Abstract

This study illustrates the biophysicochemical properties of an alkaline protease, BAP (Beauveria sp. alkaline protease) from Beauveria sp. MTCC 5184. This protease exhibited maximum activity at 50 °C, pH 9.0, and stability in a broad pH range, in the presence of organic solvents, denaturants, as well as detergents. Wash performance studies revealed that BAP was able to remove blood clots/stains from blood-soaked cloth. Peptide mass fingerprinting results demonstrated partial homology of BAP with subtilisin-like proteinase. BAP showed catalytic activity against natural as well as synthetic substrates. Active site characterization of BAP confirmed the involvement of serine, tryptophan, and aspartic acid in catalytic activity. Detailed kinetic and thermodynamic studies of BAP demonstrated that the activation energy (Ea) for casein hydrolysis was 82.55 kJ/M, the specificity constant (Kcat/K m), and the values of ∆G (change in Gibbs free energy) decreased with increase in temperature, whereas ∆H (change in enthalapy) and ∆S (change in entropy) were constant. The results of the present study indicate that BAP has potential for applications as detergent additive, in peptide synthesis, and in basic research.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Proteases constitute a large group of hydrolytic enzymes that cleave peptide bonds of protein and degrade them into small peptides and amino acids [1]. The requirements of many industrial applications of proteases are very different from their physiological properties. For industrial processes, very few proteases have been reported from natural origin without any modification. Therefore, exploring biological sources is considered to be one of the promising alternatives to isolate proteases which are well suited for their diverse applications, improved yields, and their properties [2]. Amongst the vast microbial diversity, there is always a ray of finding microorganisms producing novel enzymes with better properties and conducive for commercial exploitation. The multitude of physicochemically diverse habitats has challenged the nature to develop equally numerous molecular adaptations in the microbial world [3]. Proteases from microbial sources have attracted greater attention of the researchers worldwide because of their biochemical diversity, broad industrial applications, being easy to maintain and produce on a large scale, and their ease in gene manipulation [4].

The manifold applications of proteases in detergent, leather, feed, food, silk, and photographic industries are reported in various literatures [5–10]. However, the stability of protease in organic solvents is an attention-grabbing area of research, because, on one hand, it catalyzes the hydrolysis of protein in aqueous solution, but on the other hand, encourages peptide synthesis in organic solvents or in solvents with low water content [11]. Organic solvents exert a profound effect on the dynamism of proteases by inactivating their binding sites to make them less specific and less stable in organic solvents. Therefore, the application of proteases in peptide synthesis is confined as these reactions are carried out in organic media [12]. Therefore, there is a constant urge for proteases supplemented with natural stability in organic solvents. Over the decades, methods like chemical modification, immobilization, protein engineering, and directed evolution have been attempted for stabilization of the enzymes in the organic solvents [13]. The proteases stable in organic solvent have been reported from microorganisms [14], plants [15], and animals [16]. Gupta and Khare [13] reviewed the organic solvent stable proteases from bacterial origin. Very few reports are available on solvent stable fungal proteases such as Beauveria brongniartii [17] and Aspergillus nidulans [18].

Beauveria sp. MTCC 5184, isolated from rabbit dung, produces hydrolytic enzymes such as protease, amylase, lipase, etc., singly or in combination. Optimization of protease production and scale-up, as well as various applications of BAP in dehairing of animal skins, removal of silver from photographic films, separation of cells in animal cell culture, and synthesis of silver and gold nanoparticles have been patented [19]. Purification and preliminary characterization of this novel alkaline protease (BAP), which is active at pH 9.0, 50 °C, and stable over a wide range of pH and temperature with half life of 2 h at 50 °C, is already published [1]. Since, BAP has been an industrially important enzyme; the present study was focused on kinetic and thermodynamic, biochemical, and biophysical properties of the protease and its application as detergent additive. The present study was undertaken to investigate the functional and structural modifications of BAP in a wide range of surfactants, detergents, modulators, as well as to explore its potential as detergent additive. The understanding of the properties of BAP will help to find its use in hitherto unknown biotechnological applications for the future.

