Abstract

Corrosion inhibition performance of three sodium polyacrylates polymers was analyzed for carbon steel type OLC 45 in 0.5 M H2SO4 solution. Effectiveness of this polymers were investigated by potentiostatic and potentiodynamic polarization methods, electrochemical impedance spectroscopy (EIS), Fourier transform infrared (FT-IR) spectroscopy, scanning electron microscopy (SEM) and metallurgical microscopy techniques. The polymers involved in this study are three sodium polyacrylates hydrophobically modified with linear and cyclododecyl and, respectively, dihexyl chain (NaPADD, NaPACDD and NaPADH). We assume that, these polymers prevent corrosion of metal electrodes by a protective process can be due to either the adsorption of inhibitor molecules building a protective film or achievement an insoluble complex. Results showed that these polymers accomplished a considerable inhibiting action on OLC 45 corrosion and act that a mixed corrosion inhibitors and it could be proved by the effects of polymers on the electrochemical properties of metal electrodes. The adsorption of the polymers on the electrodes surface obeys to the Langmuir isotherm model. The temperature influence on the corrosion behavior of the metal electrodes in 0.5M H2SO4 with and without the inhibitor at 800 ppm was analyzed in the temperature domain from 293 to 333 K. The negative value of thermodynamic parameter like Gibbs free energy of adsorption shows the spontaneity of adsorption process. The characterization by FT-IR and SEM confirms the adsorption of inhibitors and the formation of corrosion products on the working electrode surface. EIS and potentiodynamic polarization data were indicative its corrosion protection ability. The best inhibition of 97% gets at an inhibitor concentration of 800 ppm for NaPACDD.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The metallic materials are widely utilized in diverse industry applications, such as: chemical processing, petroleum production and refining, technological equipment and marine applications; this improved the exploration in corrosion protection in various aggressive media. Because corrosion is the real element in the degradation of industrial components, numerous tests have been realized to find techniques of diminishing corrosion and wear costs (Jones 1992; Sastri 2011; Popova et al. 2004; Migahed et al. 2018; Branzoi and Branzoi 2002). Protection of these metals can be achieved by numerous methods of which the treatment of the aggressive media and by using of inhibitors is one of the most important. Many studies achieved for protection of materials used in engineering fields revealed using corrosion inhibitors as the most efficacious and easy approach of preventing damaging of metals and its alloys in aggressive media (Branzoi and Branzoi 2002; Fouda and Ellithy 2009; Obot and Obi-Egbedi 2010; Branzoi et al. 2014; Gong et al. 2019; Yadav et al. 2012a, b). Acid solutions are intensively used in a numerous of industrial processes such as oil well acidification, acid pickling, acidic cleaning, acid descaling and the petrochemical procedures, which generally determine to grave metallic corrosion of various metal structures and equipment in industry. Also, the rate of corrosion at which metals are deteriorated in acidic media is very raised, mainly when soluble corrosion products are obtained. Consequently, studying and exploring corrosion inhibitors for carbon steel corrosion in acid solutions are important both for field of research and as well for its practical applications. Hence, the development of novel corrosion inhibitors is significant for practical applications pointing to reduction the metal corrosion process. The corrosion of metals in corrosive media was meaningfully eliminated through improvement of the metal area by adsorbed of organic compounds. Numerous researches were achieved to determine the suitable inhibitors that utilized to protect the metal from the excessive deterioration by corrosion (Branzoi et al. 2014; Gong et al. 2019; Yadav et al. 2012a, b; Ansari et al. 2015; Branzoi and Branzoi 2017; Li et al. 2009; Obot et al. 2017a, b). Corrosion inhibitor is an organic or inorganic compound introduced in tiny quantities to aggressive medium for hinder of corrosive attack on the metallic materials. The advantageous inhibitors must be enough in small concentrations and very efficacious in corrosion diminish. Prevention of the corrosion in aggressive medium is possible by forming a barrier between the electrode surface and the corrosive solution. The inhibitor must have suitable properties to adsorb on the metal surface to establish a solid barrier film. Some studies revealed that most organic inhibitors operate by adsorption on the metal surface and in general, inhibitors can act either by physical adsorption and/or chemisorption (Branzoi and Branzoi 2017; Li et al. 2009; Obot et al. 2017a, b; Gopi et al. 2010; Branzoi and Branzoi 2016; Hegazy et al. 2012). In the last years, the development of new green organic compounds (surfactants, polymers, plants extract) as acid inhibitors with biodegradable, environmentally accommodative, relatively inexpensive and non-toxic features on active metals is one of the on a wide scale researched domain the area of anticorrosion protection (Branzoi and Branzoi 2016; Hegazy et al. 2012; Branzoi et al. 2018; Obot et al. 2017a, b; Hejazi et al. 2015; Chikh et al. 2005; Amin et al. 2009; Branzoi and Băran 2019; Gong et al. 2019;). The existence of heteroatoms like as oxygen, nitrogen, sulfur, phosphorus, double, triple bonds, and aromatic rings in the inhibitors chemical composition increase the adsorption mechanism. Organic compounds of this kind adsorb on the metal surface and establish a relationship from the heteroatom pair and/or the π electron and the metal, thus minimizing the corrosion in acidic media (Hejazi et al. 2015; Chikh et al. 2005; Amin et al. 2009; Branzoi and Băran 2019; Gong et al. 2019; Abd-El-Naby et al. 2016; Hegazy 2015; Khaled and Amin Mohammed 2009). The polymers are considered very favorable as corrosion inhibitors because they may adsorb on the electrode surface and that determine to a diminution in the unprotected area of the active electrode surface and increase the activation energy (Amin et al. 2009; Branzoi and Băran 2019; Gong et al. 2019; Abd-El-Naby et al. 2016; Hegazy 2015; Khaled and Amin Mohammed 2009). The polymers with their functional groups establish complexes with metal ions; onto the electrode surface these complexes take a great surface area, thus, covering the surface and preventing the metal at corrosion (Gong et al. 2019; Abd-El-Naby et al. 2016; Hegazy 2015; Khaled and Amin Mohammed 2009). Many researchers suggested that the best parts of polymers are adsorbed on the metal surface by displaced water molecules from the electrode surface and forming a strong and strengthened barrier film (Hegazy et al. 2012; Branzoi et al. 2018; Obot et al. 2017a, b; Amin et al. 2009; Branzoi and Băran 2019; Gong et al. 2019; Abd-El-Naby et al. 2016; Hegazy 2015; Khaled and Amin Mohammed 2009). It can be said that, the polyacrylates polymers as inhibitors have numerous benefits like as great inhibition effectiveness, reduced price, low toxicity and simple obtaining. A sodium polyacrylate polymer (Fig. 1) molecule has oxygen and nitrogen atoms and double bond which are supposed to be possible active centers of adsorption. The ability of a polymer molecule to adsorb is mainly directly connected to its feature to aggregate and to form micelles. Water-soluble hydrophobically modified polyacrylates are considered intelligent materials with high applicative potential. The wide range of applications is given by their self-assembly ability to form intra- and inter-molecular hydrophobic micro-domains (Aricov et al. 2016a, b). Due to the occurrence of inter-molecular associations, these polymers develop strong hydrophobic networks, making them useful as rheological modifiers (Aricov et al. 2016a, b). Their aggregation mechanism, especially in diluted regime, is very sensitive to external stimuli such as pH, addition of salt or surfactants, which leads to the modification of their conformation in aqueous solutions. We demonstrated, in our previously work, that the hydrophobically modified polyacrylates, in the absence or presence of surfactants, exhibit hosting properties for hydrophobic compounds (Aricov et al. 2017). Also, depending on concentration, grafted alkyl chain length, pH and amount of the added electrolyte, they can be used in the field of viscoelastic foams (Aricov et al. 2016a, b). The associative polyacrylates, which are weak polyelectrolytes, have been used to build, by electrostatic deposition, layer-by-layer films with water repellent properties (Gîfu et al. 2016). Further, it has been shown that the multilayer films based on hydrophobic modified polyacrylates can be applied as long-term hydrophobic coatings (Gîfu et al. 2017). As have been shown above, our group is mainly focused on synthesizing and investigating these multifunctional materials with different applications in various fields. The adsorption of sodium polyacrylates polymers notably affected the corrosion resisting estate of metallic materials. The aim of this research is to examine the corrosion inhibitory properties of sodium polyacrylates polymers as novel inhibitors for the corrosion of carbon steel OLC 45 in 0.5M sulfuric acid media. Therefore, the purpose of this paper is to build novel hydrophobic modified polyacrylates with anticorrosion properties. Their behavior in aqueous solution was also monitored by surface tension, viscosity, and refractive index and steady-state fluorescence measurements. The inhibiting performance of these polymers was assessed by polarization curves, electrochemical impedance spectroscopy (EIS), Fourier transform infrared (FT-IR) spectroscopy, scanning electron microscopy (SEM) and metallurgical microscopy techniques. Furthermore, the influence of inhibitor concentration, temperature and immersion time on the corrosion inhibition has been studied.

