Abstract

Xylanase production by Streptomyces sp. S1M3I was optimized by response surface methodology (RSM), followed by a partial characterization of these enzymes. Olive pomace was used as a substrate for growing Streptomyces sp. S1M3I in submerged fermentation. Effects of incubation time, pH, temperature, carbon source, nitrogen source, and inoculum size on xylanase production were studied, through the one-factor-at-a-time method. Then, a 33-factorial experimental design with RSM and the Box–Behnken design was investigated for the major influence factors. Maximum xylanase production (11.28 U/mL) was obtained when the strain was grown in mineral medium supplemented with 3% (w/v) of olive pomace powder and 0.3% (w/v) of ammonium sulfate, at a pH 7.4 and an incubation temperature of 40 °C. The xylanases in the supernatant degraded all tested substrates, with higher activity for the low-viscosity wheat arabinoxylan substrate. Two xylanases with close molecular masses were detected by zymogram analysis: Xyl-1 and Xyl-2 with molecular masses of 24.14 kDa and 27 kDa, respectively. The optimization of enzyme production parameters of Streptomyces sp. S1M3I and the characterization of these enzymes are prerequisites to enhancing xylanase production yield, which is crucial for further biotechnological processes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Actinobacteria are a group of gram-positive bacteria [1]. There are some that form branching filaments that resemble the mycelia of unrelated fungi, among which they were originally classified as the actinomycetes [2]. There are a large number of them found in soil, and they play an important role in decomposing the soil and forming humus [2, 3]. Streptomyces is the most important genus in this group, being able to produce a large variety of enzymes, including lignocellulolytic enzymes. Their enzymes are particularly attractive because of their high stability and substrate specificity [4]. There is a huge potential for the commercialization of Actinobacteria enzymes found in extreme habitats. This shows the global importance of enzymes and extends to signify Actinobacteria as promising harbingers of green technology [4].

Xylanases are a class of enzymes that involve in the breakdown and hydrolysis of xylan, a key component of hemicellulose found in plant cell walls and second only to cellulose in abundance [5]. These enzymes are generated by various microorganisms, including Actinobacteria [6], and can be obtained through two methods: submerged fermentation and solid-state fermentation. However, submerged fermentation has garnered more interest but is considered expensive due to the associated process engineering costs [7]. Additionally, the majority of the reports on the microbial production of lignocellulolytic enzymes utilize submerged fermentation technology [8]. Xylanases have potential applications in various fields, including functional food additives, the improvement of bread quality, biofuel, paper, and pulp industries [5, 9] as well as the animal feed industry [5, 10].

Utilizing inexpensive residues derived from agro-industries as the primary substrates for microbial growth could present a compelling option for enzyme production, as it can considerably decrease expenses [11]. Olive pomace, the solid residue obtained after extracting olive oil, stands out as one of the plentiful by-products in the Mediterranean region [10]. Comprising a lignocellulosic matrix, olive pomace contains phenolic compounds, uronic acids, and oily residues [12], thereby serving as a significant alternative source for enzymatic processes [11]. Using olive pomace as a substrate in fermentation could potentially have economic implications in some industries, as it induces lignocellulolytic enzymes, such as xylanase, due to its lignocellulosic nature [13].

In the realm of industrial technology, meticulous optimization of fermentation operating conditions is vital for achieving maximum production. One strategy for such optimization is the one-factor-at-a-time method (OFAT), which entails adjusting a single variable while keeping others constant [14]. Nonetheless, this conventional approach to optimizing variables has limitations and is time-consuming since it fails to consider the interactive effects among variables [9]. Alternatively, response surface methodology (RSM) presents a statistical-mathematical approach that utilizes quantitative data within an experimental design. Its primary goal is to identify and solve multivariable equations, enabling process optimization while overcoming the limitations associated with traditional methods. By employing RSM, it becomes possible to significantly reduce the number of required assays, resulting in substantial savings in operational costs and time [15].

In our previous studies [16, 17], the soil around agricultural crops, such as olive pomace showed promising Actinobacteria isolates producing carboxymethyl cellulases (CMCases), xylanases, and laccases. Among these isolates, Streptomyces sp. S1M3I was tested for the production of cellulase, xylanase, and laccase activities; it was shown that this strain presents a high xylanase activity. In the present work, RSM was performed for the optimization of xylanase production by Streptomyces sp. S1M3I, monitored by a partial characterization of xylanases produced in submerged fermentation using olive pomace as the substrate. The diagram in Fig. 1 summarizes the experimental procedures used to optimize and characterize the xylanase produced by Streptomyces sp. S1M3I.

Material and Methods

Collection of Lignocellulose Material

The plant material is represented by olive pomace (OP) of the Chemlal variety, resulting from a traditional extraction system from an oil mill located in Ait Bouadda, Azzazga region, in the city of Tizi Ouzou (Algeria). The collection took place during the olive fruit pressing season. OP was dried at room temperature for 3 weeks, ground to a fine powder, and then passed through sieves (

≤ 1 mm) to provide a homogeneous powder. The resulting product was called raw olive pomace (ROP). A part of these powders was treated with hexane (1:10 (w/v) ratio of pomace to hexane) to eliminate the existing lipids by the method described by Lilitchan et al. (2008) [18]; in this case, the obtained product was called exhausted olive pomace (EOP).

≤ 1 mm) to provide a homogeneous powder. The resulting product was called raw olive pomace (ROP). A part of these powders was treated with hexane (1:10 (w/v) ratio of pomace to hexane) to eliminate the existing lipids by the method described by Lilitchan et al. (2008) [18]; in this case, the obtained product was called exhausted olive pomace (EOP).

