Abstract

Tea polyphenols and probiotic powder were incorporated into milk-enriched purple potato puree in order to investigate quality changes of the products printed using different ink formulations during the fermentation process. After the fermentation of the printed products containing tea polyphenols and probiotic powder, the number of probiotics increased and the growth of harmful microorganisms (mold as a model) was inhibited. Additionally, the growth of probiotics brought about the changes in pH in the printed samples, resulting in a controllable color change of the incorporated anthocyanin from purple to red. The textural properties (e.g., hardness and adhesiveness) were different with the difference in fermentation times, which were correlated with the dynamic change in probiotic count. This gave rise to the development of 5D food printing based on the dynamic change in the live cell count of probiotics.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Since its introduction into the food sector, the concept of additive manufacturing has gained the attention of many academics, manufacturers and consumers (Chen et al., 2022a; Diaz-Gomez et al., 2022; Rajabi et al., 2021). Additive manufacturing technology, which is popularly known as 3D printing, was initially focused on accurately printing foods in their three dimensions (Chen et al., 2022b; Liu et al., 2017; Wang et al., 2021). Currently, there have been many reports on whether or how food materials can be successfully 3D printed (Huang et al., 2019; Pallottino et al., 2016; Sun et al., 2015; Wang et al., 2021). The keys to 3D food printing depend on the physicochemical properties of the food material, various printing parameters and post-processing parameters (Liu et al., 2017; Teng et al., 2021).

4D food printing means that 3D printed foods are allowed to undergo one or more controlled and desirable changes in quality attributes by the application of various physicochemical stimulants such as microwaves, light, electricity, and pH values (He et al., 2020b; Kumar et al., 2019). For example, Ghazal et al. (2019) reported a pH-responsive discoloration system including anthocyanins and potato starch gels. He et al. (2020b) reported a double-layered printed product that could change color through the molecular migration between mashed potatoes and anthocyanins. This approach achieves sensorially desirable color change and indicates a new research direction in 4D food printing. Besides desirable changes in color, 4D food printing has also enabled desirable shape changes. For example, Wang et al. (2017) used gelatin and ethyl cellulose to prepare 3D printed films; Tao et al. (2019) achieved various shape changes of the double-layer structure of flours under water simulation; He et al. (2020b) used the puree of purple potatoes as a printing ink to achieve a shape change from 2 to 3D by microwave dehydration simulation. Additionally, there are some reports of 4D food printing where variations in the nutrition of the printed products have been achieved. For example, Chen et al. (2021a) reported the conversion of ergosterol to vitamin D2 in purple potato puree by applying ultraviolet irradiation.

Although 4D food printing has expanded the scope of 3D printing, it has not yet achieved synchronous changes in multiple quality attributes after printing in order to meet the needs of special populations such as the elderly and children who struggle to swallow. Therefore, the concept of 5D printing food is proposed to overcome this problem. 5D printer with 5 directional changes, including X–Y-Z movement of the print head and two-dimensional rotation of the print bed, has now been reported in mechanical manufacturing engineering (Reddy & Devi, 2018). Compared with 4D printing, 5D printing can use fewer materials to produce more complex and curved shapes. However, this printer is not used in the food industry because the printing ink properties do not match the printer (Anas et al., 2021; Haleem et al., 2019). In the field of medicine, Gillaspie et al. (2016) proposed a medical 5D concept to simulate printing of a patient's lung tumor area, which incorporates information about the tumor over time (the fourth dimension) and physiological activity (fifth dimension) to guide surgery. Referring to the concept of 5D printing in the medical field, the development of 5D food printing should be able to overcome the deficiencies of 3D and 4D printing by adding life activities in the dimension of time. In other words, the goal of 5D food printing is to have not only the customization function of 3D printing, but also the ability to controllably change color, shape and nutritional value throughout the life of printed products. The post-printing changes in foods come from the reaction, synthesis and transformation of the biological food matrix. In this way, the properties of foods can have the function of undergoing dynamic change; and when the change is completed, this kind of food can be greatly beneficial to human health (Fig. 1). The incorporation of live cells/bacteria in foods and their subsequent metabolic transformation can improve properties of the food products. Compared with probiotics, live cells are more costly and require specific growth conditions (Teng et al., 2021), so probiotics as living organisms will be more widely used in the food sector.

