Abstract

Polyhydroxyalkanoates (PHAs) are promising alternatives to plastics since they have similar properties to polyolefin but are biodegradable and biocompatible. Recently, the conversion of propionate wastewater to PHAs by undefined mixed microbial cultures becomes attractive. However, how microbial community changes remains unclear during the enrichment step, which is critical for a robust PHA-producing system. In this study, PHA-accumulating cultures were enriched under feast/famine condition using propionate-rich substrates. Our results showed that during the first 2 h of the enrichment, dissolved oxygen of cultures increased remarkably until saturation, and amounts of C, N, and chemical oxygen demand of cultures decreased significantly to a very low level. High-throughput sequencing revealed that bacterial populations affiliated with Alphaproteobacteria and Bacteroidetes dominated the cultures enriched. Most of these dominant populations contributed to the conversion of short-chain fatty acids to PHAs. Being fed with the substrate rich in propionate but without nitrogen, the cultures enriched could accumulate nearly 27% PHAs at 72 h with higher content of hydroxyvalerate. Our work reveals the process in which environmental microbes responded to propionate-rich condition and shifted to populations for accumulating PHAs; it also will be helpful to develop an efficient PHA-producing system using propionate-rich waste.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Natural polyesters polyhydroxyalkanoates (PHAs) are emerging as promising alternatives to petroleum-based plastics because they have similar properties to polyolefin but are biodegradable and biocompatible. Therefore, they hold great potentials in chemical, medical, or energy industries [1, 2]. Recently, the production of PHAs by undefined mixed microbial cultures (MMC) becomes attractive [3] as the MMC process is strongly adaptive to various conditions, free of aseptic conditions [3–5], and cost-effective to accomplish waste minimization [6–8].

The production of PHA by MMC comprises three sequential steps: (i) acidogenesis (to produce fatty acids), (ii) the enrichment of microbial community, and (iii) the production of PHAs. Among these steps, the enrichment of microbial cultures is critical. This step via either anaerobic/aerobic regime [9] or feast/famine (F/F) aerobic dynamic selection [4] allows the specific microbial members which accumulate PHAs with certain structures and properties to dominate while non-PHA producing members to decline.

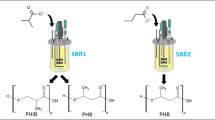

Currently, there are numerous reports on the conversion of volatile fatty acids (VFAs) to PHAs by MMC [4, 10, 11]. Among these fatty acids, the conversion of propionate is full of significance. In the presence of propionate, poly(3-hydroxybutyrate-co-hydroxyvalerate) (PHBV) can be synthesized. Compared to homopolymer poly(3-hydroxybutyrate) (PHB), copolymer PHBV has more desirable thermal and mechanical properties [12]. So far, effects of propionate concentration or/and fermentation parameters on PHA content and polymer structure have been well studied, and growing numbers of bacteria producing PHAs are being reported [13–18]. However, little is known about how microbes respond to nutrient variations under the propionate-rich enrichment condition [19].

In the present study, PHA-producing cultures were enriched using the mix of propionate with acidified food waste, and the microbial community was analyzed based on the Miseq high-throughput sequencing of 16S ribosomal RNA (rRNA) genes and fungal internal transcribed spacer 1 (ITS1). This work helps reveal how microorganisms can respond to propionate-rich condition. It will also contribute to the development of a PHA-producing system using propionate-rich waste in the future.

Materials and Methods

Continuous Acidogenic Fermentation Reactor

Food waste (FW) was collected from a local restaurant in Chengdu, China. Acidification of FW was carried out at 35 ± 1 °C under microaerobic condition in a 0.36-m3 reactor with working volume of 0.27 m3. Air was flushed in the reactor for 15 min/h at the aeration rate of 13 l/min. FW and the water (1:4, v/v) were fed in the reactor every day until the organic loading reached 6.04 kg volatile solids (VS)/(m3/day) and hydraulic retention time reached 3 days. The acidified FW was centrifuged at 4500×g, 4 °C for 20 min. The supernatant was stored at 4 °C.

Sequencing Batch Reactor for Culture Enrichment

A sequencing batch reactor (SBR) with a working volume of 3 l was operated for the enrichment of PHA-accumulating cultures. Based on the setup designed by Albuquerque et al. [13, 20], an SBR cycle endured 12 h long and was consisted of five sequential regimes: (1) a feeding regime (5 min), in which 1400 ml of fresh medium, 100 ml of trace element, and thiourea (10 mg/l) were supplied; (2) a feast/famine regime (10 h and 55 min); (3) a biomass removal regime (5 min), in which 37.5 ml [when sludge retention time (SRT) was 4 days] or 75 ml (when SRT was 2 days) of sludge was removed; (4) a settling regime (45 min); and (5) an effluent regime (10 min), in which 1470 ml (when SRT = 4 days) or 1425 ml (when SRT = 2 days) of reactor liquid was removed.

