Abstract

Fluoroalkyl end-capped 2-acrylamido-2-methylpropanesulfonic acid oligomer/poly(vinyl alcohol) composite [RF-(AMPS)n-RF/PVA] films were prepared by casting homogeneous aqueous methanol solutions containing RF-(AMPS)n-RF/PVA composites, which were prepared by the reactions of the corresponding oligomer with PVA. The transparent colorless RF-(AMPS)n-RF/PVA composite films thus obtained were subjected to tensile testing to evaluate the values of Young’s modulus, tensile strength, and elongation at break. The RF-(AMPS)n-RF/PVA composites films are capable of greater Young’s modulus than the original PVA film (PVA/HCl film), which was prepared by casting the aqueous methanol solution of PVA in the presence of 1 N hydrochloric acid. The polymer film bearing a higher Young’s modulus is, in general, tough and brittle to providing lower elongation at break; however, we can observe a significant increase in both the tensile strength and elongation at break of the RF-(AMPS)n-RF/PVA composite films, compared to those of the PVA/HCl film. In addition, it was demonstrated that the RF-(AMPS)n-RF/PVA composite films can exhibit a higher water adsorption ability than that of the PVA/HCl film.

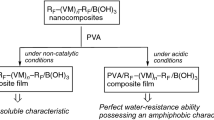

Graphic abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

ABA triblock-type two fluoroalkyl end-capped oligomers [RF-(M)n-RF; M = radical polymerizable monomers; RF = fluoroalkyl group] are attractive fluorinated polysoaps, due to their wide variety of unique properties such as high surface active property, self-assembled molecular aggregate ability which cannot be achieved by the corresponding randomly fluoroalkylated and AB-block-type fluoroalkylated polysoaps.1,2,3 In these two fluoroalkyl end-capped oligomers, fluoroalkyl end-capped oligomers possessing sulfobetaine-type units can cause a gelation not only in water but also in organic polar solvents, such as methanol, ethanol and dimethyl sulfoxide through the synergistic interaction between the aggregation of fluoroalkyl segments at the oligomer end sites and the ionic interaction of the sulfobetaine-type segments under noncrosslinked conditions.4,5 Two fluoroalkyl end-capped oligomers possessing hydroxy segments can also form gels in water and polar organic media through the synergistic interaction between the aggregation of fluoroalkyl groups at the oligomer end sites and the intermolecular hydrogen bonding interactions of the hydroxy units at the oligomer side chains under similar conditions.6,7,8 Moreover, fluoroalkyl end-capped 2-acrylamido-2-methylpropanesulfonic acid oligomer can cause a gelation in ionic liquids such as 1-methylpyrazolium tetrafluoroborate under noncrosslinked conditions.9 This fluorinated oligomer gel formed in the ionic liquid afforded a high ionic (proton) conductivity of 10−2 S/cm level at room temperature.9 Fluoroalkyl end-capped 2-acrylamido-2-methylpropanesulfonic acid co-oligomers containing poly(oxyethylene) units can also form gels in dimethyl sulfoxide under noncrosslinked conditions, and these fluorinated oligomeric gelling electrolytes containing lithium salts exhibit a considerably high ionic conductivity of 10−3 S/cm level at room temperature.10 Therefore, from the developmental viewpoint of new fluorinated functional materials, it is of particular interest to develop the new fluorinated oligomeric composite gels through the interaction with the traditional polymers. In these traditional polymers, poly(vinyl alcohol) [PVA] is commercially among the most promising polymers; however, application of PVA into a wide variety of fields is extremely restricted due to its poor resistance toward water.11 To improve such water-sensitive characteristics, previously there have been numerous reports on the crosslinking reactions of PVA with maleic acid, glutaraldehyde and formaldehyde to increase the strength of the PVA films.12,13,14,15,16 The hybridizations of PVA with alkoxysilanes such as tetraethoxysilane, vinyltriethoxysilane and 2,2-bis(triethoxysilyl)ethane are also useful for the improvement in the strength and the permeation properties of the PVA films.17,18,19 We have very recently reported that two fluoroalkyl end-capped vinyltrimethoxysilane oligomer/boric acid/poly(vinyl alcohol) composite films [RF-(VM)n-RF/B(OH)3/PVA] can provide not only a high amphiphobic characteristic but also a water-resistant ability.20 Therefore, it is suggested that two fluoroalkyl end-capped oligomer gels will have high potential for affording the unique characteristics toward PVA. In fact, PVA hydrogels serve as a candidate for artificial cartilage21,22,23; however, such hydrogels in general suffer from lack of mechanical strength.24 From this point of view, Gong et al. have already reported on the mechanically strong hydrogels obtained by inducing a double-network structure for numerous combinations of hydrophilic polymers such as poly(2-acrylamido-2-methylpropanesulfonic acid) and polyacrylamide.24,25 Here, we report that fluoroalkyl end-capped 2-acrylamido-2-methylpropanesulfonic acid oligomer [RF-(AMPS)n-RF] can react with PVA to supply the corresponding RF-(AMPS)n-RF/PVA composite gels. The transparent colorless RF-(AMPS)n-RF/PVA composite films were prepared by casting the homogeneous aqueous methanol solutions of the corresponding fluorinated composites. Interestingly, it was clarified that mechanical properties and the water adsorption ability of these films are superior to those of the original PVA film, which was prepared under acidic conditions. These results will be described in this article.

