Abstract

The optimization of fermentation parameters for higher yield of bacterial enzymes have significant contribution to the industries. The qualitative enzymatic assay of strain HK2 in xyan agar and xylose agar plates showed a zone of clearance which indicated that the strain has potential to produce xylanase and xylose/glucose isomerase (GI) respectively. The strain produced highest xylanase activity of 23.09 ± 0.009 U/ml when grown in beechwood xylan and yeast extract in a ratio of 3:2 (w/w) at 37 °C and pH 7 for 96 h. Similarly, the strain preferred 35 to 40 °C temperature and 8 to 9 pH for efficient GI production. The GI activity was 3.3 folds higher than control when 1.5% xylose and 1:3 (w/w) ratio of peptone and yeast extract were used in the culture medium. SDS-PAGE of crude enzyme revealed that the molecular weight of xylanase and GI were about 55 kDa and 63 kDa respectively. The strain HK2 was identified as the Serratia marcescens by 16S rRNA gene sequencing. The strain has an ability to utilize low cost agricultural residue and the whole cell immobilization of strain improved the enzyme production which can further minimize the cost of down streaming processing. Thus, S. marcescens HK2 could be a promising candidate for foods and biofuels industries.

Graphic Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

To the best of our knowledge this is the first recorded xylose/glucose isomerase (GI) and xylanase activities from Serratia marcescens strain HK2 with relatively higher enzyme activities than several other earlier reported strains. The production of xylanase and GI enzymes from isolated strain Serratia marcescens HK2 was optimized and an improvement in GI yield has been observed by immobilization of strain.

Introduction

The bioconversion of organic materials, usually the lignocellulosic biomass performed by microorganisms have an enormous potential to fulfill the global energy demand and mitigate the environmental challenges associated with consumption and flaring of fossil fuel. Hemicellulose, a major component of lignocellulosic biomass, formed of a cross-linked network of complex heteropolymers, requires xylanase enzymatic components- endoxylanase, β-xylosidase, α-glucuronidase, α-arabinofuranosidase, and acetylxylan esterase [1] which act synergistically to disarray the recalcitrant biopolymers. The cross-linked hemicelluloses are cleaved by endo- and exoxylanases to form xylo-oligosaccharides, which can be further hydrolyzed by β-xylosidases, α-arabinofuranosidase and esterases into monosaccharides [2]. The glucose so formed after enzymatic saccharification can be utilized directly in microbial fermentation for biofuel production or can be converted into fructose for other industrial applications.

Recently, fructose is discovered as a more reactive feedstock than glucose for the production of 5-hydroxymethylfurfural (5-HMF), a high-value platform chemical to produce carbon neutral, high efficiency, furan based biofuels and other value-added bioproducts such as levulinic acid, furan dicarboxylic acid (FDCA) and bio-based polyesters such as polyethylene furanoate (PEF)- a green substitute for polyethylene terephthalate (PET), polyamides, polyurethanes, etc. [3, 4]. Several studies have been conducted on catalytic compounds such as CrCl2 or CrCl3 for the conversion of glucose to 5-HMF [5, 6] with fructose as a reaction intermediate. Although, the single step catalytic conversion of glucose to HMF is highly desirable for industrial applications, the HMF yield was still low due to the chemical equilibrium limitation of isomerization step involved in the process. Moreover, financial and environmental concerns associated with isomerization is another major limitation of catalytic conversion. Thus, there is an increasing interest on biological conversion of glucose to fructose where the microbes produce xylose/glucose isomerase (GI) enzyme, which help in the isomerization of glucose and xylose to fructose and xylulose respectively. Bacteria such as: E. coli, Aerobacter sp., Pseudomonas sp., Sarcina sp., Arthrobacter sp., Streptomyces murinus have been reported for their ability of converting glucose to fructose [7]. Although the GI production has also been reported from several bacteria including Bacillus licheniformis [8], Anoxybacillus gonensis [9], the majority of commercial GI is produced from Streptomyces or Actinoplanes species [10], and the enzyme immobilization has been widely practiced for industrial applications to minimize the production cost and maximize its recovery. Study was mainly focused on to isolate effective bacterial strain that can produce xylanase and GI enzymes, optimize the enzyme production and immobilized the strain for possible industrial application.

Materials and Methods

Bacterial Isolation and Characterization

The soil sample taken from forest nearby the Kingfisher lake was kept in 10% xylose solution for 5 days followed by streaking in xylose agar plate (containing 1.5 g xylose, 0.1 g NaNO3, 0.1 g K2HPO4, 0.1 g KCl, 0.05 g MgSO4.7H2O, 1.15 g agar and distilled water up to 100 ml). The plate was incubated at 37 °C for 24 h. The bacterial colonies were isolated, and loop transferred into 5 ml of LB broth (containing 10 g peptone, 5 g yeast extract, 5 g NaCl and distilled water up to 1000 ml) for overnight incubation at 37 °C in a shaking incubator at 200 rpm. Single bacterial colonies were selected after successive streaking and re-cultured in LB nutrient media. DNA was extracted after the confirmation of xylanase and GI activities from qualitative enzyme assays. The 16S rRNA was amplified using polymerase chain reaction (PCR) where the PCR thermal cycle was adjusted as follows: initial denaturation at 94 °C for 3 min, 30 successive amplification cycles (denaturation: 94 °C for 30 s, annealing: 58 °C for 30 s and extension: 72 °C for 1.3 min) and final extension at 72 °C for 10 min. The PCR product was run through 1% agarose gel-electrophoresis and purified using PCR/Gel fragments extraction kit (Geneaid, FroggaBio). Purified 16S rRNA was sent to Eurofins Genomics, ON, Canada for sequencing and finally characterized using basic local alignment search tool of national center for biotechnology information (NCBI) data base.