Microorganism

The strain used in this study was isolated from the soil of the natural discharge of an oil mill from Bejaia, Algeria (36° 37′ N; 5° 01′ E). 16S rRNA gene sequencing was used to identify the isolated strain by the identification services at the German collection of microorganisms and cell cultures (DSMZ). The strain was identified as an Actinobacterium belonging to the genus Streptomyces. The sequence was deposited in GenBank under the accession number MF662612, and the organism has been assigned the name Streptomyces sp. S1M3I.

Experimental Procedure for Xylanase Production

Submerged fermentation for enzyme production was carried out in Erlenmeyer flasks (250 mL) containing 50 mL of a mineral solution containing: 1.15 g/L KH2PO4; 3.74 g/L K2HPO4; 3 g/L (NH4)2SO4; 1.2 g/L NaNO3; 0.2 g/L MgSO4 × 7H2O; 0.05 g/L CaCl2; 0.01 g/L MnSO4 × 7H2O; 0.001 g/L FeSO4 × 7H2O; 0.05 g/L yeast extract and 30 g/L ROP powder (

≤ 1 mm). The pomace powder and mineral solution were autoclaved separately at 120 °C for 20 min and then mixed in sterile conditions. Following the mixing, the flasks were inoculated with three agar discs of 6 mm diameter taken from a 7-day-old stock culture of Streptomyces sp. S1M3I (on average, a disc contains (4 ± 0.08) × 106 spore/mL) and incubated at 30 °C for 6 days on a rotary shaker at 150 rpm. After incubation, microbial cells and residues of substrate were removed by centrifugation (10,000 rpm for 20 min). The clarified supernatant, representing the crude enzyme preparation, was used for assessing xylanase activity. The xylanase activity was determined by measuring the release of reducing sugar, using birch xylan (Sigma-Aldrich) as described by Tuncer et al. (1999) [19]. Xylanase activity is given as international units (U), where U is defined as the amount of enzyme required to liberate 1 µmol of xylose equivalent per minute.

≤ 1 mm). The pomace powder and mineral solution were autoclaved separately at 120 °C for 20 min and then mixed in sterile conditions. Following the mixing, the flasks were inoculated with three agar discs of 6 mm diameter taken from a 7-day-old stock culture of Streptomyces sp. S1M3I (on average, a disc contains (4 ± 0.08) × 106 spore/mL) and incubated at 30 °C for 6 days on a rotary shaker at 150 rpm. After incubation, microbial cells and residues of substrate were removed by centrifugation (10,000 rpm for 20 min). The clarified supernatant, representing the crude enzyme preparation, was used for assessing xylanase activity. The xylanase activity was determined by measuring the release of reducing sugar, using birch xylan (Sigma-Aldrich) as described by Tuncer et al. (1999) [19]. Xylanase activity is given as international units (U), where U is defined as the amount of enzyme required to liberate 1 µmol of xylose equivalent per minute.

Selection of Xylanase Production Parameters by the OFAT Approach

For optimization of the xylanase production by Streptomyces sp. S1M3I, the effect of medium components and physicochemical and kinetic parameters was first investigated in single-factor experiments to limit the total experimental workload. The rest of the variables were kept constant when one variable was optimized. The factors studied were as follows:

-

Carbon source: olive pomace concentration (1–5% (w/v)) of both olive pomace types (ROP and EOP);

-

Nitrogen source: ammonium sulfate ((NH4)2SO4) (Sigma-Aldrich) concentration (0.1–0.5% (w/v));

-

Initial pH of production medium (4–10);

-

Inoculum size (1–5 disc(s));

-

Incubation time (1–10 days);

-

Incubation temperature (20, 25, 30, 35, 40, 45, and 50 °C).

Optimization of Xylanase Production Conditions by RSM Using the Box-Behnken Design

Based on the single-factor experimental results, major influence factors were selected. RSM-based experiment on a Box–Behnken design was conducted to optimize the process. To obtain the optimum operating conditions while explaining the performance of the method, a second-order model was introduced according to the following equation (Y1):

Y1 is the predicted response (xylanase activity (U/mL)), βo, βi, βii, and βij are regression coefficients for intercept, linear, quadratic, and interaction terms, respectively, and Xi and Xj are the actual levels of the independent variables. The models were simplified by the elimination of statistically insignificant terms to the following equation. The analysis of variance (ANOVA) is used for fitting the selected quadratic polynomial model by the mean square method.

Partial Characterization of Xylanases in the Crude Supernatant

The properties of xylanases from Streptomyces sp. S1M3I were studied by growing the strain under optimal conditions in 500-mL Erlenmeyer flasks. At the end of fermentation, the culture medium was centrifuged at 10,000 rpm for 20 min. The supernatant which was the crude enzyme was stored at 4 °C until use. The optimal temperature was determined by testing the enzyme activity at different temperatures: 30 °C, 40 °C, 50 °C, 60 °C, 70 °C, and 80 °C. The enzyme activity was measured by incubating 250 µL of the enzyme with 250 µL of the xylan for 10 min. The optimal pH was determined by incubating a reaction mixture composed of 250 µL of xylan and 250 µL of the enzyme at a pH ranging from 4 to 10. Three different buffers of 50 mM concentration were used; citrate buffer for testing pH 4 to 6, phosphate buffer for testing pH 6 to 8, and Tris–HCl buffer for testing pH 8 to 10. The specificity towards substrates was determined by testing birch xylan (Sigma-Aldrich), beech xylan (Sigma-Aldrich), and low-viscosity wheat arabinoxylan (LVAX) (Megazyme) at a concentration of 1% in 50 mM phosphate buffer at the obtained optimum pH.

