Abstract

The composition and structural parameters of W/O microemulsions containing the gemini surfactant 1,4-bis(3-alkylimidazolium-1-yl) butane bromide [(Cn-4-Cn)Br2, n = 12, 14, 16] + pentan-1-ol + octane + water and W/O microemulsions containing the ionic liquid surfactant 1-alkyl-3-methylimidazolium (CnmimBr, n = 12, 14, 16) + pentan-1-ol + octane + water were studied and compared. The mole fractions of the n-alkyl alcohol at the interfacial layer \(X_{\text{a}}^{\text{i}}\) in (Cn-4-Cn)Br2 based microemulsion systems are always larger than those in CnmimBr based microemulsion systems. However, the mole fractions of the n-alkyl alcohol in the oil phase \(X_{\text{a}}^{\text{o}}\) are nearly the same for both the microemulsion systems. The (Cn-4-Cn)Br2 based microemulsion systems have greater absolute values of the free enthalpy values \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\) than that for CnmimBr based systems. In the (Cn-4-Cn)Br2 based microemulsion systems, a large number of cosurfactants at the interfacial layer is conducive to the formation of a smaller droplet W/O microemulsion. The effects of n-alkyl alcohols, alkanes, salinity and temperature on the composition and structural parameters of the (Cn-4-Cn)Br2 based and CnmimBr based microemulsion systems were also investigated and discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Gemini surfactants (GS) contain two hydrophilic groups and two hydrophobic groups. The two head groups of GS are connected by a spacer group. Compared to conventional surfactants containing a similar single hydrophilic group and a single hydrophobic group, the properties of interest of GS include their lower-than-usual critical micelle concentration (CMC) values and high efficiency in decreasing the surface tension of water [1–7]. GS have been attracting considerable interest in the academic and industrial fields. Their behavior at the air/solution interface, the thermodynamics of micellization, the mixed micellization with various conventional surfactants, and the phase behavior of GS have been widely studied and reviewed [8–13]. Recently, a micellization study on aqueous solutions of a series of symmetrical cationic GS with different spacer lengths was systematically conducted, and the effect of spacer length on the micellization of the synthesized GS was investigated [14]. The values of CMC suggest that the shorter the spacer length, the higher the surface activity of the ionic liquid-type gemini imidazolium surfactants [15]. Ethylene glycol, ionic liquids and organic hydrotropes have often been used to modify the properties of aqueous solutions of GS. The addition of ethylene glycol to aqueous gemini micellar solutions causes the sphere-to-rod transition to occur at high surfactant concentrations [16]. The effect of ionic liquids on cationic gemini solutions could be regarded as the comprehensive effects of inorganic salt, cosurfactant, and cosolvent on the surfactant solution [17]. The properties of aqueous solutions of cationic GS can be efficiently modified by the addition of organic hydrotropes. When the volume fraction of hydrotrope increases, the value of CMC of GS in water + hydrotrope media increases [18]. The interactions between the surfactants and the hydrotropes are synergistic in nature, greatly reducing the CMC values [19–21]. Mixed micellization properties of the cationic [22] and anionic [23] monomeric surfactants with GS have been studied. The mixed system in water exhibits synergism in the formation of mixed micelles. In addition, GS had more influence on the TCP (temperature of cloud point) of the nonionic polymer cellulose ether. This might be due to the stronger interactions of GS as compared to their single-chain counterparts [24]. Recently, researchers showed that GS had more influence on the cloud point of amphiphilic drugs, and could serve as a better drug carriers [25–27]. In the presence of GS, the thermodynamic parameters were also evaluated at TCP [28–30].

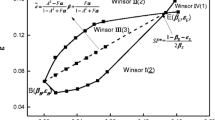

In comparison to the micellization study in aqueous solutions of GS mentioned above, there have been fewer research studies done on the microemulsions formed by GS. The middle-phase microemulsions of GS were investigated by salinity scan [31]. It was shown that the oil-in-water single phase could form a Winsor III type microemulsion over a wide salt concentration range. The oil in water (O/W) microemulsion of GS could be used in the polymerization of styrene [32, 33].

A dilution method of W/O microemulsions was commonly used to determine the composition and structural parameters of W/O microemulsions [34, 35]. In this paper, the composition and structural parameters of the W/O microemulsion systems containing 1,4-bis(3-alkylimidazolium-1-yl) butane bromide [(Cn-4-Cn)Br2] was investigated using the above-mentioned dilution method, and a comparison with the microemulsion system containing their monomeric analogues was also made.

