Abstract

An eco-friendly and expedient procedure for one-pot synthesis of bis-(indolyl)methane derivatives via electrophilic substitution reaction at C-3 position of indole with various aldehydes has been developed by using silica-diphenic acid as a novel heterogeneous catalyst. This method has various promising features such as short reaction time, easy work-up procedure, good yield of products and remarkable activity and selectivity of the catalyst.

The aim of this work is to highlight the efficiency and suitability of silica-diphenic acid as a supported solid acid catalyst for the synthesis of bis-(indolyl)methane derivatives from a one-pot condensation reaction of various substituted aldehydes and indole in acetonitrile at 60°C.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Indole, the most important heterocycle present in natural compounds, has become an important structural moiety required in many pharmaceutical agents[1] due to its extensive pharmacological and biological activities.[2] One of the most important groups of indole derivatives which possess such activities and those found in cruciferous plants and marine sources are bis-(indolyl)methanes.[3] They exhibit different pharmaceutical activities such as anti-cancer, anti-bacterial, cytotoxic, anti-oxidative, insecticidal, anti-hyperglycaemic, anti- viral, and anti-microbial activities.[4–6] Bis-(indolyl)methane derivatives are also known to promote oestrogen metabolism in both men and women and are expected to have an application in the prevention of breast cancer.[7] These derivatives also possess significant anti-proliferative activity and induce apoptosis in human prostate cancer cells.[8]

Due to the unique biological properties of bis-(indolyl)methane derivatives, many research groups have shown interest to find feasible and efficient synthetic methods for this class of compounds. The best synthetic route towards bis-(indolyl)methane derivatives is the condensation reaction between indole and carbonyl compounds using different catalysts.[9,10]

In literature, a number of synthetic methods for their preparation have been reported. Of these methods, the acid catalysed electrophilic addition reaction of indole and aldehydes is one of the most simple and straightforward approaches for the synthesis of bis-(indolyl)alkane derivatives. Many reagents such as silica-supported boric acid,[11] [cmmim]Cl,[12] silica gel,[13] n-dodecylbenzene sulfonic acid (DBSA),[14] ß-cyclodextrin sulphuric acid,[15] cyclic phosphonic acid anhydride (T3P),[16] monoammonium salt of 12-tungstophosphoric acid [(NH4)H 2 PW 12 O 40],[17] nanocatalyst H5 PW10 V 2 O 40/TPI-Fe3 O 4,[18] 1,3-Dibromo-5,5-dimethylhydantoin (DBDMH),[19] BF3·Et2O,[20] N-butyl-pyridinium bromide,[21] PEG-SO3H,[22] triphenylphosphonium perchlorate,[23] iodine,[24] silica sulphuric acid (SSA),[25] fruit juice of citrus-lemon,[26] Ni-nanoparticles,[27] etc. Although some of these protocols are valuable, most of them suffer from one or more drawbacks, including long reaction times, low yields of products, harsh reaction conditions, and use of expensive and/or toxic catalysts and solvents. Therefore, there is a strong demand for the development of mild, clean, and highly efficient procedures for the synthesis of bis-(indolyl) methane derivatives.

In this context, we report here one-pot synthesis of bis-(indolyl) methane derivatives by reaction of indole and aromatic/heteroaromatic/aliphatic aldehydes in the presence of silica-diphenic acid as a heterogeneous and recyclable catalyst in acetonitrile at 60 °C (scheme 1).

2 Experimental

All the chemicals and solvents were purchased from Sigma-Aldrich and Merck and were used without further purification. The mass spectra were recorded on Esquire 3000 Bruker Daltonics spectrometer (ESI). 1H- NMR and 13C-NMR spectra were recorded in DMSO- d 6 on Bruker Avance III 400 MHz spectrometer using TMS as an internal standard. TGA was recorded on Linesis Thermal Analyser with heating rate of 10 °C/min. FTIR was recorded on SHIMADZU prestige spectrophotometer. SEM images were recorded on JSM-7600F scanning electron microscope. TEM images were recorded on CM200 PHILIPS transmission electron microscope. All physical and spectroscopic data of products were compared with those reported in the literature.

