Abstract

In the present study, ~2.0-μm microspheres of blended poly(lactide-co-glycolide) (PLGA) and poly lactide (PLA), both are biodegradable and biocompatible, were prepared either through a preparation technique for particles using a microhomogenizer or membrane emulsification technique. To understand the potential of the drug delivery system (DDS) formulation, fundamental physical properties, degradation and drug release studies on microspheres prepared using two particle preparation techniques were analysed. The PLGA/PLA particles prepared using the microhomogenizer were polydisperse or irregular-shaped, but the particles prepared using the membrane emulsification technique were very monodisperse and spherical. Increasing the PLA fraction in PLGA/PLA microspheres allowed control over the degradation of the prepared particles. Furthermore, such microspheres could also be used for the controlled drug release behaviour of particles. The particles prepared using the membrane emulsification technique exhibited better controlled drug releasing behaviour than those prepared using the microhomogenizer. From the above, this study revealed that PLGA/PLA microspheres prepared using the membrane emulsification method were advantageous for the study of DDS formulations.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

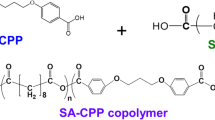

Poly(lactide-co-glycolide) (PLGA) and poly lactide (PLA) are representative biodegradable and biocompatible polymers that are often applied in drug delivery system (DDS) and biomaterials research [1,2,3,4,5]. The particles composed of PLGA or PLA can be applied as DDS formulations [6,7,8,9]; in fact, anti-cancer agents and active ingredients of cosmetics encapsulated in PLGA particles have already been commercialized [10,11,12]. Since their commercialization, a great deal of research has been conducted using PLGA or PLA particles [13,14,15,16,17,18]. To expand the knowledge of DDS formulations, the author et al [19,20,21,22,23,24,25,26,27] have studied the preparation of functional PLGA-based particles and developed novel preparation techniques. Monodisperse PLGA microspheres containing hydrophobic or hydrophilic drugs, created by combining a membrane emulsification technique and a solvent evaporation method, were prepared [19,20,21,22,23]. Monodisperse PLGA microspheres combined with silica nanospheres were also prepared [24]. A preparation technique of monodisperse PLGA nanospheres using the membrane emulsification technique and solvent diffusion method were developed [25]. In addition, a new technique for fine particle preparation that can produce monodisperse nanosized PLGA particles in a simple manner was also developed [26,27].

Control over the degradation of drug carriers, such as polymer particles, is of great importance in the field of DDS formulations. The degradation may be controlled by blending polymers, focussing on the polymer crystallinity. Because PLA is more crystalline and less degradable than PLGA, the author et al believe that the degradability of the prepared particles can be adjusted using the blend ratio of PLGA and PLA. Such an approach with polymer blending is recognized as effective in various polymer applications including colloidal lithography [28,29,30], membrane separation [31,32,33], etc.

To figure out their functionality as DDS formulations, for microspheres prepared using a microhomogenizer and membrane emulsification technique, the physical properties, such as diameter, monodispersity and surface potential of the particles, drug loading efficiency, polymer degradability, and drug release behaviour of the prepared microspheres were analysed in the present study. The careful investigation of these properties will greatly expand the potential applications of the prepared monodisperse microspheres. The authors will briefly report these results in the present paper.

2 Experimental

2.1 Materials

PLGA7510 (75:25, Mw 10,000) and PLA0010 (Mw 10,000) were purchased from Wako Pure Chemical Industry, Japan, and stored at −80°C prior to use. Rifampicin (RFP) was purchased from SIGMA and used as a model hydrophobic drug for loading into the microspheres. Polyvinyl alcohol (PVA) with a degree of polymerization of 500 and 86–90 mol% saponification, was purchased from Wako Pure Chemical Industry, Japan, and used as a dispersant for the prepared microspheres and emulsion. Polyethylene glycol (PEG, Wako Pure Chemical Industry, Mw 20,000) was used as a co-dispersant in the PVA solution. Disodium hydrogen phosphate 12-water and sodium dihydrogen phosphate dihydrate were purchased from Wako Pure Chemical Industry, Japan, and these reagents were used for the preparation of phosphate buffer saline (PBS). All other chemicals used in the experiment were of the highest grade that was commercially available.

