Abstract

Enzymatic deramnosylation of flavonoids is a convenient tool for improving the quality of citrus juices. α-L-rhamnosidase with a specific activity of 33.1 units/mg was isolated and characterized from the culture liquid of Penicillium tardum. The molecular weight of the enzyme was 95 kDa according to the data of gel filtration on Sepharose 6B and gel electrophoresis in SDS-PAGE. The pH optimum of the enzyme activity was 5.0, and the thermo optimum was 60 °C. Enzyme showed high stability in the temperature range of 45–50 and at 60–70 °C. It retained 80 to 50% of the initial activity for 90 min. The half-life of α-L-rhamnosidase at 70 °C increased twofold in the presence of 20–40% glycerol and 2.3-fold in the presence of 4 M sorbitol. The enzyme was completely inhibited in the presence of 10−3 M Ag+ and Cd2+ and approximately by 90% in the presence of Fe2+, Fe3+, and Al3+ ions. More than 60%, the enzyme activity was inhibited by Hg2+, Co2+, and 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide methiodide. Activating effect of Ca2+ ions was also noted. Km and Vmax for the hydrolysis of p-nitrophenyl-α-L-rhamnopyranoside and naringin were 0.7 mM and 38.3 µM/min/mg and 1.34 mM and 43.7 µM/min/mg, respectively. Penicillium tardum α-L-rhamnosidase hydrolyzed naringin, neohesperidin, hesperidin, rutin, and narirutin at high rate, which allowed us to consider it as an effective tool for transformation of bioflavonoids in food industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Plant flavonoids have long been widely present in the human diet. They can be found in fruits and vegetables as flavonols, flavonones, and their glycosides. The most common flavonoids include quercetin and its glycosyl rutin, isorhamnetin and its glycoside narcissin, and naringenin and its glycosides prunin and naringenin [1]. Biological properties of these compounds are very diverse, and they have anti-inflammatory, antioxidant, antimutagenic, antiproliferative, and antiatherogenic effects [2]. Also, flavonoids are used in the treatment of neurodegenerative and cardiovascular diseases [3].

Glycosylated forms of flavonoids often have limited bioavailability and activity compared to deglycosylated ones [4, 5]. Removal of the carbohydrate component of such compounds (rhamnose, glucose, rutinose, neohesperidoside) improves their digestibility and active influence on the human body [6]. To facilitate recovery of active flavonoids, various enzymes are used: α-L-rhamnosidases, β-glucosidases, and naringinases [7,8,9,10]. α-L-rhamnosidase (α-L-rhamnoside rhamnohydrolase, EC 3.2.1.40) cleaves terminal non-reducing α-1,2, α-1,4, and α-1,6-linked L-rhamnose residues from a wide range of rhamnoglycosides, rhamnolipids, and glycoconjugates. Highly purified enzyme preparations with α-rhamnosidase activity can be used in various food industries to obtain high-quality raw materials and dietary products [5]. The use of α-L-rhamnosidase to release aromatic compounds from terpene glycosides (rutinosides) enhances the aroma of grape juices and wines, and derhamnosylation of flavonoid glycosides improves the quality of fruit juices and purees [10, 11]. The ability of α-L-rhamnosidase to modify the bitter component naringin (naringenin-7-neohesperidoside) into the sweeter prunin (naringenin-7-O-glucoside) has been used to eliminate bitterness in citrus juices. Enzymatic deglycosylation of hesperidin (hesperetin-7-rutinoside) avoids crystallization during the production of orange and tangerine juices [13]. The use of α-L-rhamnosidases for the processing of green tea, berry, and vegetable juices makes possible to obtain functional drinks with a high content of bioavailable glucoside flavonoids [14].

α-L-rhamnosidase is found in different groups of organisms: bacteria, fungi, higher plants, and animals [15,16,17,18,19,20]. Bacteria and fungi are known to be the most technologically advanced sources of α-L-rhamnosidases, since they are able to multiply extremely quickly and synthesize extracellular metabolites, making production at scale economical. Active α-L-rhamnosidases producers are described among many representatives of the micromycete genera Aspergillus and Penicillium [8, 12, 21,22,23,24,25,26]. Previously, the glycosidase activity of 135 strains of the genus Penicillium was studied, and a culture of Penicillium tardum 3024 with high extracellular rhamnosidase activity was isolated [27]. The selected strain, in addition to high α-L-rhamnosidase activity, favorably differentiates from other tested strains by a relatively narrow spectrum of other glycosidases and insignificant proteolytic activity.

The aim of this work was to obtain purified α-L-rhamnosidase from P. tardum, to study its properties and substrate specificity, and to evaluate feasibility of its use in the food industry.

Materials and Methods

Strain, Medium, and Growth Conditions

P. tardum 3054, from the collection of living cultures of the D. K. Zabolotny Institute of Microbiology and Virology NAS of Ukraine, was grown in medium containing (g/l) 5.0 rhamnose, 2.0 yeast autolysate, 1.0 KH2PO4, 0.5 MgSO4·7H2O, 0.5 KCl, and 0.015 FeSO4·7H2O. pH of the liquid medium was adjusted to 5.0, and culture was incubated at 25 °C in an orbital shaker at 220 rpm for 5 days until the maximum of L-rhamnosidase activity was achieved.

