Abstract

Accumulation of succinate as a fermentation product of Fusobacterium varium was enhanced when the anaerobic bacterium was grown on complex peptone medium supplemented with fumarate. Residual substrates and fermentation products were determined by proton NMR spectroscopy. Cells collected from the fumarate-supplemented medium (8–10 h after inoculation) supported the conversion of fumarate to succinate when suspended with fumarate and a co-substrate (glucose, sorbitol, or glycerol). Succinate production was limited by the availability of fumarate or reducing equivalents supplied by catabolism of a co-substrate via the Embden-Meyerhof-Parnas (EMP) pathway. The choice of reducing co-substrate influenced the yield of acetate and lactate as side products. High conversions of fumarate to succinate were achieved over pH 6.6–8.2 and initial fumarate concentrations up to 300 mM. However, at high substrate concentrations, intracellular retention of succinate reduced extracellular yields. Overall, the efficient utilization of fumarate (≤ 400 mM) combined with the significant extracellular accumulation of succinate (corresponding to ≥ 70% conversion) indicated the effective utilization of fumarate as a terminal electron acceptor by F. varium and the potential of the methodology for the bioproduction of succinate.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

A notable example of industrial biochemistry based on renewable resources is the bio-based production of succinic acid [1,2,3,4,5,6,7], a platform chemical used in the food, chemical, and pharmaceutical industries [2, 6, 8, 9]. Recent implementations of large-scale, industrial fermentation processes [1,2,3, 10, 11] have increased the supply of bio-derived succinic acid in support of subsequent chemical transformations used in the sustainable manufacture of other commodities, such as 1,4-butanediol, γ-butyrolactone, tetrahydrofuran, and biodegradable polymers [2, 6,7,8,9, 11, 12].

The organisms studied for the bioproduction of succinic acid are either natural over-producers or genetically modified organisms [1, 3, 5, 8, 13,14,15,16]. Improvements achieved through genetic engineering include the enhancement of succinate-producing pathways, the elimination of competing metabolic pathways yielding unwanted by-products, and the enhanced production of reduced co-factors [1, 5, 9, 13, 17]. Aerobic production of succinate relies on disruption of the tricarboxylic cycle by gene deletion (e.g., succinate dehydrogenase) [3, 5, 9, 17, 18]. By contrast, the reductive branch of the tricarboxylic acid pathway (oxaloacetate ➔ malate ➔ fumarate ➔ succinate) is the main route utilized under anaerobic conditions [3, 5, 9, 13, 17] with the final step catalyzed by fumarate reductase. The availability of reducing equivalents and the formation of oxaloacetate by carboxylation of phosphoenolpyruvate are important factors sustaining the anaerobic production of succinate. In both aerobic and anaerobic circumstances, succinate may also be formed by metabolism of acetyl-CoA via the glyoxylate cycle [3, 5, 8, 9, 13, 17], whereas catabolism of glucose by the Embden-Meyerhof-Parnas (EMP) pathway (glycolysis) is the usual source of succinate precursors and reduced co-enzymes [1,2,3, 5, 9, 14, 16].

Otherwise, small amounts of succinate are commonly produced in mixed acid fermentations by many microorganisms [8, 9, 13]. Increased accumulations, however, were obtained simply by addition of fumarate to glycerol cultures of the facultative anaerobe Enterococcus faecalis [19, 20]. High rates of succinate production were achieved when the approach was extended to immobilized cells and a flow system [21, 22]. Succinate also has been identified as one of several fermentation products of the anaerobic bacterium Fusobacterium varium in complex or chemically defined culture media [23]. Although Fusobacterium species are recognized for their ability to produce butyrate and to obtain energy from amino acids [24], F. varium has more diverse metabolic capabilities [25,26,27]. Herein, we report the conversion of exogenous fumarate to succinate by F. varium and the investigation of cell suspensions [28] mediating this biotransformation under anaerobic conditions.

Materials and Methods

General Methods and Microorganism

Bacterial transfers and centrifugations were performed in air; cultures were incubated and stored in anaerobic jars containing a palladium catalyst (Oxoid Canada, Nepean, ON) and an atmosphere of N2:H2:CO2 (80:10:10 v/v/v) established by three evacuation/pressurization cycles. Culture media were autoclaved at 121 °C for 20 min. F. varium ATCC 8501 was maintained on brain heart infusion (BHI) agar (Fluka, Buchs, Switzerland) under anaerobic conditions; a freshly inoculated BHI agar plate was prepared biweekly, incubated at 37 °C for 24 h, and then stored at 4 °C.