Experimental

Materials

In present study, the elaborated organic inhibitors were three sodium polyacrylates hydrophobically modified with linear and cyclododecyl and, respectively, dihexyl chain. Aqueous solution of polyacrylic acid (PAA, 25 wt%) was purchased from Wako Pure Chemical Industries Ltd. Anhydrous N-methyl-2- pyrrolidinone (NMP), dicyclohexylcarbodiimide (DCC), dodecylamine (DA, 99%), cyclododecylamine (CD, 97%), dihexylamine (DH, 97%), sodium hydroxide, methanol and pyrene were supplied by Sigma-Aldrich Chemie GmbH. Pyrene was supplied by Merck, Germany. The chemicals were used without further purification. Millipore water was used to prepare the solution for measurements. The corrosive medium was 0.5M H2SO4 has been prepared by dilution of AG 96% H2SO4 (from Merck) with bi-distilled water. Corrosion tests have been accomplished onto OLC 45 electrode with structure: C% 0.48, Si 0.03%, Mn 0.79%, Fe% 98.32, P% 0.02, S% 0.025, Al% 0.027, Ni % 0.05, Cr% 0.06, Cu% 0.18, Sn% 0.012 and As% 0.006. The working electrode is carbon steel OLC 45 with cylindrical form and with an area of 0.5 cm2. This shape is preference, because it assures a considerable surface and without edges. The working specimen was mechanically abraded with emery papers with diverse dimension (600–4000 grid) up to mirror-luster. Then, the working specimen was cleaned in benzene at boiling temperature to eliminate all traced of grease, after that, the working electrode was washed in doubly distilled water, dried at room temperature and inserted in the polarization cell. All measurements have been accomplished at 25 °C in atmospheric oxygen without agitation. Corrosion samples have been achieved with and without of diverse dosages of polymers. The electrochemical methods have been accomplished by using the electrochemical cell with a three conventional electrode: a platinum sheet as auxiliary electrode, a saturated calomel electrode like the reference electrode and a working electrode: OLC 45 disk with a surface area 0.5 cm2. This cell was attached to an automated model VoltaLab 40 potentiostat/galvanostat coupled to a PC running VoltaMaster software.

Methods

Synthesis and chemical composition

The hydrofobically modified sodium polyacrylates were synthesized using an earlier reported procedure (Aricov et al. 2016a, b). The chemical modification consisted of attaching a hydrophobic molecule to the PAA chain by amidation. The hydrophobic parts are derived from dodecyl-, cyclododecyl- and dihexyl-amines. Accordingly, three new polymers having a theoretical grafting degree of 2% (mole) were obtained. The amidation reaction was proved previously by FT-IR and 1H-NMR measurements (Aricov et al. 2016a, b). Also, from 1H-NMR spectra, the grafted hydrophobic amount of PAA was found to be 1.91% (mol) for NaPADD, 1.82% (mol) for NaPACDD and 1.83% (mol) for NaPADH. The chemical structures of NaPADD, NaPACDD and NaPADH are illustrated in Scheme 1.

Measurements of polymers

The surface tension measurements were done on a K11 MK3 Krűss tensiometer, the Du Noüy platinum ring method being employed. The viscosities were determined using an Ostwald viscometer having a flow time for water of about 102 s. A digital Abbe refractometer AR2008 (KRUSS, Germany) was used for refractive index measurements. Steady-state fluorescence measurements were done on a Horiba Jobin–Yvon FluoroMax 4P spectrofluorimeter, the pyrene being the probe. The excitation was set at 335 nm and the slits were of 2 nm for excitation and 1 nm for emission. The polarity index (I1/I3) was calculated as the ratio of the intensities of the first (I1 at 371 nm) and the third (I3 at 381 nm) vibronic peaks.

Electrochemical measurements

The electrochemical behavior of an OLC 45 electrode in 0.5M H2SO4 with and without of polymers has been investigated by registering anodic and cathodic potentiodynamic polarization curves and electrochemical impedance spectroscopy measurements. Experimental methods have been described previously (Branzoi et al. 2014; Branzoi and Băran 2019). The inhibiting action has been elaborate from the polarization curves accomplished utilizing the potentiodynamic techniques and estimation of the electrochemical parameters for corrosion of working electrodes with and without diverse concentration of polymers. Examination of Tafel polarization curves was accomplished by plotting the potential from cathodic to anodic potentials in the potential domain from − 800 to − 50 mV (SCE) at a sweep rate of 2 mV s−1 for OLC 45 working electrode. The Tafel sections of anodic and cathodic curves have been extrapolated to corrosion potential; the corrosion current density (icorr) was achieved from the Tafel curves. All potentials were recorded versus the SCE. The electrochemical impedance spectroscopy (EIS) techniques have been obtained at open circuit potential (OCP) on the frequency range from 100 kHz to 40 mHz with an AC wave of ± 10 mV (peak-to-peak) and the impedance tests were achieved at a rate of 10 points per decade change in frequency. The experimental tests were repeated for each solution until a very good agreement of the data was performed. The all electrochemical experiments were realized using a VolaLab PGZ 301 instrument Potentiostat/Galvanostat.

Surface characterization of working electrode

To determine the protective film obtained over the electrode surface with polymers has been investigated by FT-IR data. Fourier transform infrared (FT-IR) spectra have been effectuated with a Bruker optik spectrometer (Tensor 37) at room temperature. All spectra in this study have been effectuated at a resolution 4 cm−1 in the spectral range 4000–650 cm−1. The getting of the adsorption protective film of these polymers over the metal area was verified by the scanning electron microscopy (SEM) and by metallurgical research microscope observation. The SEM has been investigated with JEOL JSM-5500LV microscope working at 30 kV and metallographic micrographies by Microscope Hund H660.

Results and discussion

Characterization of inhibitors

The ability of hydrophobically modified polyacrylates to self-associate

Firstly, the behavior of the three polymers in aqueous solution was investigated by several methods, namely surface tension (ST), viscosity (RV), refractometry (RI) and steady-state fluorescence. The results are presented in Fig. 1 and they will be briefly discussed, as the main objective of the study is the corrosion properties of these C12-hydrophobically modified sodium polyacrylates. From Fig. 1 one may observe that, at low polymer concentration, all the properties have almost constant values. This happens till a polymer concentration of about 0.1% when surface tension and pyrene polarity index (I1/I3, Aricov et al. 2016a, b) start to decrease, while relative viscosity and refractive index start to increase.