2.2 Preparation of microspheres with and without drug

In the present study, two microsphere preparation techniques were applied, as shown in figure 1. The first one was the conventional solvent evaporation method using a microhomogenizer (figure 1a), and the second one involved combining the solvent evaporation method and membrane emulsification technique (figure 1b). In the first method, the desired weights of PLGA and PLA were dissolved in dichloromethane (DCM) in a 10.0 ml screw-cap tube. For the preparation of the drug-loaded microspheres, the model drug RFP was also added to the screw-cap tube. After being mixed using a vortex mixer, the solution was used as the oil phase of an oil-in-water (o/w) emulsion. To prepare the emulsion, the PLGA/PLA solution was poured into 190 ml of a 1.0% PVA solution in a 200 ml beaker; the mixture was then homogenized for 90 s at 25,000 rpm using a microhomogenizer (NS-310E, Microtec Nition Co. Ltd.). The resulting o/w emulsion was transferred into a 300 ml beaker containing 100 ml of a 1.0% PVA solution. Solvent evaporation was performed by stirring at 250 rpm for 4 h at room temperature to prepare the polymer microspheres.

For the preparation of the microspheres using the membrane emulsification technique, the desired weights of PLGA and PLA were dissolved in DCM in a 10.0 ml screw-cap tube. Similar to the first method, the drug-loaded microspheres were prepared by adding RFP to the screw-cap tube. After being mixed in a vortex mixer, the solution was used as the oil phase for an o/w emulsion by injecting it into an oil tank on a Shirasu porous glass (SPG) membrane with a pore size of 1.0 μm. The membrane emulsification technique using the membrane emulsification apparatus was performed based on a previous report [19]. The apparatus was soaked in 190 ml of a 1.0% PVA solution (continuous phase) containing 0.026% PEG in a 200 ml beaker and was precisely wetted between the continuous and dispersion phases of the SPG membrane through the gentle stirring for 1 h. The membrane emulsification technique was initiated by streaming nitrogen gas into the oil phase through the pores in the membrane. The critical pressure of nitrogen gas at which droplets emerged from the membrane pores into the continuous phase was 0.19–0.26 kg cm−2.

After the membrane emulsification was terminated, the prepared o/w emulsion was transferred to a 300 ml beaker containing 100 ml of 1.0% PVA solution. Solvent evaporation was performed by stirring at 250 rpm for 4 h at room temperature. The microspheres prepared using the above two methods were washed three times: the water phase and the particles were separated through centrifugation at 1500 rpm for 3 min followed by re-dispersion of particles with fresh distilled water.

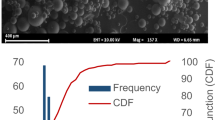

2.3 SEM observation of the prepared microspheres

A droplet of the suspension of prepared microspheres was placed on an aluminium sample stage and dried for 1 day in a vacuum desiccator. Gold sputtering was carried out using an ion sputtering device (Auto Fine Coater, JFC-1600, JEOL Ltd.). Microscopic observation of the microspheres was performed using a scanning electron microscope (SEM, JSM-6060LA, JEOL Ltd.). Images of the particles were obtained at 1000× and 2000× magnification.

2.4 Measurements of ζ-potential of the prepared microspheres

The surface potentials of the prepared microspheres were evaluated using ζ-potential measurements. The prepared microspheres were dispersed in 1.0 × 10−4 M solutions of NaCl. The ζ-potential of the prepared microspheres was measured at 25°C using a ζ-potential analyser (ELS-Z Otsuka Co.).

2.5 Measurement of particle sizes

The average diameter and value of the coefficient of variation (CV) of the prepared microspheres were calculated for 200 particles in the obtained SEM image. The CV was calculated using equation (1):

where σ denotes the standard deviation and Dp denotes the average particle diameter obtained from the SEM images. A low CV value corresponds to uniformly sized particles.

2.6 Measurements of drug loading efficiency of microspheres

For the measurement of the concentration of RFP in microspheres, the previously reported means were adopted [19,20,22,27]. To measure the RFP loading efficiency of the microspheres, 10 mg of microspheres containing RFP were dissolved in 5.0 ml of chloroform in a 10.0 ml screw-cap tube. The RFP concentration in the solution was measured spectrophotometrically at 475 nm. The loading efficiency of RFP in the microspheres was calculated from the measured RFP concentration and the initial composition ratio used to prepare the particles. The measurements were performed in triplicate.

