Abstract

The effect of repeated deep frying of potatoes versus repeated heating/quenching on the chemical profile of palm oil was investigated. The novelty of the work is that the frying and heating/quenching experiments were conducted under similar time-temperature profiles. The effects of the frying load (potato-to-oil ratio: 1/7 and 1/35 kgpotatoes/loil) and of the time-temperature profile were examined. Whole palm oil and its polar fraction were analyzed using high pressure size exclusion chromatography. Both repeated frying and repeated heating/quenching generated polar and polymerization products in palm oil. Interestingly, no hydrolysis or other decomposition products were generated under any of the examined conditions. The presence of potatoes during frying in palm oil increased the concentration of polymerization products and polar compounds compared to oils without potatoes significantly. The effects of frying load on oil quality depended on frying time. No significant effect of frying load was observed up to frying times of 13 h (or 10 frying batches). However, frying oil quality was affected by frying load once frying times exceeded 24 h (or 20 batches).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Frying, as applied in industries, catering, or restaurants, changes the chemical composition of fats and oils substantially [1]. During frying, the frying medium is exposed to the simultaneous conditions of moisture from the foodstuff, atmospheric oxygen, and high temperatures [2]. In the presence of atmospheric oxygen, oxidation is the primary reaction, resulting in the formation of oxidized monomers, dimers, and oligomers of triacylglycerides [3]. Evaporation of water during frying produces a steam blanket over the frying oil. If during frying the oxygen supply is limited by steam blanketing [4], the main reactions lead to polymerization rather than oxidation [2]. Apart from the above, it is generally accepted that moisture interacts with oil, causing hydrolytic reactions, which yield free fatty acids, diacylglycerides, monoacylglycerides, and glycerol [1]. Nevertheless, although some experimental studies have reported the increase in hydrolysis products during frying [4–6], others have not detected such an increase [7, 8]. All these chemical reactions lead to a lengthy list of primary, secondary, and tertiary products [1]. Many of these products are volatile and thus are partly eliminated during frying. The non-volatile compounds, such as the dimers and oligomers of triacylglycerides, accumulate in the frying medium, and their concentration can be related to the total oil/fat chemical changes [3].

Several chemical and physical methods have been employed in the past in order to analyze fried fats and oils and describe the chemical changes induced by frying. Each method provides different information on these changes. Among them, a very powerful tool is high pressure size exclusion chromatography (HPSEC). With HPSEC, by using one or two SEC columns connected in series, and by analyzing the whole oil and/or its polar fraction, it has been possible to determine oligomers and dimers of triacylglycerides, oxidized monomers, diacylglycerides, monoacylglycerides, as well as free fatty acids and sterols [6]. Therefore, this method appears capable of evaluating thermal oxidation, polymerization, and hydrolytic degradation at the same time [9].

A literature survey shows that many factors can affect the chemical profile of an oil or fat during frying. These include processing variables and variables related to the frying medium as well as to the food being fried. Regarding processing variables, it has been reported that chemical changes in the frying medium increase with frying time, whereas an increase in frying/heating temperature may either enhance chemical reactions or not affect them at all [10, 11]. Temperature effects depend on the value of the employed temperature and on the extent of temperature change and oil type [2, 10, 11].

Oil type and composition are also very significant factors affecting the stability of oil during heating or frying. The factors with the highest significance are the fatty acid composition and the type and concentration of natural antioxidants (if present). The degree of saturation and the concentration of polyunsaturated fatty acids seem to affect the various chemical reactions in the oil/fat differently [11, 12]. Furthermore, natural antioxidants have proved to play a protective role against oil alteration [2, 12].

Finally, food constituents interact with the oil or fat. Fedeli [13] and Dana et al. [4] studied separately the effect of water in the form of steam bubbles and the effect of starch and of protein, and showed that each constituent interacts differently with the frying oil or fat. Some inhibit, while others promote chemical reactions during frying, and this depends highly on the oil type.

Despite the vast literature on frying and the general acceptance that food presence plays a significant role in the degradation of the frying medium [1], a serious gap appears in the literature. To the best of our knowledge, no comparative study exists contrasting the chemical alteration of oil during frying in the presence of potatoes to the alteration in the absence of potatoes under the same processing conditions. This gap is not due to lack of interest in the subject, but rather is mainly due to experimental difficulties. Adding food to a fryer induces a considerable drop (quench) in the oil temperature, which cannot be easily replicated in the absence of food. If the time-temperature profile is different between the frying and heating experiments, it is evident that comparisons cannot be made. This is because there not only is a quantitative effect of temperature on chemical changes (increasing the temperature in general increases the rate of chemical reactions [10]), but also because different chemical reactions are promoted at different temperatures [2].