Peptone medium [23] containing proteose peptone, trypticase peptone, yeast extract (each at 5 g L−1), NaCl (5 g L−1, 86 mM), l-cysteine HCl (0.8 g L−1), and varying concentrations of a carbon source (e.g., 30 mM glucose, sorbitol, or glycerol; 5.40, 5.47, or 2.76 g L−1, respectively) was adjusted to pH 7.4 and autoclaved. Starter cultures in peptone medium (glucose, sorbitol, or glycerol; 30 mM) were inoculated with a colony of F. varium from BHI agar and incubated at 37 °C under anaerobic conditions for 24 h.

Optical densities in cell cultures were measured at 660 nm (OD660) in 1-cm cuvettes using an Agilent 8453 UV-Vis spectrophotometer. Cells were separated from liquid cultures by centrifugation (8000g, 20 °C, 10 min).

[2,3-2H2]Fumaric acid (98 atom% 2H) and [2H5]glycerol (99.5 atom%) were obtained from Cambridge Isotope Laboratories, Inc. (Tewksbury, MA, USA) and CDN Isotopes, Inc. (Pointe-Claire, QC, Canada), respectively. Fumaric acid, d-glucose, glycerol, sorbitol, succinic acid, l-tartaric acid, l-malic, and l-aspartic acid were supplied by Sigma-Aldrich, Canada (Oakville, ON, Canada).

Growth Cultures

Peptone medium (glucose, sorbitol, or glycerol; 30 mM) was inoculated (1% v/v) from a starter culture (glucose, sorbitol, or glycerol; 30 mM) and incubated anaerobically at 37 °C. When peptone medium was supplemented with a potential precursor (20 or 40 mM) to evaluate the effect on succinate production, culture supernatants were collected after the incubation period (typically 14 h), and processed for product/residual substrate determinations as described below. F. varium cells for suspension experiments were harvested from peptone medium (normally 40 mM fumarate; 30 mM glucose) after incubation for 8 h (typically OD660 ≥ 2) and washed with phosphate-buffered saline (PBS; 138 mM NaCl, 2.7 mM KCl, 5 mM Na2HPO4, 5 mM NaH2PO4, pH 7.4).

Suspension Experiments

Washed F. varium cells from growth culture (typically 200 mL) were suspended in an autoclaved solution (typically 10 mL, pH 7.4) containing fumarate and a co-substrate (glucose, sorbitol, or glycerol) at various concentrations. After incubation under anaerobic conditions for 3 or 6 h, the cells were separated by centrifugation; in the time course experiments, samples (1 mL) were removed periodically up to 24 h and centrifuged. The supernatants were processed for product/residual substrate determinations as described below. For the determination of intracellular substrates, cells collected from a 10-mL suspension experiment (0.78 g) were suspended in 70% ethanol (10 mL). The mixture was stirred for 1 h at ambient temperature and centrifuged. The supernatant was rotary evaporated at reduced pressure. A portion of the residue (44 of 98 mg) was mixed with l-tartaric acid (21 mg) and dissolved in 2H2O for 1H NMR analysis.

MS and 1H NMR Analysis

The supernatants from growth cultures and cell suspensions were adjusted to pH 9.5 by addition of 5 M NaOH and lyophilized. For mass spectral analysis, the lyophilized residues were dissolved in methanol/water (1:1 v/v; 1 mg mL−1) and analyzed by flow injection (20 μL min−1) using electrospray ionization (ESI; negative mode) and a Thermo-Finnigan LCQ Duo mass spectrometer [29].

For analysis using 1H NMR spectroscopy, l-tartaric acid (20 mg/10 mL supernatant) was added to the supernatant prior to pH adjustment. The spectra (typically 16 scans) of the lyophilized residues in 2H2O (15 mg/0.75 mL) were acquired on a Bruker AVANCE 300-MHz spectrometer using standard acquisition parameters, except for a 10-s delay between pulses [23]. The data were processed using TopSpin software with line broadening of 0.3 Hz prior to Fourier transformation. The baseline was corrected manually with a polynomial function. Peaks were phase adjusted manually; chemical shifts were referenced to the residual water signal (δ 4.80). Concentrations were calculated from the integrated peak areas of metabolic products and residual substrates relative to that of a known concentration of the internal standard l-tartrate (δ 4.28, s, 2H). Quantitative data for acetate (δ 1.86, s, 3H), lactate (δ 1.28, d (J = 7 Hz), 3H), fumarate (δ 6.47, s, 2H), and succinate (δ 2.35, s, 4H) were obtained from the area of one representative signal, whereas the peak areas of doublets (1H) at δ 5.19 (J = 4 Hz) and 4.61 (J = 8 Hz) were combined to determine the concentration of glucose and the collection of resonances at δ ≈3.80–3.50 were integrated to determine the concentrations of sorbitol (8H) and glycerol (5H).

