Abstract

Polyunsaturated plant oils have gained great interest as monomers to produce biodegradable polymers obtained from renewable resources due to the limited existing sources of petroleum oil and environmental issues. Soybean oil was autoxidized by exposure to atomospheric oxygen at room temperature with or without the presence of gold nanoparticles (Au NPs) 5–41 days. When the autoxidation process was catalyzed with Au NPs, the molecular weight of the oxidized oil was increased in 5 days. In contrast to this, without Au NPs, the oxidized oil was still a fluidized liquid. Autoxidized soybean oil polymer in toluene solution with gold NP showed a surface plasmon resonance at λmax = 540 nm in a UV–VIS spectrometer and a fluorescence emission spectrum at λmax = 450 nm, when it was irradiated at λmax = 390 nm. The higher molecular weight of the polymeric oils was successively fractionated by the extraction from the solvent-non-solvent mixture CHCl3/petroleum ether with the volume ratio of 5:15. Three polymeric oils fractions with different molecular weight (ca 1000, 4000, and 40,000 g/mol) were obtained. GC–MS analysis, 1H-NMR and GPC techniques were used in the structural analysis of the fractionated polymeric oils.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In view of the limited range of fossil fuel feed stocks, polymers prepared from alternative renewable resources are desirable in the long-term [1–4]. Vegetable-oil-based polymers play an important role in biomaterials and have attracted increasing attention from the polymer community. The utilization of vegetable oils is currently in the spotlight of the chemical industry, as they are one of the most important renewable platform chemicals due to their universal availability, inherent biodegradability, low price, and superb environmental credentials (i.e., low ecotoxicity and low toxicity toward humans) [5–7]. Autoxidation of double bonds is mild, renewable, cheap and non-toxic in nature. Autoxidation leads to the polymerization of the polyunsaturated moieties together with epoxidation, peroxidation, hydro peroxidation and cyclization [8–11]. Polyunsaturated fatty acids (PUFA) and polyunsaturated triglycerides (PUTG) are readily susceptible to autoxidation. A chain oxidation is initiated by hydrogen abstraction from allylic or bis-allylic positions leading to oxygenation and subsequent formation of peroxyl radicals [12, 13]. This peroxyl radical forms another alkyl radical and lipid hydroperoxide (ROOH) together with cyclization. Thus, propagation involves the transfer of a free radical from one fatty acid to another. This leads to dimers, trimers and oligomers [14–17]. These autoxidized polymeric oils/polymeric fatty acids acting as macro peroxide initiators can initiate free radical thermal polymerization of vinyl monomers to obtain graft copolymers [18–20]. Autoxidation of ethyl linolenate and methyl docosahexaenoate was performed to expose to atmospheric oxygen using UV illumination [21]. Some autoxidation studies of the PUFA and PUTG were also performed at elevated temperatures in the presence of oxygen [22–24]. When lipids are exposed to oxygen at elevated temperature they undergo oxidative modifications, leading to the formation of a variety of products. These processes play an important role in frying and cooking, where oils with different contents of saturated and unsaturated fatty acids are used [25–27]. Autoxidation of aliquoted PUFA was carried out in 150-mL clear glass bottles, leaving sufficient headspace for oxygen to react with PUFA in the sample. Photooxidation of PUFA was tested in a parallel set of samples exposed to light at 1500 ± 160 lux at 22 °C [28]. In another example, linoleic acid was oxidized neat or in a benzene solution in a round bottom flask, at 10, 30, 37, and 50 °C. The oxidation was normally carried out under air and was initiated by di-tert-butyl hyponitrite. By this way, trans–cis and trans–trans conjugated diene hydroperoxides from linoleic acid were isolated [29, 30]. The same experiment performed in the autoxidation of PUFA in benzene/1,4-cyclohexadiene has also been studied [31]. Generally, autoxidation at elevated temperatures was studied to determine the side product aldehydes [32–35]. The oxidation of lipids has long been a topic of interest in biological sciences, and the fundamental principles of non-enzymatic free radical attack on phospholipids are well established [36]. In vivo and in vitro lipid peroxidation of some polyunsaturated moieties including arachidonate esters is well studied [37–40]. The nonenzymatic and enzymatic oxidations of ω-alkynyl linoleic acid and ω-alkynyl arachidonic acid were compared to that of linoleic and arachidonic acid. There was no detectable difference in the primary products of nonenzymatic oxidation, which comprised cis, trans-hydroxy fatty acids [41, 42]. In fact, lipid oxidation is a problem in food because it produces compounds that degrade product quality, alters textural properties, and adversely affects the color and nutrition of a food product [43]. Very recently, Kumar et al. [44] have reported the preparation of a scratch-free coating. For this aim, cardanyl acrylate was coated on the glass slides and autoxidized in the presence of precious metal nanoparticles in order to obtain a scratch-free coating. Our research area is focused on the graft copolymerization of olefin monomers initiated by oxidized polymeric peroxides of PUFA and PUTG which act as macroperoxide initiator. For this purpose, we have recently performed autoxidation by exposing PUFA/PUTG to atmospheric oxygen at room temperature. The polymeric peroxide PUFA/PUTG initiated the olefin polymerization to obtain graft copolymers [45–49]. The biomedical applications of some graft copolymers were also reported [50, 51]. A water soluble soy bean oil polymer was obtained by the reaction of polymeric soy bean oil with diethanol amine [52]. In the oxidation process of soybean oil, the increasing oxidation time causes increase in molecular weight of the oil polymer formed. This autoxidation also showed decreased viscosity with increasing layer thickness. In this work, we have focused on the characterization of the oxidized polymeric soya oil and unsaturated fatty acids in view of the polymer chemistry. In this manner, soya oil spreading out in Petri dishes was exposed to atmospheric oxygen at room temperature for several weeks, without needing extra effort such as mechanical stirring, extra heating, and/or extra irradiation. For the first time, the polymeric soybean oil was fractionated using a solvent/non-solvent system. Then they were analyzed by using gel permeation chromatography (GPC), NMR and GC–MS techniques. To the best of our knowledge, the effect of gold nanoparticles on the autoxidation at room temperature was studied for the first time. In our recent work, we found the catalyst efficacy of the gold nano particles on the autoxidation of the pendent double bonds of the poly-3-hydroxy alkanoates obtained from soya oil [53]. Inspired by this catalyst effect on the autoxidation of the double bonds, the mixture of the pure soya oil with HAuCl4 was exposed to the oxygen in the air. Gold nanoparticles formed in oxidized soybean oil were confirmed by TEM and energy dispersive X-ray spectroscopy (EDS) analysis.

