Abstract

A new thermostable and solvent-tolerant lipase was isolated from newly isolated Staphylococcus warneri from oil-contaminated soil. Optimization of the fermentation media for production of thermostable and organic solvent-tolerant lipase was carried out using two statistical methods, i.e., Plackett–Burman design (PBD) and central composite design (CCD) were used for the optimization of the media components. PBD was used to efficiently select important medium components affecting the lipase production. Out of 15 medium components screened, four components, i.e., olive oil, peptone, maltose, and K2HPO4 were found to contribute positively to lipase production. CCD and response surface methodology (RSM) were used to determine the optimum levels of the selected components using Design-Expert 8.0 software. Production medium with olive oil (1.45 %), peptone (0.28 %), maltose (0.054 %), and K2HPO4 (0.091 %) was optimized with a maximum lipase production of 10.43 IU/ml/min. Similarly, production conditions for the lipase production were optimized by using CCD and RSM. Optimized conditions were found to have an incubation temperature of 55 °C, medium pH of 8.0, agitation of 120 rpm, and inoculum volume of 2 %. RSM revealed the maximum lipase production of 17.21 IU/ml using these optimized production conditions. Crude lipase showed enhanced activity in organic solvents such as diethyl ether, hexane, and cyclohexane.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Triacylglycerol hydrolases (E.C. 3.1.1.3), also known by their trivial name as lipases, are the enzymes that catalyze the hydrolysis of long-chain acylglycerols in aqueous emulsions [1]. They are also capable of catalyzing other reactions, namely transesterification, interesterification, and esterification between a fatty acid and an alcohol which are the reverse of hydrolysis [2]. Thermostable enzymes are particularly attractive for industrial applications because of their high activity at elevated temperatures and stabilities in organic solvents [3, 4]. In addition, the ability of enzymes being active in the presence of organic solvents has received a great deal of attention over the past two decades [5].

Optimization of medium composition is essential in order to produce optimum production of microbial enzymes [6]. The greatest difficulty in optimization of culture conditions is the presence of interactive effects of medium compositions and culture condition factors [7]. The “one-factor-at-a-time” method, in which one independent variable is studied while maintaining all the other factors at a fixed level, is laborious and time-consuming and cannot provide the information about mutual interactions of the parameters on the desired outcome [8]. Statistical experimental design, which is a collection of statistical techniques applicable to experimental design, model building, evaluating the effect of factors, and screening optimum conditions of factors for desirable responses, can overcome these shortages [9, 10].

Plackett–Burman design (PBD) is one of the “screening designs”. Such designs are traditionally used for identifying important factors from among many potential factors [11]. In this context, this study was aimed at selecting the significant medium through PBD for lipase production by Staphylococcus warneri. This design was selected based on its ability to screen and evaluate the relevant medium components that affect the lipase production so as to generate a reliable and more manageable set of components and to indicate how each component affects the overall response [12, 13].

The use of a sequential experimental design strategy is a useful tool for process optimization. Response surface methodology (RSM) provides important information regarding the optimum level of each variable along with its interactions with other variables and their effects on product yield. It reduces the number of experiments without neglecting the interactions among the parameters [14–16].

The studied lipase from the S. warneri is a new thermostable and solvent-tolerant lipase; and as per literature studies, though lipase has been reported for S. warneri [17, 18], thermostability and solvent tolerance has not been reported so far. In a recent study, Lígia de Abreu and coworkers studied solvent-tolerant lipase from S. warneri EX17, but solvent tolerance is attained by immobilizing enzyme on hydrophobic support [19]. Hence, this first attempt to report thermostable solvent-tolerant lipase from S. warneri.

Materials and Methods

Isolation and Identification of Microorganism

Microorganism was isolated from oil-contaminated soil by using minimal saline medium with composition (NH4)2SO4, 0.5 %; KH2PO4, 0.1 %; K2HPO4, 0.35 %; NaCl,0.25 %; MgSO4.7H2O, 0.05 %; olive oil,1 %; and organic solvent, 10 % [20]. Lipase producers were screened using rhodamine B agar plate method [21, 22]. Biochemical studies and 16S ribosomal RNA (rRNA) gene sequencing were carried out to identify the isolate.

Production of Lipase

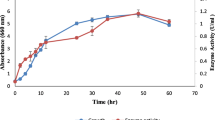

The concentrations of components were adjusted according to the experimental design. For the production of the inoculum, one loopful of the bacterial culture was transferred from a slant culture into an Erlenmeyer flask (50 ml) containing 20 ml nutrient broth (NB) medium with pH 7.0. The flask was incubated on a rotary shaker incubator at 55 °C and 100 rpm for 18 h. Inoculation of the medium was carried out using the 18-h-old culture with 1 % inoculum volume. The fermentation was carried out at 55 °C on a rotary shaker incubator at 100 rpm for 48 h.

