Abstract

In this study, bioethanol was produced from the seaweed Gelidium amansii as biomass through separate hydrolysis and fermentation (SHF) processes. The SHF processes examined in this study include thermal acid hydrolysis pretreatment, enzymatic saccharification, detoxification, and fermentation. Thermal acid hydrolysis pretreatment was conducted using H2SO4, with a slurry content of 8–16% and treatment time of 15–75 min. The optimal conditions for thermal acid hydrolysis pretreatment were 12% (w/v) seaweed slurry content and 180 mM H2SO4 at 121 °C for 45 min, at which 26.1 g/L galactose and 6.8 g/L glucose were produced. A monosaccharide (mainly glucose) was also obtained from the enzymatic saccharification of thermal acid hydrolysate using 16 U/mL Celluclast 1.5 L enzyme at 45 °C for 36 h. Detoxification was performed using the adsorption method with activated carbon, the overliming method with Ca (OH)2, and the ion exchange method with polyethyleneimine. Among those detoxification methods, activated carbon showed the best performance for hydroxymethylfurfural removal. Ethanol fermentation was performed using 12% (w/v) seaweed hydrolysate with Saccharomyces cerevisiae adapted to galactose as well as various detoxification treatments.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Seaweed, which is among the most abundant raw materials on Earth, comprises green, red, and brown types. Of these, red seaweed is known as a potential substrate for the production of value-added products such as agar [1] and K-carrageenan [2], which are used to produce pharmaceuticals, cosmetics, and culture media for laboratory microorganisms and other purposes. Major carbohydrates of red seaweed are carrageenan, agar, and glucans such as floridean starch and cellulose that provides monosaccharides for ethanol fermentation following hydrolysis [3].

Hydrolysis yield can be enhanced by various pretreatment techniques [4]. For economic reasons, thermal acid hydrolysis is usually used to hydrolyze seaweed and enhance cellulose accessibility for subsequent enzymatic saccharification [5]. However, a considerable number of inhibitors, such as phenolic compounds, furfural, aliphatic acids, and hydroxymethylfurfural (HMF), are generated during thermal acid hydrolysis; these in turn affect microbial fermentation [6]. The HMF has been known as a main inhibitor of red seaweed hydrolysates for ethanol fermentation [7]. Therefore, hydrolysate detoxification is required prior to ethanol fermentation. Detoxification by activated carbon is a cost-effective method with high capacity to absorb inhibitors without affecting hydrolysate monosaccharides levels [8]. Overliming is a promising lignocellulosic hydrolysate detoxification method [9], in which toxic components are precipitated and inhibitors destabilized at high pH [10]. The ion exchange method is one of the most efficient detoxification methods for removing inhibitors, and significantly improves fermentation yield [11].

In this study, we used Gelidium amansii as a substrate for ethanol production through thermal acid hydrolysis pretreatment and enzymatic saccharification. Detoxification was performed using the adsorption method with activated carbon, the overliming method with Ca (OH)2, and the ion exchange method with polyethyleneimine (PEI). Ethanol fermentation of detoxified G. amansii hydrolysates was carried out using wild-type (WT) Saccharomyces cerevisiae and S. cerevisiae adapted to high concentrations of galactose through adaptive evolution.

Materials and Methods

Source and Composition Analysis

G. amansii was purchased from the Gijang fisheries market in Busan, Korea. The seaweed was dried in sunlight, ground in a hammer mill, and sieved through a 45-mesh (0.35-mm) sieve prior to pretreatment. The determination of G. amansii composition was carried out by the Feed and Foods Nutrition Research Center at Pukyong National University in Busan, Korea, following a protocol of the Association of Official Analytical Chemists (AOAC) [12].