Experimental

Materials

Soya oil was a gift from Çotanak/Altaş Yağ Su ve Tarım Ürünleri Gıda İnşaat Otomotiv Nakliyat San ve Tic AŞ Ordu Turkey. It contains palmitic acid (11.6 wt%), stearic acid (4.9 wt%), oleic acid (33.7 wt%), linoleic acid (42.0 wt%) and linolenic acid (3.63 wt%). HAuCl4 and Linoleic acid (cis–cis-9–12-octadeca dienoic acid) (98 wt%) was supplied from Sigma-Aldrich. Oleic acid (95 wt%) and epoxidized soya oil (oleoxol) are gift from CHS (İstanbul).

Autoxidized polymeric soybean oil (PSbox) Autoxidation of soya oil was performed according to the modified procedure reported in our previous work [49]. For example, 2.7 g of soya oil spread out in a Petri dish (Φ = 7 cm, oil thickness: 0.7 mm) was exposed to daylight in the air at room temperature. After a given time of autoxidation (ca. 1 month), a sticky, pale yellow viscous liquid polymer layer was formed. The synthesis of polymeric soya oil (PSbox) was repeated in 10–12 times in Petri dishes with different radii.

Preparation of PSyox Containing Gold Nanoparticles (AuPSyox)

The same autoxidation procedure was applied on the oil/fatty acids mixed with HAuCl4. Briefly, 10 g of soy oil was spread out in a Petri dish (Φ = 14 cm). 0.250 g of HAuCl4 was added to this oil and mixed with a glass rod until HAuCl4 was completely dissolved in the oil (if a nickel or iron spatula is used, an immediate electrochemical reduction occurs). The yellow color of the air exposed oil solution turns purple in 3–4 days, which is attributed to surface plasmon resonance (spr) of the gold nanoparticles coming from the reduction of the gold cation [54].

Fractionation of the Autoxidized Samples

For this purpose, chloroform (solvent) and petroleum ether (40–60) (non-solvent) were used.

In the beginning, PSyox (5.0 g) was leached with 30 mL of petroleum ether in a bottle with a screw cap. The mixture was stirred with a magnetic stirrer for 2 h and then left for 2 h without stirring to form 2 phases.

The crude oxidized soya oil polymer (Psyox) was leached by the mixtures of chloroform and petroleum ether with the volume ratios 8/12, 7/12, 6/15 and 5/15, respectively. PSbox was all dissolved in the solvent/non-solvent mixtures with volume ratios 8/12, 7/12, and 6/15. When 20 mL of the solvent/non-solvent mixture with a volume ratio of 5/15 was stirred with the crude Psbox, two liquid phases were formed after settled down for 2 h without stirring. The upper solution was decanted. The precipitate was leached with pure petroleum ether. The precipitated waxy solid was dried under vacuum for 24 h and it was called the I. fraction. The decanted solutions were combined and the solvent was evaporated. The viscous liquid residue was dried under vacuum for 24 h. It was called the II. fraction. The yields obtained were 50 wt% for the spongy solid, first fraction, and 50 wt% for the viscose oil, second fraction. The same fractionation procedure was applied in the AuPSbox sample and the same fractions were obtained.