Initial inocula of the SBR were the mix of aerobic activated sludge from a municipal wastewater treatment plant in Chengdu and a pharmaceutical plant in Jianyang of Sichuan Province. The SBR was fed with the mix of acidified FW supernatant and sodium propionate. The clarified FW solution was diluted using tap water to adjust N concentration to 3.6 N-mmol/l. Sodium propionate was then supplemented to adjust carbon concentration to 45 C-mmol/l. In the influent phase of each SBR cycle, carbon source and mineral-N solution [21] were pumped to the reactor, maintaining C/N/P ratios at 100:8:1. Meanwhile, 10 mg/l thiourea (Sigma-Aldrich, USA) was added to inhibit nitrification. Air was supplied through two ceramic diffusers by a pump.

The fermentation temperature was maintained at 30 °C using a water jacket. The pH of the reactor was controlled using the software MFCS/win (Sartorius Stedim Systems, USA), maintaining at 7.0 ± 0.1 using 1 mol/l HCl and 1 mol/l NaOH. MFCS/win was also used for acquiring online data (DO, pH, temperature, acid dosage, base dosage). The hydraulic retention time (HRT) was kept at 1 day. The SRT was adjusted according to the reactor performance. When the reactor was considered to be in a steady state, which was indicated by constant DO changes for at least 5 days [21], the SRT was adjusted. The reactor was operated initially at the SRT of 4 days and continued at the SRT of 2 days after 25 days.

Polyhydroxyalkanoate Production by Batch Fermentation

PHAs accumulation was carried out in batch mode in 500-ml flasks with working volume of 150 ml. The batch system was consisted of 20 ml of the enriched sludge, 10 mg/l thiourea, trace element solution, and carbon and/or nitrogen substrate. The enriched sludge was collected from the biomass remove phase. Substrates containing different carbon and/or nitrogen were used to test the effect of substrate composition on PHA production: (1) acetate/propionate/butyrate/NH4Cl (APBN), consisting of 11.3 mmol/l sodium acetate trihydrate, 3.3 mmol/l sodium propionate, 3 mmol/l sodium butyrate, and 3.6 mmol/l NH4Cl; (2) APB, the same as APBN except NH4Cl was omitted; and (3) acidogenic food waste plus propionate (FWP), the mix of propionate with the acidified FW supernatant that was the same as the substrate used in enrichment process. A system without adding substrates worked as the control. The effluent obtained from the SBR-enriched culture was supplemented to make the working volume of 150 ml. VFA concentrations in APBN or APB were determined according to components in the acidified FW supernatant to ensure the carbon concentration at 45 C-mmol/l VFA. The pH value was initially adjusted to 7 and left uncontrolled during the PHA production. Cultures were grown for 3 days at 30 °C with shaking at 300 rpm.

DNA Extraction

A half gram of the sludge from the wastewater plant or enrichment cultures was centrifuged for 10 min at 12,000×g and 4 °C. The resulting pellets were used to extract microbial DNAs using the Omega Soil DNA Extraction Kit (Omega BioTek Inc., USA). For each sample, DNAs were extracted in triplicates and pooled. Concentration and quality of the extracted DNA were checked on a 0.7% agarose gel electrophoresis and NanoView Plus spectrometer (GE Healthcare Bio-Sciences, USA).

Miseq High-Throughput Sequencing

Bacterial and fungal diversities were investigated using 16S rRNA genes or ITS1 sequences, respectively, based on the Illumina Miseq pyrosequencing platform. DNAs were PCR-amplified by TranStart Fast pfu DNA polymerase (TransGen Biotech, China) using primer sets 338F (5′-ACTCCTACGGGAGGCAGCA-3′)/806R (5′-GGACTACHVGGGTWTCTAAT-3′) for bacterial 16S rRNA genes and 1737F (5′-GGAAGTAAAAGTCGTAACAAGG-3′)/2043R (5′-GCTGCGTTCTTCATCGATGC-3′) for fungal ITS1 regions. For each sample, triplicates of the PCR products were mixed and assembled. The bacterial and archaeal PCR products were purified from agarose gel using the AxyPrep DNA kit (AXYGEN), followed by fluorometric quantitation using the QuantiFluor™-ST system (Promega, Madison, WI, USA) and then sequenced by an Illumina Miseq PE300 platform.