Results and Discussion

Bioconversion of Fumarate to Succinate

As a component of the metabolic footprint of F. varium, succinate typically accumulates at 1–2 mM in cultures grown on complex or chemically defined minimal media [23]. In the current experiments, a possible connection between low succinate production and the meager supply of a metabolic precursor was probed by culturing F. varium on complex peptone medium supplemented with a putative precursor [1,2,3, 5, 13, 17]. The lyophilized culture supernatant was analyzed by 1H NMR spectroscopy, a technique that detects organic substances containing nonexchangeable hydrogens.

When fumarate was added to the peptone growth medium (Table 1), significantly greater accumulations of succinate and acetate were obtained, whereas the lactate concentration was unchanged from the control culture lacking fumarate. The enhanced production of succinate was consistent with fumarate reduction catalyzed by fumarate reductase [19], an enzyme annotated in the F. varium genome [30, 31] and expressed during a proteomics study [26]. By contrast, l-malate and l-aspartate were ineffective in stimulating succinate production in parallel cultures, although genes for fumarate hydratase and aspartate ammonia lyase also have been annotated in the F. varium genome [30, 31].

The elevated succinate accumulation (Table 1) implied a metabolic connection with exogenous fumarate. When the experiment was repeated with addition of [2,3-2H2]fumarate, 1H NMR analysis showed resonances corresponding to acetate (19 mM) and lactate (19 mM); as well, two closely spaced signals at about 2.35 ppm were attributed to unlabelled succinate (3 mM) and [2,3-2H2]succinate (32 mM). ESI(−)MS analysis (Fig. 1) showed predominant accumulation of [2H2]succinate (m/z 119) along with unlabelled acetate (m/z 59) and lactate (m/z 89). The low-intensity peaks at m/z 115 and 117 in the mass spectrum indicated low levels of unlabelled fumarate, unlabelled succinate, and [2H2]fumarate. The labelling results establish that succinate was produced by reduction of exogenous fumarate with little or no synthesis of fumarate and succinate from other sources in the complex peptone medium.

Development of Cell Suspension Conditions

Variables affecting succinate production by F. varium were investigated using cells collected from peptone growth cultures and suspended in fumarate solutions of defined composition under anaerobic conditions. Consequently, potential effects and/or interferences of undefined components in the culture medium were minimized. The number of fermentation products was limited by incubating the suspended cells with only one or two substrates, an outcome that may also simplify the subsequent purification of metabolic products [5, 8,9,10, 32]. By using suspensions at high cell densities [28], the incubation time needed to observe high conversion of fumarate to succinate was substantially shorter than that utilized for growth cultures (Table 1) and the need for aseptic conditions was reduced. The results of the series of experiments described below guided the establishment of conditions for the reliable bioconversion of fumarate to succinate.

A dependence of succinate production on substrate availability was indicated when F. varium cells collected from peptone medium were suspended in phosphate-buffered saline containing combinations of fumarate (0 or 40 mM) and glucose (0 or 30 mM) as substrates (Supplementary Table S1). The accumulation of succinate was low (≤ 5 mM) when one substrate was supplied and substantial amounts of unutilized substrate were detected. When both substrates were present, conversions of about 80% were achieved in PBS or in water, the latter demonstrating that a separate buffering system was not required. Furthermore, similar efficient conversions of fumarate to succinate were attained when the initial pH was varied from 6.6 to 8.2 (Supplementary Table S2).

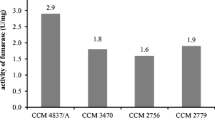

A comparison of succinate production by cells from combinations of starter/growth cultures prepared on peptone medium (± fumarate) showed that the capacity of the suspended cells to convert fumarate to succinate depended on growth culture conditions (Supplementary Table S3). When fumarate at 40 mM was included in the growth medium, greater growth was attained and the suspended cells efficiently converted fumarate to succinate. If fumarate was included in only the starter culture medium, or omitted from both starter and growth medium, the suspended cells had limited ability to produce succinate from fumarate. Furthermore, the capacity of the cell suspensions to reduce fumarate increased as the concentration of fumarate in the growth medium was increased up to 40 mM (Fig. 2a). Residual fumarate was detected in suspension fluids when cells were grown with ≤ 30 mM fumarate, whereas complete transformations of fumarate to succinate were achieved reproducibly by the suspended cells when the growth medium had ≥ 40 mM fumarate.

