Abstract

Beverages are an ideal food format to deliver health-promoting polyphenols (PPs) and dietary fibres (DFs) to consumers. In this study, complex beverage systems, smoothies, were formulated containing high concentrations of apple PPs (500 mg per 300 ml beverage), apple fibres of two different particle sizes (AF01, 250 μm; AF09, 300–700 μm; each containing soluble and insoluble fibres), and stabiliser carboxymethylcellulose (CMC; 0.05–2.00 %). The beverages were pasteurised at 85 °C for 15 s, and subjected to total extracted PP content (TEPC) and rheological measurements (viscosity, elastic modulus G′ and viscous modulus G″ at 4, 20, 37 and 60 °C). Scanning electron microscopy (SEM), FT-IR spectroscopy and N2 physisorption measurements on the AF01 and AF09 fibre powders showed that they differed in particle size, yet were similar in particle surface morphology, chemical composition and specific surface area. Characterisation of smoothies prepared from the AF01 and AF09 fibres showed that the particle size of the apple fibres, testing temperature and CMC concentration strongly influenced the extractability of PPs and rheological behaviour of the smoothies. The peak TEPC values of the AF01 and AF09 beverages, 327 and 351 mg catechin equivalent per 300 ml beverage, occurred at 1.50 % and 1.00 % CMC, respectively. The temperature dependence of smoothie viscosity was examined, and an Arrhenius relationship was observed for both the AF01 and AF09 smoothie systems. The stabilising effect of CMC for this type of smoothie beverage was confirmed. CMC concentrations of 1.00–1.50 % afford high extracted PP content, good phase stability and beverage flow properties. These results presented here can be used to guide the development of stable beverages containing relatively high concentrations of PPs and DFs (including both insoluble and soluble).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Convenience and healthiness are two of the most important food attributes for today’s fast-moving lifestyle. Dietary changes have been considered as the first-line treatment for improving human wellness (Williams et al. 2004; Sabbe et al. 2009; Verbeke et al. 2009; Faresjö et al. 2010; Krystallis et al. 2010). The positive influence of polyphenols (PPs) and dietary fibres (DFs) from dietary sources on good human health and nutrition is now well recognised (Kampa et al. 2004; Schulze et al. 2004; Arts & Hollman 2005; Slavin & Green 2007; Scott et al. 2008; Adams & Chen 2009; Lauren et al. 2009; Vauzour et al. 2010; Turner & Lupton 2011). These discoveries have motivated attempts to increase the consumption of these bioactives through novel formats of functional foods and beverages (Sun-Waterhouse et al. 2010a, b, c, 2011b, c, 2012; Törrönen et al. 2012). Apples contribute to a healthy diet due largely to their high PP and DF contents and associated benefits to prevent digestive problems, chronic diseases, lung cancer, asthma, type 2 diabetes, thrombotic stroke and ischaemic heart disease (Lee et al. 2003; Boyer & Liu 2004; Schulze et al. 2004; McGhie et al. 2005; Okoko et al. 2007; Hansen et al. 2009; Sun-Waterhouse et al. 2008a, b, 2011a; Chai et al. 2011). In recent years, smoothies have been promoted as a health-conscious beverage option for “wellness”. Technically, a smoothie is a blended beverage. Smoothies can serve either as a main meal or as a nutritious between-meal snack depending on the serving size, and hence are gaining increasing market leverage in the beverage sector. In this study, smoothies were selected to carry high amounts of apple PPs and soluble and insoluble DFs.

The inclusion of high concentrations of PPs and DFs (especially insoluble DFs) in foods not only contributes to undesirable sensory issues such as bitterness, astringency and grittiness, but also present technical challenges related to the stability and bioaccessibility of incorporated bioactives during and after production (Jaeger et al. 2009; Sun-Waterhouse et al. 2010). Stability of PPs and DF is a vital requirement for foods carrying bioactive compounds, and this may be influenced by food format, formulation, processing and storage conditions. Adding a small amount of stabiliser to beverage formulations is a typical approach for preventing phase separation and ameliorating product texture. Gum polysaccharide additives such as CMC, carrageenan, guar gum, locust bean gum, pectin, xanthan gum have been used as stabilisers to prevent instability issues in beverages including phase separation and precipitation (Du et al. 2007; Mirhosseini et al. 2010; Bosso et al. 2010). Different types and different concentrations of these stabilisers exert different degrees of stabilizing power (Bosso et al. 2010). These stabilisers may interact with PPs and DF network during beverage processing, thus influencing the stability and properties of these bioactives (Renard et al. 2001; Sun-Waterhouse et al. 2008a, 2011b, c, 2012).

CMC is an important cellulose derivative, containing linear β-(1 → 4)-linked glucopyranose residues of different molecular weights. The properties of CMC depend on the degree of substitution (DS; typically in the range 0.6–0.95 for food applications) and the degree of polymerization (DP; 500–2000) (Belitz et al. 2009). As a typically anionic polysaccharide, CMC is widely used as an emulsifying agent, stabilizer, binding agent, thickener, water retaining agent, because of its solubility in cold water, odorless, colorless and neutral flavor. CMC molecules have a heterogeneous molecular structure consisting of both amphipathic anhydrous glucopyranose (AHG; hydrophilic equatorial sides and a hydrophobic axial plane) and hydrophilic CM units (Ueno et al. 2007). Depending on its concentration, CMC imparts a certain viscosity which is affected by pH and temperature (i.e., viscosity drops during heating) (Cancela et al. 2005). The average chain length and DS are of great importance in this regard; the more-hydrophobic lower substituted CMCs are thixotropic but more-extended higher substituted CMCs are pseudoplastic. At low pH, CMC may form cross-links through lactonisation between carboxylic acid and free hydroxyl groups (Phillips & Williams 2000; Belitz et al. 2009). CMCs behave like polar adhesives forming complexes with other substances such as casein proteins (Phillips & Williams 2000; Cancela et al. 2005).

This paper examines the effects of CMC addition on the chemical and physical (including rheological) properties of smoothie beverages formulated with PPs and apple fibres (AF01 and AF09) of different particle size. Emphasis is placed on the evaluation of important physicochemical characteristics such as phase stability, viscosity and mouthfeel (via visual observations and rheological examinations). The stability and extractability of PPs within smoothie systems are also explored. The main aim of this research is to establish the viability of smoothies as a stable beverage system for the delivery of high concentrations of PPs and soluble and insoluble DFs to consumers.

Materials and Methods

Chemicals and Materials

Apple phenolic extract (APE) was purchased from Penglai Marine Bio-tech Co. (Shandong, China), containing 770 mg oligoproanthocyanidins complex/g dried weight (manufacturer information). Carboxymethylcellulose (GRINDSTED® NR 67 CMC) was purchased from Danisco New Zealand Ltd (Auckland, New Zealand), having a minimum viscosity of 1,500 cps (cold, 1 % solution, 4 h). Citric acid was purchased from Hawkins Watts (Auckland, New Zealand). Herbacel Classic apple fibre (light brown) with typical pleasant apple flavor and high contents of insoluble and soluble DFs (total fibre content 50–70 %, of which approximately 20 % is soluble): AF01 (very finely milled; particle size (90 % max. 250 μm) and AF09 (coarse milled, 200–700 μm) were purchased from Herbstreith & Fox (Neuenbürg, Germany). In this study, the AF09 apple fibre was dry sieved using a 300-μm test sieve, and the fibres with particle size >300 μm were collected and used for further ingredient analysis and smoothie preparation. Hereafter, the AF09 apple fibre refers to fibre with particles ranging from 300 to 700 μm.

