Abstract

Despite the rise of globalization, industrial clusters remain vibrant spaces for the generation of knowledge and innovation. Aware of this reality, multinational enterprises (MNEs) seek to reconcile the advantages of international operations with the specific endowments of individual territories. By studying the case of the Inditex subsidiary in the Vinalopó footwear cluster, this research shows how the creation and activity of a specialized subsidiary and the evolution of the industrial system interweave. The study shows that, rather than agglomeration per se, access to specific resources guides location as the cluster matures. Furthermore, local embeddedness shapes post-entry dynamics at the micro and meso levels. Autonomous decisions boost the subsidiary’s access to local networks and the exploitation of cluster advantages, aiding the resilience of the cluster by contributing extra-cluster knowledge.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The globalization and digitalization processes that characterize the new economy have caused far-reaching transformations in production and consumption as well as in the knowledge sphere. Goods are produced and acquired in different places, while knowledge has gained in terms of codification and transferability. Even though such changes would seem to herald a “flat” world where geographical proximity lacks relevance, the interaction of coalescent forces in specific territories continues to trigger the appearance of concentrated clusters of economic and innovative activity (Rodríguez-Pose and Crescenzi 2008).

Coopetition (i.e. collaboration between competitors) has received growing attention from practitioners and scholars, who have explored a wide range of subjects in this field (see Kraus et al. 2017; Gast et al. 2015; Ritala et al. 2016). Industrial clusters are understood as geographical groups of interrelated firms and institutions that operate in a specific sector (Porter 1998). These clusters illustrate the existence of areas that are endowed with a particular dynamism within which firms cooperate and compete. Thanks to proximity, firms belonging to the same cluster benefit from a wide range of externalities and specific knowledge that enhance their competitiveness and innovativeness. The importance of these externalities over time depends on the stage of the life cycle (Potter and Watts 2011), the heterogeneity of the cluster (Ter Wal and Boschma 2011), and frontiers’ permeability to external knowledge.

Although geographical proximity promotes interaction and the transfer of valuable information (Audretsch and Feldman 1996), certain knowledge flows transcend cluster boundaries. Through non-local relationships, cluster organizations access ubiquitous global knowledge that complements the territory’s specific knowledge (Bathelt et al. 2004; Maskell et al. 2006). Over time, the cluster’s competitive capacity is reinforced by annexing extra-cluster nodes to a local knowledge network with an increasing supra-regional orientation (Lorenzen and Mudambi 2013).

Acting as bridges between the local and the global domains, multinational enterprises (MNEs) are key contributors to clusters’ innovative nature and dynamism (Enright 2000; Hervás-Oliver and Albors-Garrigós 2008). In a symbiotic relationship with the territory, MNEs’ subsidiaries in clusters not only absorb specific knowledge through interactions with local organizations, but also transfer knowledge generated anywhere within the MNE framework to the host territory (Foss and Pedersen 2002; Agrawal and Cockburn 2003; Mudambi and Navarra 2004). The capacity to integrate knowledge and manage the geographical dispersion of business activities, helps MNEs solidify their advantages and influence the cluster’s innovative nature and future (Mudambi and Swift 2012).

Because MNEs are dominant actors locally and globally, the explanations and implications of their locational patterns warrant further study (Beugelsdijk et al. 2010; McCann and Acs 2011; Beugelsdijk and Mudambi 2013), particularly in the context of clusters (Mudambi and Swift 2012; De Marchi et al. 2017). Very few studies have considered the consequences of choosing a particular host territory in terms of the future of the subsidiary and the local environment (Uhlenbruck 2004). The scarce research conducted on this issue has depicted both local environment and subsidiaries autonomously (Asmussen et al. 2009), treated the geographical levels of analysis fuzzily (McCann and Mudambi 2004), or omitted evolutionary aspects (Østergaard and Park 2015). This study sheds light on two issues: (1) the specific mechanisms that allow newly established subsidiaries to quasi-instantaneously reap the locational benefits of the host cluster; and (2) the way synergies provided by the new subsidiary promptly prevent inertia and decline in advanced stages of the agglomeration life cycle.

In response to calls to bring subnational levels into models and analysis (Arregle et al. 2009), this study blends insights from two theoretical bodies. The first is the cluster literature, which incorporates MNEs and their subsidiaries into models used to examine location behavior (McCann and Mudambi 2004, 2005; Piscitello 2013), the innovation interplay between subsidiary, cluster, and parent company (Enright 2000; Bunnell and Coe 2001; Andersen and Christensen 2005) and the MNE’s role in the way the cluster evolves (Mudambi and Swift 2012; Østergaard and Park 2015). The second body of theory is the international business literature, which highlights the network-based structure of MNEs that allows the integration of resources and different knowledge flows (Mudambi 2002; Cantwell 2009; Meyer et al. 2011).

Inditex is the world’s largest fashion retailing group, with eight brands (the flagship brand being Zara) and 7385 stores in 94 markets around the world. Our analysis of the Inditex subsidiary Tempe, located in the Vinalopó cluster, makes a valuable contribution to this research stream. First, by studying how sources of capability and local factors shape the location and development of a subsidiary, we add to the state of the art on the influence exerted on subsidiaries by territorial endowments and the MNE’s internal resources (Cantwell 2009; Marin and Bell 2010; Figueiredo 2011). Second, we shed light on the role of MNEs and subsidiaries in the way traditional clusters evolve in developed countries. Third, we mediate between those who consider Inditex an exception to globalization for keeping manufacturing at home (e.g. Berger 2005), and those who refute this view (e.g. Tokatli 2014). Fourth, methodologically, we endorse the relevance of the case study method (Yin 2009). This single-firm case study shows how a reflective review of a unique event can yield revelatory and transferable findings.

The next section describes the theoretical foundations regarding clusters and MNEs. The following section describes the method and presents the main evidence of the study. The article closes with a summary of conclusions and the implications for managers and public policymakers.

2 Literature

2.1 Evolutionary trends, knowledge linkages, and diversity in clusters

Clusters display different trends in terms of growth or innovative activity. Overcoming static visions of clusters as pre-established, successful structures, certain compelling theoretical frameworks suggest that clusters have a life cycle (Crespo 2011) consisting of birth, growth, maturity, and decline or reinvention (Bergman 2008). Bearing in mind the traditional parallelism between the industry and cluster life cycles, the transition from one phase to another largely depends on the technological profile of the constituent industries (Li et al. 2012).

However, cluster life cycle is not just the representation of the industry at the local level (Østergaard and Park 2015). Micro-level routines, search processes, memory, and history are also factors that shape changes in clusters (Maskell and Malmberg 2007). To explain long-term survival (Menzel and Fornahl 2010), evolutionary research has recently emphasized the cumulative and path-dependent nature of cluster dynamics (Belussi and Sedita 2009; Sonderegger and Täube 2010; Elola et al. 2012), the role of the institutional context (Maskell and Malmberg 2007), the way the industry, local firms’ capabilities, and the industry’s knowledge network co-evolve with the cluster (Ter Wal and Boschma 2011), and the relevance of knowledge diversity and heterogeneity within cluster boundaries.

Although scholars embrace this novel approach because it provides opportunities for detecting drivers and building testable hypotheses of cluster evolution (Boschma and Fornahl 2011), it has been criticized because of a certain historical determinism and the over-accentuation of continuity versus structural shocks (Li et al. 2012). Based on the same evolutionary premises, Martin and Sunley (2011) proposed an alternative “adaptive cycle” model that recognizes how endogenous constraints and opportunities and external pressures and challenges move each industrial system through the different phases of the model. Despite these limitations, the four-stage life cycle of cluster evolution is now widely accepted and applied (Jia et al. 2015).

Life cycle research shows that maturation in clusters implies an increasingly intensified competition characterized by the achievement of optimal scales, focus on efficiency and cost, routinization of operations, standardization of technologies, and overpopulation (Iammarino and McCann 2006; Wang et al. 2014). To the extent that knowledge also becomes increasingly codified (Cowan et al. 2004), cluster firms may disperse activities geographically or leave the cluster as detrimental effects overcome the benefits of agglomeration (Audretsch and Feldman 1996; Swann and Prevezer 1996; Klepper 2006).