Optimization of Thermal Acid Hydrolysis Pretreatment and Enzymatic Saccharification

The optimization of thermal acid hydrolysis pretreatment of G. amansii was carried out using the one-factor-at-a-time method. The thermal acid hydrolysis conditions were optimized in terms of seaweed slurry content (8–16%, w/v), H2SO4 concentration (90–450 mM), and thermal acid hydrolysis time (15–75 min). The experiment was performed at 121 °C. G. amansii hydrolysate was adjusted to pH 5 using 10 N NaOH. After thermal acid hydrolysis pretreatment, high-performance liquid chromatography (HPLC) (1100 Series; Agilent Technologies, Santa Clara, CA, USA) was used for determination of the sugar concentrations of each sample. The efficiency was calculated using Eq. (1) as follows:

where Ep is the thermal acid hydrolysis pretreatment efficiency (%), ΔSmono is the increase in glucose and galactose (g/L) during the experiment, and TC is the concentration of total carbohydrate (g/L) of G. amansii.

Optimization of enzymatic saccharification of G. amansii was evaluated. Celluclast 1.5 L (854 endoglucanase units/mL; Novozymes, Bagsværd, Denmark) was used to hydrolyze the fiber. Celluclast 1.5 L (16 U/mL) was added to 120 g/L of G. amansii slurry following thermal acid hydrolysis pretreatment at pH 5.0, 45 °C, and 150 rpm for 0–48 h. Celluclast 1.5 L contains cellulase, which hydrolyzes the β(1, 4)-d-glucosidic linkages of cellulose and other β-d-glucans. We determined β-glucosidase and cellulase activities following the methods of Mandels et al. [13] and Kubicek et al. [14]. The efficiency was calculated using Eq. (2) as follows:

where Eps is the thermal acid hydrolysis pretreatment and enzymatic saccharification efficiency (%) and ΔSmono is the increase in glucose and galactose (g/L).

Removal of HMF Using Various Methods

Activated carbon (Duksan Pure Chemical Co., Ltd., Ansan, Korea) was used to remove HMF from G. amansii hydrolysates following enzymatic saccharification. The adsorption surface areas of the active carbon used were 1400–1600 m2/g. These experiments were conducted using a 250-mL flask with a working volume of 100 mL hydrolysate containing 0, 1, 2, 3, 4, or 5% activated carbon. The experiments were carried out in a shaking water bath at 100 rpm and 50 °C for adsorption times of 0, 1, 2, 3, 4, 5, and 10 min. The supernatant was recovered by centrifugation (14,240×g, 10 min) and used to determine sugar and HMF content.

The overliming method was used to remove HMF by adding Ca (OH)2 (Duksan Pure Chemical Co., Ltd., Ansan, Korea) at pH 11.0 and incubating for 0, 15, 30, 45, and 60 min at 30 °C. After incubation, the mixture was centrifuged at 14,240×g for 10 min and the supernatant was then neutralized to pH 5.0 using a 5 M H2SO4 solution, and used to determine sugar and HMF content.

The ion exchange method was then used to remove HMF by adding branched PEI with a molecular weight (MW) of 10,000 (PEI; Polysciences, Inc., Warrington, PA, USA). PEI is highly branched liquid water with high cationic charge density, containing amine groups of primary, secondary, and tertiary at a ratio of approximately 25:50:25. PEI was added to the hydrolysates at ratios of 1:2, 1:1, 2:1, and 3:1 (g PEI:g HMF) for 30 min to determine the optimal ratio. Treatment times were varied as 0, 15, 30, and 45 min. The resulting mixture was stirred at room temperature (~ 22 °C). Following the reaction, the mixture was centrifuged at 14,240×g for 10 min and the pH of the supernatant was then neutralized to 5.0 with 5 M H2SO4 and used to determine sugar and HMF content.

