Abstract

The main objective of this study was to determine the effect of different frying oils and frying methods on the formation of trans fatty acids and the oxidative stability of oils. Sunflower, canola and commercial frying oils, the most commonly used oils for frying potatoes in the fast food industry, were used as the frying medium. The value for total polar compounds was highest when commercial frying oil was used in the microwave oven (22.5 ± 1.1). The peroxide value, as an indicator of oil oxidation, was lowest for microwave oven frying (2.53 ± 0.03). The K232 and K270 values were 0.41 ± 0.04 and 0.18 ± 0.02, respectively, for commercial frying oil in the microwave oven. The lowest free fatty acid content was recorded for the commercial frying oil used in the deep-fat fryer at 190 °C. The highest iodine value was measured for sunflower oil used in the deep-fat fryer (148.14 ± 0.07), indicating a greater degree of unsaturation. The lowest trans fatty acid value was recorded for sunflower oil in the microwave oven (0.17 ± 0.05), with a higher overall amount of total trans fatty acids observed for oils after frying in the electrical deep-fat fryer compared to the microwave. Sunflower oil was favourable for both frying methods in terms of the trans fatty acid content.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

trans Fatty acids (TFA) are a group of unsaturated fatty acids that contain one or more isolated, non-conjugated double bonds in a trans geometric configuration. Consumption of TFA has been associated with an increased risk of cerebrovascular disease, coronary heart disease, diabetes and even breast cancer [1,2,3,4,5]. In addition, TFA have been found to have adverse effects on blood lipids, including increased LDL cholesterol and decreased HDL cholesterol concentrations [6]. The presence of TFA in the human diet is thought to be partly due to hydrogenated oils. Vegetable oils are hydrogenated to produce a more stable product, which usually requires the presence of a metal catalyst and hydrogen. As a result, the number of double bonds in unsaturated fatty acids is decreased, also associated with a conformational conversion from cis to trans to some extent [6]. Besides hydrogenation, other processes including thermal refining, bleaching and deodorisation can lead to the formation of trans isomers. Considering the wide use of thermal-based processes in food, the trans isomerisation of unsaturated fatty acids gains high significance in these processes, and are amongst the most common unsaturated fatty acids. Furthermore, linolenic acid is considered to be the fatty acid responsible for the majority of TFA production [7]. Frying, primarily deep-fat frying, is the most widely used thermal-based cooking method by food manufacturers, with different vegetable oil sources used as the heating medium in these processes. Deep-fat frying has been accepted as a cooking process that increases TFA production, in which the formation of TFA is dependent on the processing conditions applied, including the temperature, time and oil type and also fatty acid composition of oil and presence of antioxidants affected formation of TFA [8,9,10,11,12].

Frying is one of the most widely used food preparation procedures worldwide. The remarkable popularity of frying is due to its favourable properties, including a short cooking time, easy handling, low investment cost and attractive taste and colour of the final product. However, frying and fried foods are not without fault, and some issues need to be considered regarding the frying processes. These primarily involve negative changes in the frying oil due to extreme time-temperature, the high sensitivity of vegetable oils to thermal effects, effects of intermittent or continuous heating, the content of fresh oil and the fryer model [9,10,11,12,13]. During the frying process, an edible fat is heated above the boiling point of water, resulting in food becoming partially or totally dry. Fat also migrates into the food, accompanying the movement of water out of the food product [14,15,16]. Thus, deep-fat frying is accepted as a complicated physicochemical process [17,18,19]. During the frying process, a number of chemical reactions take place in the oil, including hydrolysis, oxidation, cyclisation and polymerisation, and the resulting products can modify the physical and chemical characteristics of edible oils, such as the viscosity, fatty acid composition and total polar materials [20].

As mentioned above, both the favourable and adverse effects of thermal processing is dependent on the temperature and time pairs applied. Consequently, new techniques that provide a potential alternative to conventional frying methods are being investigated in order to overcome these issues. For frying processes, including deep-fat frying, microwave technologies are increasingly being considered as a new technique to improve the quality of processed foods and the processing medium. The mechanisms underlying microwave technologies have been well-documented. Briefly, heating occurs due to the generation of internal heat from absorption of energy from the microwave field, resulting in the generation of internal vapour. An increase in the internal pressure leads to an acceleration in mass transfer, and consequently, faster movement of moisture throughout the frying material compared to that observed for conventional heating methods [21,22,23].

In the current study, the effect of the oil type, frying conditions (time and temperature) and frying technique were investigated in terms of formation of TFA in the frying oil and the overall product quality. No studies in the literature have evaluated the microwave-assisted frying (MAF) techniques on both the TFA content and oxidative parameters of frying oil. Therefore, MAF was compared to commercial deep-fat frying methods in this study. Different frying oils and frying techniques were selected to compare the formation of undesirable oil characteristics. Sunflower, canola and commercial frying oils were used to determine the effect of oil type. These oils were chosen as canola and sunflower oils represent the preferred frying medium in homes and the fast food industry, and commercial frying oil was included to widen the scope of this study. Several processing conditions were applied for each frying method in order to compare the effect of temperature on oxidative parameters and TFA content of the oils. Microwave assisted-frying was also compared to conventional deep-fat frying to determine differences in product quality parameters.