2.1 Preparation of Activated Silica

Activated silica was prepared by adding silica gel (15 g, K 60) to a solution of 1:1 HCl (150 mL) and H2O (150 mL) in a 500 mL round-bottom flask and the reaction mixture was stirred at 120 °C for 12 h. The activated silica was filtered at pump, washed with water till washings were neutral, and dried in oven at 110 °C for 5 h.

2.2 Preparation of silica supported diphenic acid

In a round-bottom flask, diphenic acid (1 mmol, 0.242 g) was dissolved in ethanol (10 mL). To this solution, the activated silica gel (1 g) was added. The mixture was shaken for a few minutes and then refluxed for 12 h. After refluxing, the solvent was evaporated under reduced pressure of 250 mm Hg (333.3 mbar) for 25 h to give free-flowing powder. The complete preparation procedure for silica-supported diphenic acid is represented in scheme 2.

2.3 Characterization of Silica-Diphenic Acid

Silica-diphenic acid was characterized by FTIR, thermal gravimetric analysis (TGA), TEM, and SEM analysis.

2.3.1 FTIR

The anchoring of diphenic acid onto the surface of silica was confirmed by FTIR spectra (figure 1) of the catalyst silica-diphenic acid. The spectra showed the characteristic absorption peaks at 1089.78 cm-1, 800.46 cm-1 and 466.77 cm-1, which were assigned to asymmetric stretching, symmetric stretching, and bending modes of Si–O–Si bonds, respectively. Due to the anchoring of diphenic acid onto the surface of the activated silica through one of the carbonyl group (C =O) of diphenic acid by ester linkage, the absorption peak of carbonyl group (C =O) appears at 1720.50 cm-1 and peaks at 1487.12 cm-1 and 1392.61 cm-1 were related to asymmetric and symmetric stretching vibrations of another carboxylic (-CO\(_{2}^{{-}})\) group. The formation of ester linkage between diphenic acid and silica was further confirmed by absorption peaks at 1359.52 cm-1 and 1151.50 cm-1, which were attributed to Si–O–C bonds. The FTIR spectrum of the catalyst also shows the absence of characteristic –OH stretching vibration of –COOH group near 3300–3000 cm-1 and the absorption peak at 3676.32 cm-1 may be due to the presence of some of the free Si-OH groups in the catalyst. Further, the absorption peak at 1656.85 cm-1 corresponds to the stretching mode of vibrations of benzene rings of diphenic acid. From the above spectral data analysis of the catalyst, it has been concluded that diphenic acid was chemically adsorbed onto the surface of activated silica by forming ester linkages.

2.3.2 Thermal Gravimetric Analysis

The stability of the silica-diphenic acid was determined by thermal gravimetric analysis (figure 2). The curve showed an initial weight loss up to 90 °C, which may be due to the removal of surface-adsorbed solvent and gases. The next weight loss up to 263.7 °C was probably due to the loss of structural water within amorphous SiO2. The weight loss up to 340.7 °C may correspond to the decomposition of two benzenes of diphenic acid, followed by continuous weight loss up to 560.7 °C, which may be attributed to the loss of CO and CO2 groups. This thermal analysis indicates that catalyst is stable up to 100 °C and hence it is safe to carry out the reaction at 60 °C.

2.3.3 Transmission Electron Microscopy (TEM)

The TEM micrographs of the catalyst provide a direct observation of the morphology and distribution of the diphenic acid in silica-diphenic acid catalyst. The TEM micrographs indicated that diphenic acid is uniformly distributed onto the surface of silica as shown in figure 3 and the mean diameter was found to be 5.27 nm.

2.3.4 Scanning Electron Microscopy (SEM)

The microstructure and morphology of silica-diphenic acid was studied using a scanning electron microscope (SEM). The surface of silica-diphenic acid was found to be fine homogeneous powder with porous structure and it was observed that diphenic acid particles are adsorbed onto the surface of silica as shown in figure 4.