2.7 Degradation study of the prepared microspheres

By mixing water with disodium hydrogen phosphate 12-water and sodium dihydrogen phosphate dihydrate, pH 7.4 PBS with an ionic strength of 0.154 M was prepared. Here, the ion strength of PBS was set at 0.154 M because it is close to the value of the ion strength in human blood. Twenty milligrams of the microspheres prepared through the membrane emulsification technique were re-dispersed in 5.00 ml of PBS. The PBS was replaced with fresh PBS every day. This suspension was shaken at a rate of 60.0 times per minute at 37°C. An aliquot of the suspension was taken every day. The microspheres were precipitated through centrifugation at 1500 rpm for 3 min and dried in a vacuum desiccator for one day. The sample was dissolved in chloroform, and the resulting solution was used for the measurement of the weight-averaged molecular weight of the microspheres using a high performance liquid chromatograph (Shimadzu LC-5A) equipped with a refractive index detector (Shimadzu RID-10A) and gel permeation chromatography columns (Shodex K-806 and K-803). The mobile phase was chloroform, and the flow rate was 1.0 ml per minute. The degradation behaviour of the prepared microspheres was evaluated after 14 days.

2.8 Testing the release of RFP from the prepared microspheres

The measurements in release test of RFP of the prepared microspheres were based on the measured means in the previously reported paper [19,20,22]. To study the release of RFP from the drug-loaded microspheres, 10 mg of the prepared microspheres were dispersed in 5.0 ml of PBS in a 10 ml screw-cap tube. The dispersion was shaken at 60.0 times per minute at 37°C. Each day, the dispersions were centrifuged for 5 min at 2000 rpm, and the supernatant was measured spectrophotometrically at 475 nm. The PBS was replaced every day after performing the measurements. The measurements were performed every day for 14 days in total.

3 Results and discussion

3.1 Differences among the physical properties of PLGA/PLA microspheres

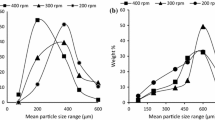

First, microspheres composed solely of PLGA or PLA or various blends of PLGA and PLA were prepared through the conventional solvent evaporation method using a microhomogenizer (figure 1a); their compositions are listed in samples 1–5 of table 1. The total amount of polymer used to prepare each sample was 0.5 g, and their PLGA:PLA blend ratios were 100:0 (sample 1), 75:25 (sample 2), 50:50 (sample 3), 25:75 (sample 4) and 0:100 (sample 5). The ζ-potentials of the prepared microspheres decreased as the fraction of PLA in the microspheres is increased. The particle size and CV values of the microspheres prepared through solvent evaporation (samples 1–5) are shown in figure 2a. As can be seen from figure 2a, these microspheres had a particle size of ~2.0 µm, and a CV value, which is an indicator of monodispersity, of ~30%. These results show that the particle size and monodispersity of the microspheres prepared using the microhomogenizer were independent of the type of polymer and blend ratio. SEM images of the prepared microspheres with PLGA:PLA blend ratios of 100:0 (sample 1), 50:50 (sample 3) and 0:100 (sample 5) are presented in figure 3a–c. Characteristic results were obtained for each of the polymer. As shown in figure 3a, the all-PLGA microspheres (sample 1) are mainly spherical, but some irregularly shaped particles can also be seen. In the SEM images of samples 3 (figure 3b) and 5 (figure 3c), which contain PLA, a larger number of spherical particles is observed than in the image of sample 1. Irregularly shaped particles are generated when phase separation occurs during the preparation of the emulsion or preparation of the microspheres [34]. Based on these results, it seems that for microspheres prepared using a microhomogenizer, phase separation and the generation of irregular particles are more likely to occur with PLGA than PLA.

SEM images of the microspheres prepared using the microhomogenizer and membrane emulsification technique. (a) Microhomogenizer; PLGA:PLA = 100:0 (sample 1), (b) PLGA:PLA = 50:50 (sample 3), (c) PLGA:PLA = 0:100 (sample 5), (d) membrane emulsification technique; PLGA:PLA = 100:0 (sample 6), (e) PLGA:PLA = 50:50 (sample 8), and (f) PLGA:PLA = 0:100 (sample 10).

