, and there were 2.68 × 106 cfu/ml of bacterial cells in the fermented broth (Table 7). Cell dry weight was significantly associated with GABA production of L. futsaii CS3 in batch and fed-batch fermentation (Table 6 and 7). Figure 4a, b displays the GABA concentrations in batch and fed-batch fermentation as measured by the HPLC analysis.

MSG content had an impact on L. futsaii CS3′s fed-batch fermentation's ability to produce GABA. When 10% (w/v) of MSG concentration was added to the fermentor at the 36 h of fermentation, GABA synthesis decreased (13.42 g/l). The result indicated that GABA production of L. futsaii CS3 could inhibit with excessive MSG. The elevated glutamate concentration inhibited GAD action and was harmful to microbial growth [2]. Moreover, High glutamate concentrations increase the osmotic pressure in the cells, and this stress can disturb the bacterial metabolism [31]. The optimal concentrations of MSG are different for various microorganisms in GABA production. GABA synthesis of L. brevis K203 increased as glutamic acid concentration rose from 4 to 6% (w/v). However, GABA synthesis decreased at glutamic acid concentrations more than 8% (w/v). When the glutamate content in the medium was initially 400 mM, L. brevis NCL912 could grow and produce GABA in the fed-batch process. However, L. brevis NCL912 cell development was reduced when the initial glutamate concentration exceeded 500 mM. This strain could grow and produce GABA when glutamate was added at concentrations between 0.25 and 0.5 M [10]. Cell growth and GABA production of L. plantarum EJ2014 was inhibited when added MSG 82.5 g/l [16]. The highest GABA of Lc. lactis was obtained by adding MSG over 6–96 h during fermentation at 6-h interval of time. The production of the highest GABA by microorganisms can also be based on suitable media additives and optimum additive time [19].

It is interesting to note that using cane sugar as a carbon source and tuna condensate as a nitrogen source allowed L. futsaii CS3 to produce GABA at high quantities in batch and fed-batch fermentation (17.24–23.01 g/l, respectively), which is far higher than has been previously reported for other strains. For instance, prior studies indicate that L. brevis IFO-12005 produced GABA at a concentration of approximately 10.18 mM from distillery [29]. After 60 h of cultivation in MRS medium, L. plantarum FNCC 260 produced GABA at a concentration of about 809.2 mg/l [30].

Conclusion

This work demonstrates a new possibility for upgrading agri-food industries by-products on GABA production. Under the optimized condition; 3.48% (w/v) cane sugar, 3.84% (w/v) tuna condensate, and 10.77% (w/v) MSG at an initial pH of 5, with a temperature of 37 °C, the yield of GABA reached 20.63 g/l and 17.24 g/l after 48 h cultivation by flask-scale and batch fermentation, respectively and 23.01 g/l after 72 h cultivation by fed-batch fermentation. A large amount of GABA produced from L. futsaii CS3 by using low-cost substrates from renewable resources can reduce the production cost and has potential for GABA formation on an industrial scale. The results from this study provide a background for further production of GABA from L. futsaii CS3’s microencapsulation.

Data Availability

All data included in this study are available from the corresponding author upon reasonable request author.

References

Afonso D, Borguez R (2002) Review of treatment of seafood processing wastewaters and recovery of proteins therein by membrane separation processes-prospects of the ultrafiltration of wastewaters from the fish meal industry. Desalin 142:29–45. https://doi.org/10.1016/S0011-9164(01)00423-4

Binh TTT, Ju WT, Jung WJ, Park RD (2013) Optimization of γ-amino butyric acid production in a newly isolated Lactobacillus brevis. Biotechnol Lett 10:1007–10013. https://doi.org/10.1007/s10529-013-1326-z

Cho YR, Chang JY, Chang HC (2007) Production of gamma aminobutyric by Lactobacillus buchneri isolated from kimchi and its neuroprotective effect on neuronal cells. J Microbiol Biotechnol 17:104–109

Cui Y, Miao K, Niyaphorn S, Qu X (2020) Production of gamma-aminobutyric acid from lactic acid bacteria: a systematic review. Int J Mol Sci 21:1–21. https://doi.org/10.3390/ijms21030995

H-Kittikun A, Bourneow C, Benjakul S (2012) Hydrolysis of surimi wastewater for production of transglutaminase by Enterobacter sp. C2361 and Providencia sp. C1112. Food Chem 135:1183–1191. https://doi.org/10.1016/j.foodchem.2012.05.044