Effect of growth culture conditions on the conversion of fumarate (black square) to succinate (black circle) by suspensions of F. varium cells. a Variation of fumarate concentration in the peptone medium used for the growth of the cells. b Variation of the time at which the suspended cells were harvested from the growth culture. The cell suspensions were incubated with 40 mM fumarate and 30 mM glucose for 3 h (numerical data is given in Supplementary Tables S4 and S5)

The incubation time at which the cells were harvested from the growth cultures also was an important consideration. Cells collected from growth cultures incubated for 8–10 h showed greater capabilities for fumarate reduction than cells collected after longer incubations (Fig. 2b).

As a result of these initial experiments, reproducible high conversions of 40 mM fumarate to succinate were achieved within 3 h by cells conditioned during the growth phase to express fumarate reductase and suspended (ca. 70 g/L) in 30 mM glucose.

Co-Substrate Requirements

Glucose

The dependence of succinate production on the availability of glucose was investigated in cell suspensions at fixed concentrations of fumarate. The conversion of 40 mM fumarate to succinate improved from 50 to 95% (i.e., 21 to 38 mM) as the concentration of glucose was increased from 10 to 25 or 30 mM (Supplementary Table S6). The detection of residual fumarate (≥ 6 mM) at 10–20 mM glucose was consistent with the lower accumulations of succinate (≤ 33 mM). Parallel incubations of suspended cells with higher concentrations of fumarate (80–200 mM) and 30 mM glucose gave similar accumulations of succinate, acetate, and lactate and corresponding amounts of residual fumarate. In each case, the results indicated glucose as a limiting factor of succinate production.

In accordance with the observations described above, the yield of succinate from 200 mM fumarate proportionally increased with increasing glucose concentration reaching 90% after 6 h at ≥ 120 mM glucose (Fig. 3). At the highest glucose concentration (150 mM), negligible residual fumarate and excess glucose were detected, whereas residual fumarate and negligible glucose were observed at lower glucose concentrations (≤ 90 mM). Thus, succinate production is limited by fumarate at high concentrations of glucose and by glucose at lower concentrations of glucose. Indeed, at both 40 and 200 mM fumarate, the molar ratio of glucose to fumarate had to be greater than approximately 0.6 to observe greater than 70% conversion of fumarate to succinate (Fig. 3 and Supplementary Table S6). At the highest glucose concentration (150 mM), fumarate was depleted, and the elevated level of lactate as a side product indicated more extensive reduction of pyruvate.

Substrate utilization and product accumulation when F. varium cells (cell density = 77 ± 3 g/L) were suspended for 6 h in fumarate (200 mM) and glucose (various concentrations) solution. Fumarate (black square) and glucose (black diamond) were consumed, while succinate (black circle), acetate (black triangle), and lactate (black inverted triangle) accumulated in each culture

The notable production of succinate in the above experiments indicated that fumarate is utilized by F. varium as an effective terminal electron acceptor to facilitate the regeneration of reduced co-enzymes formed by the oxidative catabolism of glucose via the EMP pathway [26, 27]. Thus, fumarate and glucose have complementary roles in succinate production. The catabolism of glucose via the EMP pathway generates reducing equivalents and pyruvate, a metabolic intermediate that is subsequently converted to the side products acetate and lactate.

Sorbitol and Glycerol

Sorbitol, a reduced form of glucose, and glycerol, a reduced form of dihydroxyacetone and glyceraldehyde, are also connected to the EMP pathway. Sorbitol is likely converted to fructose-6-phosphate by phosphorylation and oxidation [33], whereas genes encoding enzymes that catalyze the oxidative conversion of glycerol to dihydroxyacetone phosphate are annotated in the F. varium genome [30, 31]. Consequently, sorbitol and glycerol are expected to generate reducing equivalents more efficiently than glucose [1, 3, 16, 17]. The higher yields of 1.5 and 2 mol of NADH per pyruvate, versus the 1 NADH per pyruvate from glucose, may support succinate production with lower accumulations of side products [1, 3, 16, 17].

The feasibility of sorbitol and glycerol as replacements for glucose was assessed by culturing F. varium on peptone medium containing one of these polyols as the carbon source (Supplementary Table S7). Both sorbitol and glycerol supported bacterial growth and the conversion of exogenous fumarate to succinate accompanied by lower accumulations of acetate and lactate. The formation of only acetate and lactate as side products confirmed the metabolic connections of sorbitol and glycerol to the EMP pathway [30, 31, 33].