Subsequently, microspheres were prepared using the membrane emulsification technique with the same ratios of PLGA and PLA as in the previous study, as shown in samples 6–10 of table 1. In preparing the microspheres, the blend ratios of PLGA and PLA were 100:0 (sample 6), 75:25 (sample 7), 50:50 (sample 8), 25:75 (sample 9) and 0:100 (sample 10). The critical pressure for the formation of emulsion droplets during the membrane emulsification technique was 0.19–0.21 kg cm−2. Microspheres with diameters of ~2.0 μm were prepared to compare them with the microspheres prepared using the microhomogenizer. As in the case of the microspheres produced through solvent evaporation, the ζ-potential of the microspheres by membrane emulsification technique decreased as the fraction of PLA in the microspheres increased. Figure 2b shows the particle size and CV values of the microspheres prepared using the membrane emulsification technique with different PLGA:PLA ratios. The particle sizes of the prepared microspheres changed slightly with the blend ratio, and were found to be 2.18 (sample 6, PLGA:PLA = 100:0), 2.25 (sample 7, PLGA:PLA = 75:25), 2.05 (sample 8, PLGA:PLA = 50:50), 2.14 (sample 9, PLGA:PLA = 25:75) and 2.06 μm (sample 10, PLGA:PLA = 0:100). The CV values of the microspheres were 12.2 (sample 6), 15.5 (sample 7), 12.8 (sample 8), 17.5 (sample 9) and 13.3% (sample 10). The results indicated that the PLGA:PLA blend ratio had little effect on the particle size and size distribution of the microspheres prepared via the membrane emulsification technique. As further evidence of this result, figure 3d–f shows the SEM images of samples 6, 8 and 10 (PLGA:PLA of 100:0, 50:50 and 0:100, respectively). As shown, all the microspheres prepared using the membrane emulsification technique were monodisperse with very uniform particle sizes. Furthermore, the irregularly shaped particles observed in the image of the PLGA-only particles in figure 3a were not observed in the membrane emulsification technique. These results indicated that almost no phase separation occurred during the preparation of microspheres using the membrane emulsification technique. Presumably, the irregularly shaped particles will show different drug release behaviour than the spherical particles. Therefore, the membrane emulsification technique, which reliably prepares spherical particles, has a great advantage over the conventional microhomogenizer technique in terms of producing DDS formulations. Overall, these results show that in addition to producing monodisperse microspheres, the membrane emulsification technique also consistently produces spherical particles. This shape uniformity represents an advantage in designing DDS formulations.

3.2 Testing the degradation of monodisperse PLGA/PLA microspheres prepared by membrane emulsification technique

In the previous section, monodisperse PLGA/PLA microspheres with various blend ratios were prepared using the membrane emulsification technique. The degradability of these monodisperse microspheres was then investigated. The reason for not applying the test on the particles created using the microhomogenizer is that these particles have a wide particle size distribution and the data obtained from the degradation tests would be unreliable. In contrast, the particles produced using the membrane emulsification technique are sharper in size and the data obtained in the tests are more reliable. Therefore, the samples to be tested for degradation were microspheres prepared using the membrane emulsification technique. The results of the degradation tests of samples 6–10 are presented in figure 4. The initial molecular weight of all the polymers was 10,000. During the 14-day degradation test, sample 6 (100% PLGA) showed the greatest polymer degradation. The PLGA sample showed gradual degradation approximately until the 10th day; subsequently, its molecular weight dropped to ~1000 between the 12th and 14th days. Thus, during this time period, the degradation of the polymer chains in the PLGA matrix was promoted. In contrast, the molecular weight of 100% PLA (sample 10) had decreased by ~200 at day 2, but remained almost constant after that, and no further degradation was observed. These results indicated that each of the two polymers showed a characteristic degradation behaviour. Based on these results, the mechanism of PLGA/PLA microsphere degradation was predicted, as shown in figure 5. That is, PLGA and PLA exist inside the particles of ~2.0 μm, as shown in figure 5. Then, as the degradation begins, the PLGA in the microspheres becomes lactic acid and glycolic acid, and PLA becomes lactic acid.