Saponification of the PSbox Samples

Briefly, 20 g of PSbox (201), 100 mL of aqueous NaOH solution (20 wt% NaOH) and 100 mL of absolute ethanol were mixed in a bottle at room temperature for 24 h. The soft waxy layer was collected, washed with distilled water, neutralized with an aqueous solution of HCl (20 wt%) and then distilled water. The saponified oil was dried under vacuum at room temperature for 24 h.

GC–MS Analysis: Procedure of the Pre-treatment and Instrumentation

For determination of the autoxidized soybean oil and PUFA composition; the same procedure described in the cited Ref. [55] was used as a reference method. Briefly, 0.5 g of oil sample was weighed into a test tube with a screw cap with 1 mL internal standard of 5a-cholestan-3b-ol (1000 mg/L) and saponified with 5.0 mL saturated methanolic KOH at 80 °C for 1 h. It was then extracted with 5 mL of hexane three times. Under nitrogen gas, the volume of hexane was reduced to 10 mL and the resulting solution was dried with anhydrous sodium sulfate. A 0.5-mL sample of dried hexane extract was silylated with 250 mL of a solution of bis(trimethylsilyl) trifluoroacetamide/trimethylchlorosilane (4:1) and 250 mL of dry pure pyridine at 60 °C for 15 min. After pre-treatment, the silylated extract of the autoxidized soybean oil/PUFA was analyzed using GC–MS, GC (Thermo, Trace GC ultra, Italy) equipped with FID and MS (Thermo, Polaris Q, USA). Separation of the components was performed using SE-54 (5 %-phenyl-1 %-vinylmethyl polysiloxane, 30 m × 0.32 mm × 0.25 mm and the following method parameters were used for the autoxidized soybean oil and PUFA composition analysis. Working conditions were as follows: carrier gas, helium; flow rate was 0.8 mL/min; injector temperature, 280 °C; detector temperature, 300 °C; oven temperature program, initial temperature was 60 °C for 2 min, increased at 40 °C/min to 220 °C, held for 1 min and then increased at 5 °C/min to 310 °C, held for 30 min. GC KOLON: DB 5MS (60 m-0,25 mm-0,1 µm). Individual samples without standards were identified using relative retention time (RRT) of 5a-cholestan-3b-ol. Data collected and quantified with a TotalChrom Navigator, the result of each sample was expressed as a percentage concentration and the total amount was stated as mg/kg of oil.

Instrumentation

Molecular weights were determined by gel permeation chromatography instrument, a Viscotek GPCmax Auto sampler system, consisting of a pump, three ViscoGEL GPC columns (G2000H HR, G3000H HR and G4000H HR), and a Viscotek differential refractive index (RI) detector with a THF flow rate of 1.0 mL/min at 30 °C. A calibration curve was generated with four polystyrene green standards: 2960, 50,400, and 696,500 Da, of low polydispersity. Data were analyzed using Viscotek Omni SEC Omnie 01 software.

Proton and carbon NMR spectra were acquired at a temperature of 25 °C with an Agilent NMR 600 MHz NMR (Agilent, Santa Clara, CA, USA) spectrometer equipped with a 3-mm broadband probe.

The toluene solution of AuPSyox (sample no. PSyox-32.2-I) was dried on a 200-mesh carbon-coated TEM grid (Electron Microscopy Sciences (CF200-Cu) (USA)) to use for analysis. A JEOL JEM-2100 (Japan) high resolution transmission electron microscope (HRTEM) at 200 kV (LaB6 filament) was used. Images were taken with a Gatan Model 794 Slow Scan CCD Camera (USA). Low magnification TEM imaging and HRTEM (atomic lattice imaging and fast Fourier transformation (FFT) diffractograms) techniques were used. Gatan Digital Micrograph software was used for noise filtering and fast Fourier transformation purposes.

UV–visible absorption spectra of the polymer solutions in toluene were recorded at room temperature using a Shimadzu 1700 Spectrometer with UV-quartz cuvettes (1-cm optical path) as the containers.

The fluorescence emission spectra measurements were done using a Cary Eclipse model Fluorescence Spectrometer instrument at a 390-nm wavelength at room temperature.

Thermal analysis of the obtained polymers was carried out under nitrogen using a TAQ2000 DSC and Q600 Simultaneous DSCTGA (SDT) series thermal analysis systems. Differential Scanning Calorimeters (DSC) measured temperatures and heat flows associated with thermal transitions in the polymer samples obtained. The dried sample was heated from −60 to 170 °C under a nitrogen atmosphere. Thermo Gravimetric Analysis (TGA) measures weight loss of the samples under a nitrogen atmosphere heating from 20 to 600 °C at a rate of 10 °C/min.

Results and Discussion

Autoxidation Process

Autoxidation processes of unsaturated fatty acids and their esters were carried out by spreading them out on flat surfaces of glass cups under atmospheric oxygen at room temperature for several weeks. The photos of the autoxidation process on the glass cups can be seen in SI-Fig. 1 in the supplementary information. The representative reaction design of linoleic acid oxidation process can be seen in Scheme 1.

