Abstract

The objective of this study was to understand the effect of operating parameters, including ultrasound amplitude, spraying pressure, nozzle orifice diameter, and initial cell concentration on microalgal cell disruption and lipid extraction in an ultrasonic nozzle spraying system (UNSS). Two algal species including Scenedesmus dimorphus and Nannochloropsis oculata were evaluated. Experimental results demonstrated that the UNSS was effective in the disruption of microalgal cells indicated by significant changes in cell concentration and Nile red-stained lipid fluorescence density between all treatments and the control. It was found that increasing ultrasound amplitude generally enhanced cell disruption and lipid recovery although excessive input energy was not necessary for best results. The effect of spraying pressure and nozzle orifice diameter on cell disruption and lipid recovery was believed to be dependent on the competition between ultrasound-induced cavitation and spraying-generated shear forces. Optimal cell disruption was not always achieved at the highest spraying pressure or biggest nozzle orifice diameter; instead, they appeared at moderate levels depending on the algal strain and specific settings. Increasing initial algal cell concentration significantly reduced cell disruption efficiency. In all UNSS treatments, the effectiveness of cell disruption and lipid recovery was found to be dependent on the algal species treated.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Microalgae have been considered one of the most promising biofuel feedstocks that can potentially address the challenges of energy security, global warming, and environmental protection [1, 2]. There are at least four main stages in algal biofuel production, including algae cultivation, harvesting, lipid extraction, and biofuel conversion. Algae cultivation and harvesting have been extensively studied in the USA since the 1990s [3]. Tremendous improvements were achieved in algae open pond production and biomass harvesting technologies under the support from the US Department of Energy through the Aquatic Species Program. However, oil extraction, which significantly affects algae oil yield and quality, has been left far behind. Due to their strong cell wall structures, most microalgal cells are difficult to break for cell content release. Several technologies have been investigated such as direct extraction, supercritical CO2, French press, bead beater, and wet milling [4–7]. These methods can be effective at the lab scale but have not been viable at the commercial level for biofuel production. Large equipment and machines, such as bead mills, homogenizers, and expellers, are available in the market, but they are not developed to handle microalgal cells in an effective way.

Ultrasonication as one of the algal cell disruption methods has also received attentions in inactivation, disruption, or removal of various algal species. For example, Mahvi et al. [8] found that short exposure (150 s) to ultrasound caused algae sedimentation and reduced the photosynthetic activity of algae population. Tang et al. [9, 10] examined the effect of ultrasonic waves on growth inhibition of irradiated algal cells, Spirulina (Arthrospira) platensis, and concluded that the growth rate of algal cells was reduced to 38.9 % of the control in 5-min treatment due to changes in the functioning and integrity of cellular and subcellular structures. In a similar study using ultrasound to repress the growth of Microcystis aeruginosa, Ahn et al. [11] concluded that ultrasound was the most effective in reducing the growth rate because of the disruption of gas vesicles in cells and disturbance of the cell cycle and divisions. In addition, it has also been reported that algal cells can be ultrasonically disrupted to release lipids for biofuel production [12–14].

In addition to ultrasonic treatment, liquid spraying is another method that can be potentially effective in algal cell disruption. Liquid spraying is a process of crucial importance in improving the performance of internal combustion engines and rocket engines [15, 16]. A spray is defined as a flow of individual liquid droplets evolving in a surrounding gaseous medium. The spray results in deformation and breakup of large drops into smaller liquid fragments/droplets [16–18]. The fine droplets are produced by strong shear forces when a longitudinal oscillation imposing on a liquid stream causes periodic surface instabilities. The wave and surface friction result in strong shear tensions to break up the liquid into a chain of uniform droplets [19]. However, to the best knowledge of the authors, combining ultrasound treatment and liquid spraying for algal cell disruption has never been investigated elsewhere. In this study, for the first time, an ultrasonic nozzle spraying system (UNSS) was applied to disrupt microalgal cells for lipid extraction. The system achieves atomization of a pressurized liquid by applying ultrasonic energy to a specific volume of liquid contained in a capillary chamber immediately before it is passed through an orifice. The nozzle is not ultrasonically excited; instead, the liquid is ultrasonically pumped by the tip of the horn moving with a piston-like (linear) motion relative to the inner face of the fixed nozzle orifice (capillary zone). This generates a very high but instantaneous pressure in the nozzle which provides very high particle velocities at the nozzle exit for cell disruption. The objective of this study was to understand the effect of UNSS operating parameters on algal cell disruption and lipid recovery. Ultrasound amplitude, nozzle orifice diameter, spraying pressure, and initial microalgal cell concentration were individually evaluated.