Experimental

Measurements

Stress–strain curve testing was performed using an A&D STB-1225S (Tokyo, Japan). Molecular weights of fluoroalkyl end-capped 2-acrylamido-2-methylpropanesulfonic acid oligomer [RF-(AMPS)n-RF; molecular weight (Mn): 20,500 g/mol] was determined by using a Shodex DS-4 (pump) and Shodex RI-71 (detector) gel permeation chromatograph (Tokyo, Japan) calibrated with poly(ethylene glycol) (molecular weight: 1000–40,000) standards by using 0.5 mol dm−3 Na2HPO4 aqueous solution as the eluent. Thermal analyses were recorded by raising the temperature to around 800°C (the heating rate: 10°C/min) under atmospheric conditions by using a Bruker AXS TG-DTA2000SA differential thermobalance (Kanagawa, Japan).

Materials

2-Acrylamido-2-methylpropanesulfonic acid was purchased from FUJIFILM Wako Pure Chemical Industries (Osaka, Japan). Fluoroalkyl end-capped 2-acrylamido-2-methylpropanesulfonic acid oligomer [RF-(CH2–CHC(=O)NH2+CMe2CH2SO3−)n-RF; RF = CF(CF3)OC3F7] was synthesized by reaction of fluoroalkanoyl peroxide with the corresponding monomer according to our previously reported method.4,5 The RF-(AMPS)n-RF oligomer was obtained as a white powder by reprecipitation with water/tetrahydrofuran and was dried under vacuum at 50°C for 2 days. Poly(vinyl alcohol) (KL-118TR; molecular weight (Mw): 200,000 g/mol; degree of hydrolysis: 95.0–99.0%) was kindly supplied from Kuraray Co., Ltd. (Tokyo, Japan).

Preparation of fluoroalkyl end-capped 2-acrylamido-2-methylpropanesulfonic acid oligomer [RF-(AMPS)n-RF]/poly(vinyl alcohol) [PVA] composites

To a methanol solution (10 ml) of RF-(AMPS)n-RF oligomer, RF = CF(CF3)OC3F7 (80 mg) was added an aqueous homogeneous solution (10 ml) containing PVA (420 mg). The mixture was stirred with a magnetic stirring bar at room temperature for 1 day. After the removal of solvent, the obtained product was dried under vacuum at 50°C for 1 day to afford the expected product [375 mg; isolated yield based on the used oligomer (80 mg) and PVA (420 mg): 89%]. The material loss (125 mg) would be due to the recovery process of the expected composites. Other composites were also prepared under similar conditions. Each isolated composite was successively mixed with water in a tube. The mixture was treated under ultrasonic conditions until the solid was dissolved. The resulting solution was kept at 25°C for 1 h, and then the gelation was checked visually. When it was formed, the gel was stable and the tube was able to be inverted without changing the shape of the gel.