Over time, the traditional elements of a cluster’s strength may turn into drivers of inertia and inflexibility (Grabher 1993). Spatial proximity promotes interaction and transfer of knowledge, trust, opportunities for monitoring, and a suitable framework within which to innovate (Malmberg and Maskell 2006). However, the coalescence of mimetic and myopic behaviors leading to isomorphism (Maskell and Malmberg 2007) and the subsequent depletion of the local knowledge sources may reduce innovativeness and diversity (Stuart and Podolny 1996).

Heterogeneity, particularly in terms of knowledge, is responsible for perpetuating or renewing the cluster (Bergman 2008; Menzel and Fornahl 2010). When clusters enter a period of exhaustion because of a drastic reduction of diversity, access to distant repositories of knowledge provides local firms with new knowledge (Bathelt et al. 2004) that offsets the increasing homogeneity. Local leaders and supporting organizations may act as technological gatekeepers, channeling absorbable external knowledge into the cluster (Morrison 2008; Giuliani 2011). The benefits that these extra-cluster relationships bring depend on the existence of adequate mechanisms for disseminating knowledge at the cluster level (Morrison et al. 2013).

Actors from outside the cluster can encourage diversity by driving the inflow of external knowledge (Valdaliso et al. 2011). This is the case of MNE subsidiaries, which convey knowledge in a two-way street through their intra-firm networks (Cooke 2005). When effectively embedded in the territory, these MNEs complement the pre-existing stock of resources through the dissemination of valuable information acquired through local–global or inter-cluster knowledge transfers (Hervás-Oliver and Albors-Garrigós 2008; Lorenzen and Mudambi 2013). Although subsidiaries may bring new business models, international quality standards, know-how, time to market (Giblin and Ryan 2012, 2015), external connectivity (Lorenzen and Mudambi 2013), spatial concentration of production (Nguyen and Diez 2017), and international reputation (Malmberg and Maskell 2002), clusters may weaken because of dependence on large subsidiaries that neglect the local milieu (Markusen 1996).

2.2 MNEs and industrial clusters: knowledge, networks, and autonomy

Home-country operations are still the main contributors to MNE’s knowledge creation, but valuable knowledge may emerge anywhere in an MNE’s network (Meyer et al. 2011). By learning across different networks and locations, MNEs enlarge their stock of knowledge and capabilities (Cantwell 2009; Collinson and Wang 2012). Accordingly, the network of exchange relations built by the parent company, subsidiaries, suppliers, customers, and competitors is crucial to safeguard the MNE’s leadership in activities that add value.

Some subsidiaries principally focus on routine replication and local adaptation (Cantwell and Mudambi 2005, 2011), whereas others are responsible for considerable innovative activity. These subsidiaries represent a source of competitiveness depending on level of autonomy, specialization in one echelon of the value chain (Mudambi 2008), and appropriate integration within the host territory and the parent company (Marin and Bell 2010). Although generalizations should always be made with caution, vibrant clusters usually have more autonomous and embedded subsidiaries (Birkinshaw and Hood 2000).

The autonomy of the subsidiary enhances its intrinsic motivation and, consequently, its knowledge output (Mudambi et al. 2007) through, for instance, the subsidiary’s superior ability to form appropriate networks in the local environment (Birkinshaw and Hood 1998; Cantwell and Mudambi 2005). Collinson and Wang (2012) assessed the degree of autonomy and self-determination in terms of: (a) input activities (selecting suppliers, hiring senior management, and global sourcing strategy); (b) output activities (sales and service, assembly, manufacturing, product development, and international strategy development); and (c) internal activities (operations and training).

Subsidiaries need territorial integration and networking to retrieve local resources (Gertler and Levitte 2005; Heidenreich 2012; Beugelsdijk and Mudambi 2013), particularly complex knowledge that is often embodied in a skillful labor force (Mudambi and Swift 2012). The stickiness of a cluster’s knowledge to the local context hinders its procurement beyond the cluster boundaries, making colocation essential to benefit from the local buzz (Bathelt et al. 2004). Therefore, the location of a subsidiary is guided by access to a valuable knowledge base (McCann and Mudambi 2004), whose spatial proximity increases over time through pervasive interactions, shared institutions, and trust. The richness of knowledge available not only in the cluster but also in the MNE’s network determines the subsidiary’s knowledge outcomes (Almeida and Phene 2004; Marin and Bell 2010; Figueiredo 2011).

The replication of this strategy allows subsidiaries to tap into resources and knowledge accumulated in other clusters (Enright 2000; Nadvi and Halder 2005). The network consisting of these subsidiaries and the parent company enables the configuration of global knowledge through incoming flows from broad geographical areas (Cantwell and Piscitello 1999) and converts each branch of the MNE into a potential source of competitiveness (Mudambi and Navarra 2004; Cantwell and Mudambi 2005). The balance between the internal organizational fit and the embeddedness of subsidiaries in local networks shapes the contribution of this global network to the MNE’s capacity to compete (Narula 2014).

2.3 Clusters, MNEs’ decisions, and the life cycle perspective

There is a growing perception that the micro-level perspective is relevant to understand a cluster’s organization (Boschma and Frenken 2011) and evolution (Ter Wal and Boschma 2011). Not all cluster firms evolve in synchrony. Factors of competitiveness stemming from location and successful upgrading strategies help some local organizations outperform competitors (Cainelli et al. 2006). Over time, the prevalence and contribution to cluster connectivity of these outperformers result in increasing systemic complexity (Iammarino and McCann 2006; Randelli and Boschma 2012) and influence the cluster’s evolution (Markusen 1996; Randelli and Boschma 2012; Randelli and Lombardi 2014). Some of these local leaders become genuine MNEs with their own structures in different territories (Randelli and Lombardi 2014). These local leaders add attraction for hosting MNEs and subsidiaries that search for knowledge and competencies (Birkinshaw and Hood 2000) by feeding knowledge to the cluster through their global networks (De Propris et al. 2008).

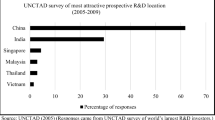

The raison d’être of MNEs in a region or cluster varies across the evolutionary cycle of the host territory (Sedita et al. 2013). While manufacturing abilities or availability of inputs at low cost are crucial factors in early stages (Fromhold-Eisebith and Eisebith 2005) and may even trigger the formation of the whole cluster (Manning 2008; Giblin and Ryan 2012), knowledge and competency seeking prevail in advanced stages (Aharoni and Ramamurti 2008). Therefore, the accumulated resources and capabilities of the host cluster act as signposts to attract MNEs (De Propris and Driffield 2006) and play an important role in decisions of large externally owned firms regarding where to locate key activities (Cantwell and Piscitello 2002).

According to these considerations, therefore, the location decision regarding a subsidiary in mature clusters should be driven by the systemic knowledge stock (Cantwell 2009) and the synergies resulting from complementary features (Nachum and Wymbs 2005). Despite potential gains, however, this location decision is not risk free. Information spillovers and unintended knowledge outflows may prevent subsidiaries from establishing themselves in a cluster because the parent MNE may decide that these unplanned knowledge flows can benefit rivals and jeopardize its own position (Hervás-Oliver 2015).

3 Method

To deal with the complex interdependencies and implications stemming from the embeddedness of MNEs in industrial clusters, we studied the case of Tempe, a specialized subsidiary of Inditex in the Vinalopó cluster. The importance of Tempe S.A. in one of the largest footwear clusters in Europe justifies our choice of case and ensures the validity of our conclusions.

Although case study methods have typically been confined to theory and hypothesis development through induction (Eisenhardt 1989; Yeung 2003), their utility has recently been acknowledged for broader purposes such us refinement or refutation of existing theories (Lowe and Wrigley 2010; Tokatli 2014). Their value owes to the potential for combining different types of data, thereby facilitating an applied, comprehensive study of a phenomenon that is difficult to understand over time (Meyer 2001).