Experimental Methods and Analysis

Plackett–Burman Design

PBD, an efficient technique for medium component selection, was used to determine the factors that significantly influence the lipase production [23]. Fifteen variables (Table 1) were screened in 16 experimental runs (Table 2), and the insignificant variables were eliminated to obtain a smaller, more manageable set of factors. The low level (−1) and high level (+1) of each factor are listed in Table 1.

Central Composite Design

Central composite design (CCD) was employed to optimize the most significant factors screened by PBD. It is one of the most commonly used response surface designs for fitting second-order models [24]. CCD consists of F factorial points, 2k axial points (±α), and natural center points. The factorial portion is used for fitting all linear and interaction terms. The axial points provide additional levels of the factor for purposes of estimation of the quadratic terms.

CCD for Media Constituents

According to the CCD, four independent factors, namely, olive oil (X1), peptone (X2), maltose (X3), and K2HPO4 (X4), were studied at five different levels (coded −2, −1, 0, +1, and +2) with six repetitions at the central point and two replicates at axial and factorial points (Tables 3 and 4).

CCD for the Production Process Optimization

According to the CCD, four independent factors, namely, pH (X1), temperature (X2), agitation (X3), and inoculum volume (X4), were studied at five different levels (coded: −2, −1, 0, +1, and +2) with six repetitions at the central point and two replicates at axial and factorial points (Tables 5 and 6).

Statistical Analysis

Design-Expert 8.0 software was employed for the experimental designs and regression analysis of the experimental results.

Assay of Lipase

Lipase activity was checked using p-nitrophenol as a standard and p-nitrophenyldodecanoate as substrate. A standard curve from 0.005 to 0.05 mmol p-nitrophenol was prepared using 0.1 M Tris-Cl buffer of pH 8.2 as diluents. Absorbance was measured at 410 nm using 0.1 M Tris-Cl buffer of pH 8.2 as a blank. Lipase activity of the test sample was calculated on the basis of release of the p-nitrophenol from substrate p-nitrophenyldodecanoate. One unit enzyme activity is defined as the micromole of p-nitrophenol release [25].

Effect of Organic Solvents on Lipase Activity

S. warneri was cultured aerobically in the absence of the organic solvents at 55 °C for 48 h in shaking incubator at 120 rpm. Culture medium was centrifuged at 10,000 rpm at 4 °C for 15 min. Supernatant was filtered through 0.45-μm filter paper. One milliliter of organic solvent was added to 3.0 ml of the cell free supernatant and preincubated at 55 °C while shaking at 150 rpm for 30 min to insure the continuous mixing of the enzyme and solvent. The enzyme stability was expressed as the remaining activity assayed according to p-nitrophenol assay for lipase relative to the control value. For control, distilled water was added instead of solvent. The tested organic solvents were ethyl acetate, xylene, propanol, benzene, chloroform, petroleum ether, DMSO, n-hexane, and cyclohexane [26].

Results and Discussion

Isolation and Identification of the Organism

Initial screening of lipase producers was carried out using rhodamine B agar and tributyrin agar. Rhodamine B agar showed orange fluorescence around the colonies of lipase producers as shown in Fig. 1. The complete 16S rRNA gene of isolate was sequenced, and the analysis clearly demonstrated that the isolated strain was a member of the genus Staphylococcus and exhibited maximum similarity with the 16S rRNA gene sequence of S. warneri strain (99 % sequence similarity).

Screening of Nutrients Using PBD

PBD for 16 trials with two levels of concentrations for 15 different variables were carried out according to the experimental matrix as shown in Table 1 and Table 2, and lipase activity was measured as response. The maximum lipase activity (10.37 IU/ml/min) was observed in trial number 1, while the minimum lipase activity (0.91 IU/ml/min) was observed in trial number 4. Main effects of the examined variables on lipase production were calculated using a formula mentioned below and presented graphically in Fig. 2.

Out of 15 variables studied, the lipase production was influenced by an increase in the concentration of olive oil, peptone, maltose, and K2HPO4.