Experimental

Materials and Apparatus

Gemini imidazolium surfactants with a four-methylene spacer group (Cn-4-Cn)Br2 (n = 12, 14, 16) [1,4-bis(3-dodecylimidazolium-1-yl) butane bromide, 1,4-bis(3-tetradecyl imidazolium-1-yl) butane bromide, 1,4-bis(3-cetyl imidazolium-1-yl) butane bromide], and their corresponding monomers CnmimBr(n = 12, 14, 16) [1-dodecyl-3-methylimidazolium, 1-tetradecyl-3-methylimidazolium, 1-cetyl-3-methylimidazolium] (Scheme 1) were synthesized and purified according to literatures [6, 36–40]. The purities of the surfactants synthesized were checked using 1H-NMR spectroscopy in DMSO and LC–MS. The purities were also examined by observing the curves of surface tension and no minimum points were found from the curves. The surfactants were left to dry in vacuum for 2 days prior to use.

Heptane, octane, decane, dodecane, butan-1-ol, pentan-1-ol and heptan-1-ol (with mass fraction purity >0.99) were all of A. R. grade and purchased from Alfa Aesar Johnson Matthey, USA. All these chemicals were used without further purification. NaCl (with mass fraction purity >0.99) was A.R. grade and purchased from Sinopharm Chemical Reagent Co., Ltd., Shanghai, China. Doubly distilled water of conductivity less than 3 μS · cm−1 at 298 K was used in the experiments.

Methods

A fixed amount of surfactant (0.5 mmol) was placed in a dry test tube, and was mixed with fixed amounts of oil and water. The molar ratio of water to surfactant (ω o) was kept constant. The tube was then placed in a thermostatted water bath. N-alkyl alcohol was added slowly using a burette under stirring using a magnetic mixer at constant temperature until the original turbid system became just clear. Then a small predetermined amount of oil was added into the tube and the system turned cloudy. The n-alkyl alcohol was added again until the system became clear. The procedure was repeated several times. The volumes of n-alkyl alcohol and alkane required were recorded. Each experiment was repeated two times, and the average values were used for data processing. Except for the experiments on the effects of temperatures, all the other experiments were performed at 313.15 K (uncertainty ±0.1 K). The error limit of the dilution method was ca. ±3 % [41, 42].

Results and Discussion

Composition and Structural Parameters of the W/O Microemulsions

Figure 1 shows the W/O microemulsion dilution curves for the microemulsion systems (Cn-4-Cn)Br2(a), CnmimBr(b) + pentan-1-ol + octane + 5 % NaCl solution. From the slopes (I) and intercepts (k) of the straight lines in Fig. 1, the composition and structural parameters for the microemulsion systems, i.e. n s (the number of moles of the surfactant), \(n_{\text{a}}^{\text{o}}\) (the moles of the n-alkyl alcohol in the oil phase), \(n_{\text{a}}^{\text{i}}\) (the number of moles of the n-alkyl alcohol in the interfacial layer), \(R_{\text{e}}\) (the effective radius of the water pool), \(N_{\text{d}}\) (the total number of the droplets), \(\bar{N}_{\text{s}}\) (the average aggregation number of the surfactant), and \(\bar{N}_{\text{a}}\) (the average aggregation number of n-alkyl alcohols) were calculated [43] according to the S1 section of the Supporting Material and listed in Table 1.

Plots of \({\raise0.7ex\hbox{${n_{\text{a}} }$} \!\mathord{\left/ {\vphantom {{n_{\text{a}} } {n_{\text{s}} }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${n_{\text{s}} }$}}\) vs \({\raise0.7ex\hbox{${n_{\text{o}} }$} \!\mathord{\left/ {\vphantom {{n_{\text{o}} } {n_{\text{s}} }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${n_{\text{s}} }$}}\) for (Cn-4-Cn)Br2(a), CnmimBr(b) + pentan-1-ol + octane + 5 % NaCl solution W/O microemulsions with different surfactants at ω 0 = 20. a Filled circles (C12-4-C12)Br2, filled squares (C14-4-C14)Br2, filled triangles (C16-4-C16)Br2. b Filled circles C12mimBr, filled squares C14mimBr, filled triangles C16mimBr

For the two types of microemulsion systems containing (Cn-4-Cn)Br2 and CnmimBr as surfactants, respectively, the mole fraction of the n-alkyl alcohol in the oil phase \(X_{\text{a}}^{\text{o}}\), the mole fraction of the n-alkyl alcohol in the interfacial layer \(X_{\text{a}}^{\text{i}}\), and the standard free energy change of transferring n-alkyl alcohol from the continuous oil phase to the interfacial layer \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\) were calculated according to Eqs. 1–3 from Table 1.