Formation of the Gold NP and Their Catalyst Effect

Due to its green chemistry, the biosynthesis of nanostructures has attracted much interest in materials science because of the minimal adverse environmental effects [56]. For the first time, catalysis of gold nano particles was used in the autoxidation of soybean oil at room temperature. The catalyst effect of the Au NPs was first studied in detail. Colloidal distribution of Au NPs in oxidized soy bean oil was characterized by surface plasmon resonance, fluorescence emission spectra and TEM techniques. Inspired by the Au NPs catalyst effect on the autoxidation of the double bonds of poly(3-hydroxy alkanoates) derived from soybean oil [53], the mixture of the pure soya oil with HAuCl4 was exposed to the air oxygen. The yellow color of the Au(III) solution in soya oil turned to a deep red color coming from the surface plasmon resonance (spr) of gold nanoparticles (Au NPs) formed by daylight for 3–4 days [57, 58].

Scheme 2 shows the formation of the Au NPs in the soya oil polymer. In this manner, we not only observed a very efficient catalyst effect of Au NPs, but also bio-based Au NPs were obtained in this way. SI-Fig. 2a and b in the supplementary information show the photos of the deep red color of the toluene solution of the spongy, soft AuPsbox first fraction and its film (autoxidation time: 10 days), respectively. Without the gold catalyst, 10 days of oxidation was not enough to obtain any film of Psyox I. fraction, instead 41 days of oxidation was needed to get Psbox I. fraction film cast from chloroform. This catalyst effect was also confirmed by the GPC measurements. After 10 days oxidation, Mn of the AuPsbox is 69,201 g/mol while that of Psbox is 3326 g/mol. In the longer oxidation times, Mn’s of the Psbox samples obtained with or without Au nano particles are getting closer each other when comparing AuPsbox-29d-I.fr (#57) with Psbox-29d-I.fr (#59) in Table 1. Figure 1 shows the GPC chromatograms of the Psbox with or without gold NPs, as well. Interestingly, yield of the first fraction of the nano composite, AuPsbox-29d-I.fr was two times greater than that of Psbox-29d-I.fr. One can conclude that Au NPs are also very efficient to obtain the high yield of the oxidized soya oil composite. Fractionation of these oxidized soya oil polymers gave the same results. The second fractions completely separated from the highest molecular weight of the soya oil polymer. GPC curves of the AuPsbox-29d-I.fr (#57) with Psbox-29d-I.fr (#59) can be seen in Fig. 2. TEM analysis results of the gold-Psbox nanocomposite will be mentioned later into the text.

GPC curves of Psyox fractions: a PSbox-523, I. fraction extracted with solvent mixture 5/15 (#201); b PSbox-523, II. fraction (#48); c Psyox30.5, I. fraction (#54), d Psyox30.5, II.fraction (#50), e AuPsbox-29d-I.fraction (#57), f AuPsbox-29d-II.fraction (#58); g Psbox29d-I.fraction (#59), h Psbox29d-II.fraction (#60). Their molecular weights can be seen in Table 1

The spr of AuPsbox toluene solution was observed as λmax = 540 nm in a UV–VIS spectrometer. The fluorescence emission spectrum of the toluene solution of AuPsbox was observed at λmax = 450 nm, when it was irradiated at λmax = 390 nm. UV–VIS and fluorescence spectra of the toluene solution of AuPsbox can be seen in SI-Fig. 3 in the supplementary information. These results are in good agreement with the cited literature [54].

Fractionation of the Oxidized Polymeric Soya Oil (Psbox)

Because soy bean oil contains three different unsaturated fatty acid esters, the autoxidation process does not take place homogeneously. Polymeric soybean oil contains fractions with very different molecular weights. Solvent/non-solvent fractionation technique was also used for the first time to separate polymer fractions and the soybean oil polymer fractions were analyzed structurally in view of the molecular weight analysis (GPC technique). For the first time, we performed the fractionation of the oxidized soya oil polymer. Chloroform is a good solvent for Psyox, while petroleum ether is a non-solvent. The mixture of the chloroform and petroleum ether with volume (mL) ratio of 8/12, 7/13, 6/14, 5/15, 4/16, and 2/18, respectively was used in the fractionation of Psbox samples. Psyox was found to be relatively soluble in the solvent mixture with volume ratio of 8/12, 7/13, 6/14. The optimum fractionation was carried out with the solvent mixture 5/15 and 4/16. GPC technique was used to measure the Mn, Mw and poly dispersity index (PDI) of the polymer fractions obtained. GPC curves of the Psbox fractions can be seen in Fig. 2. All of the oxidized polymers had the multimodal gpc curves. Each multimodal chromatogram was analyzed in view of the molecular weight, separately. The highest molecular weight of the first fraction of the soya oil polymers was observed in the GPC chromatograms. For example, the PSbox523 first fraction contained the highest molecular weight of the hyper-branched polymer with Mn 54,534 g/mol (when the molecular weight of the triglyceride is taken as 900 g/mol on average, the repeating unit is calculated as 60, Psbox60), which is presumably Psyox containing the higher polylinolenate content. The middle polymer fraction with Mn 4945 g/mol (Psbox5.5) mostly contains polylinoleates. The lowest molecular weight of the fraction with Mn 1421 g/mol is a mixture of monomeric oleate and saturated fatty acid triglycerides. The GPC chromatogram of the second fraction (PSbox523-II.fr) is bimodal. The polymer fractions with Mn 4945 g/mol (ca. linoleates, Psbox5.5) and with Mn 971 (monomer of the triglycerides of oleates and saturated fatty acids) were observed. Thus, the highest molecular weight of polylinolenate was successfully isolated by this extraction which was partially cross-linked by the time at room temperature.