Optimization of the Nutrients Concentration Using CCD

The levels of the factors selected based on PBD: olive oil (X1), peptone (X2), maltose (X3), and K2HPO4 (X4), and the effect of their interactions on thermostable solvent-tolerant lipase production were determined by CCD of RSM. The experimental range selected for CCD is shown in Table 3. The predicted and observed responses along with the design matrix were presented in Table 4. The results were analyzed by Analysis of Variance (ANOVA). The experimental results were fitted with a second-order polynomial equation. Two-factor interaction model (2FI) was used to study CCD (p < 0.05). The model used for the study was found statistically significant as p = 0.0011 which is less than 0.05. Effect of interaction of peptone with maltose, KH2PO4 with maltose, and peptone with KH2PO4 was found statistically significant. p value was found less than 0.05 as shown in Table 7.

The values of regression coefficients (in coded units) were calculated, and the fitted equation was used for predicting enzyme activity. The second-order regression equation provided levels of lipase activity as a function of olive oil, peptone, maltose, and K2HPO4 concentration which can be presented in terms of coded factors as in the following equation:

where Y is the lipase activity (IU/ml/min) produced as a function of the coded levels of olive oil (A), peptone (B), maltose (C), and K2HPO4 (D) concentration.

From the abovementioned equation, highest predicted lipase activity was found to be 10.56 IU/ml/min at optimized levels of factors, i.e., olive oil 1.45 %, peptone 0.28 %, maltose 0.054, and K2HPO4 0.091 % as mentioned in Table 8.

RSM Plots

The interactive effects of variables on lipase production were studied by plotting 3D surface curves against two independent variables, while keeping the other variables at their central (0) level. Response surface plots are more helpful in understanding both the main effects and interaction effects of these factors [27].

The 3D curves of the predicted lipase production and contour plots from the statistically significant interactions between the variables (p < 0.05) were shown in Figs. 3, 4, and 5. Figure 3 shows the response surface plot effects of peptone and maltose, while other two variables are kept constant at zero level. It was observed that the lipase activity was high at lower levels of both maltose and peptone. But lipase activity was decreased at higher levels of both maltose and peptone. Figure 4 shows the response surface plot effects of peptone and K2HPO4 concentration, and from the figure, it is seen that activity increases at a lower level of peptone and a high level of K2HPO4. Decrease in the lipase activity was observed at both lower and higher levels of peptone and also at low levels of K2HPO4. Figure 5 shows the effect of maltose and KH2PO4 concentration, while two other variables were kept fixed at zero levels. It was observed that activity increased at a lower level of maltose and higher level of KH2PO4, and the lipase activity seemed to decrease at a lower level of KH2PO4 and a higher level of maltose.

Optimization of the Process Parameters Using CCD

Production conditions like pH (X1), temperature (X2), agitation (X3), and inoculum volume (X4) and the effect of their interactions on thermostable solvent-tolerant lipase production were determined by CCD of RSM. The experimental range selected for CCD is shown in Table 5. The predicted and observed responses along with the design matrix were presented in Table 6. The results were analyzed by ANOVA. The experimental results were fitted with a second-order polynomial equation. Two-factor interaction model (2FI) was used to study CCD (p < 0.05). The model used for the study was found statistically significant as p = 0.0287 which is less than 0.05. Effects of individual parameters like temperature and pH on the lipase production were found to be statistically significant (p < 0.05). Effect of interaction of pH and temperature was found to be statistically significant (p < 0.05) as shown in Table 9.

The values of regression coefficients (in coded units) were calculated, and the fitted equation was used for predicting enzyme activity. The second-order regression equation provided levels of lipase activity as a function of pH, temperature, agitation, and inoculum volume which can be presented in terms of coded factors as in the following equation:

where Y is the lipase activity (IU/ml/min) produced as a function of the coded levels of pH (A), temperature (B), agitation (C), and inoculum volume (D).

From the abovementioned equation, highest predicted lipase activity was found to be 16.33 IU/ml/min at optimized levels of production parameters, i.e., as mentioned in Table 10.

RSM Plots

In process parameter optimization, interaction of the pH and temperature was found to be statistically significant which has been shown as a contour plot in Fig. 6. Lipase production was increased at high levels of both pH and temperature. There was a decrease in the production of lipase at lower levels of both pH and temperature.

Validation of the Model

Validation was carried out in shake flasks under conditions predicted by the model. The experimental values were found to be very close to the predicted values, and hence, the model was successfully validated. The predicted response for the optimized medium composition by the model was 10.56 IU/ml/min which were found to be very close to the experimental value, 10.43 IU/ml/min. The predicted response for the optimized conditions for the lipase production was 16.33 IU/ml/min which were very close to the experimental value, 17.21 IU/ml/min.

