Abstract

Pectinases catalyze the degradation of pectic substances and are used in several processes, mainly in food and textile industries. In this study, a biomimetic matrix of alginate/gelatin/calcium oxalate (AGOCa) was synthesized for the in situ immobilization via encapsulation of crude pectinase from Aspergillus niger ATCC 9642, obtaining an immobilization efficiency of about 61.7 %. To determine the performance of AGOCa matrix, this was compared to control matrices of alginate/calcium oxalate (AOxal) and alginate/water (ACa). By the evaluation of pH and temperature effects on the enzyme activity, it was observed an increase on pectinolytic activity for both three tested matrices with an increase on pH and temperature. The kinetic parameters for pectinase immobilized in the three matrices were determined using citric pectin as substrate. Values of K m of 0.003, 0.0013, and 0.0022 g mL−1 and V max of 3.85, 4.32, and 3.17 μmol min−1 g−1 for AGOCa, AOxal, and ACa matrices were obtained, respectively. After 33 days of storage, the pectinase immobilized in the three different matrices kept its initial activity, but that immobilized in AGOCa presented high stability to the storage with a relative activity of about 160 %. The enzyme immobilized in AGOCa, AOxal, and ACa could be used in 10, 8, and 7 cycles, respectively, keeping 40 % of its initial activity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pectinases are a heterogeneous group of enzymes that catalyze the hydrolysis of complex carbohydrates called pectic substances. Their basic chemical structure is constituted, essentially, by molecules of d-galacturonic acid linked by α-d-(1,4) glycosidic bonds and, in low amount, by rhamnose, arabinose, and galactose [1, 2]. These carbohydrates comprise the primary wall cell and middle lamella of higher plants, the main responsible for high viscosity and turbidity of fruit juices. In food industries, the pectinases are largely used during the extraction, filtration, and clarification of fruit juices and wines steps [3].

However, besides their technological potentialities, pectinases are capable of denaturing by several physical, chemical, and biological factors during application or storage [4, 5]. The development of immobilization techniques permits that enzymes are protected from these factors and improve their performance, as a consequence of increase on enzyme stability by chemical and physical interactions between the support and the enzyme molecules. In addition, the insoluble enzyme derivative can be recovered and reused with high half-life and lower degradation, making economically viable the biotechnological process [6, 7].

Enzymes can be immobilized on a wide variety of natural or synthetic supports. The screening of the support and/or technique of immobilization depends on the nature of the enzyme, substrate, and its further application [8]. One of the most used techniques is the immobilization by encapsulating, a physical method where the molecules of enzymes keep free in solution but have their movement restrict by the reticular structure of the gel and the diffusion of the substrate and products is through the pores of the membrane formed [9]. By this technique, the catalysts tend to be more stable than those physically adsorbed on supports, since the catalytic properties of soluble form are kept [10].

Pectinases have been immobilized by encapsulating in different organic and inorganic polymeric supports, as agar-agar [11], polyvinyl alcohol foam [12], and sodium alginate [13]. From these, calcium alginate noteworthy for its low cost and biocompatibility however has as drawback its low mechanical and chemical resistance. On the other hand, the inorganic components, as zeolites and clays, have excellent mechanical properties and resistance to different solvents [14].

Manufactured by living organisms through the process of biomineralization, biominerals are mineral and/or mineralizing materials formed from organic and inorganic components under mild conditions of pH and temperature [15]. By means of these biological systems, biomimetic mineralization technique uses biological template and synthetic analogs to catalyze the formation of inorganic oxides under mild and benign conditions to obtaining polymer-inorganic hybrid materials which have specific characteristics of both organic as inorganic matrix [16]. These materials obtained by biomimetic mineralization reactions provide biocompatible environments for enzymes immobilization, besides a simple and easy methodology, being considered the next generation of matrices for encapsulating and stabilization of enzymes [17], in contrast to sol-gel, the most common method for obtaining hybrid materials, characterized as a time-consuming and laborious method, involving the use of surfactants and organic solvents, which can cause prejudicial effects on the immobilized enzyme [18].