The molecular weight results for all the samples on day 14, show that the degradation of the samples was dependent on the PLA fraction of the microspheres. That is, the fraction of PLA within the microspheres controlled the degradation of the prepared microspheres. Based on these results, it may be possible to control the degradation rate in the future by adjusting the PLGA:PLA blend ratio when applying the microspheres in vivo.

3.3 Preparation of PLGA/PLA microspheres loaded with RFP

The physical properties of the RFP-loaded microspheres prepared through the conventional solvent evaporation method using a microhomogenizer and RFP-loaded microspheres prepared using the membrane emulsification technique were compared. The total amount of polymer used to prepare each sample was 0.5 g. Microspheres with PLGA:PLA ratios of 100:0 (sample 11), 75:25 (sample 12), 50:50 (sample 13), 25:75 (sample 14) and 0:100 (sample 15) were prepared using the microhomogenizer; 0.05 g of RFP was added during the preparation of each of these samples. The ζ-potentials of the prepared microspheres did not depend on the blend ratio, but the ζ-potentials of the PLGA-only and PLA-only samples were significantly different. In contrast, the ζ-potential of the microspheres without RFP was dependent on the PLA fraction of the microspheres (samples 1–10). The independence of the ζ-potential of the samples 11–15 with regard to the PLGA:PLA ratio is probably related to the incorporation of RFP into the microspheres. As shown in figure 6a, the particle size and CV values of samples 11–15 were 2.50 μm, 46.5% (sample 11), 2.42 μm, 44.0% (sample 12), 2.32 μm, 46.4% (sample 13), 2.61 μm, 42.2% (sample 14) and 2.59 μm, 50.9% (sample 15). These results confirmed that the particle size and particle size distribution of the drug-loaded microspheres prepared using the microhomogenizer were unaffected by the PLGA:PLA ratio. In the SEM images of figure 7a–c, the RFP-loaded microspheres prepared using the microhomogenizer were clearly polydisperse. It can also be seen that the particles are broken in some places. Here, when compared to the results of SEM images (figure 3a–c) of samples 1, 3 and 5, which did not contain RFP, the particles containing RFP were larger in size and more spherical in shape. In any case, these results may be due to the fact that the microspheres were prepared in a microhomogenizer.

SEM images of the RFP-loaded microspheres prepared using a microhomogenizer and membrane emulsification technique. (a) Microhomogenizer; PLGA:PLA = 100:0 (sample 11), (b) PLGA:PLA = 50:50 (sample 13), (c) PLGA:PLA = 0:100 (sample 15), (d) membrane emulsification technique; PLGA:PLA = 100:0 (sample 16), (e) PLGA:PLA = 50:50 (sample 18), and (f) PLGA:PLA = 0:100 (sample 20).

The RFP loading efficiencies in the prepared microspheres were 38.6% (sample 11), 36.6% (sample 12), 35.4% (sample 13), 37.2% (sample 14) and 33.6% (sample 15). In general, the loading efficiency of drugs into microspheres is influenced by various physicochemical parameters [35]. Unlike in previous studies, the drug loading was not affected by the PLGA:PLA mixing ratio.