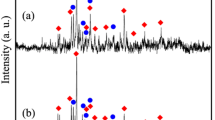

GC–MS Analysis

GC–MS analysis is a good tool to characterize oxidized unsaturated oil/fatty acids [41]. Total saturated fatty acid, total unsaturated fatty acid and total oxidized oil derivatives were measured with this technique. Retention times (min) indicate the total side products (17.07–20.97 min), total saturated fatty acids (21.76, 24.46 min), total unsaturated fatty acids (24.11 min), and total oxides (26.65–28.00 min). The summary of the GC–MS results of the fractionated AuPsbox and Psbox samples has been given in the Table 2. Autoxidized soya oil polymers were containing total oxides in range from 4.1 to 10.5 mol%. When compared 201 with 48 in Table 2, the first fractions of the oxidized soya polymers have higher total oxides than those of the second fractions.

The catalyst effect of the Au NPs increases the total oxides content, when comparing Psbox samples #54, and #51 autoxidized under similar conditions. Figure 3 shows GC–MS spectra of Psbox samples, #201, #48, #54, and #51. It is worthwhile to note that total unsaturated fatty acid content decreases in the range from 70.9 to 48.6 mol% as total oxides increase. Table 1 contains the fatty acid analysis of commercially available epoxidized soya oil (Oleoxol, CHS, İstanbul). In Table 2, a dramatic decrease in total unsaturated fatty acids up to 4.74 mol% and a high increase in total oxides up to 57.8 mol% can be seen.

GC–MS spectra of the epoxidized soya oil are given in SI-Fig. 4 in the supplementary information. In GC–MS spectra of the oxidized soya oil polymers with Au NPs in SI-Fig. 5, linolenic acid signal has completely disappeared while the linoleic acid signal has partially disappeared when compared with the GC–MS spectra of the precursor soya oil (SI-Table 1). Interestingly, first fractions of the Psbox samples with or without Au NPs became partially cross-linked after 10–15 days standing under laboratory conditions. Presumably, linolenic acid units tend to cross-linking with linoleic acid units by the time at room temperature via post polymerization leading to free radicals entrapped in the polymer mass [59]. In order to understand the structural characteristics, the Psbox samples, #201 and #48 were saponified with aqueous NaOH and alcoholic NaOH solution at room temperature for 24 h. The results in Table 1 show that the higher molecular weight of the soya oil polymer was cleaved to monomer units with Mn 625. Figure 4 shows the GPC chromatogram of the saponified Psbox (#31). The peroxide bonds can easily be cleaved in a basic solution at room temperature. Therefore, the peroxide bonds between the soya oil units are effective to form oxidized soya oil polymer together with low –C–C- and –C–O–C- bonds.

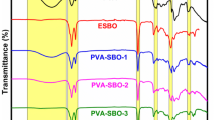

First and second fractions of the autoxidized samples were analyzed using 1H-NMR spectroscopy. Figure 5 shows the 1H-NMR spectra of the first and second fractions of an oxidized soya polymer sample, PSyox-30.5-I (#54) and PSbox-30.5-II (#50), respectively. The first fraction of the PSbox sample has typically a –OOH signal at 8.0 ppm which is a good agreement with the data reported in the cited literature [60].

The signal of the double bonds at 5.3 ppm dramatically decreases when compared to that of the second fraction. Presumably, the polymerization improves from the double bonds-linoleic and linolenic acids- with peroxyl radicals in order to obtain a higher molecular weight polymer. SI-Fig. 6 shows 1H-NMR spectra of some Psbox samples.

TEM images of the gold-Psyox nanocomposite (#57 in Table 1) with the bar a 1 μm, b 500 nm, c 50 nm, pentagonal, d 50 nm, triangular, e 50 nm, spherical, and f EDS spectrum indicating Au signals

TEM

The catalyst effect of the gold nano particles increases the molecular weight and the yield of polymer fractionation of the oxidized soya oil polymer. TEM and EDS analysis of the gold-Psbox nanocomposite (#57 in Table 1) confirmed the presence of the Au nano particles. Spherical, pentagonal and triangular nanoparticles were formed in the nanocomposite with a size of approximately 40 nm. Figure 6 shows the TEM images of the gold-Psbox nanocomposite sample with different shapes.