Figure 1 depicts the research framework in detail. The framework comprises elements of context and organizational analysis. We started by conducting context analysis of available secondary materials. This analysis was supplemented by expert interviews that focused on cluster and industrial characteristics. This part was extended to Tempe’s situation using secondary data about the subsidiary and interviews with experienced practitioners. This study method thus provides a detailed description of the industry, cluster dynamics, and firms as well as the way these elements interlink.

Business and economic geography scholars find qualitative research and case studies somewhat problematic. They have expressed concern about issues of generality, counterexamples, and so forth (Markusen 2003). These issues sometimes arise from an absence of rigor due to superficiality, limited contextualization, and careless methodology (Martin and Sunley 2001). To avoid these pitfalls, we designed the data collection process and subsequent analysis to meet the quality criteria of credibility, dependability, and confirmability (Yin 1984).

We ensured credibility by defining an action plan that covered the process of collecting and processing data from several sources presented in Table 1 (Yin 2009):

-

Documentary evidence such as annual reports, strategic plans, information available on websites, social networks, press articles, etc.

-

23 interviews to Tempe managers, footwear manufacturers, suppliers, and institutional representatives. The interviews, based on a semi-structured questionnaire, lasted 40–50 min and took place in the Tempe facilities. All interviews were transcribed, and the main insights were extracted using MaxQCA. Three additional meetings with experts were conducted to refine and validate our findings.

-

Direct observation by the researchers through visits to the subsidiary and its principal suppliers to verify the information obtained in these interviews (Pettigrew 1990).

Data analysis was ongoing after the project ended. We brought together the key insights from the aforementioned sources and organized them using a basic template based on the literature review. Given our interest in the micro and meso levels, we designed our tool to fully consider the main cluster- and subsidiary-related issues. We then combined and compared the data and applied concepts drawn from the cluster life cycle and international business theory to interpret the data.

Regarding dependability and confirmability, we confirmed that the inferences made in the study were accurate and meaningful using the triangulation method (Denzin and Lincoln 1994) and peer debriefing with academic experts (Spillett 1998). After collecting and evaluating the evidence, we cross-checked the data and insights from academics and rivals to minimize concerns about procedural or measurement bias. Single case studies frequently rely on corporate narratives written for profile raising, so this extensive procedure is extremely advisable (Lowe and Wrigley 2010; Tokatli 2014).

This research explores the foundations of successful embeddedness of MNEs in clusters and the effects of this embeddedness on systemic sustainability. According to the literature review, two considerations are important here. First, the level of integration and fit within the local socioeconomic context determines the territorial benefits accrued by the MNE. So, networking and autonomous decision practices that allow successful territorial embeddedness were explored. Second, the knowledge heterogeneity contributed by the MNE apparently determines its contribution to the cluster’s future. Therefore, we analyzed how the MNE’s connections outside the cluster enrich the knowledge that is transferred to firms within the cluster and the local system as a whole. Finally, a set of indicators was used to assess the performance of the cluster and the MNE.

4 Empirical evidence

4.1 The Vinalopó cluster in context

The Vinalopó footwear cluster is located in the south of the Region of Valencia. It is concentrated along the Vinalopó river in the towns of Elche, Crevillente, Elda, Petrer, Monovar, and Villena. This industry has its roots in the work of traditional footwear artisans, who manufactured espadrilles (canvas shoes) in the late 19th century. New inputs and the advent of a decentralized system of production caused this local industry to expand. Meanwhile, diversification processes and exploitation of knowledge accumulated by entrepreneurs, skilled workers, and suppliers progressively converted Vinalopó into one of Spain’s leading leather shoe clusters. In Elche (the core of the cluster), in 1935, firms produced 51 million pairs of shoes and espadrilles, employing 18,000 workers (Miranda Encarnación 1998).

Despite a lack of modernization following the civil war, solid foundations enabled the cluster to make a major U-turn during the 1960s and 1970s. Although some large or foreign-owned firms existed, a myriad of small firms benefited from the availability of specialized suppliers, labor force, specific knowledge, and cooperation practices to compete internationally. Joint efforts between firms and supporting organizations were at the heart of crucial initiatives such as the Footwear and Components Trade Show (FICIA), the Footwear Technology Institute (INESCOP), and the Export Promotion Center (CEPEX). Like in other footwear clusters (Humphrey and Schmitz 2002), in the metropolitan area of Elda-Petrel, the establishment of US companies such as US Shoe Inc., Intershoe, Caresa, Unisa, and Nina Footwear Inc. encouraged efficiency growth and productive upgrading through subcontracting.

This idyllic context started to deteriorate due to rising manufacturing costs and the penetration of Asian and South American footwear. From 1975 to 1990, firms and employment declined by 38.8 and 65.7%, respectively, while costs increased by over 68%. The outspread implementation of so-called informal practices caused the downsizing of firms by 33.1% (up to 13.7 employees on average) and the atomization of the whole cluster. The flight of large buyers to emerging countries not only spurred the informal economy (Ybarra 2000), but also encouraged innovative upgrading strategies (Tortajada et al. 2005), which heralded a second golden age.

Apart from a benign economic environment, the spontaneous rationalization of productive and marketing structures fostered this prosperity. In particular, numerous spin-offs and specialized firms were established based on previously acquired knowledge and relationships (Ybarra 2006). Although fragmentation remained a prominent trend, marginality descended and firms redoubled investments in technological renewal and value added activities. Some local firms became multinationals, while the efficiency and flexibility of local manufacturers convinced European buyers to purchase more Spanish shoes. Like in other developed countries, offshoring to countries with low labor costs was common (Belso-Martínez 2008). Ultimately, the structure based on networks of specialized SMEs was the engine that fueled the international competitiveness of cluster firms (Belso-Martinez 2006), multiplying exports by 1.5 in 2002.

Numerous strategies and organizational structures have emerged from these changes (see Fig. 2). There is a small group of global footwear players such as Tempe and Stuart Weitzman Co. with robust innovative capabilities and chain management. Their manufacturing is subcontracted both locally and globally. The traditional leading cluster players (Hispanitas, Pikolinos, Rebeca Sanver, Panama Jack, Kelme, Mustang, etc.) sell their own brands globally. Thanks to a solid resource base and efficient operating systems, these firms benefit from systemic advantages to innovate or optimize manufacturing. A growing number of specialized cluster players offer advanced designs for specific international niches based on intra-cluster cooperation and support. Despite differences, these three groups subcontract production to local footwear manufacturers with functional dependencies and strategies that are mostly centered on efficiency through technology acquisition and tight linkages with local suppliers.

Source: Belso-Martínez and López-Sánchez (2012) and qualitative evidence

Taxonomy of firms in the Vinalopó cluster.

Cluster providers are divided into two groups. First, highly innovative and export-orientated input producers are firmly linked to local knowledge and supporting organizations. Direct investment in top foreign clusters preserves their competitiveness and privileged relationships with top footwear players. Analco, Caster, Zahonero, Comerplast, Plaginsa, and Spumatex-Flexotex are examples. Second, there is a large group of smaller suppliers with low innovation activities and strictly local operations. Plagiarism and informal practices are common among these firms.

4.2 The Vinalopó cluster and the Spanish footwear industry in the 21st Century

The Spanish footwear industry is geographically concentrated in several industrial clusters. The Vinalopó cluster, which is by far the largest, accounts for 55% of the Spanish production and covers an area with a 25 km radius. Firms in this cluster are predominantly family-owned SME’s that specialize in one or several levels of the value chain. Accordingly, 76% of 2739 establishments have fewer than 10 employees. In contrast with other clusters, the evolution and structural changes of this structure have reinforced the relevance of larger firms versus micro-enterprises (see Fig. 3).