Folin–Ciocalteu phenol reagent, catechin, epicatechin, phlorizin, phloretin, quercetin, rutin, and ferulic, p-coumaric, chlorogenic and caffeic acids were purchased from Sigma-Aldrich (St. Louis, MO, USA). Methanol, acetone, n-hexane and formic acid were sourced from Ajax Finechem (Auckland, New Zealand). Sodium carbonate was purchased from Merck (Darmstadt, Germany). The total dietary fibre test kit (including alpha amylase, protease and amyloglucosidase enzymes) was obtained from Megazyme International (Wicklow, Ireland). Celite™ was obtained from Maville Service Corporation (USA). Milli-Q Plus water was used for the preparation of solutions of different reagents. Other chemicals were purchased from Ajax Finechem (Mt Wellington, Auckland, New Zealand).

Analysis of Apple Fibre and Phenolic Extract Ingredients

Microscopic Examination of Two Apple Fibre Ingredients

The morphology, particle size and shape, and particle size distribution of the AF01 and AF09 apple fibre ingredients were examined by scanning electron microscopy (SEM) using a field-emission gun scanning electron microscope (FEGSEM, Philips XL-30, Eindhoven, The Netherlands). All micrographs were collected at an electron gun accelerating voltage of 5 kV. Specimens were mounted on black carbon adhesive tape and platinum sputter-coated for 1 min before analysis.

N2 Physisorption Measurements of Two Apple Fibre Ingredients

N2 physisorption measurements were carried out at liquid nitrogen temperature (−195 °C) using a gas physisorption analyser (Tristar 3000 instrument; Micromeritics, Norcross, GA, USA). Samples were degassed in a Heraeus vacuum chamber (VTR 5022; Heraeus, Cologne, Germany) at 40 °C for 1 h prior to the N2 physisorption measurements. Brunauer–Emmett–Teller (BET) specific surface areas, Langmuir specific surface areas, Barrett–Joyner–Halenda (BJH) adsorption cumulative pore volumes and BJH average pore diameters were determined from N2 physisorption isotherms taken at −195 °C (Condon 2006).

Fourier Transform Infrared (FTIR) Spectroscopy Examination of Two Apple Fibre Ingredients

FT-IR spectra were obtained using a FT-IR spectrometer (Spectrum 100; Perkin Elmer®, Waltham, MA, USA) equipped with a universal ATR attachment. Spectra were collected over the range of 4,000–650 cm−1 at a resolution of 4 cm−1, and 32 accumulated scans were used to produce a spectrum. Prior to data analysis, raw spectra were baseline corrected and the absorbance was normalised using SigmaPlot (version 11.0), so that peak absorbance of the most intense band is set to unity.

Total Dietary Fibre of Two Apple Fibre Ingredients

Total dietary fibre (TDF) content of the two apple fibres was determined using the Megazyme International total DF assay (adopted from AACC method 32–05 and AOAC method 985.29).

Total Extracted Polyphenol (TEPC) Content of Apple Extract Ingredient

The APE ingredient was subjected to the Folin–Ciocalteu assay (Singleton et al. 1997). The TEPC was expressed as catechin equivalents. A microplate reader (SpectraMax Plus 384; Molecular Devices, Sunnyvale, CA, USA) was used to record the absorbance at 760 nm.

High-Performance Liquid Chromatography Polyphenol Profiling of Apple Extract Ingredient

The APE ingredient was added to 25 % methanol to give a concentration of 30 mg/ml. The mixture was vortexed (3 × 30 s) and centrifuged at 187.5 × g for 15 min (Centrifuge 5702; Eppendorf, Hamburg, Germany). The supernatant was collected and then analysed (Stevenson et al. 2006) by a Shimadzu LC10Avp HPLC with a column oven (C40-10ASVP), auto-sampler (SIL-10AF), vacuum solvent degas module and diode-array detector (SPD-M10AVP), fitted with a Synergi® Polar-RP ether-linked phenyl column (column temperature 45 °C, 250 × 4.6 mm, 4 μm particle size, 80 Å ether-linked column; Phenomenex, Auckland, New Zealand). The mobile phases included (A) acetonitrile containing 0.1 % formic acid and (B) water/acetonitrile/formic acid at a ratio of 96:2.5:1.5. The flow rate was 0.5 ml/min. The initial mobile phase, 0 % A, was ramped linearly from 0 to 5 % A (0–5 min then held for 5 min), from 5 % to 15 % A (10–25 min), from 15 % to 19 % A (25–30 min), from 19 % to 25 % A (30–39 min), from 25 % to 45 % A (39–43 min), and finally from 45 % to 95 % A (43–48 min then held for 5 min) before resetting to the original conditions. The UV–vis absorbance wavelength ranged from 200 to 600 nm, and three wavelengths (280, 320 and 370 nm) were selected. Sample injection volume was 10 μl. Individual PPs were identified based on their retention time and absorbance maximum (λmax). External standards used for PP identification included catechin, epicatechin, kaempferol glucoside, myricetin, myricetin glycosides, phloretin, phlorizin, quercetin, quercetin glycosides, rutin, caffeic acid, chlorogenic acid, 2,4-dihydroxybenzoic acid, protocatechuic acid, salicylic acid, syringic acid, ferulic acid, and p-, m- and o-coumaric acids.

Preparation of Smoothies

All smoothies were produced under the same processing conditions, using water as the beverage medium and containing the same concentration of APE (500 mg catechin equivalent/300 ml serve), one apple fibre ingredient (AF01 or AF09) at a concentration of 12.5 g/300 ml serve, citric acid (0.2 wt.%), and CMC stabiliser at different concentrations (0.05–2.00 wt.%). The CMC concentration range selected was based on manufacturer recommendations for practical food applications. These smoothies were homogenised using a Silverson mixer with a high shear screen (8,000 rpm for 4 min; L5T, Silverson Machines Inc., East Longmeadow, MA, USA), pasteurised at 85 °C for 15 s, cooled to 4 °C, and visual observations on phase stability recorded. A portion of each smoothie was directly subjected to rheological measurements (testing temperatures included 4, 20, 37 and 60 °C). The remaining smoothies were stored at −80 °C until chemical analysis of TEPC (at 20 °C).

Analysis of Total Extracted Polyphenol Content of Smoothies

Preparation of Polyphenol Extracts from Smoothies by Accelerated Solvent Extraction

An aliquot (5 g) of smoothie was mixed with Celite™ (diatomaceous earth) at a ratio of 1:1 w/w and transferred into Dionex 33 ml stainless steel extraction cells. A cellulose filter paper (30 mm; Whatman, Maidstone, UK) was placed at the end of the thimble. Extraction was performed under N2 in a pressurised multiple-sample Accelerated Solvent Extractor (ASE 300; Dionex, Sunnyvale, CA, USA) (operating conditions: 40 °C and 1,500 psi, with 5 min heating and 10 min static time). Three extraction cycles were performed using 95 % methanol. The PP extracts obtained were concentrated (to remove methanol) using the Ultra-Low Cold Trap Centrivap concentrator (Model 78100–01; Labconco Corp., Kansas City, MO, USA) followed by freeze-drying. The extracts were kept at −80 °C, and reconstituted with water at a concentration of 10 mg/ml for Folin–Ciocalteu assay.