These changes are attributed to the occurrence of intra-coil aggregation (Aricov et al. 2016a, b). As more polymer is added in the solution (concentration higher than 0.5%), the ST and I1/I3 continue to decrease, while relative viscosity and refractive index increase with a different slope. This may be attributed to the formation of some inter-coil aggregates although this concentration is below the \(c^{*}\) (the overlapping concentration) of the 3% linear C12-hydrophobically modified sodium polyacrylate (Aricov et al. 2016a, b). Because these polyacrylates have a lower grafting degree, one may expect that they have a higher \(c^{*}\). Further investigations are necessary, but they are beyond the aim of this study. Anyway, it can be observed from the Figures that, in aqueous solution and in the studied concentration range, there are not great differences in the three polymers behavior, though their labels are quite different (i.e., dodecyl, dihexyl and cyclododecyl). As was mentioned in Introduction, these novel hydrophobically modified polyacrylates-based polymers are very important in various applications: cosmetics, detergents, foods, drug delivery, protection at corrosion, etc. As can be deduced from the chemical structure, these sodium polyacrylates may have characteristics suitable for their application as corrosion inhibitors. It is supposed that these polymers will be better corrosion inhibitors because the enhanced performances of the polymeric materials are attributed to their multiple adsorption centers for bonding with the metal surface. The polymers give many advantages: a single polymer chain displaces numerous water molecules from the metal surface, thus making the process advantageous and the presence of the multiple bonding sites makes the desorption of the polymers to be a slower process. Moreover, little seems to be published regarding the corrosion inhibition of carbon steel using polymers. Therefore, in the following sections we will investigate the corrosion inhibition of OLC 45 in sulfuric acid solutions using these three novel hydrophobically modified polyacrylates-based polymers. The selection of this type of the corrosive media was made because sulfuric acid solutions are intensively used in a numerous of industrial processes which generally determine to grave metallic corrosion of various metal structures and equipment in industry.

Electrochemical studies

Potentiodynamic polarization measurements

In this research, one of the best ways for corrosion protection of metal electrodes in aggressive medium is the employment of the inhibitors, which check the corrosion of anodic or cathodic reaction and both. Figure 2 shows the polarization curves of OLC 45 electrode in 0.5M H2SO4 solution with and without different concentrations of three sodium polyacrylates polymers: NaPADD, NaPACD and NaPADH. It was established that, both cathodic and anodic polarization curves denoted lower current density in the presence of organic polymers inhibitors than those determined in non-inhibiting solutions. This behavior revealed that all used sodium polyacrylates polymers had significant influences on cathodic and anodic reactions of the electrochemical process. As well, in Fig. 2 we noticed for both the anodic metal dissolution and cathodic hydrogen evolution processes were prevented by the addition of these organic polymers to the aggressive medium. The presence of NaPADD, NaPACD and NaPADH polymers as corrosion inhibitors as well shift the corrosion potential (Ecorr) to more positively compared to the blank, appearing that the inhibitors have more important affect on the anodic reaction than the cathodic reaction (Branzoi et al. 2014; Li et al. 2009; Obot et al. 2017a, b; Gong et al. 2019; Abd-El-Naby et al. 2016; Hegazy 2015; Khaled and Amin Mohammed 2009; Singh et al. 2014). The electrochemical parameters like as corrosion potential (Ecorr), corrosion current density (icorr) cathodic and anodic Tafel slopes (bc, ba), also as inhibition efficiency (E%) are calculated and presented in Tables 1, 2 and 3. It can be observed from Fig. 2 and Tables 1, 2 and 3 that the addition of NaPADD, NaPACD and NaPADH the greatly modified corrosion potential was distinguished in shift of Ecorr to more positive and the significantly reduced in inhibited anodic Tafel slopes (ba) in the presence of polymers shows the influence of sodium polyacrylates polymers on the anodic dissolution metal process. This fact can be assigned to adsorption of the SO42− ions and/or the inhibitor molecules over the anodic active carbon steel surface and prevented by blocking the anodic metal dissolution process (Branzoi et al. 2014; Li et al. 2009; Obot et al. 2017a, b; Hegazy et al. 2012; Gong et al. 2019; Abd-El-Naby et al. 2016; Hegazy 2015; Khaled and Amin Mohammed 2009; Singh et al. 2014). This means that polymers reduced the dissolution rate of iron it have established an anodic inhibition.

The experimental results indicated that the corrosion current density decreased notably with sodium polyacrylates polymers: NaPADD, NaPACD and NaPADH concentration and at the same time the inhibition effectiveness increased. The data appear that the formed protective inhibitor layer accomplish adsorbed on the OLC 45 surface, blocking the available reaction sites.

By investigation in comparison the inhibition efficiency and the corrosion rate (Rmpy, in mil per year; P, in mm per year and Kg, in g m−2 h−1) for all inhibitors, in the same condition, it is obvious, sodium polyacrylates polymers: NaPADD, NaPACD and NaPADH have an excellent efficiency for anticorrosion protection of OLC 45 electrode in 0.5M H2SO4. Polymers present higher corrosion protection property of metal because they possess long chain carbon bond and numerous adsorption sites (oxygen, nitrogen atoms), which determine greater adsorption on the surface of the metal depending on donor/acceptor type reaction. These molecules comprise a wide surface area and protect the OLC 45 of the aggressive ions in the solution. The protection action is established onto the adsorption of the inhibitor molecules on the active centers and/or formation of the corrosion compounds over the OLC 45 electrode surface. As well, it can be noticed from Fig. 2 and Tables 1, 2 and 3 that the greater inhibition effectiveness was achieved for: NaPACD/OLC45/H2SO4 at the 500 ppm and 800 ppm concentration, for NaPADD/OLC 45/H2SO4 at the 800 ppm and 500 ppm concentration and for NaPADH/OLC 45/H2SO4 at the 800 ppm and 1000 ppm concentration. The examined of these polymers exhibited very good inhibition abilities for OLC 45 electrode in 0.5M H2SO4 medium while the corrosion current density decreased and the inhibitor efficiency increased with increasing inhibitors concentrations. Thus, the results from Tables 1, 2 and 3 indicate that the order of increased in inhibition efficiency of the sodium polyacrylates polymers is: NaPACD > NaPADD > NaPADH.

As well, the protection efficiency increases with the hydrophobic chain length molecule and with concentration of the inhibitor, to a concentration greater than the CMC, the inhibiting activity of these polymers increases quickly.

Effect of immersion time

The influence of increasing immersion time 1–144 h on corrosion protection of NaPADD, NaPACD, NaPADH inhibitor at concentration 800 ppm on the corrosion of OLC 45 in 0.5M H2SO4 at 25 °C was analyzed by potentiodynamic polarization. The result of inhibition efficiency of three sodium polyacrylates polymers with immersion time is presented in Fig. 3.

The protection efficiency slowly decreases with rise in time. The cause may be determined to some defects present on the protective layer allowing to the admission of corrosive ions at the OLC 45 electrode/polymer (Chikh et al. 2005). Moreover, the establishment of hemimicelles aggregates by the first constituted polymer molecules decrease the effective surface coated by the organic compound (Chikh et al. 2005). It is obvious that after 96 h immersion time, the organic polymer effectiveness is yet 90%, which denotes that polyacrylate polymer is a lengthy time efficacious inhibitor for OLC 45 in 0.5M H2SO4 solution.

Electrochemical impedance spectroscopy (EIS)

The corrosion inhibition effect of three sodium polyacrylates polymers on OLC 45 was also examined by electrochemical impedance spectroscopy (EIS) at the open circuit potential state. EIS tests present information about of the protection properties of sodium polyacrylates polymers as a corrosion inhibitor of working electrodes in corrosive medium. Nyquist plots for OLC 45 realized at the interface with and without at various dosages of NaPADD, NaPACD and NaPADH polymers are indicated in Fig. 4.

Figure 4 indicates the Nyquist graph of OLC 45 in 0.5M H2SO4 environment with and without of these polymers at various concentrations. The impedance spectra of OLC 45 electrode exhibit one capacitive loop and the measure of the semicircles enhances with increasing the inhibitor concentration, which denotes that the corrosion of OLC 45 in 0.5M H2SO4 medium is hindered by the presence of the inhibitor. In the principal, the one capacitive loop as introduced in the Nyquist diagrams suppose one time constant most probable correlated with the charge transfer process of the inhibitive compounds on the electrode surface (Branzoi and Branzoi 2016; Branzoi and Branzoi 2017; Hejazi et al. 2015; Zhang et al. 2012). Figure 4 shows that the diameters of the capacitance loops in the presence of the sodium polyacrylates are superior than those in the absence of these polymers, proposing that these inhibitors have excellent protection properties on OLC 45 electrode in 0.5M H2SO4. It is obvious by the Nyquist diagrams that the impedance answer of carbon steel has been meaningfully modified by the adding of the polymers which implying that the getting protective layer was confirmed by the addition of NaPADD, NaPACD and NaPADH polymers. It is evident, that these impedance plots are not perfect semicircles and this event is ascribed to frequency dispersion, largely allocated to rugosity and inhomogeneities of the OLS 45 surface (Branzoi and Branzoi 2016, 2017; Obot et al. 2017a, b; Hejazi et al. 2015; Zhang et al. 2012). Figure 4 denotes that the diameters of the capacitance loops at 1000 ppm and 800 ppm NaPADD/OLC 45/H2SO4, 800 ppm and 1000 ppm NaPACD/OLC 45/H2SO4 and 1000 ppm and 800 ppm NaPADD/OLC 45/H2SO4 are superior to these in the absence of polymers, supposing that provide a great protection influence for OLC 45 electrode in aggressive solution.

