Abstract

The complexity of infrastructures and interdependent elements among supply chain network leads to increasing inoperability. Risk management of the supply chain network can reduce the mutual ripple effects of risk and disruptions based on a risk response strategy. However, the hidden factor of the negative effects of risk responses has rarely been considered by researchers. In the present work, the impact of the COVID-19 pandemic and the negative effects of risk responses have been applied in the proposed model. The computational results indicated a decreasing in the trend of improving operability and an increasing trend in the losses caused by disruptions. A multi-objective optimization model is presented in this study that allows decision-makers to prioritize supply chain network infrastructure and risks based on the speed and importance of inoperability. The solution of the proposed model selects the best and most effective response based on the utility of decision-makers considering budget constraints. Moreover, a solution is provided to determine the appropriate time to apply risk response based on network resilience and analyze the various scenarios of objective functions and budget.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The process of identifying and assessing risks and developing strategies for managing risks is known as risk management. Risk management and business impact analysis programs are an important part of a supply chain. In the case of the occurrence of an accident in world trade, by identifying potential risks and finding ways to minimize their impact, the quick recovery of the supply chain network will be helped.

Due to disruptive events such as fuel protests, terrorist attacks in the United States, etc., the issue of supply chain risk to the international business environment has come under scrutiny. Jüttner et al. (2003) investigated the vulnerability of supply chain and risk management from four perspectives and highlighted the importance of flexible supply chains in resource risk management and assessment. Macro-level decision-making to address supply chain risks requires information from all elements of the supply chain, not all of which are necessarily accessible. Thus, qualitative data in fuzzy set theory can be used to solve this problem (Niknejad and Petrovic 2016). Additionally, due to the inherent uncertainty of some risks and inaccurate and unreliable information, experts classified the above- mentioned uncertainties for risk analysis into two categories: epistemic and Aleatory uncertainties (Der Kiureghian and Ditlevsen 2009). Epistemic uncertainty, unlike Aleatory uncertainty, which refers to the random nature of events, is declined by collecting further data.

By identifying supply chain risks and finding ways to decrease them, the impact of supply chain disruptions on business can be confined to a risk management program.

Two main types of risk should be considered in the supply chain risk management program:

-

External risks - those that are beyond your control.

-

Internal risks - those that are under your control.

Political, economic, and technical risks constitute a wide variety of supply chain risks. Identifying risks and adopting the best solutions at the lowest cost plays a key role in reducing the negative ripple effects and financial losses on the entire supply chain network (Ebrahimnejad et al. 2021; Li et al. 2021).

Understanding and identifying the complexities of the global economy with the rise of interdependent actors in today's world is important, challenging, and influential on the Global Production Network (GPN) (Coe et al. 2008).

In today's world with a more complicated and developed supply chain network infrastructure, the dependence of communications and their separation is a very ambiguous and difficult task. For example, the performance of the production infrastructure is interdependent with other supply chain network infrastructures. Such complexity presents a mutual behavior that both leads to development and progress, and on the other hand, makes supply chain network risk management difficult (Ebrahimnejad et al. 2021; Manuj and Mentzer 2008). Different strategies for reducing the risk effects on the disrupted drug supply chain were examined by Lücker et al. (2019). Their findings indicated there is a direct relationship between optimal risk reduction strategies and product characteristics.

Products of pharmacy sector are very vital and important for society, however, the negative effects of this industry on the environment are evident to everyone. Improper disposal of expired or excess tablets and drugs by patients leads to environmental pollution in domestic sewage and recycling sites. Kumar et al. (2019) proposed a mathematical model in which the concepts of the green supply chain (GSC) and the economic sectors of the pharmaceutical industry in India are integrated to achieve operational perspectives and prioritize risks in an uncertain environment.

As reported by Ivanov (2020), the onset of an epidemic poses supply chain risks with high uncertainty. Using AnyLogistix simulation and optimization software, he analyzed short- and long-term effects of the epidemic based on its unique characteristics, including onset time, contagion rate, and duration of disruption in the upstream and downstream portions of the supply chain network. Ivanov and Dolgui (2020) investigated the effect of unprecedented and unexpected Covid-19 shocks on the Intertwined Supply Network (ISN), as a set of the supply chains (SCs) with a dynamic structure.