2.4 General Procedure for the One-Pot Synthesis of Bis-(Indolyl)Methane Derivatives

To a mixture of aldehyde (1 mmol), indole (2 mmol) in a round-bottom flask (25 mL), silica-diphenic acid (0.05 g) and acetonitrile (1 mL) were added and the reaction mixture was stirred at 60 °C in an oil bath for the appropriate time. On completion of the reaction (monitored by TLC), the reaction mixture was cooled to room temperature and EtOAc (20 mL) was added to it. The reaction mixture was then filtered to separate the catalyst, followed by washing of filtrate with distilled water and, finally, dried over anhydrous Na2 SO 4. After removal of solvent under reduced pressure, the residue was purified by passing through a column of silica gel and elution with EtOAc: petroleum ether. The products obtained from column were further recrystallized in EtOAc: petroleum ether so that these were obtained in pure form. The structures of the products were confirmed by IR, 1HNMR, 13C NMR and mass spectral data and compared with authentic samples available commercially or prepared according to literature methods.

2.5 Spectral Data for the Synthesised Compounds

2.5.1 Phenyl-3,3 ' -bis-(indolyl)methane(Entry1, Table 5)

IR (υ max in cm-1, KBr): 3460, 3221, 1599, 1475, 1420, 1109, 1017, 756. 1H NMR (400 MHz, DMSO- d 6): d 5.90 (s, 1H, methine-H), 6.67 (s, 2H), 7.12–7.56 (m, 13H), 10.13 (bs, 2H, NH). 13C NMR (400 MHz, DMSO- d 6): d 51.33, 109.45, 112.12, 118.52, 120.56, 121.63, 122.46, 126.23, 127.82, 128.45, 130.31, 136.44, 139.59. MS: m/z 321 (M-1).

2.5.2 3, 4-Dimethoxyphenyl-3, 3 '-bis-(indolyl) methane (Entry 2, Table 5)

IR (υ max in cm-1, KBr): 3480, 3020, 2928, 1629, 1556, 1445, 1029, 758. 1H NMR (400 MHz, DMSO- d 6): d 3.76 (s, 3H, OCH3), 3.85 (s, 3H, OCH3), 5.83 (s, 1H, methine-H), 6.65 (s, 2H), 6.45–6.54 (m, 3H), 7.1–7.22 (m, 4H), 7.41(d, 2H), 7.59 (d, 2H), 10.86 (bs, 2H, NH). 13C NMR (400 MHz, DMSO-d6): d 42.41, 48.64, 111.30, 112.44, 114.21, 115.46, 119.80, 120.31, 121.02, 122.10, 122.52, 122.90, 131.11, 136.82, 146.34, 148.97. MS: m/z 381 (M-1).

2.5.3 4-Methoxyphenyl-3,3 '-bis-(indolyl)methane(Entry 3, Table 5)

IR (υ max in cm-1, KBr): 3480, 3018, 2853, 1615, 1507, 1346, 1088, 783, 742. 1H NMR (400 MHz, DMSO-d6): d 3.94 (s, 3H), 5.85 (s, 1H, methine-H), 6.71 (s, 2H), 6.88–7.27 (m, 4H), 7.85–7.92 (m, 8H), 10.63 (bs, 2H, NH). 13C NMR (400 MHz, DMSO- d 6): d 48.23, 51.18, 111.10, 112.53, 115.70, 119.19, 120.08, 122.19, 124.73, 127.16, 130.02, 130.90, 136.42, 148.86. MS: m/z 351 (M-1).

2.5.4 4-Methylphenyl-3,3 '-bis-(indolyl)methane(Entry 4, Table 5)

IR (υ max in cm-1, KBr): 3475, 3145, 3020, 2970, 1636, 1506, 1086, 736. 1H NMR (400 MHz, DMSO-d6): d 2.51 (s, 3H), 5.77 (s, 1H, methine-H), 6.79 (s, 2H), 6.85–6.87 (m, 4H), 7.22-7.39 (m, 8H), 10.8 (bs, 2H, NH). 13C NMR (400 MHz, DMSO- d 6): d 39.90, 111.03, 112.23, 116.58, 117.90, 118.57, 121.33, 123.90, 128.64, 129.07, 131.21, 132.13, 135.80, 139.21. MS: m/z 335 (M-1).