TGA Analysis

Peroxygen content of the oxidized soybean oil polymers was approximately determined using TGA curves (Fig. 7). The first decomposition related to peroxide decomposition in the range between 130 and 180 °C was observed for all oxidized samples except epoxidized soybean oil and pure soybean oil (Table 3). The peroxygen content of the oxidized products changed from 1 to 8 wt%. The first fraction of the products usually contain a higher peroxide group than the following fraction. The gold nanoparticles do not affect the peroxygen content during autoxidation. Interestingly, a second fraction of Psbox sample (#50) has 8 wt% of the peroxide group. Similarly, DSC traces of autoxidized soybean oil showed a characteristically strong endotherm starting from nearly 120 °C while pure soybean oil did not show this peroxide decomposition (SI-Fig. 7).

Conclusion

Being green chemistry, the autoxidation of the unsaturated plant oils is carried out on a flat surface, under atmospheric oxygen and daily light without using any extra heat and mechanical energy at room temperature. This macro peroxide soya oil polymer is an attractive macro intermediate to prepare graft copolymers. The renewable resources such as plant oils gain great importance as monomers and chemicals to prepare bio-based polymers. Because soya oil contains different unsaturated fatty acid esters such as linolenic acid, linoleic acid and oleic acid, the oxidized polymer has multimodal GPC chromatograms. The solvent/non-solvent mixture is suggested to extract the highest molecular weight of the oxidized polymer from the crude Psbox.

The first time, gold NP as a catalyst were used in the autoxidation process and a soya oil polymer was obtained even after a five day oxidation period while the autoxidation time takes nearly one month to obtain an oxidized soya oil polymer without Au NPs. The oxidized part of the soya oil polymer changed from 4.1 mol% to 10.5 mol%. Au NPs also increased the oxidized parts in the soya oil polymer.

The elastomeric, soft polymer film obtained from the first fraction of the soya oil polymer with or without Au NPs can be a promising biomaterial as a biodegradable macro peroxide initiator. Autoxidation in view of the polymer science especially will be very attractive to readers. In this work, as a renewable resource, soy bean oil is also a monomer to produce bio-based materials. Soybean oil polymers also lead to the production of graft copolymers soluble in organic solvents.

A biodegradable graft copolymer can be obtained when a vinyl monomer is polymerized with a macro peroxide initiator.

References

Dodds DR, Gross RA (2007) Chemicals from biomass. Science 318(5854):1250–1251

Mecking S (2004) Nature or petrochemistry?—biologically degradable materials. Angew Chem Int Ed 43:1078–1085

Meier MAR, Metzger JO, Schubert US (2007) Plant oil renewable resources as green alternatives in polymer science. Chem Soc Rev 36:1788–1802

Xia Y, Larock RC (2010) Vegetable oil-based polymeric materials: synthesis, properties, and applications. Green Chem 12:1893–1909

Shimada K, Fujikawa K, Yahara K, Nakamura T (1992) Antioxidative properties of xanthan on the autoxidation of soybean oil in cyclodextrin emulsion. J Agric Food Chem 40:945–948

Lligadas G, Ronda JC, Galia M, Cadiz V (2013) Renewable polymeric materials from vegetable oils: a perspective. Mater Today 16:337–342

Miao S, Wang P, Su Z, Zhang S (2014) Vegetable-oil-based polymers as future polymeric biomaterials. Acta Biomater 10:1692–1704

Porter NA, Weber BA, Weenen H, Khan JA (1980) Autoxidation of polyunsaturated lipids. factors controlling the stereochemistry of product hydroperoxides. J Am Chem Soc 102:5597–5601

Porter NA (2013) A perspective on free radical autoxidation: the physical organic chemistry of polyunsaturated fatty acid and sterol peroxidation. J Org Chem 78:3511–3524

Soucek MD, Khattab T, Wu J (2012) Review of autoxidation and driers. Prog Org Coat 73:435–454

Hamalainen TI, Sundberg S, Makinen M, Kaltia S, Hase T, Hopia A (2001) Hydroperoxide formation during autoxidation of conjugated linoleic acid methyl ester. Eur J Lipid Sci Technol 103:588–593

Gardner HW (1989) Oxygen radical chemistry of polyunsaturated fatty acids. Free Radic Biol Med 7:65–86

Köckritz A, Martin A (2008) Oxidation of unsaturated fatty acid derivatives and vegetable oils. Eur J Lipid Sci Technol 110:812–824

Porter NA, Caldwell SE, Mills KA (1995) Mechanisms of free radical oxidation of unsaturated lipids. Lipids 30:277–290

Mallegol J, Lemaire J, Gardette JL (2000) Drier influence on the curing of linseed oil. Prog Org Coat 39:107–113

Singleton DA, Hang C, Szymanski MJ, Meyer MP, Leach AG, Kuwata KT, Chen JS, Greer A, Foote CS, Houk KN (2003) Mechanism of Ene Reactions of Singlet Oxygen. A Two-Step No-Intermediate Mechanism. J Am Chem Soc 125:1319–1328