The Covid-19 pandemic led to unpredicted and influential disruptions in supply chain (Sc) worldwide. Moosavi et al. (2022) clustered and analyzed the research studies based on influential contributors, main streams of research, and disruption management strategies related to Sc performance with the aim of identifying promising strategies for the Sc disruption management. Karuppiah et al. (2022) analyzed 20 major effects of Covid-19 in the supply chain using Exploratory Factor Analysis (EFA) methods, G-DEMATEL. Their findings indicated supply disruptions, ripple effects, and wear and tear of machines had the greatest impact on supply chain activities. Paul et al. (2022) proposed a stochastic mathematical model to optimize supply chain recovery strategies for high-demand goods affected by the Covid-19 pandemic, which aims to increase the total profit of Sc. Khan et al. (2022) mitigated the effects of the Covid-19 pandemic disruption in the supply chain with innovative strategies.

We have compiled a review of related works in Table 1. As can be seen, we want to integrate supply chain network infrastructure with the Dynamic Inoperability Input–output Model (DIIM), which is a powerful mechanism for analyzing the cascading effects caused by critical infrastructure interdependencies. Researchers rarely developed and implemented these two fields of work simultaneously. The purpose of this paper is to help decision makers quickly plan and recover performance and strengthen the supply chain after the occurrence of risks, considering budget constraints with a multi-objective optimization model based on resilience. The contribution of this research is as follows:

-

1.

We propose the DIIM, which is designed with a new revision, to investigate the wave and mutual trend of risks effects and disruption factor of Covid-19 on the infrastructure of the supply chain network.

-

2.

The positive and negative effects of the responses of the risks in the inoperability and utility function were implemented. The researchers mostly focused on positive effects.

-

3.

We prioritize and analyze the studied risks based on the intensity and speed of impact on inoperability and cost reduction in different periods of the supply chain network.

-

4.

Finally, in order to reduce the effects of risks and disturbances by using the concepts of resilience of the supply chain, a solution has been proposed to determine the time to apply responses to risks according to the budget limit.

We designed a road map to express the research path and proposed method in Fig. 1.

The paper is developed as follows. In Section 2, an overview of I-O models and research related to the COVID-19 pandemic in the supply chain is provided. In Section 3, the proposed multi-objective mathematical model for the IIM model in supply chain networks is presented. The sensitivity analysis of the proposed model is presented in Section 4, and finally, the discussion of the results and suggestions for future research are presented in Section 5.

2 Literature review

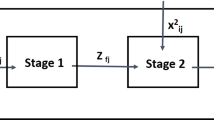

Wassily Leontief won the Nobel Prize in Economics in 1973 for development of Input–Output Model. Leontief’s I-O model was used for identifying and evaluating the dependence of different sectors of the economy. Due to the growing complexity of systems and their increasing vulnerability, Haimes and Jiang (2001) were inspired by the I-O model to investigate the dependence and effect of external disruptions on complex infrastructure so that the inoperability of each infrastructure was given a value between [0,1]. A value of 1 denotes system failure and a value of 0 represents that the system is free from failure. Santos and Haimes (2004) developed a framework for indicating the way of propagation of the perturbation resulting from terrorism based on the I-O model. IIM is formulated as follows.for analyzing the inefficiency of infrastructure and various industrial sectors:

In Eq. (1), q denotes the vector of inoperability, and A* is matrix of the correlation coefficients of industrial sectors, and C* is the disruption vector, which leads to the inoperability of the infrastructure of industrial sectors.

Haimes et al. (2005) implemented the Multi-Regional Inoperability Input–Output Model (MRIIM) using data from BEA (Bureau of Economic Analysis) website for solving risk management problems. One of the advantages of this method is prediction of different types of damages imposed on the systems. Also, they formulated discrete time Dynamic IIM (DIIM) as follows:

In Eq. (2), A* denotes the matrix of Leontief technical coefficients. c* (t) represents the vector of disruption at time t, and q (t) denotes the inoperability vector at time t. Finally, K indicates the matrix of coefficients of resilience of the industry.

Setola et al. (2009) and Oliva et al. (2011), used fuzzy sets for IIM uncertainty. Wei et al. (2010) used the IIM in an environment of uncertainty to assess the effects of disruptions in the chemical supply chain network. Moreover, they used Monte Carlo simulations to validate IIM in the supply chain. A new Fuzzy DIIM (FDIIM) was proposed by Niknejad and Petrovic (2016) in order to analyze Global Production Networks (GPNs). Using Philippine, I-O data for 2012, Jabilles et al. (2019) indicated that how a well-defined inventory planning with an appropriate pre-defined horizon can delay the onset of wave effects of inoperability of supply chain members.