Bacterial Seed Culture and Inoculum Size

The LB broth seed culture for quantitative assay was prepared from LB agar plate (containing 10 g peptone, 5 g yeast extract, 5 g NaCl, 11.5 g agar and distilled water up to 1000 ml) stock culture by single loop transferring of strain into 5 ml LB broth. The seed culture was incubated at 37 °C and 200 rpm for 24 h. The seed culture of 1 ml was transferred into a 250 ml Erlenmeyer flask containing 50 ml culture medium (i.e. 1:50 ratio of inoculum size) in each batch fermentation for both quantitative xylanase and GI enzyme activity assays.

Qualitative Enzyme Assay

The qualitative screening of xylanase and GI were carried out separately using the LB broth seed culture. The overnight grown HK2 seed culture (5 µl) was inoculated in the xylan and xylose agar plates separately. The agar plates were incubated- 96 h at 37 ºC for xylanase activity and 48 h at 30 ºC for GI activity assay. The xylan agar plate containing 1 g xylan from corn core, 0.1 g NaNO3, 0.1 g K2HPO4, 0.1 g KCl, 0.05 g MgSO4⋅7H2O, yeast extract 0.05 g, 1.15 g agar and distilled water up to 100 ml was used for qualitative xylanase assay. The xylan agar plate was flooded with 0.1% Congo Red at room temperature for 30 min followed by de-staining with 1 M NaCl and analyzed the zone of clearance [11]. Wheras xylose agar plate containing 15 g xylose, 1 g NaNO3, 1 g K2HPO4, 1 g KCl, 0.5 g MgSO4⋅7H2O, 11.5 g agar and distilled water up to 1000 ml was used for qualitative GI activity assay. The xylose agar plate was treated with 2,3,5-triphenyltetrazolium in alkaline medium (NaOH) using plate assay technique, subsequently followed by observation of zone of clearance [12].

Quantitative Enzyme Assay

The minimal salt medium composed of 0.5% (w/v) corn core xylan, 0.25% (w/v) peptone, 0.25% (w/v) yeast extract, 0.1 g NaNO3, 0.1 g K2HPO4, 0.1 g KCl, 0.05 g MgSO4⋅7H2O in 1 L distilled water was used as a standard culture medium for xylanase production. Whereas, every 100 ml of culture medium containing 1% (w/v) xylose, 0.15 g peptone, 0.15 g yeast extract, 0.1 g K2HPO4, 0.01 g MnCl2⋅4H2O, 0.1 g MgSO4⋅7H2O was used for GI production. The seed culture of 1 ml was maintained as a standard inoculum size for 50 ml culture medium in each 250 ml Erlenmeyer flask incubated in shaking incubator (200 rpm) throughout the experiments. The bacterial production of extracellular xylanase and GI were optimized by changing temperature (a constant temperature of 37 °C for xylanase and a range of 25 to 45 °C for GI), incubation time (up to 7 days), pH (5 to 10), sources of carbon (commercial carbon and agricultural residues) and sources of nitrogen (organic and inorganic nitrogenous sources) in the culture medium. The quantification of enzyme activity was made by harvesting 1 ml of culture medium each day for 5 to 7 days. The culture broth (1 ml) was centrifuged at 12,000×g for 3 min and the extracellular crude enzyme collected from the supernatant was further analyzed for enzyme activity. The enzyme activities were estimated from absorbance values at OD 540 nm using a micro-plate reader spectrophotometer (BioTek, USA) whereas the bacterial growth was measured in term of biomass at OD 600 nm. The enzyme activity was expressed in U/ml, where one unit of enzyme corresponds to the release of 1 µM of sugar equivalent per minute from the substrate.

The xylanase activity was estimated by the measurement of reducing sugars yield with some modification on 3,5-dinitro-salicylic acid (DNS) method [13]. Briefly, the aliquot (50 µl) of crude enzyme and 50 µl of 0.1 M citrate buffer (pH 4.8) with 1% beechwood xylan were mixed into a 1 ml microcentrifuge tube and the mixture was incubated at 55 °C for 30 min. The incubation was followed by addition of 200 µl of DNS solution and kept into a boiling water bath for 5 min. The reducing sugars liberated were estimated using a glucose standard curve.

Similarly, the GI activity was estimated by measurement of fructose yield after isomerization reaction. The enzyme activity assay of GI was carried out with some modifications on Cysteine-Carbazole method [14]. An aliquot of supernatant (200 µl) was transferred to a reaction mixture containing 0.5 M d-glucose solution 100 µl, 0.2 M K-Na-Phosphate buffer (pH 7.8) 75 µl and 0.1 M MgSO4⋅7H2O 25 µl. The reaction mixture was kept into the hot water bath (70 °C, 1 h) for isomerization. The reaction was terminated by adding 10 µl of 0.2 N HCl and keeping the mixture into ice-cold water for 5 min. It was followed by simultaneous addition of 50 µl of 1.5% cysteine hydrochloride solution, 50 µl of 0.12% alcoholic solution of carbazole (prepared in 99% ethanol) and 1 ml of 70% H2SO4. The solution was vigorously mixed and kept in 50 ºC hot water bath for 20 min. The development of a purple colour in the reaction mixture after 20 min of hot water (50 °C) bath represents the presence of fructose in the mixture after the isomerization reaction [15]. The measurement of fructose formed was estimated using a fructose standard curve.