2.5.5 2-Flourophenyl-3,3 ' -bis-(indolyl)methane (Entry 5, Table 5)

IR (υ max in cm-1, KBr): 3440, 3059, 1601, 1508, 1457, 1038, 865, 738. 1H NMR (400 MHz, DMSO-d6): d 6.10 (s, 1H, methine-H), 6.83 (s, 2H), 7.03–7.09 (m, 4H), 7.24–7.26 (m, 4H), 7.35–7.37 (m, 4H), 10.87 (bs, 2H, NH). 13C NMR (400 MHz, DMSO- d 6): d 49.07, 112.27, 115.55, 117.04, 118.55, 119.12, 121.76, 124.21, 124.53, 126.83, 128.35, 128.63, 130.70, 137.03, 161.74. MS(-ESI): m/z 339 (M-1), 19F NMR (400 MHz, DMSO- d 6): -118.65.

2.5.6 2-Chlorophenyl-3, 3 '-bis-(indolyl) methane (Entry 6, Table 5)

IR (υ max in cm-1, KBr): 3413, 3055, 1618, 1095, 748. 1H NMR (400 MHz, DMSO- d 6): d 5.95 (s, 1H, methine-H), 6.88 (s, 2H), 6.6–6.7 (d, 2H), 6.91–7.05 (t, 2H), 7.10–7.21 (m, 4H, Ar-H), 7.35–7.45 (m, 4H, Ar-H), 10.98 (bs, 2H, NH). 13C NMR (400 MHz, DMSO- d 6): d 39.33, 111.36, 112.21, 118.32, 118.90, 119.87, 120.23, 123.42, 126.88, 127.29, 128.90, 130.04, 134.52, 136.38, 138.49. MS: m/z 355 (M-1).

2.5.7 4-Chlorophenyl-3, 3 '-bis-(indolyl) methane (Entry 7, Table 5)

IR (υ max in cm-1, KBr): 3468, 3018, 2920, 1615, 1529, 1210, 759. 1H NMR (400 MHz, DMSO- d 6): d 5.85 (s, 1H, methine-H), 6.82 (s, 2H), 6.8–7.05 (m, 4H, Ar-H), 7.2–7.39 (m, 8H, Ar-H), 10.87 (bs, 2H, NH). 13C NMR (400 MHz, DMSO- d 6): d 40.11, 111.97, 118.01, 118.73, 119.48, 121.44, 126.91, 128.46, 129.85, 130.72, 131.67, 137.03, 144.46. MS: m/z 355 (M-1).

2.5.8 4-Bromophenyl-3, 3 '-bis-(indolyl) methane (Entry 8, Table 5)

IR (υ max in cm-1, KBr): 3413, 3055, 1618, 1095, 748. 1H NMR (400 MHz, DMSO- d 6): d 5.83 (s, 1H, methine-H), 6.83 (s, 2H), 6.89–7.08 (m, 6H, Ar-H), 7.34–7.46 (m, 4H, Ar-H), 7.85–7.86 (d, 2H, Ar-H), 10.86 (bs, 2H, NH). 13C NMR (400 MHz, DMSO- d 6): d 40.51, 111.97, 117.93, 118.74, 119.47, 121.45, 124.07, 126.90, 129.17, 131.37, 132.79, 137.03, 144.89. MS: m/z 400 (M-1).