Wang et al. (2020) proposed an approach based on the multi-region input–output (MRIO) model and data envelopment analysis (DEA) technique for the production sectors in 16 major economies to evaluate the environmental performance of global supply chains (GSCs). Their findings showed that 40% of GSCs contamination can be reduced. Pichler et al. (2022) designed a dynamic disequilibrium input–output model specific to industries to predict and understand the emissions of demand and supply shocks caused by Covid-19. The findings of their study showed that Leontief linear production function does not predict the trend of Pandemic Covid-19 effects well in the short term. Pichler and Farmer (2022) studied the severe disruptions of the Covid-19 pandemic in the economic production networks of countries. They demonstrated that the Leontief production function has difficulty in addressing simultaneous supply and demand shocks. Today, mineral goods are an integral part of the supply chain of electronic and semiconductor industries. Manley et al. (2022a) analyzed the disruption in supply of mineral commodities during the Covid-19 Pandemic in the automotive industry based on I-O data output.

Galbusera and Giannopoulos (2018) used the I-O economic model in order to analyze the resilience of economic systems and emerging and complex scenarios of natural and human-made disasters. Flooding as a disaster that occurs repeatedly at different times can potentially cause employee absenteeism in industrial areas. Using the DIIM, Yaseen et al. (2020) assessed the economic losses and inoperability of industries resulting from the employee absenteeism. Samimi et al. (2020) used IIM for evaluating the effects of flood risks on 6 infrastructures in the Tehran metropolis. According to the computational results of the IIM, energy and transportation were the most influential infrastructures and emergency services and healthcare services were the most influenced infrastructures. In their research, they defuzzified the Independence Matrix and then calculated the extent of the infrastructure inoperability. Ebrahimnejad et al. (2021) proposed a multi-objective DIIM for the simultaneous effect of risks on interdependent infrastructures. They utilized the theory of the asymmetric queuing game between the government and terrorists to estimate the effect of the disruption parameter on critical infrastructures.

The effects of risks on the influential infrastructure of any supply chain network can extend backward and forward. The disruption factor, the Covid-19 epidemic, leads to disruption in the supply and demand system and accelerates the inoperability of infrastructures of the supply chain (Li et al. 2021). The Covid-19 epidemic has led to widespread disruptions over short periods of time in the supply chain network. Chen et al. (2021) presented a product change strategy in short-term aiming at the maximization of total profit. The COVID-19 epidemic has led to shock and unpredictable ripple effects on the supply chain. Ivanov and Dolgui (2020) studied the ripple effects of disruptions in the supply chain network and categorized them based on research concepts and managerial insights into three levels: network, process, and control. In addition, their findings indicate that how to present OR methods can be used to deal with the ripple effects in five epidemic phases (i.e., Anticipation, early detection, containment, control and mitigation, and elimination or eradication) by the researchers in future research. An incomplete understanding of the negative effects of COVID-19 pandemics at different periods led to unstable conditions in the supply chain network that challenged risk management decisions to cope with time constraints. Hosseini and Ivanov (2021) developed a multi-layer Bayesian Network (BN) method for modeling and measuring the effects of the pandemic disruptions on the supply chain (SC), using which they analyzed financial performance and resilience, and flexibility. Chowdhury et al. (2021) reviewed studies related to the COVID-19 pandemic on various supply chain issues and found that studies are confined to four general topics: pandemic effects, resilience strategies for management, and recovery, the role of technology in implementing resilience strategies, and supply chain sustainability. Moreover, the focus of most studies was on the supply chains of high-demand essential goods, and low-demand goods have been largely ignored.

Yu et al. (2021) explained short-term measures and long-term strategies for the global energy market, environment, and economy to deal with the Covid-19 pandemic effects. Rozhkov et al. (2022) investigated a simulation model that combines supply chain design, pandemic dynamics, and production and inventory control policies to consider the effects of the Covid-19 pandemic on the studied supply chain. Their findings showed that two-stage supply chains are more vulnerable to disruption. Badhotiya et al. (2022) proposed a model to evaluate the resilience of a supply chain affected by disruption. They used Interpretive Structural Modeling (ISN) with Bayesian Network approach in their proposed model. The supply chain transportation system showed a contradictory behavior during the pandemic. The transportation of the goods and raw materials leads to the stability of the supply chain, while it can provide the basis for the spread of the epidemic through the increase of exchanges and movements. Bassiouni et al. (2023) proposed several deep learning (DL) approaches to reduce transportation risks and resilience of supply chain that is under the disruption of Covid-19.

Some economists believe that the impact of the Covid-19 epidemic on the global economy will not be less than the 2008 global crisis. According to the World Trade Organization (WTO), Gross Domestic Product (GDP) index in 2020 witnessed a negative growth of 5.92% compared to 2019 (Koopman et al. 2021). Pharmaceutical industry output fell by less than 10% during the Covid-19 epidemic, according to research by the European Parliament's Committee on Industry, Research and Energy (ITRE) (de Vet et al. 2021). For a more comprehensive analysis of the global economic impact of Covid-19, readers can refer to studies conducted by the Congressional Research Service (CRS) (Weiss et al. 2020).