Materials and Methods

Algae Sample Preparation

The freshwater microalga Scenedesmus dimorphus (UTEX 417) and a marine microalga Nannochloropsis oculata (UTEX 2164) were obtained from the University of Texas at Austin Culture Collection of Algae (Austin, TX). These two strains were selected because they have been well studied and identified as promising candidates for lipid production [4, 20]. Cultures were carried out in two 45-l tubular airlift photobioreactors, each containing approximately 38 l of growth media at 25 ± 1 °C. Light (100 to 120 μmol photons/m2/s) was provided by cool white fluorescent lamps with 12 h:12 h light and dark cycles. The medium recipe of N. oculata was optimized from a previous study [4], containing 36 g/l instant ocean sea salt supplemented with 0.54 g/l urea and 13.2 mg/l K2HPO4. S. dimorphus was grown in the basal medium [21] containing the following chemicals: KNO3 (1250 mg/l), K2HPO4 (850 mg/l), KH2PO4 (400 mg/l), MgSO4·7H2O (1000 mg/l), EDTA (500 mg/l), H3BO3 (114.2 mg/l), CaCl2·2H2O (111 mg/l), FeSO4·7H2O (49.8 mg/l), ZnSO4·7H2O (88.2 mg/l), MnCl2·4H2O (14.2 mg/l), CuSO4·5H2O (15.7 mg/l), and Co(NO3)2·6H2O (4.9 mg/l). Algal samples were collected during the stationary growth phase and diluted to three concentrations of approximately 4.3 × 107, 8.5 × 107, and 1.7 × 108 cells/ml, corresponding to dry weight concentrations of 0.80, 1.73, and 3.56 g/l (for S. dimorphus) and 0.55, 0.96, and 2.10 g/l (for N. oculata), labeled C1, C2, and C3, respectively.

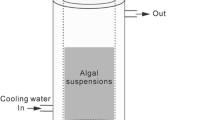

Experimental Setup

The UNSS setup is shown in Fig. 1a. The system consisted of one 3.8-l algal supply tank, an external piston pump (Hydra-Cell pump, model M03SASGHFECA, Wanner Engineering Inc, Minneapolis, MN, US), and the ultrasonic horn and nozzle set, a pressure control valve and gauge, along with an ultrasound generator (Dukane 20 kHz Model 20A3005CE) and wattmeter (Dukane 20 kHz Model 48A365), all provided by Aurizon Ultrasonics (Kimberly, Wisconsin, US). The ultrasound generator generated the wave signal with frequencies from 19,500 to 20,500 Hz at different voltage amplitudes with 1.5 gain booster. The wattmeter measured and displayed the amount of power that the ultrasonic generator delivered to the ultrasonic horn. The canister was used to receive the supply of pressurized algae solutions and direct the flow of algae solutions to the nozzle zone. In the nozzle zone, a specific arrangement (Fig. 1b) between the tip of the ultrasonic horn and the exit orifice allowed the liquid to be ultrasonically pumped when the power to the generator was on.

Experimental and Analytical Procedures

The processing parameters including initial cell concentration (C1, C2, C3), nozzle orifice diameter (NOD) (0.010, 0.015, and 0.019 in.), spraying pressure (600, 750, and 900 psi), and ultrasound amplitude (60, 73, and 87 % of full power at 1250 V, corresponding to 15, 20, and 25 % dial settings on the control panel, respectively) were individually evaluated. The experimental design is shown in Table 1. During the experiments, the algal sample flow rate was measured by directly collecting the samples out of the nozzle orifice.

After cells pass through a nozzle orifice, the shear force induced is a function of the relative velocity between the cell and surrounding air, defined as [22]

where τ is shear force (Pa), μ is fluid dynamic viscosity (Pa s), V is the velocity of the fluid along the chamber (m/s), and y is the distance to nozzle exit. Kelemen and Sharpe found that the extent of cell disruption was strongly related to shear forces [23]. Since the surrounding air was stationary and all other parameters were kept the same in this study, the shear force was dependent only on liquid viscosity and cell flow velocity. In this study, liquid viscosity was dependent on cell concentration and the cell flow velocity at nozzle exit is expressed below:

where Q is liquid flow rate (ml/s) and NOD is nozzle orifice diameter (inch).