Preparation of fluoroalkyl end-capped 2-acrylamido-2-methylpropanesulfonic acid oligomer/poly(vinyl alcohol) composite films

To a methanol solution (10 ml) containing fluoroalkyl end-capped 2-acrylamido-2-methylpropanesulfonic acid oligomer [RF = CF(CF3)OC3F7: RF-(AMPS)n-RF] (80 mg) was added an aqueous solution (10 ml) of poly(vinyl alcohol) (420 mg). The mixture was stirred at room temperature for 6 h to provide the low-viscosity and transparent colorless solution. The RF-(AMPS)n-RF/PVA composite film was easily prepared by casting this homogeneous solution on a glass plate. The solvent was evaporated at room temperature, and the film formed was peeled off and dried at room temperature for 1 day under vacuum to afford the expected composite film. The other composite films were also prepared under similar conditions.

Mechanical property of the RF-(AMPS)n-RF/PVA composite films

The film samples were cut into the dumbbell-type specimen (35 mm long at two ends, 61–75 μm thick, and 2 mm wide at the neck) and were loaded into the sample grips of materials testing machine (A&D STB-1225S, Tokyo, Japan) with a grip distance of 12 mm; the crosshead speed was 200 mm/min. The three films of each sample were used to determine the average values of Young’s modulus, tensile strength, and elongation at break.

Swelling ratio of the fluoroalkyl end-capped 2-acrylamido-2-methylpropanesulfonic acid oligomer/poly(vinyl alcohol) composite films

The RF-(AMPS)n-RF/PVA composite film was cut into a square of 10 mm × 10 mm × 61 μm (thickness) and was dried at room temperature for 1 day under vacuum. Swelling ratio of the film was measured after the preweighed dried film was swollen in water at 25°C. The swollen film was weighed after being slightly removed from the surface water. The swelling ratio was calculated by the following equation: swelling ratio (g/g) = (Ws–Wd)/Wd, where Wd is the weight of dried film and Ws is the weight of swollen film.

Results and discussion

Fluoroalkyl end-capped 2-acrylamido-2-methylpropanesulfonic acid oligomer [RF-(AMPS)n-RF] was found to react with PVA in aqueous methanol solutions at room temperature for 1 day to afford the expected RF-(AMPS)n-RF/PVA composite gel, as shown in Scheme 1.

It was demonstrated that the fluorinated composites thus obtained can cause a gelation in water, as shown in Runs 2–4 in Fig. 1.

To clarify this gelling behavior, we measured the minimum concentrations (Cmin) of these oligomers for gelation at 25°C according to the method reported by Hanabusa et al.26,27 and the results are summarized in Table 1.

As shown in Table 1, original PVA and the RF-(AMPS)n-RF/PVA composites (Run 1), which were prepared under a lower feed amount (20 mg) of oligomer based on PVA (480 mg), are unable to reveal the gelling ability. However, the Cmin values were found to decrease from 12 to 7 or 9%, with the increase in the feed amounts of oligomer from 40 to 160 mg, indicating that this gelation behavior is governed by the synergistic interaction between the aggregation of the end-capped fluoroalkyl groups in oligomer and the ionic interaction of the sulfobetaine-type segments. Thus, the higher feed amounts of oligomer such as Run 4 should enable the RF-(AMPS)n-RF/PVA composites to provide the similar gelling ability to that of the original RF-(AMPS)n-RF oligomer.

We tried to prepare the RF-(AMPS)n-RF/PVA composite films by using the corresponding composites (Runs 1–4 in Table 1) in order to clarify the mechanical properties of these films. The photograph of the obtained composite films is depicted in Fig. 2. Original PVA film and the PVA film (PVA/HCl film), which were prepared under acidic conditions, are also illustrated in Fig. 2 for comparison.

Photograph of the RF-(AMPS)n-RF/PVA composite films, which were prepared by using the corresponding composites (Runs 1–4) in Table 1, original PVA film, and the PVA/HCl film, which was prepared under acidic conditions (1 N HCl: 1 ml); * Film thickness; ** used PVA: 500 mg

As shown in Fig. 2, we have succeeded in preparing the transparent colorless composite films (Runs 1–4), quite similar to the original PVA film and the PVA/HCl film. Original PVA film is very sensitive to water, and this film was completely soluble after immersion into water within 1 min. However, the PVA/HCl film was unable to give a solubility toward water, and a swelling behavior of this film was observed after immersion into water. This finding would be due to the crosslinking reaction between the hydroxy groups on the PVA main chain to produce the crosslinked acetal units under acidic conditions.28 In addition, we studied the TGA (thermogravimetric analyses) measurements in order to clarify the presence of the residual solvent in the composite films. The results are shown in Fig. 3.