Materials and Methods

Chemicals

Malt extract, yeast extract, peptone, and agar were purchased from M/s Hi-Media Chemical, India. Acetone, 1-butanol, benzene, chloroform, dimethylsulfoxide (DMSO), ethanol, formaldehyde, hexane, isopropanol, methanol, β-mercapto ethanol ( BME), and d-glucose were obtained from M/s Qualigens, India. Hammerstein casein was obtained from M/s Sisco Research Laboratories, India. Coomassie brilliant blue G-250 and R-250, DEAE-cellulose, ammonium persulfate, SDS (sodium dodecyl sulfate), TEMED (N,N,N’N’-tetramethyl ethylene diamine), acrylamide,phenylmethylsulphonyl fluoride (PMSF), (N-tosyl-l-lysine chloromethyl ketone), L-1-tosylamide-2-phenylethyl chloromethyl ketone, Woodward’s reagent (WRK), phenylglyoxal, DEPC (diethyl pyrocarbonate), bromosuccinimide (N-NBS), 5, 5’-dithiobis 2-nitrobenzoic acid (DTNB), ammonium bicarbonate, iodoacetamide, trypsin, sinapinic acid, α-cyano hydroxy cinnamic acid (CHCA), trifluoroacetic acid, and dithiothreitol were purchased from Sigma Chemical Co, USA. NaCl and urea were procured from M/s S.D Fine Chemicals Pvt. Ltd. Triton X-100 was obtained from M/s Loba Cheime, India. Commercial detergents were obtained from the local market. All other chemicals used were of analytical grade.

Microorganism

The fungal strain, Beauveria sp. MTCC 5184, was sub-cultured once in a month on MGYP agar (malt extract, 0.3 %, w/v; glucose, 1 %, w/v; yeast extract, 0.3 %, w/v; peptone, 0.5 %, w/v; agar, 2 %, w/v) slants and preserved at 4 °C after growth and sporulation [20].

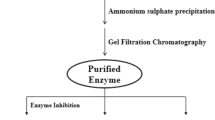

Protease Assay and Protein Determination

Protease production and purification was carried out as described by Shankar et al. [1]. All the experiments were carried out with purified BAP except wash performance, where crude protease preparation was used. The activity of protease was estimated as a caseinolytic activity at 50 °C, pH 9.0, for 10 min for all the reactions, according to Laxman et al. [20]. One unit of protease activity is defined as the amount of enzyme required to release 1 μM of Tyr/min under the assay conditions. Protein concentration was estimated according to the method of Bradford [21] with bovine serum albumin (BSA) as the standard.

Effect of Organic Solvents on BAP Activity

To ascertain the effect of organic solvents on purified protease activity, BAP was mixed with water-miscible and water-immiscible organic solvents (25 %, v/v effective concentration). The following organic solvents were used, namely, acetone, 1-butanol, benzene, chloroform, dimethylsulfoxide, ethanol, hexane, isopropanol, and methanol. All stability experiments and protease assays with organic solvents were carried out in screw-capped tubes to avoid the evaporation of organic solvents. Protease activity was measured at 50 °C, pH 9.0, and expressed as percentage of activity without any organic solvent (control) taken as 100 %.

Effect of Organic Solvents on BAP Stability

BAP was pre-incubated with 25 % (v/v) water-miscible and water-immiscible organic solvents (effective concentration) at 28 °C and 50 °C, pH 7.0. Samples were removed at different time intervals, and residual activity was determined under normal assay conditions. Sample without organic solvent served as control. Initial activity with respective solvents was taken as 100 %.

Effect of BME and Triton X-100 on BAP Activity

To study the effect of BME and Triton X-100, 10 μM of BAP in 50 mM phosphate buffer pH 7.0 was pre-incubated with 1 to 10 % (v/v) BME and 0.2 to 2 % (v/v) Triton X-100 at 28 °C for 30 min. Residual activity was measured at 50 °C, pH 9.0, and expressed as percentage of activity without any denaturants (control) taken as 100 %.

Effect of Urea and Sodium Chloride on BAP Stability

Stability of BAP was checked under two sets of conditions: (a) varying concentrations of NaCl (1 to 3 M) or urea (1 to 6 M) for fixed incubation time of 30 min and (b) fixed concentrations of NaCl (3 M) or urea (6 M) for varying incubation times (up to 2 h). The 10 μM of BAP in 50 mM phosphate buffer pH 7.0 was pre-incubated with urea or NaCl as described above at 28 °C. Samples were removed at regular intervals, and residual activity was measured at 50 °C, pH 9.0, and expressed as percentage of activity without urea and NaCl taken as 100 %.

Effect of Commercial Detergents on BAP Stability

For detergent stability, BAP was incubated with SDS (0.7 mg/mL final concentration) and commercial detergents (0.7 mg/mL final concentration) at 30 °C for 30 min. Detergents were heated at 100 °C for 10 min before use. Samples were removed after 30 min, and residual activity was estimated at pH 9.0, 50 °C, and expressed as percentage of initial activity with respective detergents taken as 100 %.