Seed Culture and Adaptation of Yeasts to High Concentration of Galactose

S. cerevisiae KCCM 1129 was purchased from the Korean Culture Center of Microorganisms (KCCM). Stocked S. cerevisiae was cultured on a YPG agar plate containing 15 g/L agar, 10 g/L yeast extract, 20 g/L peptone, and 20 g/L galactose for 24 h [15]. One yeast colony was inoculated with 30 mL YPG medium and cultured at 30 °C and 120 rpm for 24 h. We transferred 10 mL from the cultures at 5.3 g dcw/L to 100 mL of YPG medium, cultured under the same conditions. Adaptation of the seed culture to high galactose concentration was performed using 10 mL yeast that had been inoculated in 100 mL yeast extract, peptone, and high-concentration galactose (YPHG, 10 g/L yeast extract, 20 g/L peptone, and 80 g/L galactose) and cultured until the dry cell weight (dcw) of S. cerevisiae reached 8.2 g dcw/L [16].

Bioethanol Fermentation

Fermentation was carried out with a working volume of 100 mL in 250-mL flasks at 30 °C and 150 rpm for 144 h. The following nutrients were added to the fermentation medium: 2.5 g/L NH4Cl, 5 g/L K2HPO4, 0.25 g/L MgSO4, and 2.5 g/L yeast extract. Fermentation was performed using WT S. cerevisiae and S. cerevisiae adapted to high-concentration galactose. The ethanol yield coefficient was calculated using Eq. (3) as follows:

where [EtOH]max is the highest bioethanol concentration obtained during experiment (g/L) and [Sugar]ini is the total initial glucose and galactose concentration of fermentation (g/L). This definition of the yield coefficient is generally used for fermentation. The maximum yield coefficient was 0.51 [5] for a total conversion of hexose (MW 180) to 2 mol ethanol (MW 46).

Analytical Methods

Galactose, glucose, 5-hydroxymethylfurfural (HMF), and ethanol concentrations were determined using HPLC (1100 Series; Agilent Technologies) equipped with a refractive index detector (RID). An Aminex HPX-87H column (300 × 7.8 mm; Bio-Rad, Hercules, CA, USA) was used with 5 mM filtered and degassed H2SO4 as an eluent at a flow rate of 0.6 mL/min and a temperature of 65 °C. The experiment samples were centrifuged for 10 min at 14,240×g, and the supernatant was filtered (0.2 μm syringe filter) prior to analysis. Cell growth was determined based on optical density at 600 nm (OD600) and converted to dry cell weight using a standard curve.

Statistical Analyses

All experiments were carried out in triplicate. Significant differences between groups were evaluated using the one-way analysis of variance (ANOVA) and Duncan’s multiple range test (P < 0.05) in the SPSS software (ver. 23.0; SPSS Inc., Chicago, IL, USA).

Results and Discussion

Composition of G. amansii

G. amansii is a red seaweed known for its high content of carbohydrate. Its major carbohydrates comprise a sulfate polysaccharide (agaropectin), a neutral polymer (agarose) [5], and cellulose consisting of glucose [17]. G. amansii composition was analyzed using the AOAC method and found to contain 18.1% crude protein, 0.2% crude lipids, 11.6% cellulose, 7.3% crude ash, and 62.8% carbohydrate. The total carbohydrate content of the G. amansii was 74.4% including cellulose.

Thermal Acid Hydrolysis Pretreatment

Thermal acid hydrolysis pretreatment was conducted for sugars produced from G. amansii. Concentrations of G. amansii slurry and H2SO4, as well as treatment time, were determined to obtain the optimal conditions for thermal acid hydrolysis.

Optimal slurry content (8–16%, w/v) was obtained by thermal acid hydrolysis at 182 mM H2SO4 and 121 °C for 60 min. Figure 1a shows the increase in sugar as slurry content increased. The sugar concentration at slurry content from 8 to 16% (w/v) was 22.24 to 35.92 g/L. However, as slurry content increased above 12% during thermal acid hydrolysis, Ep decreased from 37.2 to 30.3%. Levels of HMF concentration increased from 4.5 to 8.4 g/L as slurry content increased from 8 to 16% (w/v). A previous study also reported that HMF increased with increasing slurry content during thermal acid hydrolysis pretreatment of red seaweed [18]. Therefore, 12% (w/v) slurry content with Ep = 37.2% was selected for thermal acid hydrolysis pretreatment.