The Vinalopó cluster still has a strong international scope, representing 51% of the Spanish footwear sector overall export activity. Figure 4 provides interesting insight into the dynamics of the footwear trade between 2003 and 2015. The Vinalopó cluster increased imports of components to a small extent and reduced exports to a comparatively larger extent. Accordingly, pressures to delocalize sourcing and assembly to developing countries seem to have abated thanks to a vibrant auxiliary industry with over 450 firms. The Vinalopó cluster has maintained a stronger export trajectory than other industrial systems. Values of imports for the Vinalopó cluster reflect the vulnerability of local manufacturing, as well as the implementation of upgrading strategies to stop poorly performing product lines and the shift to more upmarket segments (the average price rose 4.9% annually during this period). Recent research has shown the increasingly selective nature of offshoring and delocalization policies in view of the changing global circumstances (Martínez-Mora and Merino de Lucas 2014).

Data on registered designs (taken from the Spanish Patent and Trademark Office) dispel any doubt over the Vinalopó cluster’s innovation activity. This legal protection mechanism is an indicator of aesthetic and creative innovation (Alcaide-Marzal and Tortajada-Esparza 2007; Rubera and Droge 2013). From 2009 to 2015, the Vinalopó cluster was responsible for on average 67% of the operative registered designs in the footwear industry, while other clusters and regions attained 19 and 15%, respectively. As Fig. 5 reveals, the leadership of the Vinalopó cluster becomes more evident when cluster size is considered. The gap between the relative weight of registered designs and footwear establishments is more than 14 percentage points with respect to the negative values in other areas. Spillover effects due to geographical proximity and links the Vinalopó clusters (125 km) explain Murcia’s innovation performance.

Underlying this solid innovation performance is a dense network through which local organizations share knowledge and learn together in a trustful atmosphere fostered by colocation and the socio-institutional context. Likewise, temporary colocation and gatekeepers contribute extra-cluster knowledge, permitting the avoidance of lock-in. Supporting organizations such as the Footwear Technology Institute (INESCOP) or the Business Association (FICE) have helped spread external knowledge among local firms.

4.3 The embeddedness of Inditex in the Vinalopó cluster: autonomy, knowledge, and innovation

Initially founded by Amancio Ortega as a small clothing workshop in 1963, the Inditex group now represents the paradigm of world leadership in fashion distribution. Its eight retail chains (Zara, Pull & Bear, Massimo Dutti, Bershka, Stradivarius, Oysho, Zara Home, and Uterqüe; see Table 2) and more than 7000 stores spread over five continents enabled Inditex to achieve sales of 20.9 billion euros in 2015. Joint efforts by Inditex and the Vinalopó based entrepreneur Vicente García led to the launch of an Inditex subsidiary specialized in footwear and accessories.

Based on the local entrepreneur’s expertise to recruit skillful staff within the local community, Tempe S.A. was founded in 1989 and began operating next to the long-established kids footwear firm owned by the García Family. This family business mix, a common model within the cluster, is still present in the company. Vicente García has since stepped down as CEO to be replaced by his son, Antonio. Nevertheless, like Amancio Ortega, Vicente and his wife, María Isabel Peralta, are still involved in many projects and decisions. Personal similarities with Amancio Ortega have helped to preserve a status quo whereby both parties own 50% of the subsidiary.

“People speak very highly of him. He doesn’t have a reputation as a speculator. Businessmen have a very good impression of Vicente García, who is considered a serious, visionary entrepreneur” (representative from a local supporting organization).

Thanks to existing professional connections, local manufacturers and suppliers rapidly embarked on business relationships with the new subsidiary. In just 1 year, the first footwear collection reached the Zara kid’s corner. Since then, mirroring the parent company, Tempe has expanded rapidly. Over the following decade, Tempe introduced footwear lines for all of Inditex’s brands and even supplied some accessories collections. Figure 6 presents a timeline of Tempe’s growth.

Source: Developed using data from qualitative evidence and www.inditex.com

Timeline of Tempe’s growth.

To some extent, Tempe initially emulated the strategy of the extremely successful local multinational Stuart Weitzman Inc., which designs and sells over 252 million euros worth of luxury shoes produced by 12 subcontracted manufacturers, principally with local inputs. However, unlike Stuart Weitzman Inc., Tempe immediately embedded in the cluster system. Former relationships accelerated the formation of local linkages governed by the norms and values embraced by managers throughout their careers in the cluster. Both the experienced staff and the solid collaborations provided a strong platform from which operations expanded to 88 countries to produce 71,235,913 pairs of shoes.

This nascent cooperation combined with extra-cluster reinforcements enabled the implementation of a model based on unceasing innovation and optimization of the value chain. This model was imported from the parent corporation. This approach is evident when observing the creation of each collection. Coordinating with clothing colleagues at headquarters, the footwear designers launch proposals every 2 weeks using new inputs and updated data on market and fashion trends.

“Designers and buyers surf the internet and travel worldwide to detect and see fashion trends first-hand. In my view, this is a more successful approach than other alternatives like global coolhunting” (head of design at one of Tempe’s largest brands).

Each brand independently develops these ideas in profitable projects supported by a strong network of subcontractors and a common operational architecture that provides support through pooled knowledge. For instance, the raw materials department assists all brands with sourcing. Once manufactured under Tempe’s specifications, shoes are received at an automated 105,000 m2 warehouse and are instantly forwarded to stores for a maximum of 1–3 months. Finally, a strict control system allows Tempe’s most senior staff to monitor all projects and correct for deviations from their goals. This process summarizes the principles that guide Tempe.

“Product is the most important thing (…), delegation and responsibility to each business unit (…), knowledge sharing among business units and departments (…), corporate social responsibility with stakeholders (…) and profitability” (Vicente García, founder of Tempe).

Inditex’s headquarters set guidelines in the commercial sphere and oversee decisions in other aspects. The subsidiary independently decides on sourcing, manufacturing, equipment investments, human resources, and logistics. For instance, eschewing ideally located cities in Northwest Europe, Tempe built its logistics hub in Elche in view of specific storage and distribution needs. The HR department recruits all employees and prepares professional development plans, sales policy plans, and equality plans in cooperation with worker representatives.

“We were born manufacturers and still feel like manufacturers (…) The important thing for us is the stores. Although there may be places where shoes are not sold, what matters is the overall concept of the brand” (top senior manager at Tempe).

“Inditex headquarters set the sales guidelines, but Tempe has full autonomy to decide on production and sourcing” (top senior manager at Tempe).

4.4 Multi-cluster presence, activity roaming, and knowledge

Following consolidation in the Vinalopó cluster and under the auspices of the parent corporation, Tempe accelerated the internationalization process to strengthen its competitiveness.

“We cannot afford to stay at home. We have to take the suitcase and go wherever we can be competitive” (Vicente García, founder of Tempe).

“Sometimes, the same shoe is manufactured in several countries, and other times just in one. We manufacture where it is most competitive, not only because of production costs, but also because of proximity to stores and logistics costs” (top senior manager at Tempe).

This new scenario heralds a changing geography of business activities (see Fig. 7). Platforms have gradually been opened in other clusters (Sinus Valley, Brazil; Guadalajara, Mexico; Guangzhou, China; Gurgaon, India; and Ho Chi Minh City, Vietnam) to offshore activities within the value chain. The flexibility of the management systems and efficient teams led by experts from the Vinalopó cluster enable the constant roaming of business activities. These factors ensure the good selection, learning, and coordination with local suppliers and increase the effectiveness of logistics.

“The flexibility of our management system lets us constantly change the geographical distribution of production based on variables that are beyond our control. When negative events occur, part of the production is moved to another country, while maintaining a minimum to resume normal operations when the reasons for the changes subside” (top senior manager at Tempe).

Although Tempe tries to harness the resources of each new cluster, each one has something completely different to offer. Despite these advantages, core functions such as product development remain in the Vinalopó cluster. For instance, design teams travel to some clusters from time to time and try to use their inputs in new developments. Permanent presence in these territories is combined with the outsourcing of production in other established regions (Portugal, Morocco, Romania, etc.). In these cases, supervision takes place through frequent visits by those responsible for production activities in Tempe.

The correct functioning of this complex, ever-changing operational architecture is achieved through an organizational structure that guarantees excellent handling of information internally and externally. Transparency is reflected by the absence of closed spaces in Tempe’s facilities, and simple flows enable efficient transfer of information between departments. The model invites participation, facilitates coordination, and accelerates decisions.