3 Proposed model

In this paper, a DIIM multi-objective optimization is presented for supply chain network infrastructure exposed to Covid-19 epidemic disruptions and risks. This model aims at improving the performance of infrastructures and reducing the loss of goods flows over time periods.

The assumptions of the proposed optimization model for the supply chain network are as follows:

-

1.

Capacity of supply, demand, and capacity of node flows and links are known.

-

2.

Backup capacity is not considered as allowed for nodes.

-

3.

Node demand is dynamic and definite.

-

4.

The time period starts from the point when a disruption occurs in the supply chain network.

-

5.

Each the time step S is divided into several mini time steps for \(\mathop {\chi_{ijr} }\limits^{.}\).

Table 2 presents the symbols of the proposed model.

The proposed model in the present study is as follows:

St.

The first objective function is related to minimization of the function of losses resulting from perturbation. Objective Function 2 states that supply chain infrastructures should have the least amount of inoperability so that production is increased and supply flows due to supply chain disruption are reduced. Four modes were studied for Objective Function 2.

-

(I)

\(\mathop {\chi_{ijr} }\limits^{.} = a_{ijr} \chi_{ijr} + C_{i}\)

In Mode I, no countermeasure is taken for reducing the inoperability of the supply chain network infrastructures.

-

(II)

\(\mathop {\chi_{ijr} }\limits^{.} = a_{ijr} \chi_{ijr} + C_{i} - r_{ijrp} Y_{ijrp} K_{n}\)

In Mode II, the positive effects of recovery measures are applied to reduce the inoperability of infrastructures in the appropriate time period.

-

(III)

\(\mathop {\chi_{ijr} }\limits^{.} = a_{ijr} \chi_{ijr} + C_{i} - r_{ijrp} Y_{ijrp} K_{n} + \zeta_{ijrp} Y_{ijrp} K_{n}\)

In Mode III, recovery measures have positive and negative effects that lead to a decrease and increase in inoperability of infrastructures.

-

(IV)

\(\mathop {\chi_{ijr} }\limits^{.} = a_{ijr} \chi_{ijr} - r_{ijrp} Y_{ijrp} K_{n} + \zeta_{ijrp} Y_{ijrp} K_{n}\)

In Mode IV, the model is solved by eliminating the parameter Ci, which is the effect of COVID-19 pandemic on the supply chain network.

Finally, the Objective Function 3 is responsible for maximizing the utility of the selected risk responses. According to the rule of thumb (Howard 1988), the absolute risk deviation coefficient for Objective Function 3 is calculated as \(\theta = \max \left\{ {\frac{6}{{B_{i} }}} \right\}\). Also, contrary to research by Zhang (2016), we developed Objective Function 3 in terms of both positive and negative effects of risk responses. Constraints 6, 7, and 9 indicate that the output and input of nodes should not exceed the capacity of the nodes. Constraint 8 states that total customer node demand must be met. Constraints 10, 11, and 12 state the effect of inoperability of nodes on ultimate demand and production capacity of nodes. Constraints 13 and 14 indicate the difference in the output of the nodes before and after the occurrence of the risks and the cause of the perturbation. Constraints 15–18 relate to the dispatched capacity of the drug supply chain network. Constraint 19 is the balance between supply chain levels. Constraints 20–22 are related to the budget. Constraints 23–25 ensures that only one risk response is selected per each risk. Constraint 26 is the binary mode, and the Constraints 27–28 indicate the resilience factor of the supply chain to apply the appropriate time of risk responses based on products. The model was Run in MATLAB software and solved by Ordinary Differential Equations (ODE) method.

Table 5 of Appendix A presents the risks and their responses and the negative effects of the responses. Figure 2 indicates the studied topological structure of the medicine supply chain. Nodes 1–3 are the suppliers that supply the raw materials for the production of drugs. Nodes 4 and 5 are manufacturing plants. Nodes 6–8 are hospitals and pharmacies that are the end customer.

4 Results and sensitivity analysis

The performance of the supply chain network is affected by unforeseen and hidden changes in its infrastructures, and managers are always looking to manage changes and identify hidden factors with limited budgets to evaluate the process of improving the supply chain network performance and make the most desirable decision. In the present study, 3 budget scenarios (0.8B, B, 1.2B) were analyzed in 4 modes of objective functions. The most important questions that managers face when making the decision on cost management include as follows: First, how do budget changes influence the amount and duration of inoperability of nodes in the supply chain? Second, how do the budget changes influence the selected risk responses and reduction of the costs of delivering raw material and end product flows into the supply chain?