Sequence reads were analyzed using the Mothur software (http://www.mothur.org/). The reads with quality scores below 25 were removed through the filtration by UCHIME (http://drive5.com/uchime). The rest were trimmed and aligned against the Silva 16S Ribosomal Database Project [22] and clustered into operational taxonomic units (OTUs). Taxonomic classification was carried out via the Silva database. Rarefaction curves, community richness (Chao1 and ACE indices) and community diversity (Shannon and Simpson indices) were also analyzed using the Mothur.

Phylogenetic Analysis

MEGA6 [23] was conducted with maximum parsimony algorism [24] to construct phylogenetic trees. The phylogenic tree was rooted with a fungal species Trichosporonales (GenBank accession number EF060595). Bootstrap values were calculated from 1000 replicates, and the bootstrap values >50% for internal nodes are shown on the branches.

Nucleotide Sequence Accession Numbers

OTU sequences were deposited to the GenBank database under accession numbers KU000058–KU000357 for bacteria sequences and KU000358–KU000597 for fungal sequences.

Analytical Methods

Concentrations of VFAs (acetic acid, propionic acid and butyric acid) were determined using an Agilent 7890A gas chromatograph (GC), according to the description by Tian et al. [25]. Chemical oxygen demand (COD) was calculated according to the standard methods [26]. NH4 +, NO2 −, and NO3 − concentrations were analyzed with a Continuous Flow Analyzer (AutoAnalyzer3, Seal Inc., Germany). The preparation of PHA-containing samples, the extraction of PHA contents, and the measurement of PHA-based GC-MS (Aglient 5975C) followed the description by Oehmen et al. [27]. Commercial P(HB-co-HV) (Sigma-Aldrich, USA) was used as the standard, and benzoic acid (2 mg/ml) was added as a internal standard for the measurement correction.

Results and Discussion

Culture Enrichment

In this study, mixed cultures for producing PHAs were enriched using F/F regime. Representative DO statuses were analyzed: Day 5 and day 20 represented the early and late status of cultures at the SRT of 4 days, and day 32 and day 95 represented the early and late status at the SRT of 2 days.

As shown in Fig. 1 and Supplementary Figure 1, DO displayed clear evolutionary trends during either a single enrichment cycle (a F/F regime) or the entire enrichment period. When SRT was 4 days, DO significantly elevated in one F/F regime, but followed by a decline and finally came to be stable (Fig. 1a, b and Supplementary Figure 1a–c). When SRT came to 2 days, DO kept low level during the first 1–1.25 h, followed by a sharply increase until saturation (Fig. 1c, d and Supplementary Figure 1d–g). DO status reflected the change of microbes with F/F shift of nutrient and with enrichment conditions. In each enrichment cycle, a DO decline after 660 min was due to the shutdown of air supply.

Enrichment of PHA-accumulating cultures. a–d The evolution of dissolved oxygen (DO, black diamonds) and pH (gray squares) states in the enrichment process. DO values were monitored online using the software MFCS/win. The missing DO data in c and d were due to temporary troubles of the software. e The consumption of C and N substrates of an enrichment cycle on day 95. f The COD evolution of an enrichment cycle on day 95. C, N, and COD results were shown using the mean values of three repeats ± standard deviation (sd). g The PHA production of an enrichment cycle on day 95. HB 3-hydroxybutyrate, HV 3-hydroxyvalerate. The results are shown using the mean values of two repeats ± sd. Time point zero in all figures indicates the time when the feast/famine regime of an enrichment cycle (12 h) starts

F/F shift also indicated the run-out of substrates. The consumption of VFA and NH4+ in the steady state was analyzed. After a 5-min feeding regime, the culturing began a feast phase. With the sharp elevation of DO at 2 h, ammonia (NH4 +-N) and VFAs (acetate, butyrate and propionate) were exhausted quickly (Fig. 1e). The COD status was also consistent with the DO trend and substrates consumption (Fig. 1f). These results indicated that the culture enrichment entered in a steady state. The enriched cultures enabled the PHA production (Fig. 1g), but PHA amount quickly declined with the beginning of famine stage, suggesting that such PHA production during the enrichment was not steady.

Batch Production of Polyhydroxyalkanoates

To test the efficacy of PHA production, batch fermentations were carried out under uncontrolled pH condition, using the enriched microbial cultures as inocula (Table 1). As shown in Fig. 2, the PHA accumulation without nitrogen supply (i.e., feeding APB only) was higher than other two groups containing nitrogen (APBN and FWP). Stable PHA accumulation occurred after 24 h and monomer hydroxyvalerate (HV) content was higher than hydroxybutyrate (HB). In the batch reactor fed by APB substrates, more PHAs (22%) were accumulated than any other reactor at 72 h (Fig. 2a), and the maximal PHA yield reached 0.052 g/C-mol VFA.