Aiming to develop a healthy 5D printed food, we produced the purple potato puree using purple potato powder and milk, and then added probiotic powder and tea polyphenols into this puree for the subsequent printing and fermentation process. Rheological tests and 3D printing test were first carried out in order to determine the printability of the printing ink. The fermentation state of the probiotics in the printed model was then investigated. Finally, we investigated whether the fermentation process of probiotics adjusted by printing technology could achieve pH-response color change and texture change of the printed products.

Materials and Methods

Materials

Table sugar and purple potato powder were purchased from a local market (Wuxi, Jiangsu, China). Main components of purple potato powder (Particle size ≤ 48 μm) are starch of 83.90%, protein of 2.73%, water content of 4.32% and fat of 0.28%. Milk powder brought from Mengniu Dairy Co., Ltd. (Wuxi, Shandong, China) includes carbohydrate of 53.93%, protein of 27.45% and fat of 11.63%. Tea polyphenols (Purity of 98.25%) were obtained from Xingrurong Biotechnology Co., LTD (Guangzhou, Shandong, China). Commercially available lyophilized probiotic powder provided by Angie's Yeast CO. LTD (Yichang, Hubei, China) contains Lactobacillus bulgaricus SHBCC D14415 (mass fraction of 82.36%), Streptococcus thermophilus SHBCC D73678 (mass fraction of 15.19%) and maltodextrin. Active bacteria content is more than 10 billion CFU/g. The temperature range for suitable growth of probiotics is 37~45 °C. The pH range for suitable growth of Lactobacillus bulgaricus is 3.5~7.0, and it is in the range of 6.0~7.0 for Streptococcus thermophilus (Jiang et al., 2020).

Formulation of Printing Ink

Sweet milk and purple potato powder were used as the main ingredients of the ink; probiotics and tea polyphenols were used as additives. Sweet milk was prepared first using milk powder and table sugar. Twenty-five grams of milk powder and 5 g of table sugar were mixed, and 70 g of water was added to produce 100 g of sweet milk. Sweet milk was mixed with the pre-gelatinized purple potato powder. To test the printability, three purple potato puree samples were prepared using purple potato powder and sweet milk at the mass ratios of 1:3, 1:4, and 1:5. According to the accuracy of the printed product’s shape (rabbit head, butterfly and Chinese character models) and rheological properties of printing inks, the mass ratio of purple potato puree to milk that was most suitable for printing was selected. Subsequently, 2% (1 g) of probiotic powder were added into 50 g of the selected puree. After mixing at 300 r/min for 10 min, four mass concentrations of tea polyphenols (0.1%, 0.2%, 0.3%, 0.4%, and 0.5%) were added to 50 g of the selected puree containing 2% probiotic powder, respectively. Then, the material continued to be stirred at 300 r/min for 10 min. All the utensils used in the preparation process were carefully sterilized, and the preparation process was carried out in the laminar flow bench.

3D Printing Process

As complex models reflect the ink printability better than simple models (e.g., rectangles), a rabbit head model (20 mm × 30 mm × 50 mm) was printed using the purple potato puree without probiotics and tea polyphenols. In order to facilitate the measurement of color changes in printed products, a rectangular model (20 mm × 20 mm × 4 mm) was printed using the purple potato puree containing probiotics alone and the purple potato puree including probiotics and tea polyphenols. An extrusion-based 3D food printer (SHINOVE-D1, Hangzhou Shiyin Co., Ltd., China) was used for all printing experiments. Rhinoceros 5.0 software (Robert McNeel & Associates, Seattle, WA, USA) was used to design the printed models. Simplify 3D software (version 4.0.1; Cincinnati, OH, USA) was used for the slicing of the model and the control of the printing process. The printer parameters were set based on our previous research, with some modifications. All printing experiments were carried out at 25 °C, with a nozzle diameter of 0.8 mm, a printing speed of 23 mm/s, a fill ratio of 80%, a fill angle of 90° and extraction rate of 35 mm3/s. The actual length, width, and height of all models were measured after printing and compared with the designed models. The models were used in subsequent experiments only if the difference in length, width, and height was less than 0.5 mm. All instruments and utensils used in the printing process were carefully disinfected.