It must be stressed here that the aforementioned works of Fedeli [13] and Dana et al. [4] compare measurements in the presence and absence of a single food constituent every time while keeping the same temperature between experiments. Therefore, the question remains concerning how much an oil or fat is affected when potatoes are fried compared to the changes occurring when the same frying medium is simply heated under the same conditions? This is, in fact, the objective of this work.

This study focuses on the effect of potatoes on oil quality during frying. For convenience, the term frying henceforth will refer to repeated batch frying of potatoes. In contrast, the term heating will refer to repeated heating/quenching of the frying medium simulating the temperatures obtained during frying but without any added potatoes. In addition, an effort is made to examine how the potato-to-oil ratio affects chemical changes during frying and how the respective temperature profiles affect these changes during heating.

Materials and Methods

Materials

Refined palm oil was supplied by Elais S.A. (Piraeus, Greece) and kept at −18 °C until used. The composition of palm oil in fatty acids was determined by GC (gas chromatography). First, the fatty acid methyl esters (FAMEs) were prepared [14]. Then, 2 μl of the extracted FAMEs were injected into a Focus gas chromatograph (Thermo, Austin, TX) equipped with a flame ionization detector and a 30-m capillary column with helium as a gas carrier. The initial temperature was set at 150 °C, rising to 220 °C at a rate of 5 °C/min. Injection and detection temperatures were 220 and 250 °C, respectively. Retention times of FAMEs standards were used to identify the chromatographic peaks of the samples. Results of major fatty acids are shown in (Table 1).

Angria variety potatoes were bought in the local market, conditioned with a final temperature at 15.5 ± 1 °C and 95% relative humidity and selected so as to have a specific gravity between 1.07 and 1.10.

Frying Experiments

Four series of experiments were performed: two series of repeated frying experiments and two series of palm oil heating/quenching in the absence of poatoes. Frying was conducted in temperature-controlled fryers using raw potato sticks (1 cm × 1 cm × 8 cm) (Fig. 1a). Potatoes were equally spaced apart in the oil volume by using a custom-made frying basket divided into compartments (Fig. 1a). This kept the temperature homogeneous in the fryer as verified in preliminary measurements. In the intervals between frying batches, temperature homogeneity was assured by gently stirring with a three-beam paddle impeller (Fig. 1b).

In each frying series a different frying load was applied, namely 1/7 kgpotatoes/lfat (high frying load) and 1/35 kgpotatoes/lfat (low frying load). The selection of frying loads was based upon frying loads used in the food processing industry (i.e., high frying load) and catering/restaurant applications (i.e., low frying load). In order to make meaningful comparisons between the heating and frying experiments, the temperature profile of the oil during the frying experiments was replicated in the absence of potatoes. This was done by employing a custom-made cooling system that can remove high amounts of heat in a short time. In order to achieve high cooling rates, a submerged impeller was used to enhance heat transfer between the oil and the cooling coil and also assure temperature homogeneity in the fryer (Fig. 1b). Representative temperature profiles for the frying batches are presented in (Fig. 2a, b) for the high and low frying loads, respectively. Representative temperature profiles for the heating/quenching batches simulating the high and low load frying are presented in Fig. 2c, d, respectively.

Indicative temperature profiles obtained during the frying experiments at high (a) and low (b) frying load. Results for both fryers are shown. c, d Indicative temperature profiles obtained during heating/quenching experiments simulating the temperature profiles obtained during frying at high and low load, respectively

Each frying series consisted of 40 frying batches conducted in 4 consecutive days. Initially the fat was heated to 180 ± 2 °C and further kept at this temperature for 30 additional minutes [15] before adding the potatoes. The total time that the fat was kept at elevated temperatures in any of the experimental series was 46 h including the time needed for heating up the oil and the time in between frying batches. The fat was not replenished between frying batches, but the potato-to-oil ratio was kept constant through frying batches (see below). The duration of each frying batch was 12 min for the high load and 3 min for the low load. This was because the oil temperature profile was significantly different between the two frying loads (Fig. 2a, b). This was dictated by the different energy demands for frying.

In the case of heating/quenching, two experimental series were conducted. In these series 40 heating/quenching periods were conducted (instead of 40 frying batches); the rest of experimental conditions were the same as in the frying experiments.

Because there was no fat replenishment between frying or heating/quenching batches, the quantity of fat in the fryers decreased progressively along every experimental series due to fat absorption from the fries and/or sampling. However, in the frying experiments, the potato-to-oil ratio was kept constant throughout all the frying series. This was done by adjusting the quantity of potatoes added to the fryer proportionally to the quantity of the remaining fat. As a result of the decrease in the fat volume, the temperature profile in the oil bath tended to change between frying batches (this was verified during preliminary experiments). In order to overcome this problem the fat temperature was controlled during each frying batch in order to follow the same temperature profile in all batches.