In cell suspensions (Supplementary Table S8), cells grown on glucose had little capacity to utilize sorbitol and glycerol for the reduction of fumarate, whereas cells grown on sorbitol and glycerol readily utilized glucose and supported a high conversion of fumarate to succinate. Similarly, the glycerol-generated cells were unable to utilize sorbitol to support fumarate reduction. Although the cells generated on sorbitol had some capacity to utilize glycerol in support of fumarate reduction, the most efficient conversions of fumarate to succinate were obtained when cells grown on a substrate were suspended in a solution of fumarate and the same substrate. Thus, the effective utilization of sorbitol and glycerol for fumarate reduction required cells conditioned by growth on these substrates.

When the suspended cells were incubated with a higher fumarate concentration (80 mM) and sorbitol, almost quantitative conversion of fumarate to succinate was obtained (Supplementary Table S8). The lower conversions observed with glucose and glycerol at 80 mM fumarate indicated that succinate production was limited by lower yields of NADH produced by catabolism of these carbon sources (see above). Side-product formation from glucose and sorbitol were similar, but reduced levels of lactate were obtained from glycerol. The use of glycerol is also favored by its ready availability as a side product of biofuel production [34, 35].

When F. varium was cultured on peptone medium containing fumarate and [2H5]glycerol as the carbon source, 1H NMR analysis of the lyophilized culture supernatant showed accumulation of succinate along with a small amounts of acetate and lactate. The mass spectrum collected by ESI(−)MS (Supplementary Fig. S1) showed a dominant peak at m/z 117 for succinate and no indication of deuterium incorporation above natural abundance. Acetate, [2H2]acetate, lactate, [2H2]lactate, and [2H3]lactate were indicated by peaks at m/z 59, 61, 89, 91, and 92, respectively. The formation of dideuterated ions is consistent with catabolism of [2H5]glycerol by the EMP pathway, whereas incorporation of a third deuterium into lactate indicated reduction of [2H2]pyruvate by NAD2H formed by oxidation of [2H5]glycerol. The lack of deuterium in succinate, on the other hand, indicated that the coupling of glycerol oxidation with fumarate reduction involved electron transport [36].

Time Course

Sampling and analysis of a cell suspension (200 mM fumarate and 150 mM glucose) with time (Fig. 4) showed more rapid utilization of glucose near the beginning of the 3-h incubation period. The reasonably constant rates of fumarate depletion and succinate production indicated that the cells maintained reductive capabilities over the incubation period. The rate of extracellular succinate accumulation (ca. 55 mM h−1) was slightly lower than that of fumarate depletion (ca. 63 mM h−1), leading to approximately 88% (± 5%) yield of succinate when fumarate was depleted (8 ± 7% mM). However, replicate 3-h incubations at these substrate concentrations showed variable amounts of residual fumarate (8 ± 10) and incubation times were extended to 6 h when ≥ 200 mM fumarate was supplied to cell suspensions (e.g., Fig. 3).

Time course of substrate depletion and product formation. F. varium cells (cell density = 67 g/L) were suspended in fumarate (black square; initially 200 mM) and glucose (black diamond; initially 150 mM) solution. Succinate (black circle), acetate (black triangle), and lactate (black inverted triangle) accumulated with time

When glycerol (80 mM) and fumarate (160 mM) were supplied as co-substrates to suspended cells (Fig. 5), about 9 h of incubation was needed to deplete fumarate and to achieve an approximately 80% yield of succinate. Unlike the glucose time course, the formation of succinate slowed as fumarate was utilized; however, succinate was accompanied by slightly lower relative amounts of acetate and lactate formed from glycerol. Similar results were obtained from a parallel experiment at 240 mM fumarate and 120 mM glycerol. On the other hand, a lower yield of succinate (60%) and significant residual fumarate (110 mM) were observed at higher substrate concentrations (320 mM fumarate and 160 mM glycerol), indicating a limit for the coupling of glycerol oxidation to fumarate reduction in F. varium.

Time course of substrate depletion and product formation. F. varium cells (cell density = 67 g/L) were suspended in fumarate (black square; initially 160 mM) and glycerol (black diamond; initially 80 mM) solution. Succinate (black circle), acetate (black triangle), and lactate (black inverted triangle) accumulated with time

Conversions at High Fumarate/Glucose Concentrations

In keeping with the time course (Fig. 4), an increase of the initial fumarate concentration to 300 mM resulted in the incomplete utilization of fumarate by the suspended cells after 3 h of incubation (Supplementary Table S9). When sufficient glucose (≥ 150 mM) was supplied and the cell suspension was incubated for 6 h, the initial 300 mM fumarate was depleted. At 400 mM, up to 16% of the initial fumarate remained in suspension fluids at 6 h of incubation. When the 400 mM fumarate experiment was repeated at approximately twice the cell density, lower levels of residual fumarate and higher amounts of accumulated succinate were observed after 3 h of incubation, and fumarate was depleted at 6 h when glucose was supplied at ≥ 180 mM (Supplementary Table S10). However, the efficient utilization of fumarate combined with extracellular accumulation of succinate corresponding to less than 70% conversion showed a mass balance discrepancy in the suspension fluids. No other metabolic products were detected in suspension fluids by 1H NMR spectroscopy rendering other metabolic transformations of fumarate unlikely.