Fermentation of the Model After Printing

The printed rectangular samples were placed in a sterilized and transparent polytetrafluoroethylene box with a lid. Fermentation was carried out at 37 °C for 10 h. Samples were taken out every 2 h for testing.

Measurement of Rheological Properties

A parallel plate rheometer with a 20-mm diameter was used to determine the rheological properties of the samples including the mixture of purple potato powder and milk in different mass ratios (the mass ratio of 1:3, 1:4 and 1:5), and the mixture of purple potato powder, milk, probiotic powder and tea polyphenols (the mass ratio of 1:4:0.1:0.05–0.025) (Discovery HR-3, TA Instruments, New Castle, DE, USA). The parameters were set according to the previous report by Chen et al. (2021b).

Measurement of Texture Profile

Hardness, cohesiveness, adhesiveness, chewiness, adhesiveness, and springiness of the printed samples after fermentation were measured using a texture analyzer (TA.XTC-18, Shanghai Baosheng Industrial Development Co., Ltd.) according to Shi et al. (2021) with minor modifications. The samples here referred to the mixture of purple potato powder and milk (the mass ratio of 1:4) and the mixture containing purple potato powder, milk, probiotic powder and tea polyphenols (the mass ratio of 1:4:0.1:0.02). The tested samples were rectangular models taken at different fermentation times. During TPA test, a cylindrical probe (TA/36) was used and two cycles of compression was conducted. When the first compression completed, the plunger reversed at 2 mm/s, and a second compression began after holding for 5 s. Measurement was performed as follows: pre-test rate 3.0 mm/s, test and post-test rate 1.0 mm/s, holding time 5 s, trigger force 5 g, compression strain 40%, and test temperature at room temperature (25 °C).

Measurement of Color Parameters

The color of printed samples was measured using a colorimeter (CR-400, Konica Minolta, Japan). Calibration was carried out using a white reference plate, and the color was expressed as L* (lightness-dark), a* (red-green), and b* (yellow-blue) values.

Measurement of Microbial Amounts

Chinese national standards of GB 4789.35–2016 and GB 4789.15–2016 (2016a, b) were used to determine the numbers of probiotic count and mold count, respectively. Briefly, Man Rogosa Sharpe and Rose Bengal agar-based mediums were used to culture probiotics and molds, respectively. The numbers of probiotics were counted after being cultured at 36 °C for 72 h, while those of mold were counted after being cultured at 28 °C for 120 h.

Data Analysis

All experiments were carried out in triplicate unless otherwise specified. The data were analyzed using one-way analysis of variance (ANOVA) and reported as mean and standard deviation. The significance of the differences among the mean values was tested at the 95% confidence level (P < 0.05) using Duncan’s new multiple range test. All statistical calculations were performed using SPSS (version 26.0).

Results and Discussion

Determination of Basic Printed Formulation

The basis for 4D and 5D printing is the creation of fixed shapes and structures using 3D printing. Therefore, the first step in this work was to determine the flowability and supportability properties of the basic formulation (ink). Suboptimal flow properties can result in broken lines and poor adhesion of each layer during the printing process. Similarly, poor supportability propertiesx can cause the printed model to collapse (Chen et al., 2021b). In this work, a rabbit head model was first selected to assess the printability of the formulation before adding probiotic powder and tea polyphenols. The results of the printing trials are presented in Fig. 2. When the mass ratio of purple potato powder to milk was 1:3, the flow performance of purple potato puree was poor; lines in adjacent layers did not adhere to each other, and the lines were readily broken and shifted seriously during the printing process. This led to the overall chaotic lines of the printed rabbit head model. However, the ears of the rabbit model did not show obvious tilting and bending, indicating that the support performance of the printing ink was still good. When the mass ratio was 1:4, this puree had good fluidity, supportability and adhesion in terms of various details of the printed model. When the mass ratio was 1:5, it was observed that the flowability of purple potato puree was still good; but the support property became worse. At this ratio of 1:5, the printed rabbit ears underwent significant bending and collapsed, which is not desirable in 4D/5D printing. Therefore, we chose the mass ratio of 1:4 between purple potato powder and milk as the basic printing formulation. Subsequently, probiotics and tea polyphenols were added as additives to the above basic printing formulas, and the printing characteristics of these new formulas were tested.