In our prior work, a polymer-inorganic hybrid matrix for the immobilization of crude pectinase from Aspergillus niger ATCC 9642, constituted by spheres of calcium alginate recovered by a biomimetic layer of gelatin and calcium oxalate, has been successfully synthesized for biomimetic mineralization technique [19]. Based on these aspects, the main objective of this work was to evaluate the performance and the influence of biomimetic matrix on the enzymatic activity of pectinase from Aspergillus niger ATCC 9642 immobilized in situ in the biomimetic matrix of alginate/gelatin/calcium oxalate (AGOCa) by the determination of the effects of the formation of biomimetic matrix on the catalytic activity of the immobilized derivate in the AGOCa. Comparative studies in terms of efficiency and yield of immobilization, optima temperature and pH, kinetic parameters, and stability to the storage and reuse were carried out using as control not biomimetic matrices of alginate/calcium oxalate (AOxal) and alginate/distillated water (ACa).

Material and Methods

Materials

Aspergillus niger ATCC 9642 was kindly supplied by FIOCRUZ (Brazil). Sodium alginate was purchased from Cinética Reagentes-Soluções (Brazil). Gelatin (bloom ≤ 260 g) was purchased from Gelita (Brazil). Pectin, α-d-galacturonic acid monohydrate, and DNS (3,5-dinitrosalicylic acid) used in the study were purchased from Sigma-Aldrich (Germany). All other chemicals were of analytical grade and used without further purification.

Bioproduction of Pectinase from A. niger ATCC 9642

The enzymatic extract was produced as described by Gomes et al. [20]. A. niger ATCC 9642 strain was maintained in potato dextrose agar (PDA) (10 g L−1 malt extract, 4 g L−1 yeast extract, 4 g L−1 glucose, and 20 g L−1 agar), re-cultivated periodically, and stored at 4 °C. The PDA was used as medium for the inoculum production. Erlenmeyer flasks of 500 mL containing 100 mL of sterilized medium were inoculated and incubated at 30 °C by 7 days. The harvesting of the spores from the slants was done using 5 mL of Tween 80-water (0.02 %, v/v).

The bioproduction of pectinase was carried out by submerged fermentation. The liquid medium used as substrate was constituted of citric pectin (32 g L−1), l-asparagine (2 g L−1), iron sulfate II (1.0 g L−1), and potassium phosphate (0.06 g L−1). Two hundred fifty milliliters of liquid medium was transferred to Erlenmeyer of 500 mL, inoculated using 5 × 106 spores mL−1, and incubated at 30 °C and 180 rpm for 24 h. The crude pectinase was immediately kept at 4 °C until use [20].

Synthesis of Hybrid Polymer-Inorganic Support for Pectinase Immobilization

The protocol for pectinase immobilization was described in our previous work [19]. Sodium alginate (2 %, w/v) dissolved in sodium oxalate buffer (100 mM, pH 5.5) was prepared. After the solubilization, the crude pectinase was added at proportion 3:10 (v/v), considering the relation crude pectinase to sodium oxalate buffer. The gel obtained was dripped in a CaCl2 (75 mM) solution and gelatin (1 %, w/v), using a 10-mL syringe with a 0.9-mm-diameter needle, under constant agitation. The beads formed of alginate/gelatin/calcium oxalate (AGOCa) were kept 10 min in the solution of CaCl2 and gelatin. After, the beads were washed with 100 mL of distilled water and 100 mL sodium acetate buffer (100 mM, pH 5.5). After the washing process, the beads were filtered with vacuum pump (Tecnal TE-085) for 20 min and stored in desiccator at 4 °C. For the formation of the control matrix of the alginate/calcium oxalate (AOXal) and alginate/distilled water (ACa), the same procedure was adopted, with the exception of alginate dissolved using sodium oxalate buffer (100 mM, pH 5.5) and distilled water, respectively, and the solution of CaCl2 (75 mM) did not contain gelatin.

Characterization of the Support and Immobilized Enzyme

Morphology Analysis of the Beads

The morphology of the capsules surface of the AGOCa, AOxal, and ACa was observed with Lupa Leb-3 (Lambda) of eyepiece WF10x and 1280 × 1024 resolutions. The morphological structures of the images were digitally captured using the Motic Images Plus 2.0 software.

Efficiency of Immobilization

The immobilization efficiency was determined by Eq. 1:

where E I is the immobilization efficiency (%), A L represents the total activity of the free crude pectinase used for immobilization, and A S denotes the total activity in the supernatant (calcium chloride solution).