Incubations of F. varium cells with 200 mM fumarate or a mixture of 200 mM fumarate and succinate (100 or 200 mM) showed complete utilization of fumarate within 3 h (Supplementary Table S11), indicating little or no product inhibition [20, 37] by up to 400 mM succinate in suspension fluids. The amount of succinate located in the suspension fluids was similar to the levels found in the 6-h incubations of 300 and 400 mM fumarate (Supplementary Table S9), again indicating a deficiency in the mass balance. A common feature of the experiments showing poor mass balance was high salt concentration created by titrating fumaric acid and added succinic acid to the initial pH of 7.4. When cells were suspended in 200 mM fumarate with additions of sodium chloride (100–400 mM), low levels of residual fumarate were detected after incubation for 3 h (Supplementary Table S12), but the levels of succinate were also markedly lower, providing evidence for an effect of salt on the extracellular accumulation of succinate.

To examine possible intracellular accumulations, cells were suspended in 300 mM fumarate and 150 mM glucose. After incubation for 6 h, no residual fumarate was detected and the extracellular accumulations of acetate (84 mM), lactate (98 mM), and succinate (212 mM) were similar to those determined in a previous experiment (Supplementary Table S5). The cells collected from the incubation were extracted with 70% ethanol, and succinate, lactate, and acetate were detected at concentrations equivalent to 29, 16, and 12 mM, respectively, in the suspension fluid. The intracellular succinate accounted for a major portion of the mass balance deficiency and indicated that metabolic products were retained inside the cells, perhaps to balance the osmotic stress imposed by the high extracellular salt concentration.

Substrates for Reduction

Initial experiments demonstrated that the formation of succinate required both fumarate and glucose (e.g., Table S3) and that succinate production was proportional to limiting amounts of glucose (e.g., Fig. 3). The depletion of glucose and the accumulation of small amounts of acetate indicated that the F. varium cells derived most of their energy from the EMP pathway with only a minor contribution from acetate kinase [26]. Butyrate, a reduced fermentation product of F. varium [23] formed from acetyl-CoA [26], was not detected in cell suspensions. This is consistent with the conversion of small amounts of pyruvate to acetate and the reduction of pyruvate to lactate observed in the suspension experiments. On the other hand, the notable accumulation of succinate indicates that reduction of fumarate is the main route for co-enzyme regeneration. Consequently, fumarate is a preferred terminal electron acceptor and a narrower range of fermentation products are produced by F. varium when fumarate is available.

Conclusions

Large extracellular accumulations of succinate (> 250 mM) were attained when suspensions of F. varium cells were supplied with fumarate as a metabolic precursor and a co-substrate (glucose, sorbitol, or glycerol) as a source of reducing equivalents. High conversions were achieved by suspended cells when the cells had been cultured for an optimum time on growth medium containing fumarate and the same co-substrate supplied to the suspended cells. This necessary preconditioning indicated that fumarate reductase and some enzymes needed for utilization of sorbitol and glycerol were not constitutive [20], but could be expressed at elevated levels without genetic modifications. Succinate production was limited by small amounts of either fumarate or the co-substrate, and intracellular retention of succinate was significant at high fumarate concentrations (≥ 300 mM).

By employing an anaerobic bacterium, suspensions with high densities of functioning cells were readily achieved. When F. varium cells were suspended with only fumarate (≤ 400 mM) and a co-substrate supplying reducing equivalents, incubation volumes were minimized and substrates were completely utilized within 3–6 h. Consequently, the isolation of succinate from suspension fluids would simply require separation from water and the acetate and lactate side products present at lower concentrations.

The catabolism of co-substrates via the EMP pathway in F. varium [26, 27] generated reduced co-enzymes to facilitate the bioconversion of exogenous fumarate to succinate by fumarate reductase. The accompanying accumulations of acetate and lactate also were consistent with the metabolism of pyruvate formed by the EMP pathway. The lower accumulation of acetate and lactate as side products when sorbitol and glycerol were supplied as reduced co-substrates was attributed to NADH production with decreased carbon flux through the EMP pathway. Acetate increased with increasing supplies of fumarate, while less lactate accumulated at higher concentrations of fumarate. The latter indicated that fumarate was preferred over pyruvate as a terminal electron acceptor and that the coupling of glucose (or polyol) oxidation with fumarate reduction is a novel application of F. varium that has potential for the production of succinate under anaerobic conditions, particularly when combined with microbial-derived fumarate [2, 14].