An increase or decrease in cell/particle number usually indicates a positive response of cell disruption [14]. In this study, immediately after the UNSS treatment, a Millipore cell flow cytometer (guava easyCyte, Billerica, MA) equipped with two class IIIb lasers operated at 488 and 640 nm in CW mode was used to measure the absolute number of algal cells. The forward scatter (FSC) and 90° side scatter (SSC) signals were collected in linear mode. Analysis of the flow cytometer data was performed by GuavaSoft software, version 2.2. Nile red as a dye can emit fluorescence in the presence of nonpolar moieties such as triacylglycerol-rich droplets; this property was used in the detection and quantification of relative intracellular lipid content [14, 24]. In this study, a 2-μl Nile red acetone solution (250 mg Nile red per liter of acetone) was added to 2 ml of algal suspension, and then the mixture was vigorously agitated by a vortex mixer. Fluorescence was measured 30 s after staining using the Synergy Mx microplate reader (Synergy Mx, Winooski, Vermont) with a 552-nm excitation wavelength and a 636-nm emission wavelength [7].

Each treatment was conducted with four replications, and the results were presented as mean ± standard deviation (SD). The data were subjected to ANOVA analysis using SPSS version 12.0 software (SPSS Inc., Chicago, Illinois, USA), and differences (p < 0.05) between means were determined using the Duncan-Waller test.

Lipid Extraction

Before UNSS treatments, a 10-ml algae suspension was filtered through a pre-dried (75 °C for 5 h in an oven) and weighed (w 0) glass-fiber filter paper (55 mm, nominal pore size 1.2 μm) under vacuum. The filter paper was dried again in the same oven (75 °C for 5 h) and kept in a vacuum desiccator overnight before weighing (w 1). Algae biomass DW was obtained by subtracting w 0 from w 1. After UNSS treatments, algal sample of selected treatments (based on Nile red-stained lipid fluorescence density) was transferred to 50-ml centrifuge tubes. Hexane was then added to the sample to make the total volume 45 ml in each tube (hexane: sample = 1:1, V/V). The tube containing disrupted algal cells and solvent was shaken on a reciprocating shaker (150 r/min) overnight. After that, the tube was centrifuged at 2020g for 15 min to remove algal solids. The supernatant was carefully collected and evaporated and then dried in an oven at 95 °C for 1.5 h. Lipids left in the flask without solvent were weighed to calculate recoverable crude lipids [4] by the following equation:

Results and Discussion

The Effect of Ultrasound Amplitude

The amplitude of horn vibration is a function of the voltage applied to the transducer by the generator, which indicates the amount of ultrasonic energy to be transferred to the treated sample. The effect of ultrasound amplitude on cell number change can be seen in Fig. 2a. Cell concentration of S. dimorphus increased significantly under all treatments compared to the control. It is also evident that larger amplitude (73 and 87 vs. 60 %) resulted in higher cell concentration because of more input energy causing more severe cell disruption or de-clumping. There was no significant differences between 73 and 87 % amplitude treatments though, indicating that excessive energy input was not necessary for cell disruption. Increasing amplitude also caused significant changes in cell concentration of N. oculata. However, the effect of ultrasound amplitude on N. oculata was different from S. dimorphus in that cell numbers were significantly reduced rather than increased with boosted amplitude. This opposite consequence of the same treatment on the two species could be explained by the differences in cell shape and structure between N. oculata and S. dimorphus. When sufficient ultrasonic energy was applied to S. dimorphus cells, their cell clusters were de-clumped, and individual cells (10–20 μm) might break into smaller cell debris, which all increased cell/particle numbers (concentration). However, N. oculata cells are small (2–4 μm) and dispersed. When they were broken into even smaller particles, some particles might not be detected by the device [14]; therefore, there was a tendency of cell number reduction for greater degree of cell disruption. Similar to what was found with S. dimorphus, there was no significant difference in cell concentration between 73 and 87 % amplitude treatment for N. oculata.