Materials and Methods

Food Samples

Frozen pre-fried potatoes were purchased from a local market (Nimet, Turkey). Frozen potatoes (stored at −18 °C) were chosen to ensure that samples had been treated under the same conditions, and to avoid losses in quality attributes. Samples were stored at −18 °C in a freezer until frying.

Frying Procedure

Deep-fat frying was carried out using commercially available electrical deep-fat fryers (DFF) equipped with a thermostat (Remta, Turkey). The fryer had two tanks and the capacity of each tank was 3 l. Sunflower, canola and commercial frying oils were supplied by Zade Oil Industry (Konya, Turkey). Commercial frying oil is mainly used in the fast food industry to fry potatoes and this oil was produced using palm oil. The fryer utilised was able to control the oil temperature within ±5 °C from the set temperature. The temperature of the frying oil was set by fryer and also measured by an infrared thermometer (Testo 830T1). The oil (2000 ml of sunflower, canola or commercial frying oil) was heated to 160 or 190 °C, and the potato strips [1:100 (w/v) potato strips:oil remaining in the fryer] were fried for 4 min, when they had reached a desirable colour and texture. New batches of potatoes were used for each frying cycle, with the first batch used to determine the quality parameters of fried potatoes. Frying was conducted three times in the same oil at the same temperature. After each batch, 20 ml of heated oil was obtained from the fryer to analyse the oil properties, then 20 ml of fresh oil was added to replace the oil removed, which was left to reach the desired temperature. Frying was completed after three frying cycles. The frying oil was renewed after each three frying cycle to avoid accumulation of any modified oil products produced during frying, with 2000 ml of fresh oil added. Oil samples that were collected after the DFF and MAF frying experiments were maintained at −18 °C under N2 until the analysis. The oil type, frying temperature and frying cycle were the experimental factors evaluated in the electrical DFF experiment.

The MAF procedure was conducted using a domestic microwave oven (MA3882Q; LG, Korea). Two power levels, 600 and 900 W, were tested in the experiments, which were determined by the IMPI 2-L test [23]. Microwave frying was performed using a glass (28 cm in diameter and 5 cm high) container filled with 2000 ml of oil. Firstly, the room-temperature oil was heated to a temperature depending on the power level of the microwave oven (600 or 900 W). The potato strips were then placed in the hot oil, and frying was performed in the microwave at the specified power and time. The frying and sampling procedure for microwave frying was kept similar to that used for DFF, in order to compare the physical properties of the fried potato and the oxidation parameters of the frying oil. The oil was replaced after three frying cycles, as also performed for DFF. In addition to the oil type and microwave power level, the third variable tested in the experimental design was the frying cycle for both frying methods. The temperature of the oil used for MAF was determined to be 127 ± 3 °C at 600 W and 150 ± 4 °C at 900 W. All of the experiments were carried out in triplicate.

Analysis of Fried Samples

Moisture Content

The fried samples that were collected after the first cycle were dried in a forced convection oven at 105 ± 3 °C until a constant weight had been reached, in order to determine the moisture content (MC) [24]. Five potatoes (nearly 25 g) strips were picked up and dissected by a knife to determination of MC. Analysis of MC was performed 30 min after the frying cycle. The MC before and after frying was calculated, and the moisture loss is presented as a percentage of the dry weight.

Oil Content

The oil content of the fried samples was determined using a speed extraction method with n-hexane for 2 h (E06; Behr, Germany) [25]. Dried potatoes samples were used for oil content analysis. After extraction samples were dried at 60 °C and weighed. The oil content were calculated on a dry weight basis.

Texture Profile

The texture of the samples was determined in terms of their toughness (kg) and work of shear (kg·mm). A extended craft knife probe was attached to the instrument. Work of shear and toughness values were obtained by cutting the potato samples with the knife. The instrument was set to 5 mm/s for cutting the fried samples. Forces (g) vs time (s) curves were generated with the extended knife probe and peak value gave toughness value (kg) of samples. Area of the curve that was calculated by the toughness (kg) and distance (mm) of potatoes strip till the peak value gave work of shear (kg·mm) value. The texture parameters of the fried samples were measured using a texture analyser (TA.XT Plus; Stable Micro Systems, UK) 15 min after frying at room temperature.

Colour

The colour parameters of fried potatoes were measured using a colour reader (CR-400; Konica Minolta, Japan). The colour measurement was performed 15 min after frying, and colour readings are expressed as chromaticity coordinates (L * , a * and b *). L *, a * and b * values represent the whiteness-darkness, redness-greenness and blueness-yellowness of the samples, respectively. Triplicate readings were carried out at five different locations of each sample, at room temperature, and the mean value was recorded.