Total Extracted Polyphenol Content Determination

Solid phase extraction was carried out to prevent the interference of ascorbic acid and proteinaceous substances with the TEPC results. All experimental steps were carried out rapidly under low intensity lighting. A Strata C18-E cartridge (2 g/12 ml Giga tubes, 55 μm, 70A; Strata, Phenomenex) was preconditioned with 5 ml of absolute methanol followed by 5 ml of Milli-Q water. This step was repeated twice. An aliquot (5 ml) of the extracts described in the paragraph above was loaded onto the C-18 cartridge, and allowed to drip slowly through the cartridge and that fraction discarded. Absolute methanol (3 × 5 ml) was then used to elute the PPs that were trapped in the C-18 cartridge, and the eluate from each 5 ml flush was collected and kept at −20 °C for TEPC analysis. The TEPC was measured using the Folin–Ciocalteu assay (Singleton et al. 1997; George et al. 2005) and expressed as catechin equivalents.

Rheological Measurements of Smoothies

Rheological measurements were conducted at selected temperature(s), using a stress-controlled rheometer (Anton Parr Physica MCR301; Anton Parr, Graz, Austria) equipped with a Peltier temperature control device and flat plate geometry (diameter: 49.954 mm). A measurement gap of 1 mm was set. The smoothie samples were loaded carefully onto the measuring plate of the rheometer, and a humidity chamber was used to prevent water loss during measurements. The viscosity of each smoothie was measured as a function of shear rate ranging from 0.001 to 1,000 s−1 (30 measurements, in rotational mode), at 4, 20, 37 and/or 60 °C (the latter is typical for hot drinks for human consumption). The storage modulus (G′) and loss modulus (G″) were measured at frequencies ranging from 0.1 to 100 s−1 at 20 °C (to examine the viscoelastic properties at room temperature). Data were acquired and analysed with a Rheoplus software (V3.4; Anton Paar, Graz, Austria). All tests were performed in triplicate; here, only the mean values are reported (standard deviations <5 %).

Statistical Analysis

All data are expressed as the mean ± standard deviation from three replicates. Analyses were carried out using MINITAB 15 (Minitab Inc., Pennsylvania, USA). Analysis of variance (ANOVA) and Tukey's test were used to detect significant differences at p < 0.05.

Results and Discussion

Analyses of Apple Fibre and Apple Polyphenol Extract Ingredients

AF01 and AF09 Apple Fibres

Visual and SEM examinations revealed differences between the AF01 and AF09 apple fibres in particle size and colour, but similarities in terms of morphology. Optical images (Fig. 1, AF01a and AF09a) show that the AF09 fibre appeared to be slightly darker in colour (yellow-brown) and very coarse, whilst the AF01 fibre had a light creamy yellow colour and much smaller average particle size. SEM (Fig. 1, AF01b and AF09b) revealed the difference in particle size: AF01 <200 μm and AF09 >300 μm. SEM images at higher magnification (×5,000; Fig. 1, AF01 c and AF09 c) revealed similarities between the AF01 and AF09 fibres in terms of their surface characteristics (flat sheets with wrinkled surfaces) and cross-sectional morphologies (layers of sheets with gaps). The apple fibres samples are expected to be primarily composed of apple cell walls, in agreement with the SEM observations (Fig. 1). Since the AF01 fibre had a smaller particle size than the AF09 fibre, it was expected that the AF01 fibre would have the higher specific surface area. Table 1 summarises the N2 physisorption results for the AF01 and AF09 apple fibres. The results show that the AF01 and AF09 fibres had very similar specific surface areas and cumulative pore volumes. The N2 physisorption results suggest that both types of apple fibres have very similar N2 adsorption characteristics which are largely independent of particle size.

FT-IR spectroscopy was used to characterise the AF01 and AF09 fibres to qualitatively elucidate their composition (Fig. 2). The FT-IR spectra of the AF01 and AF09 fibres were near identical, and comprise bands at the spectral region of 1,800–650 cm−1 which are typical for water and plant cell wall polysaccharides, in agreement with previous literature (Kacuráková & Mathlouthi 1996; Kacuráková et al. 2000; Wang & Somasundaran 2007; Wu et al. 2008; Szymańska-Chargot et al. 2011). Intense bands in the mid-infrared region 1,200–800 cm−1 are assigned to the polysaccharides with different structure and composition, and comprise C–O stretching, CH2 twisting, C–O–H bending and C–O–C bond stretching vibrations of the polysaccharide chains (Kacuráková & Mathlouthi 1996; Kacuráková et al. 2000; Wang & Somasundaran 2007). Chemical analysis indicated that the two fibres had similar total DF contents (AF01 70.4 ± 1.8 g/100 dry fibre ingredient and AF09 68.9 ± 1.6 g/100 dry fibre ingredient, respectively). The total DF values agreed with the manufacturer’s specifications. Combination of the data obtained from SEM, N2 physisorption, FT-IR and chemical analysis indicates that the AF01 and AF09 apple fibres were near identical except in terms of particle size.

Apple Polyphenol Extract Composition

For the APE ingredient, chemical analysis show that its TEPC ranged from 768.02 to 802.09 mg catechin equivalent/g (dry weight) ingredient. This result agreed with the manufacturer’s data (770 mg oligoproanthocyanidins complex/g dry weight), although the manufacturer specifications were based on oligoproanthocyanidins rather than PPs in general (as catechin equivalents). Proanthocyanidins refer to a larger class of flavanols which are distinguished by a hydroxyl group instead of a ketone group on the pyran ring of flavonoids (such as quercetin and epicatechin). HPLC profiling of APE (Fig. 3) revealed that the predominant PPs in the APE ingredient were those typically found in apple such as phenolic acids, cinnamic acids or flavonoids and their conjugates (Lee et al. 2003; McGhie et al. 2005; Wegrzyn et al. 2008). Phloretin glycosides (peaks 13 and 15) were present in the highest concentration, followed by chlorogenic acid, epicatechin, myricetin 3-O-glucoside, kaempferol 3-O-glucoside, p-coumaric acid, quercetin 3-O-rhamnoside, procyanidin dimer B2, etc. The HPLC results provide evidence for the presence of different classes of phenolic compounds, which possess different chemical structure and different polarity (as demonstrated by their different eluting order by reverse-phase HPLC (Rice-Evans et al. 1996).

High-performance liquid chromatography polyphenol profile (λ = 280 nm) of the apple phenolic extract ingredient. Peak 1, 3-O-p-coumaroylquinic acid; peak 2, procyanidin dimer B1; peak 3, catechin; peak 4, unknown; peak 5, chlorogenic acid; peak 6, procyanidin dimer B2; peak 7, epicatechin; peak 8, p-coumaric acid; peak 9, procyanidin trimer C1; peak 10, myricetin 3-O-rutinoside; peak 11, ferulic acid; peak 12, myricetin 3-O-glucoside; peak 13, phloretin 2-O-xylo-glycoside; peak 14, quercetin 3-O-glucoside; peak 15, phloretin 2-O-glycoside; peak 16, quercetin 3-O-rhamnoside; peak 17, kaempferol 3-O-glucoside; peak 18, quercetin; peak 19, phloretin

Total Extracted Polyphenol Contents of the Smoothies

The CMC concentration and fibre particle size affected the TEPCs of smoothies (Table 2). The TEPC values were all lower than the initial dose of APE for all smoothie formulations (500 mg catechin equivalent/300 ml serve). The recovery of added APE ranged from 32.3 % to 65.4 % for AF01 smoothies, and from 34.3 % to 70.2 % for AF09 smoothies. Table 2 gives the TEPC values with two different units, i.e., mg catechin equivalent/300 ml beverage and mg catechin equivalent/L beverage.