H2SO4 concentration was varied from 90 to 450 mM at 12% (w/v) slurry content, at 121 °C for 60 min. Sugar concentration increased from 22.69 to 33.07 as the H2SO4 concentration increased from 90 to 180 mM as shown in Fig. 1b. Redding et al. [19] reported that high amounts of sugar were released at high acid concentrations; however, the range 180–450 mM of H2SO4 concentrations resulted in the same Ep value. Increasing the H2SO4 concentration during thermal acid hydrolysis has been reported to result in a decrease in HMF due to subsequent conversion of HMF into other inhibitors [20]. These results are consistent with sugar decomposition to HMF and subsequent decomposition to other acids. However, salt was generated from the acid–base reaction during pH neutralization before fermentation, which inhibits cell growth and fermentation by S. cerevisiae, requiring more NaOH to control the pH of the hydrolysates at high concentrations of H2SO4 [21]. Therefore, 180 mM H2SO4 was selected as the optimal acid concentration at Ep = 37.2%.

Thermal acid hydrolysis pretreatment time was varied in the range of 15–75 min at a slurry content of 12% (w/v) and H2SO4 concentration of 180 mM at 121 °C. Figure 1c shows that the sugar concentration increased from 22.36 to 32.89 g/L as hydrolysis time increased from 15 to 45 min. Treatment times in the range of 45–75 min resulted in similar sugar and HMF concentrations as hydrolysis time increased. A previous study reported that ethanol production was decreased with the hydrolysis pretreatment times over 60 min due to high HMF concentration [22]. Therefore, 45 min was considered the optimal time for thermal acid hydrolysis pretreatment.

From these results, the optimal conditions for thermal acid hydrolysis pretreatment were as follows: 12% (w/v) slurry content and 180 mM H2SO4 at 121 °C for 45 min. These optimal conditions produced 7.36 g/L HMF.

Enzymatic Saccharification

Enzymatic saccharification is an ideal approach for degrading cellulose into reducing sugars, because mild reaction conditions can be used to facilitate ethanol fermentation by yeasts [23]. After thermal acid hydrolysis, the glucose concentration was 6.78 g/L. The effects of Celluclast 1.5 L on glucose release with 12% (w/v) G. amansii hydrolysate are shown in Fig. 2. For cellulose hydrolysis, 16 U/mL Celluclast 1.5 L was used at pH 5.0, 45 °C, and 150 rpm with 12% (w/v) G. amansii slurry content, as saccharification time was varied from 0 to 48 h. The maximum glucose concentration was 17.26 g/L, obtained at 36 h and a saccharification efficiency of 50.8%; galactose was maintained during enzymatic saccharification. Redding et al. [19] reported high production of reducing sugars from enzymatic saccharification of the red seaweed Kappaphycus alvarezii with 16 U/mL Celluclast 1.5 L.

Detoxification of Hydrolysates Using Various Methods

HMF was generated during thermal acid hydrolysis, necessitating a detoxification step to eliminate inhibitors of fermentation efficiency. The adsorption of HMF onto activated carbon was conducted using various activated carbon content levels and adsorption times. A previous study reported that HMF was preferentially adsorbed to activated carbon [24]. Therefore, we developed a strategy to improve the adsorption process efficiency, to remove HMF and maintain high sugar concentrations. As shown in Fig. 3, HMF decreased with the addition of activated carbon and treatment time. HMF decreased by 89.5% from 7.25 g/L to 0.76 g/L at 4 min when 4% and 5% of activated carbon were applied. This increase in activated carbon content resulted in an increase in sugar removal efficiency [25]. Therefore, 4% activated carbon was selected as an optimal condition for HMF removal.