Batch production of PHAs using APB (a), APBN (b), and FWP (c) as substrates, respectively. d The control without adding substrates. APB acetate + propionate + butyrate, APBN acetate + propionate + butyrate + NH4Cl, FWP acidogenic food waste plus propionate solution. All results were shown using the mean values of two repeats ± sd

It should be noted that HB and HV peaks also appeared but sharply declined at proximately 8 h, when the PHA amount in APBN group was even higher than that in APB group. At this time point, HB monomer dominated rather than HV which dominated after 24 h (Fig. 2). This phenomenon also appeared in the enrichment process (Fig. 1g). However, these peaks did not reflect the stable and specific accumulation of PHA under propionate-rich conditions. The storage and consumption of PHAs are dynamic processes. PHA could be stored when nutrients supply was sufficient whereas utilized for cell growth when nutrients were exhausted, which can explain the appearance of sharp peaks and declines of PHAs during the enrichment and the early stage of batch fermentation (Figs. 1g and 2). In this study, HV monomer was expected to be stably and specifically accumulated instead of degraded, since propionate-rich waste was used. Therefore, to demonstrate the capability of the microbial community to accumulate PHA stably and specifically, we tested a longer fermentation time up to 72 h. So far, most of previous studies focused on how to improve the stability and efficiency of PHA production in fed batch ways. However, our results also suggested that a specific PHA structure that consisted of desirable monomer ratio can be obtained at various time points in a batch fermentation.

Differences in the substrate utilization (C and N) could explain various PHA accumulation abilities of batch fermentations. Nitrogen depletion is critical to PHA accumulation [20, 21]. These evidences, again, approved the impossibility to accumulate PHAs stably in the presence of APBN or FWP substrates. Meanwhile, a fast consumption of VFAs was also important to the PHA production (Fig. 2a). Jiang et al. [16] confirmed that high propionate/acetate ratio led to higher HV content, which also supports our results.

Compared with previous documents using fed-batch fermentation with pulse-wise or continuous feeding [21, 28], the PHA content and yield by our batch tests were low. First, the batch fermentation itself led to the low PHA-accumulating yield. However, this way was simple and quick to test our enriched cultures. Second, previous work suggested that low residual of PHAs was due to the fermentation model (e.g., pulse-wise or continuous feeding regime) or the kinetic limitation effect which limited the pressure for PHA accumulation [13, 28]. Therefore, adjusting nutrient concentration or F/F HRT ratio or employing other feeding regimes is likely to improve the PHA accumulating ability. In addition, microbial community itself is also a factor influencing PHA production, which will be discussed in the next subsection. These studies will provide hints on how to improve PHA yield using our enriched cultures in the future. However, the present work aims to evaluate the potential of the enriched cultures to accumulate PHAs; we therefore did not focus on the improvement of PHA-producing efficiency.

Changes of Microbial Community During Enrichment

To investigate the microbial diversity, the enrichment cultures on day 95 were sampled for high-throughput sequencing. The microbial diversity and richness reduced in the enrichment cultures as compared with the seed sludge (Table 2). Good’s coverage (>0.99) indicated that most phylogenetic species were captured in all of samples, which were also reflected by rarefaction curves (Supplementary Fig. 2).

Most fungal genera except Trichosporon kept low abundances after the enrichment process (Fig. 3a). In the seed sludge, over 79% of fungal OTUs were unclassified. In contrast, Trichosporon became predominant (94%) via the enrichment (Fig. 3b).

The bacterial community of the enrichment cultures also displayed a distinct pattern to seed sludge. The abundance of many populations reduced, whereas those genera with low abundances in the seed sludge turned to be abundant in the enrichment cultures (Fig. 4a and Supplementary Figure 3). The OTUs that were significantly enriched are affiliated with phyla of Proteobacteria, Bacteroidetes and Chloroflexi (Fig. 4b). Predominant OTUs in the enrichment cultures are affiliated with unclassified Rhizobiales (OTU81, 19.5%), genus Rhodobacter (OTU243, 9.4%), unclassified Bacteroidetes (OTU86, 6.5%), genus Paracoccus (OTU218, 5.8%) and genus Amaricoccus (OTU143, 5%) (Fig. 4c). All the five OTUs account for nearly a half of bacterial populations in the enrichment cultures. In addition, abundances of Lewinella (OTU50), Verrucomicrobium (OTU132), Zoogloea (OTU115) and Pseudomonas (OTU145) also remarkably increased in the enrichment cultures.