TGA (thermogravimetric analyses) of RF-(AMPS)n-RF/PVA composite films Runs 3* and 4* and the PVA/HCl film*. * Run Nos and PVA/HCl film correspond to those of Fig. 2

As shown in Fig. 3, we cannot detect the presence of the residual solvent at around 100°C for the composite films, quite similar to that of the PVA/HCl film. Thus, we studied the mechanical property of the RF-(AMPS)n-RF/PVA composite films (Runs 1–4 in Fig. 2) and the PVA/HCl film. The mechanical property of the original PVA film was not performed due to its higher solubility toward water. The composite films were subjected to tensile testing to evaluate the stress–strain relationship. The typical stress–strain behavior for the RF-(AMPS)n-RF/PVA composite film (Run 3 in Fig. 2) and the PVA/HCl film at the crosshead speed of 200 mm/min at room temperature is shown in Fig. 4.

Interestingly, the RF-(AMPS)n-RF/PVA composite film (Run 3) had an elongation at break of 215% level, higher than that (170%) of the PVA/HCl film, as illustrated in Fig. 3. The higher tensile strength and the Young’s modulus were also observed for this RF-(AMPS)n-RF/PVA composite film. The polymer film having a higher Young’s modulus is, in general, tough and brittle to provide the lower elongation at break. However, this composite film can provide a significant increase in both the tensile strength and elongation at break, compared to those of the PVA/HCl film. This would be due to the architecture of a double-network structure for the combination of RF-(AMPS)n-RF oligomeric gel network and PVA gel network. The crosslinking reactions of PVA occurred by using traditional crosslinkers such as maleic acid, glutaraldehyde and formaldehyde to form the PVA hydrogel.12,13,14,15,16 Aqueous hydrochloric acid is also effective for the formation of PVA hydrogels through the crosslinking between hydroxyl groups on the PVA main chain to produce the acetal units.28 We previously reported that aqueous RF-(AMPS)n-RF oligomer solution can exhibit an acidic characteristic (pH 2.86), due to the presence of the sulfobetaine-type segments on the oligomer side chain.29 Therefore, PVA should form the corresponding hydrogel in the presence of RF-(AMPS)n-RF oligomer to create the new RF-(AMPS)n-RF/PVA double-network gel. Such double-network gel can derive into the superior mechanical property to that of the PVA/HCl film.

The Young’s modulus, the tensile strength, and the elongation at break for the composite films (Runs 1–4) and the PVA/HCl film are summarized in Fig. 5, which are the average values of each of the three films.

Mechanical properties (Young’s modulus, tensile strength, and elongation at break) of the RF-(AMPS)n-RF/PVA composite films (*each Run No corresponds to that of Fig. 2)

As shown in Fig. 5, the RF-(AMPS)n-RF/PVA composite films (Runs 1–4) were found to have a higher Young’s modulus and tensile strength than those of the PVA/HCl film. In particular, the composite films (Runs 3 and 4) possessing a higher gelling ability, the minimum concentrations (Cmin) of which are 7–9 (see Table 1), can give a higher Young’s modulus and tensile strength than those of the PVA/HCl film. Of particular interest, only the composite film Run 3 can supply a higher elongation at break than that of the PVA/HCl film. This finding is due to the higher gelling ability, compared to that of the other composite films. Thus, the RF-(AMPS)n-RF/PVA composites (Run 3) possessing a higher gelling ability should establish the mechanically strong double-network gel to provide a higher elongation at break for the composite films. Usually, it is well known that the double-network gels are synthesized through the two-step crosslinking reactions; that is, the first step consists of the synthesis of crosslinked hydrophilic polymers such as poly(2-acrylamido-2-methylpropanesulfonic acid) [PAMPS] whose polymer is obtained by the photopolymerization of AMPS monomer in the presence of crosslinking agent (N, N’-methylenebisacrylamide (MBAAm) initiated by 2-oxoglutaric acid. In the second step, the subsequent photopolymerization of acrylamide (AAm) containing MBAAm and 2-oxoglutaric acid in the presence of the crosslinked PAMPS hydrogel can proceed to provide the double-network hydrogel as illustrated in Scheme 2.24,25,30