Effect of Bacterial Immobilization on GI Activity

The bacterial strain was immobilized in calcium alginate beads with some modification in the entrapment method [16]. Briefly, the sodium alginate of 0.25 gm was mixed in 5 ml distilled water. The LB broth seed culture of equal volume (5 ml) was thoroughly mixed into sodium alginate solution. The mixture was collected into a syringe and dropped from 15 cm height into CaCl2 solution (1.5 gm of 0.2 M CaCl2 in 100 ml distilled water) with continuous steering to form small beads of calcium alginate. The beads were left for 20 min in CaCl2 solution to become hardened. The strain HK2 entrapped into calcium alginate beads were washed with autoclaved distilled water and used for enzyme production in 50 ml culture medium in its optimum culture condition. The inoculum size of immobilized strain was maintained equivalent with the seed culture inoculum size of free strain as used in all other experiments. All the immobilization procedures were performed at room temperature by using autoclaved apparatus and chemical reagents in a laminar air flow cabinet to minimize the contamination.

SDS–Polyacrylamide Gel Electrophoresis

The xylanase and GI enzyme were separated in sodium dodecyl sulfate polyacrylamide gel electrophoresis (SDS-PAGE). The crude enzymes from strain HK2 were run along with protein marker in 10% acrylamide gel. A constant supply of 120 V was maintained throughout the experiment. The gel was immersed in Coomassie brilliant blue for 45 min and de-stained with hot water until the bands were prominent. The presence of protein bands in the gel was compared with standard protein marker (Bio Basic, Canada) to estimate the molecular weight.

Whereas the hydrolytic activity of xylanase was observed in zymogram analysis. The gel was washed with 1% (v/v) Triton X-100 followed by immersed in 0.1 M citrate buffer (pH 4.8) with 1% beechwood xylan and incubated in hot water bath (55 °C) for 30 min. The gel was stained in 0.1% Congo Red for 30 min subsequently de-stained with 1 M sodium chloride solution and treated with 4% (w/v) acetic acid solution to observe the prominent hydrolytic band. The molecular weight of xylanase was estimated by comparing the hydrolysis bands with the standard protein marker (Bio Basic, Canada).

Results and Discussion

Qualitative Screening of Xylanase and GI Activity Assay

The plate assay techniques were performed for qualitative screening of strain for xylanase and GI activities. The strain HK2 isolated from soil showed positive results with a zone of clearance when treated with Congo Red and 2,3,5-triphenyltetrazolium representing potential xylanase and GI activities respectively. Thus, the strain HK2 was further used for strain’s characterization and quantification of both xylanase and GI activities.

Bacterial Isolation and Characterization

Bacterial DNA of strain HK2 was isolated using bacterial genomic DNA isolation kit (Norgen Biotek Corp) and amplified its 16S rRNA using PCR (FroggaBio), universal forward primers HAD-1 (5′-GACTCCTACGGGAGGCAGCAGT) and reverse primer E1115R (5′-AGGGTTGCGCTCGTTGCGGG) following their protocols. The amplified DNA sample was run in 1% agarose gel-electrophoresis and validated the presence of 16S rRNA. The high-quality nucleotide sequence of 768 bp, obtained after Geneious consensus alignment, was submitted in NCBI database to identify the strain. The strain HK2 was identified as Serratia marcescens HK2 with the NCBI accession number MN795833.

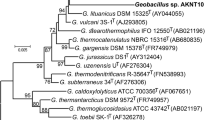

The available sequence data for related species of Serratia marcescens were downloaded from GenBank. Sequences were assembled and aligned using the Clustalw module in BioEdit v. 7.0.9.0 [17] with default settings. Phylogenetic analysis was conducted using Neighbor Joining tree with 1000 bootstrap using the program MEGA 7 [18]. The phylogenetic analysis indicates that the Serratia marcescens HK2 in this study was clustered with other strains of Serratia marcescens with high bootstrap support value (Fig. 1).

Effect of pH and Incubation Time on Enzymes Production

The effect of pH and incubation time on enzyme production was measured at 37 °C by harvesting 1 ml of culture broth each day for 5 days. The initial pH of culture medium was adjusted to 5, 6, 7, 8, 9 and 10 using 0.2 N KOH and 0.2 N HCl. The xylanase production from S. marcescens HK2 was started from 3 days which significantly increased and attained the highest yield at pH 7 in 4 days of fermentation, then after it decreased with increasing the pH values. The earlier study also reported a maximal production of xylanase from Streptomyces sp. [19]. and Aspergillus niger LPB 326 [20] with increased activity in 4 days. However, Techapun et al. [21] suggested the higher yield of xylanase from Streptomyces sp. Ab106 in neutral culture medium (pH 7) after 5 days of fermentation (Fig. 2).

On the other hand, the GI production from S. marcescens HK2 was high in a slightly alkaline medium at 96 h of incubation. Chou et al. [22] also reported the pH range of 7 to 8 for optimum GI production. Our study on extracellular GI enzyme from S. marcescens HK2 agreed with similar earlier findings where the GI production was noticed with gradually increased with increasing pH, reached the highest at pH 8 and decreased in pH 9 and 10 after 72 h of incubation. Similarly, the GI production in Streptomyces sp. CH7 was high in 72 h when grown in 1% oat-spelt xylan [23] and in Streptomyces sp. HM5, the GI production was high when grown in 1.5% xylose with an initial pH 7.5 in 72 h of incubation [24] (Fig. 3).

Effect of Temperature on Xylanase and GI Production

The enzyme production is greatly influenced by minor fluctuation in temperature. Several bacterial strains including Bacillus mojavensis AG137 [25] and Bacillus tequilensis ARMATI [26] showed their higher xylanase production at 37 °C. Thus, the xylanase production from S. marcescens HK2 was observed by growing strain HK2 at a constant temperature of 37 °C for 6 days and its enzyme activity was estimated each day by incubating the reaction mixture at 55 °C for 30 min.