The percentage of the gap between the planned and the actual level reflects inoperability, and by calculating the inoperability of nodes and infrastructures, based on quantity and time, they can be prioritized. Nodes with higher inoperability value are vulnerable to risks and perturbations in a shorter period of time and have a higher priority for supply chain risk management.

Mode I with budget B in Fig. 3 indicates that the most important node at the Supplier level for risk management is Node 1 because Nodes 4 and 5, which are related to the Manufacture level, reach the highest inoperability value in the shortest time. This is because nodes 4 and 5 are more dependent on node 1 than other Supplier level nodes based on criteria. Also, the minimum and maximum time intervals with the inoperability value of 1 are related to X242 and X152, which indicates that they have the highest and lowest risk management priority at the Supplier level. Nodes at the Manufacture level have mutual motion and affect the nodes at Supplier and Customer levels. The main focus of researchers has been on forwarding motions, while backward motions have received less attention in studies. As shown by observations, Manufacture level nodes direct Supplier level nodes to complete inoperability quicker than Customer level nodes due to the stronger dependence of the two levels. Given the greater effect of Node 5 than Node 4 on the inoperability of nodes before and after it, this node is of greater importance in supply chain risk management at the Manufacture level. The X581 has an inoperability value of 1 in the forward motions in the shortest time (T = 2.86), while this occurs in the backward motions for the X423 in the longest time (T = 5.2).

Mode II with budget B is shown in Fig. 4. Mode II shows how long nodes are recovered by risk responses. In Supplier level nodes, nodes 1, 3, 2 had the highest resilience to deal with risks, respectively, to transmit the effect of inoperability to the Manufacture level nodes with a delay. Based on Eqs. (27) and (28) for X142, the risk response was applied at the inoperability point of 0.082 at time T = 0.75 and is operational at time T = 1.05. This happened for the X251 at a point with an inoperability value of 0.075 at T = 0.75 and returned to baseline at T = 0.86. The maximum and minimum operability values for X152 and X242 are 0.085 and 0.073, respectively. The effect of risk responses in mode II for Manufacture level nodes resulted in faster recovery of Supplier -level nodes than Customer level nodes. For example, the X573 is retrieved at the longest time at T = 1.1, which is a forward motion, and X431 and X411 that belong to the backward motion are retrieved at the earliest time T = 0.85. Customer-level nodes, although having the lowest inoperability points for retrieval, have the longest operability time. This is due to their direct and indirect effects on Manufacture and Supplier level nodes and their mutual effect on Customer level nodes.

Figure 5 shows mode III with budget B. In this mode, the negative effect of risk responses to objective functions 2 and 3 was applied, and as expected, the nodes’ retrieval time increased and the supply chain network faced a more critical situation than mode II. The new conditions led to a change in the prioritization of risk management of supplier level nodes. In mode II, the priority of nodes was 1, 2, and 3, respectively, and in mode III, node 3 had a higher priority than node 2, and this shows the importance of factors that have rarely been considered by researchers in the supply chain. On a larger scale of the problem, these factors can increase risk management challenges. The total time for the operability of nodes at the manufacturing level increased to T = 1.12 compared to mode II, of which T = 0.35 and T = 0.77 are related to nodes 4 and 5, respectively. The difference in time increase in forwarding and backward motions for nodes 4 and 5 compared to mode II is T = 0.09 and T = 0.13, respectively. The greatest impact of the negative effects of risk responses and Covid-19 epidemics is related to Customer level nodes, which led to the neutralization of the positive effects of the responses and change of the motion of all charts toward inoperability with a value of 1.

Figure 6 indicates Mode IV with budget B. This scenario aims at investigating the effect of the Covid-19 epidemic on the supply chain network. The Covid-19 epidemic perturbation parameter was removed in Mode II and the results were compared with Mode III. By removing the perturbation parameter, two important changes occurred in the shape trend at all three levels: 1- The resilience time of the nodes to deal with the effects of risks increased. 2- When applying risk response, inoperability in supply chain network nodes reaches its maximum value. By comparing modes III and IV at the Manufacture level, it was concluded that the Covid-19 pandemic has caused it. When the perturbation factor was removed, the largest change in the operating operability time was related to the forward motions. The Covid-19 epidemic affected the treatment center from two directions. 1. Patients showed less willingness to receive medical services (other than Covid-19) during quarantine. 2. The upward trend of admission of patients with Covid-19, which was more than the capacity of health centers, led to the weakening of medical human resource and severe shortage of equipment and drugs. These two factors led to unforeseen changes in the demand for goods. This is evident clearly by comparing modes III and IV at the Customer level. Refer to Tables 6, 7, and 8 in Appendix A for a detailed comparison of the four modes.