Rheological Properties of Different Formulations

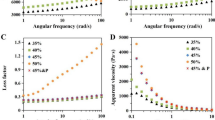

Rheological properties including viscosity, storage modulus, loss modulus, and complex modulus can help finetune support and flow properties of printed formulations (Liu et al., 2019; Theagarajan et al., 2020; Wilson et al., 2020). The viscosity and loss modulus are related to the flow properties; storage and complex modulus are related to support properties. A high viscosity value is not conducive to the extrusion of the printing ink from the nozzle. Low values of storage and complex modulus are related to poor support properties. Figure 3 shows the results of rheological properties, where Fig. 3A, B, and C show the storage, loss and complex modulus, respectively, and Fig. 3D shows the viscosity property. The rheological data show that when the mass ratio of purple potato powder to milk was 1:3, the values of viscosity, storage modulus and complex modulus were high, suggesting that this formulation had good support properties but poor flow performance, which resulted in the above-mentioned undesirable printing results. However, when the mass ratio was 1:5, the values of viscosity, storage and complex modulus of purple potato puree decreased, compared with the mass ratio of 1:3. In this formulation, although the flowability increased, the support performance became worse. Therefore, this formulation also lost the ability to customize of the model. When the mass ratio was 1:4, all rheological parameters were better. What’s more, the printability of the formulation containing probiotic powder and tea polyphenols shows no significant difference (P > 0.05), compared with those formulations without these additives.

Rheological properties of the mixture of purple potato powder and milk in different mass ratios (1:3, 1:4 and 1:5) and the mixture of purple potato puree (the mass ratio of 1:4), 2% probiotic powder and various levels of tea polyphenols (0.1%-0.5%). A Storage modulus(G’), B Loss modulus(G’’), C Complex modulus(G*), D viscosity(η). In every group t means tea polyphenols, p means probiotic powder

Color Change of 5D-Printed Foods

3D printing is the foundation of 4D printing to achieve desirable color and shape changes. 5D printing needs to be built on the foundation of 4D printing and use it to indicate the process of change in a 5D printed biomatrix. In this work, we used the above-mentioned formulations containing probiotic powder and tea polyphenols to print rectangular models of 20 mm × 20 mm × 4 mm and these models were then subjected to fermentation. Color changes in 4D foods produced by the specific fermentation can be seen in Fig. 4 and the variation of the color parameters of the model are presented in Fig. 5. These results indicated that the color of the model changed from purple to red. The reason for this change is that purple mashed potatoes are rich in anthocyanins, which is a pH-responsive pigment (He et al., 2020a). The numbers of probiotics were increased (The analysis of the numbers of probiotics is presented in the “Changes in the Numbers of Probiotics and Molds in 5D-Printed Foods” section) and metabolites such as lactic acid were produced because of extending the fermentation time. The production of lactic acid lowered the pH of the model, which in turn changed the color. This change became remarkable with the increasing fermentation time. Although the color of the model was redder after 10 h of fermentation, the smell of spoilage was detected, indicating an undesirable souring or over fermentation. Judging from the color difference, it could be assumed that the probiotics in the model proliferated and the lactic acid content increased within a defined time frame (< 10 h in this case). Longer fermentation times (> 10 h in this case) can result in overfermentation and an undesirable flavor. The intensity of the red color for the model containing tea polyphenols was substantially higher, compared with the control group without tea polyphenols. The intensity of the red color of the model was highest when the tea polyphenol content was 0.4%. It appears that the presence of an appropriate concentration of tea polyphenols could promote the growth of probiotics and could increase their metabolic activities (Sharma et al., 2022; Zhao & Shah, 2014). Based on these findings, it is concluded that the metabolism of biological substrates can be used to effect desirable changes in the printed model, thereby realizing the concept of 5D printing in biological materials.