Overliming is a widely used HMF removal method [26]. Increasing the pH of hydrolysate to 11.0 with Ca (OH)2, followed by readjustment to pH 5.0 with 10 N H2SO4, showed efficient detoxification of G. amansii hydrolysate. The overliming treatment time was optimized from 0 to 60 min, as shown in Fig. 4. HMF decreased as treatment time increased; a significant decrease (67.4%) in HMF from 7.25 to 2.36 g/L was observed after overliming G. amansii hydrolysate for 30 min. However, a marginal decrease in sugar from 45.2 to 42.9 g/L was also observed. Chandel et al. [27] reported a 41.75% reduction in furfurals and 7.61% reduction in reducing sugars from S. spontaneum hydrolysate after overliming.

The optimization of HMF removal from G. amansii hydrolysate using PEI at various treatment times is shown in Fig. 5. A ratio of 1:1 (g PEI:g HMF) was optimal for ion exchange, and the optimal treatment time was 15 min. At these conditions, HMF decreased by 76.2% from 7.25 to 1.72 g/L, and sugar decreased from 45.2 to 41.4 g/L, using the ion exchange method. A previous study also reported that ion exchange led to a significant loss of fermentable sugars [28].

Bioethanol Fermentation

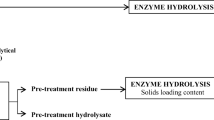

A hydrolysate of 12% (w/v) G. amansii from thermal acid hydrolysis pretreatment and enzymatic saccharification was used for ethanol fermentation. Bioethanol fermentation was performed by inoculating WT S. cerevisiae and S. cerevisiae adapted to high-concentration galactose using various detoxification methods through separate hydrolysis and fermentation (SHF) (Fig. 6).

Ethanol fermentation from G. amansii using S. cerevisiae. a No detoxification with wild-type (WT) S. cerevisiae. b No detoxification with S. cerevisiae adapted to galactose. c Activated carbon treatment with WT S. cerevisiae. d Activated carbon treatment with S. cerevisiae adapted to galactose. e Overliming treatment with WT S. cerevisiae. f Overliming treatment of S. cerevisiae adapted to galactose. g Ion exchange treatment with WT S. cerevisiae. h Ion exchange treatment with S. cerevisiae adapted to galactose

The effects of pretreatment conditions on bioethanol production were assessed without detoxification using WT S. cerevisiae and S. cerevisiae adapted to galactose as shown in Fig. 6a, b. Detoxification using activated carbon treatment with WT S. cerevisiae is shown in Fig. 6c, and those using activated carbon treatment with S. cerevisiae adapted to galactose are shown in Fig. 6d. Overliming treatment with WT S. cerevisiae is shown in Fig. 6e and that with S. cerevisiae adapted to galactose is shown in Fig. 6f. Ion exchange treatment with WT S. cerevisiae is shown in Fig. 6g and that with S. cerevisiae adapted to galactose is shown in Fig. 6h.

The WT yeast without detoxification resulted in glucose being consumed only after 12 h due to inhibition by HMF as shown in Fig. 6a. However, when HMF decreased below 5 g/L through HMF degradation during yeast fermentation [14], glucose was consumed over 60 h. After glucose was totally consumed, galactose was consumed; however, 10.11 g/L galactose remained at 144 h of fermentation [29]. An ethanol concentration of 16.62 g/L was obtained with a YEtOH of 0.37 and productivity of 0.139 g/L/h after fermentation. S. cerevisiae adapted to galactose without detoxification led to the consumption of glucose at HMF below 5 g/L; however, galactose was simultaneously consumed due to yeast adaptation to galactose as shown in Fig. 6b. Glucose was totally consumed at 48 h, and galactose remained at 1.5 g/L until 144 h. An ethanol concentration of 19.05 g/L was obtained at a YEtOH of 0.42 and productivity of 0.159 g/L/h during fermentation.