Due to the absence of replenishment, the surface-to-volume ratio varied along experimental series. In fact, as different potato-to-oil ratios were used and experiments in the absence of potatoes were conducted, the changes in the surface-to-volume ratio would have been different between the experimental series if no corrective action was taken. Any differences were corrected during each batch by removing some fat. For this correction the decrease in oil volume (due to sampling and oil uptake by potatoes) during the high frying load frying series was used as a reference. That is, the removed oil quantities during the low frying load and heating/quenching experiments were such as to match the withdrawal of oil during the high frying load. As a result, the surface-to-volume ratio in each frying series varied in a similar way among frying series, and it was between 0.15 ± 0.01 and 0.22 ± 0.02 (average maximum and minimum surface to volume ratio ± SD among experimental series).

In order to have enough oil for 40 batches, without fat replenishment, high initial fat quantities were required. To save some oil, the following scenario was employed: two fryers were used at the beginning of each series containing 4 l of palm oil each. Both fryers were operated simultaneously for the first frying batches. In the middle of the frying series (when the oil quantity decreased to about half) the oil of the two fryers was mixed, and the frying series continued in only one fryer. The repeatability of experimental conditions in both fryers was not trivial. Machado et al. [16] showed that conducting repeated frying experiments in identical fryers (with identical temperature control systems) did not assure the repeatability of experiments. This was attributed to possible differences in the time-temperature profile (not recorded in their experiments). In our case, the repeatability was verified by controlling and keeping records of the temperature in both fryers as well as taking separate fat samples before mixing.

Sampling and Storage

Oil samples were collected at the very beginning (unused oil), after the end of the initial 30 min heating period at 180 °C (preheated oil), and at the end of the 1st, 10th, 20th, 30th, and 40th frying batches or heating/quenching periods. Oil samples were also collected at the end of the 3 intermediate days of the frying series as well as at the beginning of the next day. For the early batches where both fryers were in use, aliquots of fat from both fryers were mixed together in order to give an average sample. Some samples were also kept separately from each fryer in order to check for possible differences between fryers. Samples were stored at −26 °C, under a nitrogen atmosphere, in airtight closed, dark-colored glass bottles.

Size Exclusion Chromatography of the Whole Oil

HPSEC analysis was performed using a stainless steel 300 mm × 7.5mm i.d., PL-gel 100 Å (polystyrene-divinylbenzene co-polymer in toluene) column with 5-μm packing (Polymer Laboratories Ltd.), connected to a PL-gel guard column (Polymer Laboratories Ltd.). The column and guard column were operating in a column oven set at 35 °C and connected to an injection valve equipped with a 20-μl sample loop. Tetrahydrofuran (HPLC-grade, Merck) was used as the mobile phase. Following the IUPAC method [17] as well as the instructions by the provider of the column (Polymer Laboratories, Ltd.), the mobile phase flow rate was set at 1.0 ml/min. A volume of 50–100 μl of the sample solution (i.e., whole oil dissolved in tetrahydrofuran at 100,000 ppm) was taken with a syringe, filled the 20-μl injection loop, and finally injected into the HPLC system. Detection was performed by a refractive index detector operated at 35 °C. Two to three determinations were performed for each sample.

Size Exclusion Chromatography of the Polar Fraction of the Oil

The IUPAC method [18] was used to measure the polar fraction of the oil samples. The polar and non-polar fractions were separated by using mini-columns. According to a modified method of Gertz [19], Sep-Pak™ Silica Cartridges (FA Water part no.: WAT 051900) were used following their sample preparation procedure. The measurement procedure was the same as in the case of the whole fat fraction.

Quantitative Analysis of HPSEC Chromatograms

The quantitative determination of polymerized triacylglycerides has been described by Wolff et al. [17]. The same analysis method was used to measure all compounds determined by previous researchers [7, 20]. It must be noted, however, that Gomes and Caponio [21] have shown that the different groups of compounds detected by this method present a slightly different response (approximately 5% difference). Results presented here are rounded to integer values and therefore, at least for the whole fat results, any differences in the detector response are less significant than the resolution employed. Preliminary tests of repeatability showed that results on the total polymerization compounds in the used and unused whole fat have a repeatability better than ±0.2% of the average mass percentage value.

The method used here for the determination of polymer compounds in the whole fat is not recommended by IUPAC for quantitative determination of polymer contents below 5% [17]. In some European countries, though (e.g., France) this lower limit is set to 3% [17]. Small amounts of polymerization products (<5%) have been determined by this method [2, 22]. In this work, polymer content values below 5% are displayed for qualitative comparison reasons and should not be taken as absolute quantitative values.