References

Jiang, M., Ma, J., Wu, M., Liu, R., Liang, L., Xin, F., Zhang, W., Jia, H., & Dong, W. (2017). Progress of succinic acid production from renewable resources: Metabolic and fermentative strategies. Bioresource Technology, 245, 1710–1717.

Mazière, A., Prinsen, P., García, A., Luque, R., & Len, C. (2017). A review of progress in (bio)catalytic routes from/to renewable succinic acid. Biofuels, Bioproducts & Biorefining, 11(5), 908–931.

Ahn, J. H., Jang, Y.-S., & Lee, S. Y. (2016). Production of succinic acid by metabolically engineered microorganisms. Current Opinion in Biotechnology, 42, 54–66.

Morales, M., Ataman, M., Badr, S., Linster, S., Kourlimpinis, I., Papadokonstantakis, S., Hatzimanikatis, V., & Hungerbühler, K. (2016). Sustainability assessment of succinic acid production technologies from biomass using metabolic engineering. Energy & Environmental Science, 9(9), 2794–2805.

Cao, Y., Zhang, R., Sun, C., Cheng, T., Liu, Y., & Xian, M. (2013). Fermentative succinate production: An emerging technology to replace the traditional petrochemical processes. BioMed Research International. Article ID 723412. https://doi.org/10.1155/2013/723412.

Delhomme, C., Weuster-Botz, D., & Kühn, F. E. (2009). Succinic acid from renewable resources as a C4 building-block chemical—A review of the catalytic possibilities in aqueous media. Green Chemistry, 11(1), 13–26.

Cukalovic, A., & Stevens, C. V. (2008). Feasibility of production methods for succinic acid derivatives: A marriage of renewable resources and chemical technology. Biofuels, Bioproducts & Biorefining, 2(6), 505–529.

Bechthold, I., Bretz, K., Kabasci, S., Kopitzky, R., & Springer, A. (2008). Succinic acid: A new platform chemical for biobased polymers from renewable resources. Chemical Engineering & Technology, 31(5), 647–654.

McKinlay, J. B., Vieille, C., & Zeikus, J. G. (2007). Prospects for a bio-based succinate industry. Applied Microbiology and Biotechnology, 76(4), 727–740.

Jansen, M. L. A., & van Gulik, W. M. (2014). Towards large scale fermentative production of succinic acid. Current Opinion in Biotechnology, 30, 190–197.

Debabov, V. G. (2015). Prospects for biosuccinic acid production. Applied Biochemisty and Microbiology, 51(8), 787–791.

Besson, M., Gallezot, P., & Pinel, C. (2014). Conversion of biomass into chemicals over metal catalysts. Chemical Reviews, 114(3), 1827−1870.

Zhu, L.-W., & Tang, Y.-J. (2017). Current advances of succinate biosynthesis in metabolically engineered Escherichia coli. Biotechnology Advances, 35(8), 1040–1048.

Beauprez, J. J., De Mey, M., & Soetaert, W. K. (2010). Microbial succinic acid production: Natural versus metabolic engineered producers. Process Biochemistry, 45(7), 1103–1114.

Chen, Y., & Nielsen, J. (2016). Biobased organic acids production by metabolically engineered microorganisms. Current Opinion in Biotechnology, 37, 165–172.

Thakker, C., Martínez, I., San, K.-Y., & Bennett, G. N. (2012). Succinate production in Escherichia coli. Biotechnology Journal, 7(2), 213–224.

Cheng, K.-K., Wang, G.-Y., Zeng, J., & Zhang, J.-A. (2013). Improved succinate production by metabolic engineering. BioMed Research International. Article ID 538790. https://doi.org/10.1155/2013/538790.

Li, C., Yang, X., Gao, S., Wang, H., & Lin, C. S. K. (2017). High efficiency succinic acid production from glycerol via in situ fibrous bed bioreactor with an engineered Yarrowia lipolytica. Bioresource Technology, 225, 9–16.

Ryu, H.-W., Kang, K.-H., & Yun, J.-S. (1999). Bioconversion of fumarate to succinate using glycerol as a carbon source. Applied Biochemistry and Biotechnology, 78(1–3), 511–520.

Kang, K.-H., Yun, J.-S., & Ryu, H.-W. (2000). Effect of culture conditions on the production of succinate by Enterococcus faecalis RKY1. Journal of Microbiology and Biotechnology, 10(1), 1–7.