On the other hand, RF-(AMPS)n-RF oligomer can form the gel in water through the synergistic interaction between the aggregation of the end-capped fluoroalkyl groups and the ionic interaction of sulfobetaine-type segments under noncrosslinked conditions (see Scheme 3). In particular, PVA should afford the crosslinked PVA hydrogel related to the acetal units formed from hydroxy groups on the PVA main chain in the presence of the acidic RF-(AMPS)n-RF oligomer solution (pH 2.86).29 Thus, the double-network hydrogel can be easily prepared by the reaction of the RF-(AMPS)n-RF oligomer with PVA in aqueous solutions in only one step, quite different from the traditional synthesis of the double-network hydrogels, as shown in the Scheme 3.

In this way, such double-network formation would enable the RF-(AMPS)n-RF/PVA composite possessing a higher gelling ability to create the mechanically strong composite film.

It is of particular interest to clarify the water adsorption ability of the present RF-(AMPS)n-RF/PVA composite films in order to apply these films into a variety of fields. Because the application of the original PVA film is very limited due to its higher solubility toward water,11 we studied the water adsorption behaviors of the RF-(AMPS)n-RF/PVA composite films [square of 10 mm × 10 mm × 61–76 μm (film thickness)]. The PVA/HCl film [a square of 10 mm × 10 mm × 69 μm (film thickness)] was also studied under similar conditions, for comparison. The results are shown in Fig. 6.

In the case of the PVA/HCl film, a swelling behavior was observed with keeping the shape of this film after immersion into water for 60 min. On the other hand, interestingly, the shape of the RF-(AMPS)n-RF/PVA composite films (Runs 3 and 4) was found to swell to about two times larger under similar immersion conditions, as shown in Fig. 6. Thus, we tried to study the relationship between the swelling ratio (g/g) of the composite films and the immersion time into water, and the results are summarized in Fig. 7.

Figure 7 shows that the PVA/HCl film can adsorb water to form the gelling film (swelling ratio of the film: ca. 2 g/g) after immersion in water for 5 min, and this film maintains the constant swelling ratio (2 g/g) even after immersion in water for 60 min. On the other hand, the RF-(AMPS)n-RF/PVA composite films (Runs 1 and 2) whose composites exhibit no gelation and a poor gelling ability (Cmin = 12%), respectively, afforded a soluble characteristic after immersion in water for 1 min, indicating that these composites cannot construct the double-network structure to lead the mechanically strong hydrogel films. However, of particular interest, the RF-(AMPS)n-RF/PVA composite films (Runs 3 and 4) whose composites supply a higher gelling ability (Cmin = 7 and 9%) can give a higher water adsorption behavior (6–10 times), compared to that (two times) of the PAV/HCl film after immersion in water for 5 min.

We studied the water cycling stability of the RF-(AMPS)n-RF/PVA composite films (Runs 3 and 4) for the water adsorption and desorption behavior by using the corresponding fresh composite films. In particular, we used the dried composite films after completely releasing water in the case of two cycles, and the swelling ratio was successively measured under similar conditions. The results are shown in Fig. 8.

Photograph of the RF-(AMPS)n-RF/PVA composite film (Run 3) before immersion in water (a), the swollen film (Run 3) after immersion in water for 60 min (b), and the dried film (Run 3) after completely releasing water (c) in the case of one cycle. The same dried film (Run 3) (d) was used in the case of 2 cycles (d)–(f)

As shown in Fig. 8, we succeeded in observing the good water cycling stability for the swelling behavior of the composite film (Run 3). The shape of the composite film [square of 10 mm × 10 mm × 61 μm (film thickness)] was found to swell to approximately two times after immersion into water for 60 min, quite similar to that of Fig. 6. However, interestingly, the shape of this swollen film was recovered to the original one through the drying process (see Fig. 8c). We can observe the similar swelling behavior of the dried composite film (Run 3) in two cycles as shown in Fig. 8d–f. In addition, a similar swelling behavior was observed in the composite film (Run 4) (data not shown). Furthermore, we studied the water cycling stability for the swelling ratio of the composite films (Runs 3 and 4), and the results are as follows:

The composite film | Immersion time (min) | ||||||

|---|---|---|---|---|---|---|---|

1 | 5 | 10 | 20 | 30 | 45 | 60 | |

Run 3 | Swelling ratio [g/g (swollen film/film before immersion (%)] | ||||||

|---|---|---|---|---|---|---|---|

1 cycle | 4.6 | 5.5 | 5.7 | 5.8 | 5.8 | 6.0 | 6.0 |

2 cycle | 4.8 | 5.6 | 5.6 | 5.8 | 5.7 | 5.8 | 5.8 |

Run 4 | Swelling ratio [g/g (swollen film/dried film before immersion (%)] | ||||||

|---|---|---|---|---|---|---|---|

1 cycle | 6.7 | 9.2 | 10.2 | 10.4 | 10.7 | 10.9 | 11.1 |

2 cycle | 7.1 | 9.8 | 10.5 | 10.7 | 10.7 | 10.8 | 10.6 |

As indicated previously, each swelling ratio for the film, Run 3 or Run 4, in one cycle was found to be quite similar to that of Run 3 or Run 7 in Fig. 7, respectively, and a good water cycling stability of the composite films: Runs 3 and 4, was observed for the water adsorption process in two cycles. This finding would be due to the construction of mechanically strong double-network hydrogel. In fact, as shown in Fig. 4, the composite films (Runs 3 and 4) can exhibit the higher Young’s modulus, tensile strength, and elongation at break than those of the other composite films (Runs 1 and 2).

In this way, it was clarified that the RF-(AMPS)n-RF/PVA composite films whose composites possess a higher gelling ability can exhibit a higher water adsorption ability with keeping the shape of the swollen composite films.

Conclusion

We have newly prepared RF-(AMPS)n-RF/PVA composites by reactions of the RF-(AMPS)n-RF oligomer with PVA at room temperature for 1 day. The transparent colorless films were subsequently prepared by casting their aqueous methanol solutions. It was demonstrated that the mechanical properties such as Young’s modulus and tensile strength of the obtained composite films were superior to those of the PVA/HCl film. The RF-(AMPS)n-RF/PVA composite films possessing a higher gelling ability can provide the significant increase in the Young’s modulus, tensile strength and elongation at break, compared to the other composite films possessing a poor gelling ability. The polymer film possessing the higher Young’s modulus is, in general, tough and brittle providing the lower elongation at break; however, such excellent mechanical property would be due to the formation of the double-network structure in the corresponding composite film. Mechanically strong composite films were also clarified to afford a higher water adsorption ability with maintaining the shape of the swollen films, quite different from that of the PVA/HCl film. In this way, it is suggested that our present RF-(AMPS)n-RF/PVA composite films have high potential for a wide variety of fields, especially the biomedical area, because the RF-(AMPS)n-RF oligomer hydrogels are known to be potent and selective inhibitors of HIV-1 and other enveloped viruses.31

References

Sawada, H, “Fluorinated Peroxides.” Chem. Rev., 96 1779–1808 (1996)

Sawada, H, “Synthesis of Self-Assembled Fluoroalkyl End-Capped Oligomeric Aggregates—Applications of These Aggregates to Fluorinated Oligomeric Nanocomposites.” Prog. Polym. Sci., 32 509–533 (2007)

Sawada, H, “Preparation and Applications of Novel Fluoroalkyl End-Capped Oligomeric Nanocomposites.” Polym. Chem., 3 46–65 (2012)

Sawada, H, Katayama, S, Nakamura, Y, Kawase, T, Hayakawa, Y, Baba, M, “Gelation of Fluoroalkylated 2-acrylamido-2-methylpropanesulfonic Acid Oligomers as Potential for Prevention of HIV-1 Transmission.” Polymer, 39 743–745 (1998)