Enzyme Activity Assays

α-L-rhamnosidase, β-D-glucosidase, β-D-galactosidase, and β-N-acetylglucosaminidase activities were determined using as a substrate p-nitrophenyl-α-L-rhamnopyranoside (p-NPRham), p-nitrophenyl-β-D-glucopyranoside (p-NPGlu), p-nitrophenyl-β-D-galactopyranoside (p-NPGal), and p-nitrophenyl-β-N-acetylglucosaminide (p-NPNAcGlu), respectively (Sigma-Aldrich, USA) [28]. To determine the activity, 0.1 ml of the enzyme solution was mixed with 0.2 ml 0.1 M phosphate-citrate buffer (PCB) pH 5.0 and 0.1 ml 0.01 M substrate solution in PCB. Reaction mixture was incubated for 10 min at 40 °C. The reaction was stopped by adding 2 ml of 1 M sodium bicarbonate. The amount of released nitrophenol as a result of hydrolysis was determined colorimetrically by the absorption at 400 nm. One unit of enzyme activity was defined as the amount of enzyme that releases 1 µmol of p-nitrophenol per min at 40 °C in 0.1 M PCB, pH 5.0.

Enzyme Isolation and Purification

Culture filtrate of P. tardum grown on rhamnose for 5 days was mixed with ammonium sulfate to achieve final concentration of 90% saturation. The mixture was incubated for 24 h at 4 °C followed by centrifugation at 3.5 × g, 30 min, 4 °C. Precipitate was removed and dissolved in 3 M ammonium sulfate (threefold of volume). 0.01 M of sodium azide was added for conservation. Precipitate resulted from fractionating with ammonium sulfate was dialyzed against 10 mM phosphate buffer (pH 6.0). The dialyzed enzyme solution was applied to an Toyopearl HW-60 (“TOSON,” Japan) column (2.5 × 65 cm), equilibrated with 0.01 M phosphate buffer, pH 6.0. Fraction exhibiting α-L-rhamnosidase activity was collected and concentrated by evaporating under vacuum. The resultant preparation was applied to Toyopearl DEAE-650 M (“TOSON,” Japan) column (3 × 45 cm), equilibrated with 0.01 M Tris–HCl buffer, pH 7.0. Elution was performed by the NaCl linear gradient (0–1 M, of 300 ml each) at 20 ml/h rate. Collected fractions were screened for protein content (A280) and α-L-rhamnosidase activity. Active fractions (67-82 fractions; 0.8-ml fractions) were combined and dialyzed against 0.1 M PCB, pH 5.0, and the dialysate was used as the purified enzyme throughout this study. For dialysis, membrane tubing Spectra/Por 3 Dialysis Membranes, MWCO 3500 was used at all stages.

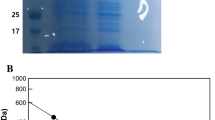

Molecular Weight Determination

Determining of the enzyme molecular weight (MW) in the native system was performed by the gel filtration on the column (1.3 × 50 cm) with Sepharose 6B. Elution was performed by the 0.01 M phosphate buffer (pH 5.0) with 0.1 M NaCl. Standard curve for MW calculations was plotted using high-molecular protein markers (“Pharmacia,” Sweden): ribonuclease (13.7 kDa), proteinase K (25 kDa), ovalbumin (43 kDa), and bovine serum albumin (67 kDa). Sodium dodecyl sulfate (SDS)-denatured proteins were separated by electrophoresis (Phast-System; Pharmacia, Uppsala, Sweden) on commercially available polyacrylamide gels (Pharmacia, Uppsala, Sweden) and were stained with a 0.1% Coomassie Brilliant Blue R-250 (Sigma-Aldrich, USA). The protocols for the separation methods and gels are described by the manufacturer’s instructions (Phast-System; Pharmacia, Uppsala, Sweden). For MW estimation was used PageRuler Plus Protein Molecular Weight Marker (10–250 kDa (Thermo Scientific).

Enzyme Characterization

The optimum pH for the activities of α-L-rhamnosidase was determined by incubating the enzyme preparation with p-NPRham in 0.1 M citrate, PCB, and 0.01 M Tris–HCl buffers at the pH range from 2 to 9. The pH stability was evaluated by preincubation of the enzymes in PCB over a pH range from 4 to 6 at 40 °C. Activities were measured at 24 h using the standard protocol. The optimum temperature of α-L-rhamnosidase was determined by incubating the assay mixture for 30 min at temperature ranging from 5 to 80 °C. Thermal stability was measured by preincubation of the enzymes at the optimum pH at different temperatures (30, 40, 50, 60, 65, 70, and 75 °C) with the exposition time of 210 min.