Bacterial populations of PHA enrichment cultures fed propionate-rich waste. a The heatmap of predominant bacterial populations in the enrichment cultures and the seed sludge. b, c Abundance changes of bacterial community at the level of phylum and genus, respectively. R, the enrichment cultures taken from the SBR. S, the seed sludge

Dominant bacterial populations in the enrichment cultures indicated that the populations producing short-chain length (scl) PHAs could adapt to propionate and were successfully enriched. On one hand, the composition of dominant bacterial populations is able to explain the presence of HB (C4) and HV (C5) as major PHA products. Genus Rhodobacter is able to synthesize scl PHAs (C3-C5) using fatty acids of C2-C12, and its genes responsible for PHAs synthesis have been identified [29, 30]. Paracoccus has a strong uptake ability of propionate to produce scl-PHAs [19, 31]. Amaricoccus was also reported as a dominant genus to converse propionate to PHAs [32]. OTU81 has 95% similarity to Alsobacter metallidurans strain SK200a-9 (GenBank accession number NR_125447) which, as well as other two species of order Rhizobiales, was recently reported to accumulate polyesters in cells [33–35]. Phylogenic analysis revealed that, except OTU86 (an unknown Bacteroidetes), the other four dominant OTUs were affiliated with alphaproteobacteria (Fig. 5). It was reported that PHA synthases (phaC) from the similar species (including many affiliated with Bacteroidetes) belong to the type I [36, 37] which specifically catalyzes the synthesis of scl PHAs [38]. These evidences could also confirm the enrichment of specific PHA-accumulating populations in this study. On the other hand, these microbial members capable of converting propionate to HV also suggested that the PHA level at 8 h could not reflect the real accumulation.

Phylogeny of dominant bacterial taxa in enrichment cultures. The phylogenic tree is rooted with a fungal species Trichosporonales (GenBank accession number EF060595). The percentage of replicate trees in which the associated taxa clustered together in the bootstrap test (1000 replicates) is shown next to the branches. The tree is drawn to scale, with branch lengths in the same units as those of the evolutionary distances used to infer the phylogenetic tree. Red circle, alphaproteobacteria; yellow triangle, betaproteobacteria; green square, gammaproteobacteria

As mentioned above, microbial composition is another factor influencing the production of PHAs. Operating conditions, such as nutrient concentration, F/F ratio, or feeding regime that were mentioned above, would likely serve as selective forces to form a microbial community. As shown in Fig. 3, various PHA amounts were produced when various nutrients were supplied. On the other hand, the resilience and resistance of mixed cultures to environment have been revealed [39], so it was believed that the core populations will be enhanced (for example, the abundance of dominant members will become higher but never be significantly changed) with the enrichment or production of PHAs, allowing the specific PHA synthetic pathway more efficient. However, it remains unknown about whether the PHA-producing populations would change between the enrichment (selection) stage and the PHA production stage. The relevant work will be necessary in the future for developing efficient PHA-producing systems.

The enrichment of fungi in our PHA enrichment cultures is worthy of being discussed. It is well known that eukaryotes are unable to produce PHAs due to the lack of PHA synthase; thus, no study has investigated the fungal population in PHA-producing cultures. However, the enrichment process was suitable (e.g., moderate temperature, pH, and air) for the enrichment of PHA-accumulating bacteria as well as fungi. Actually, our results revealed the enrichment of oleaginous Trichosporon in mixed cultures (Fig. 3). Despite little about this fungal population was known in the PHA enrichment cultures, its roles can be presumed based on its property. The enrichment cultures of this study showed strong settling property (unpublished observation), which is desirable for the recovery of PHA accumulating sludge. We hypothesized that this settlement property is most likely related to the flocculation ability of Trichosporon as well as a filamentous bacterium Verrucomicrobium that were also enriched [40, 41]. On the other hand, Trichosporon possibly affect the accumulation of PHA by competing nutrients with PHA-accumulating bacteria [42], which could be an additional factor influencing PHA accumulation but were not paid attention so far.

In this study, we could only know about the relative abundance of either bacterial or fungal populations but nothing about the absolute abundance of a certain group in the total population. So far, it is tough to find consensus DNA marker sequences in both bacteria and fungi of PHA-producing mixed cultures, and a great deal of microorganisms remains unknown in these culture, too. Therefore, it is still challenging to investigate the ratio of fungi in the total population and/or the ratio changes during the enrichment.