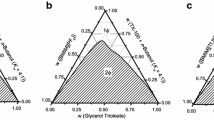

\(X_{\text{a}}^{\text{o}}\), \(X_{\text{a}}^{\text{i}}\), \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\) and the radius of the water pool R w (refer to Ref. [34]) for (Cn-4-Cn)Br2 based and CnmimBr based microemulsion systems were plotted and compared in Fig. 2. The related theoretical considerations were presented in the S1 section of the Supplementary Material.

Comparison of \(X_{\text{a}}^{\text{o}}\) (a), \(X_{\text{a}}^{\text{i}}\) (b), \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\) (c) and \(R_{\text{w}}\) (d) for the two surfactants based microemulsions (Cn-4-Cn)Br2 (filled circles), CnmimBr (open circles) + pentan-1-ol + octane + 5 % NaCl solution

Figure 2 indicates that the pattern of change of four parameters of \(X_{\text{a}}^{\text{o}}\), \(X_{\text{a}}^{\text{i}}\), \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\) and \(R_{\text{w}}\) are similar to the chain lengths (n c,s) of (Cn-4-Cn)Br2 and CnmimBr molecules increase in (Cn-4-Cn)Br2 based and CnmimBr based W/O microemulsion systems. That is, as n c,s increases, \(X_{\text{a}}^{\text{o}}\) and \(X_{\text{a}}^{\text{i}}\) values would decrease, whereas \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\) would increase. R w would decrease gradually as n c,s increases.

For all the W/O microemulsion systems in Fig. 2, the comparison of parameters (\(X_{\text{a}}^{\text{o}}\), \(X_{\text{a}}^{\text{i}}\), \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\) and R w) between surfactants (Cn-4-Cn)Br2 and CnmimBr are shown as follows. \(X_{\text{a}}^{\text{o}}\): (Cn-4-Cn)Br2 ≈ CnmimBr; \(X_{\text{a}}^{\text{i}}\) and \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\): (Cn-4-Cn)Br2 > CnmimBr; R w:(Cn-4-Cn)Br2 < CnmimBr.

It can be explained that as the carbon chain lengths (n c,s) of (Cn-4-Cn)Br2 and CnmimBr molecules increase, the hydrophobicity of the surfactants increases. Therefore the amount of the n-alkyl alcohol required to reach the balanced interfacial layer would decrease, resulting in the decrease in \(X_{\text{a}}^{\text{o}}\) and \(X_{\text{a}}^{\text{i}}\) values. The strengthened hydrophobic property of the surfactant as its carbon chain length increases enables the formation of the stable microemulsion to be more spontaneous [44] (Fig. 2c).

Compared with the corresponding mono-chain analogues CnmimBr, the gemini surfactants are more tightly packed in the interfacial layer because the two hydrocarbon chains are bridged by a short spacer chain (–CH2CH2CH2CH2–) [45]. This bridge effect implies a somewhat greater spontaneous curvature of the interfacial layer of (Cn-4-Cn)Br2, and thus more n-alkyl alcohol molecules must be incorporated into the interfacial layer of (Cn-4-Cn)Br2, in comparison to CnmimBr (Fig. 2b). This phenomenon results in the greater \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\) values for (Cn-4-Cn)Br2 based microemulsion systems than that for CnmimBr based systems (Fig. 2c). This was also explained by the differences in size and shape of the surfactants (Cn-4-Cn)Br2 and CnmimBr in the two microemulsion systems [46].

Figure 2d shows that the size of the water pool R w for the (Cn-4-Cn)Br2 based microemulsion systems are smaller than that for their monomeric analogues CnmimBr systems. The GS-based microemulsion systems can have potential application in the synthesis of nanoparticles of smaller size. As the total number of the droplets \(N_{\text{d}}\) increases, there would be a decrease in both the average aggregation number of the surfactant \(\bar{N}_{\text{s}}\) and the n-alkyl alcohols \(\bar{N}_{\text{a}}\).

Effects of N-Alkyl Alcohols and Alkanes

Figures 3, 4 show the effects of n-alkyl alcohols and alkanes on the plots of n a/n s vs n o/n s for W/O microemulsion systems (C16-4-C16)Br2(a), C16mimBr(b) + n-alkyl alcohol + alkane + 5 % NaCl solution, respectively.