Wick ZW, Jones FN, Pappas PS (1992) Film formation, component, and appearance, SPE Monograph Series, in Org. Coat. Sci. Technol Vol 1 New York

Hazer B (1987) Polymerization of vinyl monomers by a new oligoperoxide. Oligo (adipoyl 5- peroxy 2,5- dimethyl n-hexyl) peroxide. J. Polym. Sci. Polym. Chem. Ed. 25:3349–3354

Hazer B (1990) Cationic Polymerization of tetrahydrofuran Initiated by difunctional initiators. Synthesis of Block Copolymers. Eur Polym J 26:1167–1170

Hazer B (1996) Poly(beta-hydroxynonanoate) and polystyrene or poly(methyl methacrylate) graft copolymers: microstructure characteristics and mechanical and thermal behavior. Macromol Chem Phys 197:431–441

Farmer EH, Koch DA, Sutton DA (1943) The course of autoxidation reactions in poly isoprenes and allied compounds: part VII: Rearrangement of double bonds during autoxidation. J Chem Soc 144:541–547

Powers PO (1949) Mechanism of the oxidation of drying oils. Ind Eng Chem 41:304–309

Taylor WL (1950) Blowing drying oils. J Am Oil Chem Soc 27:472–476

Topallar H, Bayrak Y, Işcan M (1997) A kinetic study on the autoxidation of sunflower seed oil. J Am Oil Chem Soc 74:1323–1327

Schiller J, Süß R, Petkovic M, Arnold K (2002) Thermal stressing of unsaturated vegetable oils: effects analysed by MALDI-TOF mass spectrometry, 1H and 31P NMR spectroscopy. Eur Food Res Technol 215:282–286

Picariello G, Paduano A, Sacchi R, Addeo F (2009) MALDI-TOF mass spectrometry profiling of polar and nonpolar fractions in heated vegetable. J Agric Food Chem 57:5391–5400

Frankel EN (1980) Lipid Oxidation of soybean oil, which provides now the most important world source of vegetable food fat, develops a very complex type of lipid deterioration known incorrectly as “‘flavor reversion”. Progr Lipid Res 19:1–22

Fischer JJ, Nykiforuk CL, Chen X, Shen Y, Zaplachinksi S, Murray EW, Kuhlman P, Chen R, Harry I, Boothe JG (2014) Delayed oxidation of polyunsaturated fatty acids encapsulated in safflower (Carthamus tinctorius) Oil Bodies. Int J Eng Sci Innov Technol (IJESIT) 3:512–522

Porter NA, Weber BA, Weenen H, Khan JA (1980) Autoxidation of polyunsaturated lipids. factors controlling the stereochemistry of product hydroperoxides. J Am Chem Soc 102:5597–5601

Tallman KA, Roschek B Jr, Porter NA (2004) Factors influencing the autoxidation of fatty acids: effect of olefin geometry of the nonconjugated diene. J Am Chem Soc 126:9240–9247

Porter NA, Wujek DG (1984) Autoxidation of polyunsaturated fatty acids, an expanded mechanistic study. J Am Chem Soc 106:2626–2629

Cao J, Deng L, Zhu X-M, Fan Y, Hu J-N, Li J, Deng Z-Y (2014) Novel approach to evaluate the oxidation state of vegetable oils using characteristic oxidation indicators. J Agric Food Chem 62:12545–12552

Guillén MD, Uriarte PS (2012) Aldehydes contained in edible oils of a very different nature after prolonged heating at frying temperature: presence of toxic oxygenated α,β unsaturated aldehydes. Food Chem 131:915–926

Beltrán A, Ramos M, Grané N, Martín ML, Garrigós MC (2011) Monitoring the oxidation of almond oils by HS-SPME-GC-MS and ATR-FTIR: application of volatile compounds determination to cultivar authenticity. Food Chem 126:603–609

Poyato C, Ansorena D, Navarro-Blasco I, Astiasarán I (2014) A novel approach to monitor the oxidation process of different types of heated oils by using chemometric tools. Food Res Int 57:152–161

Yin H, Xu L, Porter NA (2011) Free radical lipid peroxidation: mechanisms and analysis. Chem Rev 111:5944–5972

Yin H, Porter NA (2005) New insights regarding the autoxidation of polyunsaturated fatty acids. Antioxid Redox Signal 7:170–184

Davis TA, Gao L, Yin H, Morrow JD, Porter NA (2006) In vivo and in vitro lipid peroxidation of arachidonate esters: the effect of fish oil ω-3 lipids on product distribution. J Am Chem Soc 128:14897–14904

Yin H, Porter NA (2003) Specificity of the ferrous oxidation of xylenol orange assay: analysis of autoxidation products of cholesteryl arachidonate. Anal Biochem 313:319–326