Oil Analysis

Free Fatty Acid Content, Peroxide Value, Specific Extinction Coefficients, Iodine Value, Saponification Value and Total Polar Compounds

Free fatty acid (FFA) content, peroxide value (PV), specific extinction coefficients (K232 and K270 value), iodine value (IV) and saponification value (SV) were determined according to the methods established by the American Oil Chemists’ Society (AOCS) (Ca 5a-40, Cd 8-53, Ch 5-91, Cd 1c-85 and Cd 3b-76, respectively [26]). Measurement of the total polar compound (TPC) content was determined using a cooking oil tester (270; Testo Inc., Sparta, NJ, USA) after potatoes had been removed from the oil. The oil sampling process was performed after the TPC measurement.

Methyl Ester Analysis by Gas Chromatography

Methyl esters of the fatty acids and their isomers were prepared according to IUPAC methods [27], and analysed using a Shimadzu GC-2010 Plus gas chromatograph (Kyoto, Japan) equipped with a DB23 column (60 m, 0.25 mm i.d., 0.25 mm film thickness, J&W). The standards of fatty acid were supplied from Supelco 37 FAME Mix. The injector, column and detector temperatures were set to 230, 190 and 240 °C, respectively. The split ratio was 1:80, and the carrier gas was helium at a flow rate of 1 ml/min.

Statistical Analysis

Each of the frying experiments was replicated three times under each experimental condition. The data obtained from analysis were evaluated by analysis of variance (ANOVA) to determine any significant differences between the oil type, frying method, frying temperature or frying power on the quality parameters of fried potatoes and oil parameters, with p < 00.05 considered statistically significant (Minitab 17.0). The parameters were compared using Tukey’s test (SPSS 15.0).

Results and Discussion

Fried Potato Results

Moisture Content

The initial MC of frozen potatoes was found to be 72.91 ± 1.34% on a wet basis, and a remarkable change was observed when they were fried. The change in MC of fried potatoes depended on both the processing conditions and the type of oil. Statistical analysis indicated that the frying temperature, microwave power and oil type significantly affected the MC of fried potatoes (p < 0.05). When canola oil was used in DFF no difference was observed between moisture loss at 160 and 190 °C (Fig. 1). Regardless of oil type, the MC of fried potatoes decreased with increasing frying temperature for the DFF technique, whereas there was a negative influence of microwave power in MAF, as moisture movement throughout the frying potatoes at 900 W was reduced when compared to those fried at 600 W (Fig. 1). This favourable effect of reduced frying temperature on moisture removal from potato samples could be attributed to the heat transfer mechanism that occurs during frying. Frying at higher temperatures increases the temperature difference between the heating medium and frying material, and as a result, higher transfer of heat energy occurs. Higher heat energy means greater evaporation of water from the solid matrix during the frying process, which enhances the reduction in water content. Similar results have been reported in the literature [16, 28]. Moisture evaporation is an important quality parameter and it will also lead to shrinkage and surface porosity and roughness of fried food samples [28]. On the other hand, microwave power had an adverse effect on the formation of a crust surrounding the material, which acts as a barrier against the loss of moisture. It is well-known that heating not only occurs by convection and conduction mechanisms of energy transfer, but also by heat generation throughout the whole solid, due to the dipolar moment of polar compounds, like water molecules. A sudden increase in the temperature of layers closer to the outer surface likely accelerates water evaporation and removal, resulting in the formation of a stronger crust which further limits moisture transfer from the internal layers to the outer surface of frying potatoes. The percentage moisture loss from frying potatoes was found to be highest when the commercial frying oil was used as the heating medium, with sunflower oil ranked second. The lowest change in MC was observed when canola oil was used as the frying medium (Fig. 1). The highest reduction in the MC of fried potatoes (~60% of initial content) was observed when they were fried in commercial frying oil by MAF at 600 W (Fig. 1). The influence of oil type on the MC of fried potato samples may be associated with the physical properties of the oil, such as the viscosity, specific heat and surface tension, as the physical properties are important determining characteristics for heat and mass transfers that occur during this process. The highest moisture removal was achieved in MAF.