Washing Performance by Protease

The white cloth piece was dipped in blood and air-dried, and the blood-stained cloth was cut into four equal pieces (10 × 10 cm). The cloth pieces were placed in four separate Petri plates and dipped in 2 % (v/v) formaldehyde for 2 min followed by rinsing with water to remove excess formaldehyde. The experiment was carried out in four sets: (a) only water as a control, (b) only detergent, (c) only protease, and (d) detergent + protease. Each cloth piece was dipped in a total reaction volume of 30 mL. The experimental sets were incubated at room temperature for 30 min. The cloth pieces were rinsed four times with tap water and air-dried, and visible observations were recorded. Surf Excel was used as a detergent at a final concentration of 0.7 mg/mL. Crude protease was added (8.5 U) wherever enzyme was used for wash performance.

Matrix-Assisted Laser Desorption Ionization

The molecular mass of BAP was determined by matrix-assisted laser desorption/ionization (MALDI) using a Voyager DE-STR (Applied Biosystems) equipped with a 337-nm nitrogen laser. The 5 μL of BAP was mixed with equal volume of 1 % (w/v) sinapinic acid (prepared in 50 % (v/v) aqueous acetonitrile containing 0.1 % (v/v) trifluoroacetic acid), spotted on the MALDI target plate, and air-dried. All peptide spectra were recorded by accumulating 50 laser shorts over each spotted sample in the mass range of 10,000–40,000 Da.

Autocatalytic Activity and Tryptic Digestion of BAP

For autocatalytic activity, BAP was incubated at 50 °C, pH 9.0, up to 5 h, and samples were removed at 1 h intervals and analyzed in MALDI. To perform tryptic digestion experiment, BAP was separated on SDS-polyacrylamide gel electrophoresis (PAGE) (12 %, w/v separating gel and 6 %, w/v stacking gel) [22]. The protein bands on the gel were visualized by Commassie brilliant blue (CBB) staining. The CBB-stained band of BAP on the gel was excised, and CBB stain from gel was removed by washing gel with 400 μL of 50 % (v/v) acetonitrile solution (3 times for 15 min). The gels were dehydrated by 100 % acetonitrile solution until the gels turned opaque white, followed by drying in a speed vacuum. Thereafter, protein was reduced by soaking the gel in 100 μL dithiothreitol (10 mM) followed by alkaylation in 100 μL of iodoacetamide (25 mM). The gel was washed with 25 mM ammonium bicarbonate solution and digested with sequencing grade bovine trypsin solution. The molar ratio of protein to trypsin was maintained between 1:10. Peptides from the gel after overnight trypsin digestion were extracted using 50 % (v/v) acetonitrile and 5 % (v/v) trifluoroacetic acid (TFA), dried, and reconstituted in 5 μl of 50 % (v/v) acetonitrile containing 0.1 % (v/v) TFA, then spotted and air-dried on the Teflon-coated MALDI plate. CHCA was added as a matrix onto the pre-spotted peptide spots and air-dried. Peptide mass fingerprinting (PMF) was obtained using MALDI in the mass range of 800–4,000 Da. The protein was identified by using MASCOT database.

Activity Towards Natural and Synthetic Substrates

Activities of BAP against various substrates were estimated according to the methods described by Laxman et al. [19]. Synthetic substrates used were azocoll, elastin-orcin, azocasein, and N-α-benzoyl-dl-arginine-p-nitroanilide. Natural substrates, viz., casein, hemoglobin, and bovine serum albumin, were included for comparison.

Substrate Kinetic and Thermodynamic Studies of Protease

K m and V max of BAP was determined by Michaelis–Menten method at different temperatures ranging from 35 to 60 °C by varying the substrate concentrations. The activity of BAP was expressed as micromolars of tyrosine released per milliliter of BAP per minute. Kcat was expressed as V max/μM of BAP. Ea (energy of activation) of BAP was calculated from the slope of the plot of ln V max Vs 1,000/T, as Ea = −slope × R (R, gas constant = 8.314 × 10−3 kJ/mol). ∆G (change in Gibbs free energy) was calculated by using the equation, ∆G = RTln Kd (here, the values of K m were used for dissociation constant Kd). ∆H (change in enthalpy) was calculated from the equation ∆H = Ea − RT and ∆S (change in entropy) by equation ∆G = ∆H − T∆S where, T is temperature in Kelvin [23].