The inoperability of supply chain network components is closely related to revenues and costs. Cost management seeks to select the best responses that lead to the reduction and neutralization of network disruption factors, and increase of the upward trend of the level of production, and reduction of the loss of sending flow caused by perturbation compared to before perturbations. A comparison of the results in Table 3, Fig. 7, and Fig. 9 in Appendix B shows that budget changes lead to changes in risk responses and the amount of inoperability of nodes, changing the trend of the total loss of sending flows before and after the perturbation as well as risk responses. When the budget is reduced by 20%, a change is observed in the risk responses of modes (II, III, IV), the total number of these changes is 14, and the number of changes in terms of modes is 4, 5, and 5 cases. Nodes 3, 4, and 5 include response changes, with the largest change in responses being related to node 4. Also, the number of changes in risk responses is the same in the forward and backward motions. These changes led to an increase in the recovery period and losses resulting from reduced sending flows after the occurrence of the perturbation. Also, the duration and loss resulting from reduced sending flow in modes II to IV increased by 2.55, 2.45 and 3.5 unit times, and 1.61*107, 1.602*107,1.605*107 $. With a 20% increase in the budget, the number of changes in risk responses to the budget reduction mode increased from 14 to 24, similar to the budget reduction mode, the changes in the forward and backward motions are equal, and the most changes are related to nodes 3, 4 and 5. Increasing the budget of the nodes reduced the total recovery time and the loss resulting from reduced sending flows. However, increasing the costs of risk responses led to an increase in the first objective function. Also, by changing the risk responses, the speed of operability of the supply chain network increases. In budget mode equal to B, a change is observed in risk responses in modes III and IV. These changes are related to the responses of Node 5, Y5121, Y5122, Y5621, Y5622. Modes II, III, and IV with budget B have a similar trend with significant differences. In all three modes, when the Covid-19 factor is eliminated from the equations, it is observed that the total costs reach the highest level with a delay of at least two time periods compared to two other cases (0.8B, 1.2B). Besides, the trend of modes II, III, and IV in the budget 0.8B compared to the other two budget scenarios after the cost peak points are significant. Explaining this trend is related to the concept of inoperability. After applying the risk response, the nodes moved to operability with a non-zero value, which in turn increased the reducing the flow of goods sent in the supply chain network.

To validate the proposed model and its outputs, we reduced the capacity of the most important node of the producer level by 20%, and we obtained significant results by examining and analyzing its graphs. In modes II, III, IV with budget scenario B, we can see that in all the graphs, the time to apply the answers has decreased non-linearly.

Also, xijrs are getting closer to operability level in an increasing rate in a shorter time span. These results express the concept that the lower the capacity of the nodes, the more sensitive the supply chain network is to events and risks, which is directly related to the resilience of the supply chain network. To better understand this issue, we analyze the issue from different point of view.

Suppose that the reduction mode of 20% capacity of node 1 is the base mode to for evaluation, and the initial base mode, it is equivalent to a 20% increase of the new base mode. A 20% increase in the capacity of node 1 is the same as the buffer capacity, which increases the inventory capacity and resilience of the supply chain network to deal with incidents and risks and reduces the loss of streams sent in the supply chain network, consistent with the movement trend of Fig. 8 and its outputs are compiled in Table 4.

5 Conclusion

With the increasing complexity and development of supply chain networks, risk and disruption management has become very important in the pandemic era. In this study, an approach was proposed to evaluate the risks and disruption factor of Covid-19 in the inoperability of nodes and their impact on supply chain networks. We developed a dynamic input–output multi-objective optimization model with the objectives of reducing the loss of flows caused by disruptions, reducing the inoperability of supply chain network infrastructures and choosing the most optimal risk response strategy with budget limitations. The results of the present study help the policy makers and upstream and downstream managers of the supply chain to prioritize and manage the effects of Covid-19 and supply chain risks in the short and medium term by planning and choosing the appropriate strategy. It also provides analysts with a clearer picture of the effects and behaviors of risks and disruptions in time periods. Despite its significant contribution to the supply chain, this study has some limitations. The main limitation in input–output models is the calculation of technical matrix coefficients, the official statistics of which are updated and presented based on states, cities and Industrial areas by countries in multi-year time intervals. An exciting research field is the use of probability distributions and Piecewise Function instead of fixed coefficients in objective function differential equations 2, which solves the weaknesses of the I-O model in estimating and simulating long-term effects and unpredicted disruptions. The parameters of the model have been checked under conditions of certainty, which can be checked under conditions of uncertainty for future research. Also, the ability to predict the impact speed of risks and disruptions in supply chain models will be very interesting. The integration of complex supply chain models with I-O models for risk analysis, disruption management and resilience of supply chain networks is a field of study for researchers in the future that has been neglected.