Bode graphs presented in Figs. 5, 6 and 7 are in concordance with Nyquist diagrams (Fig. 4). The impedance modulus, at low frequencies, increases with the rise of the inhibitor concentration, showing that the adsorption of the protective molecules of polyacrylates polymers enhances the corrosion resistance of the elaborated carbon steel OLC 45 in the H2SO4 solution. Increasing in Zmod denotes to a higher inhibition capacity and it is also evident that Zmod rises when the concentration of all studied inhibitors increases. A greater Zmod establishes superior protection effectiveness. It is obvious from Figs. 5, 6 and 7 that without of polymer the OLC 45 electrode denote one time constant suitable to a phase angle of 45° at medium and low frequencies this exhibits an inductive behavior with low diffusive disposition. From Figs. 5, 6 and 7, it can be observed that in the presence of sodium polyacrylates polymers on the graph-phase angle against the frequency logarithm presents a maximum very well established assigned at a phase angle of proximate 75° for NaPADD, 70° for NaPACDD and NaPADH, hence, in this event the electrode has a bigger capacitive comportment in agreement with the Nyquist diagrams and experimental data obtained by potentiodynamic polarization (Branzoi and Branzoi 2017; Obot et al. 2017a, b; Hejazi et al. 2015; Zhang et al. 2012; Singh et al. 2014). It can be noticed from the Bode diagrams that phase angle meaningfully increased in the presence of polyacrylates polymers due to the constitution the protection layer on the OLC 45 surface. Hence, in the elaborated frequency range, an equivalent circuit model was proposed in order to fit and analyze the obtained EIS data. In this event, the constant phase element, CPE, is introduced in the circuit instead of a pure double layer capacitor (Cdl) to offer a more accurate fit. The CPE is used to describe the depression of the capacitance semicircle, which corresponds to surface heterogeneity from surface roughness and impurities. The impedance of CPE can be defined as: ZCPE = Y−10 (jω)−n, where ω is the angular frequency, j is the imaginary number (j2 = − 1), Y0 is the amplitude comparable to a capacitance and n is the phase shift. The phase shift value offers details about the degree of metal surface inhomogeneity. The greater the n value is associated to the lower surface roughness, i.e., reduced surface inhomogeneity. The CPE can establish as resistance when n = 0, Y0 = R), capacitance when n = 1 (Y0 = R) and inductance when n = −1 (Y0 = 1/L), or Warburg impedance when n = 0.5 (Y0 = W) based on the value of n. (Obot et al. 2017a, b; Hejazi et al. 2015; Zhang et al. 2012; Singh and Quraishi 2010; Sangeetha et al. 2016; Negm et al. 2018).

Analysis of the experimental data was determined by fitting the results to the suitable equivalent circuit presented in Fig. 8 and the different impedance characteristics as the solution resistance (Rs), the charge transfer resistance (Rct), the capacitance of double layer (Cdl) and inhibition efficiency were calculated and indicated in Tables 4, 5 and 6. The results obtained from EIS reveal that the charge transfer resistance Rct raised and the double layer capacitance Cdl reduced with inhibitor concentration. Then, the inhibition efficiency can be calculated utilizing the next equation: IE (%) = Rct −R0ct/Rct × 100 where, Rct and R0ct are the charge transfer resistance amounts in the presence and in absence of different concentrations of the inhibitor. The double layer capacitance (Cdl) was evaluated from the equation: Cdl = 1/2πfmaxRct, where fmax is the frequency at which the imaginary component of the impedance is maximum. As a consequence of rising of Rct values with the concentration of polymer the inhibition effectiveness increase meaningfully which appears that inhibitor presents valuable protection for the corrosion of OLC 45 electrode. The reduction in Cdl may be possible by a reduce in local dielectric constant and/or increase in the thickness of the electrical double layer, meaning that the presence of polymer molecules operates by adsorption at the interface of the electrode/solution (Obot et al. 2017a, b; Hejazi et al. 2015; Chikh et al. 2005; Amin et al. 2009; Branzoi and Băran 2019; Singh et al. 2014; Mobin and Rizvi 2016; Labjar et al. 2010; Abd El-Lateef et al. 2017; Sangeetha et al. 2016; Negm et al. 2018). The increase in charge transfer resistance and the reduce in Cdl values can be attributed to the substituted of water molecules by the adsorption of the polymer molecules on the metal area and the obtained of a protective film on the OLC 45 surface (Obot et al. 2017a, b; Hejazi et al. 2015; Mobin and Rizvi 2016; Labjar et al. 2010; Abd El-Lateef et al. 2017; Sangeetha et al. 2016; Negm et al. 2018). The polyacrylates polymers molecules adsorbed on the surface of OLC 45 electrodes constitute a protective layer on the carbon steel surface. Through the rising in the value of Rct, the efficiency of inhibition also increased. The Nyquist and Bode plots suggest that the mechanism of corrosion were prevented by utilized these three sodium polyacrylates polymers and this fact is achieved as a diffusion barricade and by a charge transfer reaction.

Effect of temperature

The result of temperature on the inhibition properties of the of NaPADD, NaPACDD and NaPADH polymers at a concentration of 800 ppm for OLC 45 in 0.5M H2SO4 at the temperature: 298 K, 303 K, 313 K, 323 K and 333 K was investigated by potentiodynamic polarization technique. It can be noticed that, the corrosion rate was raised by increasing temperature in inhibited and uninhibited medium. The protection action of these sodium polyacrylates polymers lower with rising temperature, while the inhibitive activity of OLC 45 in acidic solution with of these organic polymers is accomplished by the adsorption of polymer, but, at higher temperature establish the desorption of these NaPADD, NaPACDD and NaPADH inhibitors since the metal surface. The variation of corrosion rate on temperature can be exhibited by the Arrhenius equation and transition equation: (Yadav et al. 2012a, b; Daoud et al. 2015; Khadraoui et al. 2014).

where icorr is the process rate, A is a pre-exponential factor, Ea the apparent activation energy of OLC 45 dissolution process, R the universal gas constant and T the absolute temperature, \(\Delta H_{\text{a}}^{*}\) the apparent enthalpy of activation, \(\Delta S_{\text{a}}^{*}\) the apparent entropy of activation, h Planck’ constant, N the Avogadro number.

Figure 9a displays the Arrhenius plot, corrosion rate versus of 1/T for carbon steel OLC 45 in 0.5M H2SO4 in presence and absence of three sodium polyacrylates polymers. The assessments of Ea in presence and absence of these polymers have been obtained by plotting corrosion rate versus of 1/T where in straight lines are accomplished in Fig. 9a, from the slope of these lines are provided activation energy (see Table 7). Figure 9b presents a graph of logarithm corrosion rate/T against of 1/T. Straight lines are realized with a slope of (\(- \Delta H^{*} /R\)) and an intercept of (ln(R/Nh) (\(\Delta S^{*} /R\)), from which the values \(\Delta H^{*}\) and \(\Delta S^{*}\) have been evaluated (see Table 7).

Examination the Table 7 and Fig. 9, it can be seen that the values of Ea increased in the presence of polymers than in the absence of inhibitors, so the value of Ea could describe the influence of temperature on corrosion protection. The higher values of the activation energy for corrosion reaction with these polymers suggest important protection effect of these inhibitors. From adsorption results it can be determined we have chemisorptions and physisorption of the polymers over the OLC 45 surface. The energy barrier for the corrosion reaction increases and the polymer molecules are adsorption onto the OLC 45 area, which decreases in the interplay of the corrosive medium and the metal surface.