Change in color parameters of the products printed using the ink formulations (probiotic powder: purple potato powder: milk = 0.1: 1: 4) containing different tea polyphenol contents (0.1–0.5%) (redness, a*; yellowness, b*; lightness, L* and tea polyphenols, t). Panels A, B, and C represent a* b*, and L* values, respectively

Changes in the Numbers of Probiotics and Molds in 5D-Printed Foods

Published reports, so far, are still addressing the changes in probiotic activity during storage after 3D printing is completed. For example, Yoha et al. (2021) reported 3D printing of microencapsulated probiotics and found that microencapsulation could enhance the degree of survival of probiotics, up to 99% survival. Liu et al. (2020) reported the incorporation of probiotics in mashed potatoes and found that there was no decrease in their viability after 12 d of storage. Changes in sensory qualities of 5D printed food can indicate a change in the biological matrix. This can be brought about by incorporating probiotics and ensuring their growth and metabolism in the 3D-printed model. Growth and metabolism should change in a time-dependent manner. However, there is a danger of contamination by harmful microorganisms during the fermentation process, which in turn makes 3D printed foods unfit for consumption. In this study, probiotics were expected to ferment the printed products and control the growth of harmful microorganisms. Molds are commonly blamed for the spoilage of many food products, so we measured the numbers of molds in the printed product. The results are presented in Fig. 6, Tables S1 and S2. It can be seen from Fig. 6A and Table S1 that in the fermentation process, the numbers of probiotics loaded in the model reached its maximum value between 6 and 8 h, and then entered a decreasing phase. When the fermentation time was more than 4 h, there was a significant difference in the numbers of probiotics among the three experimental groups (Table S1). The number of probiotics in the formulation to which 0.4% tea polyphenols were added was significantly higher than in the other two groups, indicating that tea polyphenols promote the growth and metabolism of probiotics. It has been reported that tea polyphenols can be used as a fermentation substrate for probiotics to promote their survival and metabolism (Sharma et al., 2022; Zhao & Shah, 2014).

Growth status of probiotics (A) and molds (B) with fermentation time and the correlation between color change and the numbers of probiotics/molds (C). raw material: the mixture of purple potato powder and milk in the mass ratio of 1:4 (the basic formulation), 2% probiotics: the basic formulation containing 2% probiotic powder, 2% probiotics and 0.4% tea polyphenols: the basic formulation containing 2% probiotic powder and 0.4% tea polyphenols

It is critical importance to control the mold count in 3D printed food so that it does not exceed the statutory limit (< 100 CFU/g) (Zhao & Shah, 2014). Figure 6B and Table S2 show the changes in the mold counts during the fermentation. The mold counts in the control groups without probiotics and tea polyphenols were increasing all the time and exceeded the limit. The mold counts in the samples including only probiotics or probiotics and tea polyphenols were less than 100 CFU/g at the fermentation time of 8 h. In addition, the mold counts in the formulation containing tea polyphenols was lower throughout the fermentation, compared to the formulation containing only probiotics and the formulation without probiotics and tea polyphenols. The inhibition effect was attributed to the metabolites of probiotics such as lactic acid (Sharma et al., 2022). What’s more, the presence of tea polyphenols could further inhibit the mold counts. Jiang et al. (2015) reported that tea polyphenols disrupted the cell membrane of fungal cells and thus achieved an antifungal effect (Jiang et al., 2015). Anas et al. (2021) and López de Lacey et al. (2014a, b) also reported that tea polyphenols had stronger antioxidant properties and biological activities. Our results as well as the results from other published studies indicated that tea polyphenols achieved better antibacterial effect after probiotic fermentation. Thus, under the above-mentioned conditions, the number of molds in the model decreased.

As shown in Fig. 6C, there was a good correlation between the change in the numbers of microorganisms (probiotics and molds) and the change in color, suggesting that color change was able to indicate the change of microorganisms. In summary, the desired color change and probiotic contents in the printed products were obtained when the basic formulation (purple potato powder: milk = 1: 4) was supplemented with 2% probiotic powder and 0.4% tea polyphenols.