Electrophoresis and Zymogram Analysis

The crude supernatant was subjected to SDS-PAGE, which was performed using a 12% (w/v) polyacrylamide gel according to the method of Laemmli (1970) [20]. Electrophoresis under denaturing conditions with protein renaturation was performed. Aliquots of proteins were mixed with bromophenol blue along with SDS and heated at 70 °C for 10 min, whereas the marker (Thermo Fisher Scientific, Cat no. 26619) was used directly without heating. The gels were run at a constant current of 35 mA/150 V and stained with Coomassie Brilliant Blue R-250 staining [19]. For activity staining, the gel was treated as described by Dhillon et al. (2000) [21], with one single modification of using 0.5% LVAX solution as a detector of xylanase activity.

Statistical Analysis

All the analysis was carried out in triplicates, and the experimental results obtained were expressed as means ± SD. Statistical analysis was performed using JMP (Version 7.0, SAS) to determine the response surfaces and contour plots of the response model. The data were analyzed by analysis of variance (ANOVA), and the adequacy of the response surface model was determined by evaluating the lack of fit and coefficient of determination (R2). The effect of time, pH, temperature, inoculum size, carbon, and nitrogen sources on the xylanase production in the first stage and the result of the characterization were statistically assessed by ANOVA and multiple pair-wise comparisons by the Tukey test using Xlstat® software.

Results and Discussion

Selection of Xylanase Production Parameters by OFAT Approach

Preliminary experiments were conducted to determine the optimum xylanase production parameters for Streptomyces sp. S1M3I. Significant differences (p < 0.05) in the xylanase activity were observed among the various parameters of xylanase production, as shown in Table 1.

Effect of Incubation Time on Xylanase Production

Xylanase activity reached a significant maximum value (p < 0.05) of 5.64 ± 0.09 U / mL on the 7th day of incubation (Table 1). Subsequently, this activity decreased significantly (p < 0.05). Several authors have reported that the maximum xylanase production by Actinobacteria of the genus Streptomyces requires a 7-day incubation period [22, 23]. Techapun et al. (2002) [24] showed that Streptomyces sp. Ab106 produced a higher yield of xylanase after 5 days of fermentation. On the other, Streptomyces thermocarboxydus ME742 attained the highest yield of xylanase production in only 4 days of fermentation [25]. The decrease in xylanase activity after the 7th day can be explained by the depletion of the substrate [26] or by the catabolic repression caused by the fermentation products (easily usable sugars) [27]. The change in pH during fermentation can lead to the inhibition or denaturation of enzymes [28]. Indeed, Sharma et al. 2021 [29] reported that xylanase production from Streptomyces marcescens HK decreased after 4 days of fermentation with increasing pH values.

Effect of Incubation Temperature on Xylanase Production

The xylanase activity peaked at 40 °C for Streptomyces sp. S1M3I (Table 1). These results were comparable to those reported by Adhi et al. (1989) [30] and Boucherba et al. (2011) [31] for Streptomyces badius and Jonesia denitrificans, respectively, which is, in general, consistent with the physiology of Actinobacteria [32]. The results obtained for Streptomyces sp. S1M3I are close to those observed for Bacillus strains, which reached their higher xylanase production at 37 °C [29]. The production of enzymes is significantly impacted by a small change in temperature. In the case of Streptomyces stains, an elevated temperature would facilitate enzyme production. [25, 29]. Khangkhachit et al. (2021) [25] reported that the xylanase activity at 40 °C was approximately twice as high as that produced at ambient temperature.

Effect of Olive Pomace Type on Xylanase Production

ROP and EOP were used as different carbon sources in the medium for xylanase production by Streptomyces sp. S1M3 at a concentration of 3%. The results showed that both types of pomaces gave a similar production in xylanase activity. No significant difference (p < 0.05) was observed (Table 1). However, Leite et al. (2016) [13] showed that the use of EOP as a carbon source for Aspergillus niger resulted in higher xylanase activities compared to ROP. The EOP was subjected to a second extraction with organic solvents to recover the residual olive oil. This process can be considered as a pretreatment of the pomace to improve the accessibility of the substrate by the microorganisms [13]. The production of xylanase by Streptomyces sp. S1M3 was not affected by the presence of an initial high concentration of fats in the ROP. This can be explained by the fact that the ROP has generally the same characteristics as the natural sampling environment (natural discharge of an oil mill) of Streptomyces sp. S1M3. This assumption supports the general conclusion of Vance and Chapin (2021) [33], who state that microbial metabolisms are influenced by the characteristics of the natural environment hosting the microorganism.