For the AF01 beverage, the highest TEPC (327 mg catechin equivalent/300 ml beverage) occurred at 1.5 % CMC. The smoothie containing 1.00 % CMC had the second highest TEPC, 292 mg catechin equivalent/300 ml smoothie. When the CMC concentration < 1.50 %, the TEPC increased with increasing CMC concentration, except for the smoothie formulated with 0.05 % CMC which had a higher TEPC than that with 0.10 % CMC. The smoothies formulated with 0.80 or 2.00 % CMC had almost identical TEPCs.

For the AF09 beverage, the smoothie formulated with 1.00 % CMC had the highest TEPC (351 mg catechin equivalent/300 ml smoothie), followed by the smoothie containing 1.50 % CMC (312 mg catechin equivalent/300 ml smoothie), 0.80 % CMC (275 mg catechin equivalent/300 ml smoothie) and then 2.00 % CMC (259 mg catechin equivalent/300 ml smoothie). The smoothies formulated with 0.05 % or 0.50 % CMC had almost the same TEPCs, both of which were higher than the smoothie with 0.10 % CMC. When the CMC concentration ranged from 0.10 % to 1.00 %, the TEPC increased with increasing CMC concentration. The trend was reversed in the CMC concentration range 1.00–2.00 %.

Rheological Measurements on the AF01 and AF09 Smoothies

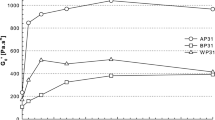

Storage or Loss Modulus as a Function of Frequency

The storage modulus (elastic modulus, G′) or loss modulus (viscous modulus, G″) as function of frequency at 20 °C for the AF01 and AF09 smoothies are reported in Fig. 4. Of particular interest is how the relative positions of G′ and G″ change with CMC concentration. For the AF01 beverage, the smoothie with 1.50 % CMC had the highest G′ but the lowest G″ (when frequency ≥19.9 s−1). The smoothie with 1.00 % CMC had the lowest G′ but the highest G″. G′ > G″ at 0.50 or 1.50 % CMC, but G′ < G″ at 1.00 % or 2.00 % CMC. Interestingly, the gap between the G′ and G″ plots was much smaller for the smoothies formulated with 2.00 and 0.05 % CMC than those formulated with 1.00 and 1.50 wt.% CMC (especially for the smoothie containing 2.00 % CMC, a cross-over point between the G′ and G″ plots occurred at 31.5 s−1). For the AF09 beverage, G′ ≥ G″ was the general trend except for the beverage with 0.05 % CMC. The smoothie containing 2.00 % generally had the highest G′ (except at frequency >12.5 s−1) and lowest G″ (except at frequency <0.996 s−1). The smoothie with 1.00 % CMC had the second highest G′ (except at frequency >3.96 s−1) and second lowest G″ (except at frequency <0.25 s−1). A cross-over point at 1.58 s−1 between the G′ and G″ plots was observed for the smoothie containing 0.05 % CMC. This behaviour was not observed for other AF09 smoothies. For the smoothie with 1.50 % CMC, the separation between the G′ and G″ plots was the smallest at lower frequency, and then the G′ and G″ gradually increased with elevated frequency until being the highest (for G′ > 12.5 s−1 and for G″ > 1.99 s−1).

A G″ > G′ value indicates the viscous properties were dominant compared to the elastic ones, and the smoothies behaved as viscous liquid-like materials. Conversely, when the storage modulus G′ was higher than the loss modulus G″, the elastic properties were dominant, and the formation of an ordered structure such as three-dimensional network was possible in the smoothie systems. The crossover of the G′ and G″ plots, where G′ = G″, indicates a change of rheological behaviour: from a dominant viscous, liquid-like to a dominant elastic solid-like behaviour, or vice versa (Larson 1999; Mezger 2002). In this study, the crossover point resulted from the irreversible disruption of the structure of macromolecules within the complex smoothie system at a specific frequency. The viscoelastic properties of this beverage system depend on the fibre particle size and CMC concentration. Interactions between CMC polymer and apple fibre particles, or between PPs and apple fibres or CMC via van der Waals forces, hydrogen bonding and hydrophobic effects may be possible (Renard et al. 2001; Edali et al. 2001; Sun-Waterhouse et al. 2008a, b).

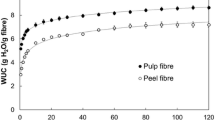

Viscosity as a Function of Shear Rate

The viscosity profiles of AF01-CMC and AF09-CMC smoothies containing minimum (0.05 %) and maximum (2.00 %) CMC, were examined over the shear rate range of 0.001 to 1000 s−1, and at 4 °C, 20 °C, 37 °C and 60 °C (Fig. 5). The viscosity profiles show distinct characteristics: At the lowest CMC concentration (0.05 %), both the AF01 and AF09 smoothies exhibit a steep viscosity decrease at low shear rates, followed by a less pronounced decrease (one can observe the slope changes at shear rates between 0.1 and 1 s−1). At the highest CMC concentration (2.00 %), the rheological behaviour is quite different: a low-shear rate viscosity plateau is observed, followed by a decrease in viscosity at higher shear rates. The AF09-2.00 % CMC smoothie had very similar viscosity profiles at 4 °C, 20 °C and 37 °C, and differed from data taken at 60 °C. The AF09-0.05 % CMC smoothie behaved in the same way at 4 °C, 20 °C, 37 °C and 60 °C. The AF01-2.00 % CMC smoothie showed similar behaviour at 4 °C and 20 °C: A plateau followed by a gradual decrease with increasing shear rate (the starting point of viscosity decrease occurred at a higher shear rate at 20 °C than at 4 °C); At 37 °C and 60 °C, the viscosity curves started from higher initial values (compared to those at 4 °C and 20 °C) with no observable plateau. The smoothie viscosities at 37 °C and 60 °C were very different. The shear-thinning behaviour is possibly due to the breakdown of the aggregates and the disentanglement of the CMC polymer coils induced by shear, causing an increased orientation of the disrupted aggregates and the elongated CMC polymer chains in the direction of flow.

Viscosity profiles of AF01-CMC and AF09-CMC samples at minimum (0.05 %) and maximum (2.00 %) CMC concentrations and different testing temperatures (4 °C, 20 °C, 37 °C and 60 °C). The vertical lines show the crossover points of the 0.05 % and 2.00 % CMC flow curves for AF01 (circle) and AF09 (triangle) smoothies. CMC refers to carboxymethylcellulose. AF01 and AF09 refer to the two types of apple fibre

The AF09 smoothie had a higher viscosity than the AF01 smoothie in the shear rate range of 0.001 to 100 s−1 at all testing temperatures, except for the smoothies containing 2.00 % CMC and tested at 60 °C, i.e., the viscosity of AF01 smoothie was either higher (at shear rate ≤0.1 s−1) or the same as that of the AF09 smoothie (at shear rate >0.1 s−1). The higher viscosity of AF09 sample can be explained by the larger particle size and size distribution of the material compared to the AF01 (finer apple fibre). The larger size of the AF09 fibres results in a stiffer structure composed of aggregates of greater size and possibly stronger intermolecular interactions. Therefore, more energy would be necessary for the breakdown of these aggregates containing AF09 fibre. In this study, shear rates in the range of 30–60 s−1 were used to simulate the effective shear rate range in the mouth (Wood & Goff 1973). In the shear rate range of 30–60 s−1, the smoothie viscosity changed in the order of AF09-2.00 % CMC≈AF01-2.00 % CMC>AF09-0.05 % CMC>AF01-0.05 % CMC. At 2.00 % CMC, the mouthfeel of the AF01 and AF09 smoothies could be the same when tasted at 4 °C, 20 °C and 60 °C, but different when tasted at 37 °C (the viscosity of AF09-2.00 % CMC>AF01-2.00 % CMC).