Yield of Immobilization

The yield of immobilization was determined by Eq. 2:

where γ is the yield of immobilization (%), A IE represents the total experimental activity of the immobilized enzyme (calculated considering the total mass of immobilized enzyme), and A IT denotes the total theoretical activity of the immobilized enzyme (A IT = A L − A S).

Determination of Enzymatic Activity

The pectinolytic activity of the free and immobilized crude pectinase was determined by the 3,5-dinitrosalicylic acid method [21] using citric pectin as substrate (0.5 %, w/v in sodium acetate buffer 50 mM) for 5 min for immobilized enzyme (pH 5.5 and 73 °C) [16] and 6 min for free enzymes (pH 5.5 and 37 °C) [20]. The quantification was carried out by the external standards method, employing a calibration curve with α-d-galacturonic acid as reducing sugar. The absorbance was measured in spectrophotometer (Beckman Coutler, model DU640) at 540 nm. One unit of pectinolytic activity was defined as the amount of enzyme necessary to liberate 1 μmol of galacturonic acid per minute (U = μmol min−1) under the studied conditions. The activities of the free and immobilized pectinase were expressed in unit of activity per milliliter (U mL−1) and per gram (U g−1), respectively.

Partial Characterization of the Immobilized Pectinase

The partial characterization of immobilized pectinase was performed in terms of optimal temperature and pH and storage stability. The kinetic parameters K m and V max were also determined using citric pectin as a substrate.

Effect of pH and Temperature of the Immobilized Pectinase

The effects of pH and temperature on the pectinolytic activity of the immobilized pectinase were evaluated using a Central Composite Rotational Design (DCCR 22). The range of pH and temperature studied was 3 to 6 and 30 to 80 °C, respectively. The enzyme activity was determined based on the amount of galacturonic acid produced.

Determination of the Kinetic Parameters K m and V max

For the determination of the Michaelis-Menten constant K m and the maximum reaction velocity V max of immobilized pectinase, the effect of substrate concentration on the initial velocity of the reaction by varying the citric pectin concentrations (0.5 to 15 mg mL−1) under optimized assay conditions was evaluated. The reaction rate was assayed at each substrate concentration. The K m and V max values were calculated from Lineweaver-Burk plots by using the initial rate of the enzymatic reaction [22].

Stability of the Immobilized Pectinase to Storage

The stability to storage was evaluated by measuring the activity of the immobilized pectinase stored at 4 °C. The enzyme activity was determined at predetermined intervals of time to follow stability of the immobilized catalyst during the storage. The storage stability (SS) was defined as the ratio between the immobilized pectinase activity during the storage (U s) and its initial activity (U I) (Eq. 3).

Operational Stability

The operational stability of the immobilized pectinase was determined after successive batch cycles of a defined amount of the immobilized extract on the hydrolysis of citric pectin. The reaction time for each batch cycle was 5 min. The activity of the first cycle was considered as 100 %. After each cycle, the beads containing the crude pectinase were removed from the reaction medium and washed with distilled water and sodium acetate buffer.

Statistical Analysis

The statistical analysis related to the estimated effects of each variable and process optimization was performed using the global error and the relative standard deviation between the experimental and predicted data. The other results were treated by analysis of variance followed by Tukey’s test. All analysis was performed using the software Statistica version 8.0 (Statsoft Inc, USA), considering a confidence level of 95 % (p < 0.05).

Results and Discussion

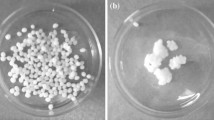

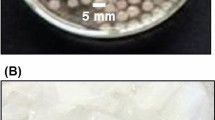

Morphology of Capsules

The visual aspect and texture of the matrix synthesized with sodium oxalate buffer were different from the matrix ACa. The spheres AGOCa and AOxal presented a white color and a harder texture when compared to the ACa spheres, which were semitransparent and with a softer texture. Regarding the size, the AGOCa matrix showed greater diameter (3.1 mm) than the control matrices of AOxal (2.9 mm) and ACa (2.6 mm). The morphological analysis of the matrices of encapsulating showed that the spheres of AGOCa (Fig. 1a) and AOxal (Fig. 1b) are more rounded and defined than the ACa (Fig. 1c) capsules. Furthermore, the surfaces of AGOCa and AOxal matrices present smaller roughness and greater uniformity than the ACa matrix. The morphological differences in immobilization matrices are related to the use of sodium oxalate buffer, which in presence of calcium leads to the formation of calcium oxalate which is incorporated in the sphere morphology during the syntheses of matrices of immobilization of both AGOCa and AOxal. This compound provides stability and structural rigidity, while minimizes the possible deformation of the matrix AGOCa and AOxal as those seen in ACa matrix which does not have the composition of calcium oxalate.