The effect of ultrasound amplitude on a cell concentration and b Nile red-stained lipid fluorescence density of S. dimorphus and N. oculata. Other processing parameters were cell concentration C2, nozzle orifice size 0.015 in., and spraying pressure 750 psi. Significant differences are marked with different letters of a, b, c, or d (p < 0.05)

Cell/particle size change is another direct indicator of cell disruption, which can be reflected by the side scatter vs. forward scatter graph of a cell flow cytometer [14]. Smaller cell sizes after the treatment usually indicate successful disruption of cells. The change of cell sizes of S. dimorphus can be seen from Fig. 3. The forward scatter intensity of the treatment shifted to the left, which means that cell sizes reduced after the treatment. The medium forward scatter intensity decreased to approximately 2000 (Fig. 3b) after the treatment number 4, compared to approximately 3000 of the control (Fig. 3a). It indicated that cells became smaller after the treatment.

The effect of ultrasound amplitude on Nile red-stained lipid fluorescence density (NRSLFD) is presented in Fig. 2b. NRSLFD of S. dimorphus and N. oculata increased significantly under all treatments compared to the control. It is also apparent that greater amplitude resulted in higher NRSLFD because the dye was more accessible to intracellular lipid droplets due to more severe cell disruption. It is important to note that there seems no direct correlation between cell concentration and NRSLFD. For example, there were no significant differences in cell concentration between 73 and 87 % amplitude treatments, but NRSLFD of the treatments were significantly different for S. dimorphus. This might suggest that cell structure change occurred before whole cell disruption. Usually cell disruption is a two-step process, which involves point break of cell envelope followed by disintegration of cell wall along with degradation of cell debris [25].

The Effect of Spraying Pressure \( \tau =\mu \times \frac{\partial V}{\partial y} \)

\( {\mu}^V=\frac{0.0062\times Q}{\pi \times {\mathrm{NOD}}^2} \) The measured average flow rate and calculated cell flow velocity are shown in Table 2. From Table 2, increasing spraying pressure led to increased cell flow velocities at the nozzle exit and consequently greater shear forces based on Eq. 1.

As can be seen from Fig. 4a, spraying pressure above 600 psi had no significant differences in cell breakup of S. dimorphus; however, all treatments had significantly higher cell concentration than the control, indicating that all treatments were similarly effective. In the case of N. oculata, 750- and 900-psi treatments generated significantly lower cell concentration, indicating that cell disruption of 750 and 900 psi was more effective than 600 psi. The effect of spraying pressure on NRSLFD can be seen from Fig. 4b. It seems 750 psi was most effective on S. dimorphus while 900 psi was the best for N. oculata in terms of lipid recovery. There might be at least two possible reasons to explain why higher spraying pressure was not necessarily better for certain algal species. One reason is that higher spraying pressure (at the same orifice size) caused a higher flow rate, so the same amount of ultrasound energy was applied to more cells. In other words, each cell received less ultrasound energy when spraying pressure was higher. Theoretically, there must be a sweet spot where the combined effect of shear force and ultrasound was maximum. Based on the experimental results, it seems the sweet spot was at moderate (750 psi) or high (900 psi) spraying pressure when ultrasound energy input was moderate (73 % amplitude). The other reason is related to the characteristics of algal cells. A previous study of the authors showed that N. oculata was not as sensitive as S. dimorphus to ultrasound treatment [14]. In that study, NRSLFD of N. oculata was significantly lower than that of S. dimorphus after the same ultrasound treatment. This seems to suggest that nozzle spraying is probably more effective to the disruption of N. oculata. When both ultrasound and nozzle spraying were applied, the effect of shear force due to nozzle spraying seemed to dominate cell disruption for N. oculata; therefore, higher spraying pressure increased NRSLFD from 600 to 900 psi. On the other hand, ultrasound-induced cavitation was probably dominant in the disruption of S. dimorphus because S. dimorphus was very sensitive to ultrasound treatment [14].

The effect of spraying pressure on a cell concentration and b Nile red-stained lipid fluorescence density of S. dimorphus and N. oculata. Other processing parameters were initial cell concentration C2, amplitude 73 %, and nozzle orifice size 0.015 in. Significant differences are marked with different letters of a, b, c, or d (p < 0.05)

The Effect of Nozzle Orifice Diameter

The effect of nozzle orifice size on cell disruption is similar to that of spraying pressure. Changing orifice size changes cell flow rate and velocity (Table 3). Bigger orifice leads to a higher flow rate and higher flow velocity under the same spraying pressure, which means greater shear force but less ultrasound energy on each cell.