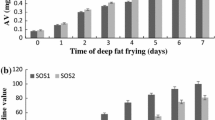

Texture

The effects of the different frying methods (DFF and MAF), related parameters (temperature for DFF and power for MAF), and the three types of oil (sunflower, canola and commercial frying oil) on the texture of fried potatoes was examined in terms of work of shear (kg·mm) and toughness (kg). After frying, samples were cut using the knife probe to investigate the external crust and internal structural properties of fried potatoes. The average work of shear value for potatoes fried by DFF in three types of oil increased with increasing temperature from 2.65 ± 0.16 to 2.95 ± 0.10 kg·mm when fried at 160 and 190 °C, respectively (Fig. 2a). Similarly, increasing the microwave power caused an increase from 2.04 ± 0.09 kg·mm (frying at 600 W) to 2.50 ± 0.83 kg·mm (frying at 900 W) for MAF (Fig. 2b). The increased work of shear value gives an indication of the internal properties of samples, such as the MC. The microwave power level of MAF and the fryer type significantly affected (p < 0.05) the work of shear value for the fried potatoes. In addition, significant changes were observed in DFF for sunflower oil and in MAF for canola and frying oil (p < 0.05) (Fig. 2a). The highest toughness value (0.92 ± 0.16 kg) was measured for the sample fried by MAF at 900 W in commercial frying oil, indicating that this sample would be harder to cut with a knife. When the toughness values of potatoes cooked by the two frying methods were compared, the mean toughness value of three frying medium from MAF (0.72 ± 0.16 kg) was slightly higher than DFF (0.69 ± 0.17 kg). Overall, harder fried potato samples were obtained by increasing the frying process parameters. These results are consistent with a previous study that investigated changes in potato texture, which reported the formation of harder samples at higher frying temperatures [29].

Colour

In this study, the colour parameters of fried potatoes were determined in addition to their textural properties in order to further evaluate the quality parameters of the fried samples. Colour is an important factor for consumer acceptance of fried potatoes, and this parameter can be controlled by using specific processing conditions. The colour parameters of fried potatoes are presented in Table 1. Higher brightness values were obtained for samples fried in sunflower oil in a commercial DFF. The temperature of the DFF and frying type both affected the L *and a * values of fried potatoes, however, the b * value was only altered by the frying temperature (p < 0.05). Similar a * and b * values were measured for potato strips fried in the three oils and for both fryer types tested (MAF and DFF). The highest a * value measured was −0.58 ± 0.02 for potatoes fried in commercial frying oil using DFF at 190 °C. The higher frying temperature resulted in a darker potato sample (low L * values) due to non-enzymatic reactions. Fried potatoes are an example of a food whose consumer appreciation is affected by its colour parameters. Baik and Mittal [30] studied the quality parameters of fried potatoes, and reported that frying at higher temperatures or for longer periods of time resulted in products with a harder crust and a darker brown colour. The change in quality parameters of fried products in the present study, specifically the values obtained for texture and colour parameters, are consistent with those reported in the literature [31].

Oil Uptake

The oil content of potatoes prior to frying was 9.26 ± 0.72% on a dry basis, as the frozen potato strips had been partially fried before freezing during the manufacturing process. The oil content of fried potatoes is shown in Fig. 3. The oil absorption of samples increased with frying temperature and microwave power. The maximum oil content measured was 27.03 ± 1.7% db for potatoes fried in canola oil by MAF at 900 W, with the lowest oil content (11.65 ± 0.56% db) observed for the frying oil at 600 W. In addition, microwave frying was associated with decreased oil uptake (17.96 ± 1.48% db) compared to commercial DFF (22.02 ± 1.54% db), determined by the mean oil content of fried potatoes that had been fried in three different oils and at two power/temperature levels. All of the evaluated factors hardly affected the oil content of potato samples (p < 0.05). Previous studies by Krokida et al. [32] and Southern et al. [33] observed that higher frying temperatures increased the oil content of the samples. Oil tends to replace water inside the product, as shrinkage of the product during frying is incomplete. Furthermore, the adhered oil is forced into the chips when they are removed from the fryer due to the vacuum produced by the condensation of steam.

Oil Results

Total Polar Compounds

Polar degradation products were produced during DFF processing through hydrolysis, oxidation and polymerisation. The values of TPC obtained for the different oils are shown in Table 2. TPC increased in all three oils with higher frying temperature and microwave power for DFF and MAF, respectively. The formation of polar compounds in these three oils, indicating oil deterioration, is strongly related with the primary and secondary oxidation processes that take place during frying. The highest increase (200%) and highest TPC value was observed in commercial frying oil using MAF at 600 W (22.5 ± 0.4%). The lowest increase in TPC was measured for sunflower oil using DFF at 160 °C (33.3 ± 2.0%), therefore, sunflower oil is favourable in terms of TPC. Guillen and Uriarte [34] previously reported that the percentage of TPC in sunflower oil increases linearly during frying under the same conditions. The frying parameters evaluated in the current study were found to be important for increasing the TPC content of oils (p < 0.05). Firestone et al. [35] reported an increase in the TPC content of frying oil by 200% as a result of microwave frying. The acceptable standard for TPC of this study is below 25%, according to guidelines established by European Countries [36].