Textural Analysis of 5D-Printed Foods

The consumption of foods rich in probiotics is beneficial to human health. The demographic groups that need to improve intestinal flora mainly include the elderly and children. However, the elderly and children often have difficulty swallowing. Therefore, processed foods intended for the elderly need to be easy to swallow. Easy-to-swallowed foods generally require customization in terms of hardness, adhesiveness, and cohesiveness (Pant et al., 2021; Sungsinchai et al., 2019). Therefore, 5D-printed foods developed in this study are expected to be not only rich in probiotics and phenolic compounds but also have desirable textural properties at the end of fermentation. Table 1 provides the texture profiles of all formulations. These data show that when the purple potato puree did not contain tea polyphenols and probiotics, the values of hardness and cohesiveness of the model increased significantly after 6 h of fermentation. As fermentation proceeded, the loss of water led to an increase in the values of hardness and cohesiveness. After 6 h of fermentation, the hardness and cohesiveness values of the basic formulation were 9.95 N and 0.72 N, respectively; the groups with probiotics had hardness and cohesiveness values of 8.37 N and 0.46 N, respectively; and the groups with probiotics and tea polyphenols had hardness values of 7.69 N and 0.40 N, respectively. The decrease in hardness and cohesiveness values of the samples inducing probiotics was due to probiotics breaking down proteins in the sweet milk as a nitrogen source (Trabelsi et al., 2019), and the decreasing trend was positively correlated with the number of probiotics. In addition, the adhesiveness values among these three groups were not significantly different. The sudden increase in adhesion at 10 h might be due to fermentation-induced substrate breakdown (Trabelsi et al., 2019). These data indicated that the addition of probiotic powder and tea polyphenols reduced the degree of hardness and chewiness after fermentation, which made the printed products more suitable for the elderly and children.

Conclusion

Probiotic powder and tea polyphenols were added to purple potato puree enriched with sweet milk to develop 5D printed food products. The basic formulation containing purple potato powder and sweet milk at a mass ratio of 1:4 provided excellent support performance and flow properties. When 2% probiotic powder and 0.4% tea polyphenols were added to the basic formulation, fermentation lowered the pH of the printed sample, causing the color to change from purple to red, thus achieving the color change effect achieved using 4D printing technology. During the fermentation process of 6–8 h, the probiotic counts increased while the mold counts decreased. Additionally, the texture of samples during fermentation became softer and was more suitable as easy-to-swallowed foods for the elderly and children.

Data Availability

The data are available from the corresponding author upon suitable request.

References

Anas, S., Khan, M. Y., Rafey, M., & Faheem, K. (2021). Concept of 5D printing technology and its applicability in the healthcare industry. Materials Today: Proceedings, 56, 1726–1732.

Chen, J., Zhang, M., & Devahastin, S. (2021a). UV-C irradiation-triggered nutritional change of 4D printed ergosterol-incorporated purple sweet potato pastes: conversion of ergosterol into vitamin D2. LWT - Food Science and Technology, 150, 111944.

Chen, J., Zhang, M., Devahastin, S., & Yu, D. (2021b). Novel alternative use of near-infrared spectroscopy to indirectly forecast 3D printability of purple sweet potato pastes. Journal of Food Engineering, 296, 110464.

Chen, T. C., Wong, C. W., & Hsu, S. H. (2022a). Three-dimensional printing of chitosan cryogel as injectable and shape recoverable scaffolds. Carbohydrate Polymers, 285, 119228.

Chen, Y., Zhang, M., Sun, Y., & Phuhongsung, P. (2022b). Improving 3D/4D printing characteristics of natural food gels by novel additives: a review. Food Hydrocolloids, 123, 107160.

Diaz-Gomez, L., Gonzalez-Prada, I., Millan, R., Da Silva-Candal, A., Bugallo-Casal, A., Campos, F., & Alvarez-Lorenzo, C. (2022). 3D printed carboxymethyl cellulose scaffolds for autologous growth factors delivery in wound healing. Carbohydrate Polymers, 278, 118924.

China Food and Drug Administration. (2016a). Microbiological examination in food - Examination of lactic acid bacteria. National Standard of the People’s Republic of China. GB 4789.35–2016.

China Food and Drug Administration. (2016b). Microbiological examination in food - Enumeration of molds and yeastsd. National Standard of the People’s Republic of China. GB 4789.15–2016.