Effect of Olive Pomace Concentration on Xylanase Production

Optimized conditions for fermentation are unique for each microorganism. In our previous study, we determined that solid-state fermentation did not apply to Algerian olive pomace by using Algerian-isolated Streptomyces strains. In this study, ROP was tested at different concentrations (1–5% (w/v)) under submerged fermentation. A value of 6.41 U/mL was obtained when the medium contained 3% olive pomace, as shown in Table 1. A significantly (p < 0.05) lower activity was recorded at 5% olive pomace. Indeed, Naidu et al. (1998) [34] showed that a high concentration of carbon sources inhibits enzyme synthesis. Salhi (2004) [35] obtained the maximum cellulase production by Phanerochaete chrysosporium in submerged fermentation based on 2% olive pomace. Olive pomace represents an interesting agricultural residue for the production of enzymes. It is a cheap agricultural by-product that can be used to produce a variety of enzymes, making it a valuable resource for the enzyme industry [10, 13] such as the animal feed industry [10]. However, the hemicellulose of olive pomace is enclosed in a lignocellulosic complex and remains inaccessible to the cellulosic complex to rumen microorganisms for degradation [10]. Therefore, the potential addition of Streptomyces sp. S1M3I to the livestock feed can enhance the digestibility of the feed as well as the absorption of nutrients by the animals, thus improving the overall health and growth of the livestock.

Effect of (NH4)2SO4 Concentration on Xylanase Production

An essential component that affects the release of enzymes by microorganisms in a cultivation media is the source of nitrogen [24]. It has been reported in the literature that different nitrogen sources have been used for bacterial growth, such as peptone, yeast extract, (NH4)2SO4, NH4NO3, and urea [25]. Several authors have used (NH4)2SO4 as a nitrogen source for enzyme production by Actinobacteria [5, 11]. In this regard, five different concentrations of ammonium sulfate have been assessed in the fermentation media of Streptomyces sp. S1M3I to select the best one that revealed the maximum induction of xylanase. The results obtained depict that xylanase activity was maximal in the medium containing 0.3% (NH4)2SO4 as a nitrogen source (Table 1). Our results are consistent with those obtained by Macedo et al. (2013) [11], who indicated that 0.3% was the best concentration of (NH4)2SO4 for cellulase production in submerged fermentation using Streptomyces sp. SLBA-08.

Effect of Inoculum Size on Xylanase Production

To achieve maximum production, it is necessary to optimize the inoculum size. High biomass consumes additional substrate and may produce more toxic compounds, while low biomass results in reduced product yields [27]. The number of spores on 3 discs of 6 mm diameter and 4 mm thickness was averaged for inoculation preparation. Inoculation of the fermentation medium with Streptomyces sp. S1M3I strain was performed with an average of (4 ± 0.08) × 106 spores/mL from a 7-day culture on the M3 medium of the strain (the composition of M3 is given in our previous studies [16]). According to the results in Table 1, the optimal size of the inoculum was 3 discs ((1.2 ± 0.24) × 107 spores/mL), giving an activity of 6.10 ± 0.08 U/mL. At inoculum sizes larger than 3 discs, the enzymatic activity remained significantly stable (p < 0.05). This could be the result of faster nutrient consumption [36]. Therefore, an optimal level of inoculum is required to maintain the balance between proliferating biomass and available nutrients to produce the maximum level of the enzyme. Similar results were reported by Bajaj and Singh (2010) [27], who used an optimal inoculum size of 2 × 107 spores/mL for maximum xylanase production by Streptomyces sp. 7b on wheat bran.

Effect of Initial pH of the Medium on Xylanase Production

To find the optimal initial pH of the xylanase production medium, experiments were carried out at different pH values ranging from 4 to 10. The analysis showed that the maximum production of xylanase for Streptomyces sp. S1M3I is at pH 7.0 (Table 1). Similar results were obtained by Adhi et al. (1989) [30] and Tuncer et al. (1999) [19] for Streptomyces viridosporus and Streptomyces matensis, respectively, who reported the same optimal pH for xylanase production. However, Nascimento et al. 2002 [37] found a lower optimum pH value (6.0) for the production of xylanase by Streptomyces sp. Enzymes are very sensitive to pH changes, and their function is optimal within a very limited range, with a defined optimal pH [38]. Any change in pH affects the structure of the protein and leads to a decrease in enzymatic activity [38].

Optimization of the RSM Conditions

The experiments conducted in the present study were targeted toward the construction of a model consisting of 27 trials using the Box-Behnken design in RSM to determine the exact optimal values and effect of four independent variables: pH (X1), temperature (X2), carbon source (X3), and nitrogen source (X4) (Table 2).

The analysis of variance (ANOVA) findings is presented in Table 3, providing a summary of the results. The significance of individual factors and interactions was assessed using p-values, which indicate the probability of error. A p-value less than 0.05 suggests significance, while values below 0.0001 indicate a high level of significance.

A very low p-value (< 0.0001) indicated that a generated model was statistically significant, suggesting that the xylanase production could be adequately described within this model. The values of R-squared were close to 1 for the model (R2 = 0.9487), which indicates a good correlation between the experimental and predicted values, confirming that this model could explain 94.87% of the variation in xylanase production. However, sometimes the presence of insignificant variables in the model may lead to a higher R2 value, which misleads the true behavior of the model. Hence, the term adjusted R2 (adj R2 = 0.8888) was introduced for R2 value corrections according to the sample size and number of terms in the model. The large difference between R2 and adj R2 indicates that the model contains too many insignificant terms [39]. Furthermore, the value of the F-value for the lack of fit was not significant (p > 0.05), thus confirming the validity of the model. Actual and predicted xylanase activities were plotted in Fig. 2, and the results suggest a satisfactory correlation between the experimental and predicted values, where the data pointed centralized adjacent to the diagonal line. In addition, the confidence curves for the line of the fit cross the horizontal line representing the hypothesis, suggesting that the model is significant (p < 0.05). All results indicated that this model could work adequately for the prediction of xylanase activity.