2.5.9 2-Nitrophenyl-3, 3 '-bis-(indolyl) methane (Entry 9, Table 5)

IR (υ max in cm-1, KBr): 3416, 1578, 1458, 1357, 1223. 1H NMR (400 MHz, DMSO- d 6): d 5.89 (s, 1H, methine-H), 6.33 (s, 2H), 6.56–6.61 (m, 4H), 7.27–7.37 (m, 4H), 7.60–7.62 (m, 3H), 8.07 (d, 1H), 10.86 (bs, 2H, NH). 13C NMR (400 MHz, DMSO- d 6): d 38.54, 111.42, 112.83, 118.63, 120.30, 121.58, 122.23, 122.91, 125.80, 127.43, 130.21, 132.11, 134.22, 136.54, 148.70. MS: m/z 366 (M-1).

2.5.10 3-Nitrophenyl-3, 3 '-bis-(indolyl) methane (Entry 10, Table 5)

IR (υ max in cm-1, KBr): 3405, 1526, 1459, 1352, 1049. 1H NMR (400 MHz, DMSO- d 6): d 5.99 (s, 1H, methine-H), 6.07 (s, 2H), 7.11–7.23 (m, 4H), 7.48–7.55 (m, 4H), 7.16 (d, 2H), 7.99–8.01 (t, 2H), 10.91 (bs, 2H, NH). 13C NMR (400 MHz, DMSO- d 6): d 39.42, 111.21, 112.63, 118.92, 119.56, 120.40, 122.01, 122.80, 124.52, 127.55, 129.81, 135.41, 136.64, 139.73, 147.82. MS: m/z 366 (M-1).

2.5.11 4-Nitrophenyl-3, 3 '-bis-(indolyl) methane (Entry 11, Table 5)

IR (υ max in cm-1, KBr): 3426, 1589, 1456, 1345, 1229. 1H NMR (400 MHz, DMSO- d 6): d 6.029 (s, 1H, methine-H), 6.58 (s, 2H), 6.89–6.91 (m, 4H), 7.27–7.37 (m, 4H), 7.62 (d, 2H), 8.16 (d, 2H), 10.94 (bs, 2H, NH). 13C NMR (400 MHz, DMSO-d6): d 40.26, 112.06, 117.12, 118.91, 119.36, 121.60, 123.90, 124.30, 126.79, 129.91, 137.02, 146.20, 153.58. MS: m/z 366 (M-1).

2.5.12 2-Bromophenyl-3, 3 '-bis-(indolyl) methane (Entry 12, Table 5)

IR (υ max in cm-1, KBr): 3410, 3063, 1565, 1086, 750. 1H NMR (400 MHz, DMSO- d 6): d 6.02 (s, 1H, methine-H), 6.77 (s, 2H), 6.99–7.05 (m, 4H, Ar-H), 7.24–7.36 (m, 4H, Ar-H), 7.64 (d, 1H, Ar-H), 7.85–7.86 (d, 2H, Ar-H), 7.9 (d, 1H, Ar-H), 10.89 (bs, 2H, NH). 13C NMR (400 MHz, DMSO- d 6): d 39.51, 111.0, 116.98, 117.74, 118.49, 121.46, 123.78, 125.91, 126.68, 128.17, 130.33, 131.79, 132.39, 135.02, 145.58. MS: m/z 400 (M-1).

2.5.13 2-Furfuryl-3, 3 '-bis-(indolyl) methane (Entry 13, Table 5)

IR (υ max in cm-1, KBr): 3457, 3029, 2359, 1610, 1466, 1429, 1226, 1095, 1031, 759, 720. 1H NMR (400 MHz, DMSO- d 6): d 5.94 (s,1H, methine-H), 6.05 (d, 1H), 6.30(d,1H), 6.87(d, 1H), 7.08(t, 2H), 7.17(t, 2H), 7.29–7.48(m, 5H), 10.95(bs, 2H, NH). 13C NMR (400 MHz, DMSO- d 6): d 42.61, 104.98, 110.32, 111.13, 112.45, 119.13, 120.16, 122.34, 122.99, 127.52, 136.55, 142.42, 152.66. MS: m/z 311 (M-1).