Ghazal, A. F., Zhang, M., & Liu, Z. (2019). Spontaneous color change of 3D printed healthy food product over time after printing as a novel application for 4D Food Printing. Food and Bioprocess Technology, 12(10), 1627–1645.

Gillaspie, E. A., Matsumoto, J. S., Morris, N. E., Downey, R. J., Shen, K. R., Allen, M. S., & Blackmon, S. H. (2016). From 3-Dimensional printing to 5-Dimensional printing: enhancing thoracic surgical planning and resection of complex tumors. Annals of Thoracic Surgery, 101(5), 1958–1962.

Haleem, A., Javaid, M., & Vaishya, R. (2019). 5D printing and its expected applications in Orthopaedics. Journal of Clinical Orthopaedics & Trauma, 10(4), 809–810.

He, C., Zhang, M., & Devahastin, S. (2020a). Investigation on spontaneous shape change of 4D printed starch-based purees from purple sweet potatoes as induced by microwave dehydration. ACS Applied Materials & Interfaces, 12(34), 37896–37905.

He, C., Zhang, M., & Guo, C. (2020b). 4D printing of mashed potato/purple sweet potato puree with spontaneous color change. Innovative Food Science & Emerging Technologies, 59, 102250.

Huang, M. S., Zhang, M., & Bhandari, B. (2019). Assessing the 3D printing precision and texture properties of brown rice induced by infill levels and printing variables. Food and Bioprocess Technology, 12(7), 1185–1196.

Jiang, X., Feng, K., & Yang, X. (2015). In vitro antifungal activity and mechanism of action of tea polyphenols and tea saponin against Rhizopus stolonifer. Journal of Molecular Microbiology and Biotechnology, 25(4), 269–276.

Jiang, Y., Jia, J., Xiong, D., Xu, X., Yang, Y., Liu, X., & Duan, X. (2020). Effects of short-term fermentation with lactic acid bacteria on egg white: characterization, rheological and foaming activities. Food Hydrocolloids, 101, 105507.

Kumar, P., Roy, S., Hegde, H., Bharti, S., & Kumar, M. (2019). 4D and 5D printing. 3D printing technology in nanomedicine (pp. 143–163). Elsevier.

Liu, Y. W., Zhang, W. J., Wang, K. Y., Bao, Y. L., Mac Regenstein, J., & Zhou, P. (2019). Fabrication of gel-like emulsions with whey protein isolate using microfluidization: rheological properties and 3D printing performance. Food and Bioprocess Technology, 12(12), 1967–1979.

Liu, Z., Bhandari, B., & Zhang, M. (2020). Incorporation of probiotics (Bifidobacterium animalis subsp. Lactis) into 3D printed mashed potatoes: effects of variables on the viability. Food Research International, 128, 108795.

Liu, Z., Zhang, M., Bhandari, B., & Wang, Y. (2017). 3D printing: printing precision and application in food sector. Trends in Food Science & Technology, 69, 83–94.

López de Lacey, A. M., Pérez-Santín, E., López-Caballero, M. E., & Montero, P. (2014a). Biotransformation and resulting biological properties of green tea polyphenols produced by probiotic bacteria. LWT - Food Science and Technology, 58(2), 633–638.

López de Lacey, A. M., Pérez-Santín, E., López-Caballero, M. E., & Montero, P. (2014b). Survival and metabolic activity of probiotic bacteria in green tea. LWT - Food Science and Technology, 55(1), 314–322.

Pallottino, F., Hakola, L., Costa, C., Antonucci, F., Figorilli, S., Seisto, A., & Menesatti, P. (2016). Printing on food or food printing: a review. Food and Bioprocess Technology, 9(5), 725–733.

Pant, A., Lee, A. Y., Karyappa, R., Lee, C. P., An, J., Hashimoto, M., & Zhang, Y. (2021). 3D food printing of fresh vegetables using food hydrocolloids for dysphagic patients. Food Hydrocolloids, 114, 106546.

Rajabi, M., McConnell, M., Cabral, J., & Ali, M. A. (2021). Chitosan hydrogels in 3D printing for biomedical applications. Carbohydrate Polymers, 260, 117768.