Chemical Modification Studies

During chemical modification studies, the residual activity of the modified BAP was determined as a caseinolytic activity. BAP incubated in the absence of modifying reagents served as control. Amino acids were modified with chemicals, namely, serine with PMSF, aspartic acid with WRK, arginine with phenylglyoxal, histidine with DEPC, tryptophan with NBS, and cysteine with DTNB. BAP (10 μM) in 10 mM phosphate buffer, pH 7.0 was incubated with PMSF prepared in DMSO, phenylglyoxal prepared in methanol, DEPC freshly prepared in absolute ethanol, WRK, NBS, and DTNB prepared in the same buffer, in a final volume of 1 mL at 28 °C, for 30 min, and residual activity was determined at 50 °C, pH 9.0. The concentration of methanol and ethanol in the reaction mixture did not exceed 2 % (v/v) and had no effect on the activity and stability of BAP during incubation.

Ligand Protection Assay

The ligand protection assay was carried out by pre-incubating BAP (10 μM) with varying concentrations of casein (1–10 mg) at 4 °C for 5 min followed by the addition of one of the inhibitors, namely, 10 μM PMSF, 5 mM WRK, or 10 μM NBS and further incubated at 4 °C for 30 min. The residual protease activity was determined at 50 °C, pH 9.0.

Statistical Analysis

All experiments were performed in triplicate, and data were represented as the average ± standard deviation. Standard deviation of each experiment was calculated using Excel spreadsheet of Microsoft Excel.

Results and Discussion

Effect of Organic Solvent on Activity and Stability of Purified Protease

The effects of organic solvents on BAP activity and stability are presented in Table 1. The effects of organic solvents (25 %, v/v) on the stability of BAP were studied at 28 °C and 50 °C. At 28 °C, BAP was highly stable in many organic solvents tested. After 24 h, more than 80 % activity was retained in ethanol, isopropanol, methanol, 1-butanol, and DMSO and decreased to 60–78 % after 48 h. However, less than 30 % residual activity was retained in acetone, benzene, chloroform, and hexane after 24 h. Under identical conditions, control without solvent showed around 26.66 % residual activity.

At 50 °C, BAP was highly stable up to 1 h in all the organic solvents tested with residual activities ranging from 60 to 90 %. After 2 h, the stability was highest in acetone and DMSO with residual activities of around 70 % while, in all other solvents, it was between 30–46 %. Amongst the organic solvents used, 1-butanol, DMSO, and methanol were found to be best at both temperatures for BAP stability. Enzymes, in general, get denatured or give very low reaction rates in organic solvents because of unfolding, structural dysfunction, and stripping of the essential water layer from the enzyme molecule. In addition, organic solvents also alter the catalytic process of enzyme by disruption of hydrogen bonds and hydrophobic interactions, as well as changes in the dynamics and conformation of the protein [24]. BAP was more stable in polar than that of non-polar solvents and also stable at both the temperatures in water-miscible (ethanol, isopropanol, and methanol) as well as in water-immiscible (1-butanol and DMSO) solvents. On the contrary, Gupta and Khare [25] reported protease from Pseudomonas aeruginosa PseA to be more stable in non-polar organic solvents (benzene, cyclohexane, isooctane, and n-dodecane) and comparatively less stable in hydrophilic solvent. Ogino et al. [26] reported the stability of PST-01 protease from P. aeruginosa to be higher in solutions containing water-soluble organic solvents or alcohols than in the absence of organic solvent. These results are similar to the present investigation where the BAP was more stable in solvents than in control which is devoid of any solvent.

Many workers have attempted to correlate the stability of protease in organic solvent with reference to their properties such as dielectric constant, water solubility, Hildebrand solubility, three-dimensional solubility parameter spaces, and log P [27]. At 28 °C, BAP was stable in polar solvents and with log P/w values between negative and or near to zero, but not stable in solvent with a log P/w value in positive with more than 1. At 50 °C, no clear correlation was observed either with polarity or with log Po/w values. Ogino et al. [26] and Gupta et al. [28] found no correlation between the stability of protease in organic solvent and its polarity (log P value).

It can be concluded that stability of enzyme in organic solvents depends on the nature of solvents used and varies from enzyme to enzyme. The replacement of some water molecules in an enzyme with organic molecules sometimes stabilizes the structure of the enzyme.