2.5.14 1-Ethyl-3, 3 '-bis-(indolyl) methane (Entry 14, Table 5)

IR (υ max in cm-1, KBr): 3457, 3022, 3061, 1466, 1226, 1085, 1042, 766, 690. 1H NMR (400 MHz, DMSO- d 6): d 1.52 (d, 3H, CH3), 4.66 (q,1H, methine-H), 6.81 (s, 2H), 7.18–7.22 (m,8H), 10.06 (bs, 2H, NH). 13C NMR (400 MHz, DMSO- d 6): d 23.67, 39.67, 111.12, 115.98, 119.33, 120.12, 122.34, 122.67, 127.58, 136.54. MS: m/z 259 (M-1).

2.5.15 1-Butyl-3, 3 '-bis-(indolyl) methane (Entry 15, Table 5)

IR (υ max in cm-1, KBr): 3466, 3019, 3052, 1501, 1196, 1079, 1038, 775, 691. 1H NMR (400 MHz, DMSO- d 6): d 0.99 (t, 3H, CH3), 1.29 (m, 2H, CH2), 1.75 (q, 2H, CH2), 4.66 (t, 1H, methine-H), 6.84 (s, 2H), 7.18–7.24 (m,8H), 10.59 (bs, 2H, NH). 13C NMR (400 MHz, DMSO- d 6): d 14.5, 19.9, 44.5, 52.3, 111.3, 115.6, 119.7, 120.1, 122.4, 122.9, 127.8, 136.8. MS: m/z 287 (M-1).

3 Results and Discussion

A number of synthetic methods for the preparation of bis-(indolyl)methane derivatives have been reported; of these methods, the acid catalysed electrophilic addition reaction of indole with aldehydes is one of the most simple and straightforward approaches for one-pot synthesis of bis-(indolyl)methane derivatives.

To the best of our knowledge, the catalytic efficiency of diphenic acid in organic transformation has been less studied. According to the literature, it has been mainly explored as a ligand in inorganic chemistry[28,29] and also as co-catalyst in a few organic syntheses.[30] Therefore, we explored the catalytic efficiency of diphenic acid for one-pot synthesis of bis-(indolyl)methane.

3.1 Optimization of the Reaction Conditions

The reaction conditions for the synthesis of bis-(indolyl)methane derivatives were optimized by selecting indole and benzaldehyde as test substrates and the reaction was carried out under a different set of conditions with respect to different types of catalysts, different amounts of catalyst, temperatures and solvents. Initially, the reaction with test substrates was carried out using different types of catalysts as shown in table 1.

From the results mentioned above, we found that diphenic acid completes the reaction in less time than silica-diphenic acid. But, the use of diphenic acid as homogeneous catalyst in the above mentioned reaction of test substrates did not provide easy work-up procedure and, moreover, the selectivity of the reaction also decreases after sometime. Therefore, the use of silica-diphenic acid as a heterogeneous catalyst overcomes the disadvantages of the homogeneous conditions and provides easy work procedure and also maintains the selectivity of the reaction.

To select a proper amount of catalyst required to produce excellent yield of products, the reaction of test substrates was carried out using different amounts of silica-diphenic acid. It was found that 0.05 g of silica-diphenic acid was sufficient to carry out the reaction in lesser time with good yield of products. There was no significant change in the yield of products when large amounts of silica-diphenic acid were used instead of 0.05 g. The results are summarized in the table 2.

The reaction of test substrates was also carried out using polar and non-polar solvents like acetonitrile, methylene chloride, toluene, and water and also under solvent-free condition. It was observed that the reaction carried out in acetonitrile gave the best results in terms of yield, selectivity, and reaction time. Therefore, acetonitrile was selected as the solvent system for the synthesis of bis-(indolyl)methane derivatives. The results are shown in table 3.

Further, to make the reaction conditions even more effective for the synthesis of bis-(indolyl)methanes in less time with good yields, the test reaction was also attempted at different temperatures such as 30 °C, 60 °C, 80 °C and 100 °C and it has been found that the reaction was very slow at low temperatures, whereas at higher temperatures, it becomes highly reactive but loses its selectivity and gave multiple products. Thus, 60 °C was selected as the optimum reaction temperature at which the reaction proceeded effectively to give a better yield of products with good selectivity. At 60 °C optimized reaction temperature, 90% yield was observed during the reaction of the test substrates, as shown in table 4.