Whereas GI production was optimized by growing strain at different temperature of 25, 30, 35, 40 and 45 °C for 5 days. The optimum GI activity was determined by incubation of reaction mixture containing an aliquot of crude enzyme and substrate (glucose) with K-Na-Phosphate buffer in hot water bath at 50, 60 70, 80 °C for 1 h. Although an extracellular GI was produced in a wider range of temperature from 35 to 45 °C, the bacterial strain S. marcescens HK2 preferred 40 °C for maximum GI production and optimum temperature of 70 °C for significantly high (P < 0.05) GI activity. This result was in harmony with species of Streptomyces which has been recorded for optimal GI activity at 70 °C [27]. Although, Bacillus licheniformis have been reported with optimum GI activity at a temperature of 50 °C [8], most of the microbial GI are known to produce maximal activity in relatively higher temperature range from 60 to 80 °C [28] more likely because the equilibrium of isomerization of glucose to fructose is driven by higher temperature [29] (Fig. 4).

Effect of Nitrogen on Xylanase and GI Production

The sources of nitrogen greatly affected in both xylanase and GI enzymes production from S. marcescens HK2. The experiments were conducted separately on various nitrogen sources including (NH4)2SO4, peptone, urea and yeast extract to observe their effect in both xylanase and GI enzymes production. The xylanase production from S. marcescens was inhibited by the presence of (NH4)2SO4 probable due to acidification of medium whereas the other nitrogen sources showed a relatively higher yield of xylanase. Although the strain HK2 showed wider selections of various nitrogen sources for xylanase production, a significantly increased xylanase activity was observed when organic nitrogen source, yeast extract was used in the culture medium. It might be due to supplemental elements present in the yeast extract [30] (Fig. 5).

On the other hand, although the peptone and yeast extract showed relatively lower GI activity when used separately in the medium, the activity was greatly increased when both used in the same culture medium (Fig. 6a). The yeast extract and peptone are organic nitrogen sources which supported in higher GI production than inorganic nitrogen [8, 31]. Similarly, the different proportion of peptone and yeast extract have a greater impact on enzyme production. Relatively, increasing yeast extract concentration in the medium resulted in higher GI activity [31] and the highest GI activity was observed when 1:3 ratio of peptone and yeast extract was added in the media (Fig. 6b). It may be due to the presence of suitable supplemental growth elements such as vitamin, trace nutrients, sulfur, etc. in yeast extract [30]. On the contrary, the presence of inorganic nitrogen such as urea in the culture medium did not support bacterial growth or enzyme production. The least activity observed in urea and (NH4)2SO4 might be due to the acidification of medium resulted from metabolism of inorganic nitrogen which in turn affects enzyme production.

Effect of Carbon on Xylanase and GI Production

Presence of different carbon sources in the culture medium has a significant impact on enzymes production. The strain HK2 was grown in various carbon sources including carboxymethyl cellulose (CMC), sucrose, xylan from corn core, beechwood xylan, barley straw and wheat straw for the production of xylanase. Similarly, the strain HK2 was grown in glucose, xylose and various lignocellulosic biomasses as the carbon sources for GI production. The strain HK2 was grown separately in minimal salt medium containing 0.5% (w/v) and 1% (w/v) of different carbon sources for xylanase and GI enzymes respectively.

The xylanase production in the medium with CMC and sucrose as a carbon source was relatively very low. However, the strain HK2 showed significantly higher xylanase production when grown in media containing 0.5% (w/v) of beechwood xylan for 96 h. The xylanase activity of 22.054 ± 0.029 U/ml was higher than the earlier reported 1.06 U/ml from Streptomyces sp. K37 [32], 14.5 U/ml from Penicillium oxalicum ZH-30 [33], however lower than 25.44 U/ml from Penicillium glabrum [34] and 55.92 U/mL from Cladosporium oxysporum GQ-3 [35]. Interestingly the strain HK2 also produced higher xylanase activity when grown in media containing 0.5% (w/v) barley straw (18.03 ± 0.062 U/ml) and wheat bran (20.861 ± 0.029 U/ml) as sole carbon sources. These values were comparable to the higher activity shown with the beechwood xylan (22.054 ± 0.029 U/ml) in this study and earlier 22.071 ± 0.186 U/ml reported with wheat bran [36]. Whereas, the xylanase activity was higher than some other earlier studies with 1.4 U/ml obtained in wheat bran [37] and 11.646 ± 4.163 U/ml obtained in barley husk [36]. The strain HK2 showed that it can utilize the cheap agricultural residues as a sole carbon source and can economize the enzyme production, presenting itself as a potential candidate in biomass saccharification process and thus useful for biofuel industries. In another experiment the concentration of beechwood xylan and yeast extract (as a carbon and nitrogen sources respectively) were optimized by considering the C:N ratios of 1:1, 1:2, 1:3, 3:1, 3:2, 2:3 and 2:1. The strain was grown in a minimal salt medium by maintaining an initial pH 7 at 37 °C for 7 days. It was observed that with the increasing proportion of nitrogen in the medium decreased the enzyme production whereas the increasing proportion of carbon increased the enzyme production. The highest xylanase activity of 23.09 ± 0.009 U/ml was observed when HK2 was grown in C:N ratio of 3:2 for 96 h (Fig. 7).