Plots of \({\raise0.7ex\hbox{${n_{\text{a}} }$} \!\mathord{\left/ {\vphantom {{n_{\text{a}} } {n_{\text{s}} }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${n_{\text{s}} }$}}\) vs \({\raise0.7ex\hbox{${n_{\text{o}} }$} \!\mathord{\left/ {\vphantom {{n_{\text{o}} } {n_{\text{s}} }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${n_{\text{s}} }$}}\) for (C16-4-C16)Br2(a), C16mimBr(b) + n-alkyl alcohol + octane + 5 % NaCl solution W/O microemulsions with different n-alkyl alcohols at ω 0 = 20. Filled triangles butan-1-ol, filled squares pental-1-ol, filled circles heptan-1-ol

Plots of \({\raise0.7ex\hbox{${n_{\text{a}} }$} \!\mathord{\left/ {\vphantom {{n_{\text{a}} } {n_{\text{s}} }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${n_{\text{s}} }$}}\) vs \({\raise0.7ex\hbox{${n_{\text{o}} }$} \!\mathord{\left/ {\vphantom {{n_{\text{o}} } {n_{\text{s}} }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${n_{\text{s}} }$}}\) for (C16-4-C16)Br2(a), C16mimBr(b) + pentan-1-ol + alkane + 5 % NaCl solution W/O microemulsions with different alkanes at ω 0 = 20. Filled circles heptane, filled squares octane, filled triangles decane, open circles dodecane

The \({\raise0.7ex\hbox{${n_{\text{a}}^{\text{o}} }$} \!\mathord{\left/ {\vphantom {{n_{\text{a}}^{\text{o}} } {n_{\text{o}} }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${n_{\text{o}} }$}}\), \({\raise0.7ex\hbox{${n_{\text{a}}^{\text{i}} }$} \!\mathord{\left/ {\vphantom {{n_{\text{a}}^{\text{i}} } {n_{\text{s}} }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${n_{\text{s}} }$}}\), n s, \(n_{\text{a}}^{\text{i}}\), \(R_{\text{e}}\), \(N_{\text{d}}\), \(\bar{N}_{\text{s}}\), \(\bar{N}_{\text{a}}\) values were calculated and listed in S2 section of Supporting Material. The values of \(X_{\text{a}}^{\text{o}}\), \(X_{\text{a}}^{\text{i}}\), \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\) and R w of these W/O microemulsion systems were obtained and are compared in Fig. 5.

Comparison of the effects of n-alkyl alcohols (left) and alkanes (right) on the values of \(X_{\text{a}}^{\text{o}}\) (a), \(X_{\text{a}}^{\text{i}}\) (b), \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\) (c) and \(R_{\text{w}}\) (d) for the two W/O microemulsions (C16-4-C16)Br2 (filled circles), C16mimBr (open circles) + n-alkyl alcohol + alkane + 5 % NaCl solution

Figure 5 indicates that for all the W/O microemulsion systems studied with different n-alkyl alcohols or alkanes, the comparison of parameters (\(X_{\text{a}}^{\text{o}}\), \(X_{\text{a}}^{\text{i}}\), \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\) and R w) between surfactants (Cn-4-Cn)Br2 and CnmimBr are shown as follows. \(X_{\text{a}}^{\text{o}}\): (C16-4-C16)Br2 ≈ C16mimBr; \(X_{\text{a}}^{\text{i}}\) and \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\): (C16-4-C16)Br2 > C16mimBr; R w: (C16-4-C16)Br2 < C16mimBr.

As the carbon chain length of the n-alkyl alcohol (n c,a) increases, \(X_{\text{a}}^{\text{o}}\) and \(X_{\text{a}}^{\text{i}}\) would decrease, whereas \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\) and \(R_{\text{w}}\) would increase (Fig. 5A). The n-alkyl alcohols with longer chain lengths have higher efficiency in changing the hydrophilicity, making the amphiphilic mixture more hydrophobic. Therefore, less n-alkyl alcohol is needed to balance the hydrophile-lipophile property of the interfacial layer and less n-alkyl alcohol is solubilized in the oil phase. Hence, the spontaneous transfer ability of the n-alkyl alcohol from oil to the interfacial layer (\(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\)) would increase.

It can be seen from Fig. 5 that the trends of change for all parameters displayed by Fig. 5B are contrary to the trends of change displayed by Fig. 5A. As the carbon chain length of alkane molecules increases, the molar fraction of both the n-alkyl alcohols at the interfacial layer, \(X_{\text{a}}^{\text{i}}\) and the molar fraction of the n-alkyl alcohol in oil phase, \(X_{\text{a}}^{\text{o}}\) would increase. However, the extent of increase for the latter was more significant, leading to a decrease in the \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\) values. This results in the weakening of the spontaneous transfer of the n-alkyl alcohol from the oil to the interfacial layer. This phenomenon can be explained in terms of the penetrating ability of oil molecules into the surfactant interfacial layer [47]. As the smaller oil molecules are prone to penetrate the surfactant palisade layer, the interfacial layer tends to be convex towards oil. This facilitates the change of the curvature of the interfacial layer. Thus, less n-alkyl alcohol is needed to adjust the hydrophile-lipophile property of the interfacial layer [48].