Ryu, H.-W., & Wee, Y.-J. (2001). Characterization of bioconversion of fumarate to succinate by alginate immobilized Enterococcus faecalis RKY1. Applied Biochemistry and Biotechnology, 91–93(1–9), 525–535.

Wee, Y.-J., Yun, J.-S., Kang, K.-H., & Ryu, H.-W. (2002). Continuous production of succinic acid by a fumarate-reducing bacterium immobilized in a hollow-fiber bioreactor. Applied Biochemistry and Biotechnology, 98–100(1–9), 1093–1104.

Resmer, K. L., & White, R. L. (2011). Metabolic footprinting of the anaerobic bacterium Fusobacterium varium using 1H NMR spectroscopy. Molecular BioSystems, 7(7), 2220–2227.

Hofstad, T. (2006). The prokaryotes: A Handbook on the Biology of Bacteria. In S. Falkow, E. Rosenberg, & K.-H. Schleifer (Eds.), The genus Fusobacterium (Vol. 7, pp. 1016–1027). New York: Springer.

Ramezani, M., Resmer, K. L., & White, R. L. (2011). Glutamate racemization and catabolism in Fusobacterium varium. The FEBS Journal, 278(14), 2540–2551.

Potrykus, J., White, R. L., & Bearne, S. L. (2008). Proteomic investigation of amino acid catabolism in the indigenous gut anaerobe Fusobacterium varium. Proteomics, 8(13), 2691–2703.

Potrykus, J., Mahaney, B., White, R. L., & Bearne, S. L. (2007). Proteomic investigation of glucose metabolism in the butyrate-producing gut anaerobe Fusobacterium varium. Proteomics, 7(11), 1839–1853.

Ramezani, M., & White, R. L. (2011). Enantioselective catabolism of racemic serine: Preparation of d-serine using whole cells of Fusobacterium nucleatum. Tetrahedron: Asymmetry, 22(13), 1473–1478.

LeBlanc, L. M., Powers, S. W., Grossert, J. S., & White, R. L. (2016). Competing fragmentation processes of β-substituted propanoate ions upon collision-induced dissociation. Rapid Communications in Mass Spectrometry, 30(19), 2133–2144.

Sekizuka, T., Ogasawara, Y., Ohkusa, T., & Kuroda, M. (2017). Characterization of Fusobacterium varium Fv113-g1 isolated from a patient with ulcerative colitis based on complete genome sequence and transcriptome analysis. PLoS One, 12(12), e0189319.

F. varium genomes. Available from https://www.ncbi.nlm.nih.gov/protein/. Accessed 5 March 2018.

Li, Q.-Z., Jiang, X.-L., Feng, X.-J., Wang, J.-M., Sun, C., Zhang, H.-B., Xian, M., & Liu, H.-Z. (2016). Recovery processes of organic acids from fermentation broths in the biomass-based industry. Journal of Microbiology and Biotechnology, 26(1), 1–8.

Doelle, H. W. (1975). Bacterial metabolism (2nd ed.pp. 269–270). New York: Academic Press.

Clomburg, J. M., & Gonzalez, R. (2013). Anaerobic fermentation of glycerol: A platform for renewable fuels and chemicals. Trends in Biotechnology, 31(1), 20–28.

Khanna, S., Goyal, A., & Moholkar, V. S. (2012). Microbial conversion of glycerol: Present status and future prospects. Critical Reviews in Biotechnology, 32(3), 235–262.

Lancaster, C. R. D. (2001). Succinate:Quinone oxidoreductases – What can we learn from Wolinella succinogenes quinol:Fumarate reductase? FEBS Letters, 504(3), 133–141.

Chung, S.-C., Park, J.-S., Yun, J., & Park, J. H. (2017). Improvement of succinate production by release of end-product inhibition in Corynebacterium glutamicum. Metabolic Engineering, 40, 157–164.

Acknowledgements

This research was funded by the Natural Sciences and Engineering Research Council of Canada (NSERC grant RGPIN/04536-2014). NMR and mass spectra were collected on instruments provided by NMR-3 and the Mass Spectrometry Laboratory, respectively (Dalhousie University).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflicts of interest.

Electronic Supplementary Material

ESM 1

(DOCX 114 kb)

Rights and permissions

About this article

Cite this article

McDonald, N.C., White, R.L. Reduction of Fumarate to Succinate Mediated by Fusobacterium varium. Appl Biochem Biotechnol 187, 163–175 (2019). https://doi.org/10.1007/s12010-018-2817-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-018-2817-0