Statistical Analysis

Quantitative results on polymerization products were analyzed using the General Linear Model of ANOVA (analysis of variance). Two factors were used for the analysis of variance: the frying or heating/quenching batch number and the experimental series. The analysis was performed using Minitab 14 (Minitab Inc.) software.

Results and Discussion

HPSEC Chromatograms

Figure 3 presents indicative HPSEC chromatograms of unused palm oil and of palm oil at the end of the high frying load series (potato-to-oil ratio: 1/7 kgpotatoes/lfat). Chromatograms on the whole fat as well as its polar fraction are shown. Two peaks characterize the unused whole palm oil (Fig. 3a): a large peak corresponding to monomer triacylglycerides (T) and a small one corresponding to a higher molecular weight compound (P3). In most research studies having conducted HPSEC analysis in auto-oxidized oils, refined oils, and oils used for frying, the latter small peak is referred to as “triacylglyceride dimers” [5, 7, 8, 19, 23]. However, IUPAC has employed the general term “polymerized triacylglycerides” to describe the same peak [17], and this is the term adopted also herein. The presence of polymerization products prior to frying can be expected due to refining, which generates small amounts of dimers due to the elevated process temperatures [22, 23].

Indicative chromatograms of whole palm oil (a, b) and of its polar fraction (c, d). Chromatograms a and c correspond to unused palm oil, whereas b and d to palm oil that has been used for 40 frying batches at high frying load. Peaks P1, P2, and P3 stand for polymerization products, T for triacylglycerides, To for oxidized triacylglycerides and D for diacylglycerides; t denotes the retention time in HPSEC analysis

At the end of the frying series (Fig. 3b), three classes of polymerization products respective to their molecular size were detected (P1, P2, P3) in whole palm oil. Moreover, a shoulder (D) emerges at the right hand side of the triacylglyceride peak (T). This peak, according to the literature [5, 23], corresponds to diacylglycerides. However, the presence of other compounds having a similar molecular size cannot be excluded (i.e., tertiary oxidation products). The D shoulder would have been better resolved by using more columns in series as previously reported [23] or with a lower mobile phase velocity [24]. Unfortunately, the latter lower mobile phase flow rate was not successful in the present system.

The presently detected compound classes here have also been detected in other oil types subjected to repeated frying [5, 7–9, 20, 23]. Chromatograms of palm oil used for frying at low load (potato-to-oil ratio: 1/35 kgpotatoes/lfat) or for heating exhibit the same qualitative characteristics as those for the high frying load experiments, and so they are not shown due to space limitations.

Figure 3c, d presents chromatograms of the polar fraction of unused palm oil and of palm oil fried in 40 batches at high frying load (1/7 kgpotatoes/lfat). The polar fraction of unused palm oil contained a small amount of polymerization products (peak P3). In addition, the T peak was significantly smaller compared to that of the whole samples (Fig. 3a), corresponding to the oxidized triacylglycerides. The presence of polar oxidized monomers in refined oils has been reported before [23]. The presence of only oxidized triacylglycerides (and not the total triacyglycerides) in the chromatograms of the polar fraction allowed for the identification of the D peak. This was also the case in previous works [5]. Diacylglycerides were present in palm oil throughout the whole frying process and even in the unused fat. Apparently, the significant T peak masked the D peak in many of the whole fat chromatograms. Thus, the D peak in the polar fraction supports the presence of diacylglycerides.

Results on Whole Palm Oil

Figure 4a collectively presents the results obtained for frying at high load. Peaks are termed as in (Fig. 3). Peaks having an area (and mass percentage) as low as 1% were displayed, as they can be clearly resolved in the chromatograms. The amount of polymerization products (P3) that was present in unused palm oil was 1%. According to Gertz and Klostermann [22], measurements on refined palm oil yielded 0.5% dimers, which is in the same order of magnitude with our results. Figure 4a clearly shows the progressive formation of polymerization products of different molecular weights (P1, P2 and P3) during frying. Furthermore, repeated frying increased the concentration of polymerization products. This is in accordance with previous works [7, 8, 20]. At the end of the repeated batch frying series, polymerization products reach 27% of the oil mass.