Effects of Salinity and Temperature

Figures 6, 7 show the effects of salinity and temperature on the dilution curves for the W/O microemulsion systems. The composition and structural parameters (\({\raise0.7ex\hbox{${n_{\text{a}}^{\text{o}} }$} \!\mathord{\left/ {\vphantom {{n_{\text{a}}^{\text{o}} } {n_{\text{o}} }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${n_{\text{o}} }$}}\), \({\raise0.7ex\hbox{${n_{\text{a}}^{\text{i}} }$} \!\mathord{\left/ {\vphantom {{n_{\text{a}}^{\text{i}} } {n_{\text{s}} }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${n_{\text{s}} }$}}\), n s, \(n_{\text{a}}^{\text{i}}\), \(R_{\text{e}}\), \(N_{\text{d}}\), \(\bar{N}_{\text{s}}\), \(\bar{N}_{\text{a}}\)) were listed in S2 section of the Supplementary Material.

Plots of \({\raise0.7ex\hbox{${n_{\text{a}} }$} \!\mathord{\left/ {\vphantom {{n_{\text{a}} } {n_{\text{s}} }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${n_{\text{s}} }$}}\) vs \({\raise0.7ex\hbox{${n_{\text{a}} }$} \!\mathord{\left/ {\vphantom {{n_{\text{a}} } {n_{\text{s}} }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${n_{\text{s}} }$}}\) for (C16-4-C16)Br2(a), C16mimBr(b) + pentan-1-ol + octane + NaCl solution W/O microemulsions with different salinities at ω 0 = 20. NaCl concentrations: open squares 0 %, open circles 2.5 %, filled triangles 5.0 %, filled squares 7.5 %, filled circles 10 %

Plots of \({\raise0.7ex\hbox{${n_{\text{a}} }$} \!\mathord{\left/ {\vphantom {{n_{\text{a}} } {n_{\text{s}} }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${n_{\text{s}} }$}}\) vs \({\raise0.7ex\hbox{${n_{\text{o}} }$} \!\mathord{\left/ {\vphantom {{n_{\text{o}} } {n_{\text{s}} }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${n_{\text{s}} }$}}\) for (C16-4-C16)Br2(a), C16mimBr(b) + pentan-1-ol + octane + 5 % NaCl solution W/O microemulsions with different temperatures at ω 0 = 20. Filled circles 303 K, filled squares 313 K, filled triangles 323 K, open circles 333 K

The effects of NaCl concentrations (Fig. 8A) and temperatures (Fig. 8B) on the values of \(X_{\text{a}}^{\text{o}}\), \(X_{\text{a}}^{\text{i}}\), \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\) and R w for the two W/O microemulsion systems (C16-4-C16)Br2 and C16mimBr + pentan-1-ol + octane + NaCl solution were calculated and compared in Fig. 8.

Comparison of the values of \(X_{\text{a}}^{\text{o}}\) (a), \(X_{\text{a}}^{\text{i}}\) (b), \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\) (c) and \(R_{\text{w}}\) (d) between the two W/O microemulsions (C16-4-C16)Br2 (filled circles), C16mimBr (open circles) + pentan-1-ol + octane + NaCl solution with ω 0 = 20

As NaCl concentration increases, \(X_{\text{a}}^{\text{o}}\) and \(X_{\text{a}}^{\text{i}}\) would decrease, whereas \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\) would increase (Fig. 8A). This phenomenon can be explained by the salting-out effect. The solubility of alcohol in oil (\(X_{\text{a}}^{\text{o}}\)) would remarkably decrease at higher salinity for ionic surfactants (C16-4-C16)Br2 and C16mimBr [49]. The hydrophilic group of (C16-4-C16)Br2 or C16mimBr was compressed upon the increase in the NaCl concentration in the microemulsion droplets. Thus, the surfactant molecules tend to be less hydrophilic and the alcohol required to form the W/O microemulsion would be reduced. Therefore, \(X_{\text{a}}^{\text{i}}\) values would decrease with increasing salt concentration for the microemulsion systems. The increase in the \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\) values with increasing salt concentration indicates that salt promotes the transfer of pentan-1-ol from the oil to the interfacial layer.

Figure 8B shows that as temperature increases, the mole fractions of alcohol at the interfacial layer (\(X_{\text{a}}^{\text{i}}\)) for both microemulsion systems would increase, and more alcohol would be needed to balance the interfacial layer. Also, as temperature increases, the mole fractions of the alcohol in the oil phase (\(X_{\text{a}}^{\text{o}}\)) would decrease, resulting in an increase in \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\) values.