Sawada, H, Katayama, S, Ariyoshi, Y, Kawase, T, Hayakawa, Y, Tomita, T, Baba, M, “Fluorinated Functional Materials Possessing Biological Activities: Gel Formation of Novel Fluoroalkylated End-Capped 2-acrylamido-2-methylpropanesulfonic Acid Polymers Under Non-crosslinked Conditions.” J. Mater. Chem., 8 1517–1524 (1998)

Sawada, H, Nakamura, Y, Katayama, S, Kawase, T, “Gelation of Fluoroalkylated End-Capped Oligomers Containing Triol Segments under Non-Crosslinked Conditions, and Binding or Releasing of Metal Ions by These Oligomers.” Bull. Chem. Soc. Jpn., 70 2839–2845 (1997)

Sawada, H, Tanimura, T, Katayama, S, Kawase, T, “Aggregation of Fluoroalkyl Units: Synthesis of Gelling Fluoroalkylated End-Capped Oligomers Containing Hydroxy Segments Possessing Metal Ion Binding and Releasing Abilities.” Chem. Commun., 15 1391–1392 (1997)

Sawada, H, Tanimura, T, Katayama, S, Kawase, T, Tomita, T, Baba, M, “Synthesis and Properties of Gelling Fluoroalkylated End-Capped Oligomers Containing Hydroxy Segments.” Polym. J., 30 797–804 (1998)

Sawada, H, Shima, K, Kyokane, J, Oharu, K, Nakagawa, H, Kitazume, T, “Gelation and Ionic Conductivity of Fluoroalkyl End-Capped 2-acrylamido-2-methylpropanesulfonic Acid Oligomers in Ionic Liquids.” Eur. Polym. J., 40 1595–1597 (2004)

Sawada, H, Ariyoshi, Y, Lee, K, Kyokane, J, Kawase, T, “A New Approach to Highly Conductive Polymer Electrolytes: Synthesis of Gelling Fluoroalkylated End-Capped 2-acrylamido-2-methylpropanesulfonic Acid Copolymers Containing Poly(oxyethylene) Units.” Eur. Polym. J., 36 2523–2526 (2000)

Wang, J, Wang, X, Xu, C, Zhang, M, Shang, X, “Preparation of Graphene/Poly(vinyl alcohol) Nanocomposites with Enhanced Mechanical Properties and Water Resistance.” Polym. Int., 60 816–822 (2011)

Huang, RYM, Rhim, JW, “Modification of Poly(vinyl alcohol) Using Maleic Acid and its Application to the Separation of Acetic Acid‐Water Mixtures by the Pervaporation Technique.” Polym. Int., 30 129–137 (1993)

Yeom, CK, Huang, RYM, “Development of Crosslinked Poly(vinyl alcohol) (type II) and Permeation of Acetic Acid—Water Mixtures.” Angew. Makromol. Chem., 184 27–35 (1991)

Yeom, CK, Lee, KH, “Pervaporation Separation of Water-Acetic Acid Mixtures Through Poly(vinyl alcohol) Membranes Crosslinked with Glutaraldehyde.” J. Membr. Sci., 109 257–265 (1996)

Rhin, JW, Yoon, SW, Kim, SW, Lee, KH, “Pervaporation Separation and Swelling Measurement of Acetic Acid–Water Mixtures Using Crosslinked PVA Membranes.” J. Appl. Polym. Sci., 63 521–527 (1997)

Bandyopadhyay, A, DE Sarkar, M, Bhowmick, AK, “Poly(vinyl Alcohol)/silica Hybrid Nanocomposites by Sol-Gel Technique: Synthesis and Properties.” J. Mater. Sci., 40 5233–5241 (2005)

Uragami, T, Okazaki, K, Matsugi, H, Miyata, T, “Structure and Permeation Characteristics of an Aqueous Ethanol Solution of Organic−Inorganic Hybrid Membranes Composed of Poly(vinyl alcohol) and Tetraethoxysilane.” Macromolecules, 35 9156–9163 (2002)

Hu, WW, Zhang, HH, Zhang, QG, Liu, QL, Zhu, AM, “Pervaporation Dehydration of Water/Ethanol/Ethyl Acetate Mixtures Using Poly(vinyl alcohol)-Silica Hybrid Membranes.” J. Appl. Polym. Sci., 126 778–787 (2012)