Changes in the composition of whole palm oil induced by potato frying at high (a) and low (b) frying load and by heating/quenching under temperature profiles simulating those of frying at high (c) and low (d) frying load. N is the number of the frying or heating/quenching batch or degree of palm oil use. U stands for unused fat and P for preheated fat; w denotes the weight percentage of each compound class. For symbols P1, P2, P3, T, and D, see Fig. 3. Error bars stand for the standard deviation of repetitions

It is noteworthy that diacylglycerides (D peak) appear for the first time at the tenth frying batch, and their concentration did not change throughout the rest of the frying series. As has been noted above (Fig. 3c, d), diacylglycerides exist in all palm oil samples. In addition, although the technique can detect monoacylglycerides and free fatty acids [6, 9], no such compounds were detected in any of the samples. The presence of diacylglycerides combined with the absence of monoacylglycerides and free fatty acids indicated that hydrolysis did not take place in palm oil throughout the whole repeated frying process. Our results, as well as some in the literature [7, 8], imply that although it is generally accepted that frying induces hydrolysis, this is not always the case. We did not find any previous publication discussing hydrolysis in palm oil; therefore, it is not possible to tell whether our finding can be related to the type of the oil or to other experimental variables. This remains to be examined in depth in the future. Given that hydrolysis products are not generated during our frying experiments, it is possible that diacylglycerides preexisted in palm oil prior to frying (e.g., possibly due to the hydrolysis in the raw material), while the rest of the hydrolysis products were removed during refining.

The experiments were conducted in 46 h spread over 4 consecutive days. Gomes da Silva and Singh [25] conducted repeated frying in corn oil for several consecutive days. They found that the oil also degraded in the waiting periods between frying days where the oil was left at ambient temperature. No differences in oil quality were found between samples taken at the end of one intermediate frying day with that at the beginning of the next day. Therefore, it is assumed that conducting the experiments in 4 days and not continuously for 46 h did not affect the results. In addition, analyzing whole palm oil samples from each fryer separately before mixing of the fat yielded the same quantitative results (<±0.5% difference in the mass percentage of any of the determined compounds). This showed that palm oil undergoes the same treatment in both fryers as expected by comparing the temperature profiles of the fat in both fryers.

Figure 4b represents results obtained during frying with palm oil at low frying load (potato-to-oil ratio: 1/35 kgpotatoes/lfat). The changes at this lower frying load were significant. By comparing results in Fig. 4a, and Fig. 4d with Fig. 4b, we see that the polymerization compounds generated at low frying load are in general less; results on P2 at the 10th frying batch somehow contradict this overall trend, but at present we can not offer any explanation for this. At the end of the frying series, total polymerization products corresponded to 14% of the palm oil mass. Moreover, the higher molecular weight polymerization products (P1) were not generated at a detectable level during this frying series. It must be recalled here that the frying temperature was distinctly different between the high and the low load frying series (Fig. 2a, b).

In order to assess separately the effects of frying load and frying temperature, the results of the repeated frying experiments series were compared with those of the prolonged oil heating experiments. Figure 4c and d display results of the heating/quenching series where the temperature profile of high- and low-load frying series were simulated, respectively (Fig. 2). By comparing Fig. 4c with Fig. 4a, and Fig. 4d with Fig. 4b, the effect of the presence or absence of potatoes in the fryer was clearly demonstrated. Polymerization products at the end of the experimental series corresponded to 12% of the total fat mass for heating following the high frying load temperature profile and to 11% for heating following the low frying load temperature profile. These values were much less than the concentrations of polymerization products determined at the end of the frying series: 27 and 14% for the high and low load, respectively. Our results show that the addition of potatoes to the fryer drastically affects the polymerization in palm oil, increasing not only the concentration, but also the molecular weight of polymerization products.

Τhe difference in the temperature profile obtained at high and low frying load did not significantly affect the generation of polymerization products measured in the fat (Fig. 4c, d). According to the literature, in most cases an increase in temperature increases the rate of chemical reactions in oils and fats during frying and heating [10, 13]. Nevertheless, in this work, it seems that palm oil is not affected by the difference in the temperature profile between the two heating/quenching series. According to Tyagi and Vasishita [10], the chemical changes induced in low unsaturated fats (which include palm oil) tend to be less affected by temperature changes. Therefore, the differences in oil parameters presented in Fig. 4a and b may be attributed chiefly to the difference in the potato-to-oil ratio in the fryer and not to the difference in the frying temperature.

The comparisons presented above were assessed by the analysis of variance using two factors (a) the batch number or degree of palm oil use (N) and (b) the experimental series (frying at high or low frying load or heating/quenching at different temperature profiles). It was found that both factors significantly affected the concentration of total polymerization products (p < 0.000 for N and p = 0.012 for the experimental series). The same effects were found for P2 (p < 0.000 for N and p = 0.037 for the experimental series) and P3 polymerization (p < 0.000 for N and p = 0.002 for the experimental series) products. No statistically significant effect was found for P1 polymerization products. When examining the same factors (N and experimental series) for the comparison between the total polymerization compounds generated during heating/quenching experiments and during frying experiments, the observed differences were statistically significant at a level of significance α = 0.05 (p < 0.000 for N and p = 0.006 for the experimental series). Comparisons between the two heating/quenching experimental series showed no statistically significant difference between them (p = 0.614). This was also true for the two frying series (p = 0.161). However, the differences became statistically significant when applying the analysis only for the 20th frying batch and above (p = 0.048).