At the inter-organizational level, information systems and regular trips by Tempe executives are essential tools through which relevant information is shared and common problems are solved. Visits to corporate offices increase opportunities to receive guidance or collaborate. Meanwhile, trips to platforms familiarize managers with the strengths of each cluster, make allies aware of problems, and coordinate with Tempe platforms in each territory.

Because of this set of relationships, Tempe lies at the nexus of multiple intra-firm, intra-cluster, and extra-cluster relationships. Figure 6 shows Tempe’s position within the parent company, the local economy, and the global footwear industry. Tempe is a network of exchange relations among the parent corporation, its own subsidiaries, its suppliers, and competitors either inside or outside the Vinalopó cluster. Each component represents a unique source of competitiveness for Tempe. The distinctive footwear knowledge and resources accrued in the Vinalopó cluster complement the knowledge stock at the MNE level, which is in turn updated through pipelines with alternative knowledge repositories. Furthermore, linkages with actors in other footwear clusters supplement industry-specific knowledge and promote inter-cluster competition, which results in gains in competitiveness.

4.5 The symbiosis between Inditex and the Vinalopó cluster: from mutualism to parasitism?

Initially, the creation of Tempe led to a new scenario, where clustered firms faced both increased demand for fashion footwear and the pressures of the manufacturing efficiency and chain integration of the Inditex model. Some leading cluster players (e.g. Fluxa Footwear and RAS) and specialized manufacturers became subcontractors to achieve internal economies of scale. Other footwear manufacturers that were frequent subcontractors of international buyers abandoned traditional customers in favor of Tempe’s impressive orders.

After a short period of intra-cluster competition, some of the leading, specialized players failed to adapt to Tempe’s prototyping needs, delivery terms, and prices, whereas others succeeded by creating spinoff companies based on the Inditex business paradigm. Traditional subcontractors adjusted their operations through enhanced integration with Tempe and input suppliers, thereby allowing manufacturing and prototyping efficiency gains. A tailored approach to the final customer and conciliation of multiple chain configurations forged close relationships and created customized value.

The cluster and the subsidiary operate in symbiosis, both benefiting from the relationship. The need for efficiency and knowledge of new business practices such as value chain integration and market trends spread through the local networks. In addition, accelerated access to local endowments boosts the commercialization of shoes. Figures presented in previous sections should allay doubts about the mutual benefits of the relationship. The cluster has outperformed other Spanish clusters, while the subsidiary has achieved phenomenal growth.

Once Tempe had internationally diversified its portfolio of relationships, competition became globalized. Subcontractors and suppliers from different clusters compete for orders to be manufactured with inputs from the corresponding region. Tempe sets product specifications based on prototypes made in the Vinalopó cluster, but manufacturers search for suppliers in their clusters to minimize costs (frequently encouraged by Tempe’s platforms).

The consequence is that relationships are kept at arm’s length, and traditional Vinalopó values have been weakened. Although support programs aspire to fortify key relationships, the need for results suppresses trust and forces opportunism that is never punished because of power asymmetries. The industrial system has become progressively fragmented into two subsystems: one governed by Tempe with fragile institutions (norms and values), weak cooperative behavior, and a vulnerable atmosphere of trust; and another where the traditional cluster values reign.

This new model poses a serious threat to subcontractors and the cluster. Many subcontractors have reoriented operations. Some have delocalized production, emulating Tempe; others have used acquired capabilities to upgrade and cooperate with prestigious brands (Prada, Gucci, LVMH group, Proenza Schouler, Laboutin, and the like) or traditional cluster leaders. However, the cluster has also reinvented itself to continue generating value for Tempe. A myriad of logistic companies has flourished to support distribution, while some firms have become re-operators of almost 2,000,000 “faulty” products.

5 Conclusions, limitations, and future research

Today, one of the most commonly repeated calls from scholars of clusters and international business is the need to incorporate a regional perspective into the analysis of MNE establishment and implications (Beugelsdijk et al. 2010; Cantwell and Mudambi 2011; Meyer et al. 2011; Beugelsdijk and Mudambi 2013; Lorenzen and Mudambi 2013). Through the analysis of the Inditex subsidiary Tempe and the Vinalopó cluster, the present study responds to this call.

First, we contribute to the ongoing debate in the business literature over the regional and cluster dimension of MNE’s subsidiaries (Arregle et al. 2009; Asmussen et al. 2009; Chidlow et al. 2009; Mudambi and Swift 2012) We show that specific territorial endowments determine the location and post-entry development of a subsidiary in a given cluster. Consequently, the comparative attractiveness of a cluster varies when the specifics of a location are considered. In view of our findings, mature industrial clusters in developed countries are desirable hosts if solid manufacturing or knowledge-seeking factors prevail with regard to operating and input costs.

Our findings confirm that subsidiary embeddedness and autonomy are at the heart of successful creation and performance. Through independent design of strategies, subsidiaries benefit from specific locational advantages and reinforce their competitiveness. Proper tools selected according to a subsidiary’s particular circumstances guarantee opportunities for instant integration in the local network, successful attainment of specific resources, and precise orientation of non-local operations.

We build on the incomplete idea of subsidiaries’ influence on the globalization of innovation. We verify that sources of knowledge and internal resources significantly affect innovation and competitiveness (Phene and Almeida 2008). Interestingly, after examining knowledge flows within and between clusters, we observe that the influence of different sources is not permanent but rather evolves over time. Accordingly, specific endowments absorbed in other clusters gain relevance, complementing the assets available in the original cluster. This finding contributes to understanding the nexus between the nature and dynamics of clusters and the benefits clusters provide (Mudambi and Swift 2012).

Furthermore, our study shows that cluster multinationals set up new subsidiaries in other similarly specialized clusters. A subsidiary benefits from extra-cluster knowledge when the subsidiary has suitable reach to capture and transfer this knowledge (e.g. skillful expatriates). However, the effect on performance is stronger if the subsidiary has solid competences to assimilate this new knowledge (Chang et al. 2012).

Second, this study adds to the literature on the cluster life cycle. We show that the creation of a large specialized subsidiary represents a disruptive process that shapes the evolution of the entire local system. Once this subsidiary is embedded in the local network, the development of the subsidiary and the cluster become interconnected. Self-reinforcing mechanisms in terms of resource enrichment lead to a benign co-evolutionary trajectory and reduce the risk of decline due to lock-in (Grabher 1993; Malmberg and Maskell 2002). We also show how accumulated territorial resources initially exert an attraction effect but are also crucial for adapting to significant threats such as the advent of a dominant actor (Martin and Sunley 2006; Østergaard and Park 2015).

Third, strictly from the perspective of Inditex, we observe the global nature of its footwear subsidiary, Tempe. However, consistent with the parent corporation, the globalized operations of Tempe are compliant with a strong territorial base. The founder’s identification with the territory binds the company to the cluster. Methodologically, the value and robustness of these findings support recent research efforts that deal convincingly with traditional objections about qualitative research. In this vein, our research sets quality criteria comparable to the scientific method (Eisenhardt and Graebner 2007; Gibbert et al. 2008; Gibbert and Ruigrok 2010; Tokatli 2014), encouraging fluent dialogue between researchers with different methodological approaches.

Some policy implications at the cluster level can be inferred from these findings. Subsidiaries of large MNEs generate disruptive processes that may renew cluster knowledge and resources. When suitably embedded in the local network, they represent powerful drivers of new knowledge and diversity. Policymakers should attract subsidiaries and anchor their activities to the local area. Local entrepreneurs may be valuable targets for public programs. Furthermore, local organizations should play a role in strengthening the cluster. However, the emergence of subsidiaries may become a double-edged sword if the cluster does not have solid endowments to face the disruption and adapt or if the subsidiary fails to embrace the cluster’s reality. Therefore, meticulous diagnosis of the existing stock of resources is advisable for effectively designing policy programs.

From a managerial perspective, our research stresses how innovation often originates from a combination of knowledge types acquired through collaboration with intra- and extra-cluster actors. Hence, subsidiary managers should design innovation strategies that balance both types of collaborations to maximize the acquisition of relevant knowledge. Our research also highlights the importance of the territory and embeddedness for post-entry performance. Firms should therefore conduct a thorough preliminary diagnosis of local endowments and design suitable strategies to accelerate their integration within the local community (e.g. hiring experienced local employees).