To study the generality of the newly developed protocol, different aromatic aldehydes substituted with electron-donating and electron-withdrawing substituents and some heteroaromatic/aliphatic aldehydes were selected and good to excellent results were obtained. The results are summarized in table 5.

From table 5, the structure–activity relationship has been inferred and found that aromatic aldehydes substituted with electron-withdrawing groups undergo faster reactions than aromatic aldehydes substituted with electron-donating groups. Moreover, aliphatic aldehydes took longer time than aromatic/hetero-aromatic aldehydes and also provide lower yield of products.

To study the effect of silica-diphenic acid as catalyst, the reaction of test substrates was also carried out in the absence of catalyst. It was found that without a catalyst, the reaction was very slow and did not proceed to completion. The reaction was also tried under microwave conditions as well as by the grinding method, but satisfactory results were not obtained as it took a very long time for completion and selectivity was also reduced.

3.2 Recyclability and Heterogeneity of Silica-diphenic Acid

To classify the catalyst as a heterogeneous catalyst, recyclability of the catalyst required to be examined. A series of five consecutive runs were carried out in case of 4-nitrobenzaldehyde and indole (Entry 11, table 5). Slight drop in the activity of the catalyst was observed. The results are shown in figure 5.

The hot-filtration test has also been performed for testing the heterogeneity of the catalyst using benzaldehyde and indole as test substrates. First, in this test, the reaction has been carried out in the presence of silica-diphenic acid in acetonitrile at 60 °C. After 10 min, catalyst was filtered off from the reaction mixture and the rest of the reaction mixture was further monitored for 20 min. It was found that the reaction had not proceed further in the absence of the catalyst. Therefore, it may be concluded that there is no leaking of the diphenic acid from the silica-diphenic acid catalyst.

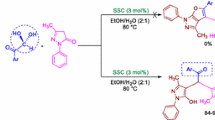

3.3 Mechanism

A plausible mechanism for the reaction between indole and aldehydes in the presence of a catalyst (silica-diphenic acid) has been proposed, as shown in scheme 3. In the first step, an aldehyde was protonated by the acid catalyst (silica-diphenic acid) and an electrophilic substitution reaction at the C-3 position of indole was carried out to give an intermediate (1) which undergoes proton rearrangement to give intermediate (2). After loss of water from an intermediate (2) activated by proton, an intermediate (3) was obtained, which serves as an electrophile to be attacked by a second molecule of an indole to form the corresponding bis-(indolyl)methane derivatives (4).

4 Conclusions

Silica-diphenic acid was found to be an effective catalyst for the electrophilic substitution reactions of indole with aldehydes, giving selectively bis(indolyl)methane derivatives in good to excellent yields. The use of this inexpensive, heterogeneous and recyclable catalyst under mild conditions provides short reaction time, greater selectivity, easy work-up and ecologically clean selective procedure which make this protocol practical and economically attractive.

References

Kaishap P and Dohutia C 2013 Int. J. Pharm. Sci. Res. 4 1312

Lounasmaa M and Tolvanen A 2000 Nat. Prod. Rep. 17 175

Garbe T R, Kobayashi M, Shimizu N, Takesue N, Ozawa M and Yukawa H 2000 J. Nat. Prod. 63 596

Hong C, Firestone G L and Bjeldance L F 2002 Bio. Chem. Pharmacol. 63 1085

Hibino S and Choshi T 2001 Nat. Prod. Rep. 18 66

Povszsz L, Katakin G P, Foleat S and Malkovics B 1996 Acta. Phys. Acad. Sci. 29 299

Karthik M, Tripathi A K, Gupta N M, Palanichamy M and Murugeson V 2004 Catal. Commun. 5 371

Marrelli M, Cachet X, Conforti F, Sirianni R, Chimento A, Pezzi V, Michel S, Statti G A and Menichini F 2013 Nat. Prod. Res. 27 2039

