Abstract

The equilibrium surface tension, dynamic surface tension, and interfacial tension (IFT) of fatty alcohol ether sulfonates (C m E n SO) were measured to investigate their adsorption behavior. The effect of NaCl and CaCl2 concentrations on the IFT was also studied. The results showed that the number of EO units has no significant effect on the critical micelle concentration (CMC) and CMC decreases with increasing the length of the hydrophobic group. The surface tension at the CMC increases with the increase of the number of EO units and the length of the hydrophobic group. At dilute surfactant concentration, the adsorption process for C m E n SO is controlled by diffusion; at higher concentration, it becomes a mixed diffusion-kinetic adsorption mechanism. The IFT between C m E n SO solution and dodecane remains around 10−1 mN/m over a wide range of electrolyte concentrations (NaCl concentration from 25 to 210 g/L, CaCl2 concentration from 0.1 to 10 g/L).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Surfactant flooding is an important enhanced oil recovery (EOR) method. Injecting surfactant solution helps to mobilize the residual crude oil from the reservoir by reducing the oil–water interfacial tension (IFT) [1,2,3,4,5,6,7,8,9]. During surfactant flooding, traditional anionic surfactants such as petroleum sulfonate and alkylbenzene sulfonate have been employed for common oil reservoirs [10,11,12,13,14]. Unfortunately, high levels of divalent ions (Ca2+ and Mg2+) in the connate water in some petroleum reservoirs could make these anionic surfactants precipitate, so it is important to develop anionic surfactants for use in high salinity oil reservoirs [10]. Ethoxylated sulfonates, as a kind of anionic-nonionic surfactant, have a higher resistance to electrolytes and chemical stability, and these excellent properties have attracted wide interest. However, only a few publications have systematically studied the adsorption behavior of fatty alcohol ether sulfonate at different interfaces [10, 15,16,17,18,19,20,21,22,23].

The aim of this work was to investigate the surface and interfacial tension of fatty alcohol ether sulfonates (C m E n SO). The effects of the number of ethylene oxide (EO) units, the length of the hydrophobic group, and the electrolytes (NaCl and CaCl2) on the adsorption behavior of C m E n SO are systematically discussed.

Experimental Sections

Materials

Fatty alcohol ethoxylate was kindly supplied by Sinolight Chemicals Co., Ltd, China. Sodium isethionate was supplied by Huanggang Yongan Pharmaceutical Co., Ltd., China. Ethyl acetate, ethanol, dodecane, KOH, CaCl2, and NaCl were obtained from Tianjin Kemiou Chemical Reagent Co., Ltd., China. All materials were used as received.

Synthesis

A 500-mL flask was charged with 0.3 mol fatty alcohol ether, 0.03 mol KOH, and 80 mL cyclohexane. The mixture was heated under reflux for 2 h to remove H2O. Then 0.25 mol sodium isethionate and 80 mL n-decane were added and the mixture was heated at reflux for 90 min [21]. The synthesis of C m E n SO is shown in Scheme 1, in which R is the hydrophobic chain of C m H2m+1, n is the number of EO units, and m is the number of carbon atoms in the hydrophobic chain. For C1214E n SO, the content of C12 and C14 in the mixture of C1214 is about 75 and 25%, respectively.

About 5.0 g crude product was dissolved in a mixture of 100 mL water and 50 mL ethanol. Then the mixed solution was extracted with 50 mL ethyl acetate in a separatory funnel. The top layer was removed, and the bottom layer was extracted successively five times with 50 mL ethyl acetate. The bottom layer was evaporated to remove water and ethanol, and then the remaining was filtered and washed with ethanol to desalt it [10, 21]. The purity of the product was above 90%.

Structure Characterization

Figure 1 shows the negative ion MS of C m E n SO ionized by ESI. Taking C16E6SO as an example (Fig. 1d), the molecular mass of C16E6SO was 328 + 44p, where p represents the actual number of EO units in C m E n SO. Figure 1d shows the ions at m/z 328 + 44n−23, corresponding to the molecule [M − Na]−, which indicates that the number of EO units in C16E6SO varies from 1 to 16.

Surface Tension Measurements

The measurements of static surface tension were carried out on the KRŰSS K12 processor tensiometer at 25.0 ± 0.1 °C. Surfactant solutions were prepared using deionized doubly distilled water.