The greater Ea value in the inhibited medium is explained with the increases thickness of the double layer which makes the activation energy of the corrosion process (Branzoi and Băran 2019; Yadav et al. 2012a, b; Daoud et al. 2015; Khadraoui et al. 2014). Furthermore, it can be said that efficiency decreases with rise in temperature can be attributed to the increased desorption of polymer molecules from electrode surface. The positive value of the enthalpy proposes the endothermic nature of the metal dissolution process and the rate of OLC 45 dissolution are low in the existence of the inhibitor and that the dissolution of this electrode is complex (Branzoi and Branzoi 2017; Branzoi and Băran 2019; Daoud et al. 2015; Khadraoui et al. 2014; Yilmaz et al. 2016; Xu et al. 2015; Bouklah et al. 2006). The higher and negative value of ΔS° in the existence and absence of polymer reveals that the activated complex in the rate-determining step establishes association rather than dissociation stage, this involves that a decrease in disorder occurs when going from reactant to the activated complex by the getting of steady adsorption layer of the polymer molecules on the electrode surface (Yadav et al. 2012a, b Khadraoui et al. 2014; Yilmaz et al. 2016; Xu et al. 2015; Bouklah et al. 2006).

Adsorption isotherms

The adsorption isotherm gives meaningful knowledge at the interaction of inhibitor and electrode surface. It is altogether supposed that the adsorption of inhibitor on the electrode surface is the main action in the protection process. To assess the influence of organic polymer concentration on the corrosion rate, it is exert to fit the rate data to equilibrium adsorption relations, as Langmuir isotherm model. The exquisite relationship from the area coverage and isotherm function has been getting employment Langmuir adsorption isotherm.

The Langmuir adsorption isotherm is relevant to examine the adsorption process by the subsequent equation: θ/(1 − θ) = KC, where C is inhibitor concentration, θ is the degree of the coverage on the metal surface by the inhibitor and K is the adsorption equilibrium constant, θ is achieved by: θ = (icorr–iinh)/icorr where icorr and iinh are the corrosion current density in 0.5M H2SO4 with and without of the inhibitor. All correlation coefficients (R2) are higher than 0.99 (NaPADD R2 = 0.9996; NaPACD R2 = 0.9997; and NaPAHD R2 = 0.9996) show that the protection was attributed to adsorption of these polymers onto the metal surface.

Application of the Langmuir comportment is often established with the reason that inhibition shall imply adsorption. The reaction to the first step of the corrosion mechanism of the metal surface in 0.5M H2SO4 with inhibitor is: Me + INH↔Me(INH)ads ↔Men+ +ne− + INH. In the presence of a significant amount of inhibitor, a compact and resistant layer is accomplished over OLC 45 electrode surface that diminutions the aggression on the working electrode. In this investigation, straight lines were obtained when concentration Cinh/θ were plotted against Cinh with a slope of unity. The linear relation proposes that the adsorption of polymers comply the Langmuir adsorption isotherm (Fig. 10). The equilibrium constant (Kads) for the adsorption reaction of these polymers can be determinate from reciprocal of the intercept and its value is presented in Table 8. It is obvious, that the big assessments of the adsorption equilibrium constant denote a strong adsorption, a higher protection efficiency of the sodium polyacrylates polymers over the OLC 45 surface in 0.5M H2SO4 and a intensive electric interaction from the double layer present and the adsorbed species (Branzoi and Baran 2019; Xu et al. 2015; Bouklah et al. 2006; Singh and Quraishi 2010). The adsorption of a polymer mainly modified the corrosion resisting state of a metal. The equilibrium constant of the adsorption process (Kads) is introduced by the standard adsorption free energy (\(\Delta G_{\text{ads}}^{^\circ }\)) accomplished by equation: \(\ln K_{\text{ads}} = - \left( {\Delta G_{\text{ads}}^{^\circ } /RT} \right)\). The established value of \(\Delta G_{\text{ads}}^{^\circ }\) achieved is negative and introduces that the adsorption of polymer is a spontaneous process and furthermore, the negative values of \(\Delta G_{\text{ads}}^{^\circ }\) also denote the pronounced interaction of the polymer molecule at the surface. The acquired value \(\Delta G_{\text{ads}}^{^\circ }\) about – 20 kJ mol−1 or lower exhibits the electrostatic interaction from charged electrode area to charge in the most of the solution (physical adsorption), whereas those approximately – 40 kJ mol−1 or superior implicate charge sharing or charge assignment, among the metal surface and polymer molecules to elaborate a co-coordinative type of bond (chemisorption-see Table 8) (Branzoi and Branzoi 2017; Branzoi and Băran 2019; Xu et al. 2015; Bouklah et al. 2006; Singh and Quraishi 2010; He et al. 2014).

Mechanism of inhibition can be interpreted from the experimental data, it was established that all the polymers analyzed (NaPADD, NaPACDD and NaPADH) impede the corrosion of OLC 45 in 0.5M H2SO4 by adsorption of polymers at electrode/solution interface. Adsorption of these of three sodium polyacrylates polymers can be accomplished by physical and chemical (chemisorption) adsorption process. The adsorption mechanism is influenced of many elements as: the characteristic and charge of the metal, chemical composition and charge of the inhibitor molecules and the kind of electrolyte (Hejazi et al. 2015; Branzoi and Băran 2019; Deng et al. 2014; Hu et al. 2016; Noor and Al-Moubaraki 2008). The protection of these polymers for the corrosion metal surface in 0.5M H2SO4 can be accomplished on the based on the number of adsorption center, molecular size and the path of interplay with the metal surface. It can be accentuated that, the great dimensions and large molecular weight by lengthy hydrophobic chain of polymers can as well influence the big inhibition effectiveness of the investigated polymers. (Obot et al. 2017a, b; Hejazi et al. 2015; Chikh et al. 2005; Amin et al. 2009; Branzoi and Băran 2019; Gong et al. 2019; Abd-El-Naby et al. 2016; Hegazy 2015; Deng et al. 2014; Hu et al. 2016; Noor and Al-Moubaraki 2008). In the case of these sodium polyacrylates polymers, the presence a several functional groups as N, O heteroatom and double bonds, which can help as the active sites for the adsorption reactions of these inhibitors. In comparison with nitrogen atom, the oxygen atom posses the most negative charge and it has the most important capability to establish to the metal surface, too as simply adsorbed on the area of the metal. The inhibition of these polymers can be realized by many manner of adsorption: physical adsorption from the negatively charged of polymers and/or (SO42−) and the positively charged of OLC 45 surface (anodic inhibition); electrostatic interplay from the positively charged Na+ ion and the negatively charged of OLC 45 area (cathodic inhibition); by the great hydrophobic chain of polyacrylates polymers influenced to protection by substitution water molecule from OLC 45 surface by trend of these labeled alkyl chains to aggressive medium and to impede the diffusion of the aggressive ions in solution, as SO42− anions; by the chemical interaction on donor–acceptor π-electrons of donor atoms O and N of the polymers and the unoccupied d-orbital of Fe surface atoms (Obot et al. 2017a, b; Hejazi et al. 2015; Chikh et al. 2005; Amin et al. 2009; Branzoi and Băran 2019; Singh and Quraishi 2010; He et al. 2014; Deng et al. 2014; Hu et al. 2016; Noor and Al-Moubaraki 2008). All types of adsorption will lessen the surface exposed at the aggressive medium, so the corrosion can be prevented. The mechanism of inhibition of NaPADD for OLC 45 in sulfuric acid medium, an adsorption and protection model is suggested as presented in Fig. 11 (the adsorption mechanisms are similar for NaPACDD and NaPADH).

Surface analysis by FT-IR spectroscopy

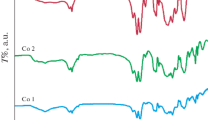

In this paper, FT-IR spectrometry has been utilized to identify the existence of the relevant absorption bands observed for NaPADD, NaPACDD and NaPADH polymers adsorbed onto OLC 45 surface after immersion in the corrosive solution. In order, to assess the protective film obtained onto OLC 45 electrode surface with polymers, also to offer new bonding acquaintance on the working electrode surface has been examined by FT-IR spectra and presented in Fig. 12.