Thermal inactivation of α-L-rhamnosidase was studied at 60–75 °C, pH 5.0 (0.1 M PCB). The enzyme samples (8 U/ml) in 3 ml of the appropriate buffer were kept at given temperature for 30–210 min; the aliquots in 0.1 ml were collected in definite intervals (10–30 min) for measurement of residual activity. Enzyme treatment with glycerol and sorbitol was carried out as follows: to 5–40% glycerol or 0.1–5.0 M sorbitol in 0.1 M PCB was added enzyme solution (8 U/ml) and the mixture was incubated at room temperature for 60 min. Thermal inactivation was carried out as described above. Half-life was calculated from the first-order rate constants of inactivation, which were obtained from linear regression in logarithmic coordinates.

Enzyme treatment with glutaraldehyde was carried out as follows: 10, 20, 30, 40, and 50 μl of 25% glutaraldehyde solution was added to 1 ml of the purified enzyme solution (8 U/ml), and the mixture was incubated at room temperature for 60 min. The remaining reagent was removed by gel filtration on Sepharose 6B. Thermal inactivation was carried out at 70 °C as described above.

Effect of Various Reagents on the Enzyme Activities

The effects of various chemical reagents and cations (EDTA, o-phenanthroline, dithiothreitol, L-cysteine, β-mercaptoethanol, p-Chlormercuribenzoate, N-ethylmaleimide, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide methiodide, Ag+, Hg2+, Cd2+, Ca2+, Co2, Pb2+, Fe2+, Fe3+, Al3+) on enzyme activity were investigated by their incorporation at a concentration of 0.01 M in standard assay. Reactions were carried out for 60 min at 40 °C and pH 5.0 (0.1 M PCB) in the presence or absence of the compounds examined.

Kinetic Characteristics of Enzyme

Kinetic experiments were carried out at 37 °C at the pH 5.0. The maximum rate (Vmax) and Michaelis constant (Km) were determined according to Lineweaver–Burk from curves defining dependence of the enzyme reaction rate on the p-NPRham or naringin level (from 0.1 to 8 mM). Inhibition studies were performed using L-rhamnose at concentrations ranging from 1 to 10 mM.

Substrate Specificity

Naringin, rutin, neohesperidin, hesperidin, and narirutin (0.5–1 mM), the five flavonoids, and synthetic p-nitrophenyl substrates p-NPRham, p-NPGlu, p-NPGal, and p-NPNAcGlu (1 mM) were used to find the α-L-rhamnosidase substrate specificity. One milliliter of diluted enzyme solution (3 U) was incubated with 1.0 mL of 1 mg/mL substrate (naringin, neohesperidin, and p-nitrophenyl-α-L-rhamnopyranoside) buffered with 0.1 M PCB (pH 5.0). The above assay mixture was incubated at 40 °C for 60 min followed by measuring the changes in the concentration of substrates by HPLC. Hydrolysis efficiency (%) is the residual concentration of substrates after enzymatic hydrolysis.

Enzymatic Hydrolysis of Citrus Juice

Grapefruit, pomelo, orange, and mandarin juice samples were obtained from fresh fruits. The juice samples were extracted and filtrated to remove the seeds and pomaces. Stock solution of flavonoids (naringin, rutin, narirutin, neohesperidin, hesperidin, and naringenin) was prepared at a concentration of 1 mg/ml by dissolving in 50% aqueous ethanol. Enzyme solutions were prepared by dissolving α-L-rhamnosidase in 0.1 M PCB (pH 5.2) at a concentration of 2 mg/ml. 0.1 ml of an enzyme solution was added to 2 ml of the juice sample. The reaction was performed at 40 °C and 50 °C for 60 min. After reaction, 1 ml juice or hydrolyzed sample was pipetted and vigorously mixed with 1 ml anhydrous ethanol. The mixture was then centrifuged at 6 × g for 10 min. The collected supernatant (1 ml) was filtered through a 0.45-µm nylon membrane and further analyzed by HPLC. Standard curve was plotted using different flavonoids.

HPLC Analysis

An Agilent 1200 HPLC coupled with a Zorbax SB C18 reverse phase column (2.5 × 150 mm, 3.5 μm) and diode-matrix detector was used for analysis. The mobile phase was acetonitrile–water (25:75, v/v) programmed at a flow rate of 0.3 ml/min, the injection volume was 3 µL, and the column was at ambient temperature. Naringin, rutin, neohesperidin, hesperidin, and narirutin in samples were detected at 280 nm and identified by comparison of retention times with standard.

Statistical Analysis

All experiments were replicated 3–5 times. Data are expressed as mean ± SD. Analysis of the data was done using Student’s t-criterion. Values were considered significant at p < 0.05.