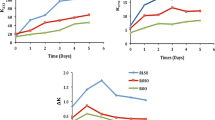

Peroxide Value (PV)

The PV is indicative of the initial stage of oxidation, and measures the primary oxidation products. According to the Turkish Codex Standards, the PV of vegetable oil should not exceed 10 mequiv O2/kg [37]. Freshly refined oils usually have a PV lower than 1 mequiv/kg oil, with oil considered to be rancid when the PV is above 10 mequiv/kg oil [38]. Sulieman et al. [39] reported that a good quality vegetable oil for frying should have PV less than 2 mequiv/kg oil. The PV of the three types of oil used under different frying conditions are shown in Table 3. The initial PV of sunflower, canola and commercial frying oils were determined to be 5.99 ± 0.22, 1.79 ± 0.09 and 2.13 ± 0.15 mequiv O2/kg, respectively. Considering these initial PV, there was a clear increase in PV for all samples after frying, regardless of the oil type, frying method or temperature. The results indicated that the oil type, fryer type, frying temperature and microwave power level all significantly affected the PV of oil samples (p < 0.05). The highest PV measured was 9.65 ± 0.13 mequiv O2/kg in sunflower oil after the first cycle of MAF at 600 W. Lower PV was observed for the commercial frying oil with the microwave oven, with the minimum value of 2.54 ± 0.03 mequiv O2/kg oil obtained after the second cycle of MAF at 600 W. Urbancic et al. [40] reported an initial sunflower oil PV of 1.21 mequiv/kg oil, which increased with frying time. The lowest mean PV (4.60 ± 0.13 mequiv O2/kg oil) was measured in commercial frying oil when MAF was used. Naz et al. [41] reported that deep frying French fries at 180 °C caused an increase in the PV of some vegetable oils. An increased PV of the frying medium was expected in the current study. Hydroperoxides are transient chemical compounds, which despite being related to the oxidative status of vegetable oils, are not always directly correlated with sample oxidation, especially for heated samples. This may explain the absence of a correlation between the number of frying cycles and the PV of fried potatoes. Furthermore, the decomposition of hydroperoxides is known to increase with increasing temperature.

Specific Extinction Coefficients (K232 and K270)

The ultraviolet spectrophotometric analysis, expressed as the specific extinction coefficients K232 and K270, indicates the oil oxidation status by providing information on the quality, preservation state and/or changes brought about by the technological processes. The K232 value is associated with the formation of conjugated dienes of polyunsaturated fatty acids, while the K270 value is indicative of the presence of primary and secondary oxidation products, including conjugated trienes and carbonyl compounds. The K232 and K270 values for sunflower, canola and commercial frying oils before frying were 2.07 ± 0.18, 1.41 ± 0.12 and 0.84 ± 0.10 for K232, and 0.81 ± 0.11, 0.30 ± 0.09 and 0.22 ± 0.09 for K270, respectively. The K232 values of sunflower oil increased by ≥20% after it had been used for MAF (Table 3). The K232 values measured for the commercial frying oil were lower than those measured for the other oil types tested, regardless of the fryer type or processing conditions. K270 values of sunflower oil were greater than those measured for the other oil types, especially for MAF. The lowest values of K270 and K232 observed were 0.17 ± 0.05 and 0.41 ± 0.02 in the commercial frying oil after the third cycle of frying in a microwave oven at 600 W. Casal et al. [42] reported an increase in K232 values in olive oil after frying, which remained within the legislation limits (Annexes II and IX of the European Community Regulation EEC/2568/91). Statistical comparison was performed to determine the differences between K232 and K270 values of oils with different processing conditions (temperature or power level), fryer type and oil type. The results showed that each of these parameters significantly affected the K232 values, but only the oil type was significant for the K270 values (p < 00.05).

Saponification Value (SV)

The SV is an index of the average molecular mass of fatty acids in the oil sample. For fresh sunflower, canola and commercial frying oils, the SV were determined to be 189.99 ± 2.01, 187.28 ± 3.89 and 193.82 ± 4.10, respectively. The oil type and fryer type were found to significantly affect the SV of oils after frying (p < 0.05). The lowest SV value was 184.66 ± 1.85, measured in commercial frying oil after the third frying cycle in the microwave oven at 900 W (Table 3). This higher SV suggests that the mean molecular weight of fatty acids was lower. This potentially suggests that the fat molecules did not interact with each other [43].

Free Fatty Acid Content

The FFA content of fresh sunflower, canola and frying oils were 0.22 ± 0.05, 0.23 ± 0.04 and 0.11 ± 0.04%, respectively, for oleic acid. The mean FFA content of each oil type was calculated for the three frying cycles under the specified processing conditions, with the highest and lowest mean values of 0.41 ± 0.00 and 0.11 ± 0.00% observed for sunflower oil and commercial frying oil, respectively (Table 3). The TPC and FFA values are related, therefore, the results for TPC supported the FFA results. The oil type, frying temperature, microwave power and fryer type were found to significantly affect the FFA content (p < 0.05), however, there was no significant change in the FFA content of sunflower oil, and this value was only slightly increased for canola and commercial frying oil used in DFF. Although the initial value for fatty acid content was almost the same as that measured for sunflower oil before frying, there was an increase in the FFA content of canola oil after frying. Lower values were observed for sunflower oil after MAF compared to DFF, but higher values were obtained for the commercial frying oil and canola oil used in MAF (Table 3). These results suggest that sunflower oil is appropriate for MAF in terms of the FFA content.