Conclusions

In this work, the mixed cultures accumulating PHAs were successfully enriched using propionate-rich waste. The populations affiliated with Rhizobiales, Rhodobacter, Bacteroidetes, Paracoccus, and Amaricoccus became enriched and predominant in the enriched microbial cultures. They were able to convert VFAs to scl-PHAs. Meanwhile, a fungal species, Trichosporon, was also enriched, which was also likely a microbial factor affecting the PHA production by MMC. With the enrichment of microbes, DO evolved to a stable state, carbon and nitrogen were quickly exhausted, and COD reduced quickly. Employing the enrichment cultures, 27 ± 7% of PHAs (TTS %) could be accumulated by batch fermentations, with the high content of HB compound. This work will enhance our knowledge on how the microbial community for producing PHA responds and adapts to propionate waste and help us to build an efficient PHA-producing system using propionate-rich waste.

COD, chemical oxygen demand; DO, dissolved oxygen; FW, food waste; GC, gas chromatograph; HMV, poly-beta-hydroxy-2-methylvalerate; HRT, hydraulic retention time; ITS1, internal transcribed spacer; MMC, mixed microbial cultures; PHA(s), polyhydroxyalkanoate(s); PHB, poly(3-hydroxybutyrate); PHBV, poly(3-hydroxybutyrate-co-hydroxyvalerate); PHV, poly(3-hydroxyvalerate); SBR, sequencing batch reactor; scl, short-chain length; SRT, solid retention time; VFAs, volatile fatty acids (VFAs); VS, volatile solids

References

Gao, X., Chen, J. C., Wu, Q., & Chen, G. Q. (2011). Polyhydroxyalkanoates as a source of chemicals, polymers, and biofuels. Current Opinion in Biotechnology, 22, 768–774.

Andreessen, B., Taylor, N., & Steinbuchel, A. (2014). Poly(3-hydroxypropionate): a promising alternative to fossil fuel-based materials. Applied and Environmental Microbiology, 80, 6574–6582.

Kleerebezem, R., & van Loosdrecht, M. C. (2007). Mixed culture biotechnology for bioenergy production. Current Opinion in Biotechnology, 18, 207–212.

Reis, M. A., Serafim, L. S., Lemos, P. C., Ramos, A. M., Aguiar, F. R., & Van Loosdrecht, M. C. (2003). Production of polyhydroxyalkanoates by mixed microbial cultures. Bioprocess and Biosystems Engineering, 25, 377–385.

Rossi, F., Olguin, E. J., Diels, L., & De Philippis, R. (2015). Microbial fixation of CO2 in water bodies and in drylands to combat climate change, soil loss and desertification. New Biotechnology, 32, 109–120.

Valentino, F., Morgan-Sagastume, F., Fraraccio, S., Corsi, G., Zanaroli, G., Werker, A., & Majone, M. (2015). Sludge minimization in municipal wastewater treatment by polyhydroxyalkanoate (PHA) production. Environmental Science and Pollution Research International, 22, 7281–7294.

Morgan-Sagastume, F., Hjort, M., Cirne, D., Gerardin, F., Lacroix, S., Gaval, G., Karabegovic, L., Alexandersson, T., Johansson, P., Karlsson, A., Bengtsson, S., Arcos-Hernandez, M. V., Magnusson, P., & Werker, A. (2015). Integrated production of polyhydroxyalkanoates (PHAs) with municipal wastewater and sludge treatment at pilot scale. Bioresource Technology, 181, 78–89.

Anterrieu, S., Quadri, L., Geurkink, B., Dinkla, I., Bengtsson, S., Arcos-Hernandez, M., Alexandersson, T., Morgan-Sagastume, F., Karlsson, A., Hjort, M., Karabegovic, L., Magnusson, P., Johansson, P., Christensson, M., & Werker, A. (2014). Integration of biopolymer production with process water treatment at a sugar factory. New Biotechnology, 31, 308–323.

Carvalheira, M., Oehmen, A., Carvalho, G., & Reis, M. A. (2014). Survival strategies of polyphosphate accumulating organisms and glycogen accumulating organisms under conditions of low organic loading. Bioresource Technology, 172, 290–296.

Nikodinovic-Runic, J., Guzik, M., Kenny, S. T., Babu, R., Werker, A., & KE, O. C. (2013). Carbon-rich wastes as feedstocks for biodegradable polymer (polyhydroxyalkanoate) production using bacteria. Advances in Applied Microbiology, 84, 139–200.

McQualter, R. B., Petrasovits, L. A., Gebbie, L. K., Schweitzer, D., Blackman, D. M., Chrysanthopoulos, P., Hodson, M. P., Plan, M. R., Riches, J. D., Snell, K. D., Brumbley, S. M., & Nielsen, L. K. (2015). The use of an acetoacetyl-CoA synthase in place of a beta-ketothiolase enhances poly-3-hydroxybutyrate production in sugarcane mesophyll cells. Plant Biotechnology Journal, 13, 700–707.