With above explanations, it is not surprising to find that the best cell disruption and lipid recovery were obtained at medium or large orifice sizes for both algal species (Fig. 5a, b), similar to spraying pressure effects. Specifically, for S. dimorphus, maximum cell disruption and NRSLFD were at a 0.015-in. orifice size although they were not significantly different from 0.019 in. For N. oculata, the best orifice size was 0.015 in. It seems to be contradictory to the results of spraying pressure effect (Fig. 4b) where the highest spraying pressure (the highest flow velocity) had the best lipid recovery. However, a careful look into Table 3 tells that a 0.019-in. orifice size caused a too large cell flow rate. From 0.015- to 0.019-in. orifice size, flow rate almost doubled, which means each cell received significantly less ultrasound energy although shear force applied on the cell was greater. Again, it was a balance or competition between cavitation (due to ultrasound energy) and shear force (due to nozzle spraying) effects.

The effect of nozzle orifice diameter on a cell concentration and b Nile red-stained lipid fluorescence density of S. dimorphus and N. oculata. Other processing parameters were initial cell concentration C2, amplitude 73 %, and spraying pressure 750 psi. Significant differences are marked with different letters of a, b, or c (p < 0.05)

It was possible that the sudden pressure change also contributed to cell disruption when cells left the nozzle orifice under pressure into the atmosphere, similar to cell disruption by a French press [4]. However, the pressure changes in this study were small (600 to 900 psi) compared to those of a French press. Figure 4 shows that higher spraying pressure was not necessarily better for cell disruption, and vice versa, Table 3 indicates that cell disruption was affected by something other than spraying pressure. Therefore, the effect of sudden pressure change on cell disruption in this study might not be significant compared to ultrasound-induced cavitation or spraying-generated shearing forces. However, more investigation is needed to confirm this hypothesis.

The Effect of Initial Algal Cell Concentration

The rate of change in cell concentration (RCCC) and the NRSLFD per cell are used to represent how cells respond to UNSS treatment when initial algal cell concentration varied. RCCC and NRSLFD per cell are expressed as follows:

As can be seen from Fig. 6a, RCCC of S. dimorphus decreased and N. oculata increased with initial algal cell concentration increased. This suggests that there was a negative correlation between cell disruption and initial cell concentration for both algal species. NRSLFD per cell of both algae strains decreased as shown in Fig. 6b, which is consistent with RCCC response to initial cell concentration. One reason for the negative correlation between cell disruption and initial cell concentration can be the reduced ultrasound energy input per cell with higher initial cell concentration, similar to what was found by Halim et al. [26]. In addition, cell concentration affects the viscosity of the liquid. More viscous liquids were believed to cause severe attenuation of the sound intensity and substantially reduced active cavitation zone [27]. This is also in agreement with the finding of Adam et al. [28], who reported that the more viscous the medium was, the lower the recovered lipid amounts were.

The effect of initial cell concentration on a the rate of change in cell concentration and b Nile red-stained lipid fluorescence density per cell of S. dimorphus and N. oculata. Other processing parameters were amplitude 73 %, nozzle orifice size 0.015 in., and spraying pressure 750 psi. Significant differences are marked with different letters of a, b, or c (p < 0.05)

UNSS Energy Consumption Analysis

Table 4 summarizes the specific energy consumption of each UNSS treatment. Both the pumping and ultrasound energy consumptions were included. The total energy consumption ranged from 12.1 to 106.4 MJ/kg dry mass depending on the treatment conditions and algal species, which are lower than what was reported by Lee et al. [29], who found that 132 MJ/kg dry mass was needed for the sonication of Chlorococcum sp. The specific energy consumption was also less than other algal cell disruption methods such as bead milling, microwave, and high pressure homogenization, which consumed more than 400 MJ/kg dry mass energy [29], indicating that UNSS treatment is relatively more energy efficient.