The dynamic surface tension (DST) was determined using a KRŰSS bubble pressure tensiometer BP100 method at 25.0 ± 0.1 °C.

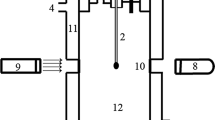

Interfacial Tension Measurements

IFT of surfactant aqueous solution/dodecane was measured using a TX-500C interfacial tensiometer at 30.0 ± 0.1 °C.

Results and Discussion

Equilibrium Surface Tension

The surface tensions of the aqueous solutions of C m E n SO were measured to evaluate their surface activities. The plots of surface tension (γ) versus log surfactant molar concentrations (logC) of C m E n SO are shown in Fig. 2, from which it can be seen that the surface tension initially decreases with increasing surfactant concentration, and then a plateau appears. The critical micelle concentration (CMC) is recorded as at the break point of the two linear portions of the γ versus logC plots. Table 1 lists the surface properties of C m E n SO obtained from these plots. The CMC of C m E6SO decreases with increasing number of carbon atoms in the hydrophobic group, which is similar to the traditional surfactants. The CMC increases with increasing number of EO units for typically nonionic surfactants containing EO units [24]. However, a slight decrease in CMC with an increase in the number of EO units is observed for the C m E n SO surfactants. Micelle formation is the result of two opposing forces. The higher the number of EO units is, the stronger the hydrophilicity which inhibits micelle formation. However, introduction of EO groups increases the molecular length, which increases the surface area of micelle and decreases the surface charge density of the micelle, which contributes to micelle formation. The net effect of increasing EO leads to no significant effects on the CMC with increasing the number of EO units.

The γ cmc of C m E n SO increases with increasing the number of EO units and the length of the hydrophobic group because the higher the number of EO units is, the larger the volume of the hydrophilic group, which leads to a looser arrangement of surfactant molecular at the air/water interface [10]. When the number of carbon atoms in a straight-chain hydrophobic chain exceeds 16, the “–CH3” density decreases and γ cmc increases because of the coiling of the long chain [24].

Surface excess concentration (Г max) in mol/cm2 and minimum area per molecule (A min) in Å2 were calculated from the following equations [24]:

where R is 8.31 J mol−1 K−1, N A is Avogadro’s constant, T is the absolute temperature, and dγ/dlogC is the slope below the CMC from the surface tension isotherms. Γ max is the maximum adsorption quantity of surfactant at the air/water interface. A min gives information on the degree of packing of surfactant molecules at the air/water interface. As can be seen from Table 1, as the number of EO units and the number of carbon atoms in the hydrophobic group of C m E n SO increase, A min increases and Г max decreases. The reasons are as follow: the EO chain immerses in the aqueous solution in the form of a coil, whose cross-sectional area increases with increasing the number of EO units [10, 24]; coiling of the long chain occurs when the number of carbon atoms in the hydrophobic chain exceeds 16, with a consequent increase in cross-sectional area of the molecule.

C 20 is the concentration of surfactant required to produce a 20 mN/m reduction in the surface tension of water, and the negative logarithm of the C 20 (pC 20) represents the efficiency of adsorption of surfactant [10, 24]. The larger the pC 20 value is, the more efficiently the surfactant is adsorbed and the surface tension is reduced [10, 24]. As listed in Table 1, the pC 20 for C m E n SO increases as the number of EO units increases. The pC 20 for C m E n SO has a maximum value when the length of the hydrophobic group increases up to 16 carbon atoms.

The CMC/C 20 ratio shown in Table 1 is an index of micellization relative to adsorption onto the water/air interface [10, 24]. It can be seen that the CMC/C 20 ratio for C m E n SO increases with increasing the number of EO units, which means that increasing the number of EO units inhibits micellization more than adsorption. The CMC/C20 ratio for C m E n SO decreases with increasing the number of carbon atoms in the hydrophobic group, which means that an increase in the length of hydrophobic group facilitates micellization more than adsorption. Usually, anionic surfactants with a single straight-chain hydrophobic group show low CMC/C 20 ratios of 3 or less, while polyoxyethylene nonionic surfactants show ratios of about 7 or more [24]. From Table 1, it can be seen that increasing the number of EO units in C m E n SO increases their nonionic surfactant characteristics, while increasing the length of the alkyl chain of C m E n SO increases their ionic surfactant characteristics.