Yield of Immobilization

The efficiency and the yield of immobilization for each capsule evaluated in this study are presented in Table 1. Among the matrices studied, the AGOCa presented the highest efficiency of immobilization (61.7 %). AOXal and ACa matrices showed efficiencies of 53.0 and 55.6 %, respectively. The highest efficiency obtained by AGOCa is linked to the formation in situ of the biomimetic layer in the matrix, minimizing the lixiviation of the enzymatic extract during the formation of the spheres, increasing the amount of enzyme retained in the support.

The yield of immobilization for the three matrices studied was higher than 100 %. The lowest yield, 127 %, was observed for the AGOCa matrix. The absence of gelatin in the AOXal matrix (203 %) and of gelatin and calcium oxalate in ACa matrix (240 %), even though there is decrease on the efficiency of immobilization (Table 1), led to an increase (>53 %) in the yield.

The tendency observed for the yield of immobilization (ACa>AOxal>AGOCa) indicates that the incorporation of calcium oxalate and gelatin acts negatively on the yield. This behavior is associated with diffusional problems caused by the presence of calcium oxalate and gelatin, which can be making the matrix more compact, leading to a decrease in the porosity of the matrix [19].

Considering that the efficiency of immobilization corresponds to the amount of enzyme theoretically incorporated to the support and the yield of the immobilization the effective activity of the supported enzyme, the results presented in Table 1 (with efficiencies <61 % and yields of immobilization >100 %) indicate that the process of immobilization, independent of the matrix used, provides an effective increase of activity of the enzyme.

Partial Characterization of the Immobilized Pectinase

Effect of pH and Temperature on the Pectinolytic Activity of Derivatives Immobilized

The effect of pH and temperature on the pectinolytic activity of immobilized extract was evaluated by a Central Composite Rotational Design (CCRD 22). Table 2 presents the matrix of the experimental design with the evaluated pH and temperature ranges and the responses in terms of pectinolytic activity (U g−1). For all evaluated conditions, the same tendency among the matrices (ACa>AOxal>AGOCa) for the enzyme activity was observed.

Higher enzyme activities of 2.50, 3.73, and 5.55 U g−1 were obtained at experiment 4 (pH 5.5, 73 °C) for the matrices AGOCa, AOxal, and ACa, respectively. The results were statistically treated and empirical models were generated (Eqs. 4, 5, and 6) corresponding to the behavior of pectinolytic activity of the immobilized extract in terms of pH and temperature. The models were validated by variance analysis (correlation coefficient higher than 0.90 and value of F calculated > F tabulated) making possible to build the response surfaces and contour curves (Fig. 2).

where

- EA:

-

pectinolytic activity (U g−1)

- X 1 :

-

pH

- X 2 :

-

temperature (°C)

An increase on pectinolytic activity was observed with the increase in pH and temperature in the range evaluated. The matrices AGOCa (Fig. 2a, b) and AOxal (Fig. 2c, d) presented a similar behavior, leading to better values of enzyme activity in pH values from 5.0 to 6.0 and temperature from 60 to 80 °C. The matrix ACa showed optima values of enzyme activity at pH values from 5.0 to 6.0 in a wide range of temperature (40 to 80 °C) as show in (Fig. 2e, f). This tendency is linked to the reduction of viscosity of the substrate with increasing the temperature, enhancing the diffusion of the substrate to the active site of the immobilized extract through the porous structure of the support [23].

The maximum enzyme activity (72.93 U mL−1) of free pectinase extract from A. niger ATCC 9642 used in this study was observed at pH 5.5 and 37 °C [20]. Compared to the free enzyme, after immobilization of crude pectinase, it retained the same value of optimum pH (5.5), indicating that the immobilization did not influence the optimum pH for maximum pectinolytic activity. However, for the free pectinase, it was observed the maximum activity at 37 °C [20], but after immobilization process, the optimum temperature of derivative immobilized was increased to 73 °C. This change can be related to the enhancement of molecular diffusion rate promoted by the increase of the temperature and to the alterations of physical properties of the enzyme after immobilization [24]. In general, due to the interactions between the enzyme and the support, the immobilization processes can improve the molecular rigidity and conformational stability of the immobilized enzymes [25]. So, high energy is necessary to the reorganization of the molecular structure to reach an adequate conformation to make possible the binding with the substrate, making the enzyme more resistant to the heat denaturation [26].