This study has some limitations. First, the analysis focuses on just one cluster; comparative analyses with other clusters could discard potential geo-industry biases, reinforce our findings, and enable generalizations. Furthermore, quantitative analyses would also be welcome. Second, the paper focuses purely on knowledge exchanges within and across clusters. Knowledge flows between the subsidiary and parent company were practically ignored. Future studies should focus on these networks, which also cross cluster boundaries. Such studies would enhance the implications for subsidiaries and the host region. Likewise, future research should further explore potential differences in knowledge gatekeeping by confronting inter-cluster versus subsidiary-parent relationships. Finally, another research opportunity relates to the sustainability of this symbiotic relationship, particularly if new territories threaten the host territory.

References

Agrawal A, Cockburn I (2003) The anchor tenant hypothesis: exploring the role of large, local, R&D-intensive firms in regional innovation systems. Int J Ind Organ 21:1227–1253. https://doi.org/10.1016/S0167-7187(03)00081-X

Aharoni Y, Ramamurti R (2008) The internationalization of multinationals. In: Boddewyn JJ (ed) International business scholarship: AIB fellows on the first 50 years and beyond. Research in Global Strategic Management, vol 14. Emerald Group Publishing Limited, Bigley, pp 177–201

Alcaide-Marzal J, Tortajada-Esparza E (2007) Innovation assessment in traditional industries. A proposal of aesthetic innovation indicators. Scientometrics 72:33–57. https://doi.org/10.1007/s11192-007-1708-x

Almeida P, Phene A (2004) Subsidiaries and knowledge creation: the influence of the MNC and host country on innovation. Strateg Manag J 25:847–864. https://doi.org/10.2307/20142164

Andersen PH, Christensen PR (2005) Bridges over troubled water: suppliers as connective nodes in global supply networks. J Bus Res 58:1261–1273. https://doi.org/10.1016/j.jbusres.2003.04.002

Arregle J-L, Beamish PW, Hébert L (2009) The regional dimension of MNEs’ foreign subsidiary localization. J Int Bus Stud 40:86–107. https://doi.org/10.1057/jibs.2008.67

Asmussen CG, Pedersen T, Dhanaraj C (2009) Host-country environment and subsidiary competence: extending the diamond network model. J Int Bus Stud 40:42–57. https://doi.org/10.1057/palgrave.jibs.8400420

Audretsch DB, Feldman MP (1996) Innovative clusters and the industry life cycle. Rev Ind Organ 11:253–273. https://doi.org/10.1007/BF00157670

Bathelt H, Malmberg A, Maskell P (2004) Clusters and knowledge: local buzz, global pipelines and the process of knowledge creation. Prog Hum Geogr 28:31–56. https://doi.org/10.1191/0309132504ph469oa

Belso-Martinez JA (2006) Do industrial districts influence export performance and export intensity? Evidence for Spanish SMEs’ internationalization process. Eur Plan Stud 14:791–810

Belso-Martínez JA (2008) Differences in survival strategies among footwear industrial districts: the role of international outsourcing. Eur Plan Stud 16:1229–1248

Belso-Martínez JA, López-Sánchez MJ (2012) Metaorganizadores, redes externas y conocimiento en los sectores manufactureros españoles: el papel de las instituciones locales en el distrito industrial del Vinalopó. Econ Soc Territ 12:1–42

Belussi F, Sedita SR (2009) Life cycle vs. multiple path dependency in industrial districts. Eur Plan Stud 17:505–528. https://doi.org/10.1080/09654310802682065

Berger S (2005) How we compete: what companies around the world are doing to make it in today’s global economy. Currency Doubleday, New York

Bergman E (2008) Cluster life-cycles: an emerging synthesis. In: Karlsson C (ed) Handbook of research in cluster theory. Edward Elgar, Cheltenham, pp 114–132

Beugelsdijk S, Mudambi R (2013) MNEs as border-crossing multi-location enterprises: the role of discontinuities in geographic space. J Int Bus Stud 44:413–426. https://doi.org/10.1057/jibs.2013.23

Beugelsdijk S, McCann P, Mudambi R (2010) Introduction: place, space and organization-economic geography and the multinational enterprise. J Econ Geogr 10:485–493. https://doi.org/10.1093/jeg/lbq018

Birkinshaw J, Hood N (1998) Multinational subsidiary evolution: capability and charter change in foreign-owned subsidiary companies. Acad Manag Rev 23:773–795. https://doi.org/10.5465/AMR.1998.1255638

Birkinshaw J, Hood N (2000) Characteristics of foreign subsidiaries in industry clusters. J Int Bus Stud 31:141–154

Boschma R, Fornahl D (2011) Cluster evolution and a roadmap for future research. Reg Stud 45:1295–1298. https://doi.org/10.1080/00343404.2011.633253

Boschma R, Frenken K (2011) The emerging empirics of evolutionary economic geography. J Econ Geogr 11:295–307. https://doi.org/10.1093/jeg/lbq053

Bunnell TG, Coe NM (2001) Spaces and scales of innovation. Prog Hum Geogr 25:569–589. https://doi.org/10.1191/030913201682688940

Cainelli G, Iacobucci D, Morganti E (2006) Spatial agglomeration and business groups: new evidence from Italian industrial districts. Reg Stud 40:507–518. https://doi.org/10.1080/00343400600757585

Cantwell J (2009) Location and the multinational enterprise. J Int Bus Stud 40:35–41

Cantwell J, Mudambi R (2005) MNE competence-creating subsidiary mandates. Strateg Manag J 26:1109–1128. https://doi.org/10.1002/smj.497

Cantwell J, Mudambi R (2011) Physical attraction and the geography of knowledge sourcing in multinational enterprises. Glob Strateg J 1:206–232. https://doi.org/10.1111/j.2042-5805.2011.00024.x

Cantwell J, Piscitello L (1999) The emergence of corporate international networks for the accumulation of dispersed technological competences. Manag Int Rev 39:123

Cantwell J, Piscitello L (2002) The location of technological activities of MNCs in European regions: the role of spillovers and local competencies. J Int Manag 8:69–96. https://doi.org/10.1016/S1075-4253(01)00056-4

Chang YY, Gong Y, Peng MW (2012) Expatriate knowledge transfer, subsidiary absorptive capacity, and subsidiary performance. Acad Manag J 55:927–948. https://doi.org/10.5465/amj.2010.0985

Chidlow A, Salciuviene L, Young S (2009) Regional determinants of inward FDI distribution in Poland. Int Bus Rev 18:119–133. https://doi.org/10.1016/j.ibusrev.2009.02.004

Collinson SC, Wang R (2012) The evolution of innovation capability in multinational enterprise subsidiaries: dual network embeddedness and the divergence of subsidiary specialisation in Taiwan. Res Policy 41:1501–1518. https://doi.org/10.1016/j.respol.2012.05.007

Cooke P (2005) Regionally asymmetric knowledge capabilities and open innovation: exploring “Globalisation 2”—a new model of industry organisation. Res Policy 34:1128–1149. https://doi.org/10.1016/j.respol.2004.12.005

Cowan R, Jonard N, Özman M (2004) Knowledge dynamics in a network industry. Technol Forecast Soc Change 71:469–484. https://doi.org/10.1016/S0040-1625(03)00045-3

Crespo J (2011) How emergence conditions of technological clusters affect their viability? Theoretical perspectives on cluster life cycles. Eur Plan Stud 19:2025–2046. https://doi.org/10.1080/09654313.2011.633824

De Marchi V, Di Maria E, Gereffi G (2017) Local clusters in global value chains. Taylor and Francis, Oxford

De Propris L, Driffield N (2006) The importance of clusters for spillovers from foreign direct investment and technology sourcing. Cambr J Econ 30:277–291. https://doi.org/10.1093/cje/bei059

De Propris L, Menghinello S, Sugden R (2008) The internationalisation of production systems: embeddedness, openness and governance. Entrep Reg Dev 20:493–515