Results and Discussion

Purification and Characterization of Enzyme

An α-L-rhamnosidase preparation was isolated from the supernatant of the culture liquid of P. tardum micromycete. The main stages of purification are presented in Table S1. As a result of 27-fold purification, a protein fraction of α-L-rhamnosidase with specific activity of 33.1 U/mg of protein was obtained. The purified preparation lacked β-glucosidase, β-galactosidase, and β-N-acetylglucosaminidase activities, which were noted at the initial stages of purification. On the electrophoregram in the SDS-PAGE system, there was one band with MW 95 kDa (Fig. S1). The molecular weight of α-L-rhamnosidase, obtained on the basis of gel filtration data on Sepharose 6B, was also 95 kDa. Based on these results, a conclusion can be drawn about the monomeric structure of the resulting enzyme. Most of the registered MW for fungal α-L-rhamnosidases is also in the range of 40–100 kDa. Thus, Aspergillus clavatonanicus MTCC-9611 α-L-rhamnosidase purified on CM-cellulose was represented by one subunit with MW 82 kDa [21]. The MW of a homogeneous preparation of Aspergillus niger DLFCC-90 α-L-rhamnosidase was 66 kDa [26], native α-L-rhamnosidase of Aspergillus terreus 98 kDa [24], Aspergillus kawachii 90 kDa [29], and Aspergillus tubingensis 110 kDa [12]. The extracellular α-rhamnosidase of Pichia augusta, obtained as a result of a 4-step purification, also had an Mm of 90 kDa [15]. In deglycosylated α-L-rhamnosidase of Aspergillus oryzae, MW was set at 60 kDa, while for the glycosylated form, MW was 90–130 kDa [23].

Thermal and pH-Stability

The pH optimum for micromycete α-L-rhamnosidases is usually in the acidic region. Thus, it was shown that for the majority of α-L-rhamnosidases from different Aspergillus species, the pH optimum was in the range of 4.0–5.0 [12, 16, 23, 26, 29]. α-L-rhamnosidases are also described for which the pH optimum is shifted to the neutral and slightly alkaline region, as in A. terreus with a pH optimum of 6–8 [8, 24]. There are also data on alkaline tolerant α-L-rhamnosidases of A. clavato-nanicus MTCC-9611 and Fusarium moniliforme MTCC-208 with a pH optimum of 10.0 and 10.5 [6, 21]. For P. tardum α-L-rhamnosidase, it was shown that the pH optimum of activity is at 5.0 (Fig. 1a), and in the pH range of 4.0–6.0 at 37 °C, the enzyme retains activity at the level of 90–100% for 300 min and at 20 °C more than 48 h.

P. tardum α-L-rhamnosidase has a rather high thermal optimum of 60 °C (Fig. 1b). Close values of thermo optimums have also been shown for a number of α-L-rhamnosidases from other mesophilic micromycetes, for example, Trichoderma longibrachiatum, A. kawachii, Penicillium aurantiogriseum, A. tubingensis, and A. oryzae [8, 12, 16]. Higher indicators of thermal optimums are noted only for enzymes of thermophilic bacteria and fungi. So, in α-L-rhamnosidase of the thermophilic bacterium Dictyoglomus thermophilum [10] with an activity range of 37–95 °C, the thermo optimum is at 95 °C and in Thermotoga maritima MSB8 at 86.5 °C [17].

P. tardum α-L-rhamnosidase retained up to 100% activity for 3 h in the temperature range from 45 to 55 °C at pH 4.0–6.0 and for 90 min retained from 50 to 80% of the initial activity at a temperature of 60–70 °C (Fig. 2). With temperature rise up to 75 °C in 60 min, the activity decreased by 50%, and after 2.5 h of incubation under these conditions, no more than 5% of the initial activity remains. The high stability of proteins in response to the action of various factors of the reaction medium is associated with their structural features. Thermostable enzymes are usually characterized by high hydrophobicity and increased ionic interaction. These properties are ensured by the presence of a high content (more than 30%) of hydrophobic amino acids. The presence of O-linked carbohydrates also contributes to the thermal stabilization of proteins and enzymes in particular.

Thermal stabilization of proteins in the presence of certain chemicals and proteins allows in many cases to increase the half-life of the enzyme and the efficiency of hydrolysis. It was shown that the use of sorbitol and glycerol can reduce the rate of thermal inactivation of the enzyme at 65–75 °C. This effect is especially pronounced in the first 120 min of incubation. The half-life of the enzyme increased from 90 to 180 min in the presence of 20–40% glycerol at 70 °C (Fig. 3a), from 60 to 75 min at 75 °C, and from 90 to 210 min at 70 °C in the presence of 4 M sorbitol (Fig. 3b). The use of polyhydric alcohols to stabilize enzymes is a fairly simple and effective way to stabilize proteins. The exact stabilization mechanism has not been fully studied, but it is speculated that it is implemented at the level of hydrophobic and hydrogen bonds of the protein molecule [30]. Thermal stabilization and of enzymes in the presence of sorbitol was noted for A. terreus α-L-rhamnosidase [8], and half-life of enzyme with addition of 2.0 M sorbitol at 70 °C were increased by 17.2-fold.

a Thermal stability profile of α-L-rhamnosidase with and without different concentration of glycerol at 70 °C, pH 5.0. b Thermal stability of α-L-rhamnosidase with and without 4.0 M of sorbitol incubated at different temperatures ranging from 65 to 75 °C, pH 5.0. Substrate—0.01 M p-NPRham. The mean values and standard errors are shown (n = 4). The percentage of residual activity was calculated by comparing to the non-incubated enzyme

It was also shown that treatment of the protein with glutaraldehyde at a concentration of 10–40 µl contributed to an increase in the thermal stability of P. tardum α-L-rhamnosidase (Fig. S2). The formation of cross-links between amino groups of a protein with the help of glutaraldehyde can lead to the fixation of the active conformation of the molecule and the formation of aggregates with increased stability compared to native enzymes, which was shown for α-L-rhamnosidase Brevundimonas sp. Ci19 [11], naringinase A. niger [31], and other hydrolytic enzymes [32].