Viscosity as a Function of CMC Concentration

At either low (0.00418 s−1) or high (1000 s−1) shear rate, the rheological behaviour of the smoothies change when the CMC concentration was increased (Fig. 6). The same trend with CMC polymer concentration is observed for AF01 and AF09 smoothie systems at 1000 s−1. At high shear rate (1,000 s−1), the smoothie viscosity was found to increase with polymer concentration and decrease with temperature (Fig. 6b and d), except for the 2.00 % CMC concentration: η60°C < η37°C < η20°C < η4°C, although the changes seen at CMC concentrations >1.00 % was different between AF01 and AF09 smoothies. At low shear rate (0.00418 s−1, close to quiescent conditions), the AF01and AF09 smoothies had very different viscosity-CMC concentration plots at all four testing temperatures 4 °C, 20 °C, 37 °C and 60 °C (Fig. 6a and c): the viscosity decreases substantially when the CMC polymer concentration is increased up to a critical value, above which the viscosity increases with increasing concentration. This phenomenon is more pronounced (or more clearly observable) for the AF01-based smoothie (much finer one). The CMC concentration at which the viscosity overshoot is observed is likely a critical polymer concentration (c*). It could be the critical overlap concentration c* where change in the polymeric regime occurs (transition from semi-diluted non-entangled solution to semi-diluted entangled solution) (Benchabane & Bekkour 2008). The critical concentration is an important parameter to indicate the turning point of two different states of a polymer solution (Liu et al. 2007; Benchabane & Bekkour 2008). The effect of temperature will be discussed in detail in the next section.

Viscosity as a Function of Testing Temperature

Figure 7 shows the plots of \( \ln\;\left( {{\eta_{{\mathop{\gamma}\limits^{\cdot }}}}} \right) \) against 1000/T for AF01 and AF09 smoothies at low (0.00418 s−1) and high (1000 s−1) shear rates for different CMC concentrations. As discussed in the section above, the high-shear rate viscosity decreases with temperature. The temperature dependence of the apparent viscosity for non-Newtonian fluids can be expressed in terms of an Arrhenius equation:

where \( {\eta_{{\mathop{\gamma}\limits^{\cdot }}}} \) and \( {E_{{\mathop{\gamma}\limits^{\cdot }}}} \) are the apparent viscosity (Pa s) and the flow activation energy (J/mol), respectively, at a given shear rate, R (8.31446 J mol−1 K−1) is the universal gas constant, T (K) is the absolute temperature, and A is a pre-exponential constant. \( {E_{{\mathop{\gamma}\limits^{\cdot }}}} \) and A are determined from experimental data. Higher activation energy \( {E_{{\mathop{\gamma}\limits^{\cdot }}}} \) values indicate more rapid change in viscosity with temperature.

At low shear rate (0.00418 s−1) and low CMC concentrations, the \( \ln\;\left( {{\eta_{{\mathop{\gamma}\limits^{\cdot }}}}} \right) \) was largely independent of 1/T (below the critical concentration c*). It is almost independent for AF01 system (Fig. 7a) and, surprisingly, increases for AF09 system (Fig. 7c). When c > c* (c = 0.50 % is shown by the dashed line in Fig. 7a), the Arrhenius law was found to accurately describe the temperature dependence of viscosity, that is, the plot of the log viscosity against the reciprocal temperature 1/T shows the expected linear relationship (except for AF01-2.00 % CMC which shows an unexpected dramatic increase). At high shear rate (1,000 s−1), the viscosity–temperature behaviour of both AF01 and AF09 smoothie systems was found to obey the Arrhenius equation at all CMC concentrations (Fig. 7b and d).

The activation energy at a given shear rate \( {E_{{\mathop{\gamma}\limits^{\cdot }}}} \), could be obtained from the plots of \( \ln\;{\eta_{{\mathop{\gamma}\limits^{\cdot }}}} \) against 1/T (Fig. 7). Figure 8 depicts the activation energy values obtained by application of the Arrhenius equation with different values of apparent viscosities measured for low and high shear rates: The activation energy can be interpreted as the energy required for an elementary flow process to occur. At CMC concentrations higher than 0.50 % (c ≈ c*), the calculated activation energies were lower when viscosity at high shear rates was used for \( {E_{{\mathop{\gamma}\limits^{\cdot }}}} \) determination. This indicates that less energy is necessary to generate the viscous flow. This can be explained by the fact that the shear-thinning behaviour is due to breakdown of the apple fibre aggregates, as well as the disentanglement, orientation and alignment of the CMC polymer chains in the direction of the flow under the action of shear (which enables the molecules to move easier and interact less, thus less resistance for the flow). When the high shear rate (1,000 s−1) was applied to AF01 or AF09 smoothie system, the activation energy was near constant (or slightly decreasing), possibly due to the fact that the rate of generation of new structures (fibre aggregates and CMC polymer coils) was balanced by disentanglement–disruption processes induced by shear. The energy needed for the material to flow is therefore constant, or more precisely slightly decreases as equilibrium is not fully reached. At low shear rates (0.00418 s−1), the activation energy increases with CMC polymer concentration, and the AF01 and AF09 smoothie systems exhibited different behaviours. At higher concentrations, the alignment, orientation and disentanglement of CMC polymer coils in this kind of beverage system became more complex, thus more energy being required to generate the viscous flow. The resistance to flow was further affected by the particle size of the apple fibres.

The Interplay of Apple Fibre Particles and CMC Stabiliser in Smoothie Systems

The differences in fruit fibre (i.e., particle size) and stabiliser (i.e., CMC concentration) influence the chemical and physical properties of smoothies containing high PP and DF contents. The interplay between apple fibre particles and CMC stabiliser during and after smoothie processing are schematically represented in Fig. 9. When c < c*, the CMC polymer chains were disentangled and therefore acted as film-forming and lubricating agent by coating the individual apple fibre aggregates in the suspension. The elongated CMC polymer chains did not penetrate the interlayer spaces in the apple fibre aggregates, but acted only on their external surfaces by coating them, hence preventing further particles interactions. This resulted in a reduction of friction between the fibre aggregates favoured by the presence of CMC polymer chains, and thus a decrease in viscosity (Fig. 9a). By increasing the CMC concentration above the critical overlap concentration (c > c*), the CMC polymer chains entangle and retain part of the suspending media (water). The CMC polymer–CMC polymer, CMC polymer–water, and CMC polymer–fibres interactions increase and lead to the formation of a stiffer inner structure, which results in an increase in viscosity (Fig. 9b). The difference between the AF01 and AF09 apple fibres in terms of their behaviour, i.e., decrease of viscosity up to a higher value of CMC concentration (between 0.80 and 1.50 %) could be explained by the fact that the AF09 fibre aggregates are of greater size, as long as the external surfaces are not fully coated by the CMC polymer chains, the suspension viscosity continues to decrease.