The regression analysis of the data showed that only the pH (X1) has a significant (p < 0.05) effect on xylanase production, whereas the effects of temperature (X2), carbon source (X3), and nitrogen source (X4) did not exhibit any significant (p > 0.05) effect. The same observation was noted for the effect of interactions X1X2, X1X3, X1X4, X2X4, and X3X4 on the xylanase production. However, interactions X2X3, X12, X22, X32, and X42 exhibited a significant effect on xylanase production. The model can be shown as follows:

The equation (Eq. 1) demonstrates that pH exerts a significant positive linear influence on xylanase production. Conversely, the quadratic interactions of parameters X12, X22, X32, and X42 have notable negative effects on xylanase production. The impact of these four parameters on xylanase production is visualized in Fig. 3. The results indicate that the yield of xylanase production increases with rising pH up to 7.33 and then declines with further pH increases. This trend aligns with previous studies that have described similar patterns of enzyme production in response to an increase in pH [5, 11]. Our findings are consistent with those of Boucherba et al. (2011) [31], who observed a maximum xylanase activity of 10.81 U/mL in Jonesia denitrificans at the optimal pH of 7.0. However, our results surpass those obtained by Tuncer et al. (1999) [19], who reported xylanase activity of 0.63 U/mL in Thermomonospora fusca BD25 at the optimum pH of 7.0.

Figure 3a–c demonstrates that regardless of pH, carbon source, or nitrogen source, xylanase activity decreased with increasing temperature from 40 to 50 °C and then slightly increased with increasing temperature from 30 to 39.44 °C. In general, a temperature of 39.44 °C resulted in the highest value of xylanase activity (10.89 ± 0.87 U/mL). However, the xylanase activity dropped off after this. Similar conclusions were reached by Boucherba et al. (2011) [31], who found that at the optimum temperature of 37 °C, Jonesia denitrificans produces a maximum xylanase activity of 10.81 U/mL. In the study conducted by Tuncer et al. (1999) [19], a lower xylanase activity value of 1.54 U/mL was observed at the optimum temperature of 50 °C for Thermomonospora fusca BD25.

Concerning carbon source and nitrogen source, the same figure can be observed for xylanase activity: when the amount of olive pomace (carbon source) and (NH4)2SO4 (nitrogen source) in the culture medium is reduced from 1 to 3.39 and from 0.1 to 0.3, respectively, xylanase activity increases. (NH4)2SO4 was used by several authors as a nitrogen source for growing actinobacterial enzyme producers. Macedo et al. (2013) [11] reported that 0.3% (NH4)2SO4 and 2.4% of sisal bagasse were best for CMCase production in submerged fermentation by using Streptomyces sp. SLBA-08. Streptomyces viridosporus grown in 2% mesh corn and 6% yeast extract produced the maximum level of xylanase activity (0.35 U/mL), whereas when using Streptomyces badius in the same conditions, an activity of 0.06 U/mL was obtained [30]. Tuncer et al. (1999) [19] obtained maximum xylanase activity (2.68 U/mL) when growing Thermomonospora fusca in 0.8% oat-spelled xylan and 0.6% yeast extract. It should be noted, however, that comparing the results reported in the literature remains difficult due to differences in the conditions used to test the enzyme activities.

The results obtained from these experiments showed that the optimum xylanase production conditions for Streptomyces sp. S1M3I cultivated in submerged culture-based olive pomace were obtained at 7.39 of pH, 39.14 °C incubation temperature, 2.87% (w/v) of olive pomace (carbon source), and 0.28% (w/v) of (NH4)2SO4 (nitrogen source) with a predicted yield of 11.28 U/mL. A verification experiment at the optimum condition was performed, and the practical recovery was 11.198 U/mL. Because both the experimental and predicted values are very close, this confirms that the generated model was statistically significant and the xylanase production could be well described with this model.

Characterization of the Xylanases in the Crude Supernatant

Temperature and pH Stability of Crude Xylanases

The optimal temperature for enzymatic activity was 50 °C, and a relative activity of 100 ± 0.06% was observed (Table 4). Similar results were reported by Bajaj and Singh (2010) [27] who obtained an optimum temperature of 50 °C for xylanases produced by Streptomyces sp. 7b. On the other hand, Nascimento et al. (2002) [37] demonstrated that the best xylanase activity produced by Streptomyces sp. AMT-3 was observed at a temperature between 55 and 65 °C. While the profile obtained for thermostability at 55 °C of partially purified xylanase from Streptomyces sp. RCK-2010 revealed that the enzyme had approximately 50% relative activity [36].

For the pH, the xylanase activity was significant between 5 and 6 (Table 4). Although, most xylanases known today are active at either acidic or neutral pH [36]. Similar results were reported by Bajaj and Singh (2010) [27] and Kumar et al. (2012) [36] who obtained an optimum pH of 6 for xylanases produced by Streptomyces strains (Streptomyces sp. 7b and Streptomyces sp. RCK-2010, respectively). Another study has reported a higher pH value. Indeed, Boucherba et al. (2011) [31] obtained a pH optimum of 7 for xylanases produced by Jonesia denitrificans. As for Sharma and Bajaj (2005) [40], an optimal pH of 8 was obtained for xylanases produced by Streptomyces sp. CD3.