Effect of Denaturants and Salts on Protease Activity

BAP retained full activity in 10 % (v/v) BME at 28 °C indicating the absence of disulphide bonds in the protease (Fig. 1a). The protease retained more than 70 % of its original activity in 2 % (v/v) Triton X-100 (Fig. 1b). The enzyme was also stable in urea and NaCl, showing a slight increase in stability with increase in their concentrations (Fig. 1c). In the presence of 6 M urea and 3 M NaCl, protease was stable and retained more than 85 % and 75 % of initial activity after 2 h incubation, respectively, whereas the control sample without any denaturants showed less than 70 % residual activity after 2 h (Fig. 1d).

An organic solvent stable protease from P. aeruginosa PseA showed stability up to 10 min in urea (1–5 mM), Triton-X (0.1–0.5 %), and BME (1–5 mM) [28]. These concentrations are several folds lower than the values tested in the present investigation. Ruiz and De Castro [29] studied the stability of purified protease produced by the haloalkaliphilic archaeon Natrialba magadii in 15–30 % organic solvents containing 0.5 and 1.5 M NaCl and found that the high salt concentration (1.5 M NaCl) increased the stability of protease in different organic solvents. Hajji et al. [30] reported protease from Aspergillus clavatus ES1 to be stable in the presence of 5 % (v/v) non-ionic surfactants like Tween 80 and Triton X-100 at 4 °C for 1 h.

Stability of BAP in Commercial Detergents

The addition of proteases to detergents considerably increases the cleaning effect by removing protein stains and the consumption of surface active substances [31]. The application of protease in detergent formulation requires that the protease/enzyme to be stable in high pH values. Since very few reports are available on the use of fungal proteases in detergent industry, prompt attention, therefore, is required to exploit fungal proteases for this application as well. BAP was stable and compatible in the presence of the locally available detergents (Ariel, Rin, Surf Excel, and Tide) and SDS (data not shown). BAP retained more than 90 % of the initial activity in all the detergents and SDS after 30 min of incubation at 30 °C. Proteases from Conidiobolus coronatus [32], Conidiobolus macrosporus [33], and Penicillium godlewskiiwere [34] are reported to be stable and compatible in the presence of commercial detergents indicative of their suitability in detergent industry.

Washing Performance of Crude BAP

To check the suitability of BAP as a detergent additive, washing performance of protease was examined alone and in combination with detergent. The washing performance was found to be best when detergent and protease used together. Only detergent could not remove the blood clots whereas protease alone could dissolve and remove the stains effortlessly (Fig. 2). As BAP is stable over a wide range of pH and temperatures and showed broader substrate specificity and compatibility with commercial detergents, therefore, it could be used as an additive in detergents.

Autocatalytic Activity of Purified Protease

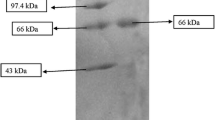

The molecular mass of BAP on SDS-PAGE was reported by Shankar et al. [1] to be 29 kDa. Molecular weight of BAP by MALDI was estimated around 28.2 kDa (Fig. 3a). BAP was incubated at 50 °C, pH 9.0, in order to check its autocatalytic activity. Initially at the onset of incubation, there were only a single peak of 28.2 kDa, and its intensity decreased with time with simultaneous appearance and increase in the intensity of two peaks of 15.6 and 10.2 kDa (Fig. 3a–f). After 5 h, the peak corresponding to 28.2 kDa vanished completely and peaks corresponding to 15.6 and 10.2 kDa remained, indicating that these peaks are autocatalytic products of 28.2 kDa. At the end of 5 h incubation, there was complete loss in protease activity in the sample which showed that the 15.6 and 10.2 kDa proteins had no proteolytic activity. Protease activity was observed only in 28.2 kDa protein.

Peptide Mass Fingerprinting

Peptide mass fingerprinting is a method to identify sample protein in a short time using protein in the femtomole range [35]. PMF of tryptic digests of purified 28.2 kDa BAP showed partial homology with only subtilisin-like protease 3 precursors from Microsporum canis in the PMF database. Out of 67 mass values searched, only 11 mass values matched with M. canis protease. For search parameter, mass values were monoisotopic, and peptide mass tolerance was ±1 Da. The PMF data confirmed our earlier results, where the N-terminal sequence of BAP showed homology to subtilisin-like protease [1].