Similarly, the strain HK2 produced GI when grown in either glucose or xylose (Fig. 8a). Although the GI activity (1.88 ± 0.004 U/ml) was higher in 48 h with the glucose as a carbon source, the activity (3.256 ± 0.003 U/ml) was significantly high (i.e. P < 0.05) in 72 h when xylose was used as a carbon source. The observed GI activity was higher than GI activity in Streptomyces sp. SB-P1 (1.3 U/ml) [38], Pseudomonas sp. 0.7 U/ml, and Bacillus sp. 0.3 U/ml [39] where xylose broth medium were used. We observed nearly 2 folds higher GI activity in the medium containing xylose than compared to the medium containing glucose as a carbon source. The GI activity in the xylose medium was increased because the GI production in most of the bacteria is induced by xylose [38]. This result was in harmony with GI activity in Streptomyces sp. SB-P1 [38] and Streptomyces sp. CH7 [23] where the activity was high in the presence of xylose as a carbon source.

The concentration of glucose or xylose in the culture medium also affect enzyme production. Thus, both carbon sources were optimized separately to estimate the GI activity. The activity gradually increased with increase in carbon concentration in the medium from 0.5% (w/v) and attained the maximum GI activity at 1.5% (w/v) in both glucose or xylose then after it decreased (Fig. 8b). The higher GI activity of 3.515 ± 0.019 U/ml and 4.384 ± 0.002 U/ml observed in the optimum concentration of glucose and xylose respectively. However, Habeeb et al. [40] recorded higher GI activity of 13.6 U/ml from Streptomyces sp. SH10 in its optimum production medium containing 1.5% xylose as a carbon source.

Various lignocellulosic biomasses including barley straw, corn stover, wheat bran, Miscanthus and wood dust were tested discretely in GI production medium. The biomass of 1% (w/v) was used as a sole carbon source at pH 8 and 40 °C followed by measurement of GI activity in standard assay condition. However, 1 ml of 2% glucose was introduced into the culture medium to initiate the bacterial growth, maintaining a constant volume of 50 ml culture medium. The HK2 strain was found to utilize various lignocellulosic biomass in GI production. The higher GI activity was observed in barley straw as a sole carbon source (Fig. 9a). It showed continues increase in activity with increased in barley concentration until it reached to 2% (w/v) which subsequently decreased above this concentration (Fig. 9b). Several studies have been conducted in GI production by using cheap carbon sources. In an earlier study, the extracellular GI (1.5 U/ml) was produced from Streptomyces flavogriseus when grown on straw hemicellulose in about 72 h [41]. Chanitnun and Pinphanichakarn [23] found the corn husk at 2.5% (optimum concentration) resulted in higher GI production from Streptomyces sp. CH7. Similarly, the agricultural residues such as corn cob and wheat husk have been recorded for high GI yield from Streptomyces sp. SB-P1 [38]. Our finding agreed with the previous suggestion that the application of barley straw, a cheap agro-residue, can act as a good substitute of expensive glucose or xylose in the production medium. Use of such agricultural residues in industrial production line not only minimize the overall economics of enzyme production but also help to overcome the environmental issues associated with agricultural waste disposal.

Bacterial Immobilization and GI Production

The seed culture (1 ml) of strain HK2 was immobilized and transferred to the 250 ml flask containing 50 ml culture medium for efficient enzyme production. The GI activity of extracellular enzyme from culture supernatant was measured for 5 days in standard assay condition. There was an improved GI production in immobilized strain than its free strain. The immobilized strain HK2 produce higher GI activity of 3.348 ± 0.02 U/ml in 48 h when 1% xylose was used in the culture medium. The improvement in GI production was also recorded when 2% barley straw used as a carbon source in 5 days of incubation in optimum condition. Similar improved GI production have been reported in whole cell immobilization of Streptomyces phaeochromogenes [42] and Streptomyces kanamyceticus [43]. As the alginate beads offered an increase in porosity and retaining property [44], the immobilized strain HK2 entrapped into the calcium alginate beads can receive nutrients or inducements from culture media into the microenvironment so as to improve the enzyme production. The encapsulation or entrapment of cells provides higher cell density and cellular interaction which create favorable microenvironment and increased productivities [45, 46]. Studies on whole cell immobilization have reported the improved activity than free cells because the immobilized cells were less sensitive to minor temperature and pH fluctuations [47] (Fig. 10).

Effect of Alginate Concentration on GI Production

The porosity, gel strength, size of alginate beads and cell activity depends on the concentration of sodium alginate and CaCl2 thereby affect the enzyme production efficiency of immobilized strains [48]. The strain HK2 was immobilized in six different concentrations- 1, 1.5, 2, 2.5, 3, 3.5% of sodium alginate and tested for enzyme production using same nutrient broth. The beads of 1% alginate were very soft, gradually lost its binding affinity and observed disruption into smaller fragments after 48 h of incubation with low enzyme yield. Whereas the immobilized strain in 3% of sodium alginate beads significantly increased the GI production and thus the activity of 7.12 ± 0.021 U/ml was observed in 48 h. The disruption of beads in 1% alginate and increased polymethylgalacturonase production in 3% alginate has been observed in immobilized Aspergillus niger 26 [49]. Similar increased enzyme production has been reported from immobilized strains in 3% sodium alginate [50, 51]. However, GI production and its activity while re-utilization of immobilized beads were reduced as reported by Bernardi et al. [50] and Ellaiah et al. [51] in contrast to increased enzyme production from successive second cycle onwards [49] in immobilization experiments (Fig. 11).

SDS-PAGE

The protein bands of xylanase and GI were observed separately in 10% acrylamide gel. Multiple bands were observed in the gel due to crude extraction and production of some other proteins in the medium. However, the band which corresponds to 55 kDa with a hydrolytic band of zymogram in Fig. 12a and 63 kDa in Fig. 12b confirm the presence of xylanase and GI enzyme respectively. A relatively similar molecular weight of 58 kDa xylanase has been reported from Streptomyces sp. [19], and 50 kDa from Pycnoporus cinnabarinus [52]. On the other hand, nearly similar size of 60 kDa has been reported for GI from Bacillus megaterium BPTK5 [53] and Enterobacter agglomerans [54].