Kenar JA, Havrilla CM, Porter NA, Guyton JR, Brown SA, Klemp KF, Selinger E (1996) Identification and quantification of the regioisomeric cholesteryl linoleate hydroperoxides in oxidized human low density lipoprotein and high density lipoprotein. Chem Res Toxicol 9:737–744

Beavers WN, Serwa R, Shimozu Y, Tallman KA, Vaught M, Dalvie ED, Marnett L, Porter NA (2014) ω-Alkynyl lipid surrogates for polyunsaturated fatty acids: free radical and enzymatic oxidations. J Am Chem Soc 136:11529–11539

Porter NA, Caldwell SE, Mills KA (1995) Mechanisms of free radical oxidation of unsaturated lipids. Lipids 30:277–290

Barden L, Decker EA (2015) Lipid oxidation in low-moisture food: a review. Crit Rev Food Sci Nutr. doi:10.1080/10408398.2013.848833

Kumar A, Vemula PK, Puickel M, Ajayan PM, John G (2008) Silver-nanoparticle-embedded anti-microbial paints based on vegetable oil. Nature Mat. 7:236–241

Cakmakli B, Hazer B, Tekin IO, Kizgut S, Koksal M, Menceloglu Y (2004) Synthesis and characterization of polymeric linseed oil grafted methyl methacrylate or styrene. Macromol Biosci 4:649–655

Allı A, Hazer B (2011) Synthesis and characterization of poly (n-isopropyl acryl amide)-g-poly(linoleic acid)/poly (linolenic acid) graft copolymers. J Am Oil Chem Soc 88:255–263

Allı A, Allı S, Becer CR, Hazer B (2015) Nitroxide mediated copolymerization of styrene and pentafluorostyrene initiated by polymeric linoleic acid. Eur J Lipid Sci Tech. doi:10.1002/ejlt.201500129

Hazer B (2014) The properties of PLA/oxidized soybean oil polymer blends. J Polym Env 22:200–208

Allı A, Allı S, Becer CR, Hazer B (2014) One-pot synthesis of poly(linoleic acid)-g-poly (styrene)-g-poly(ε-caprolactone) graft copolymers. J Am Oil Chem Soc 91:849–858

Alli S, Tığlı Aydın RS, Alli A, Hazer B (2015) Biodegradable Poly (ɛ-caprolactone)-based graft copolymers via Poly(linoleic acid): in vitro enzymatic evaluation. J Am Oil Chem Soc 92:449–458

Çakmaklı B, Hazer B, Tekin IÖ, Açıkgoz S, Can M (2007) Polymeric linoleic acid–polyolefin conjugates: cell adhesion and biocompatibility. J Am Oil Chem Soc 84:73–81

Acar M, Çoban S, Hazer B (2013) Novel water soluble soya oil polymer from oxidized soya oil polymer and diethanol amine. J Macromol Sci Part A: Pure Appl Chem 50:287–296

Hazer DB, Hazer B (2011) The effect of gold clusters on the autoxidation of poly(3-hydroxy 10-undecenoate-co-3-hydroxy octanoate) and tissue response evaluation. J Polym Res 18:251–262

Kalaycı ÖA, Cömert FB, Hazer B, Atalay T, Cavicchi K, Cakmak M (2010) Synthesis, characterization, and antibacterial activity of metal nanoparticles embedded into amphiphilic comb-type graft copolymers. Polym Bull 65:215–226

Demirtas I, Pelvan E, Özdemir İS, Alasalvar C, Ertas E (2013) Lipid characteristics and phenolics of native grape seed oils grown in Turkey. Eur J Lipid Sci Technol 115:641–647

Mann S (1993) Molecular tectonics in bio mineralization and biomimetic materials chemistry. Nature 365:499–505

Kalaycı ÖA, Cömert FB, Hazer B, Atalay T, Cavicchi K, Cakmak M (2010) Synthesis, characterization, and antibacterial activity of metal nanoparticles embedded into amphiphilic comb-type graft copolymers. Polym Bull 65:215–226

Zhang J, Du J, Han B, Liu Z, Jiang T, Zhang Z (2006) Sonochemical formation of single-crystalline gold nanobelts. Angew Chem Int Ed 45:1116–1119

Macit H, Hazer B (2007) Grafting on polybutadiene with polytetrahydrofuran macroperoxy initiators: post polymerization studies. Eur. Polym. J. 43:3865–3872

Swern D, Clements AH, Luong TM (1969) Nuclear magnetic resonance spectra of organic peroxides. Anal Chem 41:412–416

Acknowledgments

This work was supported by the Bülent Ecevit University Research Fund (#BEU-2015-72118496-12 and BEU-2015-72118496-02). The authors thank to Kevin Cavicchi for kindly proof reading.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

About this article

Cite this article

Hazer, B., Akyol, E. Efficiency of Gold Nano Particles on the Autoxidized Soybean Oil Polymer: Fractionation and Structural Analysis. J Am Oil Chem Soc 93, 201–213 (2016). https://doi.org/10.1007/s11746-015-2764-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11746-015-2764-7