Denzin NK, Lincoln YS (1994) Handbook of qualitative research. Sage, Thousand Oaks, CA

Eisenhardt KM (1989) Building theories from case study research. Acad Manag Rev 14:532–550

Eisenhardt KM, Graebner ME (2007) Theory building from cases: opportunities and challenges. Acad Manag J 50:25–32. https://doi.org/10.2307/20159839

Elola A, Valdaliso JM, López SM, Aranguren MJ (2012) Cluster life cycles, path dependency and regional economic development: insights from a meta-study on basque clusters. Eur Plan Stud 20:257–279. https://doi.org/10.1080/09654313.2012.650902

Enright MJ (2000) Regional clusters and multinational entreprises: independence, dependence, or interdependence. Int Stud Manag Organ 30:114. https://doi.org/10.2307/40397478

Figueiredo PN (2011) The role of dual embeddedness in the innovative performance of MNE subsidiaries: evidence from Brazil. J Manag Stud 48:417–440. https://doi.org/10.1111/j.1467-6486.2010.00965.x

Foss NJ, Pedersen T (2002) Transferring knowledge in MNCs: the role of sources of subsidiary knowledge and organizational context. J Int Manag 8:49–67. https://doi.org/10.1016/S1075-4253(01)00054-0

Fromhold-Eisebith M, Eisebith G (2005) How to institutionalize innovative clusters? Comparing explicit top-down and implicit bottom-up approaches. Res Policy 34:1250–1268. https://doi.org/10.1016/j.respol.2005.02.008

Gast J, Filser M, Gundolf K, Kraus S (2015) Coopetition research: towards a better understanding of past trends and future directions. Int J Entrep Small Bus 24:492–521. https://doi.org/10.1504/IJESB.2015.068640

Gertler MS, Levitte YM (2005) Local nodes in global networks: the geography of knowledge flows in biotechnology innovation. Ind Innov 12:487–507. https://doi.org/10.1080/13662710500361981

Gibbert M, Ruigrok W (2010) The what’’ and how’’ of case study rigor: three strategies based on published work. Organ Res Methods 13:710–737. https://doi.org/10.1177/1094428109351319

Gibbert M, Ruigrok W, Wicki B (2008) Research notes and commentaries: what passes as a rigorous case study? Strateg Manag J 29:1465–1474. https://doi.org/10.1002/smj.722

Giblin M, Ryan P (2012) Tight clusters or loose networks? The critical role of inward foreign direct investment in cluster creation. Reg Stud 46:245–258

Giblin M, Ryan P (2015) Anchor, incumbent and late entry MNEs as propellents of technology cluster evolution. Ind Innov 22:553–574. https://doi.org/10.1080/13662716.2015.1104243

Giuliani E (2011) Role of technological gatekeepers in the growth of industrial clusters: evidence from Chile. Reg Stud 45:1329–1348

Grabher G (1993) The wakness of strong ties. The lock-in of regional development in the Ruhr area. In: Grabher G (ed) The embedded firm: on the socioeconomic of industrial networks. Routledge, London, pp 255–277

Heidenreich M (2012) The social embeddedness of multinational companies: a literature review. Socio-Econ Rev 10:549–579. https://doi.org/10.1093/ser/mws010

Hervás-Oliver JL (2015) How do multinational enterprises co-locate in industrial districts? An introduction to the integration of alternative explanations from international business and economic geography literatures. Inv Reg J Reg Res 32:115–132

Hervás-Oliver J-L, Albors-Garrigós J (2008) Local knowledge domains and the role of MNE affiliates in bridging and complementing a cluster’s knowledge. Entrep Reg Dev 20:581–598

Humphrey J, Schmitz H (2002) How does insertion in global value chains affect upgrading in industrial clusters? Reg Stud 36:1017–1027

Iammarino S, McCann P (2006) The structure and evolution of industrial clusters: transactions, technology and knowledge spillovers. Res Policy 35:1018–1036. https://doi.org/10.1016/j.respol.2006.05.004

Jia X, Jiang M, Ma T (2015) The dynamic impact of industrial cluster life cycle on regional innovation capacity. Econ Res Istraživanja 28:807–829. https://doi.org/10.1080/1331677X.2015.1084475

Klepper S (2006) The evolution of geographic structure in new industries. Rev l’OFCE no 97 bis, pp 135–158

Kraus S, Meier F, Niemand T et al (2017) In search for the ideal coopetition partner: an experimental study. Rev Manag Sci 1–29. https://doi.org/10.1007/s11846-017-0237-0

Li PF, Bathelt H, Wang J (2012) Network dynamics and cluster evolution: changing trajectories of the aluminium extrusion industry in Dali, China. J Econ Geogr 12:127–155. https://doi.org/10.1093/jeg/lbr024

Lorenzen M, Mudambi R (2013) Clusters, connectivity and catch-up: bollywood and Bangalore in the global economy. J Econ Geogr 13:501–534. https://doi.org/10.1093/jeg/lbs017

Lowe M, Wrigley N (2010) The “continuously morphing” Retail TNC during market entry: interpreting tesco’s expansion into the United States. Econ Geogr 86:381–408. https://doi.org/10.1111/j.1944-8287.2010.01083.x

Malmberg A, Maskell P (2002) The elusive concept of localization economies: towards a knowledge-based theory of spatial clustering. Environ Plan A 34:429–449

Malmberg A, Maskell P (2006) Localized learning revisited. Growth Change 37(1):1–8. https://doi.org/10.1111/j.1468-2257.2006.00302.x

Manning S (2008) Customizing clusters: on the role of western multinational corporations in the formation of science and engineering clusters in emerging economies. Econ Dev Q 22:316–323. https://doi.org/10.1177/0891242408325585

Marin A, Bell M (2010) The local/global integration of MNC subsidiaries and their technological behaviour: argentina in the late 1990s. Res Policy 39:919–931. https://doi.org/10.1016/j.respol.2010.04.002

Markusen AR (1996) Sticky places in slippery space: a typology of industrial districts * the puzzle of stickiness in an increasingly slippery world. Econ Geogr 72:293–313. https://doi.org/10.2307/144402

Markusen A (2003) Fuzzy concepts, scanty evidence, policy distance: the case for rigour and policy relevance in critical regional studies. Reg Stud 37:701–717. https://doi.org/10.1080/0034340032000108796

Martin R, Sunley P (2001) Rethinking the “economic” in economic geography: broadening our vision or losing our focus? Antipode 33:148–161. https://doi.org/10.1111/1467-8330.00173

Martin R, Sunley P (2006) Path dependence and regional economic evolution. J Econ Geogr 6:395–437. https://doi.org/10.1093/jeg/lbl012

Martin R, Sunley P (2011) Conceptualizing cluster evolution: beyond the life cycle model? Reg Stud 45:1299–1318. https://doi.org/10.1080/00343404.2011.622263

Martínez-Mora C, Merino de Lucas F (2014) Offshoring in the Spanish footwear industry: a return journey? J Purch Supply Manag 20:225–237. https://doi.org/10.1016/j.pursup.2014.07.001

Maskell P, Malmberg A (2007) Myopia, knowledge development and cluster evolution. J Econ Geogr 7:603–618. https://doi.org/10.1093/jeg/lbm020

Maskell P, Bathelt H, Malmberg A (2006) Building global knowledge pipelines: the role of temporary clusters. Eur Plan Stud 14:997–1013

McCann P, Acs ZJ (2011) Globalization: countries, cities and multinationals. Reg Stud 45:17–32. https://doi.org/10.1080/00343404.2010.505915

McCann P, Mudambi R (2004) The location behavior of the multinational enterprise: some analytical issues. Growth Change 35:491–524. https://doi.org/10.1111/j.1468-2257.2004.00259.x

McCann P, Mudambi R (2005) Analytical differences in the economics of geography: the case of the multinational firm. Environ Plan A 37:1857–1876

Menzel M-P, Fornahl D (2010) Cluster life cycles—dimensions and rationales of cluster evolution. Ind Corp Change 19:205–238. https://doi.org/10.1093/icc/dtp036