CMC has a heterogeneous molecular structure consisting of both amphipathic anhydrous glucopyranose (hydrophilic equatorial sides and a hydrophobic axial plane) and hydrophilic CM units. In acidic media like smoothies, the free carboxylic and hydroxyl groups of CMC might act as crosslinking agents, because of the strong hydrogen interactions or intermolecular lactonisation. Interactions can be envisaged between stabiliser molecules, between stabiliser molecules and apple fibre network, between stabiliser molecules and PPs, between water and soluble or insoluble polymers, and between fibre network and PPs. Hydrophilic PP monomers/dimers likely occur in the liquid phase of smoothies as they are more water-soluble, whilst some PP molecules like proanthocyanidins may bind to CMC polymer, apple fibre network or fibre–CMC complexes via hydrogen bonding, van der Waals forces and hydrophobic effects (Hartley et al. 1990; Haslam, 1998; Reed 2001; Renard et al. 2001).

The amount of stabiliser polymer contributes to the phase stability of smoothie products especially at low shear rates. The outcome of these interplays depends on the availability of the “loop” conformation within CMC, as well as the potential steric hindrance and thermodynamic incompatibility between fibre and CMC macromolecules (especially when the CMC concentration was relatively high) (Fujimoto & Petri 2001). The degrees of crossover, chain expansion, conformation alternation and/or polarity change of the CMC polymers and fibre polysaccharides influence the resistance to flow of such smoothie systems. This ultimately affects the diffusion for small molecules such as PPs which leads to the changes in the mobility and extractability of these small molecules (Armstrong et al. 1987; Hoogendam et al. 1998; Alvarez-Lorenzo et al. 1999, 2001).

PPs are sensitive to environmental conditions such as pH, water activity, light exposure, oxygen and temperature (Bakowska et al. 2003; Buchner et al. 2006; Wang et al. 2009; Devic et al. 2010; Bakowska-Barczak & Kolodziejczyk 2010). The stability of PPs during smoothie processing depended not only on their chemical structure, but also the potential protection from the apple fibre network and CMC polymer (Rice-Evans et al. 1996; Renard et al. 2001; Edali et al. 2001; Luthria 2006). Under the same smoothie production conditions, the stability and extractability of PPs derived from APE is likely to be affected by other smoothie matrix components, i.e., the apple fibre particle size was the dominant variable in this study. The response to the difference in fibre particle size could have been further influenced by the variation in individual PP chemical structure in terms of ketone structure, benzoic structure, and hydroxyl groups (which can cause conjugation to sugars, acids or alkyl groups) (Rice-Evans et al. 1996; Duttaroy & Jørgensen 2004). PPs, in general, are weak organic acids (pK a = 8–12) that range from hydrophilic to hydrophobic (Antolovich et al. 2000; Tura & Robards 2002; Luthria 2006). Differences in the pKa values of PPs would affect the viscosity of CMC (Phillips & Williams 2000; Cancela et al. 2005; Belitz et al. 2009). The polarity of PPs and the viscosity of smoothie, in turn, both influence the transfer of electrons/protons (e.g., a slower transfer rate due to high viscosity and steric hindrance), which possibly occurred during the degradation of PPs and the release of PPs from the smoothie matrix (Perez-Jimenez & Saura-Calixto 2006). Due to differences in chemical structure, molecule size and polarity of PPs in APE, selective effects between some particular PPs and CMC/fibre network/fibre–CMC complexes would be expected. These effects contribute to the extractability and bioaccessibility of various PPs, and ultimately influence their digestability and bioavailability.

Conclusions

Smoothie beverages containing high concentrations of apple soluble and insoluble fibres and PPs can be successfully formulated for functional food markets. The particle size of the apple fibre, testing temperature (simulated beverage consumption temperature) and CMC concentration all influenced the viscoelastic properties, phase stability and PP extractability (indicative of bioaccessibility) of such smoothies. CMC can stabilise smoothies at moderate concentrations such as 1.00–1.50 % to achieve relatively high PP extractability and good stability and flow. Interactions among stabiliser molecules, between fibre network and stabiliser molecules, and between water and soluble or insoluble polymers, influence smoothie rheology, and stability and extractability of PPs in smoothie matrix. Smoothie viscosity increased with increasing apple fibre particle size. Larger apple fibres caused a stiffer structure with larger aggregates and stronger intermolecular interactions (thus requiring more energy to break down these aggregates). This study demonstrates the feasibility of using rheological measurements to predict the stability of complex beverages containing high concentrations of PPs, soluble and insoluble fibres, and guides the formulation of a stable smoothie product.

References

Adams, L. S., & Chen, S. (2009). Phytochemicals for breast cancer prevention by targeting aromatase. Frontiers in Bioscience, 14, 3846–3863.

Alvarez-Lorenzo, C., Gomez-Amoza, J. L., Martínez-Pacheco, R., Souto, C., & Concheiro, A. (1999). Microviscosity of hydroxypropylcellulose gels as a basis for prediction of drug diffusion rates. International Journal of Pharmaceutics, 180(1), 91–105.

Alvarez-Lorenzo, C., Duro, R., Gómez-Amoza, J. L., Martínez-Pacheco, R., Souto, C., & Concheiro, A. (2001). Influence of polymer structure on the rheological behaviour of hydroxypropyl-methylcellulose–sodium carboxymethyl-cellulose dispersions. Colloid & Polymer Science, 279, 1045–1057.

Antolovich, M., Prenzler, P., Robards, K., & Ryan, D. (2000). Sample preparation in the determination of phenolic compounds in fruits. Analyst, 125, 989–1009.

Armstrong, N. A., Gebre-Mariam, T., James, K. C., & Kearney, P. (1987). The influence of viscosity on the migration of chloramphenicol and 4-hydroxybenzoic acid through glycerogelatin gels. Journal of Pharmacy and Pharmacology, 39, 583–586.

Arts, I. C. W., & Hollman, P. C. H. (2005). Polyphenols and disease risk in epidemiologic studies. American Journal of Clinical Nutrition, 81(1), 317S–325S.

Bakowska, A. M., Kucharska, A. Z., & Oszmianski, J. (2003). The effects of heating, UV irradiation and storage on stability of anthocyanin–polyphenol copigment complex. Food Chemistry, 81, 349–355.

Bakowska-Barczak, A. M. & Kolodziejczyk, P. P. (2010). Black currant polyphenols: their storage stability and microencapsulation. Industrial Crops and Products. doi:10.1016/j.indcrop.2010.10.002

Belitz, H.-D., Grosch, W., & Schieberle, P. (2009). Carbohydrates (Chapter 4). In: Food chemistry (4th ed., pp. 329–330). Berlin, Germany: Springer.

Benchabane, A., & Bekkour, K. (2008). Rheological properties of carboxymethyl cellulose (CMC) solutions. Colloid & Polymer Science, 286, 1173–1180.

Bosso, A., Salmaso, D., De Faveri, E., Guaita, M., & Franceschi, D. (2010). The use of carboxymethylcellulose for the tartaric stabilization of white wines, in comparison with other oenological additives. Vitis, 49(2), 95–99.

Boyer, J., & Liu, R. H. (2004). Apple phytochemicals and their health benefits. Nutrition Journal, 3(5), 1–15.

Buchner, N., Krumbein, A., Rohn, S., & Kroh, L. W. (2006). Effect of thermal processing on the flavonols rutin and quercetin. Rapid Communications in Mass Spectrometry, 20, 3229–3235.