Activity Towards Natural and Synthetic Substrates

To discriminate among competing substrates is an important feature of an alkaline protease. In general, alkaline proteases hydrolyze a variety of natural as well as synthetic substrates because of their broad substrate specificity. BAP was able to degrade casein, bovine serum albumin, and hemoglobin to varying degrees. It was more active against casein compared with hemoglobin and BSA. The activity of BAP against casein, hemoglobin, and BSA was 11.5, 5.45, and 0.58 U/mL, respectively. These results are in agreement with other reports where proteases from Conidiobolus sp. [36], Cephalosporium sp. KM388 [37], and Beauveria bassiana [38] reported to be more active towards casein compared with bovine serum albumin. Since hemoglobin and albumins are present in the body secretions, BAP may find application in detergent formulations. BAP also showed activity against synthetic substrates like azocasein, azocoll, BAPNA, and elastin-oricin, which demonstrated that it has peptidase and elastase activities in addition to caseinolytic activity (azocasein). The activity of BAP against azocasein, azocoll, BAPNA, and elastin-oricin was 16.05, 1.84, 0.018, and 0.011 U/mL, respectively.

Kinetic and Thermodynamic Parameters

The V max and K m values of BAP were calculated from the Michaelis–Menten plots using casein as a substrate at each temperature. The K m and V max of protease increased with the increase in temperature. The specificity constant Kcat/K m of protease were 6.08, 4.29, 5.87, 3.28, and 3.7/mg/min at 35, 40, 45, 50, and 55 °C, respectively, indicating the affinity of BAP for the substrates, and the rate of the reaction is in decreasing order with increase in temperature (Table 2). From the slope of the Arrehnius plot of ln V max versus 1,000/T, energy of activation, Ea, of protease for casein was calculated to be 82.55 kJ/M. The value of enthalpy (∆H) of BAP was 79.99 kJ/M at 35 °C and marginally decreased with increase in temperature, confirming that lower energy was required to denature the enzyme at higher temperatures. The observed change in ∆H values also indicates that, at higher temperatures, the enzyme undergoes considerable change in conformation [39]. The Gibbs free energy (∆G) of BAP decreased from 2.28 to −4.21 kJ/M when the temperature was increased from 35–55 °C. The decrease in ∆G with increasing temperature makes the enzyme thermally unstable [40]. The values of ∆S did not show significant alterations with the change in temperature. The positive values of ∆S indicate that there is no significant process of protein aggregation at higher temperature [41].

Chemical Modification

Active site-directed chemical modification is an important tool for studying the structure–function relationship of enzymes and other biologically active proteins and can be done without knowing the structure of proteins [42]. The importance of amino acid functional groups for the activity of BAP was determined by chemical modification studies using amino acid side chain-specific chemical reagents. Lack of inhibition of BAP activity by 1 mM DTNB and 10 mM phenylglyoxal suggested the non-involvement of cysteine and arginine in the BAP catalysis. BAP was completely inhibited by 9 mM WRK, 60 μM NBS, and 20 μM PMSF whereas 40 % inhibition was observed with 10 mM DEPC. Besides histidine, DEPC also reacts with tyrosine, cysteine, and lysine residues [42]. The complete inhibition of protease activity with PMSF, WRK, and NBS indicated that serine, aspartic acid, and tryptophan may present at or near the active site of BAP, as these amino acids were found essential for BAP activity. It is remarkable that, in all serine proteases, serine, histidine, and aspartic acid form a triad at the active site [43]. In the present study, we observed the novel triads (Ser, Asp, and Trp) which mediated the catalysis of BAP.

Ligand Protection

To ascertain the presence of serine, aspartic acid, and tryptophan at the active site of BAP, ligand protection studies were carried out. BAP showed decreasing trend of inhibition in the presence of inhibitors when it was pre-incubated with increasing concentration of substrate (Table 3). BAP without inhibitors demonstrated no inhibition while complete inhibition was observed with 0.01 mM PMSF or 5 mM WRK or 0.01 mM NBS. When BAP was pre-incubated with 10 mg of casein at 4 °C for 5 min followed by addition of either 5 mM WRK or 0.01 M PMSF, or 0.01 M NBS showed inhibition of approximately 9, 26, and 16 %, respectively. The above result demonstrated that the substrate competes with the inhibitors for the active site, indicating the presence of aspartic acid, serine, and tryptophan at the active site of the protease.