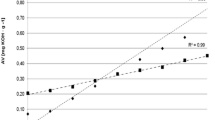

If it is assumed that the employed temperature difference did not significantly affect polymerization in palm oil, one can further attempt to assess the effect of frying load on the chemical profile of palm oil. For that reason, w f-h was calculated. Specifically, w f-h is the percentage difference between the total polymerization products generated during frying and total polymerization products generated during heating/quenching under the same experimental conditions (temperature profile and batch number). In Fig. 5 results were plotted as a function of batch number (N). Up to the first ten frying batches there is virtually no effect of frying load, but only an effect of the presence of potatoes in the fryer (non-zero w f-h). However, as repeated frying proceeds, the effect of frying load becomes more and more profound (Fig. 5). Again differences between the two frying loads were found statistically significant from the 20th frying batch and above (p = 0.022).

Results on the Polar Fraction of Palm Oil

Figure 6 presents the mass fraction of different compounds in the polar fraction of palm oil. Figure 6a–c corresponds to the same experiments as Fig. 4a–c, respectively. It must be noted that in Fig. 6, comparisons can be made only among different components in the same frying batch and not for the same component among different frying batches. This is because these chromatograms display the relative concentration of each constituent in the polar fraction of the oil (whose mass changes considerably throughout the frying series) and not in the whole oil. Thus, in order to compare results among frying batches the mass of the polar fraction is required (not known in this case).

Changes in the composition of the polar fraction of palm oil induced by frying of potatoes at high (a) and low (b) frying load and by heating/quenching under temperature profiles simulating that of frying at high frying load (c). N is the number of the frying or heating/quenching batch or degree of palm oil use. U stands for unused fat; w denotes the weight percentage of each compound class. For symbols P1, P2, P3, To, and D, see Fig. 3. Error bars stand for the standard deviation of repetitions

A major part of the polar fraction in unused palm oil (U) consisted of diacylglycerides, while as repeated frying proceeded, oxidized triacylglycerides and polymerization products increased in concentration (Fig. 6a). This was in accordance with the findings for sunflower oil and palm olein [7, 20]. Since diacylglycerides are polar, their peaks in the chromatograms of the whole fat or oil and in those of polar fraction correspond to the same quantity. Based on the above, the total polar materials at the end of the frying series at high frying load were estimated to be around 31% (w/w).

Figure 6b shows the relative concentration of different constituents in the polar fraction of palm oil in the low load series (1/35 kgpotatoes/lfat). As in Fig. 6a, at the beginning of the frying series, diacylglycerides prevail in the polar fraction, while as frying proceeds the relative concentrations of oxidized triacylglyceride monomers and polymerization products increase. Comparing Fig. 6a with Fig. 6b shows that the relative concentration of polar polymerization products, respective to the total polar compounds, is less in Fig. 6b; this is expected because polymer generation during frying at low frying load is less compared to that of higher frying load (Fig. 3a, b). At the end of this frying series, the total polar materials were estimated to be around 24% (w/w).

Figure 6c shows the results of HPSEC analysis of the polar fraction of heated palm oil following the temperature profile of the high load frying series. The same comments hold as in Fig. 6a, b, only that in this case polymer levels were even lower. This again was expected based on Fig. 4a–c. At the end of this series, the total polar materials were estimated to be around 17%.

It follows from our measurements that heating increased the concentration of polar compounds in palm oil. This is in accordance with previous works for several oil types [7]. Moreover, adding potatoes to the fryer while keeping the rest of experimental conditions constant further increased the concentration of polar compounds in palm oil. The higher the frying load, the more polar compounds were generated. If one compares the relative concentration of polymerization products of different molecular sizes in the polar fraction with that in the whole oil, differences were noticed. This shows that not all polymerization products participate in the polar fraction. This was also the case for fried high oleic sunflower oil where triacylglyceride dimers and oligomers participated in the polar fraction, whereas only triacylglyceride dimers participated in the non-polar fraction [6]. The HPSEC analysis of the polar fraction of a fried oil or fat is sometimes used for the determination of its polymer content. Nevertheless, it should be kept in mind that as not all polymerization products are polar, an underestimation of the total polymer content is conducted by performing such an analysis.