Cancela, M. A., Álvarez, E., & Maceiras, R. (2005). Effects of temperature and concentration on carboxymethylcellulose with sucrose rheology. Journal of Food Engineering, 71, 419–424.

Chai, S. C., Hooshmand, S., Saadat, R. L., & Arjmandi, B. H. (2011). Daily apple consumption promotes cardiovascular health in postmenopausal women. Journal of the Federation of American Societies for Experimental Biology, 25, 971.10.

Condon, J. B. (2006). Surface area and porosity determinations by physisorption: measurements and theory (1st ed.). Boston: Elsevier.

Devic, E., Guyot, S., Daudin, J.-D., & Bonazzi, C. (2010). Kinetics of polyphenol losses during soaking and drying of cider apples. Food and Bioprocess Technology, 3, 867–877.

Du, B., Li, J., Zhang, H., Chen, P., Huang, L., & Zhou, J. (2007). The stabilization mechanism of acidified milk drinks induced by carboxymethylcellulose. Le Lait, 87, 287–300.

Duttaroy, A. K., & Jørgensen, A. (2004). Effects of kiwi fruit consumption on platelet aggregation and plasma lipids in healthy human volunteers. Platelets, 15, 287–292.

Edali, M., Esmail, M. N., & Vatistas, G. H. (2001). Rheological properties of high concentrations of carboxymethyl cellulose solutions. Journal of Applied Polymer Science, 79, 1787–1801.

Faresjö, A., Johansson, S., Faresjö, T., Roos, S., & Hallert, C. (2010). Sex differences in dietary coping with gastrointestinal symptoms. European Journal of Gastroenterology and Hepatology, 22(3), 327–333.

Fujimoto, J., & Petri, D. F. S. (2001). Adsorption behavior of carboxymethylcellulose on aminoterminated surfaces. Langmuir, 17, 56–60.

George, S., Brat, P., Alter, P., & Amiot, M. J. (2005). Rapid determination of polyphenols and vitamin C in plant-derived products. Journal of Agricultural and Food Chemistry, 53, 1370–1373.

Hansen, L., Vehof, H., Dragsted, L. O., Olsen, A., Christensen, J., Overvad, K. & Tjønneland, A. (2009). Fruit and vegetable intake and serum cholesterol levels: a cross-sectional study in the diet, cancer and health cohort. Journal of Horticultural Science & Biotechnology, ISAFRUIT Special Issue, 42–46

Hartley, R. D., Morrison, W. H., Himmelsbach, D. S., & Borneman, N. S. (1990). Cross-linking of cell wall phenolics to arabinoxylans in graminaceous plants. Phytochemistry, 29, 3701–3709.

Haslam, E. (1998). Practical polyphenolics – from structure to molecular recognition and physiological action, p. 422. Cambridge, UK: Cambridge University Press.

Hoogendam, C. W., Peters, J. C. W., Tuinier, R., de Keizer, A., Cohen Stuart, M. A., & Bijsterbosch, B. H. (1998). Effective viscosity of polymer solutions: relation to the determination of the depletion thickness and thickness of the adsorbed layer of cellulose derivatives. Journal of Colloid and Interface Science, 207(2), 309–316.

Jaeger, S. R., Axten, L. G., Wohlers, M. W., & Sun-Waterhouse, D. (2009). Polyphenol-rich beverages: insights from sensory and consumer science. Journal of the Science of Food and Agriculture, 89(14), 2356–2363.

Kacuráková, M., & Mathlouthi, M. (1996). FTIR and laser-Raman spectra of oligosaccharides in water: characterization of the glycosidic bond. Carbohydrate Research, 284, 145–157.

Kacuráková, M., Capek, P., Sasinková, V., Wellner, N., & Ebringerová, A. (2000). FT-IR study of plant cell wall model compounds: pectic polysaccharides and hemicelluloses. Carbohydrate Polymers, 43, 195–203.

Kampa, M., Alexaki, V. I., Notas, G., Nifl, A. P., Nistikaki, A., Hatzoglu, A., et al. (2004). Antiproliferative and apoptotic effects of selective phenolic acids on T47D human breast cancer cells: potential mechanisms of action. Breast Cancer Research, 6, 63–74.

Krystallis, A., Linardakis, M., & Mamalis, S. (2010). Usefulness of the discrete choice methodology for marketing decision-making in new product development: an example from the European functional foods market. Agribusiness, 26(1), 100–121.

Larson, R. G. (1999). The structure and rheology of complex fluids. New York: Oxford University Press.

Lauren, D. R., Smith, W. A., Adaim, A., Cooney, J. M., Wibisono, R., Jensen, D. J., et al. (2009). Chemical composition and in vitro anti-inflammatory activity of apple phenolic extracts and of their sub-fractions. International Journal of Food Sciences and Nutrition, 60(S7), 188–205.

Lee, K., Kim, Y., Kim, D., Lee, H., & Lee, C. (2003). Major phenolics in apple and their contribution to the total antioxidant capacity. Journal of Agricultural and Food Chemistry, 51, 6516–6520.

Liu, W.-H., Yu, T. L., & Lin, H.-L. (2007). Shear thickening behavior of dilute poly(diallyl dimethyl ammonium chloride) aqueous solutions. Polymer, 48, 4152–4165.

Luthria, D. L. (2006). Significance of sample preparation in developing analytical methodologies for accurate estimation of bioactive compounds in functional foods. Journal of the Science of Food and Agriculture, 86, 2266–2272.

McGhie, T. K., Hunt, M., & Barnett, L. E. (2005). Cultivar and growing region determine the antioxidant polyphenolic concentration and composition of apples grown in New Zealand. Journal of Agricultural and Food Chemistry, 53, 3065–3070.

Mezger, T. G. (2002). The rheology handbook: for users of rotational and oscillatory rheometers. Hannover, Germany: Vincentz.

Mirhosseini, H., Tan, C. P., & Naghshineh, M. (2010). Influence of pectin and CMC content on physicochemical properties of orange beverage emulsion. Journal of Food, Agriculture & Environment, 8(2), 134–139.

Okoko, B. J., Burney, P. G., Newson, R. B., Potts, J. F., & Shaheen, S. O. (2007). Childhood asthma and fruit consumption. European Respiratory Journal, 29, 1161–1168.

Perez-Jimenez, J., & Saura-Calixto, F. (2006). Effect of solvent and certain food constituents on different antioxidant capacity assays. Food Research International, 39, 791–800.

Phillips, G. O., & Williams, P. A. (2000). Celllulosics. In: Handbook of hydrocolloids (pp. 219–229). Abington, England: Woodhead Publishing.

Reed, J. D. (2001). Effects of proanthocyanidins on digestion of fiber in forages. Journal of Range Management, 54, 466–473.

Renard, C. M. G. C., Baron, A., Guyot, S., & Drilleau, J.-F. (2001). Interactions between apple cell walls and native apple polyphenols: quantification and some consequences. International Journal of Biological Macromolecules, 29(2), 115–125.

Rice-Evans, C. A., Miller, N. J., & Paganga, G. (1996). Structure–antioxidant activity relationships of flavonoids and phenolic acids. Free Radical Biology & Medicine, 20, 933–956.

Sabbe, S., Verbeke, W., & Damme, P. V. (2009). Analysing the market environment for acai (Euterpe oleracea Mart.) juices in Europe. Fruits, 64(5), 273–284.