Kinetic Parameters

The kinetic parameters of the immobilized enzyme extract (V max and K m) were determined using different concentrations of substrate citric pectin (0.5 to 15 mg mL−1) at 73 °C and pH 5.5 (best condition observed in the maximization of enzyme activity assay; Table 2—experiment 4). Table 3 presents the kinetic parameters for each matrix studied here.

Higher values of K m were obtained for the matrix AGOCa, compared to AOxal and ACa matrices. This result is corroborated by the low yield of immobilization obtained for this matrix, related to the formation of an inorganic layer around the spheres of AGOCa, minimizing the affinity of the enzyme by the substrate, as well as the reaction initial rate. Increases in the values of K m can be caused by the low accessibility of the substrate to the catalytic site of the enzyme, as a result of diffusional limitation, as well as the conformational changes of the enzyme, resulting on the decrease of the formation of enzyme-substrate complex [27].

These limitations are due mainly to the size of beads, form, porosity, and charge of immobilized enzyme, as well as the structural changes of the enzyme, where the molecules may have taken an inactive conformation [28, 29]. Higher values of V max were obtained for the pectinolytic extract immobilized in AOxal.

Stability to the Storage

The stability to the storage of the pectinolytic extract immobilized in AGOCa, AOxal, and ACa was studied at 4 °C (Fig. 3). All the matrices were dry stored, since the immersion in buffer solution conducted to swelling due to the water adsorption [19].

From Fig. 3, we can observe that different profiles of relative activity were obtained during the storage at 4 °C as a function of the matrix of immobilization. The extract immobilized in AGOCa presented higher stability to the storage as well as relative activity (≅160 %) compared to the control matrices, that presented relative activities of ≅100%. It is worth to mention that independent from the matrix used as support, the pectinolytic immobilized extract stored at 4 °C kept its initial activity after 33 days of storage. Similar values have been reported for relative activity (≅100 %) obtained for the free enzymatic extract after 30 days of storage at 4 °C [20].

The increased residual activity of the immobilized pectinase in AGOCa after storage may be explained by protecting the outside environment and adverse effects of temperature that the support offers to enzyme, which enables increases in pectinolytic activity as a result of improving the microenvironment created around the enzyme molecules and simulation of the effects of agglomeration and confinement that take place in living cells [14, 30]. Immobilized pectinase in nanoparticles of Fe3O4 kept relative activities of about 65 % after 30 days of storage at 4 °C [31].

Reuse of the Immobilized Derivatives

The operational stability of the immobilized pectinase in AGOCa, AOxal, and ACa was evaluated by the reuse of a defined amount of the immobilized derivative and substrate. After each reaction cycle, a new amount of substrate was added for a new reaction, until obtaining a residual activity less than 50 % (Fig. 4).

It was observed after the first cycle of use a decrease on the catalytic activity of the immobilized pectinase, for all matrices studied here. The derivative immobilized obtained using AGOCa as support of immobilization presented the best results, 42.38 % of residual activity after 10 cycles of use. Relative activities of 46.33 and 44.89 % were obtained after 8 and 7 cycles, for AOxal and ACa matrices, respectively. The loss of enzyme activity can be attributed to the lixiviation of the enzyme from the support as a result of successive washings after each cycle, in addition to possible conformational alterations and mechanical damages after repeated cycles [32, 33].

Conclusions

The strategy of immobilization of crude pectinase in situ of the AGOCa matrix permitted to obtain good results in terms of pectinolytic activity, showing a promising matrix for the immobilization of enzymes aiming at industrial applications. A hybrid polymer-inorganic of alginate/gelatin/calcium oxalate (AGOCa) presented the higher efficiency of immobilization due to the formation of an inorganic layer of calcium oxalate, favoring the binding of the enzyme to the support. This efficiency was not converted in yield of immobilization due to the diffusional problems between the substrate and the active site of the enzyme. The formation of the inorganic layer bring beneficial effects in terms of storage and operational stabilities during the hydrolysis of citric pectin, keeping more than 40 % of the initial activity after 10 cycles of use.