Detoxification of activated carbon treatment with WT S. cerevisiae for the production of ethanol is shown in Fig. 6c. After detoxification, only 0.74 g/L of HMF remained; therefore, glucose was consumed immediately at the start of fermentation and totally consumed at 18 h; galactose was continuously consumed until 120 h. An ethanol concentration of 18.91 g/L was obtained at a YEtOH of 0.44 and productivity of 0.158 g/L/h during fermentation. Detoxification by activated carbon treatment using S. cerevisiae adapted to galactose is shown in Fig. 6d. Galactose and glucose were simultaneously consumed by S. cerevisiae adapted to galactose and were completely consumed in 24 h and 76 h, respectively. An ethanol concentration of 20.28 g/L was obtained at a YEtOH of 0.47 and productivity of 0.281 g/L/h during fermentation.

Fermentation was performed by overliming treatment with WT S. cerevisiae as shown in Fig. 6e. After detoxification, 2.36 g/L HMF remained, and glucose was consumed during 18 h. After glucose was totally consumed, galactose was consumed; however, 8.1 g/L galactose remained at 144 h of fermentation. After fermentation, an ethanol concentration of 15.88 g/L was obtained at a YEtOH of 0.37 and productivity of 0.265 g/L/h. When overliming treatment with S. cerevisiae adapted to galactose was used for fermentation as shown in Fig. 6f, galactose and glucose were simultaneously and totally consumed in 18 h and 96 h, respectively. An ethanol concentration of 19.66 g/L was obtained at a YEtOH of 0.46 and productivity of 0.273 g/L/h during fermentation.

When hydrolysates detoxified using ion exchange treatment were used for fermentation, the time to glucose and galactose consumption was reduced in a manner similar to the other detoxification methods. WT S. cerevisiae was used to totally consume glucose and galactose in 36 h and 120 h, respectively as shown in Fig. 6g. The fermentation time was reduced from 120 h to 72 h when S. cerevisiae adapted to galactose was used as shown in Fig. 6h. After fermentation, ethanol concentrations of 17.02 and 18.90 g/L were obtained at YEtOH values of 0.41 and 0.46 and productivity of 0.142 and 0.263 g/L/h, using WT S. cerevisiae and S. cerevisiae adapted to galactose, respectively.

Table 1 presents the overall ethanol production through fermentation of G. amansii via SHF. The activated carbon method showed the highest efficiency, reducing HMF by 89.5%, at an ethanol concentration of 20.28 g/L and YEtOH of 0.47. These results indicate that the activated carbon method is suitable for detoxification of G. amansii hydrolysate in ethanol fermentation.

Conclusion

In this study, we evaluated ethanol production from G. amansii hydrolysate through HMF detoxification. We determined that a slurry content of 12% and 182 mM H2SO4 at 121 °C for 45 min was the optimal conditions for thermal acid hydrolysis pretreatment of G. amansii. We used 16 U/mL Celluclast 1.5 L at 45 °C for 36 h for enzymatic saccharification. HMF was reduced from 7.25 to 0.74, 2.36, and 1.72 g/L using the activated carbon, overliming, and ion exchange detoxification methods, respectively. Among these detoxification methods, activated carbon treatment with S. cerevisiae adapted to galactose resulted in the highest ethanol production comparing to those by HMF removal treatments with overliming and ion exchange.

References

Li, H., Yu, X., Jin, Y., Zhang, W., & Liu, Y. (2008). Development of an eco-friendly agar extraction technique from the red seaweed Gracilaria lemaneiformis. Bioresource Technology, 99(8), 3301–3305.

Manuhara, G. J., Praseptiangga, D., & Riyanto, R. A. (2016). Extraction and characterization of refined K-carrageenan of red algae [Kappaphycus alvarezii (Doty ex P.C. Silva, 1996)] originated from Karimun Jawa Islands. Aquat Procedia, 7, 106–111.