Reddy, P. R., & Devi, P. A. (2018). Review on the advancements to additive manufacturing-4D and 5D printing. International Journal of Mechanical and Production Engineering Research and Development, 8(4), 6.

Sharma, R., Diwan, B., Singh, B. P., & Kulshrestha, S. (2022). Probiotic fermentation of polyphenols: potential sources of novel functional foods. Food Production Processing and Nutrition, 4, 21.

Shi, Y., Zhang, M., & Bhandari, B. (2021). Effect of addition of beeswax based oleogel on 3D printing of potato starch-protein system. Food Structure, 27, 100176.

Sungsinchai, S., Niamnuy, C., Wattanapan, P., Charoenchaitrakool, M., & Devahastin, S. (2019). Texture modification technologies and their opportunities for the production of dysphagia foods: a review. Comprehensive Reviews in Food Science and Food Safety, 18(6), 1898–1912.

Sun, J., Zhou, W. B., Huang, D. J., Fuh, J. Y. H., & Hong, G. S. (2015). An overview of 3D printing technologies for food fabrication. Food and Bioprocess Technology, 8(8), 1605–1615.

Tao, Y., Do, Y., Yang, H., Lee, Y.-C., Wang, G., Mondoa, C., & Yao, L. (2019). Morphlour. Proceedings of the 32nd annual ACM symposium on user interface software and technology (pp. 329–340). Association for Computing Machinery.

Teng, X., Zhang, M., & Mujumdar, A. S. (2021). 4D printing: Recent advances and proposals in the food sector. Trends in Food Science & Technology, 110, 349–363.

Theagarajan, R., Moses, J. A., & Anandharamakrishnan, C. (2020). 3D extrusion printability of rice starch and optimization of process variables. Food and Bioprocess Technology, 13(6), 1048–1062.

Trabelsi, I., Ben Slima, S., Ktari, N., Triki, M., Abdehedi, R., Abaza, W., & Ben Salah, R. (2019). Incorporation of probiotic strain in raw minced beef meat: study of textural modification, lipid and protein oxidation and color parameters during refrigerated storage. Meat Science, 154, 29–36.

Wang, M., Li, D., Zang, Z., Sun, X., Tan, H., Si, X., & Liu, R. (2021). 3D food printing: applications of plant-based materials in extrusion-based food printing. Critical Reviews in Food Science and Nutrition, 62, 1911929.

Wang, W., Yao, L., Zhang, T., Cheng, C. -Y., Levine, D., & Ishii, H. (2017). Transformative appetite. Proceedings of the 2017 CHI conference on human factors in computing systems (pp. 6123–6132). Association for Computing Machinery.

Wilson, A., Anukiruthika, T., Moses, J. A., & Anandharamakrishnan, C. (2020). Customized shapes for chicken meat-based products: feasibility study on 3D-printed nuggets. Food and Bioprocess Technology, 13(11), 1968–1983.

Yoha, K. S., Anukiruthika, T., Anila, W., Moses, J. A., & Anandharamakrishnan, C. (2021). 3D printing of encapsulated probiotics: Effect of different post-processing methods on the stability of Lactiplantibacillus plantarum (NCIM 2083) under static in vitro digestion conditions and during storage. LWT - Food Science and Technology, 146, 111461.

Zhao, D., & Shah, N. P. (2014). Effect of tea extract on lactic acid bacterial growth, their cell surface characteristics and isoflavone bioconversion during soymilk fermentation. Food Research International, 62, 877–885.

Funding

The authors acknowledge financial supports from the National Key R&D Program of China (Contract No. 2022YFF1102000), National Natural Science Foundation Program of China (No. 31872902), China State Key Laboratory of Food Science and Technology Innovation Project (Contract No. SKLF-ZZA-201706), Jiangsu Province Key Laboratory Project of Advanced Food Manufacturing Equipment and Technology (No. FMZ202003), all of which had enabled the authors to carry out this study.

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, J., Teng, X., Zhang, M. et al. 5D Food Printing with Color Change Induced by Probiotic Growth in a Starch-Protein-Based Gel System. Food Bioprocess Technol 16, 2304–2314 (2023). https://doi.org/10.1007/s11947-023-03064-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-023-03064-7