Conclusions

The composition and structural parameters of W/O microemulsions containing the gemini surfactant 1,4-bis(3-alkylimidazolium-1-yl)butane bromide [(Cn-4-Cn)Br2] + pentan-1-ol + octane + water were studied and compared with that of W/O systems containing ionic liquid surfactant 1-alkyl-3-methylimidazolium (CnmimBr) + pentan-1-ol + octane + water. Compared with the corresponding mono-chain analogues CnmimBr, the gemini surfactants are more tightly packed in the interfacial layer in the microemulsions, and more n-alkyl alcohol molecules are incorporated into the interfacial layer of (Cn-4-Cn)Br2 (\(X_{\text{a}}^{\text{i}}\)). This results in the greater \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\) values for (Cn-4-Cn)Br2 based microemulsion systems. The size of the water pool R w for the (Cn-4-Cn)Br2 based microemulsion systems are smaller than those for their monomeric analogues CnmimBr systems.

As the carbon chain length of the n-alkyl alcohol increases, both \(X_{\text{a}}^{\text{o}}\), the mole fraction of the n-alkyl alcohol in the oil phase, and \(X_{\text{a}}^{\text{i}}\), the mole fraction of the n-alkyl alcohol in the interfacial layer would decrease, whereas \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\), the standard free energy change of transferring n-alkyl alcohol from the continuous oil phase to the interfacial layer would increase. As the carbon chain length of alkane molecules increases, both \(X_{\text{a}}^{\text{i}}\) and \(X_{\text{a}}^{\text{o}}\) would increase, while \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\) values would decrease.

As NaCl concentration increases, \(X_{\text{a}}^{\text{o}}\) and \(X_{\text{a}}^{\text{i}}\) would decrease, whereas \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\) would increase. This phenomenon can be explained by the salting-out effect.

As temperature increases, the values of \(X_{\text{a}}^{\text{i}}\) for both microemulsion systems would increase, whereas \(X_{\text{a}}^{\text{o}}\) would decrease, resulting in an increase in \(- \Delta G_{{{\text{o}} \to {\text{i}}}}^{\text{o}}\) values.

References

Menger FM, Littau CA (1991) Gemini surfactants: synthesis and properties. J Am Chem Soc 113:1451–1452. doi:10.1021/ja00014a056

Menger FM, Littau CA (1993) Gemini surfactants: a new class of self-assembling molecules. J Am Chem Soc 115:10083–10090. doi:10.1021/ja00075a025

Dam T, Engberts JBFN, Karthaiuser J, Karaborni S, Van Os NM (1996) Synthesis, surface properties and oil solubilisation capacity of cationic gemini surfactants. Colloids Surf A 118:41–49. doi:10.1016/0927-7757(95)03383-1

Bhadani A, Singh S (2011) Synthesis and properties of thioether spacer containing gemini imidazolium surfactants. Langmuir 27:14033–14044. doi:10.1021/la202201r

Menger FM, Mbadugha BNA (2001) Gemini surfactants with a disaccharide spacer. J Am Chem Soc 123:875–885. doi:10.1021/ja0033178

Baltazar QQ, Chandawalla J, Sawyer K, Anderson JL (2007) Interfacial and micellar properties of imidazolium-based monocationic and dicationic ionic liquids. Colloids Surf A 302:150–156. doi:10.1016/j.colsurfa.2007.02.012

Ding YS, Zha M, Zhang J, Wang SS (2007) Synthesis, characterization and properties of geminal imidazolium ionic liquids. Colloids Surf A 298:201–205. doi:10.1016/j.colsurfa.2006.10.063

Rosen MJ, Tracy DJ (1998) Gemini surfactants. J Surfact Deterg 1:4. doi:10.1007/s11743-998-0057-8

Zana R (2002) Dimeric and oligomeric surfactants: behavior at interfaces and in aqueous solution: a review. Adv Colloid Interface Sci 97:203–251. doi:10.1016/S0001-8686(01)00069-0

Zana R (2002) Dimeric (gemini) surfactants: effect of the spacer group on the association behavior in aqueous solution. J Colloid Interface Sci 248:203–220. doi:10.1016/S0001-8686(01)00069-0

Khan IA, Mohammad R, Alam MS, Kabir-ud-Din (2009) Effect of alkylamine chain length on the critical micelle concentration of cationic gemini butanediyl-α, ω-bis(dimethylcetylammonium bromide) surfactant. J Dispers Sci Technol 30:1486–1493. doi:10.1080/01932690903123361

Khan IA, Mohammad R, Alam MS, Kabir-ud-Din (2010) Surface properties and mixed micellization of cationic gemini surfactants with ethylene amines. J Chem Eng Data 55:370–380. doi:10.1021/je9003756

Khan IA, Mohammad R, Alam MS, Kabir-ud-Din (2010) Mixed micellization of cationic gemini surfactants with primary linear alkylamines. J Surfact Deterg 13:179–188. doi:10.1007/s11743-009-1148-0