The obtained data on the high stability of P. tardum α-L-rhamnosidase in the range from 45 to 60 °C at neutral and slightly acidic pH is a strong argument in favor of the feasibility of further use of this enzyme preparation in the food industry. Observed thermal stabilization of the enzyme in the presence of sorbitol and glycerol, as well as after treatment with glutaraldehyde, indicates the possibility of obtaining industrial preparations of prolonged action on its basis.

Inhibition of α-L-rhamnosidase by Several Chemical Compounds

The influence of certain metal cations and chemical compounds on the activity of P. tardum α-L-rhamnosidase was studied. It was shown that chelating agents at a concentration of 10−3 M did not affect the activity of P. tardum α-L-rhamnosidase (Fig. 4), in contrast to Lactobacillus plantarum α-L-rhamnosidase, which was activated by 10 mM EDTA and inhibited by 50% 10 mM o-phenanthroline [33]. Reagents that reduce disulfide bonds had different effects on the enzyme. In the presence of β-mercaptoethanol, the activity of the enzyme did not change; however, dithiothreitol activated P. tardum α-L-rhamnosidase by 41%, while L-cysteine inhibited the activity by 32%, which may be due to conformational changes involving sulfide groups (Fig. 4). β-Mercaptoethanol also did not inhibit L-rhamnosidase from A. luteo albus, L. plantarum, and P. angusta [15, 33, 34].

Thiol inhibitors had little effect on P. tardum α-L-rhamnosidase under experimental conditions. At the same time, a significant inactivation (> 60%) of the enzyme was observed under the influence of the carboxyl group modifier 1-[3-(dimethylamino) propyl]-3-ethylcarbodimide method. These data are consistent with those of structural studies of the family GH78 enzymes for which the important role of conserved negatively charged residues Asp and Glu was shown [23, 29].

Inactivation of α-L-rhamnosidase sulfhydryl oxidant metal Hg2+ and p-CMB was observed in enzymes from P. tardum (Fig. 4) and other enzyme from A. oryzae [8], B. thetaiotaomicron [18], P. angusta [15], Bacillus sp. [35], and T. stercorarium [36]. These data may indicate the importance of sulfhydryl groups for maintaining the active conformation and activity of α-L-rhamnosidases from various sources.

A number of metal cations (K+, Li+, Na+, Mg2+, Mn2+, Cu2+, Ba2+) had virtually no effect (loss activity ≤ 5%) on the activity of P. tardum α-L-rhamnosidase. It was shown that Ag+ and Cd2+ ions completely inhibited the activity of the enzyme. Hg2+, Co2+, Pb2+, Fe2+, Fe3+, and Al3+ at concentration of 10–3 M reduced the activity by 60–90% within 60 min. Activity inhibition (by 50–99%) in the presence of Cu2+, Fe2+, Fe 3+, Hg2+, and Ni2+ was shown for alpha-L-rhamnosidase from Bacteroides thetaiotaomicron [18] and A. oryzae [8]. Co2+, Cu2+, Ni2+, and 0.2 mM Zn2+ completely inactivated alpha-L-rhamnosidase from A. alternata [19] and A. luteo albus [34]. 100 mM Fe2+ completely inhibited the enzyme from A. niger, while 10 mM caused activation by 1.1 times [25]. P. angusta α-L-rhamnosidase was also inhibited by Cu2+ and Hg2+ at a concentration of 10−3 M by 89 and 94% [15], and also activation of the enzyme in the presence of Ca2+ by 1.63 times was noted. α-L-rhamnosidase from B. thetaiotaomicron was activated by Ca2+ and Mg2+ by 30 and 26%, respectively [18], and α-L-rhamnosidase A. alternata was activated by 1.35 and 1.2 times by Ba2+ cations and Al3+, respectively [19]. Ca2+, Co2+, and Cu2+ at a concentration of 100 mM activated A. niger α-L-rhamnosidase by 1.4–1.6 fold [25], but did not affect the activity of α-L-rhamnosidase from A. luteo albus [34]. The effect of the Ca2+ cation may be related to the stabilization of the tertiary structure of the described proteins. Forming ionic bonds with two different amino acid residues, Ca2+ ions can act as a stabilizing bridge similar to disulfide bonds. It has also been reported that Ca2+ may bind to conserved residues in the active site of enzymes of the GH106 family [37].