Kim DH, Dasagrandhib C, Parka SK, Eomc SH, Huhc MK, Mokd JS, Kim YM (2018) Optimization of gamma-aminobutyric acid production using sea tangle extract by lactic acid bacterial fermentation. J Food Sci 90:636–642. https://doi.org/10.1016/j.lwt.2018.01.011

Liao WC, Wang CY, Shyu YT, Yu RC, Ho KC (2013) Influence of preprocessing methods and fermentation of adzuki beans on γ-aminobutyric acid (GABA) accumulation by lactic acid bacteria. J Funct Foods 5:1108–1115. https://doi.org/10.1016/j.jff.2013.03.006

Li HX, Cao YS (2010) Lactic acid bacterial cell factories for gamma-aminobutyric acid. Amino Acids 39:1107–1116. https://doi.org/10.1007/s00726-010-0582-7

Li H, Gao D, Cao Y, Xu H (2008) A high γ-aminobutyric acid-producing ability: Lactobacillus brevis isolated from Chinese traditional paocai. Ann Microbiol 58:649–653. https://doi.org/10.1007/BF03175570

Li H, Qiu T, Huang G, Cao Y (2010) Production of gamma-aminobutyric acid by Lactobacillus brevis NCL912 using fed-batch fermentation. Microb Cell Fact 9:1–7. https://doi.org/10.1186/1475-2859-9-85

Lin S, Chen L, Chen H (2005) The change of thermal gelation properties of horse mackerel mince led by protein denaturation occurring in frozen storage and consequential air floatation wash. Food Res Int 38:19–27. https://doi.org/10.1016/j.foodres.2004.08.001

Luo X, Wang Y, Li Q, Wang D, Xing C, Zhang L, Xu T, Fang F, Wang F (2018) Accumulating mechanism of γ-aminobutyric acid in soybean (Glycine max L.) during germination. Int J Food Sci Technol 53:106–111. https://doi.org/10.1111/ijfs.13563

Mohd Lazim MI, Mohamad S, Abdul Rahman I, Koh SP, Abdul Manan M, Mohd Asri MA (2023) Optimization of process parameters for GABA and L-DOPA production on fermented coconut drink. Food Res 4:102–108. https://doi.org/10.26656/fr.2017.6(S4).012

Nguyen-Sy T, Yew GY, Chew KW, Nguyen TDP, Tran TNT, Le TDH, Vo CT, Tran HKP, Mubashir M, Show PL (2020) Potential cultivation of Lactobacillus pentosus from human breastmilk with rapid monitoring through the spectrophotometer method. Processes 8:902. https://doi.org/10.3390/pr8080902

Palmonari A, Cavallini D, Sniffen J, Fernandes L, Holder P, Fagioli L, Fusaro I, Biagi G, Formigoni A, Mammi L (2020) Short communication: characterization of molasses chemical composition. J Diary Sci 103(7):6244–6249. https://doi.org/10.3168/jds.2019-17644

Park SJ, Kim DH, Kang HJ, Shin M, Yang SY, Yang J, Jung YH (2021) Enhanced production of γ-aminobutyric acid (GABA) using Lactobacillus plantarum EJ2014 with simple medium composition. LWT-Food Sci Technol 137:110443. https://doi.org/10.1016/j.lwt.2020.110443

Prasertsan P, Jaturapornpipat M, Siripatana C (1997) Utilization and treatment of tuna condensate by photosynthetic bacteria. Pure Appl Chem 89:2439–2445. https://doi.org/10.1351/pac199769112439

Sanchart C, Rattanaporn O, Haltrich D, Phukpattaranont P, Maneerat S (2017) Enhancement of gamma-aminobutyric acid (GABA) levels using an autochthonous Lactobacillus futsaii CS3 as starter culture in Thai fermented shrimp (Kung-Som). World J Microbiol Biotechnol 33:152. https://doi.org/10.1007/s11274-017-2317-3

Sarasa SB, Mahendran R, Muthusamy G, Thankappan B, Selta DRF, Angayarkann J (2020) A brief review on the non-protein amino acid, gamma-amino butyric acid (GABA): its production and role in microbes. Curr Microbiol 77:534–544. https://doi.org/10.1007/s00284-019-01839-w

Sanchart C, Rattanaporn O, Haltrich D, Phukpattaranont P, Maneerat S (2016) Lactobacillus futsaii CS3, a new GABA-producing strain isolated from Thai fermented shrimp (Kung-Som). Indian J Microbiol 57:211–217. https://doi.org/10.1007/s12088-016-0632-2

Sanchart C, Rattanaporn O, Haltrich D, Phukpattaranont P, Maneerat S (2016) Technological and safety properties of newly isolated GABA-producing Lactobacillus futsaii strains. J Appl Microbiol 121:734–745. https://doi.org/10.1111/jam.13168