The significant peaks in the transmittance spectrum of three sodium polyacrylates polymers: NaPADD, NaPACD and NaPADH pure are indicated in Fig. 12a–c. The absorption bands at 3366 cm−1, 3359 cm−1 and 3282 cm−1 correspond to NH-stretching vibration. The peaks around 2958–2860 cm−1, 2928–2861 cm−1 and 2959–2926 cm−1 are attributed to the aliphatic of CH3 and –CH2 symmetric and asymmetric stretching vibration. The sharp band at 1733 cm−1, 1736 cm−1 and 1662 cm−1 is attributed to the C=O stretching vibration. The spectrum in the 1600–1500 cm−1 region is assumed to stretching vibration of C–N. The peak at 1460 cm−1, 1466 cm−1 and 1452 cm−1 is associated to CH bending vibration of the CH2. The peaks remarked at 1355, 1358, 1322 cm−1 and 893, 891, 884, 727, 733, 723 cm−1 (for NaPADD, NaPACD and NaPADH) are assumed to corresponding to the aliphatic C-H stretching vibration of the CH2 and CH3 groups. The bands at 1235–1200 cm−1 and 1100–1052 cm−1 are assigned to C–O and C–N stretching vibration (Branzoi et al. 2014, 2018; Obot et al. 2017a, b; Hejazi et al. 2015; Bahrami et al. 2010; Jyothi and Ravichandran 2014; Abd El-Lateef et al. 2017; Sangeetha et al. 2016; Negm et al. 2018). The FT-IR spectra of adsorbed protective layer established on the OLC 45 electrode surface after immersion in 0.5M H2SO4 medium with optimum concentration of polymer 800 ppm NaPADD and NaPACD and 500 ppm NaPADH are presented in Fig. 12d–f. It can be noticed that the all meaningful peaks in pure polymer appeared in adsorption layer onto OLC 45 working electrode area. The band placed at 3530 cm−1, 3493 cm−1 and 3482 cm−1 (NaPADD, NaPACD and NaPADH) is assigned to O–H stretching vibration, which that denotes the protective film includes H2O. The weak bands at 2965–2893 cm−1, 2927–2858 cm−1 and 2990–2928 cm−1 NaPADD, NaPACD and NaPADH) are attributed to the aliphatic CH2 asymmetric and symmetric stretching vibration (Branzoi et al. 2014; Branzoi and Branzoi 2017; Obot et al. 2017a, b; Branzoi et al. 2018; Bahrami et al. 2010; Jyothi and Ravichandran 2014; Abd El-Lateef et al. 2017; Sangeetha et al. 2016). The peaks about 1667–1670 cm−1 correlate with C=O and 1272–1210 cm−1 is ascribed to the C-O stretching vibration. The weak band at 3324–3097 cm−1 corresponds to N–H stretching vibration. The spectrum in the 1055–1179 cm−1 domain is attributed to stretching vibration of C-N. The small peaks presented at 1388, 1363, 1341 cm−1 and 884, 881, 864, 753, 715, 708 cm−1 are supposed to suitable to the aliphatic C-H stretching vibration of the CH2 and CH3 groups. From Fig. 12d–f it can be observed a weak band showed up at 3839–3749 cm−1 (NaPADD), 3819–3767 cm−1 (NaPACD), and 3806–3735 cm−1 (NaPADD), is assumed to Fe–O bending, where the direct bonding from Fe atoms and NaPADD, NaPACD and NaPADH molecules via O atoms and the bans at 683–672 cm−1, 692–660 cm−1 and 761–680 cm−1 is assigned to Fe-inhibitor complex and this fact leads that there is chemisorptions achieved over the area of OLC 45 (Branzoi et al. 2014; Branzoi and Branzoi 2017; Obot et al. 2017a, b; Branzoi et al. 2018; Bahrami et al. 2010; Jyothi and Ravichandran 2014; Abd El-Lateef et al. 2017; Sangeetha et al. 2016; Negm et al. 2018). Comparing Figs. 12a–c and d–f it can be assumed that: NaPADD, NaPACD and NaPADH organic polymers are adsorbed onto the OLC 45 working electrode surface.

Surface analysis by scanning electron microscopy (SEM)

SEM images achieved from carbon steel surface OLC 45 electrodes immersion in 0.5M H2SO4 medium with and without of 800 ppm NaPADD, NaPACD and NaPADH polymers are presented in Fig. 13. Figure 13a presents the SEM image surface of OLC 45 electrode after immersion in 0.5M H2SO4 solution, this look that the metal surface was strongly damaged in the absence of the inhibitor. It can be noticed from Fig. 13c–e that in presence of 800 ppm NaPADD, NaPACD and NaPADH polymers that the OLC 45 electrode area has a better and improved morphology surface in comparison with that of the OLC 45 surface in sulfuric acid solution and indicates an considerable hindering capacity to corrosion onto carbon steel surface. It is showed that there is a significant protective layer adsorbed over OLC 45 surface so that there is a reduction of the contact from OLC 45 electrode and the corrosive solution, which is responsible for the protection at corrosion (Ansari et al. 2015; Branzoi and Baran 2019; Branzoi et al. 2018; Chikh et al. 2005; Branzoi et al. 2013; Hasanov et al. 2010).

SEM micrographs of OLC 45 electrode after 144 h immersion time of 800 ppm sodium polyacrylates polymers solution show the complete surface coated with polymer molecules and a consolidated inhibitory layer has been established. It can be seen from Fig. 13—that the good protection efficacy of polymers after greater immersion periods can be as a result to the adsorption of polymers molecules on the active centers of OLC 45 surface (Ansari et al. 2015; Branzoi and Baran 2019; Branzoi et al. 2018; Chikh et al. 2005; Branzoi et al. 2013; Hasanov et al. 2010). This revealed that the coated polymer layer achieved ensures an excellent corrosion protection of carbon steel in aggressive medium.

Surface analysis by metallographic spectroscopy

Figure 14 exhibits some micrographies which were examined for our systems: polymer/0.5M H2SO4/OLC 45 before and after a certain time immersion in aggressive solution. The getting of the protective layer of three sodium polyacrylates polymers as corrosion inhibitors over OLC 45 surface has been determined by metallurgical research microscope observation on the working electrode area. It is obvious that, in existence of organic polymers the surface gets more uniform, compact and homogeneous than the uninhibited surface. This fact shows that protective film is realized by adsorption of sodium polyacrylates polymers and corrosion compounds.

It can be observed from Fig. 14 that the existence of organic inhibitors considerable decrease the corrosion rate on the metal surface and excellent inhibitory layer is adsorbed onto working electrode surface which is capable to the protection at corrosion. Also, these protective layers act like a barrier from corrosive solution and OLC 45 area and as a result the corrosion reaction is prevented. Some investigation and surface analyze such as FT-IR, SEM and metallographic spectroscopy were accomplished in order to certify the obtaining of protective layer on the metal surface and revealed the adsorption process of all organic polymers over OLC 45 surface in 0.5M H2SO4 medium.

Conclusions

In this paper were investigated three novel sodium polyacrylates hydrophobically modified with linear and cyclododecyl and, respectively, dihexyl chain (NaPADD, NaPACDD and NaPADH) with anticorrosion properties.

The three sodium polyacrylates polymers (NaPADD, NaPACD and NaPADH) presented very good protection properties for OLC 45 electrode in 0.5M H2SO4 solution while the corrosion current density decreased and the effectiveness increased with increasing inhibitor concentration.

The potentiodynamic polarization curves specify that anodic metal dissolution and cathodic hydrogen evolution reactions are significantly inhibited by these sodium polyacrylates polymers with predominant anodic efficacy.

The results of EIS show that the charge transfer resistance increases with inhibitor concentration, which indicates the getting of a protective layer on the metal surface by the adsorption of polymer molecules which determine rise in the inhibition result.