As reported earlier, BAP has a unique N-terminal sequence and has potential applications in various industries as well as in molecular biology [1, 19]. In the present study, BAP was characterized in detail and stability towards organic solvents, and detergents were studied to explore its possible use in hitherto unknown biotechnological applications in future. Comparison of biophysicochemical properties of BAP with other microbial proteases presented in Table 4 indicate that BAP has better half life at its optimal temperature, broader stability in polar as well as non polar solvents, detergents like Triton X-100, SDS, urea, and salts like NaCl making it a suitable candidate for use in detergents formulations and in reactions in organic media.

Conclusions

BAP, an alkaline protease from Beauveria sp. MTCC 5184, is highly stable in organic solvents, detergents, denaturants, and salts, as well as showed good wash performance. The protease also showed broad substrate specificity and was active on natural as well as synthetic substrates. BAP had a molecular weight of 28.2 kDa by MALDI and completely degraded by autocatalytic activity to give two peptides of 15.6 and 10.2 kDa after 5 h, indicating a single breakage site in the peptide chain. Peptide mass fingerprinting studies revealed homology to subtilisin-like protease 3. K m study indicated that substrate affinity of BAP decreased with increasing temperature. Thermodynamic properties showed that lower energy is required to denature BAP at higher temperature and no significant protein aggregation at higher temperature. These properties of BAP suggest its potential in various industrial and biotechnological applications such as detergent additive in detergent industry as well as where organic solvents are used.

References

Shankar, S., Rao, M., & Laxman, R. S. (2011). Process Biochemistry, 46, 579–585.

Rao, M. B., Tanksale, A. M., Ghatge, M. S., & Deshpande, V. V. (1998). Microbiology and Molecular Biology Reviews, 62, 597–635.

Gupta, R., Beg, Q. K., & Lorenz, P. (2002). Applied Microbiology and Biotechnology, 59, 15–32.

Karbalaei-Heidari, H. R., Shahbazi, M., & Absalan, G. (2013). Applied Biochemistry and Biotechnology, 170, 573–586.

Paul, T., Das, A., Mandal, A., Halder, S. K., DasMohapatra, P. K., Pati, B. R., & Mondal, K. C. (2013). Waste Biomass Valor. doi:10.1007/s12649-013-9265-4.

Zambre, V. P., Nilegaonkar, S. S., & Kanekar, P. P. (2013). IIOAB Letter. doi:10.5195/iioablett.2013.19.

Makhdum, Z., Rehman, H., Larik, J. M., Bux, P., & Hameed, A. (2013). Journal of Applied Animal Research, 41, 218–222.

Boyce, A., & Walsh, G. (2012). Chemosphere, 88, 211–218.

More, S. V., Khandelwal, H. B., Joseph, M. A., & Laxman, R. S. (2013). Journal of Natural Fibres, 10, 98–111.

Shankar, S., More, S. V., & Laxman, R. S. (2010). Kathmandu University Journal of Science Engineering & Technology, 6, 60–69.

Wang, S. L., Yang, C. H., Liang, T. W., & Yen, Y. H. (2008). Bioresource Technology, 99, 3700–3707.

Ghorbel, B., Kamoun, A. S., & Nasri, M. (2003). Enzyme and Microbial Technology, 32, 513–518.

Gupta, A., & Khare, S. K. (2009). Critical Reviews in Biotechnology, 29, 44–54.

Vijayaraghavan, P., Vijayan, A., Arun, A., Jenisha, J. K., & Vincent, S. G. P. (2012). SpringerPlus, 1, 76–84.

Patel, G. K., Kawale, A. A., & Sharma, A. K. (2012). Plant Physiology & Biochemistry, 52, 104–111.

Rathinaraj, K., Sakhare, P. Z., Sachindra, N. M., & Mahendrakar, N. S. (2010). Food Bioprocess Technology, 3, 783–788.

Erlacher, A., Sousa, F., Schroeder, M., Jus, S., Kokol, V., Cavaco-Paulo, A., & Guebitz, G. M. (2006). Biotechnology Letter, 28, 703–710.

Pena-Montes, C., González, A., Castro-Ochoa, D., & Farres, A. (2008). Applied Microbiology & Biotechnology, 78, 603–612.

Laxman, R. S., Shankar, S., More, S. V., Khandelwal, H. B., Narasimhan, C. B. K., Palanivel, S. & Balaram, P. (2013). Euro. Patent. EP 2531596. US. Patent. US 20130095523

Laxman, R. S., Sonawane, A. P., More, S. V., Rao, B. S., Rele, M. V., Jogdand, V. V., Deshpande, V. V., & Rao, M. B. (2005). Process Biochemistry, 40, 3152–3158.