Conclusion

The strain HK2 isolated from soil sample was identified as Serratia marcescens HK2 from partial sequence of 16S rRNA (NCBI accession: MN795833). Several bacterial species of Arthrobacter, Streptomyces, Bacillus etc. were reported in the production of GI and xylanase however, to the best of our knowledge this study was the first recorded GI and xylanase activities from S. marcescens HK2. Thus, we preferred to provide evidence of these enzymes based on genomic analysis of S. marcescens. The NCBI database records of S. marcescens genome study showed that xylose isomerase genes are present on Serratia marcescens subsp. marcescens ATCC 13880 (accession: WP_033639090.1), Serratia marcescens CAV1761 (accession: WP_047729570.1), Serratia marcescens AR_0027 (accession: WP_033636544.1).

It is also known that most of the xylanases are related to glycosylhydrolase (GH) families 10, 11, and 30 which play a crucial role in degrading complex carbohydrates. Moreover, GH family 10 is composed of endo-1,4- and 1,3-β-xylanases [55]. According to the recent genomic study of S. marcescens recorded in NCBI database, the GH family’s genes including GH 10 is present on Serratia marcescens subsp. marcescens Db11 (accession: WP_025302710.1). On the other hand, GH families 18, 19, and 85 are chitinases [56]. Most of the chitinases have potential to degrade plant structural polysaccharides. Whereas some potential cellulose degraders also known to target xylan and chitin [57]. Our strain S. marcescens HK2 showed unique ability to secret extracellular xylanase and GI enzymes with broader selection in substrates utilization. Higher yield of xylanase and GI enzymes from S. marcescens HK2 showed that our strain HK2 is competent to the other known strains. Production of these high valued enzymes from single strain opened up new scope in food and biofuel industries. Furthermore, it can effectively utilize the barley straw, a cheap agriculture residue as an alternative to expensive xylose carbon source for GI production. Additionally, the whole cell immobilization of strain in the alginate can further facilitate the purification steps and economize the downstream processing.

References

Liu, X., Kokare, C.: Microbial enzymes of use in industry. In: Biotechnology of Microbial Enzymes, pp. 267–298. Elsevier (2017).

Zhang, Z., Donaldson, A.A., Ma, X.: Advancements and future directions in enzyme technology for biomass conversion. Biotechnol. Adv. 30, 913–919 (2012). https://doi.org/10.1016/j.biotechadv.2012.01.020

Thombal, R.S., Jadhav, V.H.: Efficient conversion of carbohydrates to 5-hydroxymethylfurfural (HMF) using ZrCl4 catalyst in nitromethane. Biofuel Res. J. 1, 81–84 (2014). https://doi.org/10.18331/BRJ2015.1.3.4

Yong, G., Zhang, Y., Ying, J.Y.: Efficient catalytic system for the selective production of 5-hydroxymethylfurfural from glucose and fructose. Angew. Chemie Int. Ed. 47, 9345–9348 (2008). https://doi.org/10.1002/anie.200803207

Yuan, Z., Xu, C., Cheng, S., Leitch, M.: Catalytic conversion of glucose to 5-hydroxymethyl furfural using inexpensive co-catalysts and solvents. Carbohydr. Res. 346, 2019–2023 (2011)

Zhao, H., Holladay, J., Brown, H., Zhang, Z.: Metal chlorides in ionic liquid solvents convert sugars to 5-hydroxymethylfurfural. Science 316, 1597–1600 (2007)

Suekane, M., Iizuka, H.: Enzymes of glucose isomerization in various microorganisms. Z. Allg. Mikrobiol. 21, 457–468 (1981). https://doi.org/10.1002/jobm.19810210607

Nwokoro, O.: Studies on the production of glucose isomerase by Bacillus licheniformis. Pol. J. Chem. Technol. 17, 84–88 (2015). https://doi.org/10.1515/pjct-2015-0054

Yanmiş, D., Karaoǧlu, H., Çolak, Ḑ.N., Şal, F.A., Çanakçi, S., Beldüz, A.O.: Characterization of a novel xylose isomerase from Anoxybacillus gonensis G2T. Turk. J. Biol. 38, 586–592 (2014). https://doi.org/10.3906/biy-1403-76

Hua, X., Yang, R.: Enzymes in starch processing. In: Chandrasekaran, M. (ed.) Enzymes in Food and Beverage Processing, p. 139. Taylor & Francis Group, CRC Press, Florida (2016)

Samanta, A.K., Kolte, A.P., Senani, S., Sridhar, M., Jayapal, N.: A simple and efficient diffusion technique for assay of endo β-1,4-xylanase activity. Braz. J. Microbiol. 42, 1349–1353 (2011). https://doi.org/10.1590/S1517-838220110004000016

Sapunova, L.I., Lobanok, A.G., Kazakevich, I.O., Evtushenkov, A.N.: A plate method to screen for microorganisms producing xylose isomerase. Microbiology 73, 107–112 (2004). https://doi.org/10.1023/B:MICI.0000016378.43654.0a

Miller, G.L.: Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31, 426–428 (1959). https://doi.org/10.1021/ac60147a030

Tsumura, N., Sato, T.: Enzymatic conversion of D-glucose to D-fructose part V: partial purification and properties of the enzyme from Aerobacter cloacae. Agric. Biol. Chem. 29, 1123–1128 (1965)

Nakamura, M.: Determination of fructose in the presence of a large excess of glucose Part V: A modified cysteine-carbazole reaction. Agric. Biol. Chem. 32, 701–706 (1968)