The adsorption of sodium polyacrylates polymers: NaPADD, NaPACD and NaPADH examined onto the OLC 45 electrode obeys by Langmuir adsorption isotherm model and include both physisorption and chemisorption. The negative value of thermodynamic parameter like Gibbs free energy of adsorption shows the spontaneity of adsorption process.

Analysis and surface inspection by FT-IR, SEM and metallographic spectroscopy establish the acquiring of a protective layer over the OLC 45 surface and denote the protection mechanism of sodium polyacrylates polymers on metal surface in 0.5M H2SO4 solution.

The inhibition efficiency takes the order: NaPACD > NaPADD > NaPADH, since the presence of these polymers leads a considerable decrease in corrosion rate.

Availability of data and material

My manuscript has not associated data or the data will not be deposited in a data repository.

References

Abd-El-Naby BA, Abdullatef OA, Khamis E, El-Mahmody WA (2016) Effect of cetyltrimethylammonium bromide surfactant as novel inhibitor for the corrosion of steel in 0.5M H2SO4. Int J Electrochem Sci 11:1271

Abd El-Lateef HM, Soliman KA, Tantawy AH (2017) Novel synthesized Schiff base-based cationic gemini surfactants: electrochemical investigation, theoretical modeling and applicability as biodegradable inhibitors for mild steel against acidic corrosion. J Mol Liq 232:478–498. https://doi.org/10.1016/j.molliq.2017.02.105

Amin MA, Abd-EL I-Rehim SS, El-Sherbini EEF, Hazzaz OA (2009) Polyacrylic acid as a corrosion inhibitor for aluminium in weakly alkaline solutions. Part I: weight loss, polarization, impedance EFM and EDX studies. Corros Sci 51:658–667. https://doi.org/10.1016/j.corsci.2008.12.008

Ansari KR, Quraishi MA, Singh A (2015) Isatin derivatives as a non-toxic corrosion inhibitor for mild steel in 20% H2SO4. Corros Sci 95:62–70. https://doi.org/10.1016/j.corsci.2015.02.010

Aricov L, Băran A, Simion EL, Gîfu IC, Anghel DF, Jerca VV, Vuluga DM (2016a) New insights into the self-assembling of some hydrophobically modified polyacrylates in aqueous solution. Colloid Polym Sci 294:667–679. https://doi.org/10.1007/s00396-015-3825-z

Aricov L, Petkova H, Arabadzhieva D, Iovescu A, Mileva E, Khristov K, Stîngă G, Mihailescu CF, Anghel DF, Todorov R (2016b) Aqueous solutions of associative poly(acrylates): bulk and interfacial properties. Colloids Surf A Physicochem Eng Asp 505:138–149. https://doi.org/10.1016/j.colsurfa.2016.02.018

Aricov L, Băran A, Stîngă G, Simion EL, Gîfu IC, Anghel DF, Rădiţoiu V (2017) Formation and hosting properties of polyacrylate–surfactant complexes. Colloid Polym Sci 295:1017–1038. https://doi.org/10.1007/s00396-017-4102-0

Bahrami MJ, Hosseini SMA, Pilvar P (2010) Experimental and theoretical investigation of organic compounds as inhibitors for mild steel corrosion in sulfuric acid medium. Corros Sci 52:2793–2803. https://doi.org/10.1016/j.corsci.2010.04.024

Bouklah M, Hammouti B, Lagrenée M, Bentiss F (2006) Thermodynamic properties of 2,5-bis(4-methoxyphenyl)-1,3,4-oxadiazole as a corrosion inhibitor for mild steel in normal sulfuric acid medium. Corros Sci 48:2831–2842. https://doi.org/10.1016/j.corsci.2005.08.019

Branzoi V, Branzoi F (2002) Inhibiting effects of carbon steel corrosion by N-alkyl quaternary ammonium salts in hydrochloric acid solutions. Rev Roum Chim 47:1193

Branzoi F, Branzoi V (2016) Investigation of some nonionic surfactants as corrosion inhibitors for carbon steel in sulfuric acid medium. Int J Electrochem Sci 11:6564–6578. https://doi.org/10.20964/2017.08.27

Branzoi F, Branzoi V (2017) Investigation of some nonionic surfactants as corrosion inhibitors for carbon steel in sulfuric acid medium. Int J Electrochem Sci 12:7638–7658. https://doi.org/10.20964/2017.08.27

Branzoi F, Băran A (2019) The inhibition effect of some organic compounds on corrosion of brass and carbon steel in aggressive medium. Int J Electrochem Sci 14:2780–2803. https://doi.org/10.20964/2019.03.55

Branzoi F, Branzoi V, Musina A (2013) Coatings based on conducting polymers and functionalized carbon nanotubes obtained by electropolymerization. Prog Org Coat 76:632–638. https://doi.org/10.1016/j.porgcoat.2012.12.003

Branzoi F, Branzoi V, Licu C (2014) Corrosion inhibition of carbon steel in cooling water systems by new organic polymers as green inhibitors. Mater Corros 65:637. https://doi.org/10.1002/maco.201206579

Branzoi F, Pahom Z, Nechifor G (2018) Corrosion protection of new composite polymer coating for carbon steel in sulfuric acid medium by electrochemical methods. J Adhes Sci Technol 32:2364–2380. https://doi.org/10.1080/01694243.2018.1478611

Chikh ZA, Chebabe D, Dermaj A, Hajjaji N, Srhiri A, Montemor MF, Ferreira MGS, Bastos AC (2005) Electrochemical and analytical study of corrosion inhibition on carbon steel in HCl medium by 1,12-bis(1,2,4-triazolyl)dodecane. Corros Sci 47:447–459. https://doi.org/10.1016/j.corsci.2004.05.028

Daoud D, Douadi T, Hamani H, Chafaa S, Al-Noaimi M (2015) Corrosion inhibition of mild steel by two new S-heterocyclic compounds in 1 M HCl: experimental and computational study. Corros Sci 94:21–37. https://doi.org/10.1016/j.corsci.2015.01.025

Deng SD, Li XH, Xie XG (2014) Hydroxymethyl urea and 1,3-bis(hydroxymethyl) urea as corrosion inhibitors for steel in HCl solution. Corros Sci 80:276–289. https://doi.org/10.1016/j.corsci.2013.11.041

Fouda AS, Ellithy AS (2009) Inhibition effect of 4-phenylthiazole derivatives on corrosion of 304L stainless steel in HCl solution. Corros Sci 51:868–875. https://doi.org/10.1016/j.corsci.2009.01.011

Gîfu IC, Maxim ME, Iovescu A, Simion EL, Aricov L, Anastasescu M, Munteanu C, Anghel DF (2016) Surface hydrophobization by electrostatic deposition of hydrophobically modified poly(acrylates) and their complexes with surfactants. Appl Surf Sci 371:519–529. https://doi.org/10.1016/j.apsusc.2016.03.036

Gîfu IC, Maxim ME, Iovescu A, Aricov L, Simion EL, Anastasescu M, Munteanu C, Anghel DF (2017) Natural aging of multilayer films containing hydrophobically modified poly(acrylate)s or their complexes with surfactants. Appl Surf Sci 412:489–496. https://doi.org/10.1016/j.apsusc.2017.03.250

Gong W, Yin X, Liu Y, Chen Y, Yang W (2019) 2-Amino-4-(4-methoxyphenyl)-thiazole as a novel corrosion inhibitor for mild steel in acidic medium. Prog Org Coat 126:150–161. https://doi.org/10.1016/j.porgcoat.2018.10.001

Gopi D, Govindaraju KM, Kavitha L (2010) Investigation of triazole derived Schiff bases as corrosion inhibitors for mild steel in hydrochloric acid medium. J Appl Electrochem 401:349–1356. https://doi.org/10.1007/s10800-010-0092-z

Hasanov R, Bilge S, Bilgic S, Gece G, Kılıc Z (2010) Experimental and theoretical calculations on corrosion inhibition of steel in 1 M H2SO4by crown type polyethers. Corros Sci 52:984–990. https://doi.org/10.1016/j.corsci.2009.11.022