Meyer CB (2001) A case in case study methodology. Field Methods 13:329–352. https://doi.org/10.1177/1525822X0101300402

Meyer KE, Mudambi R, Narula R (2011) Multinational enterprises and local contexts: the opportunities and challenges of multiple embeddedness. J Manag Stud 48:235–252. https://doi.org/10.1111/j.1467-6486.2010.00968.x

Miranda Encarnación JA (1998) La industria del calzado en España (1860–1959): la formación de una industria moderna y los efectos del intervencionismo estatal. Instituto de Cultura Juan Gil-Albert

Morrison A (2008) All gatekeepers of knowledge within industrial districts: who they are, how they interact. Reg Stud 42:817–835. https://doi.org/10.1080/00343400701654178

Morrison A, Rabellotti R, Zirulia L (2013) When do global pipelines enhance the diffusion of knowledge in clusters? Econ Geogr 89:77–96. https://doi.org/10.1111/j.1944-8287.2012.01167.x

Mudambi R (2002) Knowledge management in multinational firms. J Int Manag 8:1–9. https://doi.org/10.1016/S1075-4253(02)00050-9

Mudambi R (2008) Location, control and innovation in knowledge-intensive industries. J Econ Geogr 8:699–725. https://doi.org/10.1093/jeg/lbn024

Mudambi R, Navarra P (2004) Is knowledge power? Knowledge flows, subsidiary power and rent-seeking within MNCs. J Int Bus Stud 35:385–406. https://doi.org/10.1057/palgrave.jibs.8400093

Mudambi R, Swift T (2012) Multinational enterprises and the geographical clustering of innovation. Ind Innov 19:1–21

Mudambi R, Mudambi SM, Navarra P (2007) Global innovation in MNCs: the effects of subsidiary self-determination and teamwork. J Prod Innov Manag 24:442–455. https://doi.org/10.1111/j.1540-5885.2007.00262.x

Nachum L, Wymbs C (2005) Product differentiation, external economies and MNE location choices: M&As in global cities. J Int Bus Stud 36:415–434. https://doi.org/10.1057/palgrave.jibs.8400151

Nadvi K, Halder G (2005) Local clusters in global value chains: exploring dynamic linkages between Germany and Pakistan. Entrep Reg Dev 17:339–363

Narula R (2014) Exploring the paradox of competence-creating subsidiaries: balancing bandwidth and dispersion in MNEs. Long Range Plan 47:4–15. https://doi.org/10.1016/j.lrp.2013.10.006

Nguyen TXT, Diez JR (2017) Multinational enterprises and industrial spatial concentration patterns in the Red River Delta and Southeast Vietnam. Ann Reg Sci 59:101–138. https://doi.org/10.1007/s00168-017-0820-y

Østergaard CR, Park E (2015) What makes clusters decline? A study on disruption and evolution of a high-tech cluster in Denmark. Reg Stud. https://doi.org/10.1080/00343404.2015.1015975

Pettigrew AMA (1990) Longitudinal field research on change: theory and practice. Organ Sci 1:267–292. https://doi.org/10.1287/orsc.1.3.267

Phene A, Almeida P (2008) Innovation in multinational subsidiaries: the role of knowledge assimilation and subsidiary capabilities. J Int Bus Stud 39:901–919. https://doi.org/10.1057/palgrave.jibs.8400383

Piscitello L (2013) Multinationals and economic geography: location, technology and innovation. J Int Bus Stud 44:861–863. https://doi.org/10.1057/jibs.2013.38

Porter ME (1998) Clusters and the new economics of competition. Harv Bus Rev 76:77–90. https://doi.org/10.1042/BJ20111451

Potter A, Watts HD (2011) Evolutionary agglomeration theory: increasing returns, diminishing returns, and the industry life cycle. J Econ Geogr 11:417–455. https://doi.org/10.1093/jeg/lbq004

Randelli F, Boschma R (2012) Dynamics of industrial districts and business groups: the case of the Marche Region. Eur Plan Stud 20:1961–1974

Randelli F, Lombardi M (2014) The role of leading firms in the evolution of SME clusters: evidence from the leather products cluster in Florence. Eur Plan Stud 22:1199–1211. https://doi.org/10.1080/09654313.2013.773963

Ritala P, Kraus S, Bouncken RB (2016) Introduction to coopetition and innovation: contemporary topics and future research opportunities. Int J Technol Manag 71:1–9. https://doi.org/10.1504/IJTM.2016.077985

Rodríguez-Pose A, Crescenzi R (2008) Mountains in a flat world: why proximity still matters for the location of economic activity. Cambr J Reg Econ Soc 1:371–388. https://doi.org/10.1093/cjres/rsn011

Rubera G, Droge C (2013) Technology versus design innovation’s effects on sales and Tobin’s Q: the moderating role of branding strategy. J Prod Innov Manag 30:448–464. https://doi.org/10.1111/jpim.12012

Sedita S, Caloffi A, Belussi F (2013) Heterogeneity of MNEs entry modes in industrial clusters: an evolutionary approach based on the cluster life cycle model. druid8.sit.aau.dk

Sonderegger P, Täube F (2010) Cluster life cycle and diaspora effects: evidence from the Indian IT cluster in Bangalore. J Int Manag 16:383–397. https://doi.org/10.1016/j.intman.2010.09.008

Spillett MA (1998) Peer debriefing: who, what, when, why, how. Acad Exch Q 7:36

Stuart TE, Podolny JM (1996) Local search and the evolution of technological capabilities. Strateg Manag J 17:21–38. https://doi.org/10.1002/smj.4250171004

Swann P, Prevezer M (1996) A comparison of the dynamics of industrial clustering in computing and biotechnology. Res Policy 25:1139–1157. https://doi.org/10.1016/S0048-7333(96)00897-9

Ter Wal ALJ, Boschma R (2011) Co-evolution of firms, industries and networks in space. Reg Stud 45:919–933

Tokatli N (2014) Single-firm case studies in economic geography: some methodological reflections on the case of Zara. J Econ Geogr. https://doi.org/10.1093/jeg/lbu013

Tortajada E, Fernández I, Ybarra J (2005) Evolución de la industria española del calzado: factores relevantes en las últimas décadas. Econ Ind 355:211–227

Uhlenbruck K (2004) Developing acquired foreign subsidiaries: the experience of MNES in transition economies. J Int Bus Stud 35:109–123. https://doi.org/10.1057/palgrave.jibs.8400070

Valdaliso J, Elola A, Aranguren M, Lopez S (2011) Social capital, internationalization and absorptive capacity: the electronics and ICT cluster of the Basque Country. Entrep Reg Dev 23:707–733. https://doi.org/10.1080/08985626.2010.505268

Wang L, Madhok A, Xiao Li S, Francisco S (2014) Agglomeration and clustering over the industry life cycle: toward a dynamic model of geographic concentration. Strateg Manag J 1012:995–1012. https://doi.org/10.1002/smj

Ybarra JA (2000) La infomalización como estrategia productiva. Un análisis del calzado valenciano. Rev Estud Reg 57:199–217

Ybarra JA (2006) La experiencia española en distritos industriales: realidad de un concepto para la PYME y el territorio. Econ Ind 359:89–94

Yeung HWC (2003) Practicing new economic geographies: a methodological examination. Ann Assoc Am Geogr 93:442–462. https://doi.org/10.1111/1467-8306.9302011

Yin RK (1984) Case study research: design and methods. SAGE Publications, New Delhi

Yin RK (2009) Case study research: design and methods (Applied social research methods). Sage, Newbury Park, CA

Acknowledgements

José Antonio Belso-Martínez wishes to thank the Project ECO2015-67122-R funded by the Ministry of Economy and Competitiveness (Spain) and Francisco Más-Verdú for their support for this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Belso-Martínez, J.A., López-Sánchez, M.J. & Mateu-García, R. New MNE subsidiaries in old clusters: when, why, and how. Rev Manag Sci 12, 441–467 (2018). https://doi.org/10.1007/s11846-017-0268-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11846-017-0268-6