Tan, D., Wu, Q., Chen, J. C., & Chen, G. Q. (2014). Engineering Halomonas TD01 for the low-cost production of polyhydroxyalkanoates. Metabolic Engineering, 26C, 34–47.

Albuquerque, M. G., Martino, V., Pollet, E., Averous, L., & Reis, M. A. (2011). Mixed culture polyhydroxyalkanoate (PHA) production from volatile fatty acid (VFA)-rich streams: effect of substrate composition and feeding regime on PHA productivity, composition and properties. Journal of Biotechnology, 151, 66–76.

Carvalheira, M., Oehmen, A., Carvalho, G., & Reis, M. A. (2014). The effect of substrate competition on the metabolism of polyphosphate accumulating organisms (PAOs). Water Research, 64, 149–159.

Johnson, K., Kleerebezem, R., & van Loosdrecht, M. C. (2010). Influence of the C/N ratio on the performance of polyhydroxybutyrate (PHB) producing sequencing batch reactors at short SRTs. Water Research, 44, 2141–2152.

Jiang, Y., & Chen, Y. (2009). The effects of the ratio of propionate to acetate on the transformation and composition of polyhydroxyalkanoates with enriched cultures of glycogen-accumulating organisms. Environmental Technology, 30, 241–249.

Liu, C., Wang, H., Xing, W., & Wei, L. (2013). Composition diversity and nutrition conditions for accumulation of polyhydroxyalkanoate (PHA) in a bacterial community from activated sludge. Applied Microbiology and Biotechnology, 97, 9377–9387.

Fradinho, J. C., Oehmen, A., & Reis, M. A. (2013). Effect of dark/light periods on the polyhydroxyalkanoate production of a photosynthetic mixed culture. Bioresource Technology, 148, 474–479.

Albuquerque, M. G., Carvalho, G., Kragelund, C., Silva, A. F., Barreto Crespo, M. T., Reis, M. A., & Nielsen, P. H. (2013). Link between microbial composition and carbon substrate-uptake preferences in a PHA-storing community. The ISME Journal, 7, 1–12.

Albuquerque, M. G., Eiroa, M., Torres, C., Nunes, B. R., & Reis, M. A. (2007). Strategies for the development of a side stream process for polyhydroxyalkanoate (PHA) production from sugar cane molasses. Journal of Biotechnology, 130, 411–421.

Johnson, K., Jiang, Y., Kleerebezem, R., Muyzer, G., & van Loosdrecht, M. (2009). Enrichment of a mixed bacterial culture with a high polyhydroxyalkanoate storage capacity. Biomacromolecules, 10, 670–676.

Quast, C., Pruesse, E., Yilmaz, P., Gerken, J., Schweer, T., Yarza, P., Peplies, J., & Glöckner, F. (2013). The SILVA ribosomal RNA gene database project: improved data processing and web-based tools. Nucl Acids Res, 41, D590–D596.

Tamura, K., Stecher, G., Peterson, D., Filipski, A., & Kumar, S. (2013). MEGA6: molecular evolutionary genetics analysis version 6.0. Molecular Biology and Evolution, 30, 2725–2729.

Tamura, K., Nei, M., & Kumar, S. (2004). Prospects for inferring very large phylogenies by using the neighbor-joining method. Proceedings of the National Academy of Sciences of the United States of America, 101, 11030–11035.

Tian, Z., Zhang, Y., Li, Y., Chi, Y., & Yang, M. (2015). Rapid establishment of thermophilic anaerobic microbial community during the one-step startup of thermophilic anaerobic digestion from a mesophilic digester. Water Research, 69, 9–19.

Rice, E., Baird, R., Eaton, A., & Cleseri, L. (Eds.) (1998). Standard methods for the examination of water and wastewater. Washington, DC: American Public Health Association, American Water Works Association, and Water Environmental Federation.

Oehmen, A., Keller-Lehmann, B., Zeng, R. J., Yuan, Z., & Keller, J. (2005). Optimisation of poly-β-hydroxyalkanoate analysis using gas chromatography for enhanced biological phosphorus removal systems. Journal of Chromatography A, 1070, 131–136.

Albuquerque, M. G., Concas, S., Bengtsson, S., & Reis, M. A. (2010). Mixed culture polyhydroxyalkanoates production from sugar molasses: the use of a 2-stage CSTR system for culture selection. Bioresource Technology, 101, 7123–7133.

Kranz, R. G., Gabbert, K. K., & Madigan, M. T. (1997). Positive selection systems for discovery of novel polyester biosynthesis genes based on fatty acid detoxification. Applied and Environmental Microbiology, 63, 3010–3013.