Bradford, M. M. (1976). Analytical Biochemistry, 72, 248–254.

Laemmli, U. K. (1970). Nature, 227, 680–685.

Shashidhara, K. S., & Gaikwad, S. M. (2009). International Journal of Biological Macromolecule, 44, 112–115.

Barberis, S., Quiroga, E., Morcelle, S., Priolo, N., & Luco, J. M. (2006). Journal of Molecular Catalysis B: Enzymatic, 38, 95–103.

Gupta, A., & Khare, S. K. (2007). Enzyme & Microbial Technology, 42, 11–16.

Ogino, H., Watanabe, F., Yamada, M., Nakagawa, S., Hirose, T., Noguchi, A., Yasuda, M., & Ishikawa, H. (1999). Journal of Bioscience & Bioengineering, 87, 61–68.

Barberis, S., Quiroga, E., Arribére, M. C., & Priolo, N. (2002). Journal of Molecular Catalysis B: Enzymatic, 17, 39–47.

Gupta, A., Roy, I., Khare, S. K., & Gupta, M. N. (2005). Journal of Chromatography. A, 1069, 155–161.

Ruiz, D. M., & De Castro, R. E. (2007). Journal of Industrial Microbiology & Biotechnology, 34, 111–115.

Hajji, M., Kanoun, S., Nasri, M., & Gharsallah, N. (2007). Process Biochemistry, 42, 791–797.

Esposito, T. S., Marcuschi, M., Amatal, I. P. G., Carvalho, L. B., & Bezerra, R. S. (2010). Journal of Agricultural Food Chemistry, 58, 6433–6439.

Phadatare, S. U., Srinivasan, M. C., & Deshpande, V. V. (1993). Enzyme & Microbial Technology, 15, 72–76.

Tanksale, A., Manish, C. P., Rao, M., & Deshpande, V. (2001). Biotechnology Letter, 23, 51–54.

Sindhu, R., Suprabha, G. N., & Shashidhar, S. (2009). African Journal of Microbiological Research, 3, 515–522.

Pappin, D. J. C., Hojrup, P., & Bleasby, A. J. (1993). Current Biology, 3, 327–332.

Sutar, I. I., Srinivasan, M. C., & Vartak, H. G. (1991). Biotechnology Letter, 13, 119–124.

Tsuchiya, K., Arai, T., Seki, K., & Kimura, T. (1987). Agricultural BioChemistry, 51, 2959–2965.

Bidochka, M. J., & Khachatourians, G. G. (1987). Applied & Environmental Biology, 53, 1679–1684.

Pol, D., Menon, V., & Rao, M. (2012). Extremophiles, 16, 135–146.

Singh, R. S., Saini, G. K., & Kennedy, J. F. (2010). Carbohydrate Polymer, 81, 252–259.

Marin, E., Sanchez, L., Perez, M. D., Puyol, P., & Calvo, M. (2003). Journal of Food Science, 68, 89–93.

Gote, M. M., Khan, M. I., & Khire, J. M. (2007). Enzyme & Microbial Technology, 40, 1312–1320.

Phadtare, S., Rao, M., & Deshpande, V. (1997). Archive of Microbiology, 166, 414–417.

Chellappan, S., Jasmin, C., Basheer, S. M., Kishore, A., Elyas, K. K., Bhat, S. G., & Chandrasekaran, M. (2011). Journal of Industrial Microbiology & Biotechnology, 38, 743–752.

Savitha, S., Sadhasivam, S., Swaminathan, K., & Lin, F. H. (2011). Journal of the Taiwan Institute of Chemical Engineers, 42, 298–304.

Papagianni, M., & Sergelidis, D. (2014). Applied Biochemistry & Biotechnology, 172, 3926–3938.

Cavello, I. A., Hours, R. A., Rojas, N. L., & Cavalitto, S. F. (2013). Process Biochemistry, 48, 972–978.

Acknowledgments

Shiv Shankar is grateful to the Council of Scientific and Industrial Research (CSIR) for financial assistance. Authors acknowledge the financial support from NMITLI project funded by CSIR, Govt. of India, and Dr. Mahesh J Kulkarni for analysis of samples in MALDI.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Shankar, S., Laxman, R.S. Biophysicochemical Characterization of an Alkaline Protease from Beauveria sp. MTCC 5184 with Multiple Applications. Appl Biochem Biotechnol 175, 589–602 (2015). https://doi.org/10.1007/s12010-014-1314-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-014-1314-3