Yanagisawa, M., Kawai, S., & Murata, K. (2013). Strategies for the production of high concentrations of bioethanol from seaweeds. Bioengineered, 4(4), 224–235.

Agbor, V. B., Cicek, N., Sparling, R., Berlin, A., & Levin, D. B. (2011). Biomass pretreatment: fundamentals toward application. Biotechnology Advances, 29(6), 675–685.

Park, J. H., Hong, J. Y., Jang, H. C., Oh, S. G., Kim, S. H., Yoon, J. J., & Kim, Y. J. (2012). Use of Gelidium amansii as a promising resource for bioethanol: a practical approach for continuous dilute-acid hydrolysis and fermentation. Bioresource Technology, 108, 83–88.

Klinke, H. B., Thomsen, A. B., & Ahring, B. K. (2004). Inhibition of ethanol-producing yeast and bacteria by degradation products produced during pre-treatment of biomass. Applied Microbiology and Biotechnology, 66(1), 10–26.

Ra, C. H., Kim, M. J., Jeong, G. T., & Kim, S. K. (2017). Efficient utilization of Eucheuma denticulatum hydrolysates using an activated carbon adsorption process for ethanol production in a 5-L fermentor. Bioprocess and Biosystems Engineering, 40(3), 373–381.

Canilha, L., Carvalho, W., das Graças Almeida Felipe, M., & Batista de Almeida Silva, J. (2008). Xylitol production from wheat straw hemicellulosic hydrolysate: hydrolysate detoxification and carbon source used for inoculum preparation. Brazilian Journal Microbiology, 39(2), 333–336.

Chandel, A. K., Kapoor, R. K., Singh, A., & Kuhad, R. C. (2007). Detoxification of sugarcane bagasse hydrolysate improves ethanol production by Candia shehatae NCIM 3501. Bioresource Technology, 98(10), 1947–1950.

Palmqvist, E., & Hahn-Hägerdal, B. (2007). Fermentation of lignocellulosic hydrolysates. II: inhibitors and mechanisms of inhibition. Bioresource Technology, 74, 25–33.

Ranjan, R., Thust, S., Gounaris, C. E., Woo, M., Floudas, C. A., von Keitz, M., Valentas, K. J., Wei, J., & Tsapatsis, M. (2009). Adsorption of fermentation inhibitors from lignocellulosic biomass hydrolysates for improved ethanol yield and value added product recovery. Microporous and Mesoporous Materials, 122(1-3), 143–148.

AOAC (Association of Official Analytical Chemists). (1995). Official methods of analysis of the Association of Official Analytical Chemists (16th ed.). Arlington: Association of Official Analytical Chemists.

Mandels, M., Andreotti, R., & Roche, C. (1976). Measurement of saccharifying cellulose. Biotechnology and Bioengineering Symposium, 6, 21–23.

Kubicek, C. P. (1982). β-glucanase excretion by Trichoderma pseudokoningii correlation with cell wall bound β-1,3-glucanase activities. Archives of Microbiology, 132(4), 349–354.

Cho, H. Y., Ra, C. H., & Kim, S. K. (2014). Ethanol production from seaweed. Gelidium amansii using specific sugar acclimated yeasts. Journal of Microbiology and Biotechnology, 24(2), 264–269.

Nguyen, T. H., Ra, C. H., Sunwoo, I. Y., Jeong, G. T., & Kim, S. K. (2016). Evaluation of galactose adapted yeasts for bioethanol production from Kappaphycus alverazii hydrolysates. Journal of Microbiology and Biotechnology, 26(7), 1259–1266.

Yanagisawa, M., Kawai, S., & Murata, K. (2013). Strategies for the production of high concentrations of bioethanol from seaweeds. Bioengineered, 4(4), 224–235.