Iodine Value (IV)

The IV measures the degree of unsaturation in fat or vegetable oil. It represents the stability of oil against oxidation, and allows the overall unsaturation of fats to be qualitatively determined [44]. The IV for sunflower, canola and frying oils were 128.89 ± 0.05, 110.13 ± 0.95 and 56.13 ± 0.51, respectively. These low IVs may have contributed to its greater oxidative storage stability. Table 3 shows the IV of the different frying oils. The lowest IV was 50.90 ± 0.25, observed for the commercial frying oil used for frying at 190 °C in the DFF. On the other hand, the highest IV was recorded as 148.14 ± 0.078 in sunflower oil at 160 °C in the DFF. The IVs obtained are consistent with the FFA results. The oxidative and chemical changes in oils during storage are characterised by an increase in FFA content and a decrease in the total unsaturation of oils [45].

Total trans Fatty Acids and Fatty Acid Composition

The detailed fatty acid composition of the oils prior to frying and after frying is presented in Table 4. The TFA detected in fried oils were elaidic acid (18:1t), linoelaidic acid (18:2t) and linolenic acid (18:3t). Linoelaidic acid (18:2t) comprised between 50 and 90% TFA for the three types of vegetable oils. The fatty acid peaks obtained from gas chromatography of canola oil are shown in Fig. 4. The TFA content of commercial frying oil was higher than the other oil types, with the lowest value (0.0836%) measured in sunflower oil (Table 4). TFA decreased in sunflower oil used for frying at 160 °C (or 600 W), whereas it was increased at 190 °C (or 900 W) for both frying methods. When canola oil was used, the total TFA values were similar for the two frying procedures. The highest TFA content for canola oil was 0.4618% after the third frying cycle by MAF at 600 W. For canola oil, increased TFA were observed after the third frying cycle for both methods, however, a similar increase was only measured for sunflower oil after the third frying cycle using the microwave frying method. Similar total TFA values were obtained from both frying methods for commercial frying oil, and results were not affected by the frying temperature or microwave power. Thermal oxidation explains the increase in total TFA values, in addition to the frying time and presence of oxygen. In previous studies that have evaluated the frying of potatoes, an increased TFA content was observed in soybean and vanaspati oils with increasing frying time and temperature [46, 47]. A decrease in the level of total TFA was observed in sunflower oil used for DFF at 160 °C. This decrease is likely due to breaking of the fatty acid chains and degradation of the chain structure. The abundance of trans linoleic acids in sunflower oil has also been reported previously [48]. The fatty acid composition of fresh sunflower, canola and commercial frying oils are also shown in Table 4. Sunflower oil showed a much lower value for total TFA compared to the other oil types. One of the reasons for this difference was related to the initial TFA content of sunflower oil, as the TFA value was decreased after frying. The total TFA content was decreased by 8.47% in sunflower oil after frying, whereas an increase was observed for both canola and commercial frying oils. The highest increase in TFA content observed was 69.05% for canola oil and 22.78% for commercial frying oil.

Frying altered the fatty acid composition of oils, which was affected by both the frying temperature and time. Table 4 shows the change in fatty acid composition for the different frying temperatures, oils and frying methods. The oleic acid content of sunflower oil increased with frying temperature and microwave power, but no other important changes were observed in the other oil types. The content of linoleic acid in the frying oil increased after MAF due to oil oxidation, which occurred due to the heat in the microwave oven. The monounsaturated fatty acid (MUFA) content of canola oil was higher than the other oils, within the meaning of unused oils, despite sunflower oil containing the highest polyunsaturated fatty acid (PUFA) content (Table 4). While the MUFA content of sunflower oil decreased after frying (5.90%), this value was increased in canola oil (5.21%) and commercial frying oil (14.42%). The PUFA content of canola oil decreased (9.97%) after frying, but was increased in the other oils. The sum of MUFA and PUFA gives the total unsaturated fatty acid (UFA) content of the oils, which was found to be lowest in the commercial frying oil, accompanied by the highest saturated fatty acid (SFA) content (44.26%), due to the frying process.