Schulze, M. B., Liu, S., Rimm, E. B., Manson, J. A. E., Willett, W. C., & Hu, F. B. (2004). Glycemic index, glycemic load, and dietary fiber intake and incidence of type 2 diabetes in younger and middle-aged women. American Journal of Clinical Nutrition, 80, 348–356.

Scott, K. P., Duncan, S. H., & Flint, H. J. (2008). Dietary fibre and the gut microbiota. Nutrition Bulletin, 33, 201–211.

Singleton, V. L., Orthofer, R., & Lamuela-Raventos, R. M. (1997). Analysis of total phenols and other oxidation substrates and antioxidants by means of the Folin Ciocalteu reagent. Methods in Enzymology, 229A, 152–178.

Slavin, J., & Green, H. (2007). Dietary fibre and satiety. Nutrition Bulletin, 32, S32–S42.

Stevenson, D., Wibisono, R., Jensen, D., Stanley, R., & Cooney, J. (2006). Direct acylation of flavonoid glycosides with phenolic acids catalysed by Candida antarctica lipase B (Novozym 435®). Enzyme and Microbial Technology, 39, 1236–1241.

Sun-Waterhouse, D., Melton, L. D., O’Connor, C. J., Kilmartin, P. A., & Smith, B. G. (2008). Effect of apple cell walls and their extracts on the activity of dietary antioxidants. Journal of Agricultural and Food Chemistry, 56(1), 289–295.

Sun-Waterhouse, D., Farr, J., Wibisono, R., & Saleh, Z. (2008). Fruit-based functional foods: I. Production of novel food grade apple fibre ingredients. International Journal of Food Science and Technology, 43, 2113–2122.

Sun-Waterhouse, D., Nair, S., Wibisono, R., Wadhwa, S. S., Massarotto, C., Hedderley, D. I., et al. (2010). Insights into smoothies with high levels of fibre and polyphenols: factors influencing chemical, rheological and sensory properties. World Academy of Science, Engineering and Technology, 65, 276–285.

Sun-Waterhouse, D., Teoh, A., Massarotto, C., Wibisono, R., & Wadhwa, S. (2010). Comparative analysis of fruit-based functional snack bars. Food Chemistry, 119, 1369–1379.

Sun-Waterhouse, D., Zhou, J. & Wadhwa, S. S. (2010c). Effects of adding apple polyphenols before and after fermentation on the properties of drinking yoghurt. Food and Bioprocess Technology, doi:10.1007/s11947-011-0563-1

Sun-Waterhouse, D., Luberriaga, C., Jin, D., Wibisono, R., Wadhwa, S. S. & Waterhouse, G. I. N. (2011a). Juices, fibres and skin waste extracts from white, pink or red fleshed apple genotypes as potential food ingredients: a comparative study. Food and Bioprocess Technology, doi:10.1007/s11947-011-0692-6

Sun-Waterhouse, D., Sivam, A. S., Cooney, J., Zhou, J., Perera, C. O., & Waterhouse, G. I. N. (2011). Effects of added fruit polyphenols and pectin on the properties of finished breads revealed by HPLC/LC-MS and size-exclusion HPLC. Food Research International, 44(9), 3047–3056. doi:10.1016/j.foodres.2011.07.022.

Sun-Waterhouse, D., Wang, S.-Y., Wadhwa, S. & Zhou, J. (2011c). Comparative studies on the rheological and chemical properties of food gels incorporating freshly pressed fruit juice. Journal of Advances in Food, Hospitality and Tourism, 1(4), May on-line.

Sun-Waterhouse, D., Wadhwa, S. S. & Waterhouse, G. I. N. (2012). Spray-drying microencapsulation of polyphenol bioactives: a comparative study using different natural fibre polymers as encapsulants. Food and Bioprocess Technology, doi:10.1007/s11947-012-0946-y

Szymańska-Chargot, M., Cybulska, J., & Zdunek, A. (2011). Sensing the structural differences in cellulose from apple and bacterial cell wall materials by Raman and FT-IR spectroscopy. Sensors, 11, 5543–5560.

Törrönen, R., McDougall, G. J., Dobson, G., Stewart, D., Hellström, J., Mattila, P., Pihlava, J.-M., Koskela, A. & Karjalainen, R. (2012). Fortification of blackcurrant juice with crowberry: impact on polyphenol composition, urinary phenolic metabolites, and postprandial glycemic response in healthy subjects. Journal of Functional Foods, doi:10.1016/j.jff.2012.05.001

Tura, D., & Robards, K. (2002). Sample handling strategies for the determination of biophenols in food and plants. Journal of Chromatography. A, 975, 71–93.

Turner, N. D., & Lupton, J. R. (2011). Dietary fiber. Advances in Nutrition, 2, 151–152.

Ueno, T., Yokota, S., Kitaoka, T., & Wariishi, H. (2007). Conformational changes in single carboxymethylcellulose chains on a highly oriented pyrolytic graphite surface under different salt conditions. Carbohydrate Research, 342, 954–960.

Vauzour, D., Rodriguez-Mateos, A., Corona, G., Oruna-Concha, M. J., & Spencer, J. P. E. (2010). Polyphenols and human health: prevention of disease and mechanisms of action. Nutrients, 2, 1106–1131.

Verbeke, W., Scholderer, J., & Lähteenmäki, L. (2009). Consumer appeal of nutrition and health claims in three existing product concepts. Appetite, 52(3), 684–692.

Wang, J., & Somasundaran, P. (2007). Study of galactomannose interaction with solids using AFM, IR and allied techniques. Journal of Colloid and Interface Science, 309, 373–383.

Wang, X., Wang, Y.-W. & Huang, Q. (2009). Enhancing stability and oral bioavailability of polyphenols using nanoemulsions. In: Micro/nanoencapsulation of active food ingredients (Q. Huang, P. Given & M. Qian, Eds.). ACS symposium series, Chapter 13, Vol. 1007, pp. 198–212. Washington, DC, US: American Chemical Society.

Wegrzyn, T. F., Farr, J. M., Hunter, D. C., Au, J., Wohlers, M. W., Skinner, M. A., et al. (2008). Stability of antioxidants in an apple polyphenol-milk model food system. Food Chemistry, 109, 310–318.

Williams, E., Stewart-Knox, B., & Rowland, I. (2004). A qualitative analysis of consumer perceptions of mood, food and mood-enhancing functional foods. Journal of Nutraceuticals, Functional & Medical Foods, 4(3/4), 61–83.

Wood, F. W., & Goff, T. C. (1973). The determination of the effective shear rate in the Brabender Viscograph and in other systems of complex geometry. Starch, 25(3), 89–91.

Wu, T.-H., Yen, F.-H., Lin, L.-T., Tsai, T.-R., Lin, C.-C., & Cham, T.-M. (2008). Preparation, physicochemical characterization, and antioxidant effects of quercetin nanoparticles. International Journal of Pharmaceutics, 346, 160–168.

Acknowledgments

We acknowledge the 2010–2011 Bilateral Research Activities Fund by Royal Society New Zealand for the collaborative project. The authors thank A/Prof. Yacine Hemar (The University of Auckland) for his assisting this New Zealand–France link.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun-Waterhouse, D., Bekkour, K., Wadhwa, S.S. et al. Rheological and Chemical Characterization of Smoothie Beverages Containing High Concentrations of Fibre and Polyphenols from Apple. Food Bioprocess Technol 7, 409–423 (2014). https://doi.org/10.1007/s11947-013-1091-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-013-1091-y