RFP-loaded PLGA/PLA microspheres were also prepared using the membrane emulsification technique (samples 16–20 of table 1) with the same drug and polymer compositions in samples 11–15. The critical pressure for the formation of the emulsion droplets was 0.22–0.26 kg cm−2. The results of ζ-potential of the microspheres prepared using the membrane emulsification technique showed a trend that is similar to those prepared using the microhomogenizer. The RFP loading efficiency was ~40% in all the prepared microspheres and showed almost no variation with the PLGA:PLA ratio. As presented in figure 6b, the particle size and CV values of the samples were 1.94 μm, 9.72% (sample 16), 1.95 μm, 12.6% (sample 17), 2.12 μm, 13.2% (sample 18), 2.26 μm, 15.2% (sample 19) and 2.43 μm, 17.8% (sample 20). The particle size and CV values increased slightly with increasing PLA fraction in the microspheres. This result was further confirmed from the SEM images of the microspheres prepared using 100:0 (sample 16), 50:50 (sample 18) and 0:100 (sample 20) ratios of PLGA:PLA, which are presented in figure 7d–f. As the PLA fraction of the prepared microspheres increased, a slight enlargement of the particle size and a small expansion of the particle size distribution were observed. Because this result was not observed in samples 6–10, which did not contain RFP, this result can be attributed to the RFP addition. Additionally, for samples 6–10, the ζ-potential due to anions decreased with increasing PLA content. That is, increasing the PLA content reduced the dispersion stability of the microspheres due to electrostatic interactions. It can be predicted that loading RFP into such microspheres would further reduce the dispersion stability of microspheres. Based on these considerations and the results shown in figures 6b and 7d–f, when PLA is present in the microspheres, some aggregation occurs during the preparation of the microspheres, the particle size increases and the particle size distribution tends to expand. Thus, it is preferable to use PLGA as a base in the membrane emulsification technique to prepare more uniform drug-loaded microspheres composed of biodegradable and biocompatible polymers.

3.4 Testing the release of RFP from the prepared PLGA/PLA microspheres

The release of RFP from the PLGA/PLA microspheres with various blend ratios was investigated at 37°C. Here, the release behaviours of samples 11–15, which were prepared using the microhomogenizer, and samples 16–20, which were prepared using the membrane emulsification technique, were compared. The results are presented in figure 8. Figure 8a depicts the data for the samples prepared using the microhomogenizer. All the RFP contained in the PLGA-only microspheres (sample 11, symbol: ♢) were released after 3 days. On the other hand, 9 days were required for all the RFP to be released from the PLA-only sample (sample 15, symbol: ×). Essentially, as the PLA fraction of the microspheres increases, the release of the drug is slowed [36]. All the RFP-loaded microspheres prepared using the microhomogenizer released 100% of the loaded RFP within 10 days. Moreover, sample 14 (symbol: ○, 25:75 PLGA:PLA ratio) exhibited the most suppressed release of RFP.

Results of the RFP release tests for the microspheres prepared using both preparation techniques. (a) Microhomogenizer; ♢: PLGA:PLA = 100:0 (sample 11), □: PLGA:PLA = 75:25 (sample 12), △: PLGA:PLA = 50:50 (sample 13), ○: PLGA:PLA = 25:75 (sample 14), and ×: PLGA:PLA = 0:100 (sample 15). (b) Membrane emulsification technique; ♢: PLGA:PLA = 100:0 (sample 16), □: PLGA:PLA = 75:25 (sample 17), △: PLGA:PLA = 50:50 (sample 18), ○: PLGA:PLA = 25:75 (sample 19), and ×: PLGA:PLA = 0:100 (sample 20).

The release test results for the RFP-loaded microspheres prepared using the membrane emulsification technique were obviously different from those of the microhomogenized samples. A comparison of figure 8a, b reveals that the RFP release of the microspheres prepared through membrane emulsification was clearly slower. In particular, none of the microspheres prepared using the membrane emulsification technique released 100% of the loaded RFP after 14 days (figure 8b). The particle size of the microspheres produced using both techniques was ~2.0 μm; thus, the particle size should have almost no influence on the release behaviour. Furthermore, the drug loading efficiency of all microspheres was ~40%, ruling out the influence of different drug-loading efficiencies. Therefore, as shown in figure 9, the different release behaviours are believed to be related to the regions of the particles where RFP is loaded. The release mechanism in figure 9 was created with reference to the results of the previous study [23]. That is, the RFP loaded in the microspheres produced using the microhomogenizer tends to be present near the particle surface (figure 9a), while the RFP in the microspheres produced using the membrane emulsification technique tends to be located inside the microspheres (figure 9b). Depending on the localization of the drug within the particle, there will be significant differences in the leakage of the drug via diffusion to the outside of the particle. Therefore, the release rate of the drug from microspheres prepared using the two preparations technique is considered different.