References

Jayani, R., Saxena, S., & Gupta, R. (2005). Microbial pectinolytic enzymes: a review. Process Biochemistry, 40, 2931–2944.

Pedrolli, D., Monteiro, A., Gomes, E., & Carmona, E. (2009). Pectin and pectinases: production, characterization and industrial application of microbial pectinolytic enzymes. Open Biotechnology Journal, 3, 9–18.

Kashyap, D. R., Vohra, P. K., & Tewari, R. (2001). Application of pectinases in the commercial sector: a review. Bioresource Technology, 77, 215–227.

Coghetto, C., Scherer, P., Silva, M., Golunski, S., Pergher, S., de Oliveira, D., Oliveira, V., & Treichel, H. (2012). Natural montmorillonite as support for the immobilization of inulinase from Kluyveromyces marxianus NRRL Y-7571. Biocatalysis and Agricultural Biotechnology, 1, 284–289.

Wu, R., He, B., Zhao, B., Qian, L., & Li, X. (2013). Immobilization of pectinase on oxidized pulp fiber and its application in whitewater treatment. Carbohydrate Polymers, 97, 523–529.

Datta, S., Christena, L., & Rajaram, Y. (2013). Enzyme immobilization: an overview on techniques and support materials. 3 Biotech, 3, 1–9.

Mateo, C., Palomo, J. M., Fernandez-Lorente, G., Guisan, J. M., & Fernandez-Lafuente, R. (2007). Improvement of enzyme activity, stability and selectivity via immobilization techniques. Enzyme and Microbial Technology, 40, 1451–1463.

Buga, M., Ibrahim, S., & Nok, A. (2010). Physico-chemical characteristics of immobilized polygalacturonase from Aspergillus niger (SA6). African Journal of Biotechnology, 9(52), 8934–8943.

Abdelmajeed, N., Kheli, O., & Danial, E. (2012). Immobilization technology for enhancing bio-products industry. African Journal of Biotechnology, 11(71), 13528–13539.

Fernandez-Arrojo, L., Rodriguez-Colinas, B., Gutierrez-Alonso, P., Fernandez-Lobato, M., Alcalde, M., Ballesteros, A., & Plou, F. (2013). Dried alginate-entrapped enzymes (DALGEEs) and their application to the production of fructooligosaccharides. Process Biochemistry, 48, 677–682.

Rehman, H., Aman, A., Zohra, R., & Qader, S. (2014). Immobilization of pectin degrading enzyme from Bacillus licheniformis KIBGE IB-21 using agar-agar as a support. Carbohydrate Polymers, 102, 622–626.

Esawy, M., Gamal, A., Kamel, Z., Ismail, A., & Abdel-Fattah, A. (2013). Evaluation of free and immobilized Aspergillus niger NRC1ami pectinase applicable in industrial processes. Carbohydrate Polymers, 92, 1463–1469.

Bogra, P., Kumar, A., Kuhar, K., Panwar, S., & Singh, R. (2013). Immobilization of tomato (Lycopersicon esculentum) pectinmethylesterase in calcium alginate beads and its application in fruit juice clarification. Biotechnology Letters, 35, 1895–1900.

Zhang, L., Jiang, Y., Shi, J., Sun, X., Li, J., & Jiang, Z. (2008). Biomimetic polymer-inorganic hybrid microcapsules for yeast alcohol dehydrogenase encapsulation. Reactive and Functional Polymers, 68, 1507–1515.

Weiner, S., & Dove, P. (2003). An overview of biomineralization processes and the problem of the vital effect. Reviews in Mineralogy and Geochemistry, 54(1), 1–29.

Lu, Z., Zhang, J., Ma, Y., Song, S., & Gu, W. (2012). Biomimetic mineralization of calcium carbonate/carboxymethylcellulose. Materials Science and Engineering, 32, 1982–1987.

Shen, Q., Yanga, R., Hua, X., Ye, F., Zhang, W., & Zhao, W. (2011). Gelatin-templated biomimetic calcification for β-galactosidase immobilization. Process Biochemistry, 46, 1565–1571.

Betancor, L., & Luckarift, H. (2008). Bioinspired enzyme encapsulation for Biocatalysis. Trends in Biotechnology, 26(10), 566–572.