Dynamic Surface Tension (DST)

The DST as a function of time for C m E n SO is shown in Fig. 3, from which it can be seen that the time required to attain the equilibrium surface tension decreases with increasing surfactant concentration. For C1214E n SO solution of very low concentration, there is an induction region at the beginning; whereas, for C16E6SO and C18E6SO, there is still an induction region even at higher surfactant concentration such as 5 mM. In addition, when the surfactant concentration is the same, the induction region becomes smaller with increasing the number of EO units and decreasing the length of the hydrophobic group.

Apparent Diffusion Coefficient

The Ward and Tordai model is usually used to analyze the DST. Equation (3) allows one to quantitatively analyze the process:

where Γ(t) is the surface excess concentration at time t, D is the apparent diffusion coefficient, C 0 is the bulk surfactant concentration, C s is the concentration in the subsurface, and τ is a dummy variable of integration [10, 25, 26]. Values of D at short time and long time could be obtained from Eqs. (4) and (5), respectively,

where R is 8.31 J mol−1 K−1, C 0 is the surfactant concentration, T is the absolute temperature, γ(t) is the surface tension at time t, γ 0 is the surface tension of the solvent, γ eq is the equilibrium surface tension at infinite time, n = 2 for ionic surfactant, and Γ eq is the equilibrium surface excess concentration [10, 26,27,28]. Figure 4 shows the plots of DST versus t, t 1/2 (short time) and t −1/2(long time) for C1214E4SO at different concentrations, and it can be seen that these plots exhibit linear behavior. Similar plots were obtained for the other C m E n SO (not shown).

The apparent diffusion coefficients of C m E n SO with various concentrations obtained from the gradients of the plots based on Eqs. (4) and (5) are shown in Fig. 5. Figure 5a shows that for C1214E n SO the diffusion coefficients at short time (D short) increase first and then decrease with increasing the concentration, while for C16E6SO and C18E6SO the D short decreases with increasing the concentration. In addition, at the same concentration the D short increases with increase of the number of EO units, and decreases with increase of the number of carbon atoms in the hydrophobic group. Figure 5b shows that the diffusion coefficients of C m E n SO decrease almost linearly with increasing the concentration. The ratio of D long/D short could reflect the adsorption mechanism. When the ratio is relatively close to 1, the adsorption process is diffusion-controlled. When it is far less than 1, the adsorption process is a mixed diffusion-kinetic adsorption mechanism [29, 30]. As seen in Fig. 5c, the ratio of D long/D short decreases with increasing the concentration when the concentration is less than 1 mM, and only at low concentration is the ratio close to 1, which indicates that there is a significant adsorption barrier with increasing the concentration of C m E n SO.

Interfacial Tension

Figure 6a shows the influence of NaCl concentration on IFT between C m E n SO solutions and dodecane. The results shows that IFT decreases with increasing NaCl concentration because NaCl could decrease the electrostatic repulsive force between intermolecular headgroups [10, 20]. As a result, C m E n SO concentration increases at the dodecane/water interface, which leads to the decrease of IFT. For C1214E n SO, the IFT increases with the increase of the number of EO units because of increasing the cross-sectional area of C m E n SO. The effect of increasing NaCl concentration on IFT decreases with increasing the number of EO units because the higher the number of EO units is, the more obvious the nonionic surfactant characteristic is, which is insensitive to electrolyte. For C m E6SO, the IFT decreases first and then increases with increasing the length of the hydrophobic group, which may contribute to the coiling of the long chain of C18E6SO, with a consequent increase in cross-sectional area of the molecule and decrease in interaction between surfactant and oil.

Figure 6b shows the influence of concentration of CaCl2 on IFT. It can be seen that the IFT does not significantly change with increasing the CaCl2 concentration from 1 to 10 g/L. The trend of the change of IFT for the C m E n SO/CaCl2/dodecane system is similar that of the C m E n SO/NaCl/dodecane system with increasing the number EO units and the length of the hydrophobic group. Usually, the IFT has a minimum value in a certain electrolyte concentration [20, 31]. However, it is worth noting that the IFT of C m E n SO has no minimum value except for C16E6SO, which indicates that the IFT of C m E n SO is not sensitive to electrolyte concentration because C m E n SO possess more nonionic surfactant characteristics than ionic surfactant characteristics as a result of the EO group.