As shown in figure 8b, ~50% of the loaded RFP was released from PLGA-only microspheres (sample 16, symbol: ♢) prepared using the membrane emulsification technique on the first day. Subsequently, the release behaviour slowed, and ~80% of the loaded RFP was released by the 14th day. Similarly, the PLA-only microspheres (sample 20, symbol: ×) released 6% of their RFP on the first day, followed by a slower release with ~33% of the RFP having been released on the 14th day. Based on the RFP release behaviour of samples 16–20 in figure 8b, the PLA fraction of the microspheres had a strong influence on the RFP release rate. This result was slightly different than the release behaviour observed in figure 8a. The microspheres prepared using a microhomogenizer showed uneven RFP release behaviour due to their non-uniform particle size distribution. This release behaviour is believed to have caused the inconsistency between the release rate and the blend ratio. Because the microspheres prepared by the membrane emulsification technique were monodisperse, the amount of RFP released from the individual particles should show little variation. Additionally, at PLGA:PLA ratios of 50:50 and 25:75 (∆ and ○ on figure 8b), the RFP release behaviour was clearly controlled. These results confirm that well-controlled release behaviour can be achieved using 50:50 or 25:75 PLGA/PLA microspheres. Based on the above results, it was also found that when drug-loaded microspheres were prepared using the membrane emulsification technique, the factors that could not be confirmed with microspheres prepared using a microhomogenizer could be confirmed more accurately.

4 Conclusion

In the present study, PLGA/PLA blend microspheres were prepared using either the microhomogenizer or membrane emulsification technique. The PLGA/PLA microspheres prepared using the membrane emulsification technique showed higher monodispersity than those prepared using the conventional solvent evaporation method with a microhomogenizer. The membrane emulsification technique also suppressed phase separation during the particle preparation to yield consistently spherical particles. The fraction of PLA in the prepared PLGA/PLA microspheres allowed control over the degradation of the prepared microspheres. As a result, it may be possible to control the degradation rate in the future by adjusting the PLGA:PLA blend ratio when applying the microspheres in vivo. Increasing the PLA fraction in the RFP-loaded microspheres prepared using the membrane emulsification technique, slightly increased the particle size and slightly expanded the particle size distribution. The microspheres prepared using the microhomogenizer and membrane emulsification techniques clearly showed different RFP release rates, although the particle size and drug-loading efficiency were almost same. For this reason, it was surmised that the location of the encapsulated drug in the microspheres differs depending on the microsphere preparation technique. Based on the polymer degradability, drug release behaviour, control of particle size and control of particle size distribution; the membrane emulsification technique was found to be more effective for the preparation of DDS formulations using PLGA/PLA blends.

References

Betty Tyler, David Gullotti, Antonella Mangraviti, Tadanobu Utsuki and Henry Brem 2016 Adv. Drug Deliv. Rev. 107 163

Ganesh Narayanan, Varadraj N Vernekar, Emmanuel L Kuyinu and Cato T Laurencin 2016 Adv. Drug Deliv. Rev. 107 247

Dingying Shan, Ethan Gerhard, Chenji Zhang, John William Tierney, Daniel Xie, Zhiwen Liu et al 2018 Bioact. Mater. 3 434

Huailan Wang, Wenjia Sun, Dongliang Fu, Yueliang Shen, Ying-ying Chen and Lin-Lin Wang 2018 J. Orthop. Translat. 13 41

Ranjeet A Bapat, Chaitanya P Joshi, Prachi Bapat, Tanay V Chaubal, Rohit Pandurangappa, Naveen Jnanendrappa et al 2019 Drug Discov. Today 24 85

James M Anderson and Matthew S Shive 1997 Adv. Drug Deliv. Rev. 28 5

Patrick B O’Donnell and James W McGinity 1997 Adv. Drug Deliv. Rev. 28 25

Rajeev A Jain 2000 Biomaterials 21 2475

Maria Mir, Naveed Ahmed and Asim Ur Rehman 2017 Colloids Surf. B 159 217

Yasuaki Ogawa, Masaki Yamamoto, Hiroaki Okada, Takatsuka Yashiki and Tsugio Shimamoto 1988 Chem. Pharm. Bull. 36 1095

Yasuaki Ogawa, Masaki Yamamoto, Shigeyuki Takada, Hiroaki Okada and Tsugio Shimamoto 1988 Chem. Pharm. Bull. 36 1502

Hiroyuki Tsujimoto, Kaori Hara, Yusuke Tsukada, Huang C C, Yoshiaki Kawashima, Minoru Arakaki et al 2007 Bioorg. Med. Chem. Lett. 17 4771