Bustamante-Vargas, C. E., Mignoni, M. L., de Oliveira, D., Venquiaruto, L. D., Valduga, E., Toniazzo, G., & Dallago, R. M. (2015). Synthesis of a hybrid polymer-inorganic biomimetic support incorporating in situ pectinase from Aspergillus niger ATCC 9642. Bioprocess and Biosystems Engineering, 8, 1569–1577.

Gomes, J., Zeni, J., Cence, K., Toniazzo, G., Treichel, H., & Valduga, E. (2011). Evaluation of production and characterization of polygalacturonase by Aspergillus niger ATCC 9642. Food and Bioproducts Processing, 89(4), 281–287.

Miller, L. (1959). Use of dinitrosalicyclic acid reagent for determination of reducing sugar. Analytical Chemistry, 37, 426–428.

Lineweaver, H., & Burk, D. (1934). The determination of enzyme dissociation constants. Journal of the American Chemical Society, 56, 658–666.

Pifferi, P., & Spagna, G. (1987). The immobilization of endopolygalacturonase on γ-alumina. Journal of Molecular Catalysis B: Enzymatic, 42, 137–149.

Spagna, G., PiVeri, P. G., & Gilioli, E. (1995). Immobilization of a pectinlyase from Aspergillus niger for application in food technology. Enzyme and Microbial Technology, 17, 729–738.

Wang, B., Cheng, F., Lu, Y., Ge, W., Zhang, M., & Yue, B. (2013). Immobilization of pectinase from Penicillium oxalicum F67 ontomagnetic cornstarch microspheres: characterization and application in juice production. Journal of Molecular Catalysis B: Enzymatic, 97, 137–143.

Wu, R., He, B., Zhao, G., & Li, X. (2014). Immobilization of pectinase on polyethyleneimine-coated pulp fiber for treatment of whitewater from papermaking. Journal of Molecular Catalysis B: Enzymatic, 99, 163–168.

Lei, Z., Bi, S., Hu, B., & Yang, H. (2007). Combined magnetic and chemical covalent immobilization of pectinase on composites membranes improves stability and activity. Food Chemistry, 105, 889–896.

Yang, J., Ma, X., Zhang, Z., Chen, B., Li, S., & Wang, G. (2010). Lipase immobilized by modification-coupled and adsorption-cross-linking methods: a comparative study. Biotechnology Advances, 28, 644–650.

Yigitoglu, M., & Temoçin, Z. (2010). Immobilization of Candida rugosa lipase on glutaraldehyde-activated polyester fiber and its application for hydrolysis of some vegetable oils. Journal of Molecular Catalysis B: Enzymatic, 66, 130–135.

Bustamante-Vargas, C. E., de Oliveira, D., Nyari, N. L. D., Valduga, E., Soares, M. B. A., Backes, G. T., & Dallago, R. M. (2015). In situ immobilization of commercial pectinase in rigid polyurethane foam and application in the hydrolysis of pectic oligosaccharides. Journal of Molecular Catalysis B: Enzymatic, 122, 35–43.

Bahrami, A., & Hejazi, P. (2013). Electrostatic immobilization of pectinase on negatively charged AOT-Fe3O4 nanoparticle. Journal of Molecular Catalysis B: Enzymatic, 93, 1–7.

Reham, H., Aman, A., Silipo, A., Qader, S., Molinaro, A., & Ansari, A. (2014). Degradation of complex carbohydrate: immobilization of pectinase from Bacillus licheniformis KIBGE-IB21 using calcium alginate as a support. Food Chemistry, 139, 1081–1086.

Won, K., Sangbum, K., Kwang-Je, K., Hong, P., & Sang-Ji, M. (2005). Optimization of lipase entrapment in Ca-alginate gel bead. Process Biochemistry, 40, 2149–2154.

Acknowledgments

The authors thank URI-Erechim, CNPq, FAPERGS, and CAPES for the infrastructure and financial support.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Bustamante-Vargas, C.E., de Oliveira, D., Valduga, E. et al. Biomimetic Mineralization of the Alginate/Gelatin/Calcium Oxalate Matrix for Immobilization of Pectinase: Influence of Matrix on the Pectinolytic Activity. Appl Biochem Biotechnol 179, 1060–1072 (2016). https://doi.org/10.1007/s12010-016-2050-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-016-2050-7