Anisha, G.S., Prema, P.: Cell immobilization technique for the enhanced production of α-galactosidase by Streptomyces griseoloalbus. Bioresour. Technol. 99, 3325–3330 (2008). https://doi.org/10.1016/J.BIORTECH.2007.08.023

Hall, T.A.: BIOEDIT: a user-friendly biological sequence alignment editor and analysis program for Windows 95/98/ NT. Nucleic Acids Symp. Ser. 41, 95–98 (1999)

Kumar, S., Stecher, G., Tamura, K.: MEGA7: Molecular evolutionary genetics analysis version 7.0 for bigger datasets. Mol. Biol. Evol. 33, 1870–1874 (2016). https://doi.org/10.1093/molbev/msw054

Rawashdeh, R., Saadoun, I., Mahasneh, A.: Effect of cultural conditions on xylanase production by Streptomyces sp. (strain Ib 24D) and its potential to utilize tomato pomace. Afr. J. Biotechnol. 4, 251–255 (2005)

Maciel, G.M., Vandenberghe, L.P.D.S., Haminiuk, C.W.I., Fendrich, R.C., Bianca, B.E.D., Da Silva Brandalize, T.Q., Pandey, A., Soccol, C.R.: Xylanase production by Aspergillus niger LPB 326 in solid-state fermentation using statistical experimental designs. Food Technol. Biotechnol. 46, 183–189 (2008)

Techapun, C., Charoenrat, T., Watanabe, M., Sasaki, K., Poosaran, N.: Optimization of thermostable and alkaline-tolerant cellulase-free xylanase production from agricultural waste by thermotolerant Streptomyces sp Ab106, using the central composite experimental design. Biochem. Eng. J. 12, 99–105 (2002). https://doi.org/10.1016/S1369-703X(02)00047-5

Chou, C.C., Ladisch, M.R., Tsao, G.T.: Studies on glucose isomerase from a Streptomyces species. Appl. Environ. Microbiol. 32, 489–493 (1976)

Chanitnun, K., Pinphanichakarn, P.: Glucose(xylose) isomerase production by Streptomyces sp CH7 grown on agricultural residues. Braz. J. Microbiol. 43, 1084–1093 (2012). https://doi.org/10.1590/S1517-83822012000300035

Muhyaddin, M., Jabur, H., Dalaly, B.: Production of glucose isomerase from local isolate of Streptomyces sp. HM52-Optimization of enzyme production conditions by submerged cultures. J. Res. Diyala Humanit 31, 11–32 (2008)

Akhavan Sepahy, A., Ghazi, S., Akhavan Sepahy, M.: Cost-effective production and optimization of alkaline xylanase by indigenous Bacillus mojavensis AG137 fermented on agricultural waste. Enzyme Res. 2011, 593624 (2011). https://doi.org/10.4061/2011/593624

Khusro, A., Kaliyan, B.K., Al-Dhabi, N.A., Arasu, M.V., Agastian, P.: Statistical optimization of thermo-alkali stable xylanase production from Bacillus tequilensis strain ARMATI. Electron. J. Biotechnol. 22, 16–25 (2016). https://doi.org/10.1016/j.ejbt.2016.04.002

Dhungel, B., Subedi, M., Tiwari, K.B., Shrestha, U.T., Pokhrel, S., Agrawal, V.P.: Thermostable glucose isomerase from psychrotolerant Streptomyces species. Int. J. Life Sci. 1, 6–10 (2009). https://doi.org/10.3126/ijls.v1i0.2300

Walsh, G.: Proteins: Biochemistry and Biotechnology, p. 547. Wiley, New York (2002)

Jia, D.X., Zhou, L., Zheng, Y.G.: Properties of a novel thermostable glucose isomerase mined from Thermus oshimai and its application to preparation of high fructose corn syrup. Enzyme Microb. Technol. 99, 1–8 (2017). https://doi.org/10.1016/J.ENZMICTEC.2017.01.001

Grant, C.L., Pramer, D.: Minor element composition of yeast extract. J. Bacteriol. 84, 869–870 (1962)

Givry, S., Duchiro, F.: Optimization of culture medium and growth conditions for production of L-arabinose isomerase and D-xylose isomerase by Lactobacillus bifermentans. Mikrobiologiia. 77, 324–330 (2008). https://doi.org/10.1134/S0026261708030053

El-Dein, N., Nour El-Dein, M.M., Eldyme, A., Shereif, A., Mansour, F.A., Abou-Dobara, M.I., Ball, A.S.: Optimization of xylanase and peroxidase production from Streptomyces sp. K37. J. Biosci. Biotechnol. 3, 29–42 (2014)

Li, Y., Liu, Z., Zhao, H., Xu, Y., Cui, F.: Statistical optimization of xylanase production from new isolated Penicillium oxalicum ZH-30 in submerged fermentation. Biochem. Eng. J. 34, 82–86 (2007). https://doi.org/10.1016/J.BEJ.2006.11.011

Knob, A., Beitel, S.M., Fortkamp, D., Terrasan, C.R.F., de Almeida, A.F.: Production, purification, and characterization of a major Penicillium glabrum xylanase using Brewer’s spent grain as substrate. Biomed. Res. Int. 2013, 728735 (2013). https://doi.org/10.1155/2013/728735

Guan, G.-Q., Zhao, P.-X., Zhao, J., Wang, M.-J., Huo, S.-H., Cui, F.-J., Jiang, J.-X.: Production and partial characterization of an alkaline xylanase from a novel fungus Cladosporium oxysporum. Biomed. Res. Int. 2016, 4575024 (2016). https://doi.org/10.1155/2016/4575024

Bharathiraja, S., Suriya, J., Krishnan, M., Manivasagan, P., Kim, S.-K.: Production of enzymes from agricultural wastes and their potential industrial applications. In: Advances in Food and Nutrition Research, pp. 125–148. Academic Press, Washington, DC (2017)