Chavda S, Kuperkar K, Bahadur P (2011) Formation and growth of Gemini surfactant (12-s-12) micelles as a modulate by spacers: a thermodynamic and small-angle neutron scattering (SANS) study. J Chem Eng Data 56:2647–2654. doi:10.1021/je2001683

Ao MQ, Huang PP, Xu GY, Yang XD, Wang YJ (2009) Aggregation and thermodynamic properties of ionic liquid-type gemini imidazolium surfactants with different spacer length. Colloid Polym Sci 287:395–402. doi:10.1007/s00396-008-1976-x

Rodrıguez A, Graciani MM, Munoz M, Robina I, Moya ML (2006) Effects of ethylene glycol addition on the aggregation and micellar growth of gemini surfactants. Langmuir 22:9519–9525. doi:10.1021/la062225e

Shang YZ, Wang TF, Han X, Peng CJ, Liu HL (2010) Effect of ionic liquids CnmimBr on properties of gemini surfactant 12-3-12 aqueous solution. Ind Eng Chem Res 49:8852–8857. doi:10.1021/ie100896z

Kabir-ud-Din PAK (2010) Micellar properties and related thermodynamic parameters of the 14-6-14·2Br− gemini surfactant in water + organic solvent mixed media. J Chem Eng Data 55:1921–1929. doi:10.1021/je900894x

Wattebled L, Laschewsky A (2007) Effects of organic salt additives on the behavior of dimeric (“Gemini”) surfactants in aqueous solution. Langmuir 23:10044–10052. doi:10.1021/la701542k

Khan IA, Khanam AJ, Sheikh MS, Kabir-ud-Din (2011) Influence of ionic and nonionic hydrotropes on micellar behavior of a cationic gemini surfactant butanediyl-1,4-bis(dimethylcetylammonium bromide). J Colloid Interface Sci 359:467–473. doi:10.1016/j.jcis.2011.03.083

Khan IA, Khanam AJ, Khan ZA, Kabir-ud-Din (2010) Mixing behavior of anionic hydrotropes with cationic gemini surfactants. J Chem Eng Data 55:4775–4779. doi:10.1021/je100256w

Tikariha D, Ghosh KK (2010) Mixed micellization properties of cationic monomeric and gemini surfactants. J Chem Eng Data 55:4162–4167. doi:10.1021/je100113r

Wang YJ, Bai GY, Marques EF, Yan HK (2006) Phase behavior and thermodynamics of a mixture of cationic gemini and anionic surfactant. J Phys Chem B 110:5294–5300. doi:10.1021/jp054323z

Sardar N, Ali MS, Kamil M, Kabir-ud-Din (2010) Phase behavior of nonionic polymer hydroxypropylmethyl cellulose: Effect of gemini and single-chain surfactants on the energetics at the cloud point. J Chem Eng Data 55:4990–4994. doi:10.1021/je100572d

Alam MS, Naqvi AZ, Kabir-ud-Din (2007) Tuning of the cloud point of promethazine hydrochloride with surfactants and polymers. J Surfact Deterg 10:35–40. doi:10.1007/s11743-006-1008-0

Alam MS, Naqvi AZ, Kabir-ud-Din (2007) Role of surfactants in clouding phenomenon of imipramine hydrochloride. Colloids Surf B 57:204–208. doi:10.1016/j.colsurfb.2007.02.013

Alam MS, Naqvi AZ, Kabir-ud-Din (2008) Study of the cloud point of the phenothiazine drug chlorpromazine hydrochloride: effect of surfactants and polymers. J Dispers Sci Technol 29:274–279. doi:10.1080/01932690701707597

Alam MS, Kabir-ud-Din Asit Baran, Mandal (2010) Evaluation of thermodynamic parameters of amphiphilic tricyclic antidepressant drug imipramine hydrochloride-additive systems at the cloud point. Colloids Surf B 76:577–584

Alam MS, Kabir-ud-Din, Mandal AB (2010) Thermodynamics at the cloud point of phenothiazine drug chlorpromazine hydrochloride-additive systems. J Chem Eng Data 55:1693–1699. doi:10.1021/je9007487

Alam MS, Kabir-ud-Din, Mandal AB (2010) Amphiphilic drug promethazine hydrochloride-additive systems: evaluation of thermodynamic parameters at cloud point. J Chem Eng Data 55:1893–1896. doi:10.1021/je9008975

Chen LF, Shang YZ, Liu HL, Hu Y (2007) Middle-phase microemulsion induced by brine in region of low cationic gemini surfactant content. Colloids Surf A 305:29–35. doi:10.1016/j.colsurfa.2007.04.037

Dreja M, Tieke B (1998) Polymerization of styrene in ternary microemulsion using cationic gemini surfactants. Langmuir 14:800–807. doi:10.1021/la9710738