He X, Jiang Y, Li C, Wang W, Hou B, Wu L (2014) Inhibition properties and adsorption behavior of imidazole and 2-phenyl-2-imidazoline on AA5052 in 1.0 M HCl solution. Corros Sci 83:124–136. https://doi.org/10.1016/j.corsci.2014.02.004

Hegazy MA (2015) Novel cationic surfactant based on triazole as a corrosion inhibitor for carbon steel in phosphoric acid produced by dihydrate wet process. J Mol Liq 208:227–236. https://doi.org/10.1016/j.molliq.2015.04.042

Hegazy MA, El-Tabei AS, Bedair AH, Sadeq MA (2012) An investigation of three novel nonionic surfactants as corrosion inhibitor for carbon steel in 0.5M H2SO4. Corros Sci 54:219–230. https://doi.org/10.1016/j.corsci.2011.09.019

Hejazi S, Mohajernia Sh, Moayed MH, Davoodi A, Rahimizadeh M, Momeni M, Eslami A, Shiri A, Kosari A (2015) Electrochemical and quantum chemical study of Thiazolo-pyrimidine derivatives as corrosion inhibitors on mild steel in 1 M H2SO4. J Ind Eng Chem 25:112–121. https://doi.org/10.1016/j.jiec.2014.10.020

Hu Z, Meng Y, Ma X, Zhu H, Li J, Li C, Cao D (2016) Experimental and theoretical studies of benzothiazole derivatives as corrosion inhibitors for carbon steel in 1 M HCl. Corros Sci 112:563–575. https://doi.org/10.1016/j.corsci.2016.08.012

Jones D (1992) Principle and prevention of corrosion. MacMillan Publishing Company, New York

Jyothi S, Ravichandran J (2014) corrosion inhibition of mild steel in sulphuric acid using luffa aegyptiaca leaves extract. Acta Metall Sin 27:969–980. https://doi.org/10.1007/s40195-014-0107-6

Khadraoui Khelifa A, Boutoumi H, Hamitouche H, Mehdaoui R, Hammouti B, Al-Deyab SS (2014) Adsorption and inhibitive properties of Ruta chalepensis L. oil as a green inhibitor of steel in 1 M hydrochloric acid medium. Int J Electrochem Sci 9:3334–3348

Khaled KF, Amin Mohammed A (2009) Corrosion monitoring of mild steel in sulphuric acid solutions in presence of some thiazole derivatives–molecular dynamics, chemical and electrochemical studies. Corros Sci 51:1964–1975. https://doi.org/10.1016/j.corsci.2009.05.023

Labjar N, Lebrini M, Bentiss F, Chihib NE, El Hajjaji S, Jama C (2010) Corrosion inhibition of carbon steel and antibacterial properties of aminotris-(methylenephosphonic) acid. Mater Chem Phys 119:330–336. https://doi.org/10.1016/j.matchemphys.2009.09.006

Li X, Deng S, Fu H, Mu G (2009) Inhibition effect of 6-benzylaminopurine on the corrosion of cold rolled steel in H2SO4 solution. Corros Sci 51:620–634. https://doi.org/10.1016/j.corsci.2008.12.021

Migahed MA, EL-Rabiei MM, Nady H, Zaki EG (2018) Novel Gemini cationic surfactants as anti-corrosion for X-65 steel dissolution in oilfield produced water under sweet conditions: combined experimental and computational investigations. J Mol Struct 1159:10–22. https://doi.org/10.1016/j.molstruc.2018.01.033

Mobin M, Rizvi M (2016) Inhibitory effect of xanthan gum and synergistic surfactant additives for mild steel corrosion in 1 M HCl. Carbohydr Polym 136:384–393. https://doi.org/10.1016/j.carbpol.2015.09.027

Negm NA, Migahed MA, Farag RK, Fadda AA, Awad MK, Shaban MM (2018) High performance corrosion inhibition of novel tricationic surfactants on carbon steel in formation water: electrochemical and computational evaluations. J Mol Liq 262:363–375. https://doi.org/10.1016/j.molliq.2018.04.092

Noor EA, Al-Moubaraki AH (2008) Thermodynamic study of metal corrosion and inhibitor adsorption processes in mild steel/1-methyl-4[4′(-X)-styryl pyridinium iodides/hydrochloric acid systems. Mater Chem Phys 110:145–154. https://doi.org/10.1016/j.matchemphys.2008.01.028

Obot IB, Obi-Egbedi NO (2010) Adsorption properties and inhibition of mild steel corrosion in sulphuric acid solution by ketoconazole: experimental and theoretical investigation. Corros Sci 52:198–204. https://doi.org/10.1016/j.corsci.2009.09.002

Obot IB, Onyeachu IB, Kumar AM (2017a) Sodium alginate: a promising biopolymer for corrosion protection of API X60 high strength carbon steel in saline medium. Carbohydr Polym 178:200–208. https://doi.org/10.1016/j.carbpol.2017.09.049

Obot IB, Ankah NK, Sorour AA, Gasem ZM, Haruna K (2017b) 8-Hydroxyquinoline as an alternative green and sustainable acidizing oilfield corrosion inhibitor. Sustain Mater Technol 14:1–10. https://doi.org/10.1016/j.susmat.2017.09.001

Popova A, Christov M, Raicheva S, Sokolova E (2004) Adsorption and inhibitive properties of benzimidazole derivatives in acid mild steel corrosion. Corros Sci 46:1333–1350. https://doi.org/10.1016/j.corsci.2003.09.025

Sangeetha Y, Meenakshi S, Sairam Sundaram C (2016) Interactions at the mild steel acid solution interface in the presence of O-fumaryl-chitosan: electrochemical and surface studies. Carbohydr Polym 136:38–45. https://doi.org/10.1016/j.carbpol.2015.08.057

Sastri VS (2011) Green corrosion inhibitors, theory and practice. Wiley, New Jersey

Singh AK, Quraishi MA (2010) Inhibiting effects of 5-substituted isatin-based Mannich bases on the corrosion of mild steel in hydrochloric acid solution. J Appl Electrochem 40:1293–1306. https://doi.org/10.1007/s10800-010-0079-9

Singh K, Singh AK, Ebenso EE (2014) Inhibition effect of cefradine on corrosion of mild steel in HCl solution. Int J Electrochem Sci 9:352–364

Xu B, Gong W, Zhang K, Yang W, Liu Y, Yin X, Shi H, Chen Y (2015) Theoretical prediction and experimental study of 1-butyl-2-(4-methylphenyl)benzimidazole as a novel corrosion inhibitor for mild steel in hydrochloric acid. J Taiwan Inst Chem E 51:193–200. https://doi.org/10.1016/j.jtice.2015.01.014

Yadav DK, Quraishi MA, Maiti B (2012a) Inhibition effect of some benzylidenes on mild steel in 1 M HCl: an experimental and theoretical correlation. Corros Sci 50:254–266. https://doi.org/10.1016/j.corsci.2011.10.030

Yadav DK, Maiti B, Quraishi MA (2012b) Inhibition effect of some benzylidenes on mild steel in 1 M HCl: an experimental and theoretical correlation. Corros Sci 55:254–266. https://doi.org/10.1016/j.corsci.2011.10.030

Yilmaz N, Fitoz A, Ergun Ü, Emregül K (2016) A combined electrochemical and theoretical study into the effect of 2-((thiazole-2-ylimino)methyl)phenol as a corrosion inhibitor for mild steel in a highly acidic environment. Corros Sci 111:110–120. https://doi.org/10.1016/j.corsci.2016.05.002

Zhang J, Song WW, Shi DL (2012) A dissymmetric bis-quaternary ammonium salt gemini surfactant as effective inhibitor for Q235 steel in hydrochloric acid. Prog Org Coat 75:284–291. https://doi.org/10.1016/j.porgcoat.2012.08.007

Acknowledgements

Financial support from EU (ERDF) &Romanian Government infrastructure POS-CCE O 2.2.1. Grant Number: 169 INFRANANOCHEM is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Branzoi, F., Băran, A., Ludmila, A. et al. The inhibition action of some organic polymers on the corrosion carbon steel in acidic media. Chem. Pap. 74, 4315–4335 (2020). https://doi.org/10.1007/s11696-020-01242-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-020-01242-x