Kinetic Characteristics and Substrate Specificity of P. tardum α-L-rhamnosidase

The kinetic parameters for α-L-rhamnosidase toward naringin and p-NPRham were determined at pH 5.0 and at 37 °C (Table 1). Activity on rhamnosyl flavonoid naringin was high than its enzymatic activity on unnatural rhamnoside. The high catalytic efficiency (kcat/Km) of α-L-rhamnosidase toward p-NPRham was a result of low Km value for this substrate. The Km value of different α-L-rhamnosidases varies in the range of 0.057–2.8 mM and for naringin 0.021–1.9 mM. Similar Km values for p-NPRham were shown for A. terreus rhamnosidase [8]. Inhibition by end-product (L-rhamnose) was also studied. L-rhamnose was found to be a competitive inhibitor of the P. tardum α-L-rhamnosidase, Ki values of 2.5 mM and 4.2 mM when using p-NPRham and naringin as substrates, respectively.

The affinity of α-L-rhamnosidases to different substrates for different enzymes can vary greatly depending on their specificity. The substrate specificity of α-L-rhamnosidase with respect to synthetic substrates and some flavonoids was studied (Fig. 5, Table 2), and a high affinity for natural and synthetic rhamnoglycosides was noted. Thus, α-L-rhamnosidase effectively hydrolyzed naringin, neohesperidin, hesperidin, rutin, narirutin, and p-NPRham. Efficiency of hydrolysis of substrates containing α-1,2-linked rhamnose was the highest under experimental conditions. The rate of hydrolysis of narirutin and hesperidin was slightly lower, but also high, and P. tardum α-L-rhamnosidase hydrolyzed rutin least efficiently. The enzyme showed no activity toward synthetic substrates with β-linked carbohydrates, which indicates the ability to derhamnosylate plant flavonoids, but not completely deglycosylate them.

Thus, based on the data on the substrate specificity of P. tardum α-L-rhamnosidase, it can be concluded that it is highly selective for terminal α-1,2-linked rhamnose. This property of P. tardum α-L-rhamnosidase can be useful in fine studies of the structure of glycosides of various nature, as well as in the production of deglycosylated flavonoids. Deramnosylation of naringin by P. tardum rhamnosidase predominantly results in prunin formation, which is sweeter than naringin and glucosylated naringenin. Enzymes of precisely this specificity are most suitable for removing the bitterness of citrus juices. However, in terms of its ability to hydrolyze rutin, this enzyme is significantly weaker compared to the rhamnosidases from A. niger [8] or Novosphingobium sp. [36].

Degradation of Citrus Juice Flavonoids by P. tardum Rhamnosidase

The presence of flavonoids in citrus fruits can have a significant effect on the quality of citrus juices, especially grapefruit and orange. The use of α-L-rhamnosidase in the production of such juices allows the degradation of flavonoids such as naringin, thereby greatly improving the taste of the product. In Fig. 6, the HPLC chromatograms show results of enzymatic hydrolysis of pomelo, grapefruit, orange, and mandarin juices with P. tardum α-L-rhamnosidase. It was demonstrated that after treatment of grapefruit juice with α-L-rhamnosidase, the concentration of naringin decreased by 84% at 40 °C and 98% at 50 °C after 60 min of incubation (Fig. 6a). A similar pattern was observed after enzyme treatment of pomelo juice samples, with a decrease in the concentration of naringin from 950 to 10.5 µg/ml within 60 min. In both cases, in parallel with the decrease in the concentration of naringin, an increase in the concentration of prunin was observed (Fig. 6b). It was also shown that P. tardum α-L-rhamnosidase actively hydrolyzed narirutin, naringin, and hesperidin in orange and tangerine juice (Fig. 6c,d). By its ability to transform the flavonoids of natural juices, this enzyme is close to α-L-rhamnosidases of A. aculeatus [14] and A. niger [38]. The bioconversion yields, concentrations, and productivities of flavonoid glycosides in this study are high. α-L-rhamnosidase of P. tardum may be useful for the industrial hydrolysis of flavonoids in citrus extracts.

Conclusion

Thus, α-L-rhamnosidase from P. tardum with high biotechnological potential was isolated and characterized. The effectiveness of the use of polyhydric alcohols and modification with glutaraldehyde to increase the stability of the enzyme has been shown. The enzyme’s high thermal stability and broad substrate specificity for α-1,2 and α-1,6-rhamnosylated flavonoids characterize the enzyme as a valuable tool for use in food technologies to improve the quality of citrus juices.

References

Quideau, S., Deffieu, D., Douat-Casassus, C., & Pouysegu, L. (2011). Plant polyphenols: Chemical properties, biological activities, and synthesis. Angewandte Chemie. International Edition, 50, 586–621.

Yadav, V., & Yadav, K. D. S. (2010). New fungal for α-L-rhamnosidase an important enzyme used in the synthesis of drugs and drug precursors. Applied Biochemistry and Microbiology, 48, 295–301.

Valentova, K., Vrba, J., Bancirova, M., Ulrichova, J., & Kren, V. (2014). Isoquercitrin: Pharmacology, toxicology, and metabolism. Food and Chemical Toxicology, 68, 267–282.

Xiao, J. (2017). Dietary flavonoid aglycones and their glycosides: Which show better biological significance? Critical Reviews in Food Science and Nutrition, 57, 1874–1905.

Slamova, K., Kapesova, J., & Valentova, K. (2018). “Sweet flavonoids”: Glycosidase-catalyzed modifications. International Journal of Molecular Sciences, 19, 2126.