Tayebee R, Amini M N, Nehzat F, Sadeghi O and Armaghan M 2013 J. Mol. Catal. A: Chem. 366 140

Shirini F and Khaligh N G 2013 Chin. J. Catal. 34 1890

Kumar V, Singh C, Sharma U, Verma P K, Singh B and Kumar N 2014 Ind. J. Chem. 53B 83

Zarea A R M, Borazjanib M P and Nazb Z 2014 Iran. Chem. Commun. 2 34

Mendes S R, Thurow S, Fortes M P, Penteado F, Lenardao E J, Alves D, Perin G and Jacob R G 2012 Tetrahedron Lett 53 5402

Pawar B, Shinde V and Chaskar A 2013 Green Sustainable Chem 3 56

Alinezhad H and Haghighi A H 2012 Caspian J. Chem. 1 1

Prasanna T S R and Raju K M 2012 J. Korean. Chem. Soc. 56 74

Giri B Y, Devi B L A P, Vijayalakshmi K, Prasad R B N, Lingaiah N and Prasad P S S 2012 Ind. J. Chem. 51B 1731

Tayebee R and Razib M K 2014 Res. Rev: J. Mater. Sci. 2 13

Hojati S F, Zeinali T and Nematdoust Z 2013 Bull. Korean Chem. Soc. 34 117

Xu X F and Xiong Y 2014 Chin. Chem. Lett. 25 406

Gupta G, Chaudhari G, Tomar P, Gaikwad Y, Azad R, Pandya G, Waghulde G and Patil K 2012 Eur. J. Chem. 3 475

Hasaninejad A, Shekouhy M, Zare A, Ghattali S M S H and Golzara N 2011 J. Iran. Chem. Soc. 8 411

Nagarajan R and Perumal P T 2002 Synth. Commun. 32 105

Bandgar B P, Bettigeri S A and Joshi N S 2004 Monatsh. Chem. 135 1265

Pore D M, Desai U V, Thopate T S and Wadgaonkar P P 2006 ARKIVOC xii 75

Pal R, Khannobis S and Sarkar T 2013 Chem. J. 3 7

Olyaei A, Vaziri M, Razeghi R, Shams B and Bagheri H 2013 J. Serb. Chem. Soc. 78 463

Prats A E P, Bernini M C, Medina M E, Torres E L, Puebla E., Monge M A and Snejko N 2011 Cryst. Eng. Comm. 13 4965

Dietzel P D C, Bloma R and Fjellvag H 2006 Dalton Trans 586

Kour G, Gupta M, Paul S, Rajnikant and Gupta V K 2014 J. Mol. Catal. A: Chem. 392 260

Li J T and Sun S F 2010 Eur. J. Chem. 7 922

Kaishap P P, Dohuti C and Chetia D 2012 Int. J. Pharm. Sci. Res 3 4247

Qu H E, Xiao C, Wang N, Yu K H, Hu Q S and Liu L X 2011 Molecules 16 3855

Behbahani F K and Sasani M 2012 J. Serb. Chem. Soc. 77 1157

Acknowledgements

We are grateful to Director, IIIM, Jammu, for recording mass spectral data and also extend my sincere thanks to Department of Chemistry, University of Jammu, for recording 1H-NMR, 13C-NMR, and IR spectral data of products and TGA and IR of the catalyst. We are also thankful to IIT Bombay for SEM and TEM studies of the catalyst.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supplementary Information

The 1H-NMR, 13C-NMR, and mass spectra of 2-Flourophenyl-3, 3 '-bis-(indolyl) methane have been shown in the supplementary information available at www.ias.ac.in/chemsci.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

VAID, R., GUPTA, M., CHAMBYAL, O.S. et al. SiO2-Diphenic acid: An efficient and recyclable heterogeneous catalyst for one-pot synthesis of bis-(indolyl)methane derivatives in liquid phase. J Chem Sci 127, 987–997 (2015). https://doi.org/10.1007/s12039-015-0859-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12039-015-0859-1