References

Badhotiya GK, Soni G, Jain V, Joshi R, Mittal S (2022) Assessing supply chain resilience to the outbreak of COVID-19 in Indian manufacturing firms. Oper Manage Res 1–20

Bassiouni MM, Chakrabortty RK, Hussain OK, Rahman HF (2023) Advanced deep learning approaches to predict supply chain risks under COVID-19 restrictions. Expert Syst Appl 211:118604

Chen J, Wang H, Zhong RY (2021) A supply chain disruption recovery strategy considering product change under COVID-19. J Manuf Syst

Chowdhury P, Paul SK, Kaisar S, Moktadir MA (2021) COVID-19 pandemic related supply chain studies: a systematic review. Transport Res E: Logist Transport Rev 102271

Coe NM, Dicken P, Hess M (2008) Global production networks: Realizing the potential. J Econ Geogr 8(3):271–295

de Vet JM, Nigohosyan D, Ferrer JN, Gross A-K, Kuehl S, Flickenschild M (2021) Impacts of the COVID-19 pandemic on EU industries. European Parliament

Der Kiureghian A, Ditlevsen O (2009) Aleatory or epistemic? Does it matter? Struct Saf 31(2):105–112

Ebrahimnejad S, Khanbaba A, Samimi S (2021) Development of an input-output model considering simultaneous effect of risks in infrastructure under dynamic conditions. Reliab Eng Syst Saf 213:107653

Galbusera L, Giannopoulos G (2018) On input-output economic models in disaster impact assessment. Int J Disaster Risk Reduct 30:186–198

Ghorbani-Renani N, González AD, Barker K, Morshedlou N (2020) Protection-interdiction-restoration: Tri-level optimization for enhancing interdependent network resilience. Reliab Eng Syst Saf 199:106907

Haimes YY, Horowitz BM, Lambert JH, Santos JR, Lian C, Crowther KG (2005) Inoperability input-output model for interdependent infrastructure sectors. I: Theory and methodology. J Infrastruct Syst 11(2):67–79

Haimes YY, Jiang P (2001) Leontief-based model of risk in complex interconnected infrastructures. J Infrastruct Syst 7(1):1–12

Hosseini S, Ivanov D (2021) A multi-layer Bayesian network method for supply chain disruption modelling in the wake of the COVID-19 pandemic. Int J Prod Res 1–19

Howard RA (1988) Decision analysis: Practice and promise. Manage Sci 34(6):679–695

Ivanov D (2020) Predicting the impacts of epidemic outbreaks on global supply chains: a simulation-based analysis on the coronavirus outbreak (COVID-19/SARS-CoV-2) case. Transport Res e: Logist Transport Rev 136:101922

Ivanov D, Dolgui A (2020) Viability of intertwined supply networks: Extending the supply chain resilience angles towards survivability. A position paper motivated by COVID-19 outbreak. Int J Prod Res 58(10):2904–2915

Jabilles EMY, Cuizon JMT, Tapales PMA, Urbano RL, Ocampo LA, Kilongkilong DAA (2019) Simulating the impact of inventory on supply chain resilience with an algorithmic process based on the supply-side dynamic inoperability input–output model. Int J Manag Sci Eng Manag 14(4):253–263

Jüttner U, Peck H, Christopher M (2003) Supply chain risk management: Outlining an agenda for future research. Int J Log Res Appl 6(4):197–210

Karuppiah K, Sankaranarayanan B, Ali SM (2022) Modeling impacts of COVID-19 in supply chain activities: A Grey-DEMATEL approach. Sustainability 14(21):14141

Khan SAR, Waqas M, Honggang X, Ahmad N, Yu Z (2022) Adoption of innovative strategies to mitigate supply chain disruption: COVID-19 pandemic. Oper Manage Res 1–19

Koopman R, Degain C, Eberth F, d’Andrea-Adrian B, Bhatia S, Chang L, Haj Nassar Z, Nee C, Wettstein S, Yan Y (2021) World Trade Statistical Review 2021. World Trade Organization

Kumar A, Zavadskas EK, Mangla SK, Agrawal V, Sharma K, Gupta D (2019) When risks need attention: Adoption of green supply chain initiatives in the pharmaceutical industry. Int J Prod Res 57(11):3554–3576

Li Y, Chen K, Collignon S, Ivanov D (2021) Ripple effect in the supply chain network: Forward and backward disruption propagation, network health and firm vulnerability. Eur J Oper Res 291(3):1117–1131