Zheng, QG, Liu, QL, Zhu, AM, Xiong, Y, Zhang, XH, “Characterization and Permeation Performance of Novel Organic−Inorganic Hybrid Membranes of Poly(vinyl alcohol)/1,2-Bis(triethoxysilyl)ethane.” J. Phys. Chem. B, 112 16559–16565 (2008)

Aomi, Y, Sawada, H, “Preparation of Amphiphobically Modified Poly(vinyl alcohol) Film by Fluoroalkyl End-Capped Vinyltrimethoxysilane Oligomer.” J. Coat. Technol. Res., (2019). https://doi.org/10.1007/s11998-018-0148-2

Stammen, JA, Williams, S, Ku, DN, Guldberg, RE, “Mechanical Properties of a Novel PVA Hydrogel in Shear and Unconfined Compression.” Biomaterials, 22 799–806 (2001)

Anseth, KS, Bowman, CN, Brannon-Peppas, L, “Mechanical Properties of Hydrogels and Their Experimental Determination.” Biomaterials, 17 1647–1657 (1996)

Gu, Z-Q, Xiao, J-M, Zhang, X-H, “The Development of Artificial Articular Cartilage—PVA‐Hydrogel.” Biomed. Mater. Eng., 8 75–81 (1998)

Gong, JP, Katsuyama, Y, Kurokawa, T, Osada, Y, “Double–Network Hydrogels with Extremely High Mechanical Strength.” Adv. Mater., 15 1155–1158 (2003)

Gong, JP, Kurokawa, T, Narita, T, Kagata, G, Osada, Y, Nishimura, G, Kinjo, M, “Synthesis of Hydrogels with Extremely Low Surface Friction.” J. Am. Chem. Soc., 123 5582–5583 (2001)

Hanabusa, K, Tanaka, R, Suzuki, M, Kimura, M, Shirai, H, “Excellent Gelators for Organic Fluids: Simple Bolaform Amides Derived from Amino Acids.” Adv. Mater., 9 1095–1097 (1997)

Hanabusa, K, Okui, K, Karaki, K, Kimura, M, Shirai, H, “Organogels Formed by N-Benzyloxycarbonyl-l-alanine 4-Hexadecanoyl-2-nitrophenyl Ester and Related Compounds.” J. Colloid Interface Sci., 195 86–93 (1997)

Sakurada, I, Matsuzawa, S, “Crosslinking of Poly (Vinylalcohol) by Treatment with Hydrochloric Acid.” Kobunshi Kagaku, 20 353–356 (1963). https://doi.org/10.1295/koron1944.20.353

Kijima, T, Nishida, M, Fukaya, H, Yoshida, M, Sawada, H, “Coloring–Decoloring Behavior of Fluoroalkyl End-Capped 2-Acrylamido-2-methylpropanesulfonic Acid Oligomer/Acetone Composite in Methanol.” J. Polym. Sci. Part A: Polym. Chem., 51 2555–2564 (2013)

Suekama, T, Hu, J, Kurokawa, T, Gong, JP, Gehrke, SH, “Tuning Mechanical Properties of Chondroitin Sulfate‐Based Double‐Network Hydrogels.” Macromol. Symp., 329 9–18 (2013)

Fujiwara, M, Ashida, N, Okamoto, M, Mizuta, T, Ide, T, Hanasaki, Y, Katsuura, K, Sawada, H, Shigeta, S, Konno, K, Yokota, T, Baba, M, “RD6-2198, a Novel Betain-Type Fluoroalkylated Oligomer, Inhibits the Replications of Human Immunodeficiency Virus Type 1 and Other Enveloped Viruses.” Antivir. Res., 38 141–149 (1998)

Acknowledgments

This work was partially supported by a Grant-in-Aid for Scientific Research 16K05891 from the Ministry of Education, Science, Sports, and Culture, Japan.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Katayama, S., Yasuta, M. & Sawada, H. Preparation and properties of fluoroalkyl end-capped 2-acrylamido-2-methylpropanesulfonic acid oligomer/poly(vinyl alcohol) composite film. J Coat Technol Res 17, 219–230 (2020). https://doi.org/10.1007/s11998-019-00259-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-019-00259-6