Kanimozhi, K., Nagalakshmi, P.K.: Xylanase production from Aspergillus niger by solid state fermentation using agricultural waste as substrate. Int. J. Curr. Microbiol. Appl. Sci. 3, 437–446 (2014)

Bhasin, S.: Modi, H: Optimization of fermentation medium for the production of glucose isomerase using Streptomyces sp. SB-P1. Biotechnol. Res. Int. 2012, 1–10 (2012). https://doi.org/10.1155/2012/874152

Abdel-rassol, T.M., Badr, S.A., Omran, H.T.: Glucose (xylose) isomerase production from thermotolerant and thermophilic bacteria. Afr. J. Biotechnol. 11, 15798–15801 (2012). https://doi.org/10.5897/AJB12.2210

Habeeb, S., Yazaji, S., Al-Amir, L.: Optimization of glucose isomerase production from Streptomyces sp. SH10 using the response surface methodology. Int. Food Res. J. 23, 756–761 (2016)

Chen, W.P., Anderson, A.W., Han, Y.W.: Production of Glucose isomerase by Streptomyces flavogriseus. Appl. Environ. Microbiol. 37, 324–331 (1979)

Kumakura, M., Yoshida, M., Kaetsu, I.: Immobilization of glucose isomerase-containing Streptomyces phaeochromogenes cells in fine-particle form. Appl. Environ. Microbiol. 37(2), 310–315 (1979)

Mukhopadhyay, S., Majumdar, S.K.: Immobilization of whole cells of Streptomyces kanamyceticus containing glucose isomerase by a combination of heat treatment in the presence of minerals and entrapment in calcium alginate gels. Folia Microbiol. 41, 502–504 (1996)

Kierstan, M., Bucke, C.: The immobilization of microbial cells, subcellular organelles, and enzymes in calcium alginate gels. Biotechnol. Bioeng. 19, 387–397 (1977). https://doi.org/10.1002/bit.260190309

Looby, D., Griffiths, B.: Immobilization of animal cells in porous carrier culture. Trends Biotechnol. 8, 204–209 (1990). https://doi.org/10.1016/0167-7799(90)90177-Y

Pilkington, P.H.: Food bioconversions and metabolite production. In: Applications of Cell Immobilisation Biotechnology, pp. 321–335. Springer, Berlin (2005)

Jobanputra, A.H., Karode, B.A., Chincholkar, S.B.: Calcium alginate as supporting material for the immobilization of rifamycin oxidase from Chryseobacterium species. Biotechnol. Bioinf. Bioeng. 1, 529–535 (2011)

Zhu, Y.: Immobilized cell fermentation for production of chemicals and fuels. In: Bioprocessing for Value-Added Products from Renewable Resources, pp. 373–396. Elsevier (2007)

Angelova, M., Sheremetska, P., Lekov, M.: Enhanced polymethylgalacturonase production from Aspergillus niger 26 by calcium alginate immobilisation. Process Biochem. 33, 299–305 (1998). https://doi.org/10.1016/S0032-9592(97)00070-8

Bernardi, N.S., Blanco, K.C., Contiero, J.: Reutilization of microbial cells for production of cyclodextrin glycosyltransferase enzyme. Res. J. Microbiol. 12, 229–235 (2017). https://doi.org/10.3923/jm.2017.229.235

Ellaiah, P., Prabhakar, T., Ramakrishna, B., Taleb, A.T., Adinarayana, K.: Production of lipase by immobilized cells of Aspergillus niger. Process Biochem. 39, 525–528 (2004). https://doi.org/10.1016/S0032-9592(01)00340-5

Sigoillot, C., Lomascolo, A., Record, E., Robert, J., Asther, M., Sigoillot, J.: Lignocellulolytic and hemicellulolytic system of Pycnoporus cinnabarinus: Isolation and characterization of a cellobiose dehydrogenase and a new xylanase. Enzyme Microb. Technol. 31, 876–883 (2002). https://doi.org/10.1016/S0141-0229(02)00208-9

Mukesh Kumar, D.J., Silambarasan, T., Renuga, R., Ravi Kumar, M., Karthigai Devi, S., Ramamurthy, D., Kalaichelvan, P.T.: Production, optimization and characterization of α-amylase and glucose isomerase producing Bacillus megaterium BPTK5 from cassava waste. Eur. J. Exp. Biol. 2, 590–595 (2012)

Nobel, R., Pandidurai, S., Kalaichelvan, P.T., Kumar, D.J.M., Gnanaraj, M.: Production of extracellular glucose isomerase by Enterobacter agglomerans isolated from garden soil. Int. J. Curr. Res. 3, 21–25 (2011)

Liu, X., Kokare, C.: Microbial enzymes of use in industry. In: Biotechnology of Microbial Enzymes, pp. 267–298. Elsevier (2017)

Talamantes, D., Biabini, N., Dang, H., Abdoun, K., Berlemont, R.: Natural diversity of cellulases, xylanases, and chitinases in bacteria. Biotechnol. Biofuels 9, 133 (2016). https://doi.org/10.1186/s13068-016-0538-6

Berlemont, R., Martiny, A.C.: Genomic potential for polysaccharide deconstruction in bacteria. Appl. Environ. Microbiol. (2015). https://doi.org/10.1128/AEM.03718-14

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sharma, H.K., Xu, C.(. & Qin, W. Isolation of Bacterial Strain with Xylanase and Xylose/Glucose Isomerase (GI) Activity and Whole Cell Immobilization for Improved Enzyme Production. Waste Biomass Valor 12, 833–845 (2021). https://doi.org/10.1007/s12649-020-01013-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-020-01013-5