Lipid Extraction and Energy Consumption

Crude lipids in algae were extracted after UNSS treatments. The correlation between recoverable crude lipid content and NRSLFD was developed using randomly selected samples with low, medium, and high NRSLFD of both algal species. A correlation coefficient of 0.945 (Fig. 7) suggests that quantification of algae crude lipid content after UNSS treatments can be achieved by the simple, rapid, and sensitive Nile red staining method. However, the accuracy of the method depends on characteristics of individual algal strains, particularly the cell wall composition, as well as concentrations of chlorophyll, polar membrane lipids, and various other lipophilic compounds in the cell that may affect the amount of fluorescence background [30]. Therefore, it should be cautious to use the correlation to quantify algal crude lipids for other algal strains or cell disruption methods.

Summary and Conclusions

Ultrasonic nozzle spraying was effective in algal cell disruption for lipid recovery. For both algal species of S. dimorphus and N. oculata, increasing ultrasound energy input generally improved cell disruption efficiency and lipid recovery although excessive energy was not necessary for best results. Increasing spraying pressure and nozzle orifice diameter tended to enhance cell disruption because of higher cell flow velocity at nozzle exit. However, the effectiveness was restricted by less ultrasound energy applied to each cell because higher spraying pressure and bigger nozzle orifice also resulted in a higher cell flow rate. Thus, the optimal cell disruption was not always achieved at the highest spraying pressure or biggest nozzle orifice diameter; instead, they appeared at the medium levels depending on the algal strain and specific setting. Increasing initial algal cell concentration significantly reduced cell disruption efficiency as expected because of lower energy input on each cell and higher viscosity of the treated sample. In all UNSS treatments, the effectiveness of cell disruption and lipid recovery was found to be dependent on the algal species treated.

References

Brennan, L., & Owende, P. (2010). Biofuels from microalgae—a review of technologies for production, processing, and extractions of biofuels and co-products. Renewable and Sustainable Energy Reviews, 14(2), 557–577.

Scott, A. S., Davey, M. P., Dennis, J. S., Horst, I., Howe, C. J., Lea-Smith, D. J., & Smith, A. G. (2010). Biodiesel from algae: challenges and prospects. Current Opinion in Chemical Biology, 21, 277–286.

Benemann, J. R. (1997). CO2 mitigation with microalgae systems. Energy Conversion and Management, 38, S475–S479.

Shen, Y., Pei, Z. J., Yuan, W. Q., & Mao, E. R. (2009). Effect of nitrogen and extraction method on algae lipid yield. International Journal of Agricultural and Biological Engineering, 2(1), 51–57.

Nonomura, A.M., (1987). Process for producing a naturally-derived carotene/oil composition by direct extraction from algae. U. S. Patent # 4,680,314.

Rodríguez-Ruiz, J., Belarbi, E. H., Sánchez, J. L. G., & Alonso, D. L. (1998). Rapid simultaneous lipid extraction and transesterification for fatty acid analyses. Biotechnology Techniques, 12(9), 689–691.

Lee, S. J., Yoon, B. D., & Oh, H. M. (1998). Rapid method for the determination of lipid from the green alga Botryococcus braunii. Biotechnology Techniques, 12(7), 553–556.

Mahvi, A. H., & Dehghani, M. H. (2005). Evaluation of ultrasonic technology in removal of algae from surface waters. Pakistan Journal of Biological Sciences, 8(10), 1457–1459.

Tang, J. W., Wu, Q. Y., Hao, H. W., Chen, Y. F., & Wu, M. S. (2003). Growth inhibition of the cyanobacterium Spirulina (Arthrospira) platensis by 1.7 MHz ultrasonic irradiation. Journal of Applied Phycology, 15, 37–43.

Tang, J. W., Wu, Q. Y., Hao, H. W., Chen, Y. F., & Wu, M. S. (2004). Effect of 1.7 MHz ultrasound on a gas-vacuolate cyanobacterium and a gas-vacuole negative cyanobacterium. Colloids and Surfaces. B, Biointerfaces, 36, 115–121.

Ahn, C. Y., Park, M. H., Joung, S. H., Kim, H. S., Jang, K. Y., & Oh, H. M. (2003). Growth inhibition of cyanobacteria by ultrasonic radiation: laboratory and enclosure studies. Environmental Science & Technology, 37, 3031–3037.

Wiyarno, B., Yunus, R. M., & Mel, M. (2010). Ultrasound extraction assisted (UEA) of oil from microalgae (Nannochloropsis sp.). International Journal of Engineering Science, 1(3), 65–71.