Kumar, D., Yadav, S., Yadav, S., & Yadav, K. D. S. (2019). An alkali tolerant alpha-L-rhamnosidase from Fusarium moniliforme MTCC-2088 used in de-rhamnosylation of natural glycosides. Bioorganic Chemistry, 84, 24–31.

Zhang, R., Zhang, B. L., Xie, T., Li, G. C., Tuo, Y., & Xiang, Y. T. (2015). Biotransformation of rutin to isoquercitrin using recombinant α-L-rhamnosidase from Bifidobacterium breve. Biotechnology Letters, 37, 1257–1264.

Ge, L., Chen, A., Pei, J., Zhao, L., Fang, X., Ding, G., Wang, Z., Xiao, W., & Tang, F. (2017). Enhancing the thermostability of α-L-rhamnosidase from Aspergillus terreus and the enzymatic conversion of rutin to isoquercitrin by adding sorbitol. BMC Biotechnology, 17, 21.

Yadav, M., Sehrawat, N., Sharma, A. K., Kumar, V., & Kumar, A. (2018). Naringinase: Microbial sources, production, and applications in food processing industry. Journal of Microbiology, Biotechnology and Food Sciences, 8, 717–720.

Guillotin, L., Kim, H., Traore, Y., Moreau, P., Lafite, P., Coquoin, V., Nuccio, S., De Vaumas, R., & Daniellou, R. (2019). Biochemical characterization of the alpha-L-rhamnosidase DtRha from Dictyoglomus thermophilum application to the selective derhamnosylation of natural flavonoids. ACS Omega, 4, 1916–1922.

Alvarenga, A. E., Amoroso, M. J., Illanes, A., & Castro, G. R. (2014). Cross-linked α-L-rhamnosidase aggregates with potential application in food industry. European Food Research and Technology, 238, 797–801.

Li, L., Gong, J., Wang, S., Li, G., Gao, T., Jiang, Z., Cheng, Y. S., Ni, H., & Li, Q. (2019). Heterologous expression and characterization of a new clade of Aspergillus alpha-L-rhamnosidase suitable for citrus juice processing. Journal of Agriculture and Food Chemistry, 67, 2926–2935.

Terada, Y., Kometanti, T., Nishimurah, K., Taki, I., & Okada, S. (1995). Prevention of hesperidin crystal formation in canned mandarin orange syrup and clarified orange juice by hesperidin glycosides. Food Sci. Technol. Int. T., 1, 29–33.

Gonzalez-Barrio, R., Trindade, L. M., Manzanares, P., de Graaff, L. H., Tomas-Barberan, F. A., & Espin, J. C. (2004). Production of bioavailable flavonoid glucosides in fruit juices and green tea by use of fungal alpha-L-rhamnosidases. Journal of Agriculture and Food Chemistry, 52, 6136–6142.

Yanai, T., & Sato, M. (2000). Purification and characterization of an alpha-L-rhamnosidase from Pichia angusta X349. Bioscience, Biotechnology, and Biochemistry, 64, 2179–2185.

Scaroni, E., Cuevas, C., Carrillo, L., & Ellenrieder, G. (2002). Hydrolytic properties of crude alpha-L-rhamnosidases produced by several wild strains of mesophilic fungi. Letters in Applied Microbiology, 34, 461–465.

Baudrexl, M., Schwarz, W. H., Zverlov, V. V., & Liebl, W. (2019). Biochemical characterisation of four rhamnosidases from thermophilic bacteria of the genera Thermotoga. Caldicellulosiruptor and Thermoclostridium. Sci. Rep., 9, 15924.

Wu, T., Pei, J., Ge, L., Wang, Z., Ding, G., Xiao, W., & Zhao, L. (2018). Characterization of a alpha-L-rhamnosidase from Bacteroides thetaiotaomicron with high catalytic efficiency of epimedin C. Bioorganic Chemistry, 81, 461–467.

Zhang, T., Yuan, W., Li, M., Miao, M., & Mu, W. (2018). Purification and characterization of an intracellular alpha-L-rhamnosidase from a newly isolated strain, Alternaria alternata SK37.001. Food Chemistry, 269, 63–69.

Singh, P., Sahota, P. P., & Singh, R. K. (2015). Evaluation and characterization of new α-L-rhamnosidase-producing yeast strains. Journal of General and Applied Microbiology, 61, 149–156.

Yadav, V., Yadav, S., Yadav, S., & Yadav, K. D. (2012). Alpha-L-rhamnosidase from Aspergillus clavato-nanicus MTCC-9611 active at alkaline pH. Prikladnaia Biokhimiia i Mikrobiologiia, 48, 328–333.

Yadav, S., Yadava, S., & Yadav, K. D. (2017). α-L-rhamnosidase selective for rutin to isoquercitrin transformation from Penicillium griseoroseum MTCC-9224. Bioorganic Chemistry, 70, 222–228.

Ishikawa, M., Shiono, Y., & Koseki, T. (2017). Biochemical characterization of Aspergillus oryzae recombinant α-L-rhamnosidase expressed in Pichia pastoris. Journal of Bioscience and Bioengineering, 124, 630–634.