Effect of Organic Solvents on Lipase Activity

In the present study, crude lipase from S. warneri was tested with various organic solvents. Petroleum ether (102.98 ± 1.75 %), n-hexane (101.37 ± 2.04 %), and cyclohexane (110.22 ± 3.46 %) showed enhancement in lipase activity. Crude lipase was stable in the solvents benzene, xylene, and toluene with remaining lipase activity, i.e., 98.80 ± 2.59 %, 80.24 ± 2.97, and 13 ± 0.20 %, respectively, whereas propanol, DMSO, and ethyl acetate showed decrease in lipase activity, i.e., 12.58 ± 0.25, 5.12 ± 0.63, and 30.58 ± 1.64, respectively (Fig. 7 and Table 11). This could be due to high polarity of these solvents which removed the water surrounding the enzyme, causing inactivation of the enzyme. Hydrophilic solvents capable of removing water layer surrounding enzyme and lead to insufficiently hydrated enzyme molecule and decrease the enzyme activity [28].

Conclusion

A potent lipase-producing Staphylococcus spp. was isolated from the oil-contaminated soil using rhodamine B agar plate. Complete 16 s rDNA sequencing identified it as S. warneri with 99 % similarity in the sequence. The use of statistical models to optimize medium components has increased in the present bioprocess industry due to its easy applicability and reliability. In the present study, PBD was successfully used to determine the effective medium components for the production of thermostable and solvent-tolerant lipase from S. warneri. Four components found to have a positive effect on lipase production were olive oil, peptone, maltose, and K2HPO4. In further optimization using CCD and RSM, optimized values of the variables for lipase production were as follows: olive oil 1.45 %, peptone 0.28 %, maltose 0.054 %, and K2HPO4 0.091 %. By using these optimized variables in the medium experimentally, the resultant lipase activity reached up to 10.43 IU/ml/min. To enhance the production of the lipase, production parameters were optimized using CCD. Production parameters pH, temperature, agitation, and inoculum volume were optimized at levels of 8.0, 55 °C, 120 rpm, and 1 %, respectively. Using these optimized parameters experimentally, lipase production was found to be 17.21 IU/ml/min. The predicted and experimental results obtained were found to be similar, reflecting the accuracy and applicability of the CCD for process optimization. Crude lipase was very stable in various solvents and demonstrated enhanced activity in solvents like petroleum ether, n-hexane, and cyclohexane. It showed retention of >90 % lipase activity in benzene and toluene and 80 % lipase activity in xylene.

In recent studies, microorganisms like Aneurinibacillus thermoaerophilus strain HZ (lipase activity 2.78 ± 0.21 IU/mg) [29], Pseudomonas sp. strain S5 (lipase activity 3.2 U/mg) [30], Serratia marcescens ECU1010 (lipase activity 22.6 IU/ml) [31], Bacillus sphaericus MTCC 7542 (lipase activity 3.33 IU/ml) [32], Burkholderia multivorans V2 (lipase activity 6.477 IU/ml) [33], Geobacillus sp. strain ARM [34], and Streptomyces sp. CS133 [35] have been reported to produce solvent-tolerant and thermostable lipase. Compared to these reported studies, optimized production medium in the current study showed high production of thermostable and solvent-tolerant lipase from S. warneri with activity of 17.21 IU/ml/min at pH 8.2 and temperature 55 °C. Also, lipase showed high solvent tolerance in different organic solvents as compared to above mentioned lipases. Thus, S. warneri lipase possesses a unique combination of thermostability and solvent tolerance, which makes it a promising candidate for most of the industrial processes in which lipases are employed. As far as literature search, this is the first report for S. warneri producing thermostable solvent-tolerant lipase, which can fulfill various industrial applications.

References

Classification and nomenclature of enzymes by the reactions they catalyse. Enzyme Nomenclature1992. Available from http://www.chem.qmul.ac.uk/iubmb/enzyme/rules.html. Accessed 17 February, 2014

Macrae, A. R. (1983). Journal of American Oil Chemistry Society, 60(2), 291–294.

Pennisi, E. (1997). Science, 276, 705–706.

Sellek, G. A., & Chaudhuri, J. B. (1999). Enzyme Microbiology Technology, 25, 471–482.

Koops, B. C., Verheij, H. M., Slotboom, A. J., & Egmond, M. R. (1999). Enzyme Microbiology Technology, 25, 622–631.

Helen, T., de Débora, O., Marcio, A. M., Marco, D. L., & Oliveira, J. V. (2010). Food Bioprocess Technology, 3(2), 182–196.

Lima, C. J. B., Coelho, L. F., & Contiero, J. (2010). Food Technology and Biotechnology, 48, 175–181.

Kiruthika, P., Nisshanthini, S. D., Saraswathi, A., & Rajendiran, R. (2011). International Journal Advances Biotechnology Research, 2, 422–430.