Comparison with the Literature

As far as we are aware, the present study is the only one that determines the concentration of polymerization products in palm oil during heating and frying. Polymerization products have been detected in other studies conducting frying with other oil types [5, 7, 8, 12, 20, 26]. Nevertheless, it is difficult to compare these studies with our results because many other variables, apart from oil type, vary among them (frying time, number of frying batches, frying load, potato surface in contact with the oil, etc.). It should be mentioned that the higher molecular weight polymerization products detected here were detected also (and only) by Abidi and Rennick [12]. This can be linked to the higher polymer concentration generated during frying in these two studies compared to others [5, 7, 20], which makes it statistically more probable to obtain a polymerization reaction between a lower molecular weight polymerization product and a monomer or another polymerization product. This notion is further supported by the fact that the highest molecular weight products are absent in palm oil at low frying load where polymerization products are lower in concentration.

To our knowledge, the present study is the first systematic work assessing the effect of real food presence in the heated oil separately from the effect of frying temperature. In the very interesting work of Dana et al. [4], steam bubbles were generated in heated oil, and results were compared with those obtained in the absence of steam bubbles under the same time-temperature profile. These authors concluded that frying exerts a protective role on the frying medium via steaming out volatile compounds and protecting it from atmospheric oxygen by steam blanketing. Unfortunately, these authors did not measure polymerization products in their samples, which constitute the most significant (quantitatively speaking) compound in a fried fat or oil [6]. Therefore, even if certain tertiary oxidation products (measured in their study) had lower concentration in the presence of steam bubbles than in the absence of steam bubbles (oil heating), it was not possible to say whether this affected the generation of polymerization products or not. Our experimental set-up was different than that of Dana et al. [4]. They fried in conical glass flasks, which can somehow trap the steam. Our fryers (Fig. 1) were operated under an extractor hood, which allowed fast removal of steam and renewal of air over the oil surface. We believe that our set-up was closer to practical applications. We attribute our results to interactions of the oil with the steam bubbles, but also to the increased contact of the oil with atmospheric oxygen induced by agitation during steam release form the potatoes. In addition, the effect of food constituents other than water should not be excluded. Fedeli [13] showed that starch and proteins (both present in potatoes) affect the chemical reactions during frying.

Conclusion

Regulations and recommendations in several countries for frying oil usage set the limit at 23–29% for the total polar compounds and ar 12–15% for total polymerization compounds [27, 28]. Comparing the present results with the above limits, we note that the limit for total polymerization compounds in the frying experimental series conducted at high frying load has been reached after approximately 20 batches. However, the same limit was reached between the 30th and 40th batch for palm oil subjected to low frying loads. This underlines the effect of frying load on oil deterioration during frying, and it should be taken under consideration in catering units and restaurants. The same effect of frying load is observed in relation to regulations limits on total polar compounds. It is also interesting to note that the limit for polymerization compounds is surpassed before (in terms of frying batch number) the limit of polar compounds.

Our results showed that adding potatoes into heated palm oil significantly increased the concentration of polymerization products and polar compounds compared to what was measured when the fat alone was heated/quenched under a time-temperature profile simulating that of frying. According to the present results, hydrolysis is unlikely during frying with palm oil under any of the examined conditions. The frying load affects the generation of polymerization products and polar compounds. The effect of frying load depends on the total processing time (number of batches) that the fat undergoes during frying. In particular, up to a certain processing time, there is virtually no effect of frying load. After this time (or number of frying batches), the longer the time the fat undergoes frying, the more significant the effect of frying load.

References

Belitz H-D, Grosch W, Schieberle P (2004) Food chemistry, 3rd edn, Springer, Berlin

Gertz C, Klostermann S, Kochhar SP (2000) Testing and comparing oxidative stability of vegetable oils and fats at frying temperature. Eur J Lipid Sci Technol 102:543–551

Gutiérrez R, Gonzales-Quijano F, Dobarganes MC (1988) Analytical procedures for the evaluation of used frying fats. In: Varela G, Bender AE, Morton ID (eds) Frying of food, principles changes, new approaches. Ellis Horwood Ltd, Chichester, pp 141–154

Dana D, Blumenthal MM, Saguy IS (2003) The protective role of water injection on oil quality in deep frying conditions. Eur Food Res Technol 217:104–109

Dobarganes MC, Pérez-Camino MC, Márquez-Ruiz G (1988) High performance size exclusion chromatography of polar compounds in heated and non-heated fats. Fat Sci Technol 90:308–311

Dobarganes MC, Márquez-Ruiz G (1996) Dimeric and higher oligomeric triglycerides. In: Perkins EG, Erickson MD (eds) Deep frying: chemistry, nutrition and practical applications. AOCS Press, Champain, pp 89–111