Pachl, P., Skerlova, J., Simcikova, D., Kotik, M., Krenkova, A., Mader, P., Brynda, J., Kapesova, J., Kren, V., Otwinowski, Z., & Rezacova, P. (2018). Crystal structure of native alpha-L-rhamnosidase from Aspergillus terreus. Acta Crystallographica Section D, 74, 1078–1084.

Li, L., Yu, Y., Zhang, X., Jiang, Z., Zhu, Y., Xiao, A., Ni, H., & Chen, F. (2016). Expression and biochemical characterization of recombinant alpha-L-rhamnosidase r-Rha1 from Aspergillus niger JMU-TS528. International Journal of Biological Macromolecules, 85, 391–399.

Liu, T., Yu, H., Zhang, C., Lu, M., Piao, Y., Ohba, M., Tang, M., Yuan, X., Wei, S., Wang, K., Ma, A., Feng, X., Qin, S., Mukai, C., Tsuji, A., & Jin, F. (2012). Aspergillus niger DLFCC-90 rhamnoside hydrolase, a new type of flavonoid glycoside hydrolase. Applied and Environment Microbiology, 78, 4752–4754.

Gudsenko, O. V., & Varbanets, L. D. (2015). Optimization of cultivation conditions of Penicillium tardum - the α-L-rhamnosidase producer. Mikrobiolohichnyi Zhurnal, 77, 25–31.

Chaplin, M. E., & Kennedy, J. E. (Eds.). (1986). Carbohydrate analysis: A practical approach. Oxford IRL Press.

Koseki, T., Mese, Y., Nishibori, N., Masaki, K., Fujii, T., Handa, T., Yamane, Y., Shiono, Y., Murayama, T., & Iefuji, H. (2008). Characterization of an alpha-L-rhamnosidase from Aspergillus kawachii and its gene. Applied Microbiology and Biotechnology, 80, 1007–1013.

Murakami, S., & Kinoshita, M. (2016). Effects of monohydric alcohols and polyols on the thermal stability of a protein. The Journal of Chemical Physics, 44, 125105.

Awad, G., Abd El Aty, A. A., Shehata, A. N., Hassan, M. E., & Elnashar, M. M. (2016). Covalent immobilization of microbial naringinase using novel thermally stable biopolymer for hydrolysis of naringin. 3 Biotech, 6, 14.

Sandoval-Cardenas, D. I., Reyes-Guzman, E. G., Gracida, J., Rodriguez Morales, J. A., Ramos-Lopez, M. Á., & Amaro-Reyes, A. (2021). Production of combined-cross-linked hemicellulosic enzyme aggregates from paperboard residues. Biologia, 76, 3919–3924.

Avila, M., Jaquet, M., Moine, D., Requena, T., Pelaez, C., Arigoni, F., & Jankovic, I. (2009). Physiological and biochemical characterization of the two alpha-L-rhamnosidases of Lactobacillus plantarum NCC245. Microbiology, 155, 2739–2749.

Rojas, N. L., Voget, C. E., Hours, R. A., & Cavalitto, S. F. (2011). Purification and characterization of a novel alkaline alpha-Lrhamnosidase produced by Acrostalagmus luteo albus. Journal of Industrial Microbiology and Biotechnology, 38, 1515–1522.

Hashimoto, W., Miyake, O., Nankai, H., & Murata, K. (2003). Molecular identification of an alpha-L-rhamnosidase from Bacillus sp strain GL1 as an enzyme involved in complete metabolism of gellan. Archives of Biochemistry and Biophysics, 415, 235–244.

Zverlov, V. V., Hertel, C., Bronnenmeier, K., Hroch, A., Kellermann, J., & Schwarz, W. H. (2000). The thermostable alpha-L-rhamnosidase RamA of Clostridium stercorarium: Biochemical characterization and primary structure of a bacterial alpha-L-rhamnoside hydrolase, a new type of inverting glycoside hydrolase. Molecular Microbiology, 35, 173–179.

Terry, B., Ha, J., Lise, F. D., Mensitieri, F., Izzo, V., & Sazinsky, M. H. (2020). The crystal structure and insight into the substrate specificity of the α-L rhamnosidase RHA-P from Novosphingobium sp. PP1Y. Archives of Biochemistry and Biophysics, 679, 108189.

Ni, H., Xiao, A. F., Cai, H. N., Chen, F., You, Q., & Lu, Y. Z. (2012). Purification and characterization of Aspergillus niger α-L-rhamnosidase for the biotransformation of naringin to prunin. African Journal of Microbiology Research, 6, 5276–5284.

Funding

The work was funded by the National Academy of Science of Ukraine (No. 0113U001217).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Nataliya Borzova, Olena Gudzenko, and Lyudmila Varbanets. The first draft of the manuscript was written by Nataliya Borzova, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Borzova, N., Gudzenko, O. & Varbanets, L. α-L-rhamnosidase from Penicillium tardum and Its Application for Biotransformation of Citrus Rhamnosides. Appl Biochem Biotechnol 194, 4915–4929 (2022). https://doi.org/10.1007/s12010-022-04008-1

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-022-04008-1