Fengjuan Li, Aiping Zhu, Xiaoli Song, Lijun Ji and Juan Wang 2013 Int. J. Pharm. 453 506

Yunxia Jiang, Fang Wang, Hui Xu, Hui Liu, Qingguo Meng and Wanhui Liu 2014 Int. J. Pharm. 475 475

Junya Liang, Bowen Yang and Jianping Deng 2018 Chem. Eng. J. 344 262

María F Loya-Castro, Mariana Sánchez-Mejía, Dante R Sánchez-Ramírez, Rossina Domínguez-Ríos, Noé Escareño, Paola E Oceguera-Basurto et al 2018 J. Colloid Interface Sci. 518 122

Stefania Boi, Elena Dellacasa, Paolo Bianchini, Paola Petrini, Laura Pastorino and Orietta Monticelli 2019 Colloids Surf. B 179 190

Juan David Ospina-Villa, Catalina Gómez-Hoyos, Robin Zuluaga-Gallego and Omar Triana-Chávez 2019 J. Microbiol. Methods 162 1

Fuminori Ito and Kimiko Makino 2004 Colloids Surf. B 39 17

Fuminori Ito, Hiroyuki Fujimori, Hiroyuki Honnami, Hiroyoshi Kawakami, Kiyoshi Kanamura and Kimiko Makino 2008 Colloids Surf. B 66 65

Fuminori Ito, Hiroyuki Honnami, Hiroyoshi Kawakami, Kiyoshi Kanamura and Kimiko Makino 2008 Colloids Surf. B 67 20

Fuminori Ito, Hiroyuki Fujimori, Hiroyuki Honnami, Hiroyoshi Kawakami, Kiyoshi Kanamura and Kimiko Makino 2009 Eur. Polym. J. 45 658

Fuminori Ito, Hiroyuki Fujimori, Hiroyuki Honnami, Hiroyoshi Kawakami, Kiyoshi Kanamura and Kimiko Makino 2010 J. Mater. Sci.: Mater. Med. 21 1563

Fuminori Ito, Yusuke Uchida and Yoshihiko Murakami 2010 Colloids Surf. A 361 109

Fuminori Ito, Yurie Kanakubo and Yoshihiko Murakami 2011 J. Polym. Res. 18 2077

Fuminori Ito and Hiroyoshi Kawakami 2015 Colloids Surf. A 482 734

Fuminori Ito 2016 J. Nano Res. 18 262

Nandini Bhandaru 2020 Bull. Mater. Sci. 43 180

Meneka Banik and Rabibrata Mukherjee 2018 ACS Omega 3 13422

Meneka Banik, Nandini Bhandaru and Rabibrata Mukherjee 2018 Chem. Commun. 54 3484

Fuminori Ito, Yuriko Nishiyama, Shuhong Duan and Hidetaka Yamada 2020 Macromol. Res. 28 365

Hafiz Abdul Mannan, Hilmi Mukhtar, Murugesan Thanabalan, Rizwan Nasir, Dzeti Farhah Mohshim and Asim Mushtaq 2013 Chem. Eng. Technol. 36 1838

Liyuan Deng, Taek-Joong Kim and May-Britt Hägg 2009 J. Membr. Sci. 340 154

Shinzo Omi, Tatsuo Senba, Masatoshi Nagai and Guang-Hui Ma 2001 J. Appl. Polym. Sci. 79 2200

Farshad Ramazani, Weiluan Chen, Cornelis F van Nostrum, Gert Storm, Fabian Kiessling, Twan Lammers et al 2016 Int. J. Pharm. 499 358

Nikolaus Kofler, Christiane Ruedl, Jörg Klima, Heidrun Recheis, Günther Böck, Georg Wick et al 1996 J. Immunol. Methods 192 25

Acknowledgement

This work is supported by the Japan Society for the Promotion of Science (JSPS) KAKENHI Grant 19K05191.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

ITO, F., YAMADA, H. Physical properties of microspheres prepared by blending poly(lactide-co-glycolide) and poly lactide. Bull Mater Sci 44, 20 (2021). https://doi.org/10.1007/s12034-020-02310-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-020-02310-4