Arroyo R, Cuesta C, Garrido-Polonio C, López-Varela S, Sánchez-Muniz FJ (1992) High-performance size-exclusion chromatography studies for polar components formed in sunflower oil used for frying. J Am Oil Chem Soc 69:557–565

Cuesta C, Sánchez-Muniz FJ, Garrido-Polonio C, López-Varela S, Arroyo R (1993) Thermoxidative and hydrolytic changes in sunflower oil used in fryings with a fast turnover of fresh oil. J Am Oil Chem Soc 70:1069–1073

Cert M, Moreda W, Pérez-Camino MC (2000) Chromatographic analysis of minor constituents in vegetable oils. J Chromatogr 881:131–148

Tyagi VK, Vasishita AK (1996) Changes in the characteristics and composition of oils during deep-fat frying. J Am Oil Chem Soc 73:499–506

Houhoula DP, Oreopoulou V, Tzia C (2003) The effect of process time and temperature on the accumulation of polar compounds in cottonseed oil during deep-fat frying. J Sci Food Agric 83:314–319

Abidi SL, Rennick KA (2003) Determination of nonvolatile components in polar fractions of rice bran oils. J Am Oil Chem Soc 80:1057–1062

Fedeli E (1988) The behavior of olive oil during cooking and frying. In: Varela G, Bender AE, Morton ID (eds) Frying of food principles changes, new approaches. Ellis Horwood Ltd, Chichester, pp 52–81

Morrison WR, Smith LM (1964) Preparation of fatty acid methyl esters and diethylacetals from lipids with boron fluoride-methanol. J Lipid Res 5:600-608

Blumenthal MM (1991) A new look at the chemistry and physics of deep-fat frying. Food Technol 2:144–148

Machado ER, Marmesat S, Abrantes S, Dobarganes C (2007) Uncontrolled variables in frying studies: differences in repeatability between thermooxidation and frying experiments. Grasas Aceites 58:283–288

Wolff JP, Mordret FX, Dieffenbacher A (1991) Determination of polymerized triglycerides in oils and fats by high performance liquid chromatography: results of a collaborative study and the standardized method. Pure Appl Chem 63:1163–1171

Dobarganes MC, Velasco J, Dieffenbacher A (2001) Determination of polar compounds, polymerized and oxidized triacylglycerols, and diacylglycerols in oils and fats. Pure Appl Chem 72:1563–1575

Gertz C (2001) Determination of polymerized (dimeric and oligomeric) triglycerides content at low level. Eur J Lipid Sci Technol 103:181–184

Arroyo R, Cuesta C, Sánchez-Montero JM, Sánchez-Muniz FJ (1995) High-performance size-exclusion chromatography of palm olein used for frying. Fat Sci Technol 97:292–296

Gomes T, Caponio F (1999) Effort to improve the quantitative determination of oxidation and hydrolysis compound classes in edible vegetable oils. J Chromatogr 844:77–86

Gertz C, Klostermann S (2000) A new analytical procedure to differentiate virgin or non-refined from refined vegetable fats and oils. Eur J Lipid Sci Technol 101:329–336

Gomes T (1992) Oligopolymer, diglyceride and oxidized triglyceride contents as measures of olive oil quality. J Am Oil Chem Soc 69:1219–1223

Macrae R (1988) HPLC in food analysis. Academic Press, London, pp 12

Gomes da Silva M, Singh RP (1995) Viscosity and surface tension of corn oil at frying. J Food Proc Preserv 19:259–270

Matthäus B (2006) Utilization of high-oleic rapeseed oil for deep-fat frying of French fries compared to other commonly used edible oils. Eur J Lipid Sci Technol 108:200–211

Firestone D (1996) Regulation of frying fat and oil. In: Perkins EG, Erickson MD (eds) Deep frying chemistry nutrition and practical applications. AOCS Press, Champain, pp 323–334

Gertz C (2005) Legal regulations and analytical procedures to monitor the quality of fresh and degraded deep-frying fats, presented at 5th International symposium on deep-frying, Sanfransisco

Acknowledgments

The authors wish to thank Prof. Stilianos Rafaelides for his continuous support throughout this work. The work was partially supported by the Research Committee of the Technological Educational Institution of Thessaloniki under the Project “Physical-Chemical Changes and Transport Phenomena during Potato Frying.”

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Kalogianni, E.P., Karastogiannidou, C. & Karapantsios, T.D. Effect of the Presence and Absence of Potatoes under Repeated Frying Conditions on the Composition of Palm Oil. J Am Oil Chem Soc 86, 561–571 (2009). https://doi.org/10.1007/s11746-009-1380-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-009-1380-9