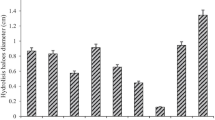

Specificity of Crude Xylanases towards the Substrates

The hydrolytic activity of xylanases from the crude supernatant on various substrates was determined (Table 4). Three types of xylan (birch xylan, beech xylan, and LVAX) were used to evaluate the specificity of the xylanases produced by Streptomyces in the crude supernatant towards the substrates. The xylanases in the supernatant degraded all substrates tested, with higher activity for the LVAX substrate. Xylanases produced by Streptomyces sp. S1M3I have a higher affinity for LVAX compared to wood xylans, and this may be due to the nature of the substituents along the xylan backbone. Arabinoxylans are linear, unsubstituted xylans that play an important role in cereal hemicelluloses [41].

Wood xylan in hardwoods is present as O-acetyl-4-O-methylglucuronoxylan, while in softwoods, it exists as arabino-4-O-methylglucuronoxylan. On the other hand, xylans in grasses and annual plants are typically arabinoxylans [42]. The complexity of xylans varies from linear to highly substituted forms, allowing for a broad distinction between different types. Additionally, within each category, there is microheterogeneity in terms of branching, which influences the solubility, physical conformation, and reactivity of the xylan molecule with other hemicellulosic components. The side chains have a significant impact on the enzymatic cleavage process, affecting the mode and extent of cleavage [42].

Electrophoresis and Zymogram Analysis

The concentrated culture supernatant contained several forms of proteins, and their separation was difficult under native conditions (data not shown). For this purpose, electrophoresis in denaturing conditions with renaturation of the proteins was performed.

SDS-PAGE results indicated that Streptomyces sp. S1M3I secreted several proteins in the culture medium (Fig. 4). Two xylanases with close molecular masses were detected by zymogram analysis: Xyl-1 and Xyl-2, with molecular masses of 24.14 kDa and 27 kDa, respectively. The sizes of these xylanases were close to those of xylanases previously reported in the literature, which had molecular masses ranging from 20 to 30 kDa [43]. In fact, Chi et al. (2012) [44] reported similar findings, obtaining a single xylanase with a size of 26.4 kDa for the strain Bacillus sp. MX47.

Conclusion

In this study, we evaluated Streptomyces sp. S1M3I for industrial application in the bioconversion of olive pomace as a low-cost agro-industrial residue that can be used as a lignocellulosic fermentation substrate. Simultaneous optimization of both cultivation conditions and medium composition through the OFAT and RSM approaches was investigated, and the results have shown that maximum production of xylanase by Streptomyces sp. S1M3I occurred when minimal salt media contained 3% (w/v) raw olive pomace powder and 0.3% (w/v) (NH4)2SO4, at a pH of 7.4 and an incubation temperature of 40 °C. The optimization of the culture parameters of Streptomyces sp. S1M3I and the activity assay conditions improved xylanase production yield. The levels of xylanase activity obtained are promising and warrant further investigation to produce enzymes for biotechnology purposes as well as improve the composition of olive pomace for use in livestock feeding.

Data Availability

All data generated or analyzed during this study are included in this published article.

References

Thrash, J.C., & Coates, J.D. (2010). Phylum XVII, Acidobacteria phyl. nov. Bergey's Manual of Systematic Bacteriology. 725‑735. https://doi.org/10.1007/978-0-387-68572-4_6

Boroujeni, M., Das, A., Prachanthi, K., et al. (2012). Enzymatic screening and rendom amplified polymorphic DNA fingerpinting of soil streptomycetes isolated from Wayanad District in Kerala. Indian Journal of Biological Sciences, 12, 1–8. https://doi.org/10.3923/jbs.2012.43.50

Aparicio, J., Zoleica, M., Solá, S., Susana, C., et al. (2015). Safety versatility of Streptomyces sp. M7 to bioremediate soils co-contaminated with Cr (VI) and lindane. Ecotoxicology and Environmental Safety, 116, 34–39. https://doi.org/10.1016/j.ecoenv.2015.02.036

Prakash, D., Nawani, N., Prakash, M., et al. (2013). Actinomycetes : A repertory of green catalysts with a potential revenue resource. BioMed Research International, 2013, 1–8. https://doi.org/10.1155/2013/264020

Irfan, M., Nadeem, M., & Syed, Q. (2014). One-factor-at-a-time ( OFAT ) optimization of xylanase production from Trichoderma viride -IR05 in solid-state fermentation. Journal of Radiation Research and Applied Sciences, 7(3), 317–326. https://doi.org/10.1016/j.jrras.2014.04.004

Garrido, M. M., Piccinni, F. E., Landoni, M., et al. (2022). Insights into the xylan degradation system of Cellulomonas sp. B6: biochemical characterization of rCsXyn10A and rCsAbf62A. Applied Microbiology and Biotechnology, 106(13), 5035–5049. https://doi.org/10.1007/S00253-022-12061-3

Gomathi, D., Muthulakshmi, C., Kumar, D. G., et al. (2012). Submerged fermentation of wheat bran by Aspergillus flavus for production and characterization of carboxy methyl cellulase. Asian Pacific Tropical Biomedical Magazine, 2(1), S67–S73. https://doi.org/10.1016/s2221-1691(12)60132-4

Singhania, R. R., Sukumaran, R. K., Patel, A. K., et al. (2010). Advancement and comparative profiles in the production technologies using solid-state and submerged fermentation for microbial cellulases. Enzyme and Microbial Technology, 46(7), 541–549. https://doi.org/10.1016/j.enzmictec.2010.03.010

Garai, D., & Kumar, V. (2013). Aqueous two phase extraction of alkaline fungal xylanase in PEG/phosphate system : Optimization by Box – Behnken design approach. Biocatalysis and Agricultural Biotechnology, 2(2), 125–131. https://doi.org/10.1016/j.bcab.2013.03.003