Wiyarno, B., Yunus, R. M., & Mel, M. (2011). Extraction of algae oil from Nannochloropsis sp.: a study of soxhlet and ultrasonic-assisted extraction. Journal of Applied Sciences, 11(21), 3607–3612.

Wang, M., Yuan, W. Q., Jiang, X. N., Jing, Y., & Wang, Z. C. (2014). Disruption of microalgal cells using high-frequency focused ultrasound. Bioresource Technology, 153, 315–321.

Ruff, G. A., Sagar, A. D., & Faeth, G. M. (1989). Structure and mixing properties of pressure-atomized sprays. AIAA Journal, 27(7), 901–908.

Kourmatzis, A., Pham, P. X., & Masri, A. R. (2013). Air assisted atomization and spray density characterization of ethanol and a range of biodiesels. Fuel, 108, 758–770.

Faeth, G. M., Hsiang, L. P., & Wu, P. K. (1995). Structure and breakup properties of sprays. International Journal of Multiphase Flow, 21, 99–127.

Dumouchel, C. (2008). On the experimental investigation on primary atomization of liquid streams. Experiments in Fluids, 45, 371–422.

Dalmoro, A., Barba, A. A., Lamberti, G., & d’Amore, M. (2012). Intensifying the microencapsulation process: ultrasonic atomization as an innovative approach. European Journal of Pharmaceutics and Biopharmaceutics, 80, 471–477.

Converti, A., Casazza, A. A., Ortiz, E. Y., Perego, P., & Borghi, M. D. (2009). Effect of temperature and nitrogen concentration on the growth and lipid content of Nannochloropsis oculata and Chlorella vulgaris for biodiesel production. Chemical Engineering and Processing, 48, 1146–1151.

Sorokin, C., & Krauss, R. W. (1958). The effect of light intensity on the growth rates of green algae. Plant Physiology, 33, 109–113.

Shaaban, A. M., & Duerinckx, A. J. (2000). Wall shear stress and early atherosclerosis: a review. American Journal of Roentgenology, 174, 1657–1665.

Kelemen, M. V., & Sharpe, J. E. (1979). Controlled cell disruption: a comparison of the forces required to disrupt different micro-organisms. Journal of Cell Science, 35(1), 431–441.

Gerde, J. A., Montalbo-Lomboy, M., Yao, L. X., Grewell, D., & Wang, T. (2012). Evaluation of microalgae cell disruption by ultrasonic treatment. Bioresource Technology, 125, 175–181.

Ramanan, R. N., Tey, B. T., Ling, T. C., & Ariff, A. B. (2009). Classification of pressure range based on the characterization of Escherichia coli cell disruption in high pressure homogenizer. American Journal of Biochemistry and Biotechnology, 5, 21–29.

Halim, R., Harun, R., Danquah, M. K., & Webley, P. A. (2012). Microalgal cell disruption for biofuel development. Applied Energy, 91, 116–121.

Gogate, P. R., Wilhelm, A. M., & Pandit, A. B. (2003). Some aspects of the design of sonochemical reactors. Ultrasonics Sonochemistry, 10, 325–330.

Adam, F., Abert-Vian, M., Peltier, G., & Chemat, F. (2012). “Solvent-free” ultrasound assisted extraction of lipids from fresh microalgae cells: a green, clean and scalable process. Bioresource Technology, 114, 457–465.

Lee, A. K., Lewis, D. M., & Ashman, P. J. (2012). Disruption of microalgal cells for the extraction of lipids for biofuels: processes and specific energy requirements. Biomass and Bioenergy, 46, 89–101.

Chen, W., Zhang, C. W., Song, L. R., Sommerfeld, M., & Hu, Q. (2009). A high throughput Nile red method for quantitative measurement of neutral lipids in microalgae. Journal of Microbiological Methods, 77, 41–47.

Acknowledgments

This research was financially supported by the US National Science Foundation (Award # CMMI-1239078) and the startup fund of North Carolina State University. The authors want to thank Aurizon Ultrasonics for providing the ultrasonic nozzle spraying system and especially Mr. Tom Bett of Aurizon Ultrasonics for his valuable assistance in system setup and testing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, M., Yuan, W. Microalgal Cell Disruption via Ultrasonic Nozzle Spraying. Appl Biochem Biotechnol 175, 1111–1122 (2015). https://doi.org/10.1007/s12010-014-1350-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-014-1350-z