Thuy DTB, Nguyen AT, Khoo KS, Chew KW, Cnockaert M, Vandamme P, Ho YC, Huy ND, Cocoletzi HH, Show PL (2021) Optimization of culture conditions for gamma-aminobutyric acid production by newly identified Pediococcus pentosaceus MN12 isolated from ‘mam nem’, a fermented fish sauce. Bioengineered 12(1):54–62. https://doi.org/10.1080/21655979.2020.1857626

Vann K, Techaparin A, Apiraksakorn J (2020) Beans germination as a potential tool for GABA-enriched tofu production. J Food Sci Technol 57:3947–3954. https://doi.org/10.1007/s13197-020-04423-4

Wang Q, Liu X, Fu J, Wang S, Chen Y, Chang K, Li H (2018) Substrate sustained release-based high efficacy biosynthesis of GABA by Lactobacillus brevis NCL912. Micro Cell Fact 17:80. https://doi.org/10.1186/s12934-018-0919-6

Wang Y, Liu C, Ma T, Zhao J (2019) Physicochemical and functional properties of γ-aminobutyric acid-treated soy proteins. Food Chem 295:267–273. https://doi.org/10.1016/j.foodchem.2019.05.128

Wang Q, Xin Y, Zhang F, Feng Z, Fu J, Luo L, Yin Z (2011) Enhanced γ-aminobutyric acid-forming activity of recombinant glutamate decarboxylase (gadA) from Escherichia coli. World J Microbiol Biotechnol 27:693–700. https://doi.org/10.1007/s11274-010-0508-2

Wu Q, Shah NP (2018) Restoration of GABA production machinery in Lactobacillus brevis by accessible carbohydrates, anaerobiosis and early acidification. Food Microbiol 69:151–158. https://doi.org/10.1016/j.fm.2017.08.006

Yang SY, Lu FX, Lu ZX, Bie XM, Jiao Y, Sun LJ, Yu B (2008) Production of gamma-aminobutyric acid by Streptococcus salivariu. subsp. thermophilus Y2 under submerged fermentation. Amino Acids 34:473–478. https://doi.org/10.1007/s00726-007-0544-x

Yokoyama S, Hiramatsu J, Hayakawa K (2002) Production of γ-aminobutyric acid from alcohol distillery lees by Lactobacillus brevis IFO-12005. J Biosci Bioeng 93:95–97. https://doi.org/10.1016/S1389-1723(02)80061-5

Yogeswara IBA, Kittibunchakul S, Rahayu ES, Domig KJ, Haltrich D (2021) Thu Ha Nguyen.: Microbial production and Eenzymatic biosynthesis of γ-aminobutyric acid (GABA) using Lactobacillus plantarum FNCC 260 isolated from Indonesian fermented foods. Processes 9:22. https://doi.org/10.3390/pr9010022

Yogeswara IBA, Maneerat S, Haltrich D (2020) Glutamate decarboxylase from lactic acid bacteria-a key enzyme in GABA synthesis. Microorganisms 8:1923. https://doi.org/10.3390/microorganisms8121923

Zhang Y, Zhu M, Lu W, Zhang C, Chen D, Shah NP, Xiao C (2023) Optimizing Levilactobacillus brevis NPS-QW 145 fermentation for gamma-aminobutyric acid (GABA) production in soybean sprout yogurt-like product. Foods 12:1–14. https://doi.org/10.3390/foods12050977

Zhuang K, Jiang Y, Feng X, Li L, Dang F, Zhang W, Man C (2018) Transcriptomic response to GABA-producing Lactobacillus plantarum CGMCC 1.2437T induced by L-MSG. PLoS ONE 13:e0199021. https://doi.org/10.1371/journal.pone.0199021

Funding

This study was financially supported by Thesis Research Grant, and the PSU-Ph.D. Scholarship, Graduate School, Prince of Songkla University. Some part of this research work was financially supported by Institute of Food Research and Innovation, Research and Development Office, Prince of Songkla University (FIRIn 2559/011).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by KT. The first draft of the manuscript was written by KT. SM supervised and approved the final manuscript.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Thongruck, K., Maneerat, S. Enhanced Production of Gamma-Aminobutyric Acid (GABA) from Lactobacillus futsaii CS3 Using Agri-Food Industries By-Products Under Batch and Fed-Batch Fermentation. Indian J Microbiol 63, 467–482 (2023). https://doi.org/10.1007/s12088-023-01101-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12088-023-01101-9