Neifar, M., Jaouani, A., Ayari, A., et al. (2013). Improving the nutritive value of olive cake by solid state cultivation of the medicinal mushroom Fomes fomentarius. Chemosphere, 91, 110–114. https://doi.org/10.1016/j.chemosphere.2012.12.015

Macedo, E. P., Cerqueira, C. L. O., Souza, D. A. J., et al. (2013). Production of cellulose-degrading enzyme on sisal and other agro-industrial residues using a new Brazilian actinobacteria strain Streptomyces sp. SLBA-08. Brazilian Journal of Medical and Biological Research, 30(4), 729–735. https://doi.org/10.1590/s0104-66322013000400005

Pagnanelli, F., Viggi, C. C., & Toro, L. (2010). Development of new composite biosorbents from olive pomace wastes. Applied Surface Science, 256(17), 5492–5497. https://doi.org/10.1016/j.apsusc.2009.12.146

Leite, P., Manuel, J., Venâncio, A., et al. (2016). Ultrasounds pretreatment of olive pomace to improve xylanase and cellulase production by solid-state fermentation. Bioresource Technology, 214, 737–746. https://doi.org/10.1016/j.biortech.2016.05.028

Alam, Z., Muyibi, S. A., & Wahid, R. (2008). Statistical optimization of process conditions for cellulase production by liquid state bioconversion of domestic wastewater sludge. Bioresource Technology, 99, 4709–4716. https://doi.org/10.1016/j.biortech.2007.09.072

Karabegović, I. T., Stojičević, S. S., Veličković, D. T., et al. (2012). Optimization of microwave-assisted extraction of cherry laurel ( Prunus laurocerasus L.) fruit using response surface methodology. Engineering and Technology, 6, 897–902. https://doi.org/10.5281/zenodo.1085596

Medouni-Haroune, L., Zaidi, F., Medouni-Adrar, S., et al. (2017) Selective isolation and screening of Actinobacteria strains producing lignocellulolytic enzymes using olive pomace as substrate. Iranian Journal of Biotechnology,15 (1), 74–77. https://doi.org/10.15171/ijb.1278.

Medouni-Haroune, L., Zaidi, F., Medouni-Adrar, S., et al. (2017). Bioconversion of olive pomace by submerged cultivation of Streptomyces sp. S1M3I. Proceedings of the National Academy of Sciences, India Section B: Biological Sciences, 88, 1425–1433. https://doi.org/10.1007/s40011-017-0880-x

Lilitchan, S., Tangprawat, C., & Aryusuk, K. (2008). Partial extraction method for the rapid analysis of total lipids and c-oryzanol contents in rice bran. Food Chemistry, 106, 752–759. https://doi.org/10.1016/j.foodchem.2007.06.052

Tuncer, M., Ball, A. S., Rob, A., et al. (1999). Optimization of extracellular lignocellulolytic enzyme production by a thermophilic actinomycete Thermomonospora fusca BD25. Enzyme and Microbial Technology, 25(1–2), 38–47. https://doi.org/10.1016/S0141-0229(99)00012-5

Laemmli, U. K. (1970). Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature, 227(5259), 680–685. https://doi.org/10.1038/227680a0

Dhillon, A., Gupta, J. K., & Khanna, S. (2000). Enhanced production, purification and characterisation of a novel cellulase-poor thermostable, alkalitolerant xylanase from Bacillus circulans AB 16. Process Biochemistry, 35, 849–856. https://doi.org/10.1016/s0032-9592(99)00152-1

Danso, B., Ali, S. S., Xie, R., et al. (2022). Valorisation of wheat straw and bioethanol production by a novel xylanase and cellulase-producing Streptomyces strain isolated from the wood-feeding termite. Microcerotermes species. Fuel, 310, 122333. https://doi.org/10.1016/j.fuel.2021.122333

Xiuting, L., Baoguo, S., Jin, Z., et al. (2011). Production and improved bleaching abilities of a thermostable xylanase from a newly isolated Streptomyces chartreusis strain. African Journal of Biotechnology, 10(64), 14132–14142. https://doi.org/10.5897/AJB10.2360

Techapun, C., Charoenrat, T., Watanabe, M., et al. (2002). Optimization of thermostable and alkaline-tolerant cellulase-free xylanase production from agricultural waste by thermotolerant Streptomyces sp. Ab106, using the central composite experimental design. Biochemical Engineering Journal, 12, 99–105. https://doi.org/10.1016/s1369-703x(02)00047-5

Khangkhachit, W., Suyotha, W., Leamdum, C., et al. (2021). Production of thermostable xylanase using Streptomyces thermocarboxydus ME742 and application in enzymatic conversion of xylan from oil palm empty fruit bunch to xylooligosaccharides. Biocatalysis and Agricultural Biotechnology, 37, 102180. https://doi.org/10.1016/j.bcab.2021.102180

Romero, P., Lussier, M., Véronneau, S., et al. (1999). Mnt2p and Mnt3p of Saccharomyces cerevisiae are members of the Mnn1p family of alpha-1,3-mannosyltransferases responsible for adding the terminal mannose residues of O-linked oligosaccharides. Glycobiology, 9(10), 1045–1051. https://doi.org/10.1093/glycob/9.10.1045

Bajaj, B. K., & Singh, N. P. (2010). Production of xylanase from an alkali tolerant Streptomyces sp. 7b under solid-state fermentation, its purification, and characterization. Applied Biochemistry and Biotechnology, 162(6), 1804–1818. https://doi.org/10.1007/s12010-010-8960-x

Miyanaga, K., & Unno, H. (2011) Reaction kinetics, and stoichiometry. Comprehensive Biotechnology, 33–46. https://doi.org/10.1016/b978-0-08-088504-9.00085-4.