Conclusion

The two frying methods (DFF and MAF), two frying temperatures (160 and 190 °C in DFF, 600 and 900 W in MAF) and three types of oil used as the frying medium (sunflower, canola and commercial frying oil) were used to determine the total TFA content and other oxidative parameters of oils for frying. The quality parameters of fried potatoes were also evaluated in terms of the frying conditions and oil type. Commercial frying oil was found to have the highest amount of total TFA, with the lowest value obtained for sunflower oil. In general, higher total TFA were observed for DFF compared to MAF for the same type of oil. Therefore, MAF may be a favourable process in terms of total TFA production. In addition, sunflower oil appeared to be the best oil for both frying techniques. The toughness of MAF samples, indicating the hardness, was found to be greater than those fried by DFF. The MC was found to decrease with increasing microwave power, however, both the TPC and oil uptake of potatoes increased. Darker fried potato samples were obtained using all frying parameters. Higher PV was observed for DFF compared to MAF, and the highest PV was measured in sunflower oil. The SV and FFA content of canola oil was also higher than the other oil types. Specific extinction values at 232 and 270 nm were highest in sunflower oil, which also presented the highest IV. The SFA content of commercial frying oil was higher than the other oil types. A slow and also less homogeneous heating process resulting from the use of conventional heating methods is considerably more aggressive than a fast homogeneous heating process in a microwave oven at higher powers. Using a microwave oven for frying in the home offers a safe and fast alternative method to the usual process. In addition, process conditions can be improved in terms of quality of final product and oxidative stability and formation of TFA in the frying oil.

References

Mozaffarian D, Katan MB, Ascherio A, Stampfer MJ, Willett WC (2006) trans Fatty acids and cardiovascular disease. New Eng J Med 354:1601–1613

Oomen CM, Ocke MC, Feskens EJM, Erp-Baart MJ, Kok FJ, Kromhout D (2001) Association between trans fatty acid intake and 10-year risk of coronary heart disease in the Zutphen Elderly Study: a prospective population-based study. Lancet 357:746–751

Kim SH, Chunawala L, Linde R, Reaven GM (2006) Comparison of the 1997 and 2003 American Diabetes Association classification of impaired fasting glucose: impact on prevalence of impaired fasting glucose, coronary heart disease risk factors, and coronary heart disease in a community-based medical practice. J Am Coll Cardiol 48:293–297

Kohlmeier L (1997) trans-fatty acids and breast cancer. Food and Chem Toxicol 35:1228–1234

Albuquerque TG, Costa HS, Castilho MC, Sanches-Silva A (2010) Trends in the analytical methods for the determination of trans fatty acids content in foods. Trends in Food Sci Technol 22(10):543–560

Khor GL, Esa NM (2008) trans Fatty acids intake: epidemiology and health implications. In: Dijkstra AJ, Hamilton RJ, Hamm W (eds) Trans fatty acids. Blackwell Publishing, Oxford, pp 25–45

Grandgirard A, Sebedio JL, Fluery J (1984) Geometrical isomerization of linolenic acid during heat treatment of vegetable oils. J Am Oil Chem Soc 61(10):1563–1568

Moreno M, Olivares DM, Lopez FJA, Adelantado JVG, Reig FB (1999) Determination of unsaturation grade and trans isomers generated during thermal oxidation of edible oils and fats by FTIR. J Mol Struc 482–483:551–556

Bansal G, Zhou WB, Tan TW, Neo FL, Hl Lo (2009) Analysis of trans fatty acids in deep frying oils by three different approaches. Food Chem 116:535–541

Albuguerque TG, Sanches-Silva A, Santos L, Costa HS (2011) An update on potato crisps content of moisture, fat, salt and fatty acids (including trans-fatty acids) with special emphasis on new oils/fats used for frying. Int J Food Sci and Nutrition 63(6):713–717

Janoszka B, Blaszczyk U, Damasiewicz-Bodzek A, Sajewicz M (2009) Analysis of heterocyclic amines (HAs) in pan-fried pork meat and its gravy by liquid chromatography with diode array detection. Food Chem 113:1188–1196

Albuguerque TG, Oliveria MBPP, Sanches-Silva A, Bento AC, Costa HS (2016) The impact of cooking methods on the nutritional quality and safety of chicken breaded nuggets. Food Funct 7:2736–2746

Ziaiifar AM, Courtois F, Trystram G (2010) Porosity development and its affect on oil uptake during frying process. J Food Process Eng 33(2):191–212

Ahromrit A, Nema PK (2010) Heat and mass transfer in deep-frying of pumpkin, Sweet potato and taro. J Food Sci and Technol 47:632–637

Dincer I (1996) Modelling for heat and mass transfer parameters in deep-frying of products. Heat Mass Transf 32:109–113

Ni H, Datta AK (1999) Moisture, oil and energy transport during deep-fat frying of food materials. Food Bioprod Process 77:194–204

Chatzilazarou A, Gortzi O, Lalas S, Zoidis E, Tsaknis J (2006) Physicochemical changes of olive oil and selected vegetable oils during frying. J Food Lipids 13:27–35

Kalogianni EP, Karastogiannidou C, Karapantsios TD (2010) Affect of potato presence on the degradation of extra virgin olive oil during frying. Int J Food Sci Technol 45:765–775

Rojo JA, Perkins EG (1987) Cyclic fatty acid monomer formation in frying fats. 1. Determination and structural study. J Am Oil Chem Soc 64:414–421

Gertz C (2000) Chemical and physical parameters as quality indicators of used frying fats. Eur J Lipid Sci Tech 102(8–9):566–572