Thermal Stability

Thermal stability of surfactants is a material property because the surfactants will degrade at high temperature which leads to loss of surface activity [32]. The TG curves of C m E n SO under nitrogen are shown in Fig. 7, from which it can be seen that three stages of degradation are evident. The second stage corresponds to rapid decomposition. Thermal stability of C m E n SO decreases in the order C1214E8SO > C1214E6SO = C16E6SO = C18E6SO > C1214E4SO. The C m E n SO with the longer EO chain exists in the form of a coil, which inhibits the thermal decomposition. Thus, the main factor that affects the thermal stability of C m E n SO is the number of EO units rather than the length of carbon chain.

Conclusion

The surface tension and interfacial tension of fatty alcohol ether sulfonates (C m E n SO) at the air/water interface and dodecane/water interface were investigated. The main results can be concluded as follows:

-

1.

Increasing the length of the hydrophobic group of C m E n SO leads to decreasing the CMC and increasing the γ CMC and A min; increasing the number of EO units has no significant effect on CMC and leads to increasing the γ CMC and A min.

-

2.

At lower concentration, the adsorption process is diffusion-controlled; at higher concentration, a mixed diffusion-kinetic mechanism controls the adsorption process.

-

3.

The IFT increases with an increase of the number of EO units, and decreases first and then increases with increasing the length of the hydrophobic group at the studied concentrations.

-

4.

Thermal stability of C m E n SO increases in the order C1214E4SO < C1214E6SO = C16E6SO = C18E6SO < C1214E8SO.

References

Guo L, Liu Y, Hu SS, Xu ZC, Gong QT, Zhang L, Zhang L. Dynamic interfacial tensions of alkyl alcohol polyoxypropylene–oxyehtylene ether sulfonate solutions. J Pet Sci Eng. 2016;141:9–15.

Rosen MJ, Wang HZ, Shen PP, Zhu YY. Ultralow interfacial tension for enhanced oil recovery at very low surfactant concentrations. Langmuir. 2005;21:3749–56.

Jiang P, Li N, Ge JJ, Zhang GC, Wang Y, Chen LF, Zhang L. Efficiency of a sulfobetaine type surfactant on lowering IFT at crude oil–formation water interface. Colloids Surf A. 2014;443:141–8.

Johannessen AM, Spildo K. Enhanced oil recovery (EOR) by combining surfactant with low salinity injection. Energy Fuels. 2013;27:5738–49.

Gao B, Sharma MM. A family of alkyl sulfate gemini surfactants. 2. Water–oil interfacial tension reduction. J Colloid Interface Sci. 2013;407:375–81.

Tichelkamp T, Teigen E, Nourani M, Øye G. Systematic study of the effect of electrolyte composition on interfacial tensions between surfactant solutions and crude oils. Chem Eng Sci. 2015;132:244–9.

Zhao ZK, Bi CG, Li ZS, Qiao WH, Cheng LB. Interfacial tension between crude oil and decylmethylnaphthalene sulfonate surfactant alkali-free flooding systems. Colloids Surf A. 2006;276:186–91.

Zhao ZK, Bi CG, Li ZS, Qiao WH, Cheng LB. Dynamic interfacial tension behavior of the novel surfactant solutions and Daqing crude oil. Colloids Surf A. 2007;294:191–202.

Yang J, Qiao WH, Li ZS, Cheng LB. Effects of branching in hexadecylbenzene sulfonate isomers on interfacial tension behavior in oil/alkali systems. Fuel. 2005;84:1607–11.

Liu XC, Zhao YX, Li QX, Jiao TL, Niu JP. Surface and interfacial tension of nonylphenol polyethylene oxides sulfonate. J Mol Liq. 2016;216:185–91.

Cayias JL, Schechter RS, Wade WH. Utilization of petroleum sulfonates for producing low interfacial tensions between hydrocarbons and water. Colloid Interface Sci. 1977;59:31–8.

Basu S, Shravan S. Preparation and characterization of petroleum sulfonate directly from crude. Pet Sci Technol. 2008;26:1559–70.

Zhao RH, Zhang L, Zhao S, Yu JY. Effect of the hydrophilic–lipophilic ability on dynamic interfacial tensions of alkylbenzene sulfonates. Energy Fuels. 2010;24:5048–52.