Kranz, R. G., Gabbert, K. K., Locke, T. A., & Madigan, M. T. (1997). Polyhydroxyalkanoate production in Rhodobacter capsulatus: genes, mutants, expression, and physiology. Applied and Environmental Microbiology, 63, 3003–3009.

Pardelha, F., Albuquerque, M. G., Carvalho, G., Reis, M. A., Dias, J. M., & Oliveira, R. (2013). Segregated flux balance analysis constrained by population structure/function data: the case of PHA production by mixed microbial cultures. Biotechnology and Bioengineering, 110, 2267–2276.

Lemos, P. C., Levantesi, C., Serafim, L. S., Rossetti, S., Reis, M. A. M., & Tandoi, V. (2008). Microbial characterisation of polyhydroxyalkanoates storing populations selected under different operating conditions using a cell-sorting RT-PCR approach. Applied Microbiology and Biotechnology, 78, 351–360.

Salgaonkar, B. B., & Braganca, J. M. (2015). Biosynthesis of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) by Halogeometricum borinquense strain E3. International Journal of Biological Macromolecules, 78, 339–346.

Samori, C., Abbondanzi, F., Galletti, P., Giorgini, L., Mazzocchetti, L., Torri, C., & Tagliavini, E. (2015). Extraction of polyhydroxyalkanoates from mixed microbial cultures: impact on polymer quality and recovery. Bioresource Technology, 189, 195–202.

Amulya, K., Jukuri, S., & Venkata Mohan, S. (2015). Sustainable multistage process for enhanced productivity of bioplastics from waste remediation through aerobic dynamic feeding strategy: process integration for up-scaling. Bioresource Technology, 188, 231–239.

Foong, C. P., Lau, N. S., Deguchi, S., Toyofuku, T., Taylor, T. D., Sudesh, K., & Matsui, M. (2014). Whole genome amplification approach reveals novel polyhydroxyalkanoate synthases (PhaCs) from Japan Trench and Nankai Trough seawater. BMC Microbiology, 14, 318.

Meng, D. C., Wang, Y., Wu, L. P., Shen, R., Chen, J. C., Wu, Q., & Chen, G. Q. (2015). Production of poly(3-hydroxypropionate) and poly(3-hydroxybutyrate-co-3-hydroxypropionate) from glucose by engineering Escherichia coli. Metabolic Engineering, 29, 189–195.

Liu, K., Chen, Y., Xiao, N., Zheng, X., & Li, M. (2015). Effect of humic acids with different characteristics on fermentative short-chain fatty acids production from waste activated sludge. Environmental Science & Technology, 49, 4929–4936.

Werner, J. J., Knights, D., Garcia, M. L., Scalfone, N. B., Smith, S., Yarasheski, K., Cummings, T. A., Beers, A. R., Knight, R., & Angenent, L. T. (2011). Bacterial community structures are unique and resilient in full-scale bioenergy systems. Proceedings of the National Academy of Sciences of the United States of America, 108, 4158–4163.

Fernandez-Dacosta, C., Posada, J. A., Kleerebezem, R., Cuellar, M. C., & Ramirez, A. (2015). Microbial community-based polyhydroxyalkanoates (PHAs) production from wastewater: techno-economic analysis and ex-ante environmental assessment. Bioresource Technology, 185, 368–377.

dos Santos, L. A., Ferreira, V., Neto, M. M., Pereira, M. A., Mota, M., & Nicolau, A. (2015). Study of 16 Portuguese activated sludge systems based on filamentous bacteria populations and their relationships with environmental parameters. Applied Microbiology and Biotechnology, 99, 5307–5316.

Wang, Y., Zhang, C., Gong, T., Zuo, Z., Zhao, F., Fan, X., Yang, C., & Song, C. (2015). An upp-based markerless gene replacement method for genome reduction and metabolic pathway engineering in Pseudomonas mendocina NK-01 and Pseudomonas putida KT2440. Journal of Microbiological Methods, 113, 27–33.

Acknowledgements

This work was supported by the Sichuan Key Technology R&D Program (2014NZ0045), Special Fund for Agro-scientific Research in the Public Interest of China (201403019), and Youth Science and Technology Foundation of Sichuan Province (2015JQO047).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

ESM 1

(DOC 2487 kb)

Rights and permissions

About this article

Cite this article

Wu, B., Zheng, D., Zhou, Z. et al. The Enrichment of Microbial Community for Accumulating Polyhydroxyalkanoates Using Propionate-Rich Waste. Appl Biochem Biotechnol 182, 755–768 (2017). https://doi.org/10.1007/s12010-016-2359-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-016-2359-2