Sharma, H. K., Xu, C., & Qin, W. (2021). Isolation of bacterial strain with xylanase and xylose/glucose isomerase (GI) activity and whole cell immobilization for improved enzyme production. Waste Biomass Valorization, 12, 833–845. https://doi.org/10.1007/s12649-020-01013-5

Adhi, T. P., Korus, R. A., & Crawford, D. L. (1989). Production of major extracellular enzymes during lignocellulose degradation by two streptomycetes in agitated submerged culture. Applied and Environmental Microbiology, 55(5), 1165–1168. https://doi.org/10.1128/aem.55.5.1165-1168.1989

Boucherba, N., Benallaoua, S., Copinet, E., et al. (2011). Production and partial characterization of xylanase produced by Jonesia denitrificans isolated in Algerian soil. Process Biochemistry, 46(2), 519–525. https://doi.org/10.1016/j.procbio.2010.10.003

McCarthy, A. (1987). Lignocellulose degrading actinomycetes. FEMS Microbiology Reviews, 46, 145–163.

Vance, E. D., & Chapin, F. S. (2001). Substrate limitations to microbial activity in taiga forest floors. Soil Biology and Biochemistry, 33, 173–188.

Naidu, G., & Panda, T. (1998). Production of pectolytic enzymes e a review. Bioprocess Engineering, 19, 355–361. https://doi.org/10.1007/pl00009023

Salhi, M.O. (2004) Valorisation de sous-produits et déchets lignocellulosiques par culture de microorganismes cellulolytiques.Dissertation, Insitut national agronomique El-harrache.

Kumar, A., Gupta, R., Shrivastava, B., et al. (2012). Xylanase production from an alkalophilic actinomycete isolate Streptomyces sp. RCK-2010, its characterization and application in saccharification of second generation biomass. Journal of Molecular Catalysis B: Enzymatic, 74(3–4), 170–177. https://doi.org/10.1016/j.molcatb.2011.10.001

Nascimento, R. P., Coelho, R. R. R., Marques, S., et al. (2002). Production and partial characterisation of xylanase from Streptomyces sp. strain AMT-3 isolated from Brazilian cerrado soil. Enzyme and Microbial Technology, 31, 549–555. https://doi.org/10.1016/S0141-0229(02)00150-3

Battestin, V., & Macedo, G. A. (2007). Effects of temperature, pH and additives on the activity of tannase produced by Paecilomyces variotii. Electronic Journal of Biotechnology, 10(2), 191–199. https://doi.org/10.2225/vol10-issue2-fulltext-9

Haaland, P. D. (1989) Experimental design in biotechnology. New York.

Sharma, P., & Bajaj, B. K. (2005). Production and partial characterization of alkali-tolerant xylanase from an alkalophilic Streptomyces sp. CD3. Journal of Scientific & Industrial Research, 64, 688–697.

Lafond, M., Tauzin, A., Desseaux, V., et al. (2011). GH10 xylanase D from Penicillium funiculosum : Biochemical studies and xylooligosaccharide production. Microbial Cell Factories, 10(1), 1–8. https://doi.org/10.1186/1475-2859-10-20

Kulkarni, N., Shendye, A., & Rao, M. (1999). Molecular and biotechnological aspects of xylanases. FEMS Microbiology Reviews, 23(4), 411–456. https://doi.org/10.1111/j.1574-6976.1999.tb00407.x

Taibi, Z., Saoudi, B., Boudelaa, M., et al. (2012). Purification and biochemical characterization of a highly thermostable xylanase from Actinomadura sp. strain Cpt20 isolated from poultry compost. Applied Biochemistry and Biotechnology, 166, 663–679. https://doi.org/10.1007/s12010-011-9457-y

Chi, W., Park, D. Y., & Chang, Y. (2012). A novel alkaliphilic xylanase from the newly isolated mesophilic Bacillus sp. MX47: Production, purification and characterization. Applied Biochemistry and Biotechnology, 168, 899–909. https://doi.org/10.1007/s12010-012-9828-z

Acknowledgements

We thank Professor S. Roussos and V. Desseaux for the training in the IMBE and ISM2, Marseille (France).

Funding

The research was supported by the Faculty of Nature and Life Sciences, University of Bejaia, Algeria.

Author information

Authors and Affiliations

Contributions

Lamia Medouni-Haroune: conceptualization, experiments, and writing original draft; Sonia Medouni-Adrar: methodology and data curation; Aicha Asma Houfani: reviewing and editing; Cilia Bouiche and Zahra Azzouz: polished the paper; Sevastianos Roussos: provides research guidance; Véronique Desseaux: analytical methodology; Khodir Madani and Mouloud Kecha: supervision. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Medouni-Haroune, L., Medouni-Adrar, S., Houfani, A.A. et al. Statistical Optimization and Partial Characterization of Xylanases Produced by Streptomyces sp. S1M3I Using Olive Pomace as a Fermentation Substrate. Appl Biochem Biotechnol 196, 2012–2030 (2024). https://doi.org/10.1007/s12010-023-04660-1

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-023-04660-1