Lücker F, Seifert RW, Biçer I (2019) Roles of inventory and reserve capacity in mitigating supply chain disruption risk. Int J Prod Res 57(4):1238–1249

Manley RL, Alonso E, Nassar NT (2022a) Examining industry vulnerability: a focus on mineral commodities used in the automotive and electronics industries. Resour Policy 78:102894

Manley RL, Alonso E, Nassar NT (2022b) A model to assess industry vulnerability to disruptions in mineral commodity supplies. Resour Policy 78:102889

Manuj I, Mentzer JT (2008) Global supply chain risk management strategies. Int J Phys Distrib Logist Manag

Moosavi J, Fathollahi-Fard AM, Dulebenets MA (2022) Supply chain disruption during the COVID-19 pandemic: Recognizing potential disruption management strategies. Int J Disaster Risk Reduct 102983

Niknejad A, Petrovic D (2016) A fuzzy dynamic inoperability input–output model for strategic risk management in global production networks. Int J Prod Econ 179:44–58

Oliva G, Panzieri S, Setola R (2011) Fuzzy dynamic input–output inoperability model. Int J Crit Infrastruct Prot 4(3–4):165–175

Paul SK, Chowdhury P, Chakrabortty RK, Ivanov D, Sallam K (2022) A mathematical model for managing the multi-dimensional impacts of the COVID-19 pandemic in supply chain of a high-demand item. Ann Oper Res 1–46

Pichler A, Farmer JD (2022) Simultaneous supply and demand constraints in input–output networks: The case of Covid-19 in Germany, Italy, and Spain. Econ Syst Res 34(3):273–293

Pichler A, Pangallo M, del Rio-Chanona RM, Lafond F, Farmer JD (2022) Forecasting the propagation of pandemic shocks with a dynamic input-output model. J Econ Dyn Control 144:104527

Rozhkov M, Ivanov D, Blackhurst J, Nair A (2022) Adapting supply chain operations in anticipation of and during the COVID-19 pandemic. Omega 110:102635

Samimi S, Ebrahimnejad S, Mojtahedi M (2020) Analysis of the susceptibility of interdependent infrastructures using fuzzy input–output inoperability model: The case of flood hazards in Tehran. Nat Hazards 100(1):69–88

Santos JR, Haimes YY (2004) Modeling the demand reduction input-output (I-O) inoperability due to terrorism of interconnected infrastructures. Risk Anal: Int J 24(6):1437–1451

Santos JR, May L, Haimar AE (2013) Risk-based input-output analysis of influenza epidemic consequences on interdependent workforce sectors. Risk Anal 33(9):1620–1635

Setola R, De Porcellinis S, Sforna M (2009) Critical infrastructure dependency assessment using the input–output inoperability model. Int J Crit Infrastruct Prot 2(4):170–178

Wang H, Pan C, Wang Q, Zhou P (2020) Assessing sustainability performance of global supply chains: an input-output modeling approach. Eur J Oper Res 285(1):393–404

Wei H, Dong M, Sun S (2010) Inoperability input-output modeling (IIM) of disruptions to supply chain networks. Syst Eng 13(4):324–339

Weiss M, Schwarzenberg A, Nelson R, Sutter KM, Sutherland MD (2020) Global economic effects of COVID-19. Congress Res Serv

Yaseen QM, Akhtar R, Khalil MKU, Jan QMU (2020) Dynamic inoperability input-output modeling for economic losses estimation in industries during flooding. Socioecon Plann Sci 72:100876

Yu Z, Razzaq A, Rehman A, Shah A, Jameel K, Mor RS (2021) Disruption in global supply chain and socio-economic shocks: a lesson from COVID-19 for sustainable production and consumption. Oper Manage Res 1–16

Zhang Y (2016) Selecting risk response strategies considering project risk interdependence. Int J Project Manage 34(5):819–830

Author information

Authors and Affiliations

Contributions

Amirhossein Khanbaba: Conceptualization, Methodology, Writing - Original Draft, Software, Validation, Formal analysis, Investigation, Data Curation, Visualization. Sadoullah Ebrahimnejad: Writing - Review & Editing mathematical model, Visualization, Supervision, Project administration.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Multi-objective optimization of the DIIM.

• Analysis of the ripple effects of risks and COVID-19 on the supply chain network.

• Budget sensitivity analysis in order to determine influence the change of risk responses on the operability of the supply chain network.

Appendices

Appendix A

Appendix B

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Khanbaba, A., Ebrahimnejad, S. A multi objective input–output model to select optimal strategies under COVID-19 conditions: In the pharmaceutical industry. Oper Manag Res 16, 2025–2047 (2023). https://doi.org/10.1007/s12063-023-00370-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12063-023-00370-3