Salihu, A., Bala, M., & Bala, S. M. (2013). ISRN Biotechnology, 2013, 1–5. doi:10.5402/2013/718352.

Cheng, S. W., Wang, Y. F., & Liua, F. F. (2011). Chemistry Biochemistry Engineering, 25, 377–383.

Plackett, R. L., & Burman, J. P. (1946). Biometrika, 33(4), 305–325.

Salihu, A., Alam, Z., Abdulkarim, M. I., & Salleh, M. (2011). African Journal of Biotechnology, 10, 18704–18708. doi:10.5897/AJB11.2741.

Rajendiran, R., Gayathri, S., Sureshkumar, B. T., & Priya, V. A. (2011). International Journal Agriculture Biology, 1, 60–63.

Lo, C.-F., Yu, C.-Y., Kuan, I.-C., & Lee, S.-L. (2012). International Journal of Molecular Sciences, 13, 14889–97. doi:10.3390/ijms131114889.

Salihu, A., Alam, Z., Abdulkarim, M. I., & Salleh, M. (2011). Journal of Molecular Catalysis B: Enzymatic, 69(1), 66–73.

Kaushik, R., Marwah, R. G., Gupta, P., et al. (2010). Indian Journal of Microbiology, 50, 456–62. doi:10.1007/s12088-011-0100-y.

Talon, R., Dublet, N., Montel, M. C., et al. (1995). Current Microbiology, 30(1), 11–16.

Kampen, M. D. V., Rosenstein, R., Gotz, F., et al. (2001). Biochimica et Biophysica Acta, 1544, 229–241.

De Abreu, L., Lafuente, R. F., Rodrigues, R. C., et al. (2014). Journal of Molecular Catalysis B: Enzymatic, 99, 51–55.

Ogino, H., Miyamoto, K., & Ishikawa, H. (1994). Applied and Environmental Microbiology, 60(10), 3884–3886.

Sirisha, E., Rajasekar, N., & Narasu, M. L. (2010). Advances Biology Research, 4, 249–252.

Stathopoulou, P. M., Savvides, A. L., Karagouni, A. D., & Hatzinikolaou, D. G. (2013). Biomedical Research International, 2013, 703130. doi:10.1155/2013/703130.

Abdel-Fattah, Y. R., Soliman, N. A., Gaballa, A. A., Sabry, S. A., & El-Diwany, A. I. (2002). Acta Microbiologica Polonica, 51(4), 353–66.

Kishan, G., Gopalakannan, P., Muthukumaran, C., et al. (2013). Journal Genetics Engineering Biotechnology. doi:10.1016/j.jgeb.2013.06.001.

Parkin, KL. and Praphan, P. (2001) in Current Protocols in Food Analytical Chemistry: Lipase Assays John Wiley & Sons, Inc, pp. C3.1.1- C3.1.13

Eltaweel, M. A., Noor, R., Raja, Z., et al. (2005). Annual Microbial, 55, 187–192.

Kanmani, P., Karthik, S., Aravind, J., & Kumaresan, K. (2013). ISRN Biotechnology. doi:10.5402/2013/528708.

Wehtje, E., & Adlercreutz, P. (1997). Biotechnology and Bioengineering, 55(5), 798–806.

Masomiana, M., Rahman, R. N. Z. R. A., Sallehb, A. B., et al. (2013). Process Biochemistry, 48, 169–175.

Rahman, R. N. Z. R. A., Baharum, S. N., Basri, M., et al. (2005). Analytical Biochemistry, 341, 267–274.

Zhao, L. L., Xu, J. H., Zhao, J., et al. (2008). Process Biochemistry, 43, 626–633.

Tamilarasan, K., & Dharmendira, K. M. (2012). Biocatal Agriculture Biotechnology, 1, 309–313.

Dandavate, V., Jinjala, J., Keharia, H., et al. (2009). Bioresource Technology, 100, 3374–3381.

Ebrahimpour, A., Rahman, R. N. Z. R. A., Basri, M., et al. (2011). Bioresource Technology, 102, 6972–6981.

Mander, P., Cho, S. S., Simkhada, J. R., et al. (2012). Process Biochemistry, 47, 635–642.

Acknowledgments

We would like to thank Dr. Yogesh Shouche from the Microbial Culture Collection (MCC), National Center for Cell Science (NCCS), Pune, for facilitating the 16S rRNA gene sequencing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yele, V.U., Desai, K. A New Thermostable and Organic Solvent-Tolerant Lipase from Staphylococcus warneri; Optimization of Media and Production Conditions Using Statistical Methods. Appl Biochem Biotechnol 175, 855–869 (2015). https://doi.org/10.1007/s12010-014-1331-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-014-1331-2