Cao Y, Zhao RH, Xu ZC, Jin ZQ, Luo L, Zhang L, Zhao S. Effect of electrolyte and temperature on interfacial tensions of alkylbenzene sulfonate solutions. Energy Fuels. 2012;26:2175–81.

Wang XG, Yan F, Li ZQ, Zhang L, Zhao S, An JY, Yu JY. Synthesis and surface properties of several nonionic–anionic surfactants with straight chain alkyl-benzyl hydrophobic group. Colloid Surf A. 2007;302:532–9.

Liu ZY, Li ZQ, Song XW, Zhang JC, Zhang L, Zhao S. Dynamic interfacial tensions of binary nonionic–anionic and nonionic surfactant mixtures at water–alkane interfaces. Fuel. 2014;135:91–8.

Xiao JX, Zhao ZG. Principles of surfactant application. Beijing: Chemical Industry Press; 2003.

Minero C, Pramauro E, Pelizzetti E, Degiorgio V, Corti M. Micellar properties of sodium dodecylpoly(oxyethylene) sulfates. J Phys Chem. 1986;90:1620–5.

Cox MF. Effect of alkyl carbon chain length and ethylene oxide content on the performance of linear alcohol ether sulfates. J Am Oil Chem Soc. 1989;11:1637–46.

Liu ZY, Zhang L, Cao XL. Effect of electrolytes on interfacial tensions of alkyl ether carboxylate solutions. Energy Fuels. 2013;27:3122–9.

Zhang YM, Niu JP, Li QX. Synthesis and properties evaluation of sodium fatty alcohol polyoxyethylene ether sulfonate. Tenside Surfactants Deterg. 2010;47:34–9.

Aoudia M, Al-Harthi Z, Al-Maamari RS, Lee C, Berger P. Novel alkyl ether sulfonates for high salinity reservoir: effect of concentration on transient ultralow interfacial tension at the oil–water interface. J Surfactants Deterg. 2010;13:233–42.

Al-Faraji S, Al-Maamari RS, Aoudia M. Sodium alkyl ether sulfonates (SAES): dual anionic-nonionic behavior in synthetic brine having high salinity and hardness. J Surfactants Deterg. 2015;18:113–21.

Rosen MJ, Kunjappu JT. Surfactants and interfacial phenomena. 4th ed. New York: Wiley; 2012.

Ward AFH, Tordai L. Time dependence of boundary tensions of solutions. 1. The role of diffusion in time effects. J Chem Phys. 1946;14:453–61.

Eastoe J, Dalton JS. Dynamic surface tension and adsorption mechanisms of surfactants at the air/water interface. Adv Colloid Interface Sci. 2000;85:103–44.

Fainerman VB, Makievski AV, Miller R. The analysis of dynamic surface tension of sodium alkyl sulphate solutions, based on asymptotic equations of adsorption kinetic theory. Colloid Surf A. 1994;87:61–75.

Jiang YG, Geng T, Li QX, Li GJ, Ju HB. Equilibrium and dynamic surface tension properties of salt-free catanionic surfactants with different hydrocarbon chain lengths. J Mol Liq. 2015;204:126–31.

Gao YY, Yang XQ. Equilibrium and dynamic surface properties of sulfosuccinate surfactants. J Surfactants Deterg. 2014;17:1117–23.

Zhi LF, Li QX, Li YL, Song YB. Adsorption and aggregation properties of novel star-shaped gluconamide-type cationic surfactants in aqueous solution. Colloid Polym Sci. 2014;292:1041–50.

Cao Y, Zhao RH, Xu ZC, Jin ZQ, Luo L, Zhang L, Zhao S. Effect of electrolyte and temperature on interfacial tensions of alkylbenzene sulfonate solutions. Energy Fuels. 2012;26:2175–81.

Hu PC, Tuvell ME. A mechanistic approach to the thermal degradation of α-olefin sulfonates. J Am Oil Chem Soc. 1988;6:1007–12.

Acknowledgements

The authors are very grateful for the financial support from the National Science and Technology Pillar Program (2014BAE03B01) of China.

Author information

Authors and Affiliations

Corresponding authors

About this article

Cite this article

Liu, X., Zhao, Y., Li, Q. et al. Adsorption Behavior of Fatty Alcohol Ether Sulfonate at Different Interfaces. J Surfact Deterg 20, 401–409 (2017). https://doi.org/10.1007/s11743-016-1918-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11743-016-1918-4