Dreja M, Hintzen WP, Mays H, Tieke B (1999) Cationic gemini surfactants with oligo(oxyethylene) spacer groups and their use in the polymerization of styrene in ternary microemulsion. Langmuir 15:391–399. doi:10.1021/la981354v

Moulik SP, Digout LG, Aylward WM, Palepu R (2000) Studies on the interfacial composition and thermodynamic properties of W/O microemulsions. Langmuir 16:3101–3106. doi:10.1021/la991028v

Paul BK, Nandy D (2007) Dilution method study on the interfacial composition, thermodynamic properties and structural parameters of W/O microemulsions stabilized by 1-pentanol and surfactants in absence and presence of sodium chloride. J Colloid Interface Sci 316:751–761. doi:10.1016/j.jcis.2007.09.009

Ao MQ, Xu GY, Zhu YY, Bai Y (2008) Synthesis and properties of ionic liquid-type gemini imidazolium surfactants. J Colloid Interface Sci 326:490–495

Pino V, Ao C, Anderson LJ (2009) Micellization and interfacial behavior of imidazolium-based ionic liquids in organic solvent–water mixtures. J Colloid Interface Sci 333:548–556. doi:10.1016/j.jcis.2009.02.037

Khadilkar BM, Rebeiro GL (2002) Microwave-assisted synthesis of room-temperature ionic liquid precursor in closed vessel. Org Process Res Dev 6:826–828. doi:10.1021/op025551j

Branco L, Rosa JN, Ramos JJM, Afonso CAM (2002) Preparation and characterization of new room temperature ionic liquids. Chem Eur J 8:3671–3677. doi:10.1002/1521-3765(20020816)8:16<3671::AID-CHEM3671>3.0.CO;2-9

Wasserscheid P, Keim W (2000) Ionic liquids-new “solutions” for transition metal catalysis. Angew Chem Int Ed 39:3772–3789. doi:10.1002/1521-3773(20001103)39:21<3772::AID-ANIE3772>3.0.CO;2-5

Zheng O, Zhao JX, Fu XM (2006) Interfacial composition and structural parameters of water/C12-S-C12·2Br/n-hexanol/n-heptane microemulsions studied by the dilution method. Langmuir 22:3528–3532. doi:10.1021/la052772k

Zheng O, Zhao JX, Yan H, Gao SK (2007) Dilution method study on the interfacial composition and structural parameters of water/C12–EOx–C12·2Br/n-hexanol/n-heptane microemulsions: effect of the oxyethylene groups in the spacer. J Colloid Interface Sci 310:331–336. doi:10.1016/j.jcis.2007.01.056

Xu L, Chai JL, Zhu ML, Liu W, Shang SS, Lu JJ (2011) Interfacial composition and structural parameters of aqueous NaCl(HCl/NaOH)/CnmimBr/1-pentanol/n-octane microemulsions. Tenside Surf Det 48:459–465. doi:10.3139/113.110153

Li Y, Chai JL, Xue XN, Zhan ZM (2009) Studies on the interfacial composition, thermodynamic properties and structural parameters of W/O microemulsions containing surfactant-like ionic liquid. Polish J Chem 83:1809–1820

Dreja M, Hintzen WP, Mays H, Tieke B (1999) Cationic gemini surfactants with oligo(oxyethylene) spacer groups and their use in the polymerization of styrene in ternary microemulsion. Langmuir 15:391–399. doi:10.1021/la981354v

Stubenrauch C, Paeplow B, Findenegg GH (1997) Microemulsions supported by octyl monoglucoside and geraniol. Langmuir 13:3652–3658. doi:10.1021/la970180z

Kunieda H, Nakano A, Pes MA (1995) Effect of oil on the solubilization in microemulsion systems including nonionic surfactant mixtures. Langmuir 11:3302–3306. doi:10.1021/la00009a006

Bansal VK, Chinnaswamy K, Ramachandran C, Shah DO (1979) Structural aspects of microemulsions using dielectric relaxation and spin label techniques. J Colloid Interface Sci 72:524–537. doi:10.1016/0021-9797(79)90354-0

Kunieda H, Aoki R (1996) Effect of added salt on the maximum solubilization in an ionic-surfactant microemulsion. Langmuir 12:5796–5799. doi:10.1021/la960472k

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant No. 21476133).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

About this article

Cite this article

Chai, J., Song, J., Wang, D. et al. Comparison of the Composition and Structural Parameters of W/O Microemulsions Containing Gemini Imidazoliums with Those Containing Monomeric Analogues. J Surfact Deterg 18, 287–295 (2015). https://doi.org/10.1007/s11743-014-1648-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11743-014-1648-4