Wu, C. H., Chien, W. C., Chou, H. K., Yang, J., & Victor Lin, H. T. (2014). Sulfuric acid hydrolysis and detoxification of red alga Pterocladiella capillacea for bioethanol fermentation with thermotolerant yeast Kluyveromyces marxianus. Journal of Microbiology and Biotechnology, 24(9), 1245–1253.

Redding, A. P., Wang, Z., Keshwani, D. R., & Cheng, J. (2010). High temperature diluted acid pretreatment of coastal Bermuda grass for enzymatic hydrolysis. Bioresource Technology, 102, 1415–1424.

Jeong, G. T., Ra, C. H., Hong, Y. K., Kim, J. K., Kong, I. S., Kim, S. K., & Park, D. H. (2015). Conversion of red-alage Gracilaria verrucosa to sugars, levulinic acid and 5-hydroxymethylfurfural. Bioprocess and Biosystems Engineering, 38(2), 207–217.

Marger, W. H., & Siderius, M. (2002). Novel insights into the osmotic stress response of yeast. FEMS Yeast Research, 2(3), 251–257.

Hsu, C. L., Chang, K. S., Lai, M. Z., Chang, T. C., Chang, Y. H., & Jang, H. D. (2011). Pretreatment and hydrolysis of cellulosic agricultural wastes with a cellulose-producing Streptomyces for bioethanol production. Biomass and Bioenergy, 32, 1878–1884.

Nguyen, T. H., Ra, C. H., Sunwoo, I. Y., Jeong, G. T., & Kim, S. K. (2016). Evaluation of galactose adapted yeasts for bioethanol production from Kappaphycus alverazii hydrolysates. Journal of Microbiology and Biotechnology, 26(7), 1259–1266.

Lee, J. M., Venditti, R. A., Jameel, H., & Kenealy, W. R. (2011). Detoxification of woody hydrolysates with activated carbon for bioconversion to ethanol by the thermophilic anaerobic bacterium Thermoanaerobicbacterium saccharolyticum. Biomass and Bioenergy, 35(1), 626–636.

Ra, C. H., Jung, J. H., Sunwoo, I. Y., Jeong, G. T., & Kim, S. K. (2015). Enhanced ethanol production by fermentation of Gelidium amansii hydrolysate using a detoxification process and yeasts acclimated to high-salt concentration. Bioprocess and Biosystems Engineering, 38(6), 1201–1207.

Zhu, J. J., Yong, Q., Xu, Y., & Yu, S. Y. (2009). Comparative detoxification of vacuum evaporation/steam stripping combined with overliming on corn stover prehydrolyzate. 2009 International Conference on Energy and Environment Technology, 3, 240–243.

Chandel, A. K., Singh, O. V., Rao, L. V., Chandrasekhar, G., & Narasu, M. L. (2011). Bioconversion of novel substrate Saccharum spontaneum, a weedy material, into ethanol by Pichia stipites NCIM3498. Bioresource Technology, 102(2), 1709–1714.

Chandel, A. K., Silva, S. S., & Singh, O. V. (2011). Detoxification of lignocellulosic hydrolysates for improved bioethanol production. In M. A. S. Bernardes (Ed.), Biofuel production - recent developments and prospects, vol. 10 (pp. 225–246). Rijeka: InTech Open Access.

Bai, F. W., Anderson, W. A., & Moo-Young, M. (2008). Ethanol fermentation technologies from sugar and starch feedstocks. Biotechnology Advances, 26(1), 89–105.

Acknowledgements

This research was supported by the Basic Science Research Program of the National Research Foundation of Korea, funded by the Ministry of Education (2016R1D1A1A09918683).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nguyen, T.H., Sunwoo, I.Y., Jeong, GT. et al. Detoxification of Hydrolysates of the Red Seaweed Gelidium amansii for Improved Bioethanol Production. Appl Biochem Biotechnol 188, 977–990 (2019). https://doi.org/10.1007/s12010-019-02970-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-019-02970-x