Barutcu I, Sahin S, Sumnu G (2009) Acrylamide formation in different batter formulations during microwave frying. LWT-Food Sci and Technol 42:17–22

Oztop MH, Sahin S, Sumnu G (2007) Optimization of microwave frying of potato slices by using Taguchi Technique. J Food Eng 79:83–91

Sahin S, Sumnu G, Oztop MH (2007) Affect of osmotic pretreatment and microwave frying on acrylamide formation in potato strips. J Sci Food Agri 87(15):2830–2836

Buffler C (1993) Microwave cooking and processing: Engineering fundamentals for the food scienti. AVI Book, New York, pp 6–7 150–151

AOAC (1984) Association of Official Analytical Chemists, 14th edn. AOAC Press, Washington

AOCS (2003) Official methods and recommended practices of the American Oil Chemists’ Society. AOCS Press, Champaign

Anonymous (1987) Standard methods for analysis of oils, fats and derivatives, 7th edn. Blackwell Scientific, Oxford IUPAC Method 2.301

Baltacioglu C, Esin A (2012) Chips production from Jerusalem artichoke (Helianthus tuberosus L.). Food and Nutri Sci 3:131–1328

Pedreschi F, Moyano P (2005) Affect of pre-drying on texture and oil uptake of potato strips. LWT-Food Sci Technol 38(6):599–604

Baik OK, Mittal GS (2003) Kinetics of tofu color changes during deep fat frying. Lebenmittel Wiss Und Technoogie 36:43–48

Pedreschi F, Moyano P, Kaack K, Granby K (2005) Color changes and acrylamide formation in fried potato slices. Food Res Int 38(1):1–9

Krokida MK, Oreopoulou V, Maroulis ZB (2000) Water loss and oil uptake as a function of frying time. J Food Eng 44(1):39–46

Southern CR, Chen XD, Farid MM, Howard B, Eyres L (2000) Determining internal oil uptake and water content of fried thin potato crisps. Food and Bioprod Process 78(C3):119–125

Guillen MD, Uriarte PS (2012) Simultaneous control of the evolution of the percentage in weight of polar compounds, iodine value, acyl groups proportions and aldehydes concentrations in sunflower oil submitted to frying temperature in an industrial fryer. Food Control 24:50–56

Firestone D, Stier RF, Bluementhal MM (1991) Regulation of frying fats and oils. Food Technol 45:90–94

Wai TNK (2007) Local repeatedly–used deep fat frying oils are generally safe. Int E-J Sci Med Educ 1(2):55–60

TCS (2010) Turkish codex standards. Notification of edible oils that mention plant name. http://www.kkgm.gov.tr/TGK/Teblig/2001-29.html (13 April 2016)

Gunstone FD (2008) Oils and fats in food industry Chapter 8, 1st edn. Wiley Blackwell, Hoboken

Sulieman AERM, Makhzangy AE, Ramadan MF (2006) Antiradical performance and physicochemical characteristics of vegetable oils upon frying of french fries: a preliminary comparative. J Food Eng 30:389–403

Urbancic S, Kolar MH, Dimitrijevic D, Demsar L, Vidrih R (2014) Stabilisation of sunflower oil and reduction of acrylamide formation of potato with rosemary extract during fat frying. Food Sci and Technol 57:671–678

Naz S, Siddiqi R, Sheikh H, Sayeed SA (2005) Deterioration of olive, corn and soybean oils due to air, light, heat and deep frying. Food Res Int 38:127–134

Casal S, Malheiro R, Sendas A, Oliveira BPP, Pereira JA (2010) Olive oil stability under deep fat frying conditions. Food Chem Toxicol 48:2972–2979

Denniston KJ, Topping JJ, Cariet RL (2004) General organic and biochemistry, 4th edn. McGraw Hill Companies, New York, pp 432–433

Asuquo JE, Anusiem ACI, Etim EE (2012) Extraction and characterization of rubber seed oil. Int J Mod Chem 1(3):109–115

Perkın EG (1992) Affect of lipid oxidation on oil and food quality in deep frying. In: Angels AJS (ed) Lipid oxidation in food, Chapter 18. ACS Symposium Series no. 500 ACS, Am. Chem Soc, Washington, pp. 310–321

Tyagi VK, Vasishta AK (1996) Changes in characteristics of oils during deep fat frying. J Am Oil Chem Soc 73(4):499–506

Aladedunye FA, Przybylski R (2009) Degradation and nutritional quality changes of oil during frying. J Am Oil Chem Soc 86:149–156

Romero A, Cuesta C, Sánchez-Muniz FJ (2000) Trans fatty acid production in deep fat frying of frozen foods with different oils and frying modalities. Nutr Res 20(4):599–608

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Baltacıoğlu, C. Effect of Different Frying Methods on the Total trans Fatty Acid Content and Oxidative Stability of Oils. J Am Oil Chem Soc 94, 923–934 (2017). https://doi.org